Page 1

March 1998

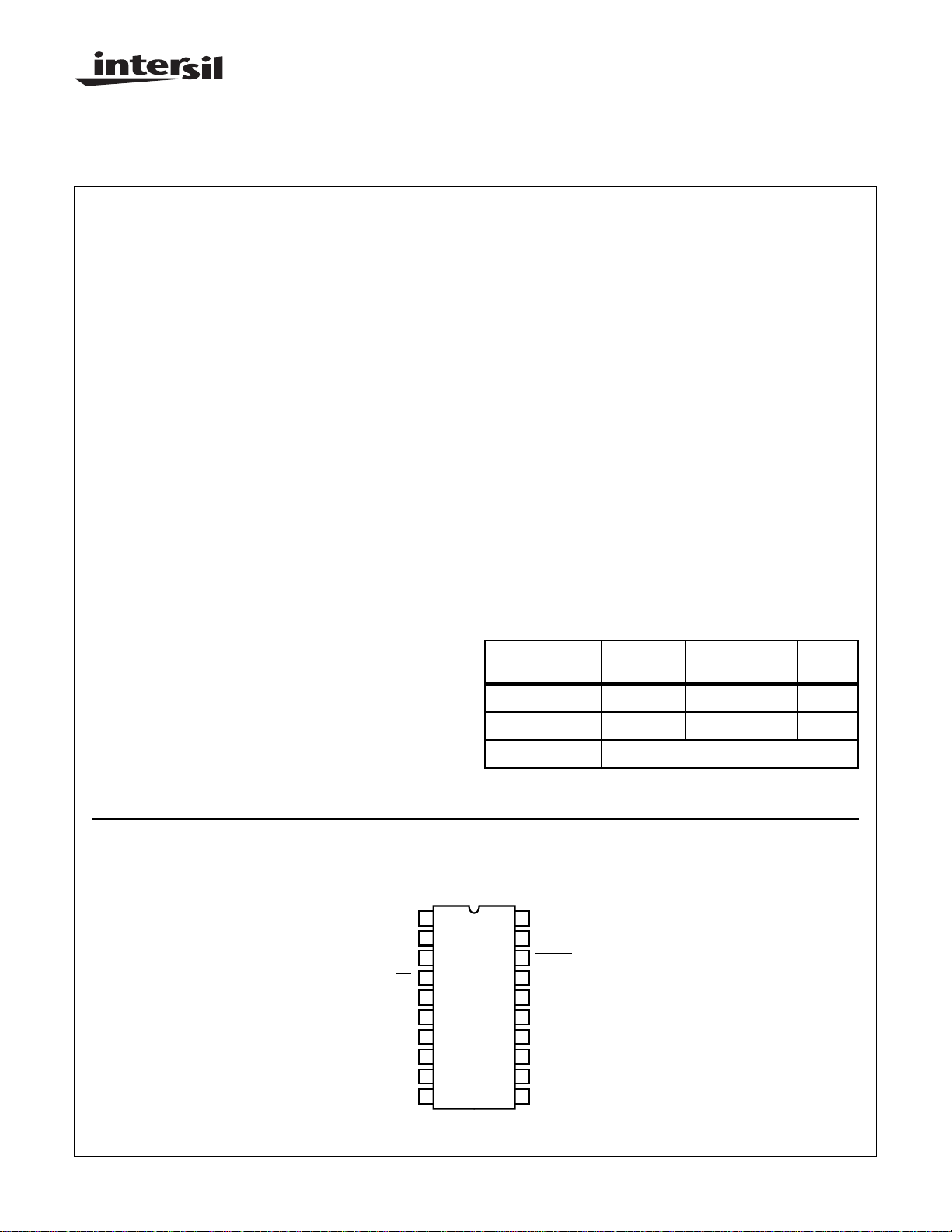

HI7191

24-Bit, High Precision,

Sigma Delta A/D Converter

Features

• 22-Bit Resolution with No Missing Code

• 0.0007% Integral Non-Linearity (Typ)

• 20mV to ±2.5V Full Scale Input Ranges

• Internal PGIA with Gains of 1 to 128

• Serial Data I/O Interface, SPI Compatible

• Differential Analog and Reference Inputs

• Internal or System Calibration

• -120dB Rejection of 60/50Hz Line Noise

• Settling Time of 4 Conversions (Max) for a Step Input

Applications

• Process Control and Measurement

• Industrial Weight Scales

• Part Counting Scales

• Laboratory Instrumentation

• Seismic Monitoring

• Magnetic Field Monitoring

• Additional Reference Literature

- TB348 “HI7190/1 Negative Full Scale Error vs

Conversion Frequency”

- AN9504 “A Brief Intro to Sigma Delta Conversion”

- TB329 “Intersil Sigma Delta Calibration Technique”

- AN9505 “Using the HI7190 Evaluation Kit”

- TB331 “Using the HI7190 Serial Interface”

- AN9527 “Interfacing HI7190 to a Microcontroller”

- AN9532 “Using HI7190 in a Multiplexed System”

- AN9601 “Using HI7190 with a Single +5V Supply”

Description

The Intersil HI7191 is a monolithic instrumentation, sigma delta

A/D converter which operates from ±5V supplies. Both the signal and reference inputs are fully differential for maximum flexibility and performance. An internal Programmable Gain

Instrumentation Amplifier (PGIA) provides input gains from 1 to

128 eliminating the need for external pre-amplifiers. The ondemand converter auto-calibrate function is capable of removing offset and gain errors existing in external and internal circuitry. The on-board user programmable digital filter provides

over -120dB of 60/50Hz noise rejection and allows fine tuning

of resolution and conversion speed ov er a wide dynamic range .

