Page 1

September 1995

HS-82C55ARH

Radiation Hardened

CMOS Programmable Peripheral Interface

Features

• Radiation Hardened

- Total Dose >10

- Transient Upset <10

- Latch Up Free EPI-CMOS

• Low Power Consumption

- IDDSB = 20µA

• Pin Compatible with NMOS 8255A and the Intersil 82C55A

• High Speed, No “Wait State” Operation with 5MHz HS-80C86RH

• 24 Programmable I/O Pins

• Bus-Hold Circuitry on All I/O Ports Eliminates Pull-Up Resistors

• Direct Bit Set/Reset Capability

• Enhanced Control Word Read Capability

• Hardened Field, Self-Aligned, Junction Isolated CMOS Process

• Single 5V Supply

• 2.0mA Drive Capability on All I/O Port Outputs

• Military Temperature Range: -55

5

RAD (Si)

8

RAD (Si)/s

o

C to +125oC

Description

The Intersil HS-82C55ARH is a high performance, radiation hardened

CMOS version of the industry standard 8255A and is manufactured using a

hardened field, self-aligned silicongate CMOS process. It is a general

purpose programmable I/O device which may be used with many different

microprocessors. There are 24 I/O pins which are organized into two 8-bit

and two 4-bit ports. Each port may be programmed to function as either an

input or an output. Additionally, one of the 8-bit ports may be programmed

for bi-directional operation,and the two 4-bit ports can be programmed to

provide handshaking capabilities. The high performance, radiation

hardness, and industry standard configuration of the HS-82C55ARH make

it compatible with the HS-80C86RH radiation hardened microprocessor.

Static CMOS circuit design insures low operating power. Bus hold circuitry

eliminates the need for pull-up resistors. The Intersil hardened field CMOS

process results in performance equal to or greater than existing radiation

resistant products at a fraction of the power.

Pinout

40 LEAD CERAMIC DUAL-IN-LINE

METAL SEAL PACKAGE (SBDIP)

MIL-STD-1835 CDIP2-T40

TOP VIEW

1

PA3

PA2

PA1

PA0

RD

CS

GND

A1

A0

PC7

PC6

PC5

PC4

PC0

PC1

PC2

PC3

PB0

PB1

PB2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

PA4

PA5

PA6

PA7

WR

RESET

D0

D1

D2

D3

D4

D5

D6

D7

VDD

PB7

PB6

PB5

PB4

PB3

Pin Description

PIN DESCRIPTION

D7 - D0 Data Bus (Bi-Directional

RESET Reset Input

CS Chip Select

RD Read Input

WR Write Input

Ordering Information

PART NUMBER TEMPERATURE PACKAGE

HS1-82C55ARH-Q -55oC to +125oC 40 Lead SBDIP

HS1-82C55ARH-8 -55oC to +125oC 40 Lead SBDIP

HS1-82C55ARH/Sample +25oC 40 Lead SBDIP

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

970

A0 - A1 Port Address

PA7 - PA0 Port A (Bit)

PB& - PB0 Port B (Bit)

PC7 - PC0 Port C (Bit)

VDD +5 volts

GND 0 volts

Spec Number

File Number 3191.1

DB NA

518060

Page 2

HS-82C55ARH

Pin Description

PIN

SYMBOL

PA0-7 1-4, 37-40 I/O Port A: General purpose I/O Port. Data direction and mode is determined by the contents

PB0-7 18-25 I/O Port B: General purpose I/O port. See Port A.

PC0-3 14-17 I/O Port C (Lower): Combination I/O port and control port associated with Port B. See Port A.

PC4-7 10-13 I/O Port C (Upper): Combination I/O Port and control port associated with Port A. See Port A.

D0-7 27-34 I/O Bidirectional Data Bus: Three-State data bus enabled as an input when CS and WR are

VDD 26 I VDD: The +5V power supply pin. A 0.1µF capacitor between pins 26 and 7 is recommend-

GND 7 I Ground.

CS 6 I Chip Select: A “low” on this input pin enables the communication between the

RD 5 I Read: A “low” on this input pin enables the HS-82C55ARH to send the data or status

WR 36 I Write: A “low” on this input pin enables the CPU to write data or control words into the

A0 and A1 8, 9 I Port Select 0 and Port Select 1: These input signals, in conjunction with the RD and WR

Reset 35 I Reset: A “high” on this input clears the control register and all ports (A, B, C) are set to the

NUMBERS TYPE DESCRIPTION

of the Control Word.

low and as an output when CS and RD are low.

ed for decoupling.

HS-82C55ARH and the CPU.

information to the CPU on the data bus. In essence, it allows the CPU to “read from” the

HS-82C55ARH.

HS-82C55ARH.

inputs, control the selection of one of the three ports or the control word registers. They are

normally connected to the Least Significant Bits of the address bus (A0 and A1).

input mode. “Bus hold” devices internal to the HS-82C55ARH will hold the I/O port inputs

to a logic “1” state with a maximum hold current of 400µA.

Functional Diagram

POWER

SUPPLIES

BIDIRECTIONAL

DATA BUS

D7 - D0

RD

WR

A1

A0

RESET

READ/WRITE

DATA

BUS

BUFFER

CONTROL

LOGIC

+5V

GND

GROUP A

CONTROL

8-BIT INTERNAL

GROUP B

CONTROL

DATA BUS

GROUP A

PORT A

(8)

GROUP A

PORT C

UPPER (4)

GROUP B

PORT C

LOWER (4)

GROUP B

PORT B

(8)

I/O

PA7 - PA0

I/O

PC7 - PC4

I/O

PC3 - PC0

I/O

PB7 - PB0

CS

Spec Number 518060

971

Page 3

Specifications HS-82C55ARH

Absolute Maximum Ratings Reliability Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+7.0V

