Page 1

Data Sheet No. PD60233 revB

IR2277S/IR2177S(PbF)

Phase Current Sensor IC for AC motor control

Features

• Floating channel up to 600 V for IR2177 & 1200 V for

IR2277

• Synchronous sampling measurement system

• High PWM noise (ripple) rejection capability

• Digital PWM output

• Fast Over Current detection

• Suitable for bootstrap power supplies

• Low sensing latency (<7.5 µsec @20kHz)

• Ratiometric analog output suitable for DSP A/D interface

Description

IR2177/IR2277 is a high voltage, high speed, single phas e current

sensor interface for AC motor drive applications. The current is

sensed by an external shunt resistor. The IC converts the analog

voltage into a time interval through a precise circuit that also

performs a very good ripple rejection showing small group delay.

The time interval is level shifted and given to the output both as a

PWM signal (PO) and analog voltage (OUT). The anal og voltage is

proportional to the measured current and is ratio metric with respect

to an externally provided voltage reference. The max throughput is

40 ksample/sec suitable for up to 20 kHz asymmetrical PWM

modulation and max delay is <7.5

current signal is provided for IGBT protection.

µsec (@20kHz). Also a fast over

Product Summary

V

(max) IR2277 1200 V

OFFSET

IR2177 600 V

V

range ±250mV

in

Bootstrap supply range 8-20 V

Floating channel quiescent

current (max)

Sensing latency (max) 7.5 µsec

Throughput 40ksample/sec

Over Current threshold

(max)

2.2 mA

(@20kHz)

(@20kHz)

±470 mV

Package

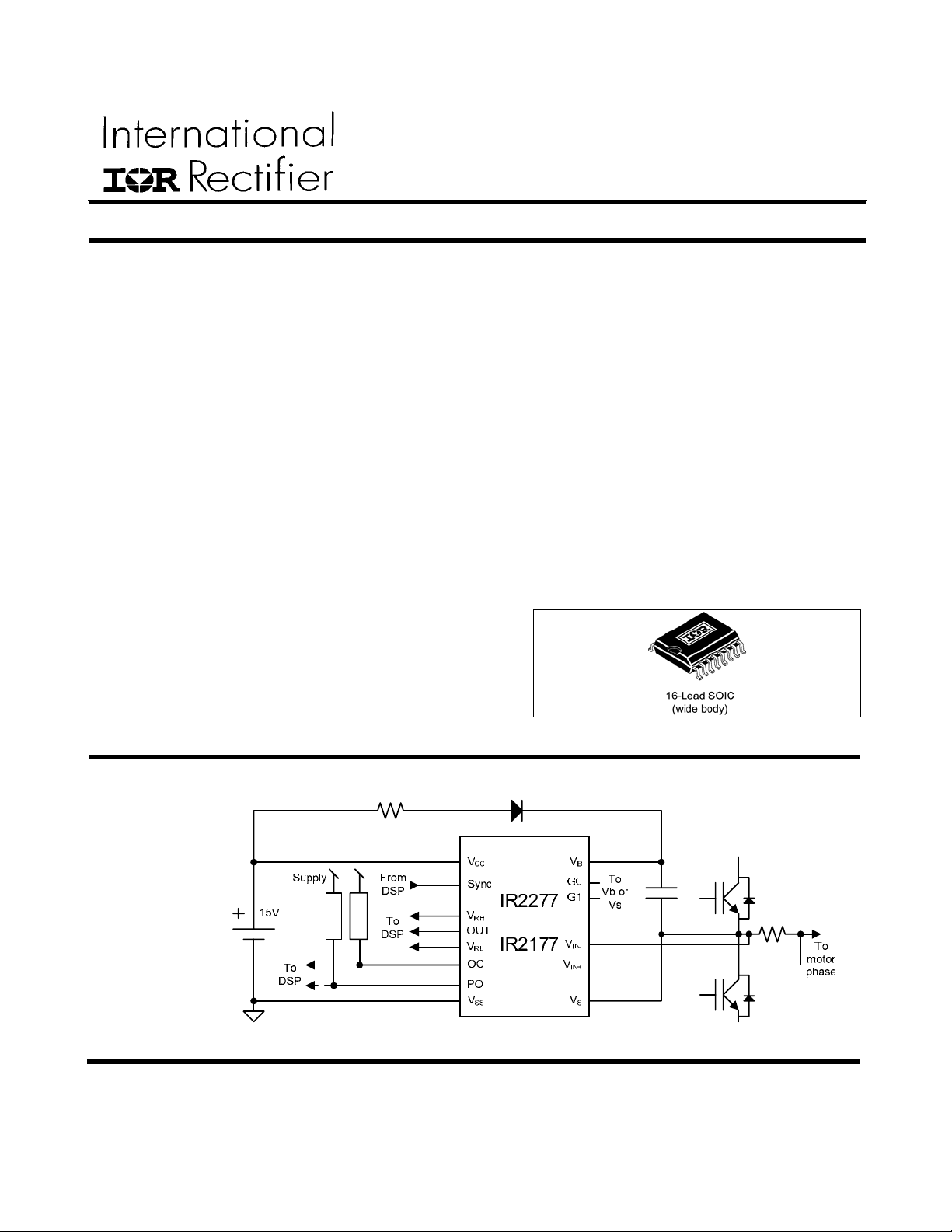

Typical Connection

(Please refer to

Lead Assignments

for correct pin

configuration. This

diagram shows

electrical

connections only)

1 www.irf.com

Page 2

IR2277S/IR2177S(PbF)