The HI7191 and HI7191 are functionally the same device so all

discussion will refer to the HI7191 for simplicity.

The HI7191 contains a serial I/O port and is compatible with

most synchronous transfer formats including both the Motorola 6805/11 series SPI and Intel 8051 series SSR protocols.

A sophisticated set of commands gives the user control over

calibration, PGIA gain, device selection, standby mode, and

several other features. The On-chip Calibration Registers

allow the user to read and write calibration data.

Ordering Information

TEMP.

PART NUMBER

HI7191IP -40 to 85 20 Ld PDIP E20.3

HI7191IB -40 to 85 20 Ld SOIC M20.3

HI7190EVAL Evaluation Kit

RANGE (oC) PACKAGE

PKG.

NO.

Pinout

HI7191

(PDIP, SOIC)

TOP VIEW

1

SCLK

SDO

2

SDIO

3

4

CS

5

DRDY

6

DGND

7

AV

SS

8

V

RLO

9

V

RHI

10

V

CM

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

1897

20

19

18

17

16

15

14

13

12

11

MODE

SYNC

RESET

OSC

1

OSC

2

DV

DD

AGND

AV

DD

V

INHI

V

INLO

File Number 4138.3

Page 2

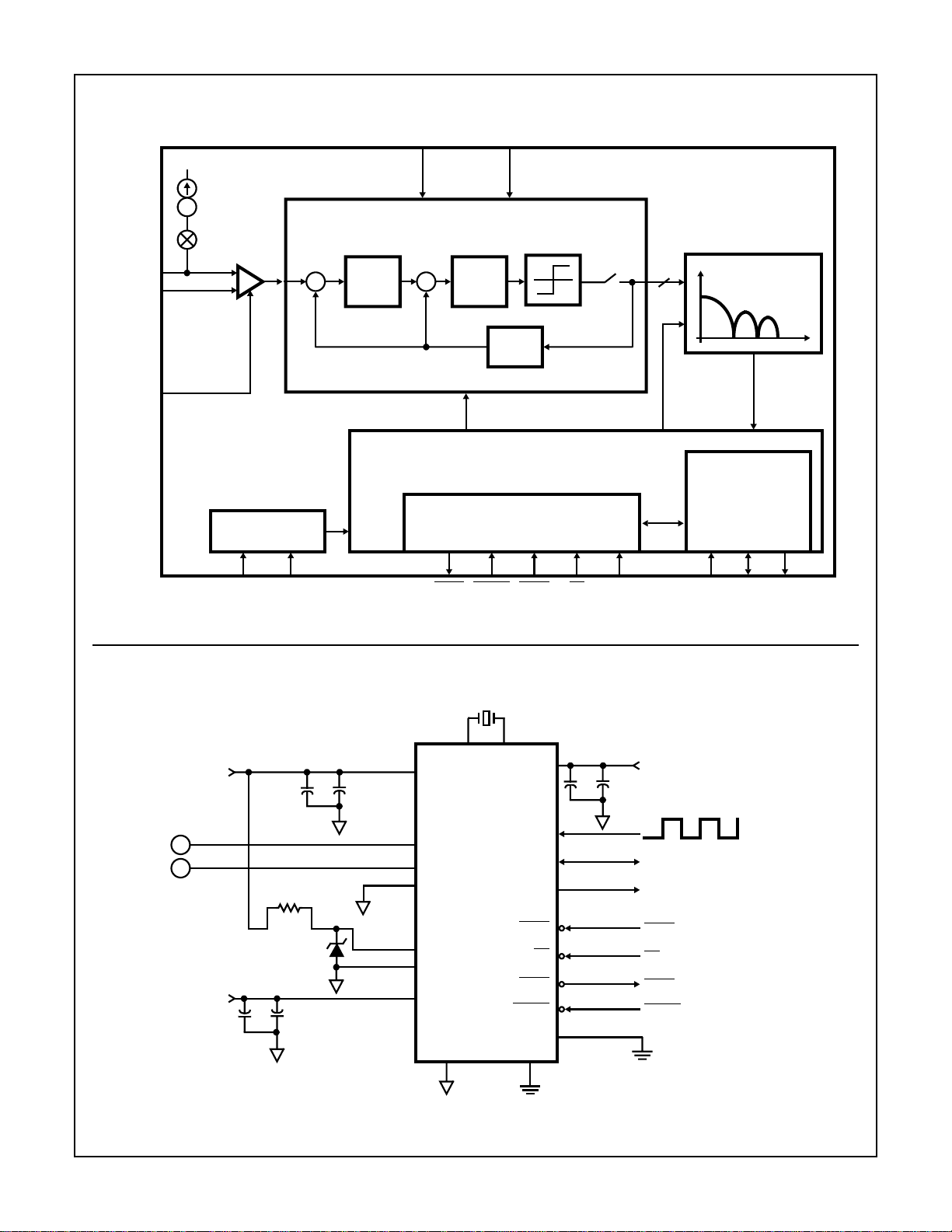

Functional Block Diagram

HI7191

V

V

INHI

INLO

V

CM

AV

DD

TRANSDUCER

BURN-OUT

CURRENT

PGIA

CLOCK

