Page 1

Preliminary Data Sheet No. PD60169-E

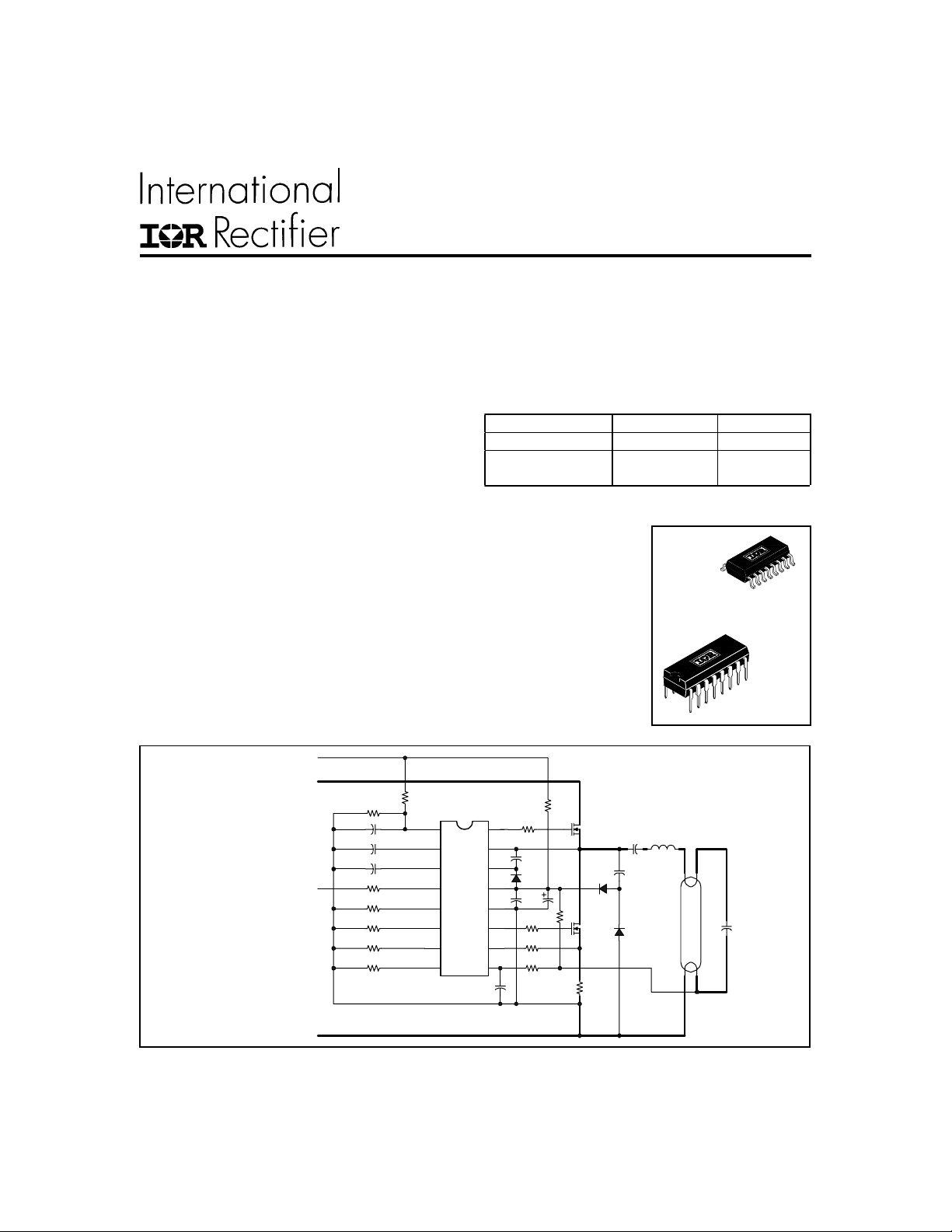

DIMMING BALLAST CONTROL IC

Features

Ballast control and half-bridge driver in one IC

•

T ransf ormer-less lamp power sensing

•

Closed-loop lamp power control

•

Closed-loop preheat current control

•

Programmable preheat time

•

Programmable preheat current

•

Programmable ignition-to-dim time

•

0.5 to 5VDC dimming control input

•

Min and max lamp power adjustments

•

Programmable minimum frequency

•

Internal current sense blanking

•

Full lamp fault protection

•

Description

Description: The IR2159/IR21591 are complete dimming ballast controllers and 600V

half-bridge drivers all in one IC. The architecture includes phase control for transformer-less lamp power sensing and regulation which minimizes changes needed to

adapt non-dimming ballasts for dimming. Externally programmable features such as

preheat time and current, ignition-to-dim time, and a complete dimming interface with

minimum and maximum settings provide a high degree of flexibility for the ballast

design engineer. Protection from failure of a lamp to strike , filament failures, thermal

overload, or lamp failure during normal operation, as well as an automatic restart

function, have been included in the design. The heart of this control IC is a voltagecontrolled oscillator with externally programmable minimum frequency. The IR2159/

IR21591 are available in both 16 pin DIP and 16 pin narrow body SOIC packages.

Brown-out protection

•

Automatic restart

•

Micro-power startup

•

Zener clamped V cc

•

Over-temperature protection

•

16-pin DIP and SOIC package types

•

Parameter IR2159 IR21591

Deadtime 1.8us 1.0us

Frequency

Range

IR2159

IR21591

See

Graph 3

Packages

16 Lead SOIC

(narrow body)

(S)

(S)

See

Graph 4

16 Lead PDIP

T ypical Connection

+ Rectified AC Line

+ DC Bus

0.5 to 5VDC

- DC Bus

R

VAC

R

VDC

C

VDC

1

C

VCO

C

PH

R

DIM

R

MAX

R

MIN

R

FMIN

R

IPH

VDC

2

VCO

3

CPH

DIM

5

MAX

6

MIN

7

FMIN

8 9

IPH

R

PULL-UP

16

HO

15

VS

14

VB

134

VCC

12

COM

11

LO

10

CS

SD

R

CS

www.irf.com 1

Single Lamp Dimmable

Page 2

IR2159/IR21591

(S)

