Datasheet ILC6370BP-50, ILC6370BP-33, ILC6370BP-25, ILC6370AP-50, ILC6371CP-50 Datasheet (Impala Linear Corporation)

...Page 1

ILC 6370/71

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Cor poration

Impala Linear Corporation

1

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

50mA boost converter in 5-lead SOT-89 package. Only 3

external components are needed to complete the switcher

design, and frequency options of 50, 100, and 180kHz gives

the designer the ability to trade off system needs with

switcher design size.

87% max duty cycle gives conversion efficiencies of 85%.

Standard voltage options of 2.5V, 3.3V, and 5.0V at ±2.5%

accuracy feature on-chip phase compensation and softstart design.

ILC6371 drives an external transistor for higher current

switcher design, with all of the features and benefits of

the ILC6370.

! 85% efficiency at 50mA

! Start-up voltages as low as 900mV

! ±2.5% accurate outputs

! Complete switcher design with only 3 external components

! 50, 100 and 180kHz switching frequency versions available

! Shutdown to 0.5µA

! External transistor option allows several hundred milliamp

switcher design

! Cellular Phones, Pagers

! Portable Cameras and Video Recorders

! Palmtops and PDAs

Ordering Information*

ILC6370CP-25

2.5V±2.5%@50kHz

ILC6370CP-25

3.3V±2.5%@50kHz

ILC6370CP-50

5.0V±2.5%@50kHz

ILC6370BP-25

2.5V±2.5%@100kHz

ILC6370BP-33

3.3V±2.5%@100kHz

ILC6370BP-50

5.0V±2.5%@100kHz

ILC6370AP-25

2.5V±2.5%@180kHz

ILC6370AP-33

3.3V±2.5%@180kHz

ILC6370AP-50

5.0V±2.5%@180kHz

ILC6371CP-25

2.5V±2.5%@50k Hz, ex ternal xtor

ILC6371CP-33

3.3V±2.5%@50k Hz, ex ternal xtor

ILC6371CP-50

5.0V±2.5%@50k Hz, ex ternal xtor

ILC6371BP-25

2.5V±2.5%@100k Hz , ex ternal xtor

ILC6371BP-33

3.3V±2.5%@100k Hz , ex ternal xtor

ILC6371BP-50

5.0V±2.5%@100k Hz , ex ternal xtor

ILC6371AP-25

2.5V±2.5%@180k Hz , ex ternal xtor

ILC6371AP-33

3.3V±2.5%@180k Hz , ex ternal xtor

ILC6371AP-50

5.0V±2.5%@180k Hz , ex ternal xtor

Standard Product offering comes in tape and reel,

quantity 1000 per reel, orientation right for SOT-89

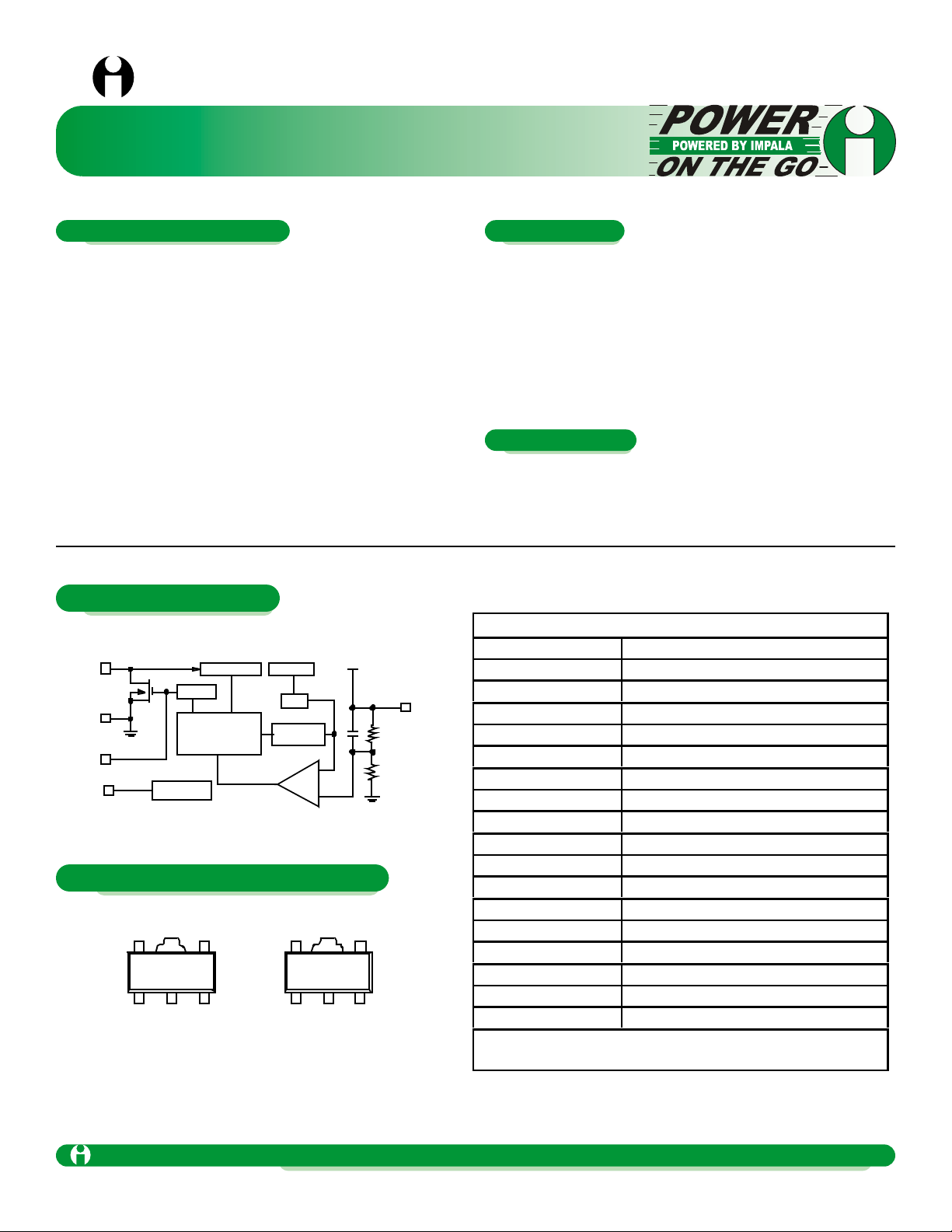

VLX LIMITER

PWM Controlled

BUFFER

L

X

V

SS

EXT

+

-

CHIP ENABLE

OSC

50/100/180KHz

V

DD

V

OUT

CE

Phase comp

V

re f

Slow St art

VDD is internally connected to the V

OUT

pin.