GENERATOR

V

RHI

REFERENCE

INPUTS

V

RLO

∑ − ∆

MODULATOR

∑

∫∫

∑

1-BIT

D/A

CONTROL AND SERIAL INTERFACE UNIT

CONTROL REGISTER

DIGITAL FILTER

1

SERIAL INTERFACE

UNIT

OSC1OSC

2

Typical Application Schematic

INPUT

INPUT

+5V

+

-

REFERENCE

-5V

0.1µF

R

+

+

0.1uF

1

+2.5V

4.7µF

4.7µF

DRDY RESET SYNC CS MODE S

10MHz

17 16

AV

V

INHI

V

INLO

V

CM

V

RHI

V

RLO

AV

AGND

DD

SS

OSC1OSC

14 6

13

12

11

10

9

8

7

2

RESET

MODE

DGND

DV

DD

SCLK

SDIO

SDO

SYNC

CS

DRDY

15

0.1µF

1

3

2

19

4

5

18

20

+

4.7µF

+5V

DATA I/O

DATA OUT

SYNC

CS

DRDY

RESET

CLK

SDIO SDO

1898

Page 3

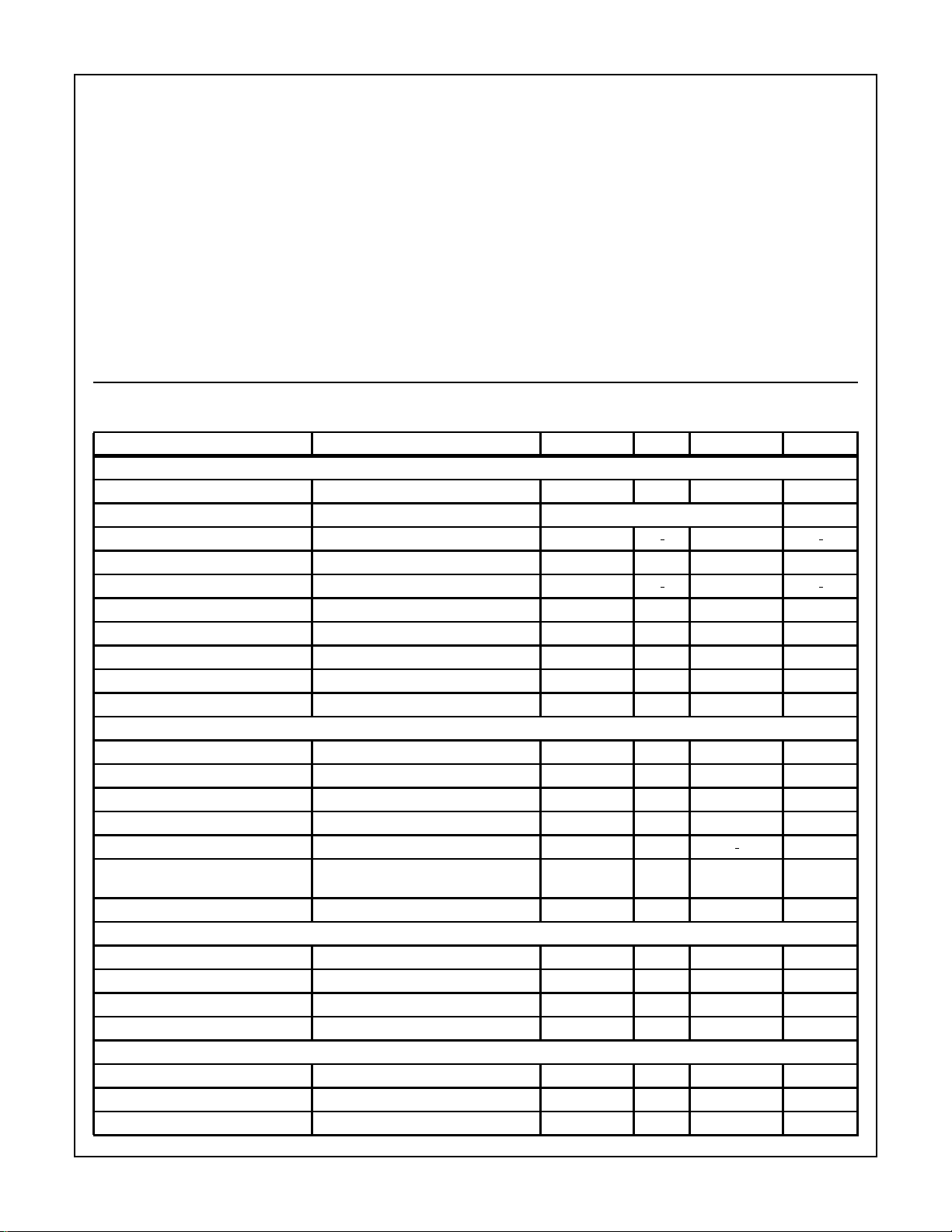

HI7191

Absolute Maximum Ratings Thermal Information

Supply Voltage

AVDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5.5V

AVSS to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -5.5V

DVDD to DGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5.5V

DGND to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.3V

Analog Input Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . AVSS to AV

Digital Input, Output and I/O Pins. . . . . . . . . . . . . . . DGND to DV

ESD Tolerance (No Damage)