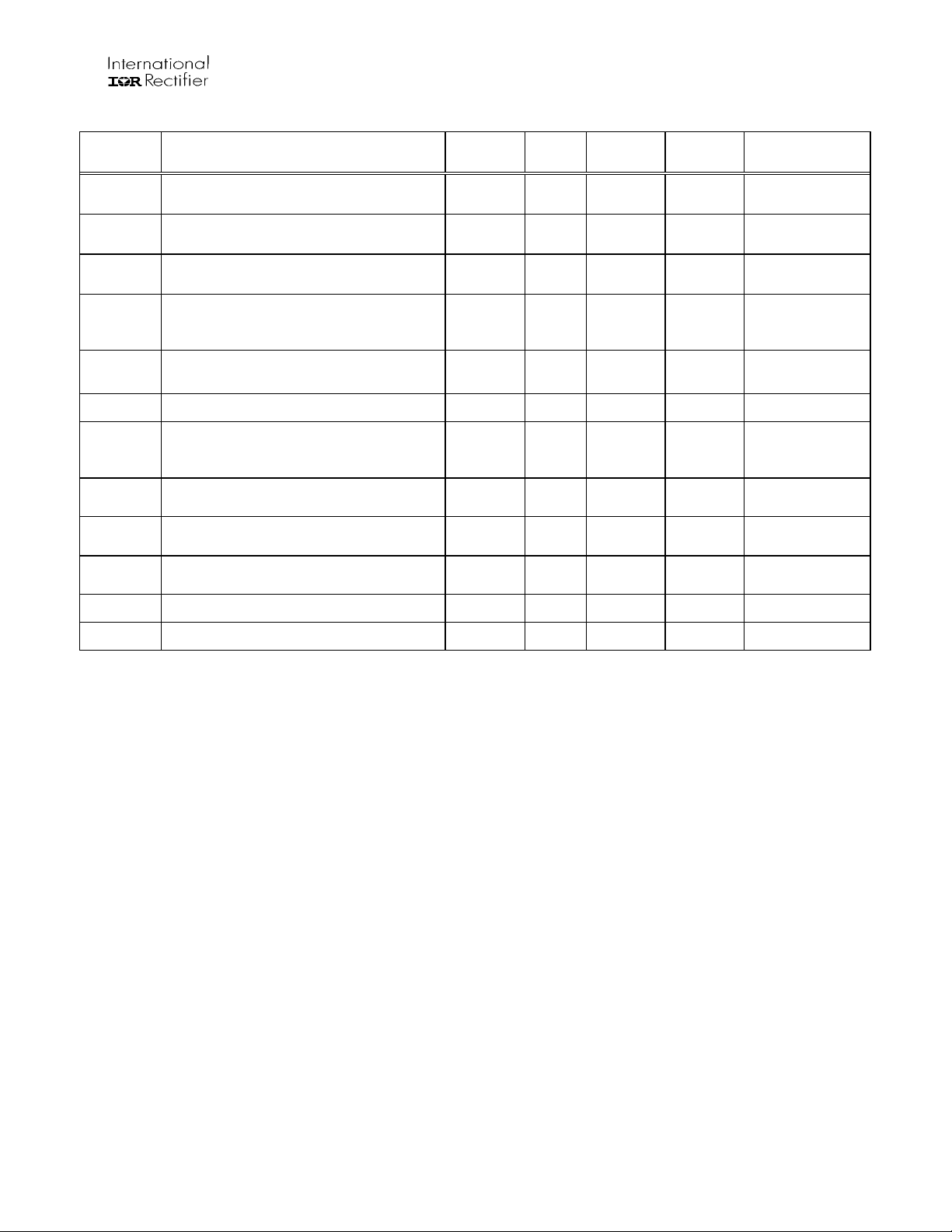

Absolute Maximum Ratings

Absolute Maximum Ratings indicate sustained limits beyond which damage to the device may occur. All voltage parameters

are absolute voltages referenced to V

Dissipation ratings are measured under board mounted and still air conditions.

, all currents are defined positive into any lead. The Thermal Resistance and Power

SS

Symbol Definition Min. Max. Units

VB High Side Floating Supply Voltage

VS High Side Floating Ground Voltage

V

/ V

in+

High-Side Inputs Voltages

in-

G0 / G1 High-Side Range Selectors

VCC Low-Side Fixed Supply Voltage - 0.3 25 V

Sync Low-Side Input Synchronization Signal

VRH/VRL DSP Reference Hi gh and Low Voltages - 0.3 VCC + 0.3 V

Out Analog Output Voltage - 0.3 VCC + 0.3 V

PO PWM Output - 0.3 VCC + 0.3 V

OC Over Current Output Voltage - 0.3 VCC + 0.3 V

dVS/dt Allowable Offset Voltage Slew Rate 50 V/ns

PD Maximum Power Dissipation 250 mW

R

Thermal Resistance, Junction to Ambient 90 ºC/W

thJA

TJ Junction Temperature -40 125 ºC

TS Storage Temperature -55 150 ºC

TL Lead Temperature (Soldering, 10 seconds) 300 ºC

IR2277 - 0.3 1225

V

V

- 25

B

- 5

S

- 0.3

S

625

+ 0.3 V

V

B

+ 0.3 V

V

B

+ 0.3 V

V

B

IR2177 - 0.3

V

- 0.3 VCC + 0.3 V

V

Recommended Operating Conditions

For proper operation the device should be used within the recommended conditions. All voltage p arameters are absolute

voltages referenced to V

. The

ss

Symbol

VBS High Side Floating Supply Voltage (V

VS

V

/ V

in+

G0 / G1 High-Side Range Selectors Note 1 Note1

VCC Low Side Logic Fixed Supply Voltage 8 20 V

Sync Low-Side Input Synchronization Signal

f

sync

PO PWM Output -0.3 Note 2 V

OC Over Current Output Voltage -0.3 Note 2 V

VRH

VRL

TA

Note 1: Shorted to VS or V

Note 2: Pull-Up Resistor to

High Side Floating Ground Voltage

High-Side Inputs Voltages VS - 5.0 VS + 5.0 V

in-

Sync Input Frequency

OUT Reference High Voltage 3 V

OUT Reference Low Voltage V

Ambient Temperature -40 125 ºC

B

V

CC

offset rating is tested with all supplies biased at 15V differential.