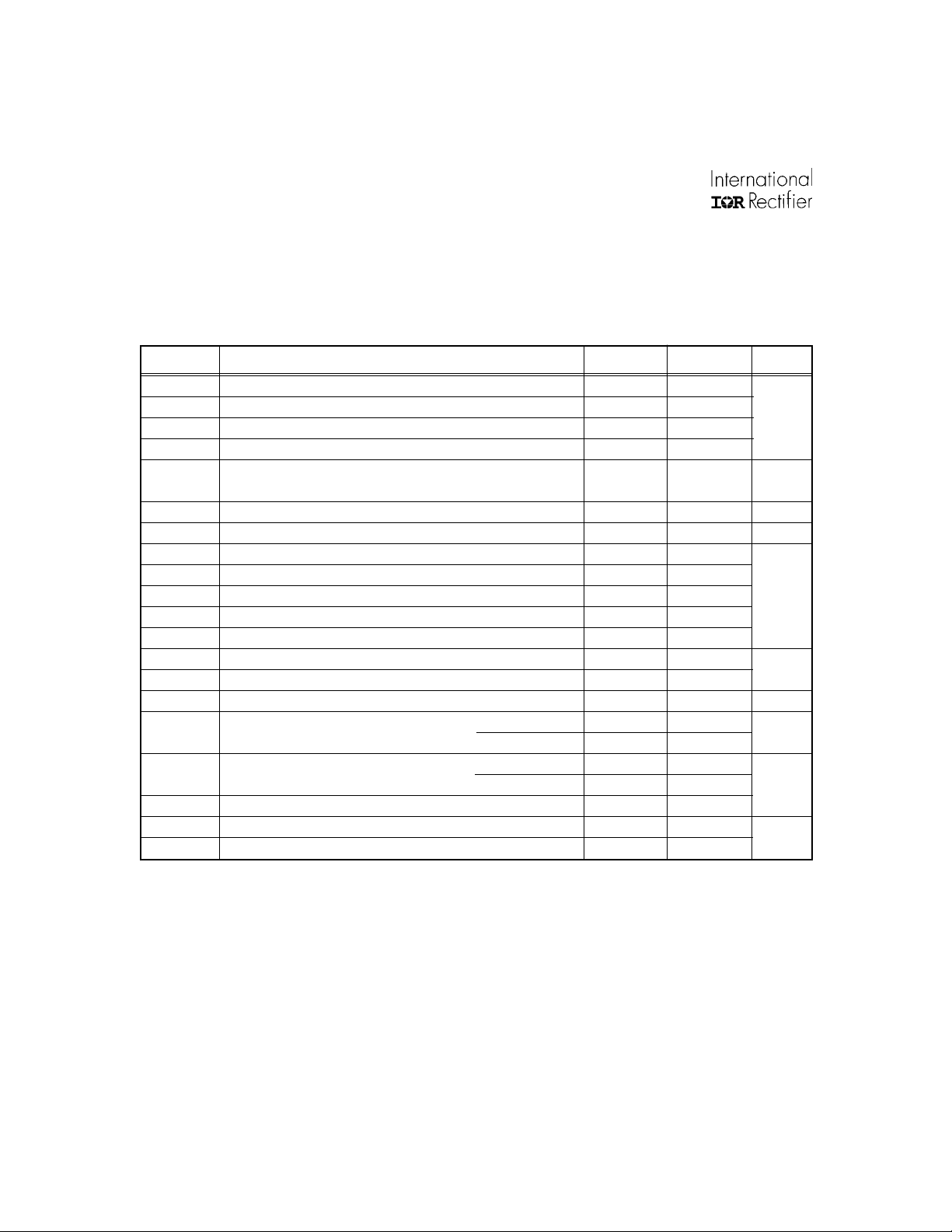

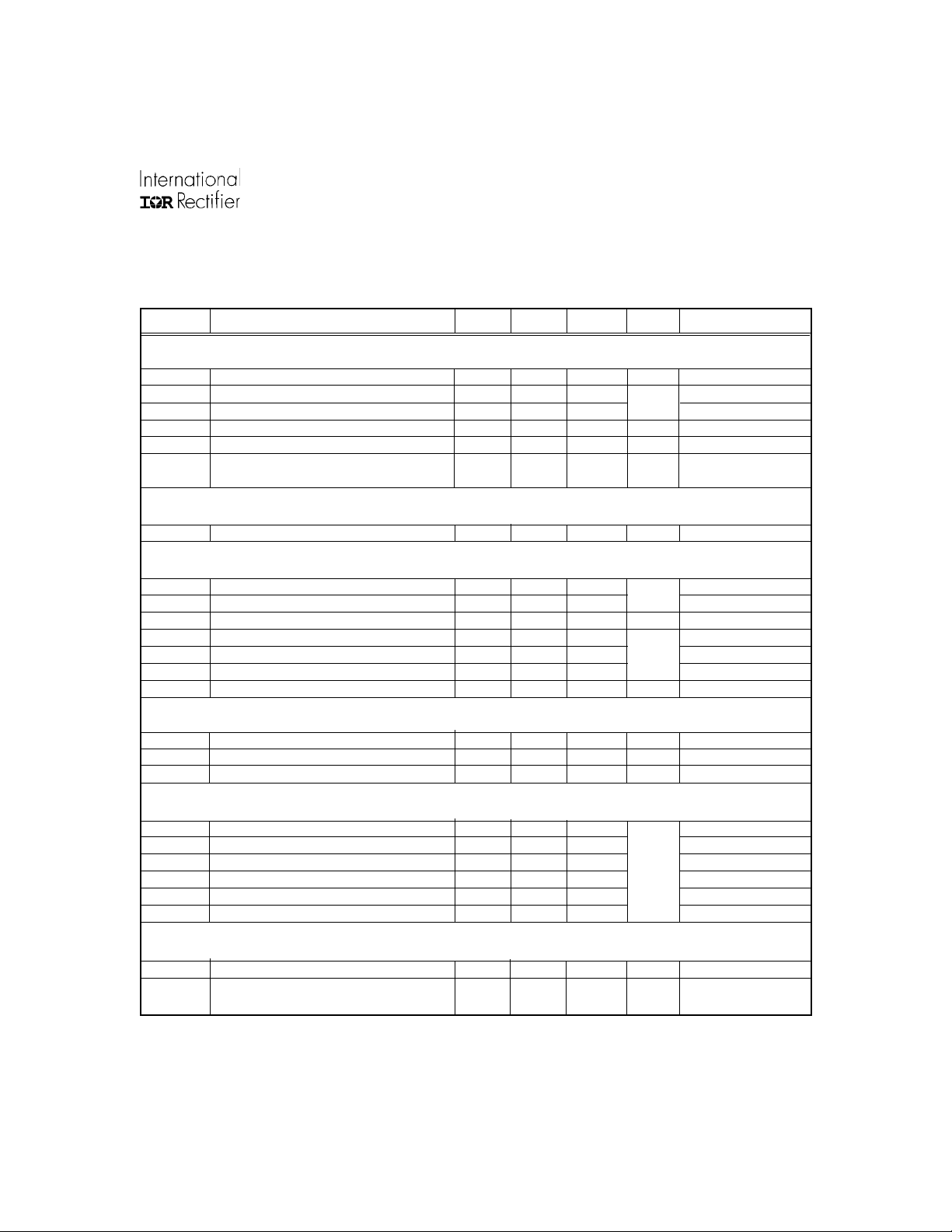

Absolute Maximum Ratings

Absolute maximum ratings indicate sustained limits beyond which damage to the device may occur. All voltage

parameters are absolute voltages referenced to COM, all currents are defined positive into any lead. The thermal

resistance and power dissipation ratings are measured under board mounted and still air conditions.

Symbol Definition Min. Max. Units

V

B

V

S

V

HO

V

LO

I

OMAX

V

VCO

I

CPH

V

IPH

V

DIM

V

MAX

V

MIN

V

CS

I

SD

I

CC

dV/dt Allowable offset voltage slew rate - 50 50 V/ns

P

D

Rth

JA

T

J

T

S

T

L

High side floating supply voltage -0.3 625

High side floating supply offset voltage VB - 25 VB + 25

High side floating output voltage VS - 0.3 V

B

+ 0.3

Low side output voltage -0.3 VCC + 0.3

Maximum allowable output current (either output) -500 500

due to external power transistor miller effect

mA

Voltage controlled oscillator input v oltage -0.3 6.0 V

CPH current -5 5 mA

IPH voltage -0.3 5.5

Dimming control pin input voltage -0.3 5.5

Maximum lamp power setting pin input voltage -0.3 5.5

V

Minimum lamp power setting pin input voltage -0.3 5.5

Current sense input voltage -0.3 5.5

Shutdown pin current -5 5

Supply current (note 1) — 25

Package power dissipation @ TA ≤ +25°C (16 pin DIP) — 1.60

P

D

(T

=

JMAX-TA

)/Rth

JA

(16 pin SOIC) — 1.25

Thermal resistance, junction to ambient (16 pin DIP) — 7 5

(16 pin SOIC) — 11 5

mA

W

o

C/W

Junction temperature -55 15 0

Storage temperature -55 15 0

o

Lead temperature (soldering, 10 seconds) — 300

V

C

Note 1: This IC contains a zener clamp structure between the chip VCC and COM which has a nominal breakdown

voltage of 15.6V (V

power source greater than the diode clamp voltage (V

). Please note that this supply pin should not be driven by a DC, low impedance

CLAMP

) as specified in the Electrical Characteristics

CLAMP

section.

2 www.irf.com

Page 3

IR2159/IR21591

(S)

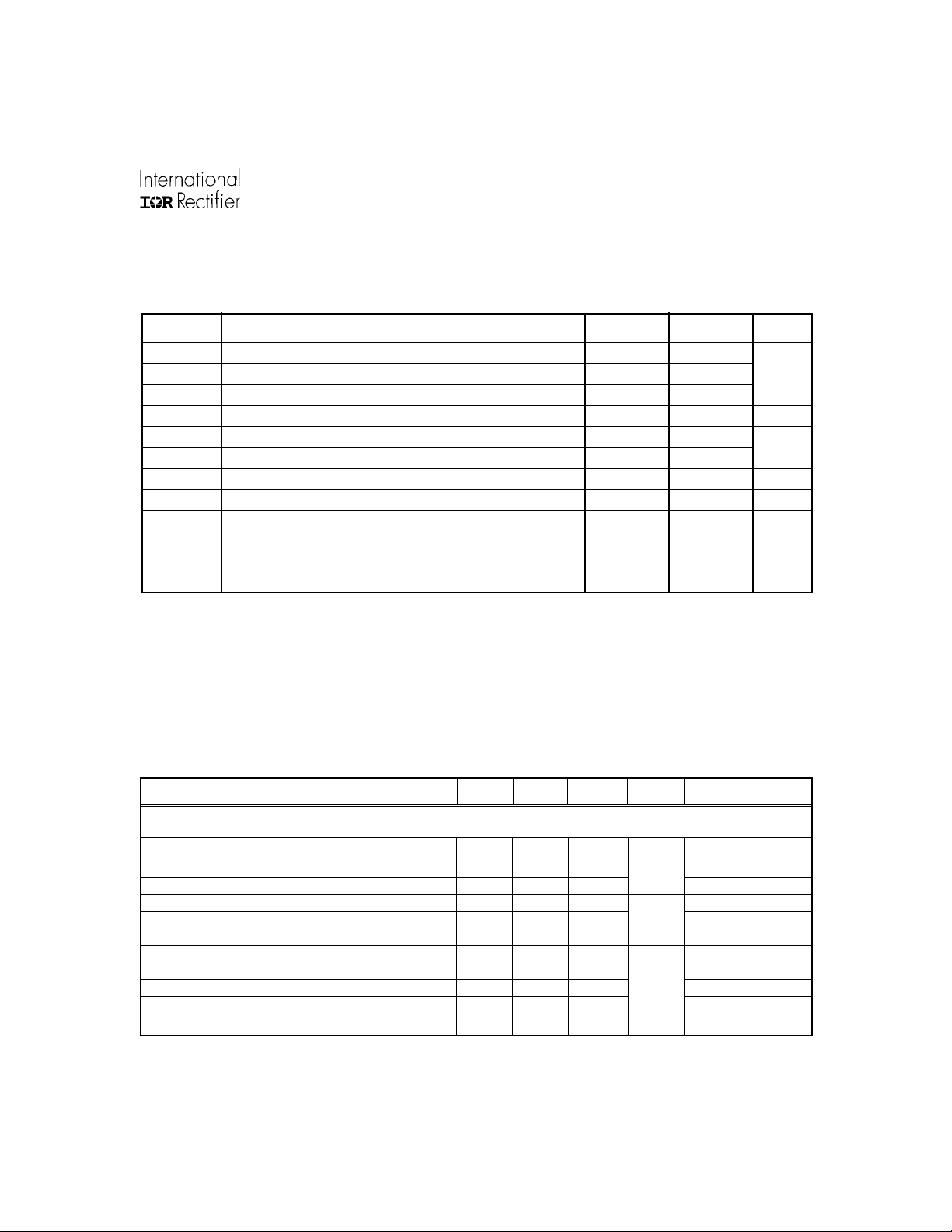

Recommended Operating Conditions

For proper operation the device should be used within the recommended conditions.

