Page 1

Data Sheet No. PD60219 rev.B

IR2161(S) & (PbF)

HALOGEN CONVERTOR CONTROL IC

Features

Intelligent half-bridge driver

•

Auto Resetting Short Circuit Protection

•

Auto Resetting Overload Protection

•

Packages

• Externally Triggerable Latching Shutdown

• Latching Overtemperature Protection

• Frequency Modulation “dither” (for lower EMI)

• Micropower Startup (<300 µA)

• Phase Cut dimmable for leading / trailing edge

• Output Voltage Shift Compensation.

8-Lead PDIP

IR2161

8-Lead SOIC

IR2161S

• Real Softstart

• Adaptive Dead Time

• Small 8 Pin DIP/SOIC Package

• Also available LEAD-FREE (PbF)

Description

The IR2161 is a dedicated Intelligent Half bridge Driver IC for a Halogen convertor (electronic transformer). It

includes all necessary protection features and also allows the Convertor to be dimmed externally with a

standard phase cut dimmer with both leading or trailing edge types. This IC provides the advantage of reduced

thermal stress in the lamp due to softstart. There is also compensation of the output voltage for load regulation.

It enables the convertor to operate with extremely low harmonic distortion over the full range of loads. The

IR2161 includes adaptive deadtime to allow cool running MOSFETs and improves the EMI behaviour due to

frequency modulation (dither). All the features are integrated in a small 8 pin DIP/SOIC package to allow for a

size reduction in the next generation of convertors.

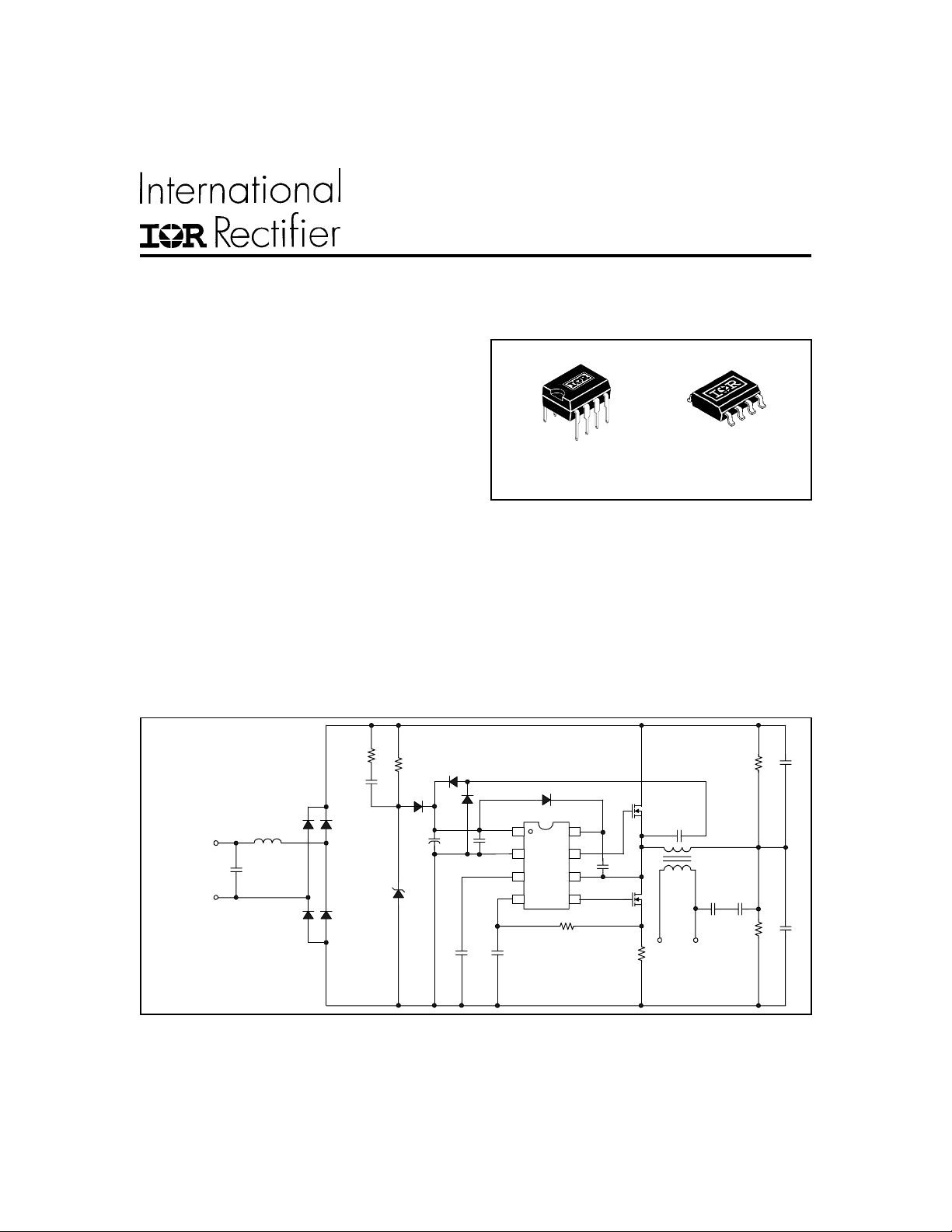

Typical Connections

AC LINE

INPUT

CLF

LF

D1 D2

D3 D4

RD

CD

RS

DCP1

CS

1

2

3

4

CCS

DB

8

IR2161

7

6

5

RL

Q1

Q2

OUTPUT

CSNUB

12VAC

VB

HO

CB

VS

LO

RCS

CVCC2

DCP2

VCC

COM

CSD

CSD

DS

CVCC1

VZ

R1

T1

C3 C4

R2 C2

C1

Note: Throughout this data sheet “convertor” is spelled in accordance with standard IEC 61047 “DC or AC supplied convertors

for filament lamps – Performance requirements”.

www.irf.com 1

Page 2

IR2161(S) & (PbF)

