Page 1

INTEGRATED CIRCUITS

DATA SH EET

HTRC11001T

HITAG reader chip

Product specification

Supersedes data of 1999 Jan 01

File under Integrated Circuits, IC11

2001 Nov 23

Page 2

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 QUICK REFERENCE DATA

5 ORDERING INFORMATION

6 BLOCK DIAGRAM

7 PINNING

8 FUNCTIONAL DESCRIPTION

8.1 Power supply

8.2 Antenna drivers

8.3 Diagnosis

8.4 Oscillator with programmable divider

8.5 Adaptive sampling time demodulator

8.6 Idle and Power-down mode

8.7 Serial interface

8.7.1 Communication protocol

8.7.2 Glitch filter

8.8 Commands

8.8.1 Command READ_TAG

8.8.2 Command WRITE_TAG_N

8.8.3 Command WRITE_TAG

8.8.4 Command READ_PHASE

8.8.5 Command SET_SAMPLING_TIME

8.8.6 Command GET_SAMPLING_TIME

8.8.7 Command SET_CONFIG_PAGE

8.8.8 Command GET_CONFIG_PAGE

9 LIMITING VALUES

10 DC CHARACTERISTICS

11 AC CHARACTERISTICS

12 APPLICATION INFORMATION

13 PACKAGE OUTLINE

14 SOLDERING

14.1 Introduction to soldering surface mount

packages

14.2 Reflow soldering

14.3 Wave soldering

14.4 Manual soldering

14.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

15 DATA SHEET STATUS

16 DEFINITIONS

17 DISCLAIMERS

2001 Nov 23 2

Page 3

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

1 FEATURES

• Combines all analog RFID reader hardware in one

single chip

• Optimized for HITAG transponder family

• Robust antenna coil power driver stage with modulator

• High performance adaptive sampling time AM/PM

demodulator (patent pending)

• Read and write function

• On-chip clock oscillator

• Antenna rupture and short circuit detection

• Low power consumption

• Very low power standby mode

• Low external component count

• Small package SO14.

2 APPLICATIONS

• RFID systems.

3 GENERAL DESCRIPTION

(1)

HITAG

is the family name of the reader chip

HTRC11001T to use with transponders which are based

on the HITAG tag ICs (HT1ICS3002x or HT2ICS2002x).

The receiver parameters (gain factors and filter cut-off

frequencies) can beoptimized to system and transponder

requirements. The HTRC11001T is designed for easy

integration into RF identification readers.

State-of-the-art technology allows almost complete

integration of the necessary building blocks. A powerful

antennademodulator and driver, together witha low-noise

adaptive sampling time demodulator, a programmable

filter, amplifier and digitizer, build the complete transceiver

unit, required to design high-performance readers.

A three-pin microcontroller interface is employed for

programming the HTRC11001T as well as for the

bidirectional communication with the transponders. The

three-wire interface can be changed into a two-wire

interface by connecting the data input and the data output.

Tolerance dependent zero amplitude modulation will

cause severe problems in envelope detector systems,

resulting in the need of very low tolerance reader

antennas.TheseproblemsaresolvedbythenewAdaptive

Sampling Time (AST) technique.

(1) HITAG - is a trademark of Philips Semiconductors

Gratkorn GmbH.

4 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DD

f

clk

f

res

I

ant(p)

T

amb

supply voltage 4.5 5.0 5.5 V

clock frequency programmable 4 − 16 MHz

antenna resonant frequency − 125 − kHz

antenna driver output current (peak value) continuous −−200 mA

ambient temperature −40 − +85 °C

5 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

HTRC11001T SO14 plastic small outlet package; 14 leads; body width 3.9 mm SOT108-1