Input, Output or I/O Voltage . . . . . . . . . . . . .VSS-0.3V to VDD+0.3V

Storage Temperature Range . . . . . . . . . . . . . . . . . -65oC to +150oC

Junction Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +175oC

Lead Temperature (Soldering 10s). . . . . . . . . . . . . . . . . . . . +300oC

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Operating Conditions

Operating Voltage Range. . . . . . . . . . . . . . . . . . . . . +4.5V to +5.5V

Operating Temperature Range. . . . . . . . . . . . . . . . -55oC to +125oC

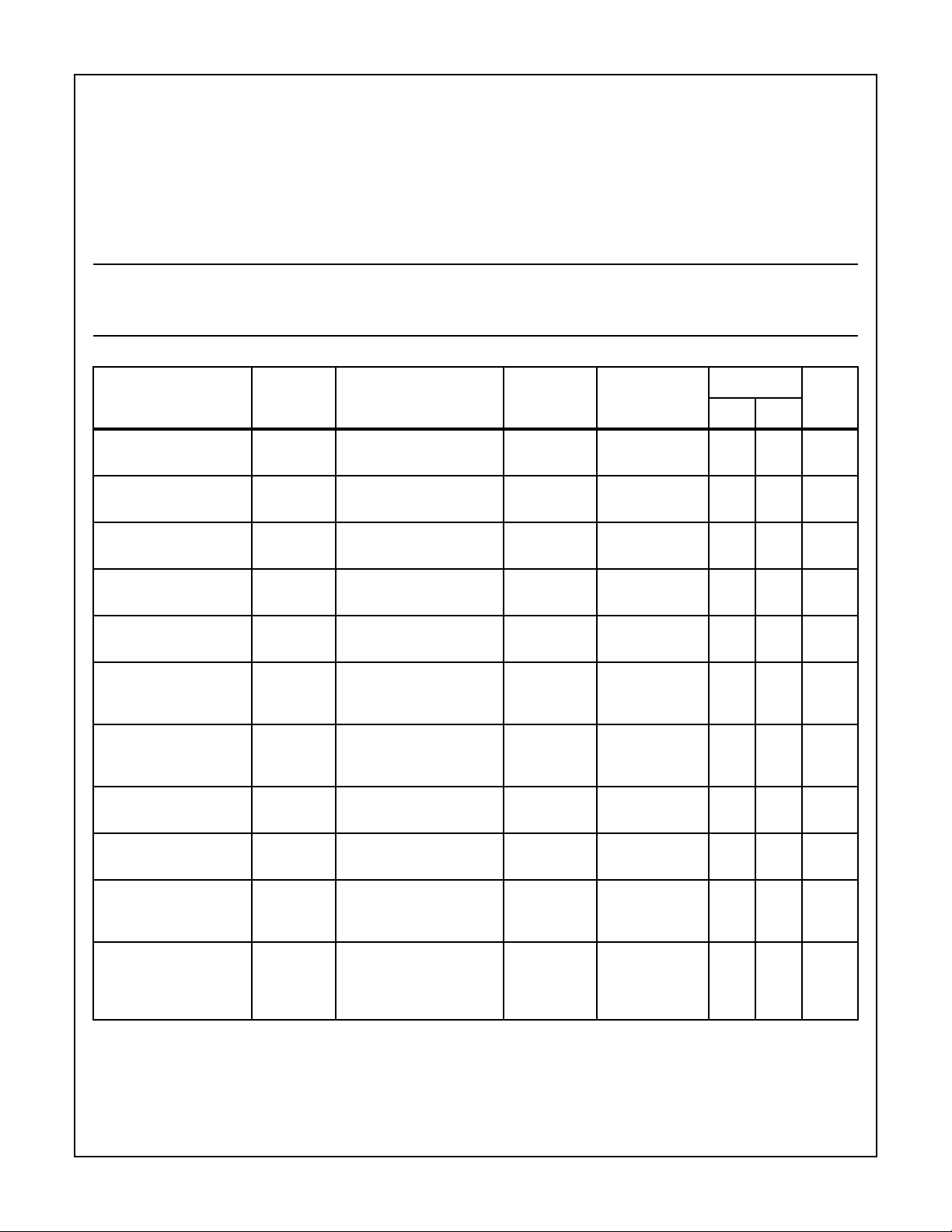

TABLE 1. DC ELECTRICAL PERFORMANCE CHARACTERISTICS

PARAMETER SYMBOL CONDITIONS

Thermal Resistance θ

SBDIP Package. . . . . . . . . . . . . . . . . . . . 40oC/W 6oC/W

Maximum Package Power Dissipation at +125oC Ambient

SBDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.25W

If device power exceeds package dissipation capability, provide heat

sinking or derate linearly at the following rate:

SBDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25.0mW/C

Input Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0V to +0.8V

Input High Voltage. . . . . . . . . . . . . . . . . . . . . . . . VDD -1.5V to VDD

GROUP A

SUBGROUP TEMPERATURE

JA

LIMITS

θ

JC

UNITSMIN MAX

TTL Output High Voltage VOH1 VDD = 4.5V, IO = -2.5mA,

VIN = 0V, 4.5V

CMOS Output High Voltage

Output Low Voltage VOL VDD = 4.5V, IO = 2.5mA,

Input Leakage Current IIL or IIH VDD = 5.5V, VIN = 0V, 5.5V 1, 2, 3 -55oC, +25oC,

Output Leakage Current IOZL or

Input Current Bus Hold

High

Input Current Bus Hold

Low

Standby Power Supply

Current

Darlington Drive Voltage VDAR VDD = 4.5V, IO = -2.0mA,

Functional Tests FT VDD = 4.5V and 5.5V,

VOH2 VDD = 4.5V, IO = -100µA,

VIN = 0V, 4.5V

VIN = 0V, 4.5V

VDD = 5.5V, VIN = 0V, 5.5V 1, 2, 3 -55oC, +25oC,

IOZH

IBHH VDD = 4.5V or 5.5V,

VIN = 3.0V (See Note 1)

Ports A, B, C

IBHL VDD = 4.5V or 5.5V,

VIN = 1.0V (See Note 2)

Port A

IDDSB VDD = 5.5V, IO = 0mA,

VIN =GND or VDD

VIN = GND or VDD

VIN = GND or VDD,

f = 1MHz

1, 2, 3 -55oC, +25oC,

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

+125oC

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

1, 2, 3 -55oC, +25oC,

+125oC

7, 8A, 8B -55oC, +25oC,

+125oC

3.0 - V

VDD-

0.4

- 0.4 V

-1.0 1.0 µA

-10 10 µA

-800 -60 µA

60 800 µA

-20µA

3.9 - V

-- -

-V

Noise Immunity Functional

Test (Note 4)

NOTES:

1. IBHH should be measured after raising VIN and then lowering to 3.0V.

2. IBHL should be measured after lowering VIN to VSS and then raising to 0.8V.

3. No internal current limiting exists on the Port Outputs. A resistor must be added externally to limit the current.

4. For VIH (VDD = 5.5V) and VIL (VDD = 4.5V) each of the following groups is tested separately with all other inputs using VIH = 2.6V,

VIL = 0.4V: PA, PB, PC, Control Pins (Pins 5, 6, 8, 9, 35, 36).

