Page 1

Integrated

Circuit

Systems, Inc.

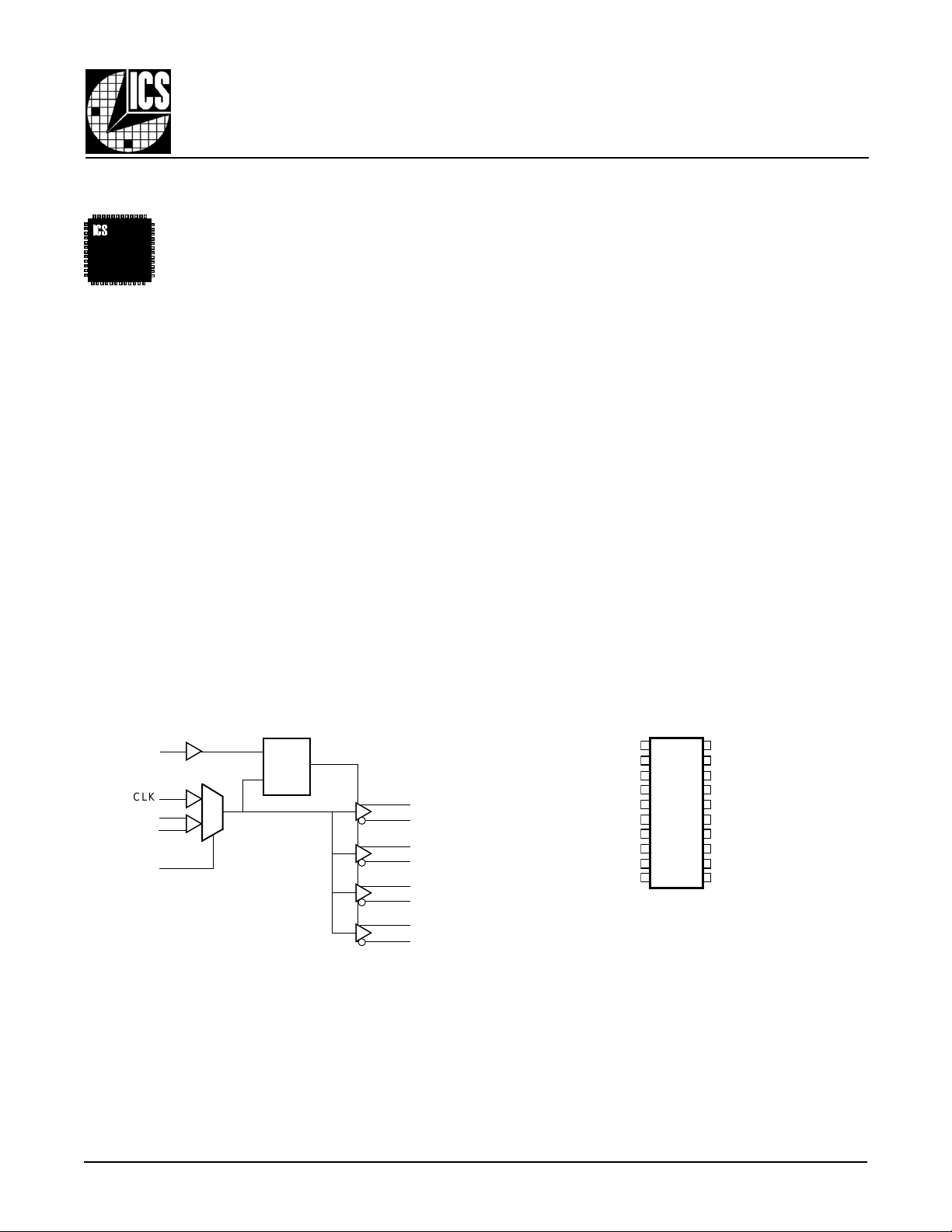

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

GENERAL DESCRIPTION

,&6

HiPerClockS™

able single ended clock or crystal inputs. The single ended

clock input accepts LVCMOS or LVTTL input levels and

translate them to 3.3V LVPECL levels. The output enable is

internally synchronized to eliminate runt pulses on the outputs during asynchronous assertion/deassertion of the clock

enable pin.

Guaranteed output and part-to-part skew characteristics

make the ICS8535-11 ideal for those applications demanding well defined performance and repeatability.