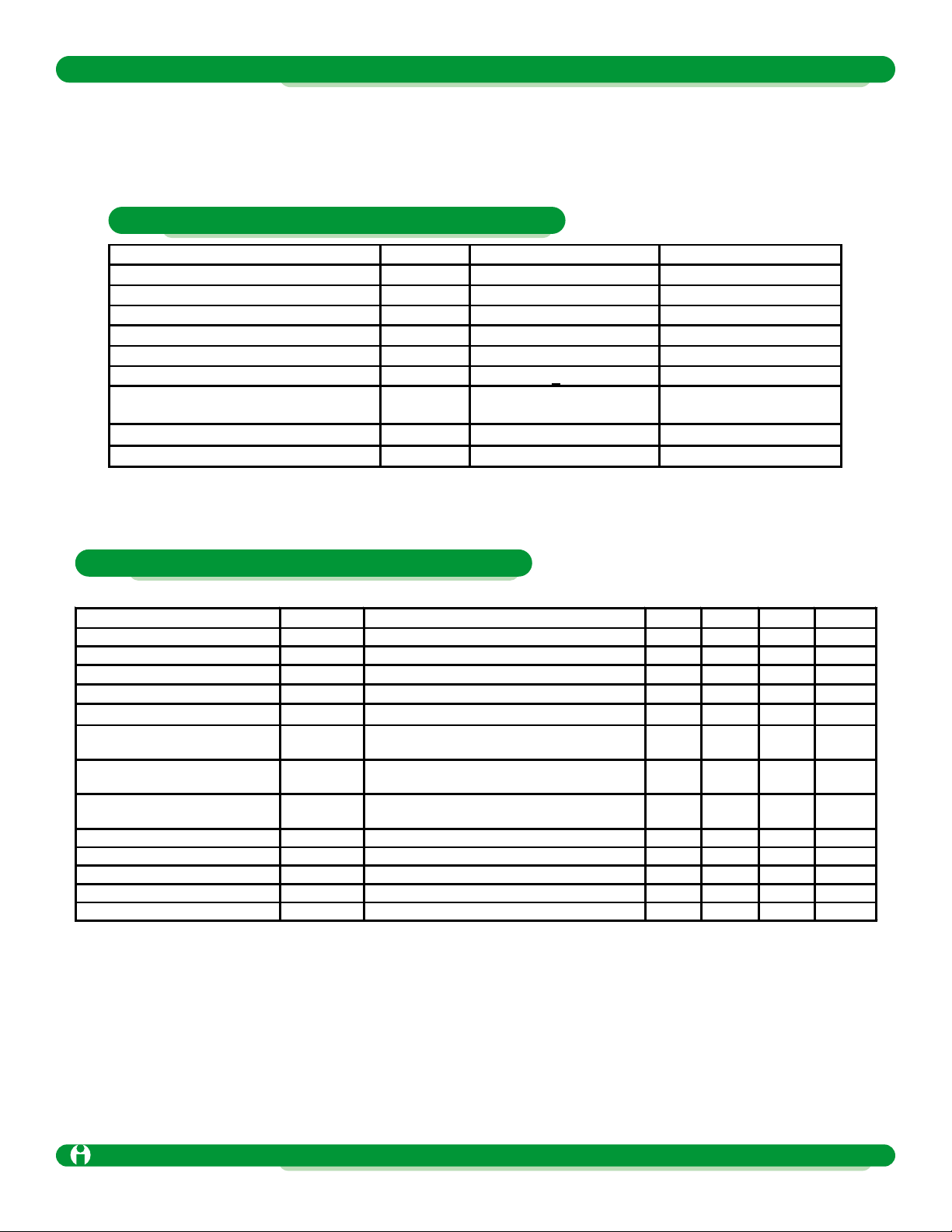

SOT -89-5

(TOP VIEW)

132

V

OUT

CE

L

X

45

V

SS

N/C

SOT -89-5

(TOP VI EW )

132

V

OUT

CE

EXT

45

V

SS

N/C

ILC6370 ILC6371

General Description

Features

Applications

Block Diagram

Pin-Package Configurations

Page 2

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

2

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

Parameter

Symbol

Ratings

Units

V

OUT

Input Voltage Pin

V

OUT

12

V

CE Input Voltage

VCE

12

V

Voltage on pin LX

VLX

12

V

Current on pin LX

ILX

400

mA

Voltage on pin EXT

V

EXT

0.3 ~V

OUT

+0.3

V

Current pin EXT

I

EXT

+50

mA

Continuous Total Power Dissipation

(SOT-89-5)