FN VDD = 5.5V, VIN = GND or

VDD - 1.5V and

VDD = 4.5V, VIN = 0.8V or

VDD

7, 8A, 8B -55oC, +25oC,

+125oC

-- -

Spec Number 518060

972

Page 4

Specifications HS-82C55ARH

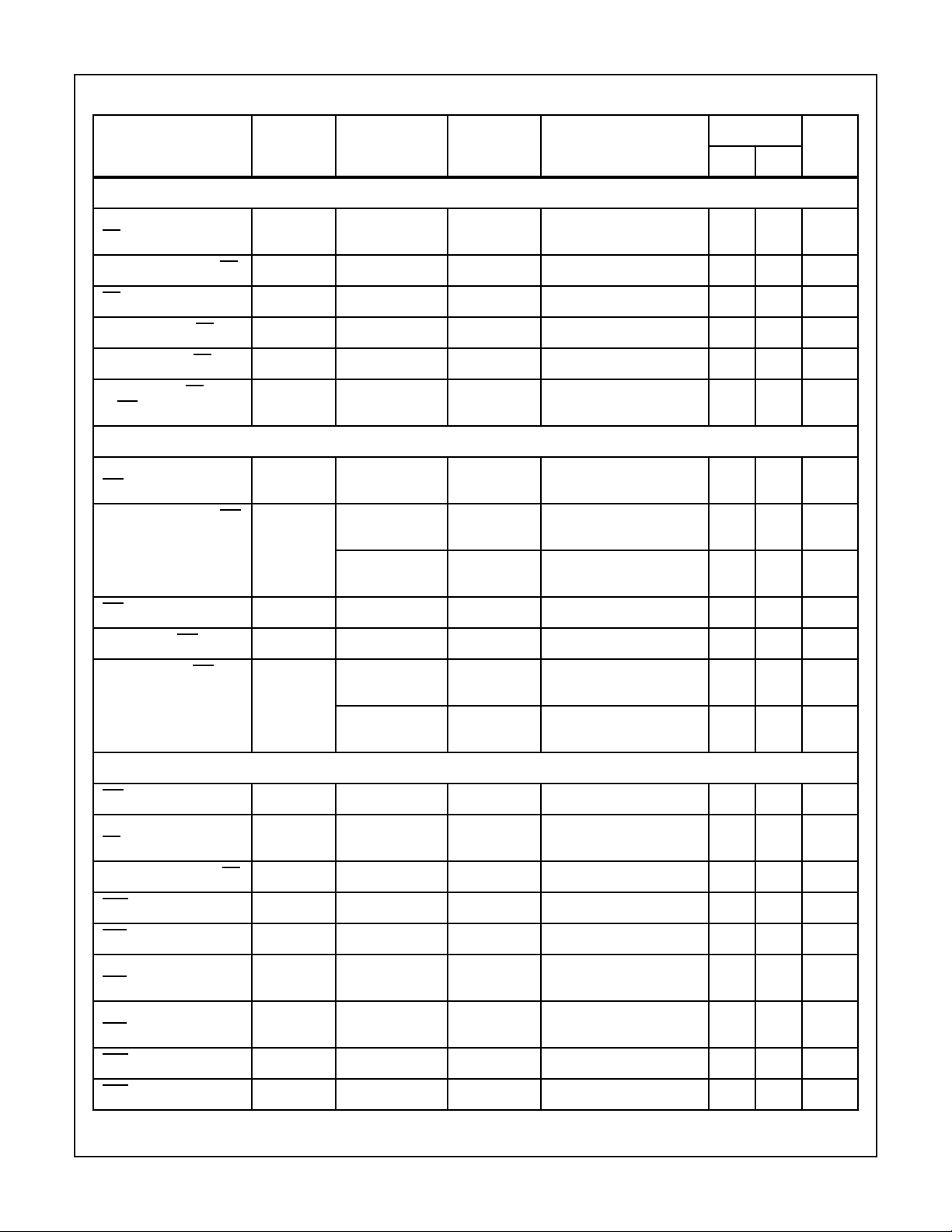

TABLE 2. AC ELECTRICAL PERFORMANCE CHARACTERISTICS TA = -55oC to +125oC

PARAMETER SYMBOL CONDITIONS

READ

SUB-

GROUPS TEMPERATURE

LIMITS

UNITSMIN MAX

Address Stable Before

RD

Address Stable After RD TRHAX VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC0-ns

RD Pulse Width TRLRH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 250 - ns

Data Valid From RD TRLDV VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 200 ns

Data Float After RD TRHDX VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC10- ns

Time Between RDs and/

or WRs

WRITE

Address Stable Before

WR

Address Stable After WR TWHAX VDD = 4.5, 5.5V,

WR Pulse Width TWLWH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 100 - ns

Data Valid to WR High TDVWH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 100 - ns

Data Valid After WR High TWHDX VDD = 4.5, 5.5V,

TAVRL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC0-ns

TRWHRWL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 300 - ns

TAVWL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC0-ns

9, 10, 11 -55oC, +25oC, +125oC20- ns

Ports A and B

VDD = 4.5, 5.5V,

Port C

Ports A and B

9, 10, 11 -55oC, +25oC, +125oC 100 - ns

9, 10, 11 -55oC, +25oC, +125oC30- ns

VDD = 4.5, 5.5V,

Port C

OTHER TIMINGS

WR = 1 to Output TWHPV VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 350 ns

Peripheral Data Before

RD

Peripheral Data After RD TRHPX VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC0-ns

ACK Pulse Width TKLKH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 200 - ns

STB Pulse Width TSLSH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC 100 - ns

Peripheral Data Before

STB High

Peripheral Data After

STB High

ACK = 0 to Output TKLPV VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 175 ns

ACK = 1 to output Float TKHPZ VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC10- ns

TPVRL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC0-ns

TPVSH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC20- ns

TSHPX VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC50- ns

9, 10, 11 -55oC, +25oC, +125oC 100 -

973

Spec Number 518060

Page 5

Specifications HS-82C55ARH

TABLE 2. AC ELECTRICAL PERFORMANCE CHARACTERISTICS TA = -55oC to +125oC (Continued)

LIMITS

SUB-

PARAMETER SYMBOL CONDITIONS

WR = 1 to OBF = 0 TWHOL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

ACK = 0 to OBF = 1 TKLOH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

STB = 0 to IBF = 1 TSLIH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

RD = 1 to IBF = 0 TRHIL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

RD = 0 to INTR = 1 TRLNL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 200 ns

STB = 1 t INTR = 1 TSHNH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

ACK = 1 to INTR = 1 TKHNH VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 150 ns

WR = 0 to INTR = 0 TWLNL VDD = 4.5, 5.5V 9, 10, 11 -55oC, +25oC, +125oC - 200 ns

GROUPS TEMPERATURE

UNITSMIN MAX

RESET Pulse Width TRSHRSL VDD = 4.5, 5.5V

(Note 2)

NOTES:

1. AC’s tested at worst case VDD, guaranteed over full operating range.

2. Period of initial RESET pulse after power-on must be at least 50µs. Subsequenct RESET pulses may be 500ns minimum.

TABLE 3. ELECTRICAL PERFORMANCE CHARACTERISTICS

PARAMETER SYMBOL CONDITIONS TEMPERATURE

Input Capacitance CIN VDD = Open, f = 1MHz, All

measurements referenced to

device ground

I/O Capacitance CI/O VDD = Open, f = 1MHz, All

measurements referenced to

device ground

Data Float After RD TRHDX VDD = 4.5V and 5.5V -55oC < TA < +125oC - 75 ns

ACK = 1 to Output Float TKHPZ VDD = 4.5V and 5.5V -55oC < TA < +125oC - 250 ns

NOTE: The parameters listed in Table 3 are controlled via design or process parameters and are not directly tested. These parameters are

characterized upon initial design release and upon design changes which would affect these characteristics

9, 10, 11 -55oC, +25oC, +125oC 500 - ns

LIMITS

UNITSMIN MAX

TA = +25oC - 10 pF

TA = +25oC - 20 pF

TALBE 4. POST 100K RAD ELECTRICAL PERFORMANCE CHARACTERISTICS

See +25oC limits in Table 1 and Table 2 for Post RAD limits (Subgroups 1, 7, 9)

974

Spec Number 518060

Page 6

Specifications HS-82C55ARH

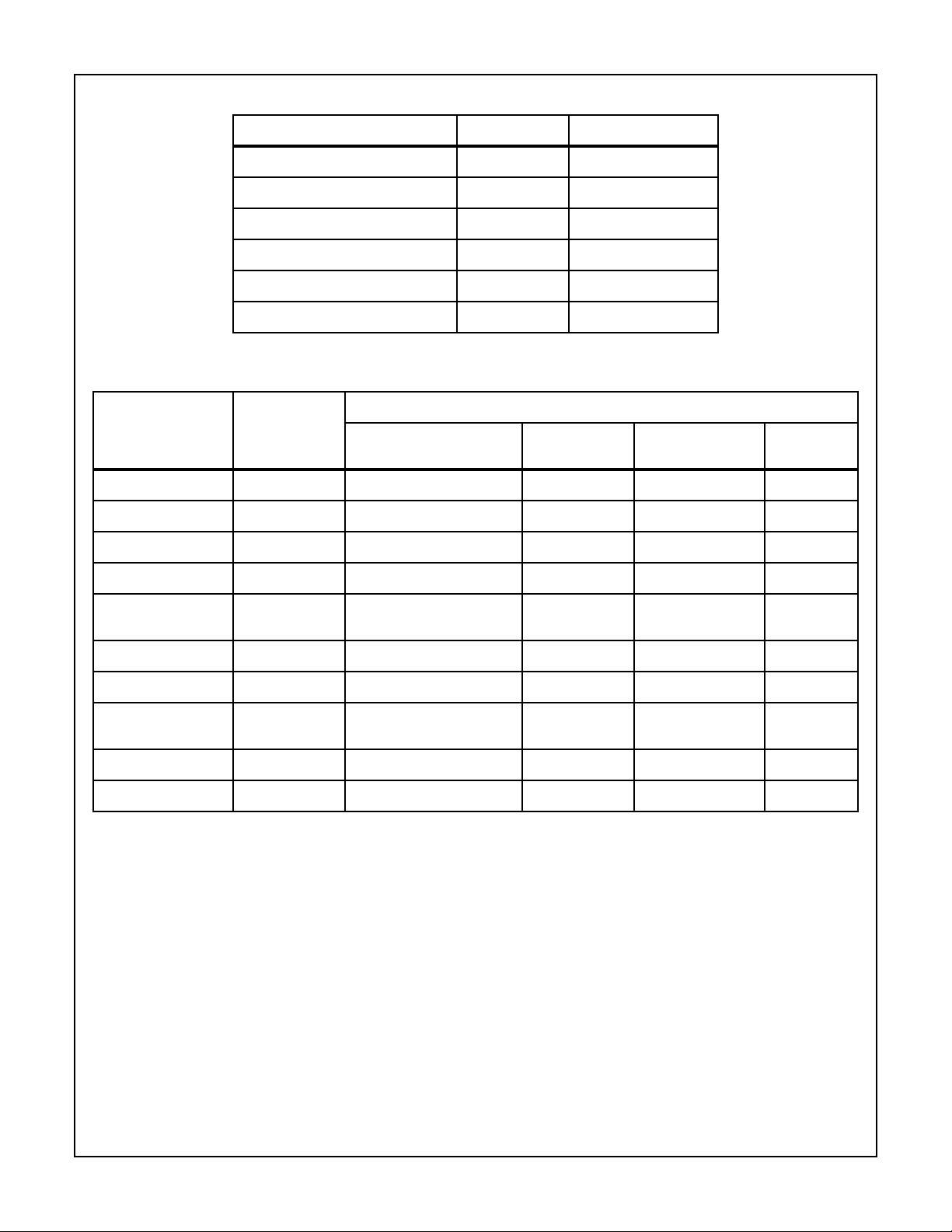

TABLE 5. BURN-IN DELTA PARAMETERS (+25oC)