The ICS8535-11 is a low skew , high performance

1-to-4 3.3V Crystal Oscillator/LVCMOS-to-3.3V

LVPECL fanout buffer and a member of the

HiPerClockS™ family of High Performance Clock

Solutions from ICS. The ICS8535-11 has select-

FEATURES

• 4 differential 3.3V LVPECL outputs

• Selectable CLK or crystal inputs

• CLK can accept the following input levels: LVCMOS, L VTTL

• Maximum output frequency up to 266MHz

• Output skew: 35ps (maximum)

• Part-to-part skew: 150ps (maximum)

• Propagation delay: 2.4ns (maximum)

• 3.3V operating supply

• 0°C to 70°C ambient operating temperature

• Industrial T emperature information available upon request

BLOCK DIAGRAM PIN ASSIGNMENT

CLK_EN

CLK

XTAL1

XTAL2

CLK_SEL

D

Q

LE

0

1

Q0

nQ0

Q1

nQ1

Q2

nQ2

Q3

nQ3

6.5mm x 4.4mm x 0.92mm Package Body

V

EE

CLK_EN

CLK_SEL

CLK

nc

XTAL1

XTAL2

nc

nc

V

CC

ICS8535-11

20-Lead TSSOP

20

1

19

2

18

3

17

4

16

5

15

6

14

7

13

8

12

9

11

10

G Package

Top View

Q0

nQ0

V

CC

Q1

nQ1

Q2

nQ2

V

CC

Q3

nQ3

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

1

Page 2

Integrated

Circuit

Systems, Inc.