V

s

Definition Min. Max. Units

V

)

V

-

B

S

IR2277 1200

IR2177

Using PO 4 20

Using OUT 8 20

+ 8.0 VS + 20 V

S

VSS V

-5

V

SS

600

V

CC

-2.5 V

CC

-3 V

RH

V

kHz

2 www.irf.com

Page 3

IR2277S/IR2177S(PbF)

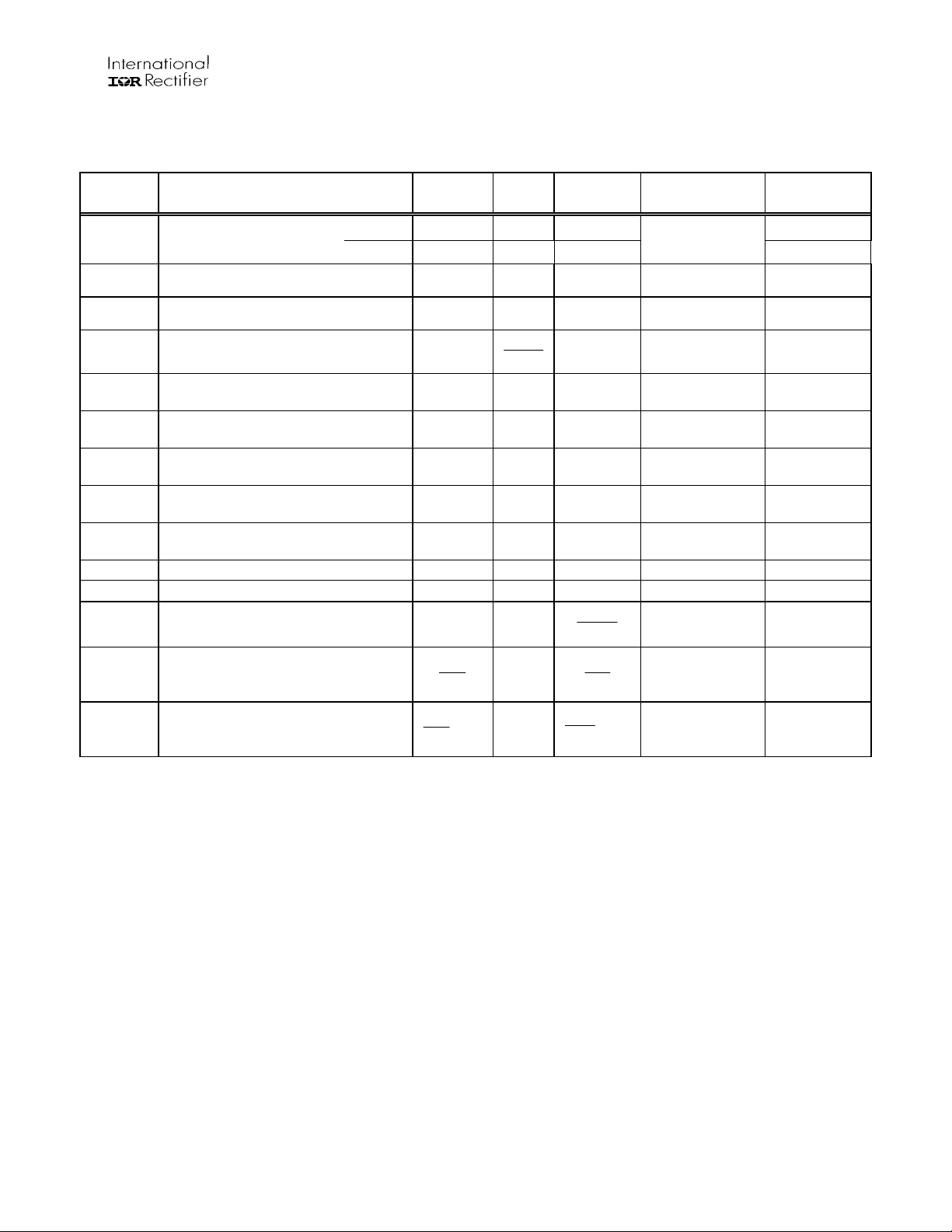

Static Electrical Characteristics

, VBS = 15V unless otherwise specified. Temp=27°C; Vin=V

V

CC

Pin: V

, VSS, VB, VS

CC

Symbol Definition Min. Typ. Max. Units

I

Quiescent VBS supply current 1 2.2 mA

QBS

I

Quiescent VCC supply current 6 mA

QCC

IR2277 50

ILK Offset supply leakage current

IR2177 50

Pin: V

in+

, V

, Sync, G0, G1, OC

in-

Symbol Definition Min. Typ. Max. Units

V

Maximum input voltage before saturation 250 mV

inmax

V

Minimum input voltage before saturation -250 mV

inmin

VIH Sync Input High threshold 2.2 V See Figure 1

VIL Sync Input Low threshold 0.8

Vhy Sync Input Hysteresis 0.2 V See Figure 1

I

V

vinp

Ipu G0, G1 pull-up Current -20 -8 µA

|V

|

octh

R

Sync

R

Over Current On Resistance 25 75

onOC

input current -18 -6 µA

in+

Over Current Activation Threshold 300 470 mV

SYNC to VSS internal pull-down 6 12

- Vin.

in+

µA

V

kΩ

Ω

Test

Conditions

f

= 10kHz,

sync

20kHz

f

= 10kHz,

sync

20kHz

V

= VS =

B

1200V

= VS = 600V

V

B

Test

Conditions

See Figure 1

f

= 4kHz to

sync

20kHz

G1, G0 = V

5V

@ I = 2mA

Figure

See

B

3

-

Schm itt trig g e r

SYNC

R

sync

V

IL

V

hy

V

IH

V

SS

Figure 1: Sync input thresholds Figure 2: Sync input circuit

Page 4

IR2277S/IR2177S(PbF)

