HS-2700RH

Data Sheet August 1999

Low Power, High Performance Radiation

Hardened Operational Amplifier

HS-2700RH is radiation hardened internally compensated

operational amplifiers which employ dielectric isolation to

achieve excellent DC and dynamic performance with very

low quiescent power consumption.

DC performance of the amplifier input is characterized by

high CMRR (106dB), low offset voltage (0.5mV), along with

low bias and offset current (5.0nA and 2.5nA respectively).

These input specifications, in conjunction with offset null

capability and open-loop gain of 300,000V/V, enable

HS-2700RH to provide accurate, high-gain signal

amplification. Gain bandwidth 1MHz and slew rate of20V/µs

allow for processing of fast, wideband signals. Input and

output signal amplitudes of at least ±11V can be

accommodated while providing output drive capability of

10mA. For maximum reliability, the output is protected in the

event of short circuits to ground.

The amplifier operates from a wide range of supplies (±5.5V

to ±20V) with a maximum quiescent supply drain of only

150µA. HS-2700RH is therefore, ideally suited to low-power

instrumentation and filtering applications that require fast,

accurate response over a wide range of signal frequency.

Specifications for Rad Hard QML devices are controlled

by the Defense Supply Center in Columbus (DSCC). The

SMD numbers listed here must be used when ordering.

Detailed Electrical Specifications for these devices are

contained in SMD 5962-95670. A “hot-link” is provided

on our homepage for downloading.

www.intersil.com/spacedefense/space.asp

File Number 3624.2

Features

• Electrically Screened to SMD # 5962-95670

• QML Qualified per MIL-PRF-38535 Requirements

• Low Power Supply Current. . . . . . . . . . . . . . 150µA (Max)

90µA (Typ)

• High CMRR . . . . . . . . . . . . . . . . . . . . . . . . . . .86dB (Min)

106dB (Typ)

• Low Input Bias Current. . . . . . . . . . . . . . . . . . .20nA (Min)

5nA (Typ)

• Low Offset Current. . . . . . . . . . . . . . . . . . . . . .10nA (Min)

2.5nA (Typ)

• Total Dose . . . . . . . . . . . . . . . . . . . . . . . . 1 x 10

4

RAD(Si)

Applications

• High Gain Amplifier

• Instrumentation Amplifiers

• Active Filters

• Telemetry Systems

• Battery-Powered Equipment

Ordering Information

INTERNAL

ORDERING NUMBER

5962D9567002VCA HS1-2700RH-Q -55 to 125

5962D9567002VCC HS1B-2700RH-Q -55 to 125

5962D9567002VGA HS2-2700RH-Q -55 to 125

MKT. NUMBER

TEMP. RANGE

(oC)