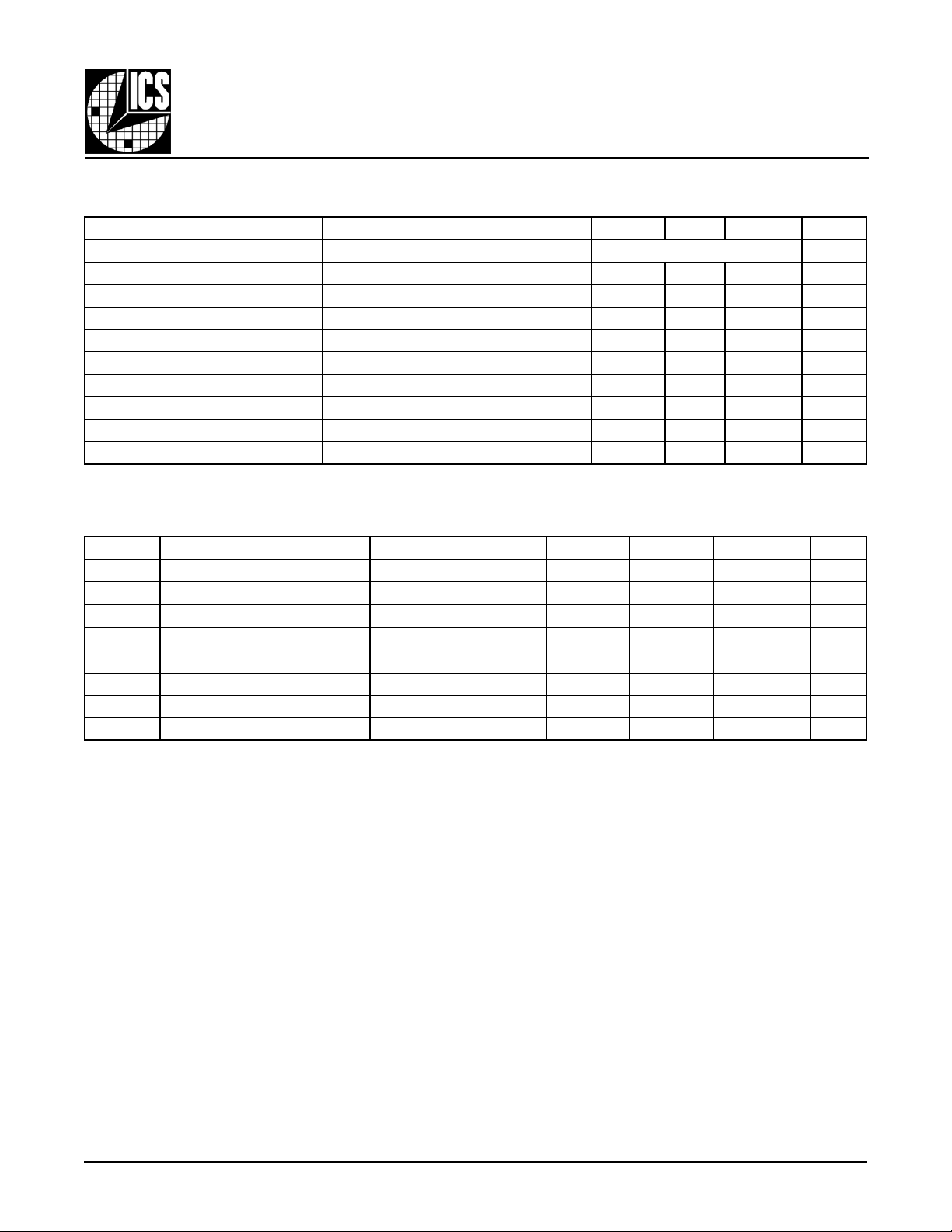

TABLE 1. PIN DESCRIPTIONS

rebmuNemaNepyTnoitpircseD

1V

2NE_KLCtupnIpulluP

3LES_KLCtupnInwodlluP

4KLCtupnInwodlluP.tupnikcolcLTTVL/SOMCVLgnitrevni-noN

9,8,5cndesunU.tcennocoN

61LATXtupnInwodlluP.tupnirotallicsolatsyrC

72LATXtupnIpulluP.tupnirotallicsolatsyrC

81,31,01V

21,113Q,3QntuptuO.slevelecafretniLCEPVL.stuptuokcolclaitnereffiD

51,412Q,2QntuptuO.slevelecafretniLCEPVL.stuptuokcolclaitnereffiD

71,611Q,1QntuptuO.slevelecafretniLCEPVL.stuptuokcolclaitnereffiD

02,910Q,0QntuptuO.slevelecafretniLCEPVL.stuptuokcolclaitnereffiD

pulluP

:ETON

EE

CC

dna

nwodlluP

rewoP.dnuorgottcennoC.nipylppusevitageN

rewoP.V3.3ottcennoC.snipylppusevitisoP

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

kcolcswollofstuptuokcolc,HGIHnehW.elbanekcolcgnizinorhcnyS

decroferastuptuoQn,woldecroferastuptuoQ,WOLnehW.tupni

.slevelecafretniLTTVL/SOMCVL.hgih

,WOLnehW.tupniKLCstceles,HGIHnehW.tupnitceleskcolC

.slevelecafretniLTTVL/SOMCVL.stupniLATXstceles

.seulavlacipytrof,scitsiretcarahCniP,2elbaTeeS.srotsisertupnilanretniotsrefer

TABLE 2. PIN CHARACTERISTICS

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

C

NI

R

PULLUP

R

NWODLLUP

KLC4Fp

ecnaticapaCtupnI

rotsiseRpulluPtupnI 15KΩ

rotsiseRnwodlluPtupnI 15KΩ

LES_KLC,NE_KLC4Fp

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

2

Page 3

Integrated

Circuit

Systems, Inc.