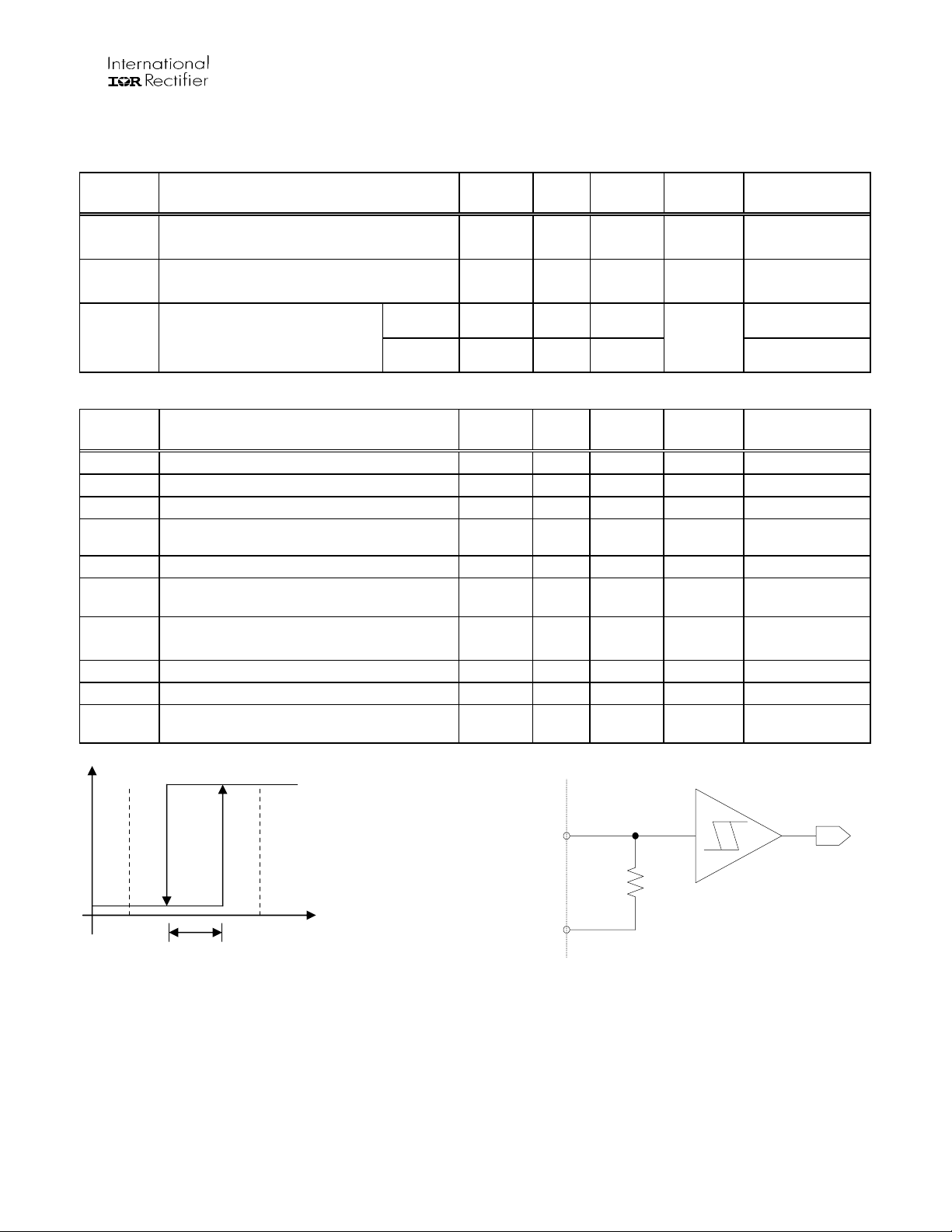

j

Pin: PO

Symbol Definition Min. Typ. Max. Units

V

POs

∆V

POs

∆T

∆V

POs

Gp PWM Output Gain -38 -40.5 -42.5 %/V Vin=±250mV

∆G

/

p

CMRR

PO

V

POlin

∆ V

lin

V

thPO

PSRR PO PSRR for PO Output 0.2 %/V

R

onPO

Note1: Refer to PO output description for channels definition

Input offset voltage measured by PWM

output

/

Input offset voltage temperature drift TBD

-50 20 mV

µV/°C

∆offset between samples on channel1

and channel2 measured at PO (See

-10 10 mV

Note1)

∆Tj

PWM Output Gain Temperature Drift TBD %/(V

PO Output common mode (V

) rejection 0.2 m%/V

S

ºC)

*

PO Linearity 0.07 0.2 % 10kHz

∆Tj

PO Linearity Temperature Drift TBD %/ºC 10kHz

/

PO threshold for OC reset 0.8 1.6 V

PO On Resistance 25 75

Ω

Test

Conditions

R

=500 Ω

pull-up

= 4, 20kHz

f

sync

V

Ext supply=5V

(See Figure 6)

OC active (See

V

=2.75V

threshold

f

= 10kHz

sync

See Figure 6

= 0,

V

s-Vss

600V

f

= 10kHz

sync

Figure 4

CC=VBS

)

=

8,20V

@ I = 2mA

See Figure 3

PO

or

OC

R

ON

V

SS

Figure 3: PO and OC open collector circuit

4 www.irf.com

Internal signal

Page 5

IR2277S/IR2177S(PbF)

Pin: OUT, VRH, VRL

Symbol Definition Min. Typ. Max. Units

R

V

REF

V

aos

∆ V

/

aos

∆Tj

∆V

aos

to VRL input resistance 36 84

RH

Input offset voltage measured by

analog output

-100 50 mV

kΩ

Input offset voltage temperature drift TBD µV / ºC

∆offset between samples on channel1

and channel2 measured at OUT

(Note1)