Human Body Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500V

Machine Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +100V

Charged Device Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Maximum Junction Temperature

Plastic Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150oC

DD

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

DD

Maximum Lead Temperature (Soldering, 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

Electrical Specifications AV

= +5V, AVSS = -5V, DVDD = +5V, V

DD

= +2.5V, V

RHI

= AGND = 0V, VCM = AGND,

RLO

PGIA Gain = 1, OSCIN = 10MHz, Bipolar Input Range Selected, fN = 10Hz

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SYSTEM PERFORMANCE

Integral Non-Linearity, INL End Point Line Method (Notes 3, 5, 6) - ±0.0007 ±0.0015 %FS

Differential Non-Linearity (Note 2) No Missing codes to 22-Bits LSB

Offset Error, V

OS

Offset Error Drift V

Full Scale Error, FSE V

Noise, e

N

Common Mode Rejection Ratio, CMRR V

See Table 1 - -- -

INHI

INHI

= V

- V

(Notes 3, 8) - 1 - µV/oC

INLO

= +2.5V (Notes 3, 5, 8, 10) - - - -

INLO

See Table 1 - - - -

CM

= 0V, V

INHI

= V

from -2V to +2V -70 - dB

INLO

Normal Mode 50Hz Rejection Filter Notch = 10Hz, 25Hz, 50Hz (Note 2) -120 - - dB

Normal Mode 60Hz Rejection Filter Notch = 10Hz, 30Hz, 60Hz (Note 2) -120 - - dB

Step Response Settling Time - 2 4 Conversions

ANALOG INPUTS

Input Voltage Range Unipolar Mode (Note 9) 0 - V

Input Voltage Range Bipolar Mode (Note 9) - V

Common Mode Input Range (Note 2) AV

Input Leakage Current, I

Input Capacitance, C

Reference Voltage Range, V

(V

= V

RHI

- V

REF

RLO

IN

IN

REF

)