PD

500

mW

Operating Ambient Temperature

T

OPR

-30~+80

οC

Storage Temperature

T

STG

-40~+125

οC

Parameter

Symbol

Conditions

Min

Typ

Max

Units

Output Voltage

V

OUT

3.218

3.300

3.383

V

Input Voltage

VIN 10

V

Oscillation Startup Voltage

V

ST2

LX :10kΩ Pull-up to.5V, V

OUT

= VST

500

600 mA

Operation Startup Voltage

V

ST1

I

OUT

+1mA

55

86

µA

Supply Current 1

IDD1

LX :10kΩ Pull-up to.5V, V

OUT

= 4.5V

1.5

2.5

µA

Supply Current 1

IDD2

Open Loop Measurement, V

S/D

= VIN,

VLX =V

IN-

0.4V, V

OUT

= 3V

0.64

0.85

Ω

L

X

Switch-On Resistance

R

SWON

Open Loop Measurement, V

OUT

= V

IN,

V

LX

= 0V

2.0

µA

L

X

Leakage Current

ILXL

Measure Waveform at EXT pin V

IN

= 3.6V

I

OUT

= 20mA

255

300

345

KHz

Oscillator Frequency

F

OSC

100 %

Maximum Duty Ratio

MAXDTY

No Load

10

17

25

%

Satndb-by Current

I

STB

95 %

CE "High " Voltage

V

CEH

Minimum V

IN

When V

ref

does not start up

1 1.8

V

CE "Low " Voltage

V

CEL

V

ref

rises to 0V from 0.9V

6.0

10.0

16.0

msec

Note: Unless otherwise spcified, VIN= V

OUT

x 0.6, I

OUT

= 50mA. See Schematic, figure 1.

Absolute Maximum Ratings (TA = 25°C)

V

OUT

= 5.0V, F

OSC

= 100kHz, TA= 25°C, Test Circuit of figure 1

Elcetrical Characteristics ILC6370BP-50

Page 3

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

3

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

Parameter

Symbol

Conditions

Min

Typ

Max

Units

CE “High” Current

I

CEH

LX: 10kΩ pull-up to 5V, V

CE

= V

OUT

= 4.5V

0.25

µA

CE “Low” Current

I

CEL

LX: 10kΩ pull-up to 5V, V

OUT

=

4.5V, VCE = 0V

-0.25

µ

LX Limit Voltage

V

LXLMT

LX: 10kΩ pull-up to 5V, V

OUT

= 4.5V, F

OSC

> F

OSC

x 2

(1)

0.7 1.1

V

Efficie ncy

EFFI

85 %

Parameter

Symbol

Conditions

Min

Typ

Max

Units

Output Voltage

V

OUT

4.875 5.000

5.125

V

Input Voltage

V

IN

10

V

Oscillation Startup Voltage

V

ST

EXT: 10kΩ pull-up to 5V, V

OUT

= V

ST

0.8

V

Supply Current 1

IDD 1

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V

38.4

64.1

µA

Supply Current 2

IDD 2

EXT: 10kΩ pull-up to 5V, V

OUT

= 5.5V

6.9

13.8

µA

EXT “High” On-Resistance

R

EXTH

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V,

V

EXT

= 4.1V

30

50

Ω

EXT “Low” On-Resistance

R

EXTL

V

EXT

= 0.4V, V

OUT

= 5.5V

30

50

Ω

Oscillator Frequency

F

OSC

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V,

Measuring of EXT pin

85

100

115

kHz

Maximum Duty Ratio

MAXDTY

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V,

Measuring of EXT pin

80

87

92

%

Stand-by Current

I

STB

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V

0.5

µA

CE “High” Voltage

V

CEH

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V,

Existance of L

X

Oscillation

0.75

V

CE “Low” Voltage

V

CEL

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V,

Stopped L

X

Oscillation

0.20

V

CE “High” Current

I

CEH

EXT: 10kΩ pull-up to 5V, V

OUT

= VCE = 4.5V

0.25

µA

CE “Low” Current

I

CEL

EXT: 10kΩ pull-up to 5V, V

OUT

= 4.5V, VCE = 0V

-0.25

µA

Efficiency

EFFI

85 %

Slow Start Time

T

SS

10 msec

V

OUT

= 5.0V, F

OSC

= 100kHz, TA= 25°C; Test Circuit of figure 1

1. Switching frequency determined by delay time of internal comparator to turn LX“OFF,” and minimum “ON” time as

determined by MAXDTY spec.

V

OUT

= 5.0V, F

OSC

= 100kHz, TA= 25°C; Test Curcuit of figure 2.