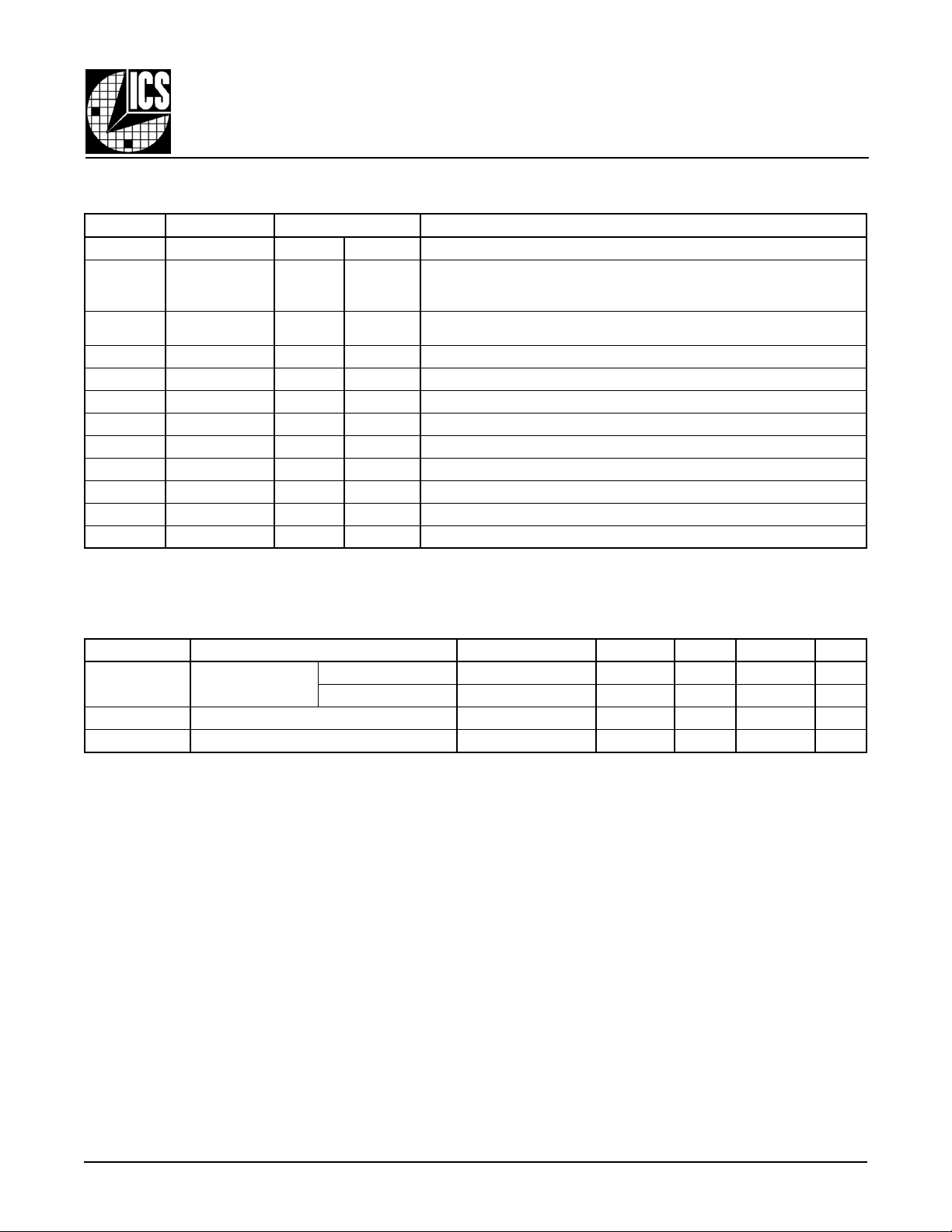

TABLE 3A. CONTROL INPUT FUNCTION TABLE

stupnIstuptuO

NE_KLCLES_KLCecruoSdetceleS3Qurht0Q3Qnurht0Qn

00 KLCWOL;delbasiDHGIH;delbasiD

01 2LATX,1LATXWOL;delbasiDHGIH;delbasiD

10 KLCdelbanEdelbanE

11 2LATX,1LATXdelbanEdelbanE

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

gnillafdnagnisiragniwollofdelbanerodelbasiderastuptuokcolceht,sehctiwsNE_KLCretfA

erugiF

ninwohssaegderotallicsolatsyrcrokcolctupni

.1

.B3elbaTnidebircsedsatupniKLCehtfonoitcnufaerastuptuoehtfoetatseht,edomevitcaehtnI

CLK

CLK_EN

nQ0 - nQ3

Q0 - Q3

TABLE 3B. CLOCK INPUT FUNCTION TABLE

stupnIstuptuO

KLC3Qurht0Q3Qnurht0Qn

0WOLHGIH

1HGIHWOL

EnabledDisabled

FIGURE 1 - CLK_EN TIMING DIAGRAM

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

3

Page 4

Integrated

Circuit

Systems, Inc.

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

ICS8535-11

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V

Inputs, V

I

Outputs, V

Package Thermal Impedance, θ

Storage T emperature, T

CCx

O

JA

STG

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These ratings

are stress specifications only. Functional operation of product at these conditions or any conditions beyond those listed in the

DC Characteristics

or

AC Characteristics

ods may affect product reliability.

4.6V

-0.5V to VCC + 0.5V

-0.5V to VCC + 0.5V

73.2°C/W (0lfpm)

-65°C to 150°C

is not implied. Exposure to absolute maximum rating conditions for extended peri-

TABLE 4A. POWER SUPPLY DC CHARACTERISTICS, V

= 3.3V±5%, TA = 0°C TO 70°C

CC

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

CC

I

EE

egatloVylppuSrewoP531.33.3564.3V

tnerruCylppuSrewoP 05Am

TABLE 4B. LVCMOS / LVTTL DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

KLC2567.3V

V

HI

V

LI

I

HI

I

LI

egatloVhgiHtupnI

,NE_KLC

LES_KLC

KLC3.0-8.0V

egatloVwoLtupnI

,NE_KLC

LES_KLC

,KLC

tnerruChgiHtupnI

LES_KLC

NE_KLCV

,KLC

tnerruCwoLtupnI

LES_KLC

V

NE_KLCV

= 3.3V±5%, TA = 0°C TO 70°C

CC

V=

V

NI

CC

V=

NI

CC

V,V0=

NI

V,V0=

NI

V564.3=051Aµ

V564.3=5Aµ

CC

CC

V564.3=5-Aµ

V564.3=051-Aµ

2567.3V

3.0-8.0V

TABLE 4C. LVPECL DC CHARACTERISTICS, V

= 3.3V±5%, TA = 0°C TO 70°C

CC

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

HO

V

LO

V

GNIWS

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

1ETON;egatloVhgiHtuptuOV

1ETON;egatloVwoLtuptuOV

4.1-V

CC

-0.2V

CC

-0.1V

CC

-7.1V

CC

gniwSegatloVtuptuOkaeP-ot-kaeP6.058.0V

05htiwdetanimretstuptuO:1ETON Ω Vot

.V2-

CC

4

Page 5

Integrated

Circuit

Systems, Inc.