Test

Conditions

f

= 8kHz, 20

sync

kHz

Measured by

analog output

f

= 8kHz, 20

sync

kHz

Ga Analog Output Gain -20% 2VR +20% V/V

-1

∆Ga / ∆Tj

CMRR

OUT

V

OUTlin

∆ V

/

lin

∆Tj

PSRR

OUT

V

Vout Low Saturation 0 50 mV Vin= -500mV

OUTl

V

OUTh

Note1: Refer to PO output description for channels definition

Analog Output Gain Temperature Drift TBD ºC

Analog Output common mode (VS

offset) rejection

100 dB

Out Linearity 0.3 0.7 %

Out Linearity Temperature Drift TBD %/ºC

PSRR for Analog Output 30 100 dB

Vout High Saturation VRH+0.2 VRH+0.7 V Vin = +500mV

VR=VRH-VRL=3V

Vs-Vss=0V,

f

sync

f

sync

f

sync

V

CC

600V

= 10kHz

= 8kHz,

20kHz

= 8kHz,

20kHz

= VBS =8V,

20V

5 www.irf.com

Page 6

IR2277S/IR2177S(PbF)

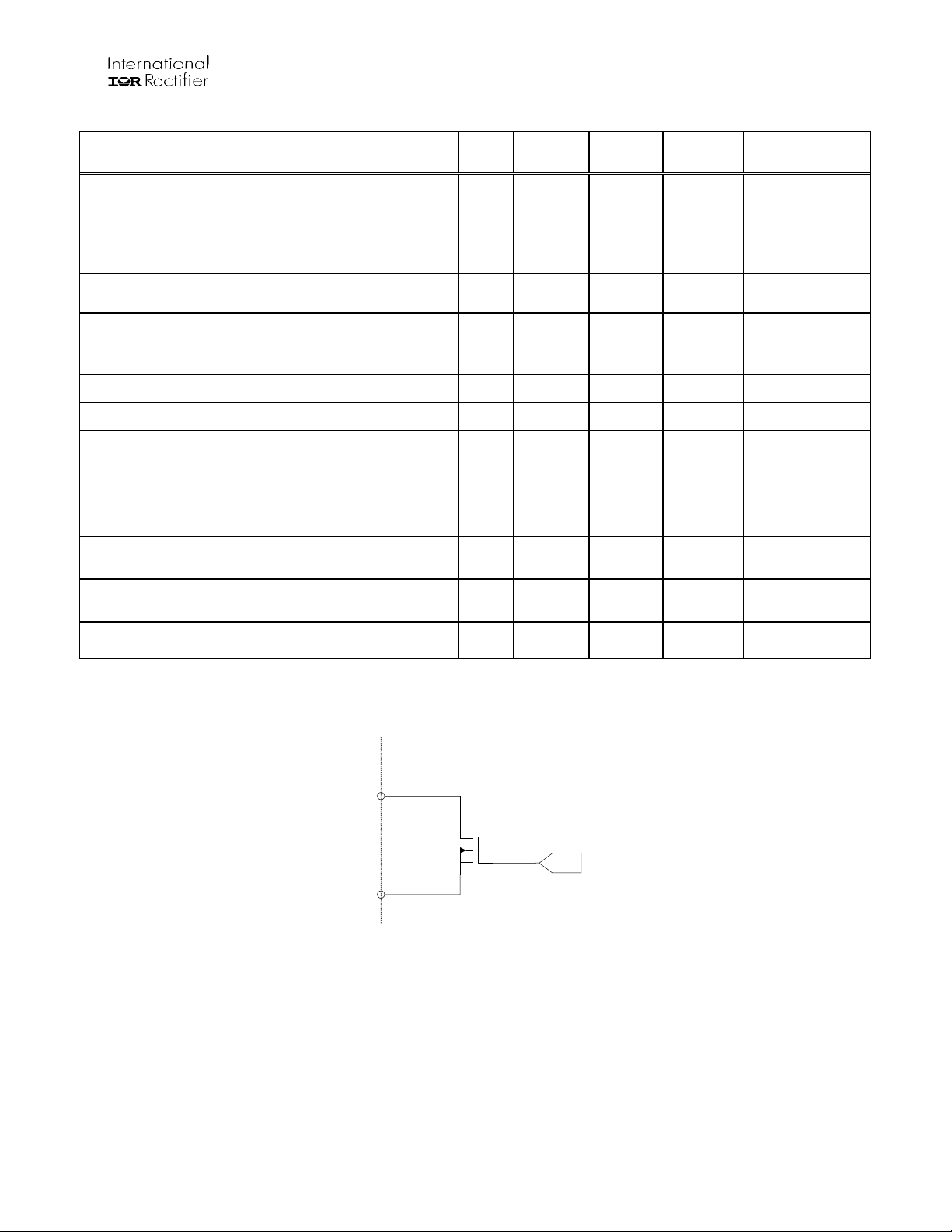

AC Electrical Characteristics

V

V

BIAS

Symbol Definition Min. Typ. Max. Units

f

sync

f

out

BW Bandwidth (@ -3 dB)

GD Group Delay (input filter)

, VBS) = 15V unless otherwise specified. Temp=27°C.

(

CC

PWM frequency

PO 4

OUT 8

Throughput

Test

Conditions

f2⋅

sync

f

sync

1

f4

⋅

sync

20

kHz

20

ksample/sec

kHz

µs

D

min

D

max

t

dOCon

T

OCoff

C

Analog output load capacitor 0 50 nF NOTE 2

load

SL

OUT

t

Output settling time (1%) 5 30 µs

settl

MD Measure Delay

SR

SR

OUT

Note 1: negative logic, see Figure 4 on page 7

Note 2: Cload < 5 nF avoids overshoot

Minimum Duty Cycle (Note 1) 10 % Vin=+V

Maximum Duty Cycle (Note 1) 30 % Vin=-V

De-bounce time of OC 2.7 3.5 4.7 µs See Figure 4

Time to reset OC forcing PO 0.5 µs

Analog output (OUT) Slew Rate 0.2 1 V/µs

Step response (max time to reach

steady state) for PO output

Step response (max time to reach

steady state) for OUT output

30.0

f2

⋅

sync

51.0

f

sync

51.0

t+

settl

f

sync

3.1

f

sync

3.1

t+

sync

settl

f

µs

µs

µs

See

See

Figure 5

See

Figure 5

C

out

C

out

inmax

inmin

Figure

≤ 5 nF

≤ 5 nF

4

6 www.irf.com

Page 7

IR2277S/IR2177S(PbF)