Electrical Characteristics ILC6370BP-50

Electrical Characteristics ILC6371BP-50

Page 4

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

4

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

Parameter

Slow Start Time

Symbol

T

SS

Conditons Min Typ

10

Max Units

msec

V

OUT

= 5.0V, F

OSC

= 100kHz, TA= 25°C; Test Circuit of figure 1

ILC6370

123

45

CE

V

OUT

C

L

+

GND

V

IN

L

SD

ILC6371

123

45

CE

V

OUT

C

L

+

L

SD

V

IN

GND

C

B

R

B

Tr

L: 100µH (SUMIDA, CD-54)

SD: Diode (Schottky diode; MATSUSHITA MA735)

CL: 16V 47µF (Tantalum Capacitor; NICHICON, F93)

L: 100µH (SUMIDA, CD-54)

SD: Diode (Schottky diode; MATSUSHITA MA735)

CL: 16V 47µF (Tantalum Capacitor; NICHICON, F93)

R

B

: 1kΩ

C

B

: 3300pF

Tr: 2SC3279, 2SDI628G

Figure 1: Test Circuit

Figure 2: Test Circuit

Applications Circuits

Electrical Characteristics ILC6370BP-50

Page 5

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

5

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

The ILC6370 performs boost DC-DC conversion by controlling the

switch element shown in the circuit below.

When the switch is closed, current is built up through the inductor.

When the switch opens, this current has to go somewhere and is

forced through the diode to the output. As this on and off switching continues, the output capacitor voltage builds up due to the

charge it is storing from the inductor current. In this way, the output voltage gets boosted relative to the input. The ILC6370 monitors the voltage on the output capacitor to determine how much

and how often to drive the switch.

In general, the switching characteristic is determined by the output

voltage desired and the current required by the load. Specifically

the energy transfer is determined by the power stored in the coil

during each switching cycle.

PL = ƒ(t

ON

, VIN)

The ILC6370 and ILC6371 use a PWM or Pulse Width Modulation

technique. The parts come in one of three fixed internal frequencies: 50, 100, or 180kHz. The switches are constantly driven at

these frequencies. The control circuitry varies the power being

delivered to the load by varying the on-time, or duty cycle, of the

switch. Since more on-time translates to higher current build up in

the inductor, the maxmim duty cycle of the switch determines the

maximum load current that the device can support. The ILC6370

and ILC6371 both support up to 87% duty cycles, for maximum

usable range of load currents.

There are two key advantages of PWM type controllers. First,

because the controller automatically varies the duty cycle of the

switche’s on-time in response to changing load conditions, the

PWM controller will always have an optimized waveform for a

steady-state load. This translates to very good efficiency at high

currents and minimal ripple on the output. [Ripple is due to the

output cap constanty accepting and storing the charge recieved

from the inductor, and delivering charge as required by the load.

The “pumping” action of the switch produces a sawtooth-shaped

voltage as seen by the output.]

The other key advatage of the PWM type controllers is that the

radiated noise due to the swtiching transients will always occur at

the (fixed) switching frequency. Many applications do not care

much about switching noise, but certain types of applications,

especially communication equipment, need to minimze the high

frequency interference within their system as much as is possible.

Using a boost converter requires a certain amount of higher frequency noise to be generated; using a PWM converter makes that

noise highly predictable; thus easier to filter out.

There are downsides of PWM approaches, especially at very low

currents. Because the PWM technique relies on constant switching and varying duty cycle to match the load conditions, there is

some point where the load current gets to small to be handled efficiently. If the ILC6370 had an ideal switch, this would not be such

a problem. But an actual switch consumes some finite amount of

current to switch on and off; at very low current this can be of the

same magnitude as the load current itself, driving switching efficiencies down to 50% and below.

The other limitation of PWM techniques is that, while the fundamental switching frequency is easier to filter out since it’s constant,

the higher order harmonics of PWM will be present and may have

to be filtered out as well. Any filtering rquirements will vary by application and by actual system design and layout, so generalizations

in this area are difficult, at best. [For other boost converter tech-

niques, please see the ILC6380/81 and ILC6390/91 data sheets.]

However, PWM control for boost DC-DC conversion is widely

used, especially in audio-noise sensitive applications or applications requiring strict filtering of the high frequency components.

Impala’s products give very good efficiencies of 85% at 50mA output (5V operation), 87% maximum duty cycles for high load conditions, while maintaining very low shutdown current levels of

0.5µA. The only difference between the ILC6370 and ILC6371

parts is that the 6371 is configured to drive an external transistor

as the switch element. Since larger transistors can be selected for

this element, higher effective loads can be regulated.