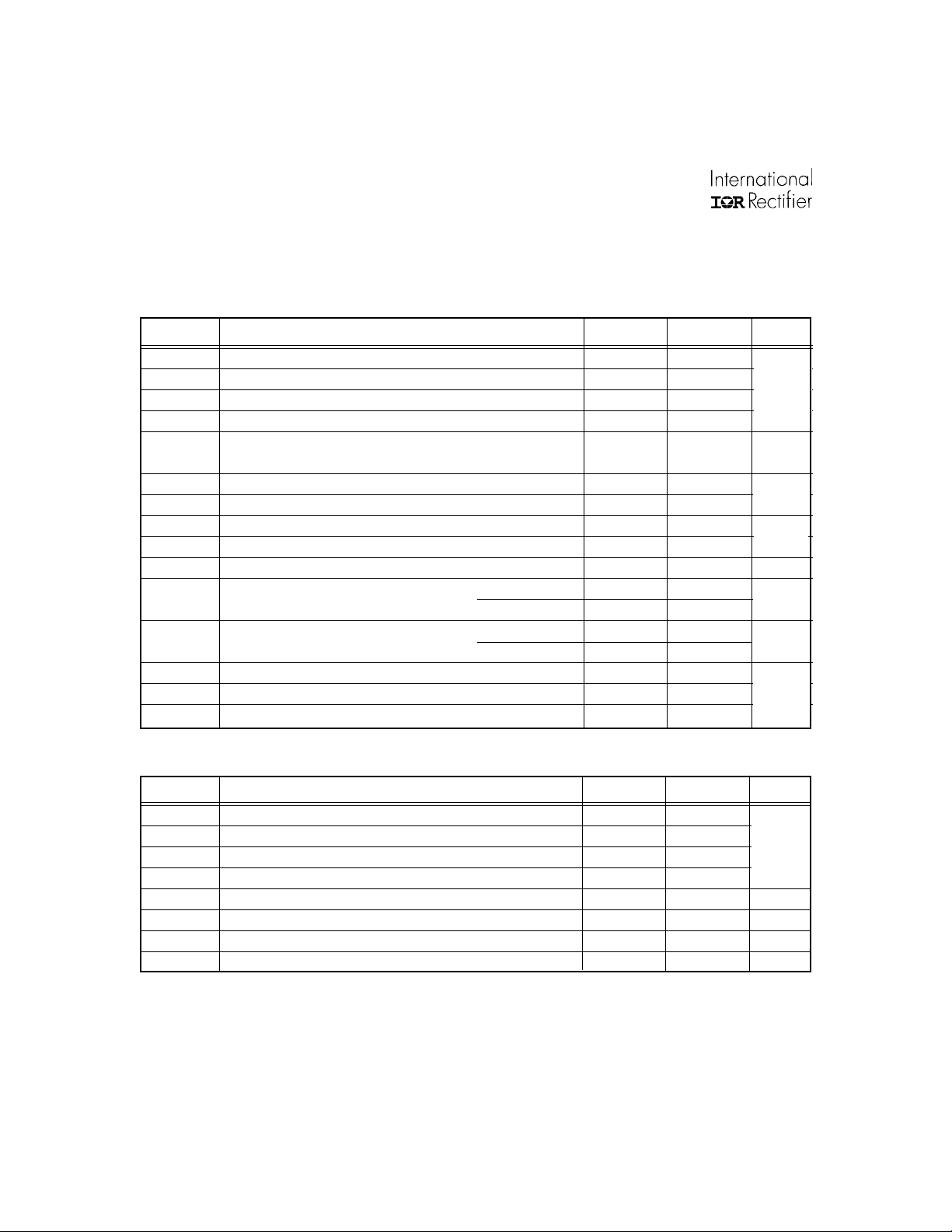

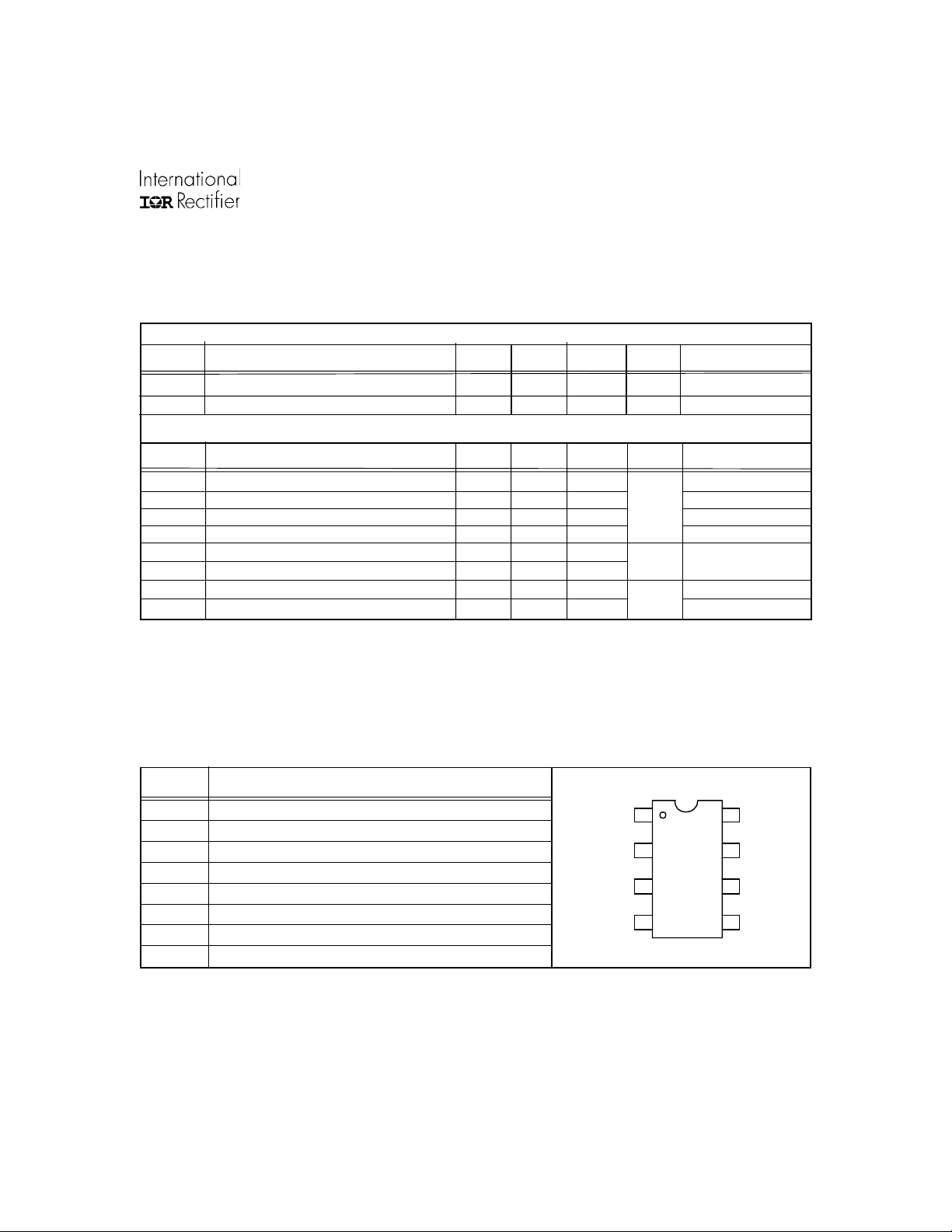

Absolute Maximum Ratings

Absolute maximum ratings indicate sustained limits beyond which damage to the device may occur. All voltage parameters

are absolute voltages referenced to COM, all currents are defined positive into any lead. The thermal resistance and power

dissipation ratings are measured under board mounted and still air conditions.

Symbol Definition Min. Max. Units

V

B

V

S

V

HO

V

LO

IO

MAX

V

CSDMAX

V

CS

I

CS

I

CC

dV/dt Allowable offset voltage slew rate -50 50 V/ns

P

D

Rth

JA

T

J

T

S

T

L

High side floating supply voltage -0.3 625

High side floating supply offset voltage VB - 25 VB + 0.3

High side floating output voltage VS - 0.3 V

B

+ 0.3

Low side output voltage -0.3 VCC + 0.3

Maximum allowable output current (HO,LO) due to external -500 500

power transistor miller effect

CSD pin voltage -0.3 V

Current sense pin voltage -0.3 V

CC

CC

+ 0.3

+ 0.3

Current sense pin current -5 5

Supply current (Note 1) -20 20

Maximum power dissipation @ T

PD = (T

JMAX-TA

)/Rth

(8 Lead SOIC) — 0.625

JA

≤ +25°C (8 Lead DIP) — 1

A

Thermal resistance, junction to ambient (8 Lead DIP) — 125

(8 Lead SOIC) — 200

Junction temperature -55 150

Storage temperature -55 150

Lead temperature (soldering, 10 seconds) — 300

V

mA

V

mA

W

°C/W

°C

Recommended Operating Conditions

For proper operation the device should be used within the recommended conditions.

Symbol Definition Min. Max. Units

V

BS

V

BSMIN

V

S

V

CC

I

CC

C

SD

I

CS

T

J

Note 1: This IC contains a zener clamp structure between the chip VCC and COM which has a nominal breakdown

Note 2: Enough current should be supplied into the VCC pin to keep the internal 15.6V zener clamp diode on this pin

2 www.irf.com

High side floating supply voltage VCC - 0.7 V

CLAMP

Minimum required VBS voltage for proper HO functionality 4.3 —

Steady state high-side floating supply offset voltage -1 600

Supply voltage V

CCUV+

V

CLAMP

V

Supply current (Note 2) 10 mA

CSD pin external capacitor 47 — nF

Current sense pin current -1 1 mA

Junction temperature -25 125 °C

voltage of 15.6V. Please note that this supply pin should not be driven by a DC, low impedance power source

greater than the V

regulating its voltage, V

specified in the Electrical Characteristics section.