2001 Nov 23 3

Page 4

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

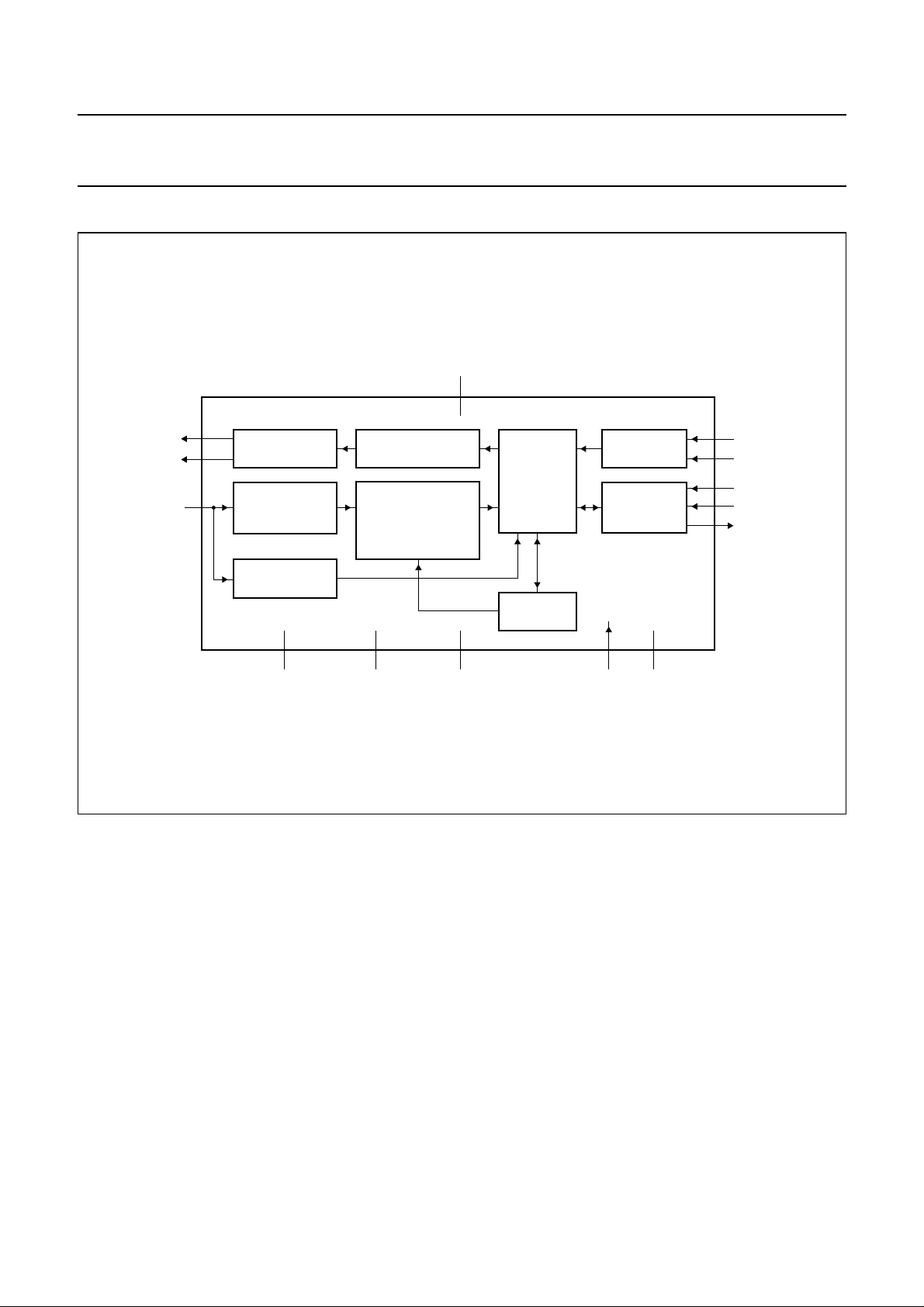

6 BLOCK DIAGRAM

handbook, full pagewidth

TX1

TX2

RX

4

2

14

SYNCHRONOUS

DEMODULATOR

MEASUREMENT

V

DD

3

ANTENNA

DRIVERS

PHASE

13 12 11

MODULATOR

BANDPASS FILTER

AMPLIFIER

DYNAMIC CONTROL

DIGITIZER

V

SS

CONTROL

UNIT

CONTROL

REGISTER

1

MODE

Fig.1 Block diagram.