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

ICS8535-11

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

TABLE 5. CRYSTAL CHARACTERISTICS

retemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

noitallicsOfoedoM latnemadnuF

ecnareloTycneuqerF 05-05mpp

ytilibatSycneuqerF 001-001mpp

leveLevirD 1.0Wm

)RSE(ecnatsiseRseireStnelaviuqE 0508

ecnaticapaCtnuhS 7Fp

ecnatcudnIniPseireS 37Hn

egnaRerutarepmeTgnitarepO 007C°

gnigAC°52@raeyreP5-5mpp

egnaRycneuqerF 4152zHM

Ω

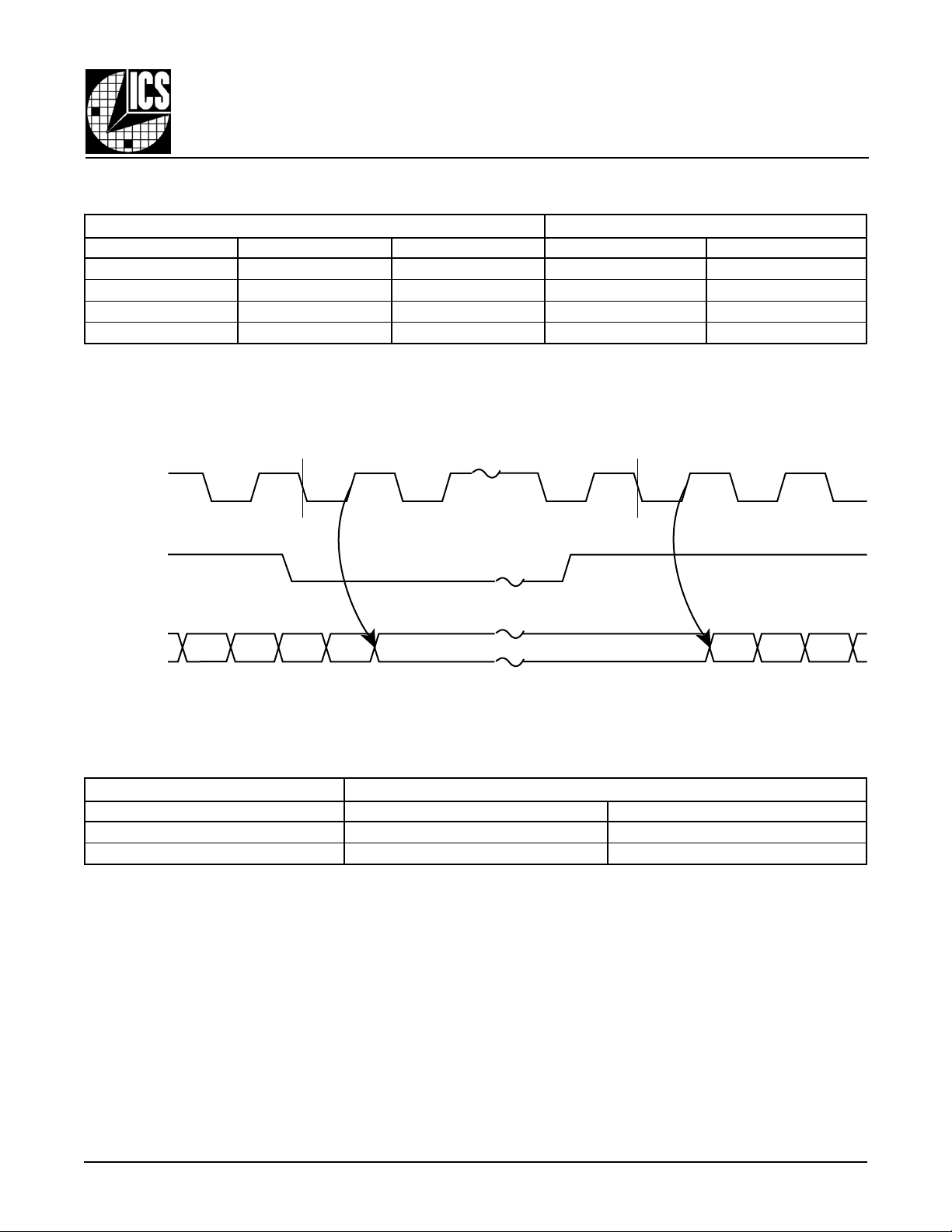

TABLE 6. AC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

f

XAM

t

DP

t

)o(ks5,2ETON;wekStuptuO 5253sp

t

)pp(ks5,3ETON;wekstraP-ot-traP 051sp

t

R

t

F

cdo4ETON;elcyCytuDtuptuO840525%

LOTcsoecnarelloTrotallicsOlatsyrC 0001mpp

=3.3V±5%, TA = 0°C TO 70°C

CC

ycneuqerFtuptuOmumixaM 662zHM

1ETON;yaleDnoitagaporP IJ zHM6620.14.2sn

emiTesiRtuptuOzHM05@%08ot%02003007sp

emiTllaFtuptuOzHM05@%08ot%02003007sp

.esiwrehtodetonsselnuzHM662taderusaemsretemarapllA

.rettijddatonseodtrapehT.tuptuoehtnorettijehtlauqelliwtupniehtnorettijelcyc-ot-elcycehT

.tniopgnissorctuptuolaitnereffidehtottupniehtfotniop%05ehtmorfderusaeM:1ETON

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuoneewtebwekssadenifeD:2ETON

.stniopssorclaitnereffidtuptuoehttaderusaeM

segatlovylppusemasehttagnitareposecivedtnereffidnostuptuoneewtebwekssadenifeD:3ETON

derusaemerastuptuoeht,ecivedhcaenostupnifoepytemasehtgnisU.snoitidnocdaollauqehtiwdna

.stniopssorclaitnereffidehtta

.etoNnoitacilppAotrefer,tupniLATXroF.tupniKLCgnisuderusaeM:4ETON

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:5ETON

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

5

Page 6

Integrated

Circuit

Systems, Inc.