CLAMP

.

CLAMP

Page 3

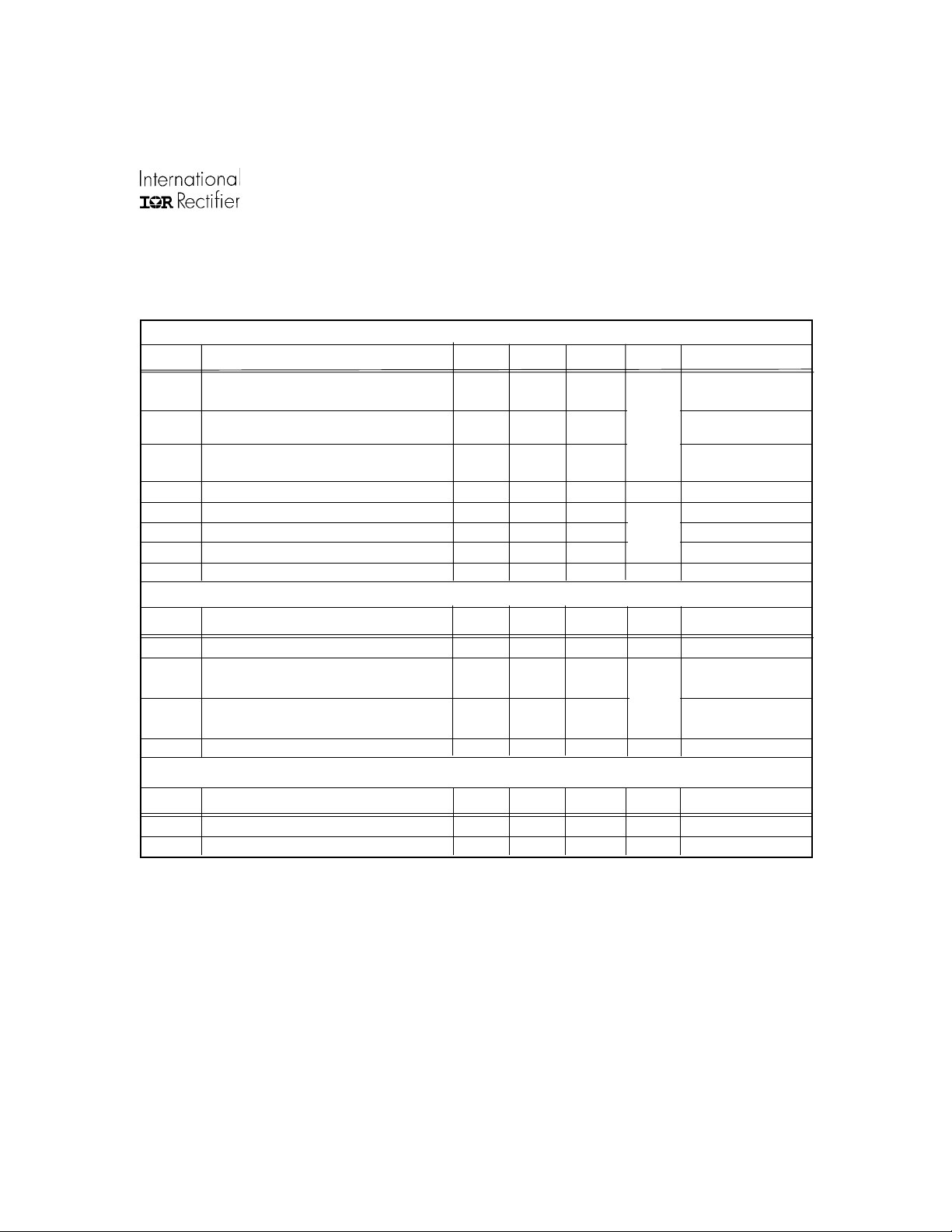

IR2161(S) & (PbF)

Electrical Characteristics

VCC = VBS = V

Supply Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

V

CCUV+VCC

V

CCUV-

V

CCUVL-VCC

I

QCCUV

I

CCFLT

I

VCC current (low frequency) — 2.0 3.0 VCC=14V,VCSD=5.2V

CC

LF

I

VCC current (high frequency) — 4.0 7.0 VCC=14V,VCSD=0V

CC

HF

V

CLAMPVCC

Floating Supply Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

V

BSM IN

I

BSHF

I

BSLF VBS

I

LEAK

= 14V, +/- 0.25V, VCSD = 5.0V, C

BIAS

supply undervoltage positive going

threshold 11.5 12.1 12.7 VCC rising from 0V

VCC supply undervoltage negative going

threshold 10 10.5 11 VCC falling from 14V

supply softstart reset negative going

threshold — — 5.5 VCC - V

UVLO mode quiescent current — 250 300 VCC = 11V

Fault-mode quiescent current — 1.4 2.0 CS=8V, VCSD=0V

zener clamp voltage 14.5 15.4 16.5 V ICC = 5mA

Minimum V

V

high frequency supply current — 3.0 — VCC=14V,VBS=14V,

BS

low frequency supply current — 0.8 — VCC=14V,VBS=14V,

Offset supply leakage current — — 50 µAV

to start oscillation at HO 3.0 3.6 4.3 V

BS

LO =CHO

= 1000 pF, and TA = 25°C unless otherwise specified.

V

(-2V)

µA

mA

mA

CCUV-

VCSD=0V

VCSD=5.2V

= VS = 600V

B

Voltage Compensation Characteristics (Run Mode)

Symbol Definition Min. Typ. Max. Units Test Conditions

V

CSD (min)

V

CSD (max)