OSCILLATOR

SERIAL

INTERFACE

HTRC11001T

5

n.c.CEXTQGND

10

MGW265

6

XTAL1

7

XTAL2

8

SCLK

9

DIN

DOUT

2001 Nov 23 4

Page 5

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

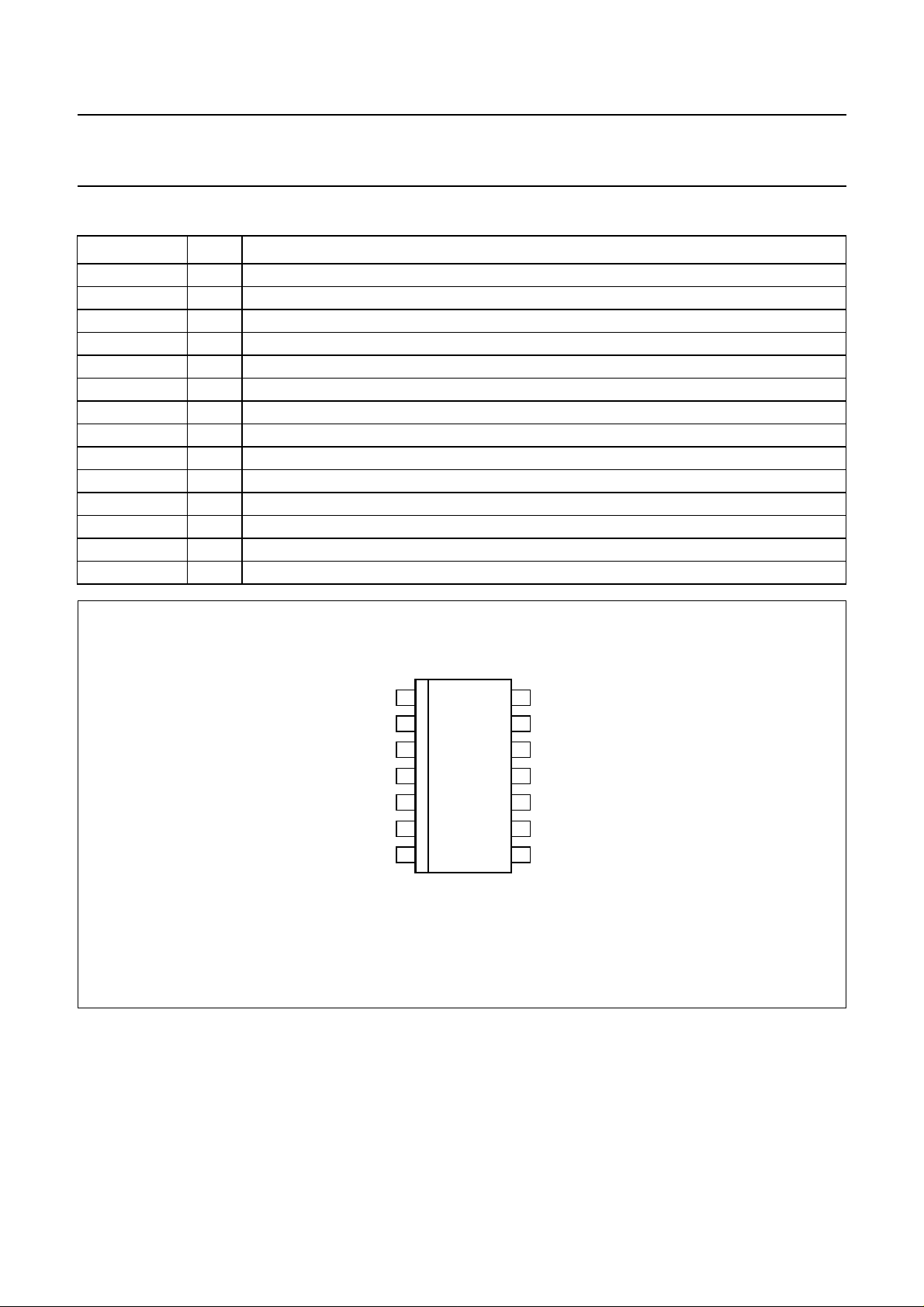

7 PINNING

SYMBOL PIN DESCRIPTION

V

SS

TX2 2 antenna driver output 2

V

DD

TX1 4 antenna driver output 1

MODE 5 control input to enable filtering of serial clock and data input; for active antenna applications

XTAL1 6 oscillator input 1

XTAL2 7 oscillator input 2

SCLK 8 serial clock input of microcontroller interface

DIN 9 serial data input of microcontroller interface

DOUT 10 serial data output of microcontroller interface

n.c. 11 not connected

CEXT 12 high-pass filter coupling capacitor connection

QGND 13 internal analog virtual ground capacitor connection

RX 14 demodulator input

1 ground supply

3 supply voltage (5 V stabilized)

handbook, halfpage

V

1

SS

TX2

2

3

V

DD

4

TX1

MODE

XTAL1

XTAL2

HTRC11001T

5

6

7

Fig.2 Pin configuration.Fig.2 Pin configuration.

MGW266

14

13

12

11

10

9

8

RX

QGND

CEXT

n.c.

DOUT

DIN

SCLK

2001 Nov 23 5

Page 6

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8 FUNCTIONAL DESCRIPTION

8.1 Power supply

TheHTRC11001Tworkswithan external 5 V ±10% power

supply at pin VDD. The maximum DC current is

10 mA + × I

2

-- -

π

ant(p)

= 137 mA.