Transducer Burn-Out Current, I

VIN = AVDD (Note 2) - - 1.0 nA

BO

REF

SS

- 5.0 -pF

2.5 - 5 V

- 200 - nA

-V

-AVDDV

REF

REF

V

V

CALIBRATION LIMITS

Positive Full Scale Calibration Limit - - 1.2(V

Negative Full Scale Calibration Limit - - 1.2(V

Offset Calibration Limit - - 1.2(V

Input Span 0.2(V

/Gain) - 2.4(V

REF

/Gain) -

REF

/Gain) -

REF

/Gain) -

REF

/Gain) -

REF

DIGITAL INPUTS

Input Logic High Voltage, V

Input Logic Low Voltage, V

Input Logic Current, I

I

IH

IL

(Note 11) 2.0 - - V

- - 0.8 V

VIN = 0V, +5V - 1.0 10 µA

1899

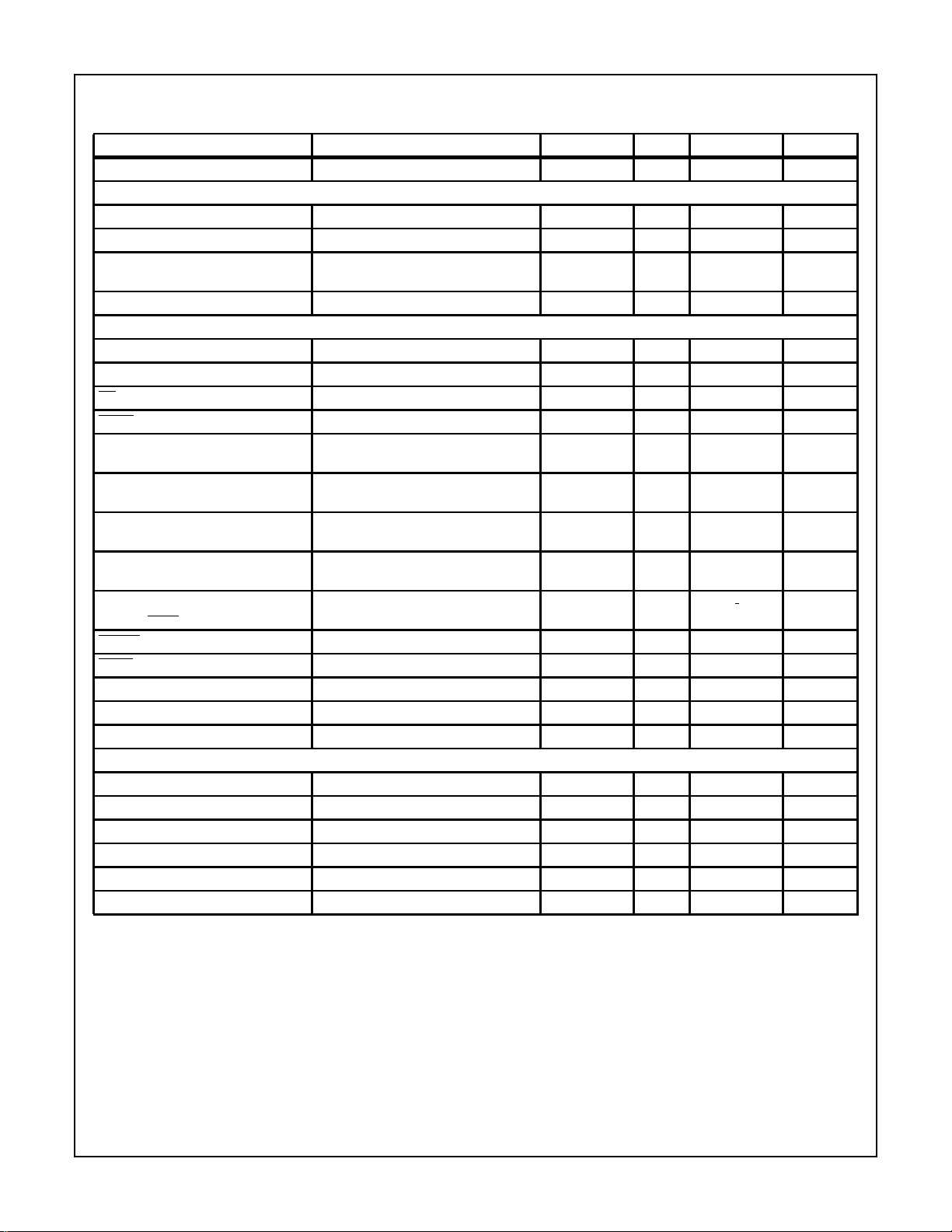

Page 4

HI7191

Electrical Specifications AV

= +5V, AVSS = -5V, DVDD = +5V, V

DD

= +2.5V, V

RHI

= AGND = 0V, VCM = AGND,

RLO

PGIA Gain = 1, OSCIN = 10MHz, Bipolar Input Range Selected, fN = 10Hz (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input Capacitance, C

IN

VIN = 0V - 5.0 - pF

DIGITAL OUTPUTS

Output Logic High Voltage, V

Output Logic Low Voltage, V

OH

OL

Output Three-State Leakage Current,

I

OZ

Digital Output Capacitance, C

OUT

I

= -100µA (Note 7) 2.4 - - V

OUT

I

= 3mA (Note 7) - - 0.4 V

OUT

V

= 0V, +5V (Note 7) -10 1 10 µA

OUT

-10- pF

TIMING CHARACTERISTICS

SCLK Minimum Cycle Time, t

SCLK Minimum Pulse Width, t

CS to SCLK Precharge Time, t

SCLK

SCLKPW

PRE

200 - - ns

50 - - ns

50 - - ns

DRDY Minimum High Pulse Width (Notes 2, 7) 500 - - ns

Data Setup to SCLK Rising Edge

(Write), t

DSU

Data Hold from SCLK Rising Edge

(Write), t

DHLD

Data Read Access from Instruction

Byte Write, t

ACC

Read Bit Valid from SCLK Falling Edge,

t

DV

Last Data Transfer to Data Ready

Inactive,t

DRDY

(Note 7) - - 40 ns

(Note 7) - - 40 ns

(Note 7) - 35 -ns

50 - - ns

0-- ns

RESET Low Pulse Width (Note 2) 100 - - ns

SYNC Low Pulse Width (Note 2) 100 - - ns

Oscillator Clock Frequency (Note 2) 0.1 - 10 MHz

Output Rise/Fall Time (Note 2) - - 30 ns

Input Rise/Fall Time (Note 2) - - 1 µs

POWER SUPPLY CHARACTERISTICS

IAV

DD

IAV

SS

IDV

DD

Power Dissipation, Active PD

Power Dissipation, Standby PD

SCLK = 4MHz - - 3.0 mA

A

SB = ‘0’ - 15 30 mW

SB = ‘1’ - 5 - mW

S

- - 1.5 mA

- - 1.5 mA

PSRR (Note 3) - -70 - dB

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. Parameter guaranteed by design or characterization, not production tested.

3. Applies to both bipolar and unipolar input ranges.

4. These errors can be removed by re-calibrating at the desired operating temperature.

5. Applies after system calibration.

6. Fully differential input signal source is used.

7. See Load Test Circuit, Figure 10, R1 = 10kΩ, CL = 50pF.

8. 1 LSB = 298nV at 24 bits for a Full Scale Range of 5V.