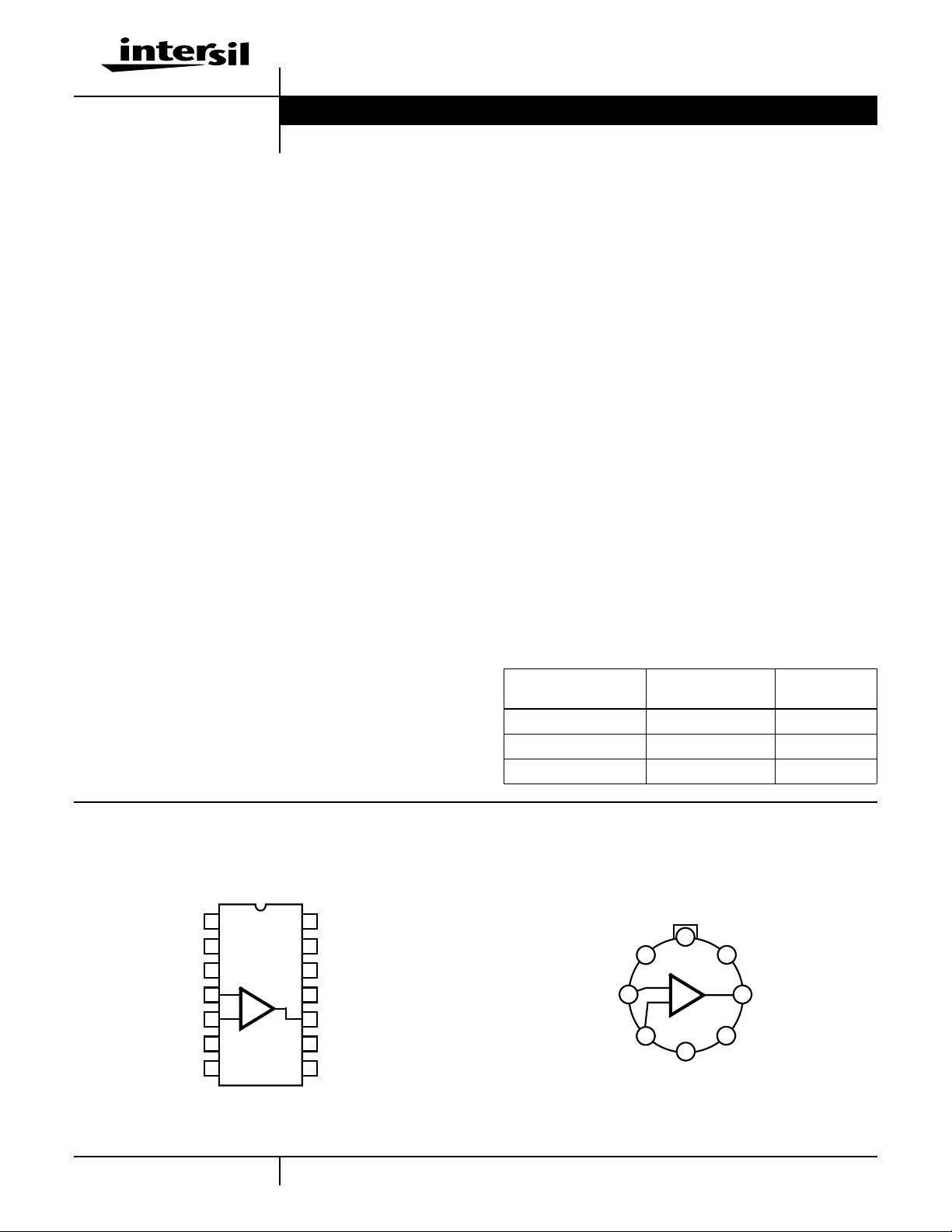

Pinouts

HS1-2700RH (CERDIP) GDIP1-T14

OR

HS1B-2700RH (SBDIP) CDIP2-T14

TOP VIEW

NC

BAL

GUARD

IN-

IN+

GUARD

1

2

3

4

-

+

5

6

7

V-

14

13

12

11

10

9

8

NC

NC

BAL

V+

OUTPUT

NC

NC

1

HS2-2700RH (CAN) MACY1-X8

TOP VIEW

BAL

8

BAL

1

2

IN-

IN+

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

-

+

3

7

V+

OUT

6

5

NC

4

V-

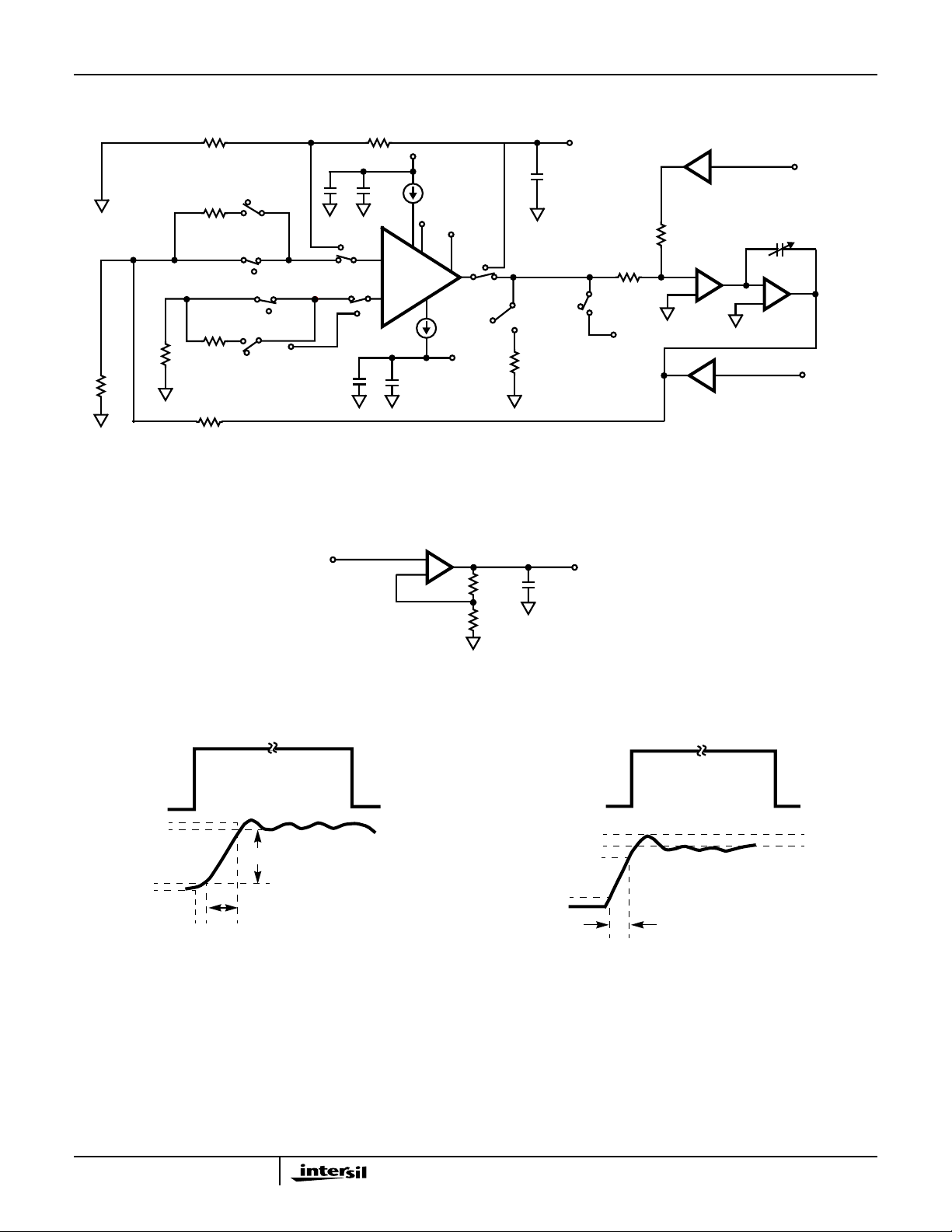

Test Circuit

HS-2700RH

400

10K

OPEN 2

10K

100

100

50K

2

S1

OPEN 2

2

1

OPEN

1 OPEN

S3A

S2

NOTE: Includes stray capacitances.

Timing Waveforms

1

S3B

1

VAC

VIN

1.6K

10.1

2

S5A

1

S6

1

2

-

DUT

+

10.1

+VCC

+

-

S5B

OPEN 1

-VEE

2

1

S8

2

2K

1.6K

ACOUT

75pF (NOTE)

OPEN

1

VOUT

75pF

S9

2

500K

V2

-1/10

FOR LOOP STABILITY,

USE MIN VALUE CAPACITOR

TO PREVENT OSCILLATION

50K

-1

-

+

BUFFER

2x

ALL RESISTORS = ±1% (Ω)

ALL CAPACITORS = ±10% (µF)