PARAMETER MEASUREMENT INFORMATION

V

CC

LVPECL

VCC = 2V

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

SCOPE

Qx

nQx

VEE = -1.3V ± 0.135V

Qx

nQx

Qy

nQy

FIGURE 2 - CHARACTERIZATION TEST CIRCUIT

tsk(o)

FIGURE 3 - OUTPUT SKEW

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

6

Page 7

Integrated

Circuit

Systems, Inc.

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

Clock Inputs

and Outputs

CLK

Q0 - Q3

nQ0 - nQ3

80%

20%

t

R

t

F

FIGURE 4 - INPUT AND OUTPUT RISING/FALL TIME

t

PD

80%

20%

V

SWING

CLK, Qx

nCLK, nQx

FIGURE 5 - PROPAGATION DELAY

Pulse Width

t

PERIOD

t

t

PERIOD

PW

odc =

FIGURE 6 - odc & t

PERIOD

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

7

Page 8

Integrated

Circuit

Systems, Inc.

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

ICS8535-11

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

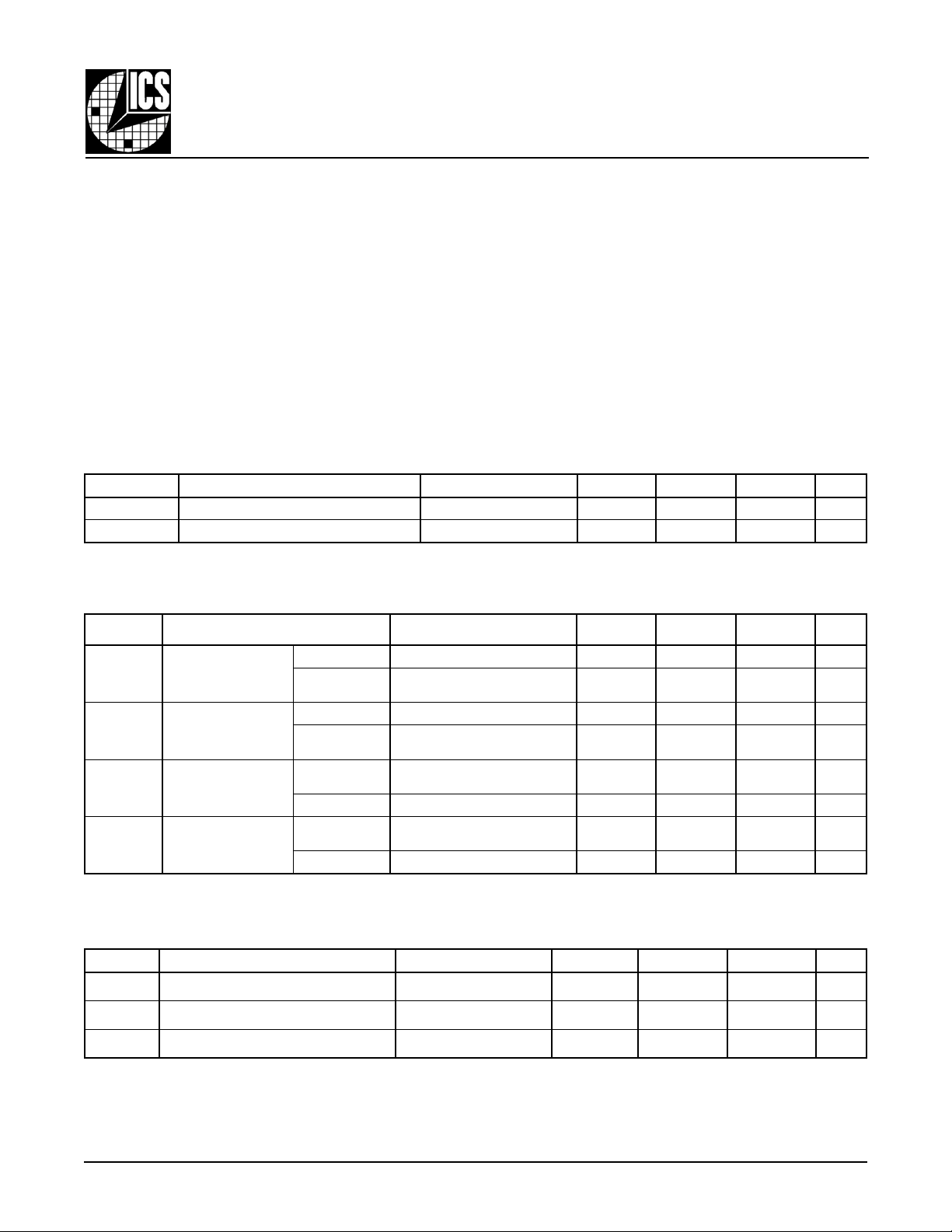

APPLICATION INFORMATION

CR YSTA L OSCILLA TOR CIRCUIT FREQUENCY FINE TUNING

A crystal can be characterized for either series or parallel mode operation. The ICS8535-11 and ICS8533-11 fanout buf fers have

built-in crystal oscillator circuits that can accept either a series or parallel crystal without additional components. The frequency

accuracy provided by this configuration is sufficient for most computer applications.

For applications requiring highly accurate clock frequencies, the output frequency can be fine tuned by inserting a small series

capacitor C1 at the XT AL1 input (Pin 6 for ICS8535-11) as shown in

parallel or series crystal. The C1 value depends on the crystal type, frequency and the board layout. The parallel crystal fine tuning

results in smaller ppm and better performance. It is difficult to provide the precise value of C1. This section provides recommended

series capacitor C1 values to start with. This example uses 18pF parallel crystals.

Figure 7.

This fine tuning approach can be applied in either

Figure 7

about 33pF .

Figure 8

figure, a 24pF, 33pF and 43pF series capacitor is used to achieve the lowest ppm error for 19.44MHz, 16.666MHz and 15MHz

respectively.

Figure 9

shows the suggested series capacitor value for a parallel crystal. For a 16.666 MHz crystal, the recommended C1 value is

shows frequency accuracy versus series capacitance for 19.44MHz, 16.666MHz and 15MHz crystals. As seen from this

shows the experiment results of crystal oscillator frequency drift due to temperature variation.

U1

XTAL2

X1

C1

XTAL1

FIGURE 7 - CRYSTAL INTERFACE WITH SERIES CAPACITOR C1.

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