PARAMETER SYMBOL DELTA LIMITS

Static Current IDDSB ±10µA

Input Leakage Current IIL, IIH ±200nA

Output Leakage Current IOZL, IOZH ±2µA

Low Level Output Voltage VOL ±80mV

TTL Output High Voltage VOH1 ±600mV

CMOS Output High Voltage VOH2 ±150mV

TABLE 6. APPLICABLE SUBGROUPS

GROUP A SUBGROUPS

CONFORMANCE

GROUP

Initial Test 100% 5004 1, 7, 9 1 (Note 2) 1, 7, 9

Interim Test 100% 5004 1, 7, 9,∆ 1, ∆ (Note 2) 1, 7, 9

PDA 100% 5004 1, 7, ∆ - 1, 7

Final Test 100% 5004 2, 3, 8A, 8B, 10, 11 - 2, 3, 8A, 8B, 10, 11

Group A (Note 1) Sample 5005 1, 2, 3, 7, 8A, 8B, 9, 10, 11 - 1, 2, 3, 7, 8A, 8B, 9,

Subgroup B5 Sample 5005 1, 2, 3, 7, 8A, 8B, 9, 10, 11, ∆ 1, 2, 3, ∆ (Note 2) N/A

Subgroup B6 Sample 5005 1, 7, 9 - N/A

Group C Sample 5005 N/A N/A 1, 2, 3, 7, 8A, 8B, 9,

Group D Sample 5005 1, 7, 9 - 1, 7, 9

Group E, Subgroup 2 Sample 5005 1, 7, 9 - 1, 7, 9

NOTES:

1. Alternate Group A testing in accordance with MIL-STD-883 method 5005 may be exercised.

2. Table 5 parameters only

MIL-STD-883

METHOD

TESTED FOR -Q

RECORDED

FOR -Q TESTED FOR -8

10, 11

10, 11

RECORDED

FOR -8

975

Spec Number 518060

Page 7

HS-82C55ARH

Intersil Space Level Product Flow -Q

Wafer Lot Acceptance (All Lots) Method 5007

(Includes SEM)

GAMMA Radiation Verification (Each Wafer) Method 1019,

2 Samples/Wafer, 0 Rejects

100% Die Attach

100% Nondestructive Bond Pull, Method 2023

Sample - Wire Bond Pull Monitor, Method 2011

Sample - Die Shear Monitor, Method 2019 or 2027

100% Internal Visual Inspection, Method 2010, Condition A

CSI and/or GSI PreCap (Note 6)

100% Temperature Cycle, Method 1010, Condition C,

10 Cycles

100% Constant Acceleration, Method 2001, Condition per

Method 5004

100% PIND, Method 2020, Condition A

100% External Visual

100% Serialization

100% Initial Electrical Test (T0)

100% Static Burn-In 1, Condition A or B, 72 Hours Min,

NOTES:

1. Failures from subgroup 1, 7 and deltas are used for calculating PDA. The maximum allowable PDA = 5% with no more than 3% of the

2. Radiographic (X-Ray) inspection may be performed at any point after serialization as allowed by Method 5004.

3. Alternate Group A testing may be performed as allowed by MIL-STD-883, Method 5005.

4. Group B and D inspections are optional and will not be performed unless required by the P.O. When required, the P.O. should include

5. Group D Generic Data, as defined by MIL-I-38535, is optional and will not be supplied unless required by the P.O. When required, the

6. CSI and/or GSI inspections are optional and will not be performed unless required by theP.O. When required, the P.O. should include

7. Data Package Contents:

tity).

o

C Min, Method 1015

+125

failures from subgroup 7.

separate line items for Group B Test, Group B Samples, Group D Test and Group D Samples.

P.O. should include a separate line item for Group D Generic Data. Generic data is not guaranteed to be available and is therefore not

available in all cases.

separate line items for CSI PreCap inspection, CSI final inspection, GSI PreCap inspection, and/or GSI final inspection.

• Cover Sheet (Intersil Name and/or Logo, P.O. Number, Customer Part Number, Lot Date Code, Intersil Part Number, Lot Number, Quan-

• Wafer Lot Acceptance Report (Method 5007). Includes reproductions of SEM photos with percent of step coverage.

• GAMMA Radiation Report. Contains Cover page, disposition, Rad Dose, Lot Number, T est Package used, Specification Numbers, Test

equipment, etc. Radiation Read and Record data on file at Intersil.

• X-Ray report and film. Includes penetrometer measurements.

• Screening, Electrical, and Group A attributes (Screening attributes begin after package seal).

• Lot Serial Number Sheet (Good units serial number and lot number).

• Variables Data (All Delta operations). Data is identified by serial number. Data header includes lot number and date of test.

• Group B and D attributes and/or Generic data is included when required by the P.O.

• The Certificate of Conformance is a part of the shipping invoice and is not part of the Data Book. The Certificate of Conformance is signed

by an authorized Quality Representative.

100% Interim Electrical Test 1 (T1)

100% Delta Calculation (T0-T1)

100% PDA 1, Method 5004 (Note 1)

100% Dynamic Burn-In, Condition D, 240 Hours, +125

Equivalent, Method 1015

100% Interim Electrical Test 2(T2)

100% Delta Calculation (T0-T2)

100% PDA 2, Method 5004 (Note 1)

100% Final Electrical Test

100% Fine/Gross Leak, Method 1014

100% Radiographic (X-Ray), Method 2012 (Note 2)

100% External Visual, Method 2009

Sample - Group A, Method 5005 (Note 3)

Sample - Group B, Method 5005 (Note 4)

Sample - Group D, Method 5005 (Notes 4 and 5)

100% Data Package Generation (Note 7)

CSI and/or GSI Final (Note 6)

o

C or

976

Spec Number 518060

Page 8

HS-82C55ARH

Intersil Space Level Product Flow -8

GAMMA Radiation Verification (Each Wafer) Method 1019,

2 Samples/Wafer, 0 Rejects

100% Die Attach

Periodic- Wire Bond Pull Monitor, Method 2011

Periodic- Die Shear Monitor, Method 2019 or 2027

100% Internal Visual Inspection, Method 2010, Condition B

CSI an/or GSI PreCap (Note 5)

100% Temperature Cycle, Method 1010, Condition C,

10 Cycles

100% Constant Acceleration, Method 2001, Condition per

Method 5004

100% External Visual

100% Initial Electrical Test

NOTES:

1. Failures from subgroup 1, 7 are used for calculating PDA. The maximum allowable PDA = 5%.

2. Alternate Group A testing may be performed as allowed by MIL-STD-883, Method 5005.

3. Group B, C and D inspections are optional and will not be performed unless required by the P.O. When required, the P.O. should include

separate line items for Group B Test, Group C Test, Group C Samples, Group D Test and Group D Samples.