V1

-

+

E

OUT

400

FIGURE 1. SIMPLIFIED TEST CIRCUIT

INPUT

OUTPUT

-4V

-1.0V

+4V

+1.0V

+2.5V

-2.5V

∆T

∆V

OUTPUT

SLEW

RATE

= ∆V/∆T

INPUT

+160mV

0V

+40mV

0V

OVERSHOOT

90%

10%

RISE TIME

FIGURE 2. SLEW RATE WAVEFORM FIGURE 3. TRANSIENT RESPONSE WAVEFORM

NOTE: Measured on both positive and negative transitions. Capacitance at Compensation pin should be minimized.

0V

-40mV

2

HS-2700RH

Typical Performance Curves T

5

4

3

2

1

0

-1

VOLTAGE (mV)

-2

-3

-4

-5

-55 -25 0 25 50 75 100 125

TEMPERATURE (

= 25oC, VSUPPLY = ±15V, Unless Otherwise Specified

A

o

C)

FIGURE 4. OFFSETVOLTAGEAS A FUNCTION OF

TEMPERATURE

500

400

300

200

100

0

-100

-200

BIAS CURRENT (nA)

-300

-400

-500

-20 -15 -10 -5 0 5 10 15

COMMON MODE VOLTAGE (V)

VS = ±15.0V

T

= 25oC

A

30

20

10

0

CURRENT (mA)

-10

-20

-55 -25 0 25 50 75 100 125

TEMPERATURE (

BIAS CURRENT

OFFSET CURRENT

o

C)