8

Page 9

Integrated

)

y

y

)

Circuit

Systems, Inc.

60

14.318

50

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

40

30

20

Series Capacitor, C1 (pF

10

0

14 15 16 17 18 19 20 21 22 23 24 25

15.000

16.666

Crystal Frequency (MHz)

19.440

20.000

FIGURE 8 - SUGGESTED SERIES CAPACITOR C1 FOR PARALLEL CRYSTAL

100

80

60

(ppm

40

20

0

Accurac

0 102030405060

-20

-40

-60

Frequenc

-80

-100

Series Capacitor, C1 (pF)

24.000

19.44MHz

16.666MHz

15.00MHz

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

FIGURE 9 - FREQUENCY ACCURACY FOR PARALLEL CRYSTAL USING SERIES CAPACITOR C1

9

Page 10

Integrated

Circuit

Systems, Inc.

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

ICS8535-11

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

POWER CONSIDERATIONS

This section provides information on power dissipation and junction temperature for the ICS8535-11.

Equations and example calculations are also provided.

1. Power Dissipation.

The total power dissipation for the ICS8535-11 is the sum of the core power plus the power dissipated in the load(s).

The following is the power dissipation for V

NOTE: Please refer to Section 3 for details on calculating power dissipated in the load.

= 3.3V + 5% = 3.465V , which gives worst case results.

CC

• Power (core)

• Power (outputs)

If all outputs are loaded, the total power is 4 * 30.2mW = 120.8mW

T otal Power

MAX

= V

MAX

_MAX

* I

CC_MAX

= 30.2mW/Loaded Output pair

= 3.465V * 50mA = 173.25mW

EE_MAX

(3.465V, with all outputs switching) = 173.25mW + 120.8mW = 294.05mW

2. Junction T emperature.

Junction temperature, Tj, is the temperature at the junction of the bond wire and bond pad and directly affects the reliability of the

device. The maximum recommended junction temperature for HiPerClockS

The equation for Tj is as follows: Tj = θ

Tj = Junction T emperature

θ

= junction-to-ambient thermal resistance

JA

Pd_total = T otal device power dissipation (example calculation is in section 1 above)

T

= Ambient T emperature

A

In order to calculate junction temperature, the appropriate junction-to-ambient thermal resistance θ

moderate air flow of 200 linear feet per minute and a multi-layer board, the appropriate value is 66.6°C/W per T able 7 below .

Therefore, Tj for an ambient temperature of 70°C with all outputs switching is:

70°C + 0.294W * 66.6°C/W = 89.58°C. This is well below the limit of 125°C

This calculation is only an example. Tj will obviously vary depending on the number of loaded outputs, supply voltage, air flow,

and the type of board (single layer or multi-layer).