4. Group C and/or Group D Generic Data, as defined by MIL-I-38535, is optional and will not be supplied unless required by the P.O. When

required, the P.O. should include a separate line item for Group C Generic Data and/or Group D Generic Data. Generic data is not guaranteed to be available and is therefore not available in all cases.

5. CSI and/or GSI inspections are optional and will not be performed unless required by theP.O. When required, the P.O. should include

separate line items for CSI PreCap inspection, CSI final inspection, GSI PreCap inspection, and/or GSI final inspection.

6. Data Package Contents:

• Cover Sheet (Intersil Name and/or Logo, P.O. Number, Customer Part Number, Lot Date Code, Intersil Part Number, Lot Number, Quan-

tity).

• GAMMA Radiation Report. Contains Cover page, disposition, Rad Dose, Lot Number, T est Package used, Specification Numbers, Test

equipment, etc. Radiation Read and Record data on file at Intersil.

• Screening, Electrical, and Group A attributes (Screening attributes begin after package seal).

• Group B, C and D attributes and/or Generic data is included when required by the P.O.

• The Certificate of Conformance is a part of the shipping invoice and is not part of the Data Book. The Certificate of Conformance is signed

by an authorized Quality Representative.

100% Dynamic Burn-In, Condition D, 160 Hours, +125

Equivalent, Method 1015

100% Interim Electrical Test

100% PDA, Method 5004 (Note 1)

100% Final Electrical Test

100% Fine/Gross Leak, Method 1014

100% External Visual, Method 2009

Sample - Group A, Method 5005 (Note 2)

Sample - Group B, Method 5005 (Note 3)

Sample - Group C, Method 5005 (Notes 3 and 4)

Sample - Group D, Method 5005 (Notes 3 and 4)

100% Data Package Generation (Note 6)

CSI and/or GSI Final (Note 5)

o

C or

AC Test Circuit

V1

R1

FROM OUTPUT

UNDER TEST

R2

* Includes stray and jig capacitance

TEST CONDITIONS DEFINITION TABLE

V1 R1 R2 C1

1.7V 523Ω Open 150pF

C1*

TEST

POINT

AC Testing Input, Output Waveforms

INPUT

2.8V

0.4V

NOTE: AC Testing: All parameters tested as per test circuits. Input

rise and fall times are driven at 1V/ns.

977

1.5V 1.5V

Spec Number 518060

Page 9

Waveforms

HS-82C55ARH

RD

INPUT

CS, A1, A0

D7 - D0

STB

IBF

INTR

RD

INPUT FROM

PERIPHERAL

TRLRH

TPVRL TRHPX

TAVRL TRHAX

TRLDV TRHDZ

FIGURE 1. MODE 0 (BASIC INPUT)

TSLSH

TSLIH

TSHNH

TPVSH

TRLNL

TRHIL

TSHPX

WR

D7 - D0

CS, A1, A0

OUTPUT

WR

OBF

INTR

ACK

OUTPUT

TAVWL

FIGURE 2. MODE 0 (BASIC OUTPUT)

TWLNL

TWHPV

TWLWH

TDVWH

TWHPV

TWHOL

TKLOH

TKLKH

TKHNH

FIGURE 3. MODE 1 (STROBED INPUT) FIGURE 4. MODE 1 (STROBED OUTPUT)

TWHDX

TWHAX

DATA FROM CPU

TO HS-82C55ARH

WR

OBF

INTR

ACK

STB

IBF

PERIPHERAL

BUS

RD

DATA FROM PERI-

PHERAL TO

HS-82C55ARH

TWHOL

TSLIH

TKLOH

TSLSH

TKLPV

TPVSH

TSHPX

DATA FROM

HS-82C55ARH

TO PERIPHERAL

TKLKH

TKHPX

TRHIL

DATA FROM

HS-82C55ARH

TO CPU

FIGURE 5. MODE 2 (BIDIRECTIONAL)

NOTE: Any sequence where WR occurs before ACK andSTB occurs

before RD is permissible.

A0 - A1, CS

DATA BUS

A0 - A1, CS

RD

DATA BUS

TAVWL TWHAX

WR

TWLWH

FIGURE 6. WRITE TIMING

TAVRL TRHAX

TAVRL

HIGH IMPEDANCE VALID

FIGURE 7. READ TIMING

TDVWH

TRLRH

TWHDX

TRHDX

HIGH IMPEDANCE

978

Spec Number 518060

Page 10

Burn-In Circuits

PROGRAMMABLE PERIPHERAL INTERFACE

HS-82C55ARH

PROGRAMMABLE PERIPHERAL INTERFACE

VDD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

F5

F0

F0

F4

F0

F2

F1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

F0

F4

F6

F5

F7

F3

VDD

NOTES:

1. VDD = 6.0V ± 0. 5%

2. IDD <500µA

3. TA Min = +125oC

STATIC CONFIGURATION

DYNAMIC CONFIGURATION

NOTES:

1. VDD = 6.0V ± 5% for Burn-In

2. VDD = 5.0V ± 5% for Life Test

3. All resistors are 10KΩ± 5%

4. -0.3V ≤ VIL ≤ 0.8V

5. VDD - 1.0V ≤ VIH ≤ VDD

6. IDD < 5mA

7. F0 = 10KHz, 50% Duty cycle

8. F1 = F0/2; F2 = F1/2; F3 = F2/2; F4 = F3/2 . . . F7 = F6/2

9. TA Min = +125oC

979

Spec Number 518060

Page 11

Irradiation Circuit

HS-82C55ARH

CMOS PROGRAMMABLE PERIPHERAL INTERFACE

NOTE:

1. VDD = 5.5V

1

2

3

4

5

6

7

+5.5V +5.5V

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

980

Spec Number 518060

Page 12

HS-82C55ARH

Functional Description

The HS-82C55ARH is a programmable peripheral interface

designed to allow microcomputer systems to control and

interface with all types of peripheral devices.It has the

ability to generate and respond to all asynchronous handshaking signals necessary to transfer data to and from

peripheral devices, and it can also interrupt the processor

when a peripheral needs servicing. These capabilities allow

the HS-82C55ARH to be used in an unlimited number of

applications including EXTERNAL SYSTEM CONTROL,

ASYNCHRONOUS DATA TRANSFER, and SYSTEMS

MONITORING.

Data Bus Buffer

This tri-state bidirectional 8-bit buffer is used to interface the

HS-82C55ARH to the system data bus (see Figure 8). Data

is transmitted or received by the buffer upon execution of

input or output instructions by the CPU. Control words and

status information are also transferred through the data bus

buffer.

POWER

SUPPLIES

BIDIRECTIONAL

DATA BUS

D7D0

RD

WR

A1

A0

RESET

CS

GND

DATA

BUS

BUFFER

READ/

WRITE

CONTROL

LOGIC

+5V

GROUP

A

CONTROL

8-BIT INTERNAL

DATA BUS

GROUP

B

CONTROL

GROUP

A PORT

A (8)

GROUP

A PORT

C UPPER

(4)

GROUP

B PORT

C LOWER

(4)

GROUP

B PORT

B (8)

FIGURE 8. BLOCK DIAGRAM DATA BUS BUFFER, READ/WRITE,

GROUP A AND B CONTROL LOGIC FUNCTIONS

I/O

PA 7PA0

I/O

PC 7PC4

I/O

PC3PC0

I/O

PB 7PB0

Ports A, B, C

The HS-82C55ARH contains three 8-bit ports (A, B and C).

All can be configured to a wide variety of functional

characteristics by the system software but each has its own

special features or “personality” to further enhance the

power and flexibility of the HS-82C55ARH.

Port A One 8-bit data output latch/buffer and one 8-bit data

input latch. Both “pull-up” and “pull-down” bus hold

devices are present on Port A. See Figure 9A.

Port B One 8-bit data input/output latch/buffer and one 8-

bit data input buffer. See Figure 9B.

Port C One 8-bit data output latch/buffer and one 8-bit data

input buffer (no latch for input). This port can be

divided into two 4-bit ports under the mode control.