www.irf.com 3

Min CSD voltage (in Run Mode) — 0 — V VCS = 0V

Max CSD voltage (in Run Mode) — 5.5 — V VCS = 0.4V

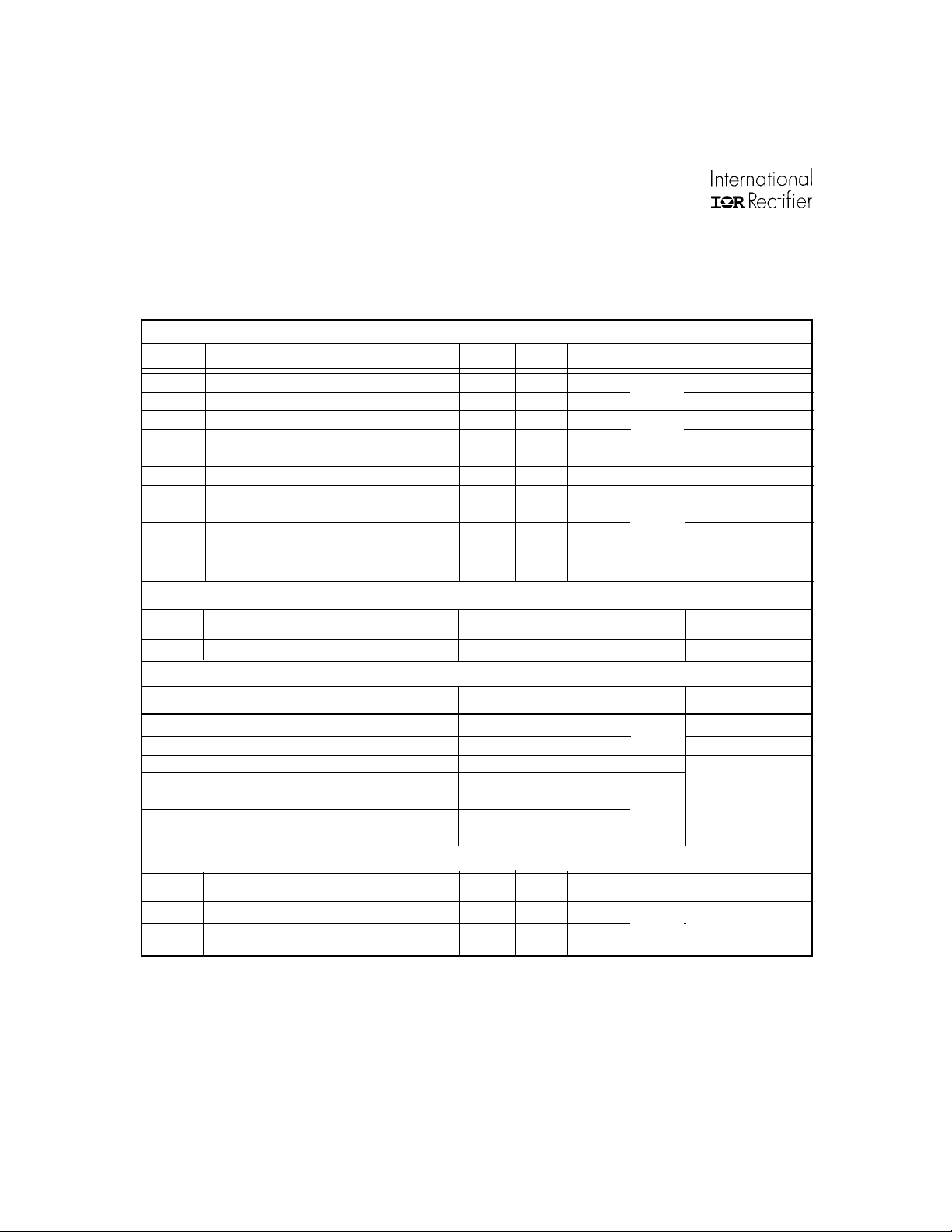

Page 4

IR2161(S) & (PbF)

Electrical Characteristics (cont’d)

VCC = VBS = V

Shutdown Circuit Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

V

CSOL

V

CSSC

I

OL

I

SC

I

RESET

V

CSLATCH

T

CSLATCH

V

CSDOL

V

CSDSD

V

CSDRS

Thermal Shutdown Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

T

SD

Oscillator Characteristics

= 14V, +/- 0.25V, VCSD = 5.0V, C

BIAS

Overload threshold (CS PID) 0.47 0.56 0.64

CSD short circuit threshold (CS PID) 1 1.2 1.4

CSD overload charging current

CSD short circuit charging current 75 100 120 VCS=1.5V,VCSD=7V

CSD shutdown reset current 0.1 0.7

Latched shutdown threshold

Latched shutdown delay 1 µsec VCS>VCSLATCH

Begin fault timing

Positive going threshold for oscillator

shutdown

Negative going threshold for oscillator restart

Latched over temperature limit

LO =CHO

= 1000 pF, and TA = 25°C unless otherwise specified.

V

6

—

—

—

—

—

9 12 VCS=0.8V,VCSD=7V

uA

9

5

12

2.4

135

—

—

—

—

—

—

oC

VCSD=14V

V

VCS>VCSOL

VCS > VCSOL

V

Symbol Definition Min. Typ. Max. Units Test Conditions

f

(min)

f

(max)

D Oscillator duty cycle

LO(max)

DT

DT

HO(max)

Minimum oscillator frequency — 34 — VCSD = 5.3V

Maximum oscillator frequency in RUN mode

Maximum LO output deadtime — 1.0 —

(run mode default)

Maximum HO output deadtime — 1.0 —

(run mode default)

—

70

— 50 — %

—

kHz

µsec

VCSD = 0V

no reset from ADT

Adaptive Dead-Time System Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

DT

DT

LO(min)

HO(min)

Minimum LO output deadtime — 700 —

Minimum HO output deadtime — 700

—

4 www.irf.com

Minimum propagation

nsec

delay from ADT to

output drivers

Page 5

IR2161(S) & (PbF)

Electrical Characteristics (cont.)

VCC = VBS = V

Soft Start Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

I

SS

f

SS

Gate Driver Output Characteristics

Symbol Definition Min. Typ. Max. Units Test Conditions

V

V

V

V

t

RISE

t

FALL

IO+ HO, LO source current — 200 —

IO- HO, LO sink current — 300 —

LO voltage when LO is low — COM —

LO=LOW

HO=LOW

LO voltage when LO is high — VCC —

LO=HIGH

HO voltage when HO is high — VCC —

HO=HIGH

Turn-off fall time — 60 140

= 14V, +/- 0.25V, VCSD = 5.0V, C

BIAS

Soft start CSD charge current — 0.5 — mA

Soft start frequency

HO voltage when HO is low — COM —

Turn-on rise time — 110 250

LO =CHO

= 1000 pF, and TA = 25°C unless otherwise specified.

—

115

—

kHz VCC>VCCUV+

CHO=CLO=1nFns

mA

Lead Definitions

Lead Assignments

Symbol Description

V

CC

COM IC power and signal ground

CSD Shutdown timing and compensation capacitor

CS Current sensing input

LO Low-side gate driver output

V

S

HO High side gate driver output

V

B

* Recommended value for CSD is 100nF (all performance data relates to this value)

NOTE: The recommended value for RL is 1K Ohm and CCS is 1nF.

www.irf.com 5

Supply voltage

High-side floating return

High side gate driver floating supply

VCC

COM

CSD

CS

1

IR2161

2

3

4

8

VB

HO

7

6

VS

5

LO

Page 6

IR2161(S) & (PbF)

Power Turned On

VCC < 5.5V (V

(Power Turned Off)

STANDBY Mode

1

/

-Bridge Off

2

≅

I

QCC

Oscillator Off

µ

A

300

VCC < 10.5V (V )

(Phase Cut Dimming)

VCC < 10.5V (V )

(Phase Cut Dimming)

Auto-Restart Timeout

(V

< 2.4V) (V

CSD

CSD switched to run mode

CCUVL-

VCC > 12.1V(V

T

<135 C

J

Oscillator On

CCUV-

CCUV-

)

CSDRS

)

CCUV+

jmax

)

)

o

(T

UVLO Mode

1

-Bridge Off

/

2

≅

I

QCC

Oscillator Off

CSD = 0V

300

A

µ

VCC > 12.1V

T

<135 C

J

o

(V

CCUV+

(T

)

jmax

VCC < 5.5V (V

(Power Turned Off)

)

CCUVL-

)

FAULT Mode

1

/

-Bridge Off

2

Oscillator Off

Oscillator On

SOFTSTART

Mode

1

/

- Bridge On

2

Initial frequency 130kHz

CSD charged from Isource

Fault Detected

CS

(Vpk at V

T

<135 C

J

> 0.56V)(V )

o

(T

)

jmax

(Over-Temperature)

CSOL

Frequency ramps down to

f(min)

CSD

V

> 5.2V

(End of SOFTSTART Mode)

CSD switched to Comp function

Fault Detected

CS

(V

<135 C

J

CSLATCH

o

> 9V)

)

(T

jmax

)

RUN Mode

Voltage compensation active

CSD varies between

VCSD (min)

to V

CSD(max)

= 0 for f

= 5.5V for f

(min)

(Vpk at V

T

(Over-Temperature)

CSD switched to

run mode

(max)

SHUTDOWN Mode

1

/

-Bridge Off

2

CSD is slowly discharged

Fault Confirmed

> 12V)

CSD

(V

(V

)

CSDSD

Fault Timing Mode

1

/

CSD initialized to 5V (V

VCS >0.56V(V

V

> 1.2V (V

CS

CSOL

CSSC

Fault Detected (Vpk at VCS > 0.56V (V ))