Symbol Definition Min. Max. Units

V

BS

V

S

V

CC

I

CC

V

VCO VCO pin voltage

V

DIM

V

MAX

V

MIN

R

FMIN

I

SD

I

CS

T

J

High side floating supply voltage VCC - 0.7 V

Steady state high side floating supply offset voltage -1 600

Supply voltage V

Supply current note 2 10 mA

DIM pin voltage 0 5

MAX pin current (note 3) -750 0

MIN pin voltage 1 3 V

Minimum frequency setting resistance 10 1 00

Shutdown pin current - 1 1

Current sensing pin current -1 1

Junction temperature -40 125

CCUV+VCLAMP (15.6)

05

CLAMP

V

V

µA

kΩ

mA

o

C

Note 2: Enough current should be supplied into the VCC lead to keep the internal 15.6V zener clamp diode on this lead

Note 3: The MAX lead is a voltage-controlled current source. For optimum dim interface current mirror performance,

regulating its voltage, V

this current should be kept between 0 and 750µA.

CLAMP

.

Electrical Characteristics

VCC = VBS = V

R

= 56k, V

MIN

Symbol Definition Min. Typ. Max. Units Test Conditions

Supply Characteristics

V

CCUV+ VCC

V

CCHYS VCC

I

QCCUV

I

QCCFLT

I

QCCFMIN VCC

I

QCCFMAX VCC

I

QCCFMIN VCC

I

QCCFMAX VCC

V

CLAMP VCC

= 14V +/- 0.25V, VCS = 0.5V, VSD = 0.0V, R

BIAS

= 0.0V, C

CPH

supply undervoltage positive going 12.0 12.5 13.0

threshold

supply undervoltage lockout hysteresis 1.5 1.6 1.7

UVLO mode quiescent current — 200 — VCC = 10V

Fault-mode quiescent current — 240 — SD=5V, CS=2V, or

supply current @ FMIN (IR2159) — 5.6 — V

supply current @ FMAX (IR2159) — 6.6 — V

supply current @ FMIN (IR21591) — 5.4 — V

supply current @ FMAX (IR21591) — 6.8 — V

zener shunt clamp voltage 14.5 15.6 16.5 V ICC = 10mA

= 1000pF, TA = 25oC unless otherwise specified.

LO,HO

FMIN

= 40k, C

VCO

= 10 nF, V

= 0.0V, R

DIM

V

µA

mA

MAX

Tj > TSD

VCO

VCO

VCO

VCO

= 33k,

= 0V

= 5V

= 0V

= 5V

www.irf.com 3

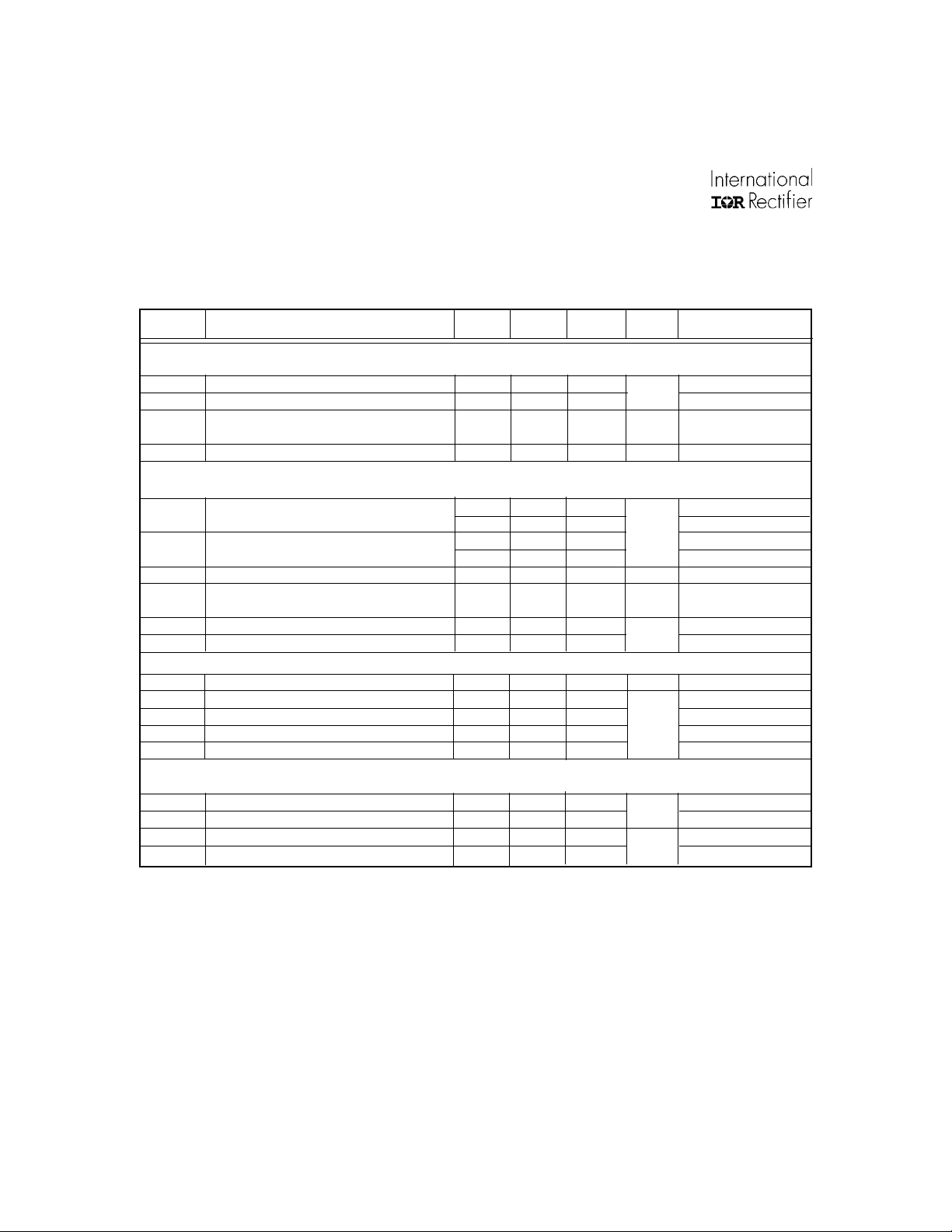

Page 4

IR2159/IR21591

(S)

Electrical Characteristics (cont.)

VCC = VBS = V

R

= 56k, V

MIN

Symbol Definition Min. Typ. Max. Units Test Conditions

Floating Supply Characteristics

I

QBS0

I

QBS1

V

BSMIN

I

LK

Oscillator I/O Characteristics

f

vco

f

vco

d Gate drive outputs duty cycle

V

VCOFLT

IVCOPH Preheat mode VCO pin discharge current

IVCODIM Dim mode VCO pin discharge current

= 14V +/- 0.25V, VCS = 0.5V, VSD = 0.0V, R

BIAS

= 0.0V, C

TPH

Quiescent VBS supply current — 0 — VHO = V

Quiescent VBS supply current —

Minimum required VBS v oltage for proper

HO functionality

Offset supply leakage current — — 50

VCO frequency range (IR2159) — 25 —

(See graph 3) —

VCO frequency range (IR21591) — 30 —

(See graph 4) —

Fault-mode VCO pin voltage (UVLO,

shutdown, over-current/temp.)

= 1000pF, TA = 25oC unless otherwise specified.

LO,HO

= 40k, C

FMIN

— 4

—

—

—

1.0

—

VCO

30

95

230

50

5 V

16.0

= 10 nF, V

—V

5 V

—

—

—

—

—

= 0.0V, R

DIM

µA

µA

kHz

% V

µA

MAX

= V

HO

VB = VS = 600V

V

=0V, RFMIN=39KΩ

VCO

V

=5V, RFMIN=10KΩ

VCO

V

=0V, RFMIN=68KΩ

VCO

V

=5V, RFMIN=10KΩ

VCO

VCO

VCPH < 5V

= 33k,

S

B

= 0V

IVCOPK

t

DTLO

t

DTHO

t

DTLO

t

DTHO

Amplitude control VCO pin charging current — 60.0 —

LO output deadtime (IR2159)

HO output deadtime (IR2159)

LO output deadtime (IR21591)

HO output deadtime (IR21591)

— 1.8 —

— 1.8 —

— 1.0 —

— 1.0 —

µA

µs

V

CPH

< 5V, V

CS

Gate Driver Output Characteristics

VOL Low-level output voltage — — 100

VOH High-level output voltage — — 100 V

tr Turn-on rise time — — 150

tf T urn-off fall time

—

—

100

4 www.irf.com

mV

ns

BIAS

- Vo

>

V

IPH

Page 5

IR2159/IR21591

(S)

Electrical Characteristics (cont.)