9. V

= V

RHI

- V

RLO

REF

10. These errors are on the order of the output noise shown in Table 1.

11. All inputs except OSC1. The OSC1 input VIH is 3.5V minimum.

1900

Page 5

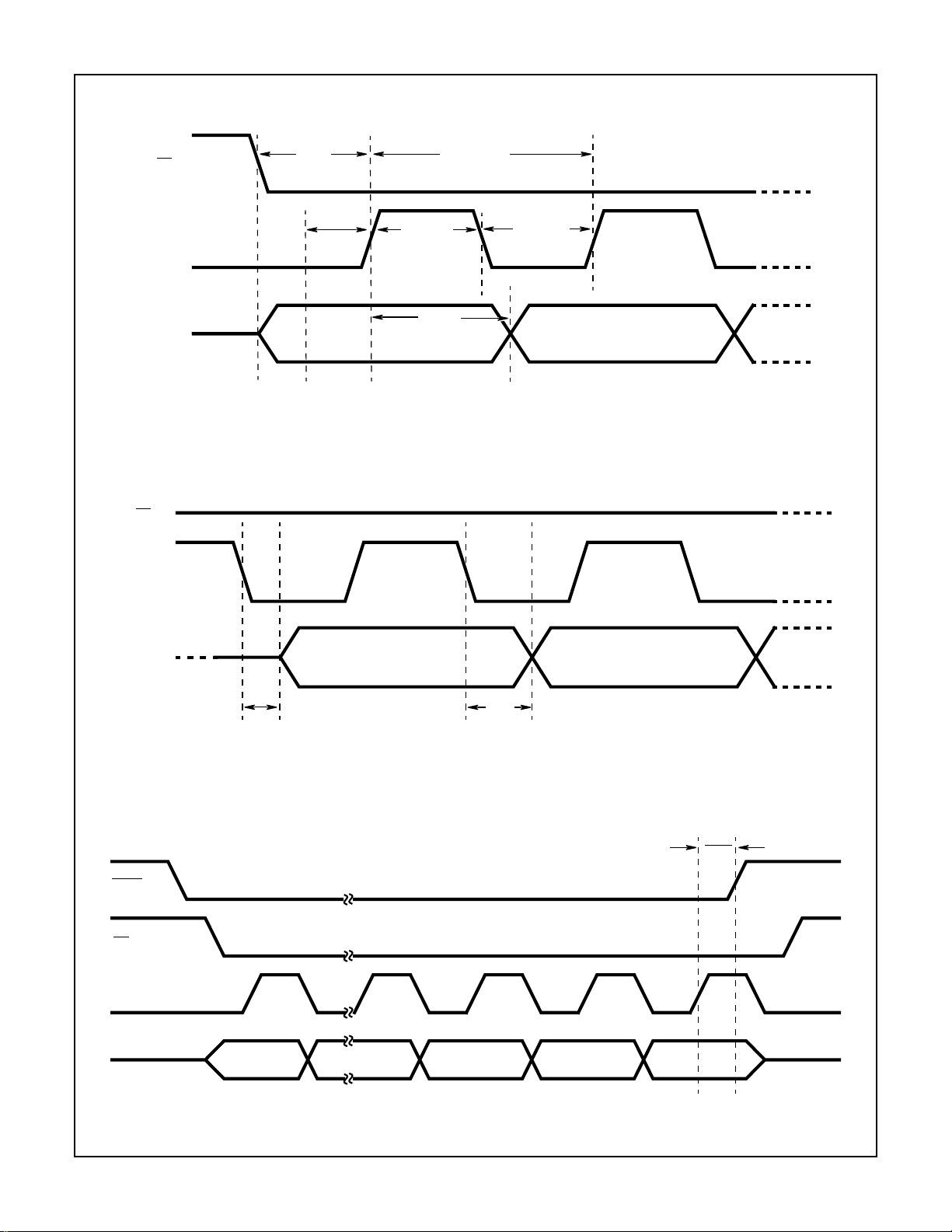

Timing Diagrams

CS

SCLK

SDIO

HI7191

t

t

DHLD

SCLK

t

SCLKPW

t

PRE

t

DSU

1ST BIT 2ND BIT

t

SCLKPW

FIGURE 1. DATA WRITE TO HI7191

SCLK

SDIO

SDO

DRDY

CS

CS

t

ACC

1ST BIT 2ND BIT

t

DV

FIGURE 2. DATA READ FROM HI7191

t

DRDY

SCLK

SDIO

87651

FIGURE 3. DATA READ FROM HI7191

1901

Page 6

HI7191

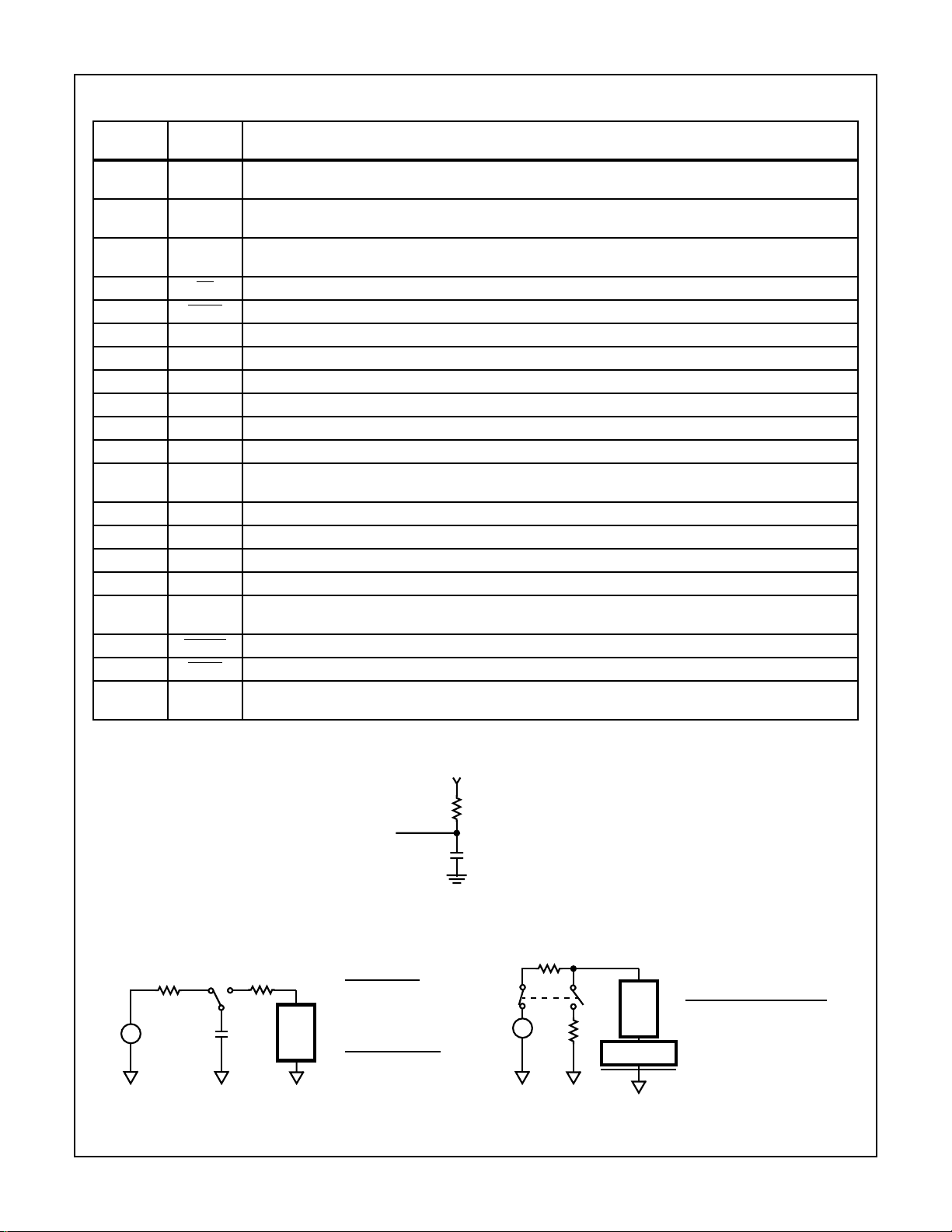

Pin Descriptions

20 LEAD

DIP, SOIC PIN NAME DESCRIPTION

1 SCLK Serial Interface Clock. Synchronizes serial data transfers. Data is input on the rising edge and output on the

falling edge.

2 SDO Serial Data OUT. Serial data is read from this line when using a 3-wire serial protocol such as the

Motorola Serial Peripheral Interface.

3 SDIO Serial Data IN or OUT. This line is bidirectional programmable and interfaces directly to the Intel Standard Serial

Interface using a 2-wire serial protocol.

4 CS Chip Select Input. Used to select the HI7191 for a serial data transfer cycle. This line can be tied to DGND.

5 DRDY An Active Low Interrupt indicating that a new data word is available for reading.

6 DGND Digital Supply Ground.

7AVSSNegative Analog Power Supply (-5V).

8V

RLO

9V

10 V