CSD switched to Shutdown Circuit

CSD discharged to 0V

Frequency defaults to f(min)

- Bridge On

2

CSDOL

)

)=Overload:CSD slow charge

Fault Removed

(Vpk at VCS < 0.5V)

(V )

) = Short Circuit : CSD

fast charge

CSOL

CSOL

Delay

CSD is slowly

discharged to 2.4V

CSDRS

(V

)

All values are typical

NOTE: If the IR2161 die temperature exceeds 135o at any time the system will enter FAULT Mode. At a typical frequency of

40kHz, the die temperature is approximately 12oC above the ambient air temperature

6 www.irf.com

Page 7

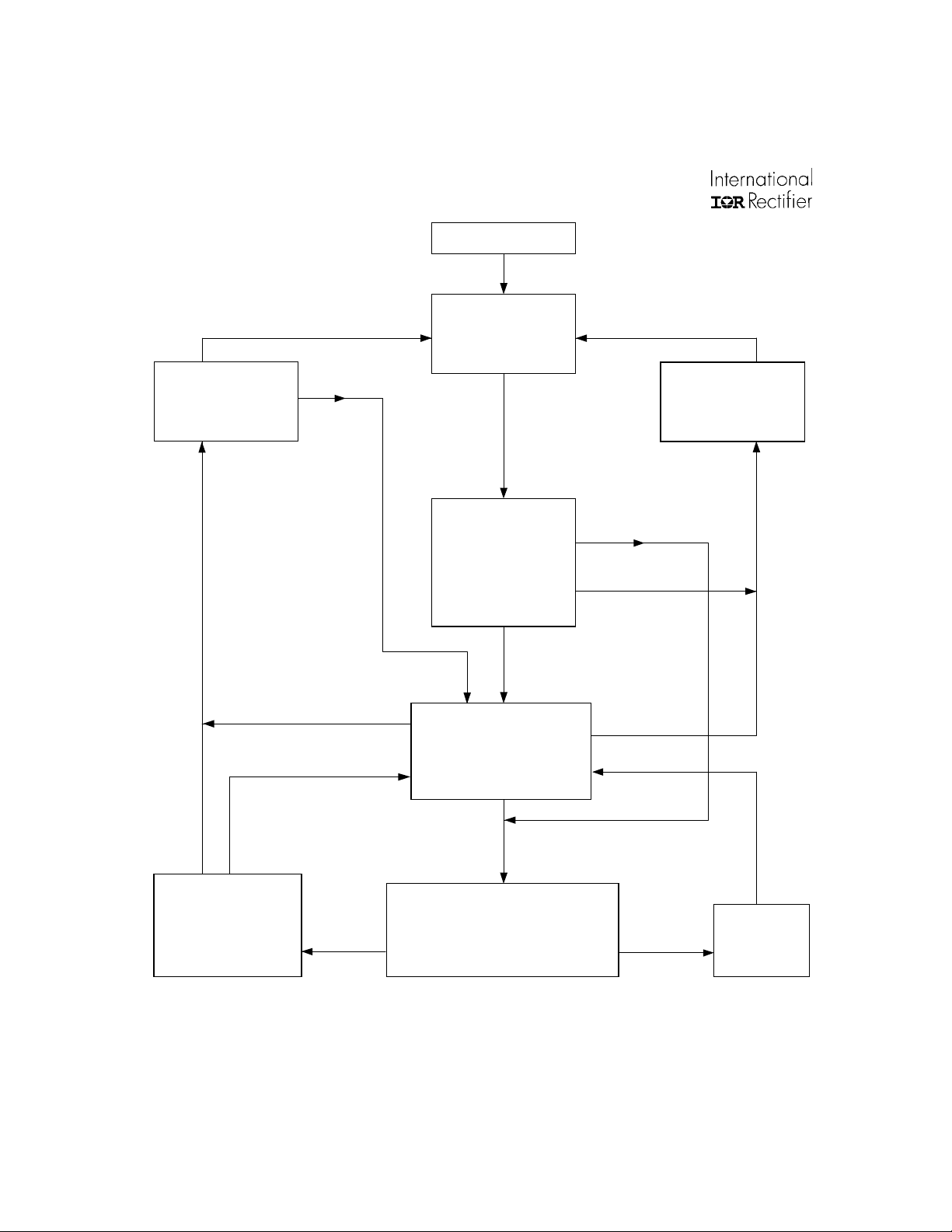

Block Diagram

IR2161(S) & (PbF)

0.54V

www.irf.com 7

Page 8

IR2161(S) & (PbF)

Halogen Convertor Controller

Functional Description

Under-voltage Lock-Out Mode (UVLO)

The under-voltage lockout mode (UVLO) is defined as the

state the IC is in when VCC is below the turn-on threshold.

To identify the different modes of operation, refer to the

State Diagram shown on page 7 of this data sheet. The

IR2161 under voltage lock-out is designed to maintain an

ultra low supply current of less than 300uA, and to guarantee the IC is fully functional before the high and low side

output drivers are activated. Figure 1 shows a simple VCC

supply arrangement that will work effectively, also when

the convertor is being dimmed from a conventional triac

based wall dimmer

RD

RS

CD

BR

LF

CF

The start-up capacitor (C

supply resistor (RS) minus the start-up current drawn by

the IC. This resistor is chosen to provide sufficient current

to supply the IR2161 from the DC bus. In a Halogen convertor it is important to consider that the DC bus is completely

unsmoothed and has a full wave rectified shape. C

be large enough to hold the voltage at Vcc above the UVLO

threshold for one half cycle of the line voltage as it will only

be charged at the peak. A charge pump consisting of two

diodes (DCP1 and DCP2) connected to CSNUB is recommended to supply VCC as this allows RS to be a large value

since it is only needed at startup. IF RS is required to supply

the circuit without a charge pump it needs to be a relatively

low value and consequently dissipates 1 to 2W, which is

undesirable.

An external 16V zener diode DZ has been added to avoid

the need for the internal zener to dissipate power (it should

DS

CVCC

DZ

DB

VCC

1

IR2161

COM

2

CSD

3

CS

4

CSD

CCS

M1

VB

8

HO

7

CB

VS

6

LO

M2

5

RL

RCS

Figure 1, Halogen Convertor.

) is charged by current through

VCC

OUTPUT

VCC

should

be rated at 1.3W). The resistor RD in series with CD is

necessary if the convertor is required to operate from a

triac based (leading edge) phase cut dimmer. When the

triac fires at a point during the mains half-cycle the high dv/

dt allows a large current to flow through this path to instantly

charge C

to the maximum Vcc voltage.

VCC

The external zener (DZ) will prevent possible damage to

the IC by shunting excess current to COM.

Once the capacitor voltage on VCC reaches the start-up

threshold the IC turns on and HO and LO begin to

oscillate.

The supply resistor (RS) and RD/CD must be selected such

that enough supply current is available over all ballast

operating conditions. A bootstrap diode (DB) and supply

capacitor (CB) comprise the supply voltage for the high

side driver circuitry. To guarantee that the high-side supply

is charged up before the first pulse on pin HO, the first

pulse from the output drivers comes from the LO pin. During

under voltage lock-out mode, the high and low-side driver

outputs HO and LO are both low.

Soft Start Mode

The soft start mode is defined as the state the IC is in at

system switch on when the lamp filament is cold. As with

any type of filament lamp, the Dichroic Halogen lamp has a

positive temperature coefficient of resistance such that the

cold resistance (at switch on when the lamp has been off

long enough to cool) is much lower than the hot resistance

when the lamp is running. This normally results in a high

inrush current occurring at switch on. Under worst-case

conditions this could potentially trigger the convertor’s shut

down circuit. To overcome this problem the IR2161

incorporates the soft start function.