VCC = VBS = V

R

= 56k, V

MIN

Symbol Definition Min. Typ. Max. Units Test Conditions

Preheat Characteristics

ICPH CPH pin charging current

VCPHIGN CPH pin ignition mode threshold voltage

VCPHCLMP CPH pin clamp voltage —

IIPH IPH pin DC source current — 25.0 — µAIIPH = 1/RFMIN

VCSTH Peak preheat current regulation threshold — 0.7 — V VCSTH =(IIPH) x (RIPH)

VCPHFLT CPH pin voltage during UVLO or fault —

Ignition Characteristics

V

CSTH

Protection Characteristics

V

SDTH+

V

VDCTH+

V

SDHYS

V

VDCHYS

V

SDCLMP

V

CSTH

T

SD

= 14V +/- 0.25V, VCS = 0.5V, VSD = 0.0V, R

BIAS

= 0.0V, C

TPH

Peak over current threshold — 1.6 — V VCPH < 5V

Rising shutdown pin threshold voltage — 2.0 —

Rising VDC pin threshold voltage — 5. 1 —

SD threshold hysteresis — 150 — mV

VDC threshold hysteresis — 2. 1 —

SD pin clamp voltage — 7. 6 — ISD = 100mA

Peak ov er-current latch threshold voltage — 1.6 —

Thermal shutdown junction temperature —

= 1000pF, TA = 25oC unless otherwise specified.

LO,HO

—

—

FMIN

= 40k, C

1.3

5.0

10

0.0

165 —

VCO

= 10 nF, V

—

—

—

—

= 0.0V, R

DIM

µA

V

V SD = 5V, or CS = 2V,

or Tj

V

V

o

C

V

MAX

CPH

= 33k,

> TSD

>

5.1V

Phase Control

V

CSTHZX

R

FB

t

Blank

Zero-crossing threshold voltage — 0.0 — V

Phase control FB resistor (Internal) — 5.7 — kΩ

Zero-crossing internal blank time — 400 — ns

Dimming Interface

V

DIMOFF

V

DIM

V

MINMIN

V

MINMAX

V

DIMTH

V

DIMTH DIM mode VCO Threshold (IR21591)

Minimum Frequency Setting

V

FMIN

V

FMINFLT

www.irf.com 5

DIM pin offset voltage — 0.5 —

DIM pin input voltage range 0.0 — 5.0

DIM minimum reference voltage (MIN pin) — 1.0 —

DIM maximum reference voltage (MIN pin) — 3.0 —

DIM mode VCO Threshold (IR2159) — 0.5 —

— 1.1 —

FMIN pin voltage during normal operation — 5.1 — V

FMIN pin voltage during fault mode — 0.0 — V

V

= 5V

DIM

V

V

= 0V

DIM

SD = 5V, or CS = 2V,

or Tj

> TSD

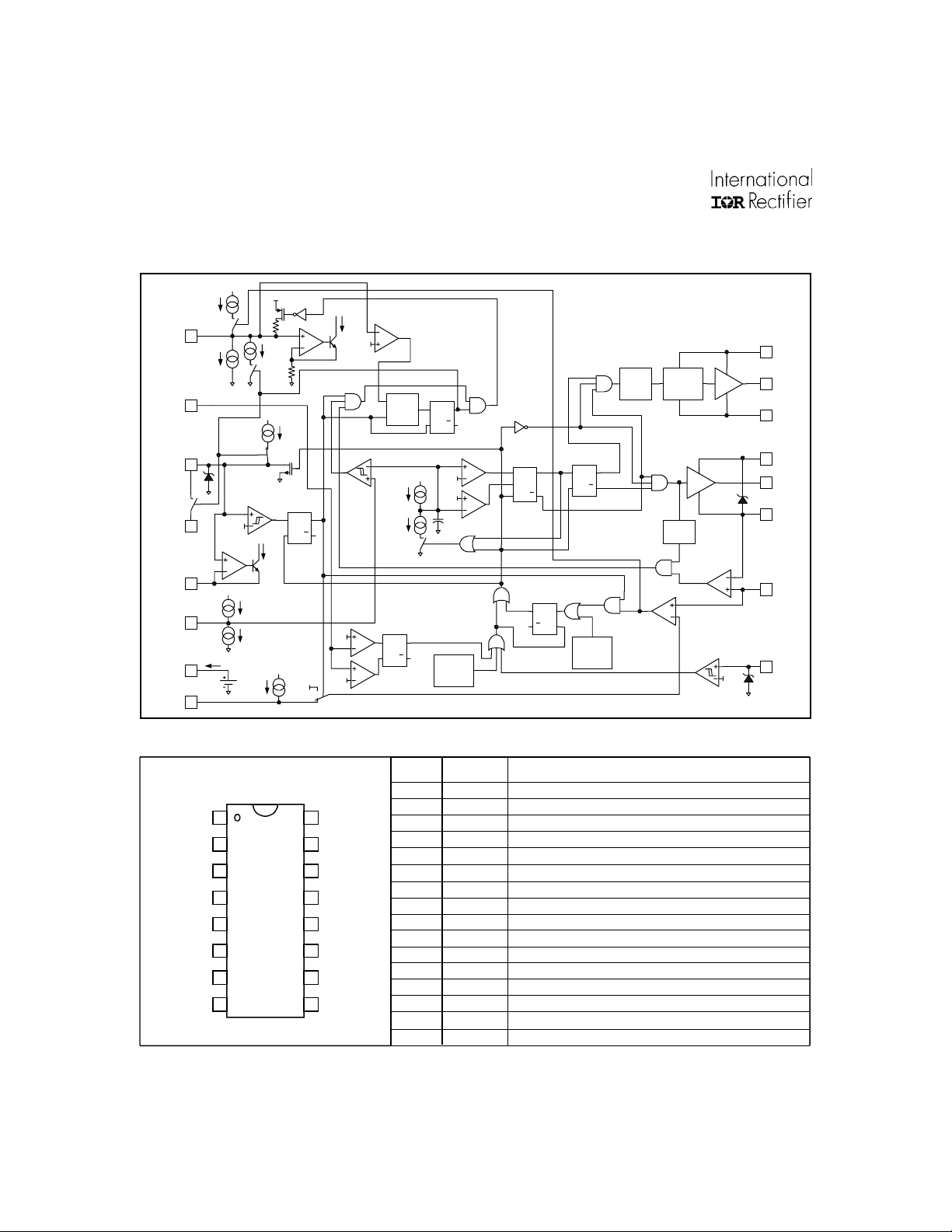

Page 6

IR2159/IR21591

Block Diagram

(S)