Each 4-bit port contains a 4-bit latch and can be used

for the control signal outputs and status signal inputs

in conjunction with Ports A and B. See Figure 9B.

(A)

RD

CONTROL

VDD

P

EXTERNAL

PORT A PIN

MASTER

RESET

INTERNAL

DATA IN

INTERNAL

DATA OUT

MASTER

RESET

WR

SIGNAL

Read/Write and Control Logic

The function of this block is to manage all of the internal and

external transfer of both Data and Control or Status words. It

accepts inputs from the CPU Address and Control busses

and in turn, issues commands to both of the Control Groups.

Group A and Group B Controls

The functional configuration of each port is programmed by

the systems software. In essence, the CPU writes a control

word to the HS-82C55ARH. The control word contains information such as “mode”, “bit set”, “bit reset”, etc., that initializes the functional configuration of the HS-82C55ARH.

Each of the Control blocks (Group A and Group B) accepts

“commands” from the Read/Write Control Logic, receives

“control words” from the internal data bus and issues the

proper commands to its associated ports.

Control Group - Port A and Port C upper (C7 - C4)

Control Group - Port B and Port C lower (C3 - C0).

INTERNAL

DATA IN

INTERNAL

DATA OUT

WR

SIGNAL

EXTERNAL

PORT B, C

PIN

(B)

FIGURE 9. I/O PORT CONFIGURATION

Operational Description

Control Word

The data direction and mode of Ports A, B and C are

determined by the contents of the Control Word. See Figure

11. The Control W ord can be both written and read as shown

in Table 1 and 2. During write operations, the function of the

Control Word being written is determined by data bit D7. If

D7 is low, the data on D0 - D3 will set or reset one of the bits

of Port C. See Figure 12. During read Operations, the

Spec Number 518060

981

Page 13

HS-82C55ARH

Control Word will always be in the format illustrated in Figure

11 with Bit D7 high to indicate Control Word Mode Information.

ADDRESS BUS

CONTROL BUS

DATA BUS

RD, WR D7 - D0 A0 - A1

MODE 0

MODE 1

MODE 2

BCA

8 4 84

I/O I/O I/O I/O

PB7 - PB0 PC3 - PC0 PC7 - PC4 PA7 - PA0

BCA

8 8

I/O I/O

PB7 - PB0 PA7 - PA0

PB7 - PB0 PA7 - PA0

CONTROL

OR I/O

BCA

8 8

I/O

I/O

CONTROL

OR I/O

CONTROL

FIGURE 10. BASIC MODE DEFINITIONS & BUS INTERFACE

TABLE 1.

INPUT OPERATION

A1 A0 RD WR CS

00010Port A - Data Bus

01010Port B - Data Bus

10010Port C - Data Bus

11010Control Word - Data Bus

TABLE 2.

OUTPUT OPERATION

A1 A0 RD WR CS

00100Data Bus - Port A

01100Data Bus - Port B

10100Data Bus - Port C

11100Data Bus - Control Word

CS

BIDIRECTIONAL

(READ)

(WRITE)

TABLE 3.

A1 A0 RD WR CS DISABLE FUNCTION

XXXX1Data Bus - 3-State

X X 1 1 0 Data Bus - 3-State

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

GROUP B

PORT C (LOWER)

1 = INPUT

0 = OUTPUT

PORT B

1 = INPUT

0 = OUTPUT

MODE SELECTION

0 = MODE 0

1 = MODE 1

GROUP A

PORT C (UPPER)

1 = INPUT

0 = OUTPUT

PORT A

1 = INPUT

0 = OUTPUT

MODE SELECTION

00 = MODE 0

01 = MODE 1

1X = MODE 2

MODE SET FLAG

1 = ACTIVE

FIGURE 11. MODE SET CONTROL WORD FORMAT

Mode Selection

There are three basic modes of operation that can be

selected by the system software:

Mode 0 - Basic Input/Output

Mode 1 - Strobed Input/Output

Mode 2 - Bidirectional Bus

When the RESET input goes “high”, all ports will be set to

the input mode with all 24 port lines held at the logic “one”

level by internal bus hold devices. After reset, the HS82C55ARH can remain in the input mode with no additional

initialization required. This eliminates the need for pullup or

pulldown resistors in all CMOS designs. During the

execution of the system program, any of the other modes

may be selected using a single output instruction. This

allows a single HS-82C55ARH to service a variety of

peripheral devices with a simple software maintenance

routine.

The modes for Port A and Port B can be separately defined

while Port C is divided into two portions as required by the

Port A and Port B definitions. All of the output registers,

including the status register, will be reset whenever the

mode is changed. Modes may be combined so that their

functional definition can be “tailored” to almost any I/O structure. For instance: Group B can be programmed in Mode 0

to monitor simple switch closings or display computational

results, Group A could be programmed in Mode 1 to monitor

a keyboard or tape recorder on an interrupt-driven basis.

982

Spec Number 518060

Page 14

HS-82C55ARH

The mode definitions and possible mode combinations may

seem confusing at first but after a cursory review of the

complete device operation a simple, logical I/O approach will

surface. The design of the HS-82C55ARH has taken into

account things such as efficient PC board layout, control

signal definition vs PC layout and complete functional

flexibility to support almost any peripheral device with no

external logic. Such design represents the maximum use of

the available pins.

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

BIT SET/RESET

XXX

DON’T

CARE

FIGURE 12. BIT SET/RESET CONTROL WORD FORMAT

1 = SET

0 = RESET

BIT SELECT

0

1

2

3

4

5

6

0

1

0

1

0

1

0

0

0

1

1

0

0

1

0

0

0

0

1

1

1

BIT SET/RESET FLAG

0 = ACTIVE

7

1

B0

1

B1

1

B2

Single Bit/Set/Reset Feature

Any of the eight bits of Port C can be Set or Reset using a

single OUTput instruction. See Figure 12. This feature

reduces software requirements in control-based

applications.

Interrupt Control Functions

When the HS-82C55ARH is programmed to operate in

Mode 1 or Mode 2, control signals are provided that can be

used as interrupt request inputs to the CPU. The interrupt

request signals, generated from Port C, can be inhibited or

enable by setting or resetting the associated INTE flip-flop,

using the Bit Set/Reset function of Port C.

This function allows the programmer to enable or disable a

CPU interrupt by a specific I/O device without affecting any

other device in the interrupt structure.

INTE Flip-Flop Definition:

(BIT-SET) - INTE is SET - Interrupt enable.

(BIT-RESET) - INTE is RESET - Interrupt disable.

NOTE: All mask flip-flops are automatically reset during

mode selection and device Reset.

Operating Modes

Mode 0 (Basic Input/Output)

This functional configuration provides simple input and output operations for each of the three ports. No handshaking it

required, data is simply written to or read from a specific

port.

Mode 0 Basic Functional Definitions:

• Two 8-bit ports and two 4-bit ports

• Any port can be input or output

• Outputs are latched

• Inputs are not latched

• 16 different Input/Output configurations possible

RD

INPUT

CS, A1, A0

D7 - D0

WR

D7 - D0

CS, A1, A0

OUTPUT

TRLRH

TPVRL TRHPX

TAVRL TRHAX

TRLDV TRHDX

FIGURE 13. MODE 0 (BASIC INPUT)

TWLWH

TDVWH

TAVWL

FIGURE 14. MODE 0 (BASIC OUTPUT)

TWHDX

TWHAX

TWHPV

983

Spec Number 518060

Page 15

Mode 0 Port Definition

HS-82C55ARH

A B GROUP A

D4 D3 D1 D0 PORT A PORT C (UPPER) PORT B PORT C (LOWER)

NO.