When the IC starts oscillating the frequency is initially very

high (about 130kHz). This causes the output voltage of the

convertor to be lower since the HF transformer in the system

has a fixed primary leakage inductance that will present a

higher impedance at higher frequency and thus allowing

less AC voltage to appear across the primary. The reduced

output voltage will naturally result in a reduced current in

the lamp which eases the inrush current thus avoiding

tripping of the shutdown circuit and will ease the stress on

the lamp filament as well as reducing the current in the half

bridge MOSFETs (M1 and M2).

The frequency sweeps down gradually from 130kHz to the

8 www.irf.com

Page 9

IR2161(S) & (PbF)

minimum frequency over a period of around 1s (assuming

CSD=100nF). During this time the external capacitor at the

CSD pin charges from 0V to 5V, controlling the oscillator

frequency through the internal voltage controlled oscillator

(VCO). The value of CSD will determine the duration of the

soft start sweep. However, since it also governs the shut

down circuit delays, the value should be kept at 100nF to

achieve the datasheet operation.

ISS

CSD

5V

Figure 2, Halogen Convertor.

It can be seen from Figure 2, that at switch on, the CSD

capacitor is internally switched to the soft start circuit input.

A current source charges CSD linearly to 5V over a period

of 0.5s at which time the comparator output goes high. The

PMOS switch opens and the ISS current source is

disconnected from CSD. The comparator latches high at this

point and this causes the oscillator range to change and the

CSD capacitor to be disconnected from the soft start circuit

and connected to the voltage compensation circuit. The

latching comparator has a built in delay of at least 20uS in

order to prevent false triggering caused by transients.

Set Oscillator

Range

Figure 4, Cold Lamp Inrush Current with Soft Start.

Run Mode (Voltage Compensation)

When soft start is completed the system switches over to

compensation mode. This function provides some regulation of the output voltage of the convertor from minimum to

maximum load. In this type of system it is desirable that the

voltage supplied to the lamp does not exceed a particular

limit. If the lamp voltage becomes too high the temperature

of the filament runs too high and the life of the lamp is

significantly reduced. The problem is that the output transformer is never perfectly coupled so there will always be a

degree of load regulation.

The transformer has to be designed such that the lamp

voltage at maximum load is sufficiently high to ensure

adequate light output.

At minimum load the voltage will consequently be higher

and is likely to exceed the maximum desired lamp voltage.

In the widely used self-oscillating system based around

bipolar power transistors, there is some frequency change

(increasing the frequency reduces the output voltage)

depending on the load that helps to compensate for this,

although this is non-linear and depends on many parameters

in the circuit and so is not easy to predict.

The IR2161 based system includes a function that monitors

the load current through the current sense resistor (RCS).

Figure 3, Typical Cold Lamp Inrush Current.

The peak current is detected and amplified within the IC

then appears at the CSD pin during run mode. The voltage

www.irf.com 9

Page 10

IR2161(S) & (PbF)

across the CSD capacitor will vary from 0V if there is no

load to approximately 5V at maximum load.

This is provided that the correct value of current sense

resistor has been selected for the maximum rated load and

line voltage supply of the convertor. This should be 0.33

Ohm (0.5W) for a 100W system running from a 220-240V

AC line. (It should be noted that the RCS resistor value is

also critical for setting the limits for the shut down circuit)

In RUN mode the oscillator frequency will vary from

approximately 34kHz when VCSD is 5V (maximum load) to

70kHz when VCSD is 0V (no load). The result of this is that

if a lighter load, such as a single 35W lamp, is connected to

a 100W convertor, the frequency will shift upwards so that

the output voltage falls below the maximum that is desirable

for the lamp. This provides sufficient compensation for the

load to ensure that the lamp voltage will always be within

acceptable limits but does not require a complicated regulation

scheme involving feedback from the output.

An additional internal current source has been included to

discharge the external capacitor. This will provide

approximately 10% ripple at twice the line frequency if CSD

is 100nF.

The advantage of this is that during the line voltage half

cycle the oscillator frequency will vary by several kHz thus

spreading the EMI conducted and radiated emissions over

a range of frequencies and avoiding high amplitude peaks

at particular frequencies. In this way the filter components

used may be similar to those used in a common bipolar self-

Figure 6, VS voltage and CSD voltage.

In the above trace it can be seen that a leading edge phase

cut (triac) dimmer is connected at close to maximum

brightness. There is a short delay at the beginning of each

half cycle before the AC line voltage is switched to the

convertor. Dimming increases the ripple in the CSD voltage

and gives more modulation. This is an inherent effect that

causes no system problems.

The startup sequence of the CSD pin can be seen from the

point where VCC increases above the UVLO+ threshold.

AV > 13

CS

12K

oscillating system.

Figure 5, Voltage Compensation Circuit

150K

CSD

Figure 7, Startup sequence of CSD.

This trace shows that after the CSD voltage has ramped up

through soft start, the system switches over to voltage compensation mode and a ripple exists which allows the frequency modulation (or “dither”) to occur. In this case the

10 www.irf.com

Page 11

IR2161(S) & (PbF)

convertor is close to maximum load. If the load is reduced,

the average level at which the ripple occurs (i.e. the DC

component) will be at a lower level.

Shut Down Circuit

The IR2161 contains a dual mode auto-resetting shutdown

circuit that detects both a short circuit or overload condition

in the convertor. The load current detected at the CS pin is

used to sense these conditions. If the output of the convertor

is short-circuited, a very high current will flow in the half

bridge and the system must shut down within a few mains

half cycles, otherwise the MOSFETs will rapidly be destroyed

due to excessive junction temperature. The internal CS pin

has an internal threshold (V

threshold so that if the voltage exceeds this level for more

than 50mS, the system will shut down.

A delay is included to prevent false tripping either due to

lamp inrush current at switch on (this current is still higher

than normal with the soft start operation) or transient

currents that may occur if an external triac based phase

cut dimmer is being used.

There also exists a lower threshold (V

much longer delay before it shuts down the system. This

provides the overload protection if an excessive number of

lamps is connected to the output or the output is shortcircuited at the end of a length of cable that has sufficient

resistance to prevent the current from being large enough

to trip the short circuit protection. Also under this condition

there is an excessive current in the half bridge that is

sufficient to cause heating and eventual failure but over a

longer period of time. The threshold for overload shutdown

is approximately 50% above maximum load with a delay of

approximately 0.5s. These timings are based on a current

waveform that has a sinusoidal envelope and a high

frequency square wave component with 50% duty cycle.

Both shutdown modes are auto resetting, which allows the

oscillator to start again approximately 1.5s after shutting

down. This is so that if the fault condition is removed the

system can start operating normally again without the line

voltage having to be switched off and back on again. It also

provides a good indication of overload to the end user as all

the lamps connected to the system will flash on and off

continuously if too many are connected.

The shut down circuit also uses the external CSD capacitor for

it’s timing functions. When the 0.5V threshold (V

ceeded at CS the CSD is internally disconnected from the voltage

compensation circuit and connected to the shutdown circuit.

). There also exists a lower

CSSC

), which has a

CSOL

CSOL

) is ex-

1.2V

Shutdown Functi on

0.54V

Overload Functi on

I_SC

I_OL

12V

2.5V

4V

RQ

I_RESET

QS

Enable OutputsCS

Switch

CSD

Figure 8, Shut Down Circuit.

The oscillator operates at minimum frequency when the

CSD capacitor is required for shutdown circuit timing.

During soft start or run mode, if the 0.5V threshold (V

CSOL

is exceeded the IR2161 charges CSD rapidly to approximately 5V (V

CSDOL

).