Start-up Mode

The ILC6370 has an internal soft-start mode which suppresses

ringing or overshoot on the output during start-up. The following

diagram illustrates this start-up condition’s typical performance

External Components and Layout Consideration

The ILC6370 is designed to provide a complete DC-DC convertor

solution with a minmum of external components. Ideally, only

three externals are required: the inductor, a pass diode, and an

output capacitor.

The inductor needs to be of low DC Resistance type, typically 1Ω

value. T oroidal wound inductors have better field containment (less

high frequency noise radiated out) but tend to be more expensive.

Some manufacturers like Coilcraft have new bobbin-wound inductors with shielding included, which may be an ideal fit for these

applications. Contact the manufacturer for more information.

The inductor size needs to be in the range of 47µH to 1mH. In

general, larger inductor sizes deliver less current, so the load current wil determine the inductor size used.

VIN - V

f

V

OUT MIN

T

SOFT-START

(~10msec)

t = 0

Functions and Operation

Page 6

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

6

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

For load currents higher than 10mA, use an inductor from 47µH to

100µH. [The 100µH inductor shown in the data sheet is the most

typical used for this application.]

For load currents of around 5mA, such as pagers, use an indcutor

in the range of 100µH to 330µH. 220µH is the most typical value

used here.

For lighter loads, an inductor of up to 1mH can be used. The use

of a larger inductor will increase overall conversion efficiency, due

to the reduction in switching currents through the device.

For the ILC6371, using an external transistor, the use of a 47µH

inductor is recommended based on our experience with the part.

Note that these values are recommended for both 50kHz and

100kHz operation. If using the ILC6370 or ILC6371 at 180kHz,

the inductor size can be reduced to approximately half of these

stated values.

The capacitor should, in general, always be tantalum type, as tantalum has much better ESR and temperature stability than other

capacitor types. NEVER use electrolytics or chemical caps, as the

C-value changes below 0°C so much as to make the overall

design unstable.

Different C-values will directly impact the ripple seen on the output

at a given load current, due to the direct charge-to-voltage relationship of this element. Different C-Values will also indirectly

affect system reliability, as the lifetime of the capacitor can be

degraded by constant high current influx and outflux. Running a

capacitor near its maximum rated voltage can deteriorate lifetime

as well; this is especially true for tantalum caps which are particularly sensitive to overvoltage conditions.

In general, this capacitor should always be 47µF, Tantalum,

16V rating.

The diode must be of shottkey type for fast recovery and minimal

loss. A diode rated at greater than 200mA and maximum voltage

greater than 30V is recommended for the fastest switching time

and best reliability over time. Different diodes may introduce different level of high frequency switching noise into the output

waveform, so trying out several sources may make the most

sense for your system.

For the ILC6371, much of the component selection is as described

above, with the addition of the external NPN transistor and the

base drive network. The transistor needs to be of NPN type, and

shoud be rated for currents of 2A or more. [This translates to

lower effective on resistance and, therefore, higher overall efficiencies.] The base components should remain at 1kΩ and

3300kΩ; any changes need to be verified prior to implementation.

As for actual physical component layout, in general, the more

compact the layout is, the better the overall performance will be. It

is important to remember that everything in the circuit depends on

a common and solid ground reference. Ground bounce can directly affect the output regulation and presents difficult behavior to

predict. Keeping all ground traces wide will elliminate ground

bounce problems.

It is also critical that the ground pin of C

L

and VSSpin of the

device be the same pin on the board, as this capacitor serves two

functions: that of the output load capacitor, and that of the input

supply bypass capacitor.

Layouts for DC-DC converter designs are critical for overall

performance, but following these simple guidlines can simplify

the task by avoiding some of the more common mistakes made

in these cases. Once actual performance is completed, be

sure to double check the design on an actual manufacturing

prototype prodcut to verfy that nothing has changed which can

affect the performance.