For optimum performance, the power supply connection

should be bypassed to ground with a 100 nF capacitor

close to the chip.

8.2 Antenna drivers

The drivers deliver a square shaped voltage to the series

resonant antenna circuit (see Fig.4). Due to the full bridge

configuration of the drivers the output voltage V

approximately 10 V, corresponding to V

ant(p)

=5V.

ant(p-p)

is

The current flowing through the antenna is sine shaped

and the peak and RMS values are approximately:

V

4

I

ant(p)

I

ant(rms)

ant(p)

×=

--------------- -

-- -

π

R

ant

1

×=

I

-------

ant(p)

2

8.3 Diagnosis

In order to detect an antenna short-circuit or open-circuit

the antenna tap voltage is monitored.

An antenna fail condition is reported in the status

bit ANTFAIL (see Table 5) if the antenna tap voltage does

not go more negative than the diagnosis level voltage

(V

= −1.15 V). This condition is checked for every coil

diag

driver cycle.

8.5 Adaptive sampling time demodulator

The demodulator senses the absorption modulation

applied by a transponder when inserted into the field. The

signal is picked up at the antenna tap point between

L

and Ca. It is divided by Rv and the internal resistor R

a

int

to a level on pin RX below 8 V (peak value) with respect to

pin QGND (see Fig.4). Internally the signal is filtered with

a second-order low-pass filter.

The antenna current and therefore the tap voltage is

modulated by the transponder in amplitude and/or phase.

This signal is fed into a synchronous demodulator

recovering the baseband signal. The amplification and the

bandpass filter edge frequencies of the demodulator can

be adapted to different transponders via settings in the

configuration pages (see Table 3).

The phase between the driver excitation signal and the

antenna tap voltage depends on the antenna tuning. With

optimum tuning, the phase of the antenna tap voltage is

90° off the antenna driver signal. Detuning of the antenna

resonant circuit results in a change of this phase

relationship. The built-in phase measurement unit allows

the measurement of this phase relationship with a

resolution of . This can be used to

-----64

1

360°× 5.625°=

compute a sampling time that compensates the detuning

of the reader antenna.

The phase measurement procedure can be carried out:

• Once before the first communication starts, if the

position of the transponder does not change with

respect to the reader antenna

• During the communication (after sending the write

pulses and before receiving the answer of the

transponder), if the tag is moving.

8.4 Oscillator with programmable divider

Thecrystaloscillatoratpins XTAL1and XTAL2workswith

either crystal or ceramic resonators. It delivers the input

clock frequency of 4, 8, 12 or 16 MHz. The oscillator

frequency is divided by a programmable divider (selection

bits FSEL1 and FSEL0) to obtain the carrier frequency of

125 kHz (see Table 3).

Alternatively, an external clock signal (CMOS compatible)

may connected to pin XTAL1. For example, this clock

signal can be derived from the microcontroller clock.

2001 Nov 23 6

Beforethesystemisswitched into WRITE_TAG mode, the

demodulator has to be frozen. This is internally done by

clamping the input of the filter amplifier unit to the level on

pin QGND. Doing so avoids large transients in the

amplifier and digitizer, which could affect settling times.

In addition to the clamping, there exist other means in the

HTRC11001T which allow further reduction of the settling

times. All the parts of the circuitry which are associated

with these functions are controlled by the bits FREEZE0,

FREEZE1 and THRESET (see Table 2).

For more details concerning write timing, demodulator

setting, power-up sequence, etc. please refer to the

application note

the HITAG Read/Write IC HTRC110”

“AN 98080 Read/Write devices based on

.

Page 7

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8.6 Idle and Power-down mode

The HTRC11001T can be switched into the Idle mode via

setting bit PD = 1 and resetting bit PD_MODE = 0

(see Table 3). In this Idle mode, only the oscillator and a

few other system components are active.

It is also possible to switch the HTRC11001T completely

off. This is achieved by the Power-down mode (bit PD = 1

and bit PD_MODE = 1). Within this mode also the clock

oscillator is switched off. This reduces the supply current

of the HTRC11001T to less than 20 µA.

8.7 Serial interface

The communication between the HTRC11001T and the

microcontroller is done via a 3-wire digital interface. The

interface is operated by the following signals:

• Clock pulse on pin SCLK

• Data input on pin DIN

• Data output on pin DOUT.

Pins SCLK and DIN are realized as Schmitt-trigger inputs.