GROUP B

0000Output Output 0 Output Output

0001Output Output 1 Output Input

0010Output Output 2 Input Output

0011Output Output 3 Input Input

0100Output Input 4 Output Output

0101Output Input 5 Output Input

0110Output Input 6 Input Output

0111Output Input 7 Input Input

1000 Input Output 8 Output Output

1001 Input Output 9 Output Input

1010 Input Output 10 Input Output

1011 Input Output 11 Input Input

1100 Input Input 12 Output Output

1101 Input Input 13 Output Input

1110 Input Input 14 Input Output

1111 Input Input 15 Input Input

Mode 0 Configurations

CONTROL WORD #0 CONTROL WORD #1

D7 D6 D5 D4 D3 D2 D1 D0

10000000

A

D7 - D0

CONTROL WORD #2 CONTROL WORD #3

D7 D6 D5 D4 D3 D2 D1 D0

10000010

D7 - D0

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

D7 D6 D5 D4 D3 D2 D1 D0

10000001

D7 - D0

D7 D6 D5 D4 D3 D2 D1 D0

10000011

D7 - D0

A

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

984

Spec Number 518060

Page 16

HS-82C55ARH

Mode 0 Configurations

CONTROL WORD #4 CONTROL WORD #5

D7 D6 D5 D4 D3 D2 D1 D0

10001000

A

D7 - D0

CONTROL WORD #6 CONTROL WORD #7

D7 D6 D5 D4 D3 D2 D1 D0

10001010

D7 - D0

C

B

A

C

B

(Continued)

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

D7 D6 D5 D4 D3 D2 D1 D0

10011001

D7 - D0

D7 D6 D5 D4 D3 D2 D1 D0

10001011

D7 - D0

A

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

CONTROL WORD #8 CONTROL WORD #9

D7 D6 D5 D4 D3 D2 D1 D0

10010000

D7 - D0

CONTROL WORD #10 CONTROL WORD #11

D7 D6 D5 D4 D3 D2 D1 D0

10010010

D7 - D0

D7 D6 D5 D4 D3 D2 D1 D0

10010001

A

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

D7 - D0

D7 D6 D5 D4 D3 D2 D1 D0

10010011

D7 - D0

A

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

985

Spec Number 518060

Page 17

HS-82C55ARH

Mode 0 Configurations

CONTROL WORD #12 CONTROL WORD #13

D7 D6 D5 D4 D3 D2 D1 D0

10011000

A

D7 - D0

CONTROL WORD #14 CONTROL WORD #15

D7 D6 D5 D4 D3 D2 D1 D0

10011010

D7 - D0

C

B

A

C

B

(Continued)

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

D7 D6 D5 D4 D3 D2 D1 D0

10011001

D7 - D0

D7 D6 D5 D4 D3 D2 D1 D0

10011011

D7 - D0

A

C

B

A

C

B

8

4

4

8

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

Operating Modes

Mode 1 (Strobed Input/Output)

This functional configuration provides a means for transferring I/O data to or from a specified port in conjunction with

strobes or “handshaking” signals. In Mode 1, Port A and Port

B use the lines on Port C to generate or accept these “handshaking” signals.

Mode 1 Basic Functional Definitions:

• Two Groups (Group A and Group B)

• Each group contains one 8-bit port and one 4-bit control/

data port.

• The 8-bit data port can be either input or output. Both

inputs and outputs are latched.

• The 4-bit port is used for control and status of the 8-bit

port.

Input Control Signal Definition

STB (Strobe Input)

A “low” on this input loads data into the input latch.

IBF (Input Buffer Full F/F)

A “high” on this output indicates that the data has been

loaded into the input latch; in essence, an acknowledgment.

IBF is set by

edge of the

STB input being low and is reset by the rising

RD input.

INTR (Interrupt Request)

A “high” on this output can be used to interrupt the CPU

when an input device is requesting service. INTR is set by

the rising edge of

STB and reset by the falling edge of RD.

This procedure allows an input device to request service

from the CPU by simply strobing its data into the port.

INTE A

Controlled by Bit Set/Reset of PC4.

INTE B

Controlled by Bit Set/Reset of PC2.

MODE 1 (PORT A)

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

10111/0

PC6, 7

1 = INPUT

0 = OUTPUT

RD

PA7 - PA0

INTE

A

PC6, 7

8

PC4

PC5

PC3

2

FIGURE 15. MODE 1 INPUT

STB

IBF

A

INTR

A

I/O

MODE 1 (PORT B)

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

RD

1

PB7 - PB0

INTE

B

11

8

PC2

PC1

PC0

STB

BA

IBF

B

INTR

B

986

Spec Number 518060

Page 18

HS-82C55ARH

TSLSH

STB

IBF

INTR

RD

INPUT FROM

PERIPHERAL

TSLIH

TSHNH

TPVSH

TRLNL

TRHIL

TSHPX

FIGURE 16. MODE 1 (STROBED INPUT)

Output Control Signal Definition

OBF (Output Buffer Full F/F)

The OBF output will go “low” to indicate that the CPU has

written data out to the specified port. This does not mean

valid data is sent out of the port at this time since OBF can

go true before data is available. Data is guaranteed valid at

the rising edge of OBF. See Note 1. The OBF F/F will be set

by the rising edge of the WR input and reset by ACK input

being low.

ACK (Acknowledge Input)

A “low” on this input informs the HS-82C55ARH that the data

from Port A or Port B is ready to be accepted. In essence, a

response from the peripheral device indicating that it is

ready to accept data. See Note 1.

INTR (Interrupt Request)

A “high” on this output can be used to interrupt the CPU

when an output device has accepted data transmitted by the

CPU. INTR is set by the rising edge of ACK and reset by the

falling edge of WR.

MODE 1 (PORT A)

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

10101/0

PC4, 5

1 = INPUT

0 = OUTPUT

WR

PA7 - PA0

INTE

A

PC7

PC6

PC3

PC4, 5

8

2

OBF

A

ACK

A

INTR

A

I/O

MODE 1 (PORT B)

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

WR

1

PB7 - PB0

INTE

B

10

8

PC1

PC2

PC0

OBF

B

ACK

B

INTR

B

INTE A

Controlled by Bit Set/Reset of PC6.

INTE B

Controlled by Bit Set/Reset of PC2.

TWHOL

WR

TKHOL

OBF

INTR

ACK

OUTPUT

NOTE:

1. To strobe data into the peripheral device, the user must operate

the strobe line in a hand shaking mode. The user needs to send

OBF to the peripheral device, generate an ACK from the peripheral device and then latch data into the peripheral device on the

rising edge of OBF.

Combinations of Mode 1: Port A and Port B can be individually defined as input or output in Mode 1 to support a wide

variety of strobed I/O applications.

PORT A (STROBED INPUT)

PORT B (STROBED OUTPUT)

D7 D6 D5 D4 D3 D2 D1 D0

1

PC6, 7

1 = INPUT

0 = OUTPUT

RD

WR

TWLNL

TWHPV

FIGURE 18. MODE 1 (STROBED OUTPUT)

PORT A (STROBED OUTPUT)

PORT B (STROBED INPUT)

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

0 1 1 1/0

PA7 - PA0

PC4

PC5

PC3

PC6, 7

PB7 - PB0

PC1

PC2

PC0

10

8

2

8

STB A

IBF A

INTR A

I/O

OBF B

ACK B

INTR B

1

0 1 0 1/0

PC4, 5

1 = INPUT

0 = OUTPUT

WR

RD

TKLKH

CONTROL WORD

PA7 - PA0

PB7 - PB0

PC7

PC6

PC3

PC4, 5

PC2

PC1

PC0

TKHNH

11

8

2

8

OBF A

ACK A

INTR A

I/O

STB B

IBF B

INTR B

FIGURE 17. MODE 1 OUTPUT

FIGURE 19. COMBINATIONS OF MODE 1

Spec Number 518060

987

Page 19

HS-82C55ARH

Operating Modes

MODE 2 (Strobed Bidirectional Bus I/O)

The functional configuration provides a means for communicating with a peripheral device or structure on a single 8-bit

bus for both transmitting and receiving data (bidirectional

bus I/O). “Handshaking” signals are provided to maintain

proper bus flow discipline similar to MODE 1. Interrupt generation and enable/disable functions are also available.