* Pd_total + T

JA

A

TM

devices is 125°C.

must be used . Assuming a

JA

T able 7. Thermal Resistance qJA for 20-pin TSSOP, Forced Convection

q

by V elocity (Linear Feet per Minute)

JA

0 200 500

Single-Layer PCB, JEDEC Standard Test Boards 114.5°C/W 98.0°C/W 88.0°C/W

Multi-Layer PCB, JEDEC Standard Test Boards 73.2°C/W 66.6°C/W 63.5°C/W

NOTE: Most modern PCB designs use multi-layered boards. The data in the second row pertains to most designs.

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

10

Page 11

Integrated

Circuit

Systems, Inc.

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

3. Calculations and Equations.

The purpose of this section is to derive the power dissipated into the load.

ICS8535-11

LVPECL output driver circuit and termination are shown in

Figure 10.

VCC

Q1

V

OUT

RL

50

V

- 2V

CC

FIGURE 10 - LVPECL DRIVER CIRCUIT AND TERMINATION

To calculate worst case power dissipation into the load, use the following equations which assume a 50Ω load, and a termination

voltage of V

Pd_H is power dissipation when the output drives high.

Pd_L is the power dissipation when the output drives low .

CC

- 2V .

Pd_H = [(V

Pd_L = [(V

• For logic high, V

Using V

• For logic low, V

Using V

OH_MAX

OL_MAX

– (V

– (V

CC_MAX

CC_MAX

- 2V))/RL] * (V

CC_MAX

- 2V))/RL] * (V

CC_MAX

= V

OUT

OH_MAX

= 3.465, this results in V

= V

OUT

OL_MAX

= 3.465, this results in V

= V

= V

CC_MAX

CC_MAX

CC_MAX

CC_MAX

- V

OH_MAX

- V

OL_MAX

– 1.0V

OH_MAX

– 1.7V

OL_MAX

)

)

= 2.465V

= 1.765V

Pd_H = [(2.465V - (3.465V - 2V))/50Ω] * (3.465V - 2.465V) = 20mW

Pd_L = [(1.765V - (3.465V - 2V))/50Ω] * (3.465V - 1.765V) = 10.2mW

T otal Power Dissipation per output pair = Pd_H + Pd_L = 30.2mW

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

11

Page 12

Integrated

Circuit

Systems, Inc.

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

RELIABILITY INFORMATION

TABLE 8. θ

TRANSISTOR COUNT

The transistor count for ICS8535-11 is: 428

VS

. AIR FLOW TABLE

JA

q

JA

Single-Layer PCB, JEDEC Standard Test Boards 114.5°C/W 98.0°C/W 88.0°C/W

Multi-Layer PCB, JEDEC Standard Test Boards 73.2°C/W 66.6°C/W 63.5°C/W

NOTE: Most modern PCB designs use multi-layered boards. The data in the second row pertains to most designs.

by V elocity (Linear Feet per Minute)

0 200 500

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

12

Page 13

Integrated

Circuit

Systems, Inc.

PACKAGE OUTLINE - G SUFFIX

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V L VPECL FANOUT BUFFER

TABLE 9. PACKAGE DIMENSIONS

LOBMYS

N02

A--02.1

1A50.051.0

2A08.050.1

b91.003.0

c90.002.0

D04.606.6

ECISAB04.6

1E03.405.4

eCISAB56.0

L54.057.0

α

aaa--01.0

Reference Document: JEDEC Publication 95, MO-153

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

NIMXAM

°0 °8

13

sretemilliM

Page 14

Integrated

Circuit

Systems, Inc.

TABLE 10. ORDERING INFORMATION

rebmuNredrO/traPgnikraMegakcaPtnuoCerutarepmeT

11-GA5358SCI11-GA5358SCIPOSSTdael02ebutrep27C°07otC°0

T11-GA5358SCI11-GA5358SCIleeRdnaepaTnoPOSSTdael020052C°07otC°0

ICS8535-11

LOW SKEW, 1-TO-4, CRYSTAL OSCILLATOR/

LVCMOS-TO-3.3V LVPECL FANOUT BUFFER

While the information presented herein has been checked for both accuracy and reliability, Integrated Circuit Systems, Incorporated (ICS) assumes no responsibility for either its use

or for infringement of any patents or other rights of third parties, which would result from its use. No other circuits, patents, or licenses are implied. This product is intended for use

in normal commercial applications. Any other applications such as those requiring extended temperature range, high reliability, or other extraordinary environmental requirements are

not recommended without additional processing by ICS. ICS reserves the right to change any circuitry or specifications without notice. ICS does not authorize or warrant any ICS

product for use in life support devices or critical medical instruments.

8535AG-11 www.icst.com/products/hiperclocks.html REV. B JULY 27, 2001

14

Loading...

Loading...