Pin DOUT is an open-drain output with an internal pull-up

resistor.

All commands transmitted to the HTRC11001T serial

interface start with the Most Significant Bit (MSB).

Input DIN and output DOUT are valid when pin SCLK is at

HIGH level.

8.7.2 GLITCH FILTER

Connectingpin MODEtoVDDenablesdigitalfilteringofthe

SCLK and the DIN input signals. This mode offers

improved immunity against noise and interference

(glitches) on these interface signals. It is intended to be

used in the so called ‘active antenna applications’ where

the microcontroller and the reader communicate via long

signal lines (e.g. 1 meter).

In other applications pin MODE has to be connected to

ground (pin VSS).

For a detailed description of this feature, refer to the

application note

the HITAG Read/Write IC HTRC110”

“AN 98080 Read/Write devices based on

.

8.7.1 COMMUNICATION PROTOCOL

Every communication between the HTRC11001T and the

microcontroller begins with an initialization of the serial

interface. The interface initialization condition is a

LOW-to-HIGH transition on pin DIN while pin SCLK is at

HIGH level (see Fig.3).

handbook, full pagewidth

SCLK

DIN

DOUT

initialization

D7 D6 D1 D0

t

h

t

su

Fig.3 Serial interface communication protocol.

D7 D6 D1 D0

MGW268

2001 Nov 23 7

Page 8

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8.8 Commands Table 1 Summary of the HTRC11001T command set

COMMAND NAME

REMARK

MSB LSB

READ_TAG 1 1 1 −−−−−READ_TAG mode

WRITE_TAG_N 0001N3N2N1N0WRITE_TAG mode with

pulse width programming

WRITE_TAG 1 1 0 −−−−−WRITE_TAG mode

READ_PHASE 00001000read command

0 0 D5 D4 D3 D2 D1 D0 response

SET_SAMPLING_TIME 1 0 D5 D4 D3 D2 D1 D0

GET_SAMPLING_TIME 00000010read command

0 0 D5 D4 D3 D2 D1 D0 response

SET_CONFIG_PAGE 0 1 P1 P0 D3 D2 D1 D0 4 × 4 configuration bits

available

GET_CONFIG_PAGE 000001P1P0read command

X3 X2 X1 X0 D3 D2 D1 D0 response

BIT 7 BIT 6 BIT5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

8.8.1 C

OMMAND READ_TAG

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Command bits 1 1 1 −−−−−

This command is used to read the demodulated bit stream from a transponder.

After the assertion of the three command bits the HTRC11001T instantaneously switches to the READ_TAG mode and

transmits the demodulated, filtered and digitized data to the microcontroller. This data should be decoded by the

microcontroller.

The READ_TAG mode is terminated by a LOW-to-HIGH transition on pin SCLK.

8.8.2 C

OMMAND WRITE_TAG_N

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Command bits 0001N3N2N1N0

This command is used to write data to a transponder.

If bits N3 to N0 are set to 0000, the signal on pin DIN is transparently switched to the drivers. A HIGH level on pin DIN

corresponds to antenna drivers switched off and a LOW level corresponds to antenna drivers switched on.

For any binary number N between 0001 and 1111, the drivers are switched off at the next positive transition on pin DIN.

This state is held for a time interval t = N × T

(for T0=8µs). This method relaxes the timing resolution requirements to

0

the microcontroller and to the software implementation while providing an exact, selectable write pulse timing.

The WRITE_TAG mode is terminated immediately by a LOW- to-HIGH transition on pin SCLK.

2001 Nov 23 8

Page 9

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8.8.3 COMMAND WRITE_TAG

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Command bits 1 1 0 −−−−−

This is the 3-bit short form of the previously described command WRITE_TAG_N. It allows to switch into the

WRITE_TAG mode with a minimum communication time.

The behaviour of the WRITE_TAG command is identical to WRITE_TAG_N with two exceptions:

• WRITE_TAG mode is entered after assertion of the third command bit

• No N parameter is specified with this command; instead the N value which was programmed with the most recent

WRITE_TAG_N command is used. If no WRITE_TAG_N was issued so far, a default N = 0 (transparent mode) will be

assumed.

8.8.4 C

Command bits 00001000

Response bits 0 0 D5 D4 D3 D2 D1 D0

This command is used to read the antenna phase, which is measured at every carrier cycle.

The response bits D5 to D0 represent the phase (coded binary).