FIGURE 5. INPUTBIAS CURRENT AND OFFSETCURRENT

AS A FUNCTION OF TEMPERATURE

10

9

8

7

6

5

4

3

BIAS CURRENT (µA)

2

1

0

20

0

5

DIFFERENTIAL INPUT VOLTAGE (V)

10

VS = ±15.0V

TA = 25oC

15

20

25

FIGURE 6. BIASCURRENT AS A FUNCTION OF COMMON

MODE VOLTAGE

1000

900

800

700

600

500

400

300

200

POWER SUPPLY CURRENT (µA)

100

0

0 100 200 300 400

DIFFERENTIAL INPUT VOLTAGE (mV)

VS = ±15.0V

= 25oC

T

A

500

FIGURE 8. POWER SUPPLY CURRENT ASA FUNCTION OF

DIFFERENTIAL INPUT VOLTAGE

3

FIGURE 7. BIASCURRENT AS A FUNCTIONOF

DIFFERENTIAL INPUT VOLTAGE

150

VS = ±20.0V

25

VS = ±15.0V

VS = ±10.0V

VS = ±5.5V

50

75

o

C)

100

125

120

90

60

30

POWER SUPPLY CURRENT (µA)

0

-55

-25

0

TEMPERATURE (

FIGURE 9. POWER SUPPLY CURRENT ASA FUNCTION OF

TEMPERATURE

HS-2700RH

Typical Performance Curves T

= 25oC, VSUPPLY = ±15V, Unless Otherwise Specified (Continued)

A

130

120

110

100

GAIN (dB)

VS = ±20.0V

90

80

-55 -25 0 25 50

VS = ±15.0V

VS = ±10.0V

VS = ±5.5V

TEMPERATURE (

o

C)

10075 125

FIGURE 10. VOLTAGE GAIN AS A FUNCTION OF TEMPERATURE

NOTE: Open loop (comparator) applications are not recommended, because of the above characteristic.

Burn-In Circuits

HS1-2700RH CERDIP

HS2-2700RH METAL CAN

V+

NC

1

2

NC

3

NC

4

5

6

NC

V-

D1C1

7

R1

14

NC

13

NC

12

NC

11

10

9

NC

8

NC

NOTES:

1. R1 = 1MΩ, ±5%, 1/4W (Min)

2. C1 = C2 = 0.01µF/Socket (Min) or 0.1µF/Row (Min)

3. D1 = D2 = 1N4002 or equivalent (per board)

4. |(V+) - (V-)| = 31V ±1V

D2

C2

V+

C2

D1

2

-

6

+

478

3

R1

V-

D2

C3

C1

NOTES:

5. R1 = 1MΩ, ±5%, 1/4W (Min)

6. C1 = 0.01µF/Socket (Min)

7. C2 = C3 = 0.01µF/Socket (Min) or 0.1µF/Row (Min)

8. D1 = D2 = 1N4002 or equivalent (per board)

9. |(V+) - (V-)| = 31V ±1V

10. Insulated scope probe must be used during board check-out.

4

HS-2700RH

Irradiation Circuit

NC

1

2

NC

3

NC

4

5

6

NC

V2

GND

7

R1

Schematic Diagram

V-

1

430K

Ω

14

NC

13

NC

12

NC

11

10

9

NC

8

NC

OS- OS+

NOTES:

11. R = 1MΩ, ±5%, 1/4W

12. V1 = +15V + 1.0V

13. V2 = -15V + 1.0V

V1

15Ω

IN+

2

V+

4

NOTE: Nominal currents shown in microamperes.

IN-

V+

15Ω

6

OUT

3

5

Die Characteristics

HS-2700RH

DIE DIMENSIONS:

70 mils x 60 mils x 20 mils

(1780µm x 1530µm x 1530µm)

INTERFACE MATERIALS:

Glassivation:

Type: Nitride

Thickness: 7k

Å ±0.7kÅ

Top Metallization:

Type: Aluminum

Thickness: 16k

Å ±2kÅ

Substrate:

Linear Bipolar, DI

Backside Finish:

Silicon

Metallization Mask Layout

ASSEMBLY RELATED INFORMATION:

Substrate Potential (Powered Up):

Unbiased

ADDITIONAL INFORMATION:

Worst Case Current Density:

< 2 x 10

HS-2700RH

+IN -IN

5

A/cm

2

V-

BAL

BAL

V+

OUTPUT

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changesin circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

6

Loading...

Loading...