5.1V

VCC

I

R

FB

15uA

1.3uA

RQ

I

DIM

4/R

FMIN

I

/5

DIM

1/R

1.6V

FMIN

CT

V

DIMTH

10 CYCLES

IGNITION

COUNTER

IDT+I

RQ

CT

I

CT

CT

QS

REF

QS

FB

3V

5.1V

1

0

VCO

VDC

CPH

DIM

MAX

MIN

FMIN

IPH

60uA

2

1uA

1

3

10V

4

5

6

I

FMIN

7

5.1V

8

Lead Assignments & Definitions

QS

RQ

5.1V

1.0V

CT

UNDER-

VOLTAGE

DETECT

14

VB

SHIFT

PULSE

FILTER &

LATCH

400ns

DELAY

15.6V

2.0V

7.6V

16

HO

15

VS

13

VCC

11

LO

12

COM

10

CS

9

SD

LEVEL

ERR

T

R1

R2 Q

QS

QS

Q

RQ

RQ

OVER-

TEMP

DETECT

Pin Assignments

1

VDC

2

VCO

3

CPH

4

DIM

5

MAX

6

MIN

7

FMIN

8

IPH

16

HO

15

VS

14

VB

13

VCC

12

COM

11

LO

10

CS

9

SD

Pin # Symbol Description

Line input voltage detection

Voltage controlled oscillator Input

Preheat timing input

0.5 to 5VDC dimming control input

Maximum lamp power setting

Minimum lamp power setting

Minimum frequency setting

Shutdown input

Current sensing input

Low-side gate driver output

IC power & signal ground

Logic & low-side gate driver supply

High-side gate driver floating supply

High voltage floating return

High-side gate driver output

15

10

11

12

13

14

16

1

2

3

4

5

6

7

8

9

VDC

VCO

CPH

DIM

MAX

MIN

FMIN

IPH Peak preheat current reference

SD

CS

LO

COM

VCC

VB

VS

HO

6 www.irf.com

Page 7

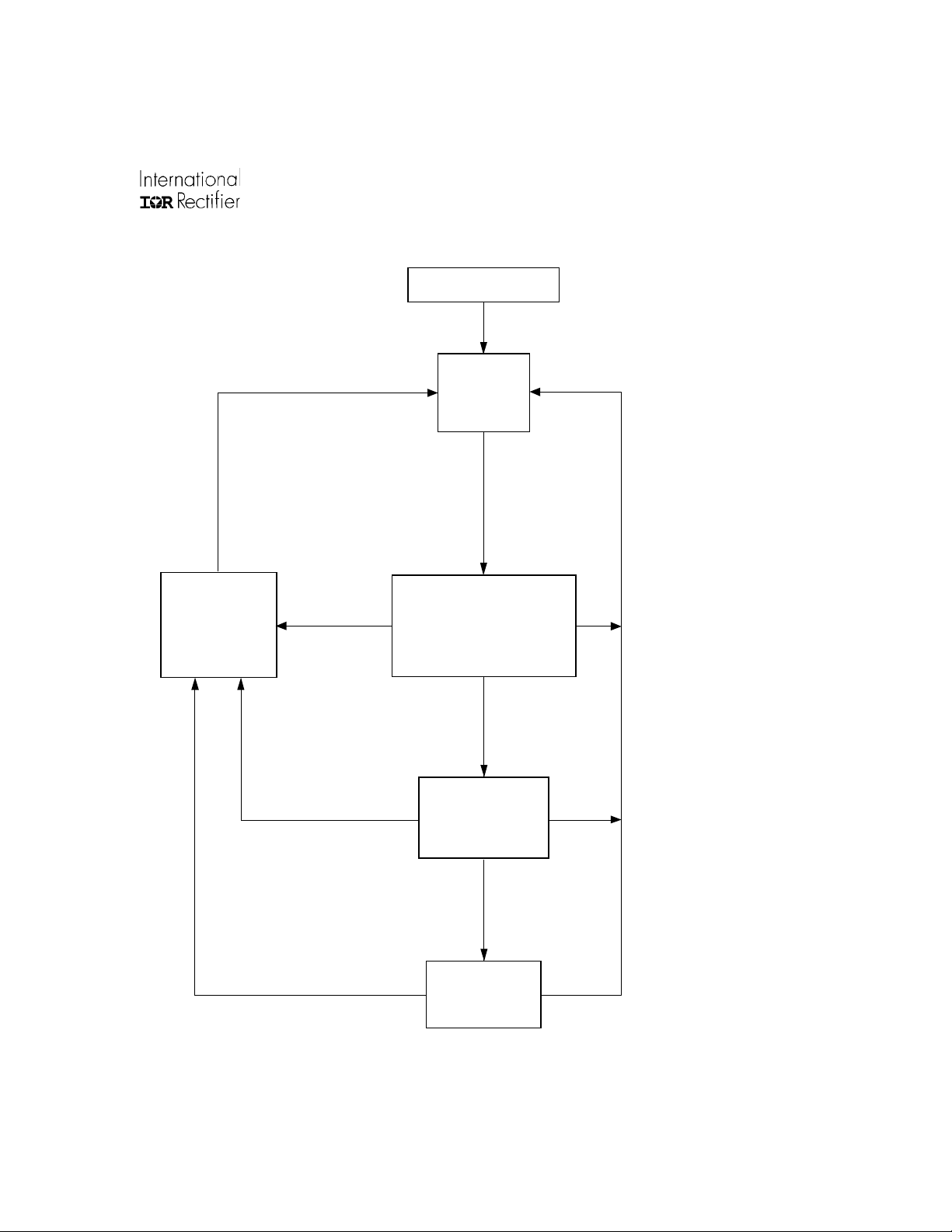

State Diagram

(

g)

(

)

Power Turned On

UVLO Mode

1/2-Bridge Off

IQCC=200mA

CPH=0V

Oscillator Off

IR2159/IR21591

(S)

SD > 2.0V

(Lamp Removal)

or

VCC < 10.9V

(Power Turned Off)

FAULT Mode

Fault Latch Set

1/2-Bridge Off

I

=240µA

QCC

CPH=0V

VCC=15.6V

Oscillator Off

CS > V

CSTH

(Over-Current or Hard Switching)

or

TJ > 165C

(Over-Temperature)

TJ > 165C

(Over-Temperature)

CS > V

CSTH

Failure to Strike Lamp

or Hard Switchin

or

TJ> 165C

Over-Temperature

(1.6V)

(1.6V)

PREHEAT Mode

1/2-BridgeOscillator On

V

(Peak Current Control)

CSPK+VIPH

CPH Charging@I

DIM+Open Circuit

Over-Current Disabled

IGNITION Mode

fPH ramps to fMIN

CPH Charging@I

DIM=Open Circuit

Over-Current Enabled

DIM Mode

PhaseCS=Phase

DIM=CPH

Over-Current Enabled

and

and

and

+1µA

+1µA

REF

DIMTH

(UV+)

(Bus OK)

(Lamp OK)

(T

jmax

VCC > 12.5V

VDC > 5.1V

SD < 1.7V

TJ < 165C

PH

CPH > 5.1V

(End of PREHEAT Mode)

PH

VCO < V

(End of IGNITION Mode)

VCC < 10.9V

(VCC Fault or Power Down)

or

VDC < 3.0V

(dc Bus/ac Line Fault or Power Down)

or

SD > 2.0V

)

(Lamp Fault or Lamp Removal)

www.irf.com 7

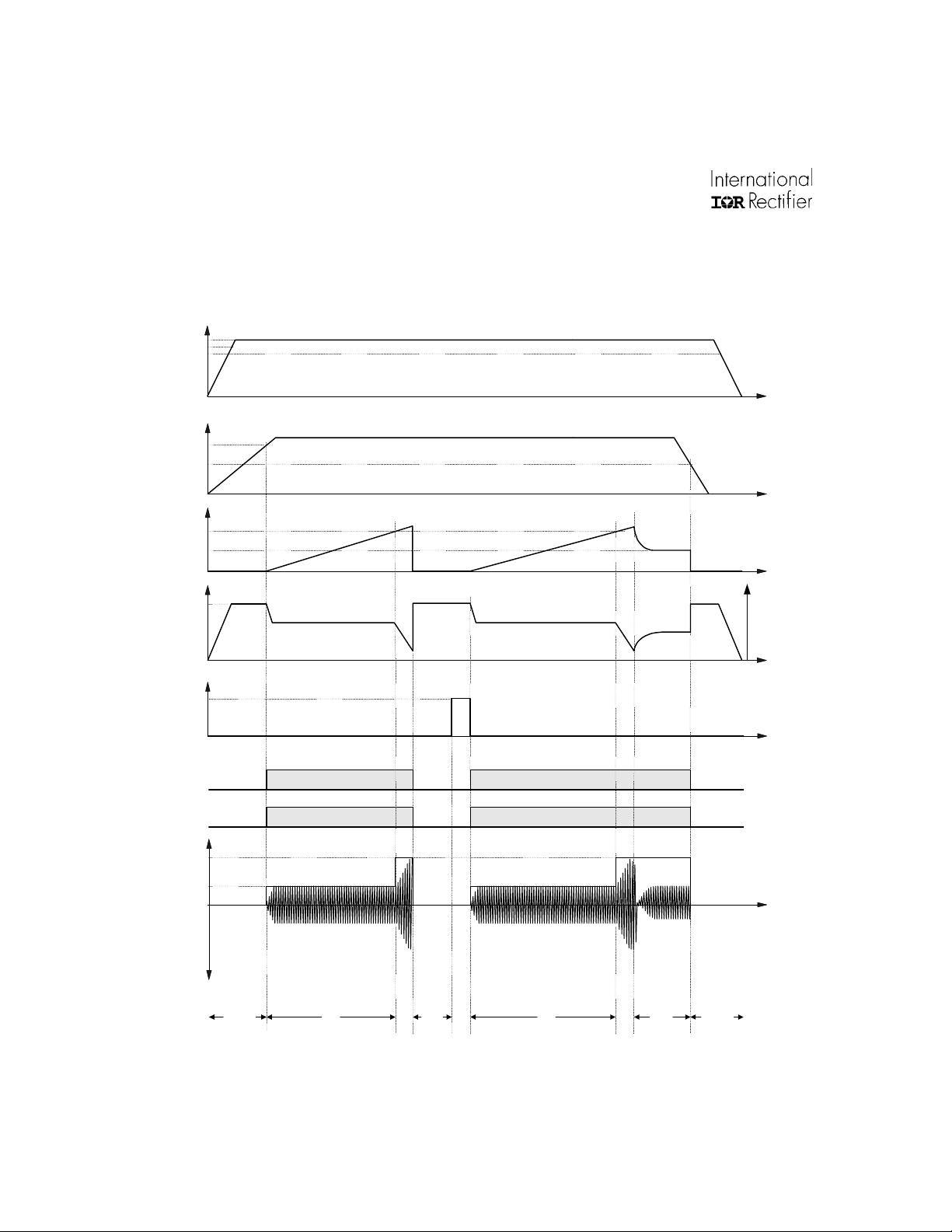

Page 8

IR2159/IR21591

(S)

Timing Diagram

Non-strike fault condition with lamp exchange

VCC

15.6V

UVLO+

UVLO-

VDC

VDCTH+

VDCTH-

CPH

5.1V

V

DIM

VCO

SD

HO

LO

CS

1.6V

V

5V

5V

IPH

PH FLT

IGN

SD PH

IGN

DIM UVLOUVLO

f

8 www.irf.com

Page 9

IR2159/IR21591

y

g

g

)

Q

g

g

g

ϕ

(Eq

)

y

ϕ

ϕ

y

)

)

(S)

External Components Selection Procedure

(Note:

Please refer to

"T

pical Connection"

dia

ram, page 1)

Set R

and R

VAC

on pin VDC will exceed 5.1 volts at the

desired line turn-on volta

The minimun operating frequency must

be lower than f

lower

. R

FMIN

, so R

I

IPH

FMIN

RCS sets the maximum ignition current

which corresponds to the maximum

i

nition voltage across the lamp.