8.8.5 COMMAND SET_SAMPLING_TIME

Command bits 1 0 D5 D4 D3 D2 D1 D0

This command specifies the demodulator sampling time t

8.8.6 COMMAND GET_SAMPLING_TIME

Command bits 00000010

Response bits 0 0 D5 D4 D3 D2 D1 D0

This command is used to read back the sampling time ts set with SET_SAMPLING_TIME.

OMMAND READ_PHASE

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

. The sampling time is coded binary in bits D5 to D0.

s

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

The response bits D5 to D0 represent the sampling time (coded binary).

2001 Nov 23 9

Page 10

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8.8.7 COMMAND SET_CONFIG_PAGE

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Command 0 1 P1 P0 D3 D2 D1 D0

This command is used to set the filter and amplifier parameters (cut-off frequencies and gain factors) and to select the

operation mode. Bits P1 and P0 select one of four configuration pages.

Table 2 Configuration page bit names

COMMAND

PAGE NUMBER

7 6 P1 P0 D3 D2 D1 D0

BIT

SET_CONFIG_PAGE 0 0 1 0 0 GAIN1 GAIN0 FILTERH FILTERL

SET_CONFIG_PAGE 1 0 1 0 1 PD_MODE PD HYSTERESIS TXDIS

SET_CONFIG_PAGE 2 0 1 1 0 THRESET ACQAMP FREEZE1 FREEZE0

SET_CONFIG_PAGE 3 0 1 1 1 DISLP1 DISSMART-

FSEL1 FSEL0

COMP

Table 3 Description of the configuration page bits

BIT NAME VALUE DESCRIPTION

INITIAL

VALUE

FILTERL main low-pass cut-off frequency

0f

1f

= 3 kHz 0

L

= 6 kHz

L

FILTERH main high-pass cut-off frequency

0f

1f

= 40 kHz 0

H

= 160 kHz

H

GAIN0 amplifier 0 gain factor

0 gain = 16 0

1 gain = 32

GAIN1 amplifier 1 gain factor

0 gain = 6.22

1 gain = 31.5 1

TXDIS disable coil driver

0 coil driver active 0

1 coil driver inactive

HYSTERESIS data comparator hysteresis

0 hysteresis OFF 0

1 hysteresis ON

PD Power-down mode enable

0 device active 0

1 device power-down

2001 Nov 23 10

Page 11

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

BIT NAME VALUE DESCRIPTION

PD_MODE select Power-down mode

0 Idle mode 0

1 Power-down mode

FREEZE1,

FREEZE0

ACQAMP store signal amplitude (see also bit AMPCOMP in Table 5)

THRESET reset threshold generation of digitizer

FSEL1, FSEL0 clock frequency selection (MSB and LSB)

DISSMARTCOMP

DISLP1 disable low-pass 1

00 normal operation 00

01 main low-pass is frozen; main high-pass is pre-charged to level on pin QGND

10 main low-pass is frozen; time constant of main high-pass is reduced by a

11 main high-pass time constant is reduced by a factor of 16 for bit FILTERH = 0

00 4 MHz 00

01 8 MHz

10 12 MHz

11 16 MHz

facility to achieve fast settling times (MSB and LSB)

factor of 16 for bit FILTERH = 0 and by a factor of 8 for bit FILTERH = 1

and by a factor of 8 for bit FILTERH = 1; second high-pass is pre-charged

0 set status bit AMPCOMP when the actual data signal amplitude is higher than

the stored reference

1 store actual amplitude of the data signal as reference for later amplitude

comparison

0 no reset 0

1 reset

disable smart comparator

0 smart comparator: on 0

1 smart comparator: off

0 low-pass: on 0

1 low-pass: off

INITIAL

VALUE

0

2001 Nov 23 11

Page 12

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

8.8.8 COMMAND GET_CONFIG_PAGE

?

NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Command bits 000001P1P0

Response bits X3 X2 X1 X0 D3 D2 D1 D0

This command has three functions:

1. Reading back the configuration parameters set by command SET_CONFIG_PAGE

2. Reading back the transmit pulse width programmed with command WRITE_TAG_N

3. Reading the system status information.

Bits P1 and P0 select one of four configuration pages.

The response bits (X3 to X0 and D3 to D0) contains the contents of the selected configuration page in its lower nibble.

For page 0 and page 1 the higher nibble reflects the current setting of the transmit pulse width N.

For page 2 and page 3 the system status information is returned in the higher nibble.