11 V

12 V

INLO

INHI

13 AV

14 AGND Analog Supply Ground.

15 DV

16 OSC2Used to connect a crystal source between OSC1 and OSC2. Leave open otherwise.

17 OSC1Oscillator Clock Input for the device. A crystal connected between OSC1 and OSC2will provide a clock to the

18 RESET Active Low Reset Pin. Used to initialize the HI7191 registers, filter and state machines.

19 SYNC Active Low Sync Input. Used to control the synchronization of a number of HI7191s . A logic ‘0’ initializes the converter .

20 MODE Mode Pin. Used to select between Synchronous Self Clocking (Mode = 1) or Synchronous External Clocking

External Reference Input. Should be negative referenced to V

External Reference Input. Should be positive referenced to V

RHI

Common Mode Input. Should be set to halfway between AVDD and AVSS.

CM

RHI

RLO

.

.

Analog Input LO. Negative input of the PGIA.

Analog Input HI. Positive input of the PGIA. The V

input is connected to a current source that can be used to check

INHI

the condition of an external transducer. This current source is controlled via the Control Register.

Positive Analog Power Supply (+5V).

DD

Positive Digital Supply (+5V).

DD

device, or an external oscillator can drive OSC1. The oscillator frequency should be 10MHz (Typ).

(Mode = 0) for the Serial Port.

Load Test Circuit

ESD Test Circuits

R

1

±

V

C

R

2

DUT

ESD

FIGURE 5A.