The voltage at pin IPH is the reference

for amplitude current control durin

preheat mode. R

R

.

FMIN

such that the voltage

VDC

e.

of f

100%

also programs I

(whichever is

IGN

must be set first.

must be set after

IPH

MIN

and

R

Use Graph 5 or Graph 6

BEGIN

Calculate R

R

−

Calculate R

=

VDC

1

Select R

Calculate R

UPPULL

−

R

=

VAC

VAC

CS

VAC

=

I

1.5

1.5

I

IGN

PULL-UP

CCUV

VDC

−

ONTURN

−

ONTURN

FMIN

CS

6.1

PK

−

Select & Calculate R

Use Graph 8 to find I

then calculate R

=

R

IPH

IPH

RI

⋅

CSPH

PK

I

IPH

ONTURN

R

VAC

IPH

:

IPH

,

R

VDC

R

FMIN

R

CS

R

IPH

VAC

f

MIN

I

IGN

I

PH

TURN-ON

V

IGN

V

PH

During preheat, an internal 1.3 µA

current source at pin CPH char

es

external capacitor CCPH. Preheat mode

ends when VCPH exceeds 5.1 volts.

R

sets the lower phase boundar

MIN

corresponding to minimum lamp

power when V

be set after R

R

sets the upper phase boundar

MAX

corresponding to maximum lamp power

when V

after R

FMIN

DIM

FMIN

= 5 volts. R

DIM

and R

= 0 volts. R

.

must be set

MAX

.

MIN

MIN

must

Calculate

Calculate C

()

Calculate R

Find I

Find V

(Graph 7

MIN

uations 8 & 9

MIN

(Graph 9

MIN

V

R

=

MIN

I

Calculate R

Use Equation 15

MIN

MIN

CPH

teC

−=

76.2

PHCPH

MIN

MAX

C

CPH

R

MIN

R

MAX

t

PH

MINPLAMP

MAXPLAMP

www.irf.com 9

Page 10

IR2159/IR21591

Characteristic Curves

125

(S)

230

105

RFMIN=10K

85

RFMIN=16K

65

Frequency (KHz)

45

25

125

105

IN=20K

RFM

RFMIN=27K

RFMIN=39K

012345

(V)

V

VCO

85

Graph 1. F requency vs V

V

VCO

=5V

VCO

(IR2159)

190

RFMIN=10K

150

RFMIN=16K

110

70

RFMIN=20K

RFMIN=27K

RFMIN=39K

RFMIN=68K

Frequency (KHz)

30

012345

Graph 2. F requency vs V

(IR21591)

VCO

230

190

V

=5V

VCO

150

65

Frequency (KHz)

45

25

10 14 18 22 26 30 34 38

Graph 3. Frequency vs R

R

V

VCO

V

VCO

FMIN

=0.5V

=0V

K

Ω

FMIN

(IR2159)

110

Frequency (KHz)

V

VCO

=1.1V

70

V

=0V

VCO

30

10 20 30 40 50 60 70

R

K

Ω

FMIN

Graph 4. Frequency vs R

FMIN

(IR21591)

10 www.irf.com

Page 11

IR2159/IR21591

(S)

90

85

80

75

70

65

60

V

55

Frequency (KHz)

50

VCO

=0.5V

45

40

35

10 14 18 22 26 30 34 38

R

K

Ω

FMIN

Graph 5. Frequency vs R

450

400

350

300

( A)

250

MIN

I

200

150

100

50

10 20 30 40 50 60 70

R

FMIN

(KΩ)

FMIN

(IR2159)

170

160

150

140

130

120

V

=1.1V

110

Frequency (KHz)

VCO

100

90

80

10 14 18 22 26 30 34 38

K

R

Ω

FMIN

Graph 6. Frequency vs R

110

100

90

80

70

60

( A)

IPH

I

50

40

30

20

10

10 20 30 40 50 60 70

R

FMIN

(KΩ)

(IR21591)

FMIN

Graph 7. I

MIN

vs R

(IR2159/IR21591) Graph 8. I

FMIN

IPH

vs R

(IR2159/IR21591)

FMIN

www.irf.com 11

Page 12

IR2159/IR21591

(S)

0

-15

-30

I

VS

I/V

-45

VS

II

-60

-75

-90

1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

V

(V)

MIN

Graph 9. ϕ IIVS/VVSI vs V

(IR2159/IR21591)

MIN

3

2.5

30

25

20

(KΩ)

MIN

R

15

10

5

2 2.2 2.4 2.6 2.8 3

(V)

V

MIN

Graph 10. R

MIN

vs V

MIN

150

140

RFMIN=39K

RFMIN=33K

RFMIN=27K

RFMIN=20K

RFMIN=16K

RFMIN=10K

2

A

µ

1.5

CPH

I

1

0.5

0

-25 0 25 50 75 100 125

Temperature °C

Graph 11. I

vs Temperature (IR2159/IR21591) Gr aph 12. I

CPH

130

A

µ

120

MIN

I

110

100

90

-25 0 25 50 75 100 125

Temperature °C

vs T emper ature (IR2159/IR21591)

MIN

12 www.irf.com

Page 13

IR2159/IR21591

(S)

40

36

32

(µA)

IPH

I

28

24

20

-25 0 25 50 75 100 125

Temperature °C

Graph 13. I

55

50

45

40

Frequency (KHz)

35

30

25

vs T emper ature (IR2159/IR21591) Graph 14. V

IPH

IR21591

IR2159

-25 0 25 50 75 100 125

Temperature °C

6

5.6

5.2

(V)

FMIN

V

4.8

4.4

4

-25 0 25 50 75 100 125

Temperature °C

vs Temperature (IR2159/IR21591)

FMIN

110

105

100

IR21591

95

90

85

80

75

Frequency (KHz)

70

65

60

IR2159

55

-25 0 25 50 75 100 125

Temperature °C

Graph 15. F requency vs Temperature

V

= 0V (IR2159/IR21591)

VCO

Graph 16. F requency vs Temperature

V

= 2V (IR2159/IR21591)

VCO

www.irf.com 13

Page 14

IR2159/IR21591

3

2.5

(S)

2

1.5

Dead Time Sec

1

0.5

0

-25 0 25 50 75 100 125

Temperature °C

Graph 17. Dead Time vs T emperature

(IR2159/IR21591)

IR2159

IR21591

14 www.irf.com

Page 15

IR2159/IR21591

%

%

%

%

g

(S)

Functional Description

Phase Control

To understand phase control, a simplified model

for the ballast output stage is used (Figure 1). The

lamp and filaments are replaced with resistors,

with the lamp inserted between the filament

resistors (R1, R2, R3 and R4).

R1 R2

L

Vin

Figure 1, Dimming ballast output stage.

During preheat and ignition (Figure 2), the circuit

is a high-Q series LC with a strong input current to

input voltage phase inversion from +90 to -90

degrees at the resonance frequency . For operating

frequencies slightly above resonance and higher ,

the phase is fixed at -90 degrees for the duration

of preheat and ignition. During dimming, the circuit

is an L in series with a parallel R and C, with a

weak phase inversion at high lamp power and a

strong phase inversion at lo w lamp power.

Rlamp

C

R3 R4

20

10

0

Magnitude [dB]

-10

-20

-30

5 101520253035404550

50%

100

Frequency [kHz]

PH/IGN

10%

50

100

PH/IGN

10

400

350

300

250

200

150

100

50

0

-50

-100

Phase [deg]

Figure 2, Typical output stage transfer function for

different lamp power levels.

In the time domain (Figure 3), the input current is

shifted -90 degrees from the input half-bridge

voltage during preheat and ignition, and

somewhere between 0 and -90 degrees after

ignition during running. Zero phase-shift

corresponds to maximum power

V

in

I

in

run

0

n

run

n

ph/ign

in

I

n

ph/i

t

Figure 3, Typical ballast output stage waveforms.

When the phase is calculated and plotted versus

lamp power (Figure 4), the result is a linear dimming

curve, even down to ultra-low light levels where

the resistance of the lamp can change by orders

of magnitude.

www.irf.com 15

Page 16

IR2159/IR21591

(S)

-60.0

-65.0

-70.0

-75.0

Phase [degrees]

-80.0

-85.0

-90.0

0 5 10 15 20 25 30

Lamp Po wer [Watts]

Figure 4, Lamp power vs. phase of output stage.