Table 4 Configuration page bit names

COMMAND

PAGE NUMBER

X3 X2 X1 X0 3210

BIT

GET_CONFIG_PAGE 0 N3 N2 N1 N0 D3 D2 D1 D0

GET_CONFIG_PAGE 1 N3 N2 N1 N0 D3 D2 D1 D0

GET_CONFIG_PAGE 2 0 (RFU) 0 (RFU) AMPCOMP ANTFAIL D3 D2 D1 D0

GET_CONFIG_PAGE 3 0 (RFU) 0 (RFU) AMPCOMP ANTFAIL D3 D2 D1 D0

Table 5 Description of the configuration page bits

BIT NAME VALUE DESCRIPTION

D3 to D0 XXXX contents of the selected configuration page

N3 to N0 XXXX current setting of the transmit pulse width

ANTFAIL antenna failure

0 no antenna failure

1 antenna failure

AMPCOMP amplitude comparison result (see also bit ACQAMP in Table 3)

0 actual data signal amplitude is lower than the stored reference

1 actual data signal amplitude is higher than the stored reference

2001 Nov 23 12

Page 13

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

9 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134); note 1.

SYMBOL PARAMETER MIN. MAX. UNIT

V

n

V

n(max)

V

RX

T

j(max)

T

stg

Note

1. Stress above one or more of the limiting values may cause permanent damage to the device. These are stresses

ratings only and operation of the device at these or at any other conditions above those given in Chapter 10 not

implied. Exposure or limiting values for extended periods may affect device reliability.

10 DC CHARACTERISTICS

All voltages are measured with respect to ground (pin VSS); T

voltage at any pin (except pinRX) −0.3 +6.5 V

maximum voltage at any pin with respect to VDD (except pin RX) −0.3 VDD+ 0.3 V

voltage at pin RX −10 +12 V

maximum junction temperature − 140 °C

storage temperature −65 +125 °C

= −40 to +85 °C

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

DD

I

DD

I

idle

I

pd

supply voltage 4.5 5.0 5.5 V

supply current VDD= 5.5 V; I

TX1=ITX2

=0 − 410 mA

idle current VDD= 5.5 V; note 1 − 0.2 0.4 mA

power-down current VDD= 5.5 V − 720 µA

Driver outputs (pins TX1 and TX2)

I

ant(p)

antennadriveroutputcurrent

(peak value)

permanent −−200 mA

pulse load; t

< 400 ms;

on

−−400 mA

ratio on : off = 1 : 4

R

o

output resistance both drivers together − 2.5 7 Ω

Demodulator input (pin RX)

V

I

V

diag

input voltage with respect to pin QGND −8 − +8 V

diagnosis level voltage with respect to pin QGND;

−1.5 −1.15 −0.8 V

VDD=5V

V

QGND

R

i

potential on pin QGND 0.35V

internal demodulator

17 25 33 kΩ

DD

0.42V

DD

0.50V

DD

V

impedance

Digital inputs

V

IH

V

IL

HIGH-level input voltage 0.7V

LOW-level input voltage −0.3 − 0.3V

− VDD+ 0.3 V V

DD

DD

V

Digital outputs

V

OL

I

OL

LOW-level output voltage I

OL(max)

LOW-level output current VOL≤ 0.4 V 1 −− mA

=1mA −−0.4 V

Note

1. Power consumption of external quartz or any other component is not included.

2001 Nov 23 13

Page 14

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

11 AC CHARACTERISTICS

T

= −40 to +85 °C.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Oscillator inputs (pins XTAL1 and XTAL2)

f

osc

oscillator frequency depending on bits FSEL1

and FSEL0

t

st

C

i

R

i

start-up time − 410ms

input capacitance on pin XTAL1 − 5 − pF

input resistance between pins XTAL1

and XTAL2

External clock input (pin XTAL1)

f

ext

external clock frequency depending on bits FSEL1

and FSEL0

δ duty cycle 40 − 60 %

Serial interface

t

su

t

h

set-up time pin MODE at V

hold time pin MODE at V

SS

SS

Receiver (pin RX)

V

RX(p-p)

t

d

sensitivity (peak-to-peak value) receiver input 2 1 − mV

receiver delay bit FILTERL = 0 290 310 340 µs

bit FILTERL = 1 160 175 190 µs

Demodulator valid time

t

rec

demodulator recovery time after clock stable; note 1 −−5ms

after WRITE-pulse; note 1 −−500 µs

after AST-step − 0.7 1.5 ms

ϕ phase measurement error −−±5.7 deg

4 − 16 MHz

0.9 1.3 3.0 MΩ

4 − 16 MHz

50 −−ns

50 −−ns

Note

1. These short times require special command sequences. Please refer to the application note

devices based on the HITAG Read/Write IC HTRC110”

.