Page 7

SOT-89 Step up Switching Regulator with Shutdown

OUTPUT VOLTAGE vs. OUTPUT CURRENT OUTPUT VOLTAGE vs. OUTPUT CURRENT

ILC6370CP-50

ILC6370CP-50

ILC6370CP-50

ILC6370CP-50, No Load Current ILC6370CP-30, No Load Current

ILC6370CP-30

ILC6370CP-30

ILC6370CP-30

5.4

5.2

5.0

4.8

4.6

4.4

4.4

4.0

5.4

5.2

5.0

4.8

4.6

4.4

4.4

4.0

0 100 200 300 400 500

0 40 80 120 160 200

OUTPUT CURRENT I

OUT

(mA)

OUTPUT VOLTAGE V

OUT

(v)

OUTPUT VOLTAGE V

OUT

(v)

VIN= 2.0V

VIN= 2.0V

VIN= 2.0V

VIN= 3.0V

VIN= 3.0V

VIN= 3.0V

VIN= 4.0V

VIN= 4.0V

VIN= 4.0V

VIN= 1.0V

VIN= 1.0V

VIN= 1.0V

VIN= 1.5V

VIN= 1.5V

VIN= 1.5V

VIN= 2.0V

VIN= 2.0V

VIN= 2.0V

VIN= 1.0V

VIN= 1.0V

VIN= .9V

L = 100µH

C = 47µF (Tantalum)

L = 100µH

C = 47µF (Tantalum)

L = 100µH

C = 47µF (Tantalum)

L = 100µH

C = 47µF (Tantalum)

L = 100µH

C = 47µF (Tantalum)

L = 100µH

C = 47µF (Tantalum)

OUTPUT CURRENT I

OUT

(mA)

0 100 200 300 400 500

OUTPUT CURRENT I

OUT

(mA)

100

80

60

40

20

0

EFFICIENCY vs. OUTPUT CURRENT

EFFICIENCY vs. OUTPUT CURRENT

EFFICIENCY: EFFI (%)

EFFICIENCY: EFFI (%)

100

80

60

40

20

0

OUTPUT CURRENT I

OUT

(mA)

0 40 80 120 160 200

OUTPUT CURRENT I

OUT

(mA)

100

80

60

40

20

0

0 50 100 150 200

RIPPLE VOLTAGE vs. OUTPUT CURRENT

RIPPLE VOLTAGE vs. OUTPUT CURRENT

RIPPLE Vr (mV p-p)

100

80

60

40

20

0

0 100 200 300 400 500

OUTPUT CURRENT I

OUT

(mA)

RIPPLE Vr (mV p-p)

INPUT VOLTAGE vs. OUTPUT CURRENT

INPUT VOLTAGE vs. OUTPUT CURRENT

100

500

400

300

200

100

0

1 2 3 4

INPUT VOLTAGE VIN(V)

INPUT CURRENT (µA)

L = 100µH

RL= 0

C = 47µF (Tantalum)

L = 100µH

RL= 0

C = 47µF (Tantalum)

INPUT VOLTAGE VIN(V)

250

200

150

100

50

0

1.0 1.2 1.4 1.6 1.8 2.0

INPUT CURRENT (µA)

Typical Performance Characteristics General conditions for all curves

ILC6370/1 1.3

Impala Linear Corporation

7

(408) 574-3939

www.impalalinear.com

July 1999

Page 8

SOT-89 Step up Switching Regulator with Shutdown

Impala Linear Corporation

8

(408) 574-3939

www.impalalinear.com

July 1999

ILC6370/1 1.3

START VOLTAGE/HOLD VOLTAGE vs. I

OUT

ILC6370CP-50

ILC6370CP-50

V

ST,

V

HLD

(

ςς

)

1.2

1.0

0.8

0.6

0.4

0.2

0

OUTPUT CURRENT I

OUT

(mA)

010 20 30

L = 100µH

C = 47µF (Tantalum)

V

HLD

V

ST

TRANSIENT RESPONSE

7.0

6.0

5.0

4.0

3.0

-20 0 20 40 60 80

VIN= 3.0V

I

OUT

= 1mA~30mA

L = 100µH

C = 47µF (Tantallum)

TIME (µsec)

OUTPUT VOLTAGE V

OUT

(V)

Typical Performance Characteristics General conditions for all curves

Loading...

Loading...