When the voltage at the CS input is greater than 0.5V, the

CSD capacitor is charged by current source IOL and when

the short circuit threshold of 1.2V is exceeded it is charged

by ISC as well. If 1.2V is exceeded CSD will charge from 5V

(V

CSDOL

) to 12V (V

), in approximately 50ms. When

CSDSD

0.5V is exceeded but 1.2V is not, CSD charges from 5V

(V

CSDOL

) to 12V (V

) in approximately 0.5s. It should

CSDSD

be remembered that, the timing accounts for the fact that

high frequency pulses with approximately 50% duty cycle

and a sinusoidal envelope appear at the CS pin.

The values of ISC and IOL take into account that only at the

peak of the mains will the comparator outputs go high and

effectively the capacitor will be charged in steps each line

half cycle. Once VCSD reaches 12V (V

discharges down to 2.4V (V

) and the system starts

CSDRS

CSDSD

), VCSD

up again. If the fault mode is still present, CSD starts

charging again.

If a fault is detected but goes away before CSD reaches

12V (V

), then CSD will discharge to 2.4V (V

CSDSD

CSDRS

and then the system will revert to compensation mode

without interruption of the output.

Following a shutdown, when the system starts up again

after the delay, the CSD capacitor will be internally switched

back to the voltage compensation circuit. However, if the

fault is still present the system will switch CSD back to the

shutdown circuit again.

)

)

www.irf.com 11

Page 12

IR2161(S) & (PbF)

Figure 9, Short Circuit Output Current.

In addition, any time Vcs exceeds VCSLATCH

(approximately half Vcc), this latching shutdown function

will be triggered and the system will remain in FAULT mode

until VCC is re-cycled.

The IR2161 also includes over temperature shutdown, which

latches the convertor off when the die temperature of the

IC exceeds 130-135

that the die temperature will be no more than 20

the ambient temperature at all operating frequencies inside

the convertor.

°C. Experimental measurements reveal

°C above

Calculating Rcs

The value of the current sense resistor Rcs is critical to

achieve correct operation in the IR2161 based Halogen

convertor.

DC Bus

Voltage

VS

LOAD

1/2 DC Bus

Voltage

VCSpk

VCS

RCS

Figure 10, Overload Output Current.

In figures 9 and 10, trace (1) shows the half bridge

oscillations during both types of fault mode and trace (2)

shows the charging and discharging of the CSD capacitor.

The IR2161 can also be externally shut off by applying a

voltage above 9V (VCSLATCH) to the CS pin. This will

cause the system to go directly to a latched fault mode,

after a delay of approximately 1uS to avoid the possibility of

false tripping caused by transients. To restart the system, it

is necessary to cycle Vcc off and on.

Ignoring the output transformer we can assume for this

calculation that the load is connected from the half bridge to

the mid point of the two output capacitors and that the

voltage at this point will be half the DC bus voltage. The

RMS voltage of the DC bus is the same as that of the AC line

so we can see that the RMS voltage across the load shown

in Figure 8, will be half the RMS voltage of the line. The load

is the maximum rated load of the convertor. The current in

Rcs will be half the load current given by :

12 www.irf.com

Figure 11, Calculating RCS

Page 13

IR2161(S) & (PbF)

P

I =

RMSCS

Since the load is resistive the current waveform will have a

sinusoidal envelope and so the peak can be easily determined taking into account that the current has a high frequency component with an approximate 50% duty cycle:

Therefore:

For correct operation at maximum load the peak voltage

should be 0.4V.

The calculation can be simplified by combining the formulae,

=

R

CS

Which can be simplified to:

R ⋅= 141.0

CS

LOAD

)(

V

AC

22

II ×=

)()(

V

⋅

4.0

⋅⋅

22

V

P

CS

P

LOAD

AC

LOAD

)()(

RMSCSPKCS

RIV ×=

CSPKCSPKCS

In this case :

2

100

=×

W062.033.0

230

It is important to bear in mind that the resistor must be rated

to handle this current in a high ambient temperature.

IMPORTANT NOTE

The filter resistor RL should be 1K, which is needed to

protect the CS input from negative going transients. CCS

should be 1nF and is also necessary to filter out switching

transients that can impair the operation of the shutdown

circuit.

Adaptive Dead Time

Because of the fact that the DC bus voltage varies during

the mains half cycle, the dead time may need to vary in

order to achieve soft switching. The IR2161 has an adaptive dead time circuit (ADT) that detects the point at which

the voltage at the half bridge slews to 0V (COM) and sets

the LO output high at this point. There is an internal sample

and hold system that allows approximately the same delay

to be used to set HO high after LO has gone low. This

reacts on a cycle-by-cycle basis of the oscillator and therefore will adjust the dead time as necessary regardless of

external conditions.

Example

For a 100W convertor working from a 230VAC supply the

current sense resistor would need to be :

×

230141.0

324.0

Ω=

100

The nearest preferred value to this would be 0.33 Ohms.

The power dissipation in Rcs should also be considered

and is given by :

2

LOAD

V

AC

R

CS

Figure 12, ADT when VS slews from VBUS to COM

P

P ×

=

CS

www.irf.com 13

Page 14

IR2161(S) & (PbF)

Figure 12, ADT when VS slews from COM to VBUS

The above waveforms are typical, showing the operation

of the ADT circuit in either direction. In this case the design

could be optimized further by increasing the snubber capacitor to slightly increase the slew time, in order to account for the propagation delays in the system. Alternatively an output transformer with a greater leakage inductance can extend the period before the VS voltage turns

around and starts to go back the other way again.

The designer does not need to take into account parasitic

capacitances in the MOSFETs or leakage inductance in the

output transformer and fix the dead time accordingly.

The system can operate reliably down to dead times in the

order of 300nS, which should be low enough to

accommodate the output transformer leakage inductance

and parasitic MOSFET capacitances of a practical Halogen

convertor.

The slew rate can easily be increased, if necessary, by

adding a small snubber capacitor across the primary of the

transformer if necessary. However, should the snubber

capacitor be too large, it will prevent the VS voltage from

slewing all the way to the opposite rail. Consequently the

ADT function will be unable to operate, causing the IR2161

to revert to the default dead time of 1µS. Snubber capacitors

would normally be in the order of hundreds of pF.

of the power MOSFETs in the half-bridge will be at a

maximum. At lighter loads there may be hard switching if

the VS voltage is unable to slew all the way or it slews so

rapidly that the voltage begins to turn around again before

the IR2161 is able to switch on the relevant MOSFET in the

half bridge.

Such a situation is not desirable but may be acceptable at

lighter loads where the conduction losses are small.

With correct optimization of the output transformer and

surrounding circuit it is possible to achieve a design that

will not hard switch from 20% to 100% of the maximum

rated load of the system.

This system avoids the need for an external resistor to

program the dead time and contributes to the multi functional nature of the CSD pin to the IR2161 being realized

with only 8 external pins

In any design when there is no load at the output, the VS

voltage will not slew and obviously the ADT circuit is not

able to function in this condition. In this case the dead time

will default to approximately 1µS, the maximum allowed by

the IC and there will be hard switching.

Although this will inevitably lead to some switching losses,

there are no conduction losses so the temperature rise of

the half bridge MOSFETs should not create a problem in this

case.

Dimming

Almost any Halogen convertor available can be dimmed by

an external phase cut dimmer that operates in trailing edge

mode. This means that at the beginning of the line voltage

half cycle, the switch inside the dimmer is closed and mains

voltage is supplied to the convertor allowing the convertor

to operate normally. At some point during the half cycle, the

switch inside the dimmer is opened and voltage is no longer

applied. The DC bus inside the convertor almost immediately

drops to 0V and the output is no longer present. In this way

bursts of high frequency output voltage are applied to the

lamp. The RMS voltage across the lamp will naturally vary

depending on the phase angle at which the dimmer switch

switches off. In this way the lamp brightness may easily

be varied from zero to maximum output.