Under-voltage Lock-Out (UVLO)

The IR2159 undervoltage lock-out is designed to

maintain an ultra low quiescent current of less

than 200uA, while guaranteeing the IC is fully

functional before the high and low side output

drivers are activated. Figure 5 shows an efficient

supply voltage using the start-up current of the

IR2159 together with a charge pump from the

ballast output stage (R1, C1, C2, D1 and D2).

(+)

V

BUS

Rectified

AC Line

R3

VDC

1

CVDC

V

(-)

BUS

RVDC

16

15

14

13

12

11

VCC

COM

R1

HO

VS

C3

VB

D3

C1

LO

Q1

D1

Q2

RCS

Figure 5, Typical application of start-up circuitry.

Half-Bridge

Output

C2

D2

The start-up capacitor (C1) is charged by current

through resistor (R1) minus the start-up current

drawn by the IC . This resistor is typically chosen

to provide 2X the maximum start-up current at

low line to guarantee start-up under the worst case

condition. Once the capacitor voltage reaches the

start-up threshold, and, the voltage on pin VDC is

above 5.1V (see Brown-out Protection), the IC

turns on and HO and LO begin to oscillate. The

capacitor begins to discharge due to the increase

in IC operating current (Figure 6).

V

C1

V

UVLO+

VHYST

V

UVLO-

R1 & C1 TIME

CONSTANT

C1

DISCHARGE

INTERNAL

CLAMP VOLTAGE

DISCHARGE

TIME

CHARGE PUMP

OUTPUT

t

Figure 6, Start-up capacitor (C1) voltage.

During the discharge cycle, the rectified current

from the charge pump charges the capacitor above

the minimum operating voltage of the device and

the charge pump and internal 15.6V zener clamp

of the IC take over as the supply voltage. The

start-up capacitor and snubber capacitor must be

selected such that worst case IC conditions are

satisfied. A bootstrap diode (D3) and supply

capacitor (C3) comprise the supply voltage for

the high side driver circuitry. To guarantee that

the high-side supply is charged up before the first

pulse on pin HO, the first pulse from the output

drivers comes from the LO pin. During UVLO,

the high and low side driver outputs are low, pin

VCO is pulled-up internally to 5V resetting the

starting frequency to the maximum, and pin CPH

is short-circuited internally to COM resetting the

preheat time.

16 www.irf.com

Page 17

IR2159/IR21591

g

g

(S)

Brown-out Protection

In addition to the voltage on VCC being above

the start-up threshold, pin VDC must also be

above 5.1V for HO and LO to begin oscillating. A

voltage divider (R3,R VDC) from the rectified AC

line connected to pin VDC measures the rectified

AC line input voltage to the ballast and programs

the turn-on and turn-off line voltages. A filter

capacitor (CVDC) is also connected to pin VDC

that must be chosen such that the ripple is low

enough and the lower turn-off threshold of 3V is

not crossed during normal line conditions. This

detection is necessary due to the possibility of

the lamp extinguishing during low-line conditions

before the IC is properly reset. Should a brownout occur, the DC bus can drop to a level below

the minimum required for the tank circuit to

maintain the necessary lamp voltage. This

detection will insure a clean turn-off before the

DC bus drops too low and properly resets the

IC to the preheat mode when the line returns.

Preheat (PH)

The IR2159 enters preheat mode when VCC

exceeds the UVLO+ threshold and VDC exceeds

5.1V. HO and LO begin to oscillate at the

maximum operating frequency with 50% duty

cycle and at the internally set dead-time of 2us.

Pin CPH is disconnected from COM and an

internal 1uA current source (Figure 7) charges

the external timing capacitor on CPH linearly .

V

(+)

BUS

60uA

VCO

2

C

VCO

C

CPH

R

R

(-)

V

BUS

1uA

1uA

CPH

3

I

FMIN

FMIN

7

5.1V

FMIN

1/R

FMIN

IPH

8

IPH

VCO

Half

Brid

Driver

PH

LOGIC

7.6V

e

IR2159

HO

16

15

11

10

12

VS

LO

CS

COM

Q2

Q2

RCS

Half

Brid

Output

I

LOAD

Load

Return

e

Figure 7, IR2159 preheat circuitry.

An internal 1uA current source slowly discharges

the external capacitor on pin VCO and the voltage

on pin VCO begins to decrease . This decreases

the frequency, which, for operating frequencies

above resonance, increases the load current.

When the peak voltage measured on pin CS,

produced by a portion of the load current flowing

through an external sense resistor (RCS), exceeds

the voltage level on pin IPH, a 60uA internal

current source is connected to pin VCO and the

capacitor charges (Figure 8). This forces the

frequency to increase and the load current to

decrease. When the voltage on pin CS decreases

below IPH, the 60uA current source is

disconnected and the frequency decreases again.

www.irf.com 17

Page 18

IR2159/IR21591

(S)

HO

LO

VS

t

t

t

t

V

V

I

CVCO

60uA

CVCO

RCS

V

-1uA

IPH

Figure 8, Peak load current regulation timing diagram.

This feedback keeps the peak preheat current

regulated to the user-programmable setting on pin

IPH for the duration of the preheat time. An

internal current source connected to an external

resistor on pin IPH sets a voltage reference for

the peak pre-heat current. The pre-heat time

continues until the voltage on pin CPH exceeds

5V.

Ignition (IGN)

The IR2159 enters ignition mode when the voltage

on pin CPH exceeds 5V. The peak current

regulation reference voltage is disconnected from

the user-programmable setting on pin IPH and is

connected to a higher internal threshold of 1.6V

(Figure 9).

V

(+)

BUS

1.6V

IR2159

HO

VS

LO

CS

COM

Q2

Q2

RCS

Half

Bridge

Output

I

LOAD

Load

Return

16

15

11

10

12

0.5 to 5V

V

BUS

VCO

2

C

VCO

1uA

1uA

CPH

3

C

CPH

DIM

4

R

DIM

(-)

VCO

Half

Bridge

Driver

PH

LOGIC

7.6V

DIM

INTERFACE

FAULT

LOGIC

PHASE

CONTROL

Figure 9, IR2159 ignition circuitry.

The ignition ramp is then initiated as the capacitor

on pin VCO discharges linearly through an internal

1uA current source. The frequency decreases

linearly towards the resonance frequency of the

high-Q ballast output stage, causing the lamp

voltage and load current to increase (Figure 10).

The frequency continues to decrease until the lamp

ignites or the current limit of the IR2159 is reached.

If the current limit is reached, the IR2159 enters

FAULT mode. The 1.6V threshold together with

the external current sensing resistor on pin CS

determine the maximum allowable peak ignition

current (and therefore peak ignition voltage) of the

ballast output stage. The peak ignition current

must not exceed the maximum allowable current

ratings of the output stage MOSFETs or IGBTs,

and, the resonant inductor must not saturate

at any time.

Should the lamp ignite, the frequency continues

to decrease until the voltage on pin VCO reaches

VDIMTH, corresponding to the minimum operating

frequency set by the external resistor on pin FMIN,

18 www.irf.com

Page 19

IR2159/IR21591

g

g

(S)

and the IR2159 enters DIM mode and the phase

control loop is closed.

V

CPH

5.1V

R

& C

DIM

TPH

TIME CONSTANT

V

DIM

V

VCO

PH

IGN

IGN-TO-DIM

TIME

DIM

t

t

Figure 10, IR2159 ignition timing diagram.

For a reliable ignition with minimal start-up flash,

the resistor on FMIN should be set to 5kHz lower

than the ignition frequency or the 100% brightness

dimming frequency , whichev er is lower .

down smoothly to the user setting. Should the

ignition-to-dim time be too fast, how ever , the loop

can respond faster than the ionization constant

of the lamp (milliseconds) causing the VCO to

over-shoot. This can result in a frequency that is

higher than the minimum brightness frequency and

can extinguish the lamp. The capacitor on pin

CPH serves multiple functions by setting the

preheat time, the travel rate just after ignition

(together with resistor RDIM), and, serving as a

filter capacitor on pin DIM during dimming to

increase high-frequency noise immunity and

minimize component count.

Dimming (DIM)

To regulate lamp power, the error between the

reference phase and the phase of the output stage

current forces the VCO to steer the frequency in

the proper direction, as determined by the transfer

function of the output stage, such that the error is

forced to zero . An internal 15uA current source is

connected to pin VCO during dimming mode

(Figure 11) to discharge the VCO capacitor and

decrease the frequency towards lock.

V

(+)

Ignition-to-Dim (IGN-to-DIM)

When the VCO decreases below VDIMTH, the

IR2159 enters dim mode. The phase control loop

is closed and the phase of the load current is

regulated against the user control input on pin DIM.