Mode 2 Basic Functional Definitions:

• Used in Group A only.

• One 8-bit, bidirectional bus port (Port A) and a 5-bit control

port (Port C).

• Both inputs and outputs are latched.

• The 5-bit control port (Port C) is used for control and

status for the 8-bit, bidirectional bus port (Port A).

Bidirectional Bus I/O Control Signal Definition

INTR (Interrupt Request)

A high on this output can be used to interrupt the CPU for

both input or output operations. INTR will be set either by the

rising edge of

(INTE2 = 1). INTR will be reset by the falling edge of

previously set by the rising edge or

RD (if previously set by the rising edge of STB), or the falling

edge of

the falling edge of

pulse (if previously set by the rising edges of both

STB).

ACK (INTE1 = 1) or the rising edge of STB

WR (if

ACK), the falling edge of

WR when immediately following a low RD pulse or

RD when immediately following a low WR

ACK and

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

1

0 1/0 1/0 1/0

FIGURE 20. MODE CONTROL WORD

PC3

PA7- PA0

PC7

INTE

PC6

1

INTE

PC7

WR

RD

FIGURE 21. MODE 2 (BIDIRECTIONAL)

2

PC6

PC2- PC0

PC2 - PC0

1 = INPUT

0 = OUTPUT

PORT B

1 = INPUT

0 = OUTPUT

GROUP B MODE

0 = MODE 0

1 = MODE 1

INTR A

8

OBF A

ACK A

STB A

IBF A

3

I/O

Output Operations

OBF (Output Buffer Full)

The OBF output will go “low” to indicate that the CPU has

written data out to Port A.

ACK (Acknowledge)

A “low” on this input enables the tri-state output buffer of Port

A to send out the data. Otherwise, the output buffer will be in

the high impedance state.

INTE 1 (The INTE Flip-Flop Associated with OBF)

Controlled by Bit Set/Reset of PC6.

Input Operations

STB (Strobe Input)

A “low” on this input loads data into the input latch.

IBF (Input Buffer Full F/F)

A “high” on this output indicates that data has been loaded

into the input latch.

INTE 2 (The INTE Flip-Flop Associated with IBF)

Controlled by Bit Set/Reset of PC4.

DATA FROM CPU

TO HS-82C55ARH

WR

OBF

TWHOL

INTR

ACK

STB

IBF

PERIPHERAL

NOTE: Any sequence where WR occurs before ACK andSTB occurs

BUS

RD

DATA FROM PERI-

PHERAL TO

HS-82C55ARH

before RD is permissible.

FIGURE 22. MODE 2 (BIDIRECTIONAL)

TSLIH

TKHOL

TSLSH

TKLPV

TPVSH

TSHPX

DATA FROM

HS-82C55ARH

TO PERIPHERAL

TKLKH

TKHPX

TRHIL

DATA FROM

HS-82C55ARH

TO CPU

988

Spec Number 518060

Page 20

PA0

AP1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

HS-82C55ARH

MODE DEFINITION SUMMARY

MODE 0 MODE 1 MODE 2

IN OUT IN OUT GROUP A ONLY

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

INTR B

IBF B

STB B

INTR A

STB A

IBF A

I/O

I/O

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

INTR B

OBF B

ACK B

INTR A

I/O

I/O

ACK A

OBF A

-

-

-

-

-

-

-

-

I/O

I/O

I/O

INTR A

STB A

IBF A

ACK A

OBF A

Mode 0 or

Mode 1 Only

Special Mode Combination Considerations

There are several combinations of modes possible. For any

combination, some or all of Port C lines are used for control

or status. The remaining bits are either inputs or outputs as

defined by a “Set Mode” command.

During a read of Port C, the state of all the Port C lines,

except the

bus. In place of the ACK and STB line states, flag status will

appear on the data bus in the PC2, PC4, and PC6 bit

positions as illustrated by Figure 25.

Through a “Write Port C” command, only the Port C pins programmed as outputs in a Mode 0 group can be written. No

other pins can be affected by a “Write Port C” command, nor

can the interrupt enable flags be accessed. To write to any

Port C output programmed as an output in a Mode 1 group

or to change an interrupt enable flag, the “Set/Reset Port C

Bit” command must be used.

With a “Set/Reset Port C Bit” command, any Port C line

programmed as an output (including IBF and

written, or an interrupt enable flag can be either set or reset.

Port C lines programmed as inputs, including

lines, associated with Port C fare not affected by a “Set/

Reset Port C Bit” command. Writing to the corresponding

Port C bit positions of the

Reset Port C Bit” command will affect the Group A and

Group B interrupt enable flags, as illustrated in Figure 25.

ACK and STB lines, will be placed on the data

OBF) can be

ACK and STB

ACK and STB lines with the “Set/

INPUT CONFIGURATION

D7 D6 D5 D4 D3 D2 D1 D0

I/O I/O IBFA INTEA INTRA INTEB IBFB INTRB

GROUP A GROUP B

OUTPUT CONFIGURATION

D7 D6 D5 D4 D3 D2 D1 D0

OBFA INTEA I/O I/O INTRA INTEB OBFB INTRB

GROUP A GROUP B

FIGURE 23. MODE 1 STATUS WORD FORMAT

D7 D6 D5 D4 D3 D2 D1 D0

OBFA INTE1 IBFA INTE2 INTRA X X X

GROUP A GROUP B

NOTE: (Defined by Mode 0 or Mode 1 Selection)

FIGURE 24. MODE 2 STATUS WORD FORMAT

989

Spec Number 518060

Page 21

HS-82C55ARH

Current Drive Capability

Any output on Port A, B or C can sink or source 2.5mA. This

feature allows the 82C55A to directly drive Darlington type

drivers and high-voltage displays that require such sink or

source current.

Reading Port C Status (Figures 23 and 24)

In Mode 0, Port C transfers data to or from the peripheral

device. When the 82C55A is programmed to function in

Modes 1 or 2, Port C generates or accepts “hand shaking”

signals with the peripheral device. Reading the contents of

Port C allows the programmer to test or verify the “status” of

each peripheral device and change the program flow

accordingly.

There is no special instruction to read the status information

from Port C. A normal read operation of Port C is executed

to perform this function.

INTERRUPT

ENABLE FLAG* POSITION

INTE B PC2 ACKB (Output Mode 1) or

INTE A2 PC4 STBA (Input Mode 1 or

INTE A1 PC6 ACKA (Output Mode 1 or

FIGURE 25. INTERRUPT ENABLE FLAGS IN MODES 1 AND 2

ALTERNATE PORT C

PIN SIGNAL (MODE)

STBB (Input Mode 1)

Mode 2)

Mode 2)

990

Spec Number 518060

Page 22

Metallization Topology

DIE DIMENSIONS:

3420µm x 4350µm x 485µm ± 25µm

METALLIZATION:

Type: Al/Si

Thickness: 11k

Å ± 2kÅ

GLASSIVATION:

Type: SiO2

4

A/cm

Å ± 1kÅ

2

Thickness: 8k

WORST CASE CURRENT DENSITY:

7.7 x 10

Metallization Mask Layout

(15) PC1

HS-82C55ARH

HS-82C55ARH

(12) PC5

(13) PC4

(14) PC0

(11) PC6

(10) PC7

(9) A0

(8) A1

(7) VSS

CS

(6)

PC2 (16)

PC3 (17)

PB0 (18)

PB1 (19)

PB2 (20)

PB3 (21)

PB4 (22)

PB5 (23)

PB6 (24)

PB7 (25)

D7 (27)

VDD (26)

D6 (28)

D5 (29)

D4 (30)

D3 (31)

D2 (32)

D1 (33)

D0 (34)

RESET (35)

(5) RD

(4) PA0

(3) PA1

(2) PA2

(1) PA3

(40) PA4

(39) PA5

(38) PA6

(37) PA7

(36)

WR

991

Spec Number 518060

Page 23

HS-82C55ARH

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

992

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Spec Number

Loading...

Loading...