Figure 4: OC timing diagram

V

max

V

in

V

min

SYNC

PO

V

RH

OUT

V

RL

SR

(PO full response time)

MD

t

settl

SR

OUT

OUT full response time

(

Figure 5: timing diagram

)

7 www.irf.com

Page 8

V

max

Vin

V

min

SYNC

IR2277S/IR2177S(PbF)

Supply=5V

PO

GP *V

POs1

20% 20%

GP *V

POs0

DV

POs

GP *V

POs1

20% 20%

= V

POs1-VPOs0

GP *V

Vth=2.75V

POs0

Figure 6: ∆offset between two consecutive samples measured at PO

8 www.irf.com

Page 9

Lead Assignments

IR2277S/IR2177S(PbF)

SOIC16WB

Lead Definitions

Pin Symbol Description

1 VCC

2 OUT

3 VSS

4 VRL

5 VRH

6 OC

7 PO

8 Sync

9 NC

10 NC

11 G0

12 G1

13 VS

14 V

15 V

16 VB

IN-

IN+

Low side voltage supply

Analog output

Low side ground supply

Lower rail of A/D voltage range

Higher rail of A/D voltage range

Over current signal (open drain)

PWM output (open drain)

DSP synchronization signal

No connection

No connection

Integrator gain lsb

Integrator gain msb

High side return

Negative sense input

Positive sense input

High side supply

9 www.irf.com

Page 10

IR2277S/IR2177S(PbF)

Timing and logic state diagrams description

** See OC and PO detailed descriptions below in this document

Functional block diagram

10 www.irf.com

Page 11

IR2277S/IR2177S(PbF)

τ

1 Device Description

1.1 SYNC input

Sync input clocks the whole device. In order to

make the device work properly it must be

synchronous with the triangular PWM carrier as

shown in Figure 8.

SYNC pin is internally pulled-down (10 kΩ) to V

1.2 PWM Output (PO)

PWM output is an open collector output (active low).

It must be pulled-up to proper supply with an

external resistor (suggested value between 500Ω

and 10kΩ).

Supply

V

low

Figure 7: PO rising and falling slopes

PO pull-up resistor determines the rising slope of

the PO output and the lower value of PO as shown

in Figure 7, where

capacitance and R is the pull-up resistance.

low

SupplyV

⋅=

where R

and R

is the internal open collector resistance

on

is the external pull-up resistance.

pull-up

PO duty cycle is defined for active low logic by the

following formula:

T

D

Eq. 1

PO duty cycle (D

Zero input voltage corresponds to 20% duty cycle.

=

n

T

n

τ

RC=

, C is the total PO pin

R

on

RR

+

uppullon

−

ncycleoff

1__ +

ncycle

_

) swings between 10% and 30%.

SS

.

A residual offset can be read in PO duty cycle

according to V

(see Static electrical

POs

characteristics).

According to

Figure 8, it can be assumed that odd cycles are

represented by SYNC at high level (let’s name

channel 1 the output related to this state of SYNC)

and even cycles represented by SYNC at low level

(channel 2).

The two channels are independent in order to

provide the correct duty cycle value of PO even for

non-50% duty cycle of SYNC signal. Small variation

of SYNC duty cycle are then allowed and

automatically corrected when calculating the duty

cycle using Eq. 1.

However, channel 1 and channel 2 can have a

difference in offset value which is specified in

∆V

(see Static electrical characteristics).

POS

To implement a correct offset compensation of PO

duty cycle and analog OUT, each channel must be

compensated separately.

1.3 Over Current output (OC)

OC output is an open drain pin (active low).

A simplified block diagram of the over current circuit

is shown in the

Figure 9.

Over current is detected when |V

If an event of over current lasts longer than t

OC pin is forced to V

and remains latched until

SS

PO is externally forced low for at least t

timing on Figure 4). During an over current event

(OC is low), PO is off (pulled-up by external

resistor).

If OC is reset by PO and over current is still active,

OC pin will be forced low again by the next edge of

SYNC signal.

To reset OC state PO must be forced to V

least T

OCoff

.

• Autoreset function

The autoreset function consists in clearing

automatically the OC fault.

To enable the autoreset function, simply short

circuit the OC pin with the PO pin.

|=|V

in

inp-Vinm

|>V

OCoff

SS

OCth

dOCon

(see

for at

.

,

11 www.irf.com

Page 12

Triangular

SYNC (0)

PO

IR2277S/IR2177S(PbF)

Cycle 1 Cycle 2 Cycle 3 Cycle 4

T

off_cycle1

Dn =

1

T

cycle1

T

cycleoff

2_

T

cycle

1

Dn =

T

off_cycle2

T

cycle2

T

cycleoff

T

cycle

3_

2

2

T

off_cycle3

Dn =

3

T

cycle3

T

T

cycleoff

cycle

T

off_cycle4

4_

3

Figure 8: PO Duty Cycle

Ext

supply

High voltage

V

IN+

V

IN-

Over current

detection

Low voltage

SRD

OC

V

SS

Level shifter

PO

Figure 9: Over current block diagram

12 www.irf.com

Page 13

IR2277S/IR2177S(PbF)

∆

1.4 Analog Output (OUT)

The analog output is internally buffered and capable

of driving capacitive loads ranging up to 50nF.

V

and VRL set the dynamic range and gain of OUT

RH

pin.

Additional circuitry to protect A/D converter input

against excessive voltage is not required.

Hereafter follow some definitions (see Figure 10

and following).

• V

in=Vinp-Vinm

• Input referred analog offset (V

): It is

aos

the input that gives an output that equals

VV

+

RLRH

OUT

=

(referred to VSS).

2

1

SYNC

OUT

=

a

V

∆

in

curve

in

.