2001 Nov 23 14

“AN 98080 Read/Write

Page 15

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

12 APPLICATION INFORMATION

Figure 4 shows a minimal application circuitry for the

HTRC11001T.

The reader coil La together with the capacitor Ca forms a

series resonant LC circuit (f0= 125 kHz). The high

voltages in the LC circuit are divided to safe operating

levels by Rv and the internal resistor Ri behind pin RX.

The two capacitors connected to pin XTAL1 and

pin XTAL2 shall be the recommended values and types

from the data sheet of the crystal.

handbook, full pagewidth

V

DD

10 µF

100 nF

R

v

C

a

L

a

V

SS

TX2

V

DD

TX1

MODE

XTAL1

XTAL2

1

2

3

HTRC11001T

4

5

6

7

Alternatively to a crystal, a ceramic resonator can be used

or an external clock source can be connected to

pin XTAL1.

RX

14

QGND

13

CEXT

12

n.c.

11

DOUT

10

DIN

9

SCLK

8

100 nF

100 nF

to microcontroller

Fig.4 Minimum application circuitry.

2001 Nov 23 15

MGW267

Page 16

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

13 PACKAGE OUTLINE

SO14: plastic small outline package; 14 leads; body width 3.9 mm

SOT108-1

y

Z

14

pin 1 index

1

D

c

8

A

2

A

1

7

e

w M

b

p

E

H

E

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT108-1

A

max.

1.75

0.069

A

1

0.25

0.10

0.010

0.004

A2A

1.45

1.25

0.057

0.049

IEC JEDEC EIAJ

076E06 MS-012

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1)

cD

8.75

8.55

0.35

0.34

REFERENCES

4.0

3.8

0.16

0.15

1.27

0.050

2001 Nov 23 16

eHELLpQZywv θ

1.05

0.041

1.0

0.4

0.039

0.016

0.7

0.25

0.6

0.028

0.01 0.004

0.024

EUROPEAN

PROJECTION

0.25 0.1

0.01

6.2

5.8

0.244

0.228

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

97-05-22

99-12-27

o

8

o

0

Page 17

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

14 SOLDERING

14.1 Introduction to soldering surface mount

packages

Thistextgivesavery brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurfacemountICs,butitisnotsuitableforfinepitch

SMDs. In these situations reflow soldering is

recommended.

14.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuit board by screen printing, stencillingor

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 220 °C for

thick/large packages, and below 235 °C for small/thin

packages.

14.3 Wave soldering

Conventional single wave soldering is not recommended

forsurfacemountdevices(SMDs)orprinted-circuitboards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackageswithleadsonfoursides,thefootprintmust

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

14.4 Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

2001 Nov 23 17

Page 18

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

14.5 Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

WAVE REFLOW

(1)

BGA, HBGA, LFBGA, SQFP, TFBGA not suitable suitable

SOLDERING METHOD

HBCC, HLQFP, HSQFP, HSOP, HTQFP, HTSSOP, HVQFN, SMS not suitable

(3)

PLCC

, SO, SOJ suitable suitable

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

(2)

(3)(4)

(5)

suitable

suitable

suitable

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

2. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

3. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

4. Wave soldering is only suitable for LQFP, TQFP and QFP packages with a pitch (e) equal to or larger than 0.8 mm;

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

5. Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

2001 Nov 23 18

Page 19

Philips Semiconductors Product specification

HITAG reader chip HTRC11001T

15 DATA SHEET STATUS

PRODUCT

DATA SHEET STATUS

Objective data Development This data sheet contains data from the objective specification for product

Preliminary data Qualification This data sheet contains data from the preliminary specification.

Product data Production This data sheet contains data from the product specification. Philips

(1)

STATUS

(2)

DEFINITIONS

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change

Notification (CPCN) procedure SNW-SQ-650A.

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

16 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

attheseorat any other conditions above those given in the

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentationorwarrantythatsuchapplicationswillbe

suitable for the specified use without further testing or

modification.

17 DISCLAIMERS Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result in personal injury.Philips

Semiconductorscustomersusingorsellingtheseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes, without notice, in the

products, including circuits, standard cells, and/or

software, described or contained herein in order to

improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for

theuseofanyoftheseproducts,conveysnolicenceortitle

under any patent, copyright, or mask work right to these

products,andmakes no representations or warranties that

these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

2001 Nov 23 19

Page 20

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2001

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 613502/02/pp20 Date of release: 2001 Nov 23 Document order number: 9397750 08329

SCA73

Loading...

Loading...