To control the rate at which the dim setting

changes from maximum brightness to the user

setting (IGN-TO-DIM time , Figure 10), pin DIM is

connected internally to pin CPH when the IR2159

enters DIM mode. The resistor on pin DIM (RDIM)

discharges the capacitor on pin CPH down to the

user dim setting. The resistor can be selected for

a fast time constant to minimize the amount of

BUS

0.5 to 5V

V

BUS

VCC

R

FB

VCO

2

16uA

C

VCO

CPH

3

C

R

R

R

(-)

7.6V

CPH

DIM

4

DIM

MAX

5

MAX

MIN

6

MIN

PHASE

CONTROL

VCO

DIM

INTERFACE

IR2159

HO

16

Half

15

Brid

e

Driver

11

FAULT

LOGIC

1.6V

CS

10

COM

12

Q2

Half

Brid

Q2

RCS

Output

I

LOAD

Load

Return

e

VS

LO

flash visible ov er the lamp just after ignition, or, a

long time constant such that the brightness ramps

Figure 11, IR2159 dimming circuitry.

www.irf.com 19

Page 20

IR2159/IR21591

(S)

Once lock is achieved, the phase detector (PDET)

outputs short pulses to an open-drain PMOS that

charges the VCO capacitor through an inter nal

resistor (RFB) each time an error pulse occurs

(Figure 12). This action "nudges" the integr ator at

the input of the VCO to keep the phase of the

output stage current exactly locked in phase with

the reference.

V

CS

t

LO

n

REF

n

FB

n

ERR

V

VCO

t

Figure 12, Phase control timing diagram.

V

MIN

5V

V

R

MIN

3V

1V

0

0.5V 5V

R

MAX

SETTING

V

DIM

Figure 13, Dimming interface

USER

CT

LO

n

REF

0 -90 -180

---

DIM

RANGE

n

The charging time of CT from 1V to 5.1V

determines the on-time of output gate drivers HO

and LO and corresponds to -180 degrees of

possible phase shift in load current (minus

deadtime). For the 0 to -90 degree dim range, the

voltage on pin MIN is bounded between 1V and

3V using pins MIN and MAX. An external resistor

on pin MAX programs the minimum phase shift

reference (maximum lamp power) corresponding

to 5V on pin DIM, and an external resistor on pin

MIN sets the maximum phase shift (minimum

lamp power) corresponding to 0.5V on pin DIM.

The IR2159 includes a dimming interface for

analog lamp power control. The DIM pin input

requires a voltage in the range of 0.5 to 5VDC,

with 5V corresponding to minimum phase shift

(maximum lamp power). The output of the dim

interface is the voltage on pin MIN, which is

compared with the internal timing capacitor (CT)

voltage to produce a frequency-independent digital

reference phase (Figure 13).

Current Sensing

During dimming, the current sensing circuitry

(Figure 14) detects over-current which can occur

during hard-switching (see Fault section), and

zero-crossing to measure the phase of the total

load current. To reject any s witching noise which

can occur at the turn-on of the low-side MOSFET

or IGBT, a digital current sense blanking circuit

blanks out the signal from the zero-crossing

20 www.irf.com

Page 21

detection comparator for 400ns after LO goes 'high'

g

(+)

(-)

g

(Figure 15).

V

BUS

IR2159

IR2159/IR21591

V

CS

Switching

Noise

(S)

t

HO

16

Half

Brid

Driver

FAULT

LOGIC

PHASE

400ns

CONTROL

BLANK

V

BUS

VS

15

e

LO

11

1.6V

CS

10

COM

12

Q2

Half

e

Brid

Output

I

LOAD

Q2

R1

RCS

Load

Return

Figure 14, Current sensing circuitry.

The internal blank time reduces the dimming range

slightly (Figure 15) when operating at minimum

phase shift (maximum lamp power). The e xternal

programming resistor on pin MAX must be

selected such that the minimum phase shift is

set a safe margin away from the blank time. A

series resistor (R1) is required to limit the amount

of current flowing out of pin CS when the voltage

across RCS goes below -0.7V. A filter capacitor

at pin CS may be required due to other possible

asynchronous noise sources present in the ballast

system.

LO

J

BLANK

Dimming

Range

Figure 15, Current sense timing diagram.

Fault Mode (F AULT)

During dimming, the peak current regulation circuit

active during preheat and ignition is disabled.

Should non-zero voltage switching at the output

of the half-bridge occur (Figure 16), high current

spikes will result. A lamp filament failure, lamp

end-of-life, lamp remov al, or a deadtime shorter

than what is required for commutation, can all

cause hard-switching.

LOAD

REMOVAL

HO

LO

VS

V

CS

1.6V

t

t

NORMAL

OPERATION

HARD

SWITCHING

FAULT

Figure 16, hard-switching with latch off

www.irf.com 21

Page 22

IR2159/IR21591

p

p

(S)

Should the peak voltage on pin CS e xceed 1.6V

at any time during dimming, the IR2159 enters

FAULT mode and the high and low-side driver

outputs, HO and LO, are both turned off . Cycling

the supply voltage on VCC below or the voltage

on pin SD will reset the IR2159 to preheat (PH)

mode (see ST ATE DIAGRAM).

Ballast Design

Lamp Requirements

Before selecting component values for the ballast

output stage and the programmable inputs of the

IR2159, the following lamp requirements must first

be defined:

Variable Description Units

I

t

V

V

P

V

P

V

I

Cath

Filam e nt pr e- he at curr en t

ph

Filam e nt pr e- he at tim e

h

Maximum lamp pre-heat voltage

h

max

Lamp ignition voltage

ign

Lamp power at 100% brightness

%100

Lamp voltage at 100% brightness

%100

Lamp power at 1% brightness

%1

Lam p volt ag e at 1% br ig htn es s

%1

Minimum cathode heating current Arms

min

Table I, Typical lamp requirements

Arms

s

Vpp

Vpp

W

Vpp

W

Vpp

Ballast Output Stage

The components comprising the output stage are

selected using a set of equations. Different ballast

operating frequencies and their respective

voltages and currents are calculated.

The inductor and capacitor values are obtained

using equations (2) through (7). The results of

these equations reveal the location of each

operating frequency and the corresponding

voltages and currents. For a given L, C, DC bus

voltage, and pre-heat current, the resulting voltage

over the lamp during pre-heat is given as:

2

=

V

ph

2

V

DC

8

L

+

C

1

2

2

2

I

ph

V

DC

−

(2)

ππ

The resulting operating frequency during pre-heat

is given as:

2

I

π

ph

[Hz]

CV

ph

(3)

=

f

ph

The resulting operating frequency during ignition

is given as:

4

V

DC

π

1

+

1

=

f

ign

2

π

V

LC

ign

[Hz]

(4)

The total load current during ignition is given as:

=

IfCV

ign ign ign

π

2

[App]

(5)

22 www.irf.com

Page 23

IR2159/IR21591

ϕ

ϕ

(S)

The operating frequency [Hz] at maximum lamp

power is given as:

2

4

V

DC

1

−

2

2

32

f

121

%100

π

LC

P

%100

4

2

%100

2

32

1

LCVC

P

%100

−+−=

−

4

2

VC

%100

π

V

(6)

%100

22

CL

The cathode heating current at minimum lamp

power is given as:

π

CfV

I

Cath

=

%1

%1%1

2

(7)

Design Constraints

The inductor and capacitor values should be

iterated until the following design constraints have

been fulfilled (T able II).

Design Constraint Reason

VV

<

ph ph

ff kHz

ph ign

II

ign ign

max

−>

5

<

max

≥

II

CathCath

Table II, Ballast design constraints

Ignition during preheat

Production tolerances

Inductor saturation

Lamp extinguishing

min%1

during dimming

−

1

2

2

LC

P

%

4%2

LCVC

2

2

V

1

−

[(tan

2

P

%

P

%

C

2

V

%

%

1

f

%

π

2

180

%

π

2

P

321321

%

−+−=

−

4%2

VC

2

V

%

−−=

fL

%

P

%

With the lamp requirements defined, the L and C

of the ballast output stage selected, and the

minimum and maximum phase calculated, the

component values for setting the programmable

inputs of the IR2159 are obtained with the following

equations:

MIN

MIN

−⋅−

ef

R

FMIN

=

[Ohms] (10)

⋅

=

R

CS

=

)6.1(2

I

ign

2

IRRR

phCSFMINIPH

−=

tEC

PHCPH

[Ohms] (11)

[Ohms] (12)

[Farads] (13)

))(76.2(

2

V

4

DC

π

V

%

(8)

−⋅−−−

(9)

)101()10000()625(

22

CL

3%32

]42)

ππ

fLC

efe

)142()10000(

IR2159 Programmable Inputs

R

FMIN

R

MIN

1

4

%1

−=

45

[Ohms] (14)

In order to program the MIN and MAX settings of

the dimming interface, the phase of the output

stage current at minimum and maximum lamp

power must be calculated. This is obtained using

the following equations:

=

R

MAX

86.0

RR

⋅⋅

RR

MINFMIN

ϕ

45

%100

−⋅−⋅

14

FMINMIN

[Ohms] (15)

www.irf.com 23

Page 24

IR2159/IR21591

This ballast design procedure has been summarized into the following 3 steps:

(S)

Define

Lamp

Requirements

Calculate

IR2159

Programmable

Inputs

Figure 19, Simplified Ballast Design Procedure

Iterate L and C

to fulfi ll

constraints

Case outline

16 Lead PDIP

24 www.irf.com

01-3065 00 (MS-001A)

01-6015

Page 25

IR2159/IR21591

(S)

16 -Lead SOIC (narrow body)

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245 Tel: (310) 252-7105

Data and specifications subject to change without notice. 10/8/2001

01-3064 00 (MS-012AC)

01-6018

www.irf.com 25

Loading...

Loading...