++≤≤++

• Gain: It is defined by the ratio G

• Linearity: It is defined by the maximum

difference between the ideal OUT/V

and the measured curve depurated of the

offset voltage and the gain error.

The analog output is also defined by some dynamic

characteristics (see figure 8):

• Slew Rate (SL

). The maximum slope of

OUT

OUT measured in V/µs

• Settling time (t

). Time needed by the

settl

analog output (OUT) to reach 90% of final

value.

• Measure delay (MD). It is defined by the

time interval between the actual SYNC

edge and PO rising edge.

• Step response (SR). Is the time needed by

Output to reach the final value after a step

of the input.

Is always within the following range:

1

f

⋅

2

SYNC

settl

SROUTtMD

f

tMD

settl

V

V

V

V

V

V

V

V

V

OUT

RH

VRH+V

RL

2

RL

SS

V

aos

Figure 10: Input offset definition

OUT

RH

G

RL

SS

a

G

V

id

in

Figure 11: Gain definition

OUT

RH

G

a

G

RL

SS

id

(V

if PO is measured

pos

instead of OUT)

OUT

Linearity

Error

V

V

V

in

in

in

Figure 12: Linearity error definition

13 www.irf.com

Page 14

IR2277S/IR2177S(PbF)

+

−

1.5 DC transfer functions

The working principle of the device can be easily

explained by Figure 13, in which the main signals

are represented.

Triangular

reference

SYNC

Vin

PO

VRH

OUT

VRL

Figure 13: Main current sensor signals and

outputs

PWM out (PO pin) gives a duty cycle which is

inversely proportional to the input signal while the

OUT pin gives the analog converted output.

Eq. 2 gives the resulting D

pin):

Eq. 2

D ⋅−=

40%20

where V

= V

in

inp-Vinm

of the PWM output (PO

n

%

V

inn

V

VV

Eq. 3

()

2

+⋅−⋅=

VVVOUT

inRLRH

RLRH

2

The same equation can be referred to V

RL

, as

follows in Eq. 4:

Eq. 4

VV

()

2

OUT

-250mV

-200mV

-100mV

Figure 15: ideal OUT/V

VVVVOUT

+⋅−⋅=−

inRLRHRL

V

RH

(VRH+VRL)/2

V

RL

0mV

100mV

transfer function

in

2

V

250mV

200mV

RLRH

in

PO duty cycle

30%

25%

20%

15%

V

10%

in

Figure 14: PO Duty Cycle (D

)

n

The Voltage-to-Time conver si on (V

to PO) must be

in

reconstructed (see Functional Block Diagram) to

give an analog voltage output at OUT pin.

OUT pin swings from V

output (referred to V

SS

to VRH, so the analog

RL

) follows Eq. 3:

14 www.irf.com

Page 15

IR2277S/IR2177S(PbF)

Filter AC characteristic

IR2177/2277 signal path can be considered as

composed by three stages in series (see Figure 17).

The first two stages perform the filtering action.

Stage 1 (input filter) implements the filtering action

originating the transfer function shown in Figure 18.

The input filter is a self-adaptive reset integrator

which performs an accurate ripple cancellation. This

stage extracts automatically the PWM frequency

from Sync signal and puts transmission zeros at

even harmonics, rejecting the unwanted PWM

noise.

The following timing diagram shows the principle by

which even harmonics are rejected (Figure 16).

As can be seen from Figure 18, the odd harmonics

are rejected as a first order low pass filter with a

single pole placed in f

PWM

.

The input filter group delay in the pass-band is very

low (see GD on AC electrical characteristics) due to

the beneficial action of the zeroes.

The second stage samples the result of the first

stage at double Sync frequency. This action can be

used to fully remove the odd harmonics from the

input signal.

To perform this cancellation it is necessary a shift of

90 degrees of the SYNC signal with respect to the

triangular carrier edges (SYNC2).

The following timing diagrams show the principle of

odd harmonics cancellation (Figure 19), in which

SYNC2 allows the sampling of stage 1 output

during odd harmonic zero crossings.

Odd harmonic cancellation using SYNC2 (i.e. 90

degree shifted SYNC signal) signal will introduce

Tsync/4 additional propagation delay.

Anther way to obtain the same result (odd

harmonics cancellation) can be achieved by

controller computing the average of two consecutive

PO results using SYNC1 (SYNC is in this case

aligned to triangular edges, i.e. 0 degree shift).

This method is suitable for most symmetric (center

aligned) PWM schemes.

For this particular PWM scheme another suitable

solution is driving the IR2x77 with a half frequency

SYNC signal (f

sync=fPWM

/2).

In this case the cut frequency of the input filter is

reduced by half allowing zeroes to be put at f

PWM

multiples (i.e. even and odd harmonics cancellation,

no more computational effort needed by the

controller).

Figure 16: Even harmonic cancellation principle

Figure 17: Simplified block diagram

15 www.irf.com

Page 16

IR2277S/IR2177S(PbF)

Figure 18: Input filter transfer function (10 kHz PWM)

16 www.irf.com

Page 17

IR2277S/IR2177S(PbF)

Switching level

Switching level

Triangular

Triangular

Phase voltage

Phase voltage

Phase current

Phase current

Current Mean

Current Mean

Fundamental

Fundamental

harmonic

harmonic

Third

Third

harmonic

harmonic

Fundamental

Fundamental

harmonic

harmonic

Third

Third

harmonic

harmonic

SYNC 1

SYNC 1

Error

Error

SYNC 2

SYNC 2

Stage 1 input:

Input signal

components

st

(1

and 2

harmonic only)

Stage 1

output

Sampling

Sampling

instant

instant

Sampling

Sampling

instant

instant

nd

Figure 19: Even harmonic cancellation principle

1.6 Input filter gain setting

G0 and G1 pins are used to change the time

constant of the integrators of the high side input

filter.

To avoid internal saturation of the input filter, G0

and G1 must be connect according to SYNC

frequency as shown in Table 1. A too small time

constant may saturate the internal integrator, while

a large time constant may reduce accuracy.