When designing a halogen convertor it is desirable to optimize

the system at maximum load, where the conduction losses

14 www.irf.com

Page 15

IR2161(S) & (PbF)

DC BUS VOLTAGE

LAMP VOLTAGE

Figure 13, Trailing Edge Dimming

Trailing edge dimmers are less common however than leading

edge dimmers. This is because they are more expensive to

make and need to incorporate a pair of MOSFETs or IGBTs

whereas a leading edge dimmer is based around a single

triac.

Conversely many Halogen convertors are not able to operate with leading edge dimmers because of the fact that

they are based around a triac. It is possible, however, to

design a Halogen convertor that will work effectively with

a triac based dimmer by designing the input filter components correctly ensuring that at the firing point of the triac

the oscillator can start up rapidly. In the IR2161 based system this is easy to achieve through the addition of RD and

CD, which conduct a large current to VCC due to the high

dv/dt that occurs when the triac fires. At the same time, the

bus voltage rises rapidly from zero to the AC line voltage. If

the VCC voltage falls below V

the triac in the dimmer is off, the soft start will not be initiated because the soft start circuit is not reset until VCC

drops approxmately 2V below V

time as the VCC capacitor discharges very slowly during

UVLO micro-power operation. The intermediate period is

referred to as Standby mode.

during the time when

CCUV-

. This takes some

CCUV-

DC BUS VOLTAGE

LAMP VOLTAGE

Figure 14, Leading Edge Dimming

holding current. If the load is purely resistive (as in a filament lamp directly connected to the dimmer) this will naturally happen at the end of the line voltage half cycle as the

current has to fall to zero. In a Halogen convertor it is necessary to place a capacitor and inductor at the AC input to

comply with regulations regarding EMI conducted emis-

sions. This means that when the line voltage falls to zero

there could still be some current flowing that is enough to

keep the triac switched on and so the next cycle will follow

through and not be phase cut as required. This can happen

intermittently resulting in flickering of the lamps. The way to

avoid the problem is to ensure that the product has the

smallest possible filter capacitor CCS and to state a minimum load for the convertor. This would be typically one

third of the maximum load to avoid problems of this kind.

During dimming the voltage compensation circuit will cause

a frequency shift upward at angles above 90° because the

peak voltage at CS will be reduced (see figure 14). This will

result in a reduction of voltage at CSD and thus an increase

in frequency. However this will not have a noticeable effect

on the light output.

The problem associated with operation of Halogen convertors with triac dimmers is due to the fact that after a triac

has been fired it will conduct until the current falls below its

Figure 15, Half Bridge voltage and current during dimming

www.irf.com 15

Page 16

IR2161(S) & (PbF)

5

5

)

a

5

15

VCCUV+

12

9

VCC(V)

6

3

0

-25 0 25 50 75 100 12

VCCUV-

Temperature (°C)

Graph : VCCUV +/- vs TEMP (IR2161)

20

VCCLAMP_25ma

15

VCCLAMP_5ma

5

4

3

2

IQCC (mA

1

0

-25 0 25 50 75 100 12

ICCHF

ICCLF

IQCCFLT

Temperature (°C)

Graph : IQCC vs TEMP (IR2161)

6

5

4

VCSDMAX

10

VCCLAMP_5_25m

5

3

VCSD (V)

2

1

VCSDMIN

0

-25 0 25 50 75 100 125

Temperature (°C)

Graph : VCCLAMP_5_25ma vs TEMP (IR2161)

0

-25 0 25 50 75 100 12

Temperature (°C)

VCSDMIN,MAX vs TEMP (IR2161)

16 www.irf.com

Page 17

IR2161(S) & (PbF)

5

5

5

5

2

1.5

VCS_SC

1

VCSOL, VCSSC (V)

0.5

VCS_OL

0

-25 0 25 50 75 100 12

Temperatur e (°C)

VCS_OL, VCS_SC vs TEMP (IR2161)

100

20

15

10

I (uA)

5

I_OL

I_RESET

0

-25 0 25 50 75 100 12

Temperature ( °C)

I_RESET, I_OL vs TEMP (IR2161)

12

VCSD_SD

VCSD_OL

I(uA)

90

80

70

I_SC

9

6

VCSD (V)

3

VCSD_RS

60

-25 0 25 50 75 100 12

Temperature (°C)

I_SC vs TEMP (IR2161)

0

-25 0 25 50 75 100 12

Temperature (°C)

Graph : VCSDSD,OL,RS vs TEMP (IR2161)

www.irf.com 17

Page 18

IR2161(S) & (PbF)

5

5

175

150

125

100

75

Frequency (kHz)

50

25

0

-25 0 25 50 75 100 12

FSS

FRUN

FMIN

Temperatur e (°C)

Frequency vs TEMP (IR2161)

1

0.8

0.6

Iss (uA)

0.4

0.2

0

-25 0 25 50 75 100 12

Temperature (°C)

Graph : Iss (uA) vs TEMP (IR2161)

18 www.irf.com

Page 19

Case outlines

IR2161 8-Lead PDIP

IR2161(S) & (PbF)

01-6014

01-3003 01

(MS-001AB)

A

E

D B

5

87

6

6X

0.25 [.010]

65

H

4312

0.25 [.010] A

e

8X b

e1

A1

A

CAB

NOTES:

1. DIMENS IO NING & TOLE RAN CING PE R ASME Y14.5M-1994.

2. CONTROLLING DIM ENSION: MILLIMETER

3. DIMENSIONS ARE SHOWN IN MILLIMETERS [INCHE S].

4. OUTLINE CONFORMS TO JEDEC OUTLINE MS-012AA.

IR2161S 8-Lead SOIC

C

0.10 [.004]

6.46 [.255]

3X 1.27 [.050]

y

DIM

FOOTPRINT

8X 0.72 [.028]

8X 1.78 [.070]

MIN MAX

.0532

A

.0040

A1

b

.013

c .0075 .0098 0.19 0.25

D

.189

E

.1497

.050 B ASIC

e

.025 BA SIC 0.635 BA SIC

e1

.2284

H

.0099

K

.016

L

y

0°

K x 45°

8X L

8X c

7

5 DIMENSION DOES NOT INCLUDE MOLD PROTRUSIONS.

MO LD P ROTR US IO NS N OT TO EX CE ED 0.15 [.006].

6 DIMENSION DOES NOT INCLUDE MOLD PROTRUSIONS.

MO LD P ROTR US IO NS N OT TO EX CE ED 0.25 [.010].

7 DIMENSION IS THE LENGTH OF LEAD FOR SOLDERING TO

A SU BSTR ATE .

01-0021 11

.0688

.0098

.020

.1968

.1574

.2440

.0196

.050

8°

MILLIMETERSIN C H E S

MIN MAX

1.35

1.75

0.10

0.25

0.33

0.51

4.80

5.00

3.80

4.00

1.27 BA SIC

5.80

6.20

0.25

0.50

0.40

1.27

0°

8°

01-6027

(MS-012AA)

www.irf.com 19

Page 20

IR2161(S) & (PbF)

LEADFREE PART MARKING INFORMATION

Part number

Date code

Pin 1

Identifier

?

MARKING CODE

Lead Free Released

P

Non-Lead Free

Released

IRxxxxxx

YWW?

ORDER INFORMATION

Basic Part (Non-Lead Free)

8-Lead PDIP IR2161 order IR2161

8-Lead SOIC IR2161S order IR2161S

IR logo

?XXXX

Lot Code

(Prod mode - 4 digit SPN code)

Assembly site code

Per SCOP 200-002

Leadfree Part

8-Lead PDIP IR2161 order IR2161PbF

8-Lead SOIC IR2161S order IR2161SPbF

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245 Tel: (310) 252-7105

20 www.irf.com

This product has been qualified per industrial level MSL-3, Lead-free available

Data and specifications subject to change without notice. 9/19/2005

Loading...

Loading...