G0 and G1 do not affect the overall current sensor

gain.

f

G0 G1

PWM

> 16 kHz * VB VB

16 / 10 kHz VS VB

10 / 6 kHz VB VS

< 6 kHz VS VS

*Æ 40 kHz

Table 1: G0, G1 gain settings

2 Sizing tips

2.1 Bootstrap supply

The V

side drivers circuitry of the IR2277S/IR2177S. V

supply sit on top of the V

floating.

The bootstrap method to generate V

be used with IR2277S/IR2177S current sensors.

The bootstrap supply is formed by a diode and a

capacitor connected as in Figure 20.

voltage provides the supply to the high

BS1,2,3

voltage and so it must be

S

supply can

BS

IR2277SorIR2177S

17 www.irf.com

Figure 20: bootstrap supply schematic

BS

Page 18

IR2277S/IR2177S(PbF)

⋅

=

=

This method has the advantage of being simple and

low cost but may force some limitations on dutycycle and on-time since they are limited by the

requirement to refresh the charge in the bootstrap

capacitor.

Proper capacitor choice can reduce drastically

these limitations.

Bootstrap capacitor sizing

Given the maximum admitted voltage drop for VBS,

namely ∆V

V

decrease are:

BS

, the influencing factors contributing to

BS

− Floating section quiescent current (I

− Floating section leakage current (I

− Bootstrap diode leakage current (I

);

QBS

)

LK

LK_DIODE

);

− Charge required by the internal level shifters

); typical 20nC

(Q

LS

− Bootstrap capacitor leakage current (I

− High side on time (T

I

is only relevant when using an electrolytic

LK_CAP

HON

).

LK_CAP

);

capacitor and can be ignored if other types of

capacitors are used. It is strongly recommend using

at least one low ESR ceramic capacitor (paralleling

electrolytic and low ESR ceramic may result in an

efficient solution).

Then we have:

+++++= )(

TIIIIQQ

__

HONCAPLKDIODELKLKQBSLSTOT

The minimum size of bootstrap capacitor is then:

Q

TOT

C

BOOT

min

=

V

∆

BS

Some important considerations

a) Voltage ripple

There are three different cases making the

bootstrap circuit get conductive (see Figure 20)

I

IGBT displaying relevant V

In this case we have the lowest value for V

This represents the worst case for the bootstrap

capacitor sizing. When the IGBT is turned off the

Vs node is pushed up by the load current until the

< 0; the load current flows in the low side

LOAD

CEon

VVVV −−=

CEonFCCBS

BS

.

high side freewheeling diode get forwarded

biased

I

on and V

= 0; the IGBT is not loaded while being

LOAD

can be neglected

CE

VVV −

FCCBS

I

> 0; the load current flows through the

LOAD

freewheeling diode

VVVV +−

FPFCCBS

In this case we have the highest value for V

Turning on the high side IGBT, I

and V

is pulled up.

S

flows into it

LOAD

BS

.

b) Bootstrap Resistor

A resistor (R

boot

) is placed in series with the

bootstrap diode (see Figure 20) to limit the current

when the bootstrap capacitor is initially charged. We

suggest not exceeding some Ohms (typically 5,

maximum 10 Ohms) to avoid increasing the V

BS

time-constant. The minimum on time for charging

the bootstrap capacitor or for refreshing its charge

must be verified against this time-constant.

c) Bootstrap Capacitor

For high T

designs where an electrolytic tank

HON

capacitor is used, its ESR must be considered. This

parasitic resistance develops a voltage divider with

R

generating a voltage step on V

boot

at the first

BS

charge of bootstrap capacitor. The voltage step and

the related speed (dV

/dt) should be limited. As a

BS

general rule, ESR should meet the following

constraint:

ESR

+

RESR

BOOT

CC

VV

3≤⋅

Parallel combination of small ceramic and large

electrolytic capacitors is normally the best

compromise, the first acting as fast charge tank for

the gate charge only and limiting the dV

/dt by

BS

reducing the equivalent resistance while the second

keeps the V

voltage drop inside the desired ∆VBS.

BS

d) Bootstrap Diode

The diode must have a BV> 600V (or 1200V

depending on application) and a fast recovery time

(t

< 100 ns) to minimize the amount of charge fed

rr

back from the bootstrap capacitor to V

supply.

CC

18 www.irf.com

Page 19

IR2277S/IR2177S(PbF)

3 PCB LAYOUT TIPS

3.1 Distance from H to L voltage

The IR2277S/IR2177S package (wide body)

maximizes the distance between floating (from DCto DC+) and low voltage pins (V

). It is strongly

SS

recommended to place components tied to floating

voltage in the respective high voltage portions of the

device (V

, VS) side.

B

3.2 Ground plane

Ground plane must NOT be placed under or nearby

the high voltage floating side to minimize noise

coupling.

VB

VS

Vin-

Vin+

Antenna

Loop

Figure 21: antenna loops

3.3 Antenna loops and inputs

connection

Current loops behave like antennas able to receive

EM noise. In order to reduce EM coupling loops

must be reduced as much as possible. Figure 21

shows the high side shunt loops.

Moreover it is strongly suggested to use Kelvin

connections for V

connect V

to V

S

and V

in+

close to the shunt resistor as

in-

to shunt paths and star-

in-

explained in Fig. 22.

VB

VS

Vin-

Vin+

Figure 22: Recommended shunt connection

3.4 Supply capacitors

The supply capacitors must be placed as close as

possible to the device pins (V

ground tied supply, V

and VS for the floating

B

supply) in order to minimize parasitic traces

inductance/resistance

and VSS for the

CC

19 www.irf.com

Page 20

Case Outline

IR2277S/IR2177S(PbF)

WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245 Tel: (310) 252-7105

Data and specifications subject to change without notice. 8/18/2005

20 www.irf.com

This part has been qualified for the Industrial Market

Loading...

Loading...