DUT

HUMAN BODY

= 100pF

C

ESD

R1 = 10MΩ

R2 = 1.5kΩ

MACHINE MODEL

C

= 200pF

ESD

R1 = 10MΩ

= 0Ω

R

2

V

1

R

1

CL (INCLUDES STRAY

CAPACITANCE)

FIGURE 4.

±

V

R

1

DUT

R

2

DIELECTRIC

CHARGED DEVICE MODEL

R1 = 1GΩ

R2 = 1Ω

FIGURE 5B.

1902

Page 7

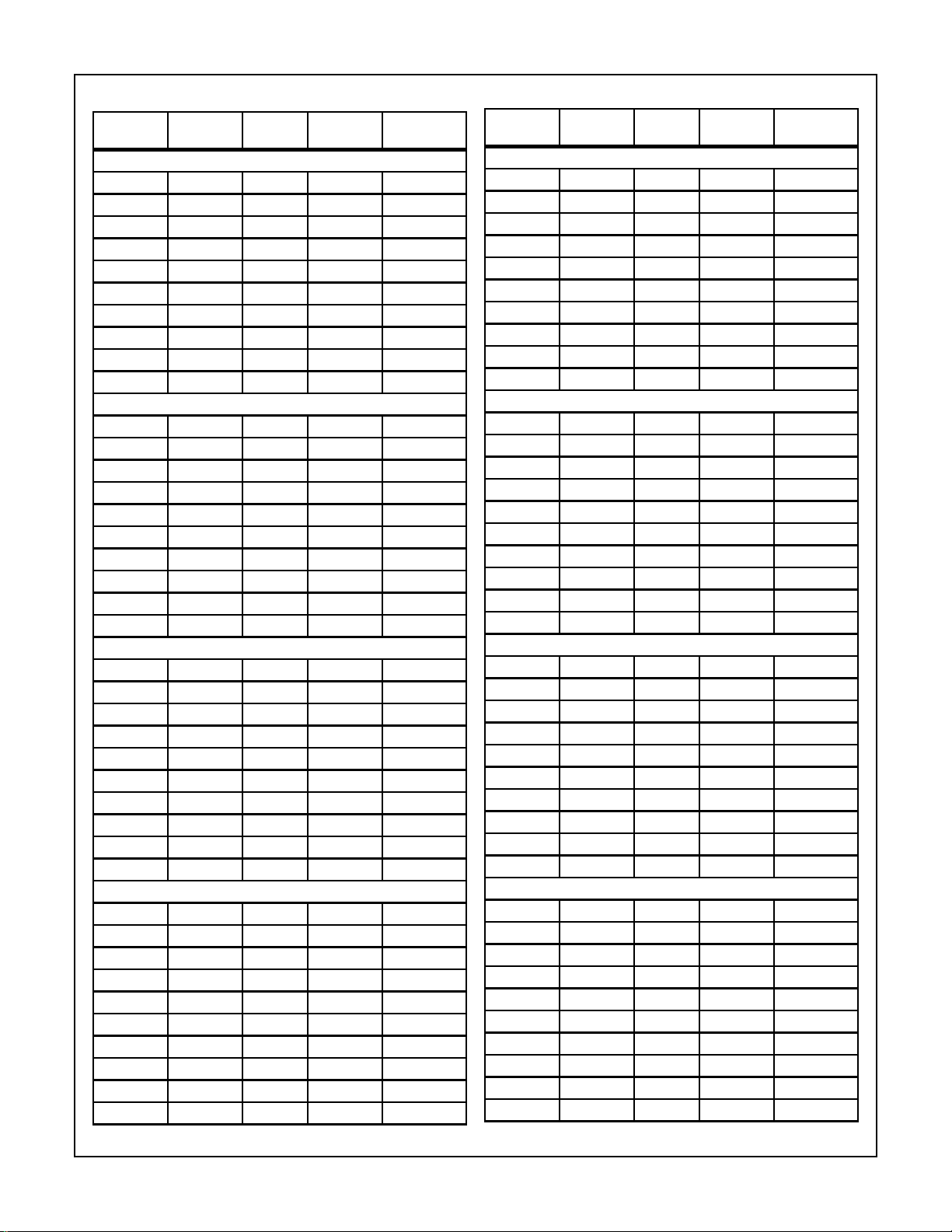

TABLE 1. NOISE PERFORMANCE WITH INPUT CONNECTED TO ANALOG GROUND

P-P NOISE

HERTZ SNR ENOB

GAIN = 1

10 132.3 21.7 9.8 1.5

25 129.5 21.2 13.6 2.1

30 127.7 20.9 16.6 2.5

50 126.3 20.7 19.5 3.0

60 125.6 20.6 21.2 3.2

100 122.4 20.0 30.7 4.6

250 107.7 17.6 166.7 25.3

500 98.1 16.0 505.3 76.6

1000 85.7 13.9 2101.8 318.5

2000 68.8 11.1 14661.6 2221.4

GAIN = 2

10 129.2 21.2 14.0 2.1

25 125.7 20.6 20.9 3.2

30 124.5 20.4 24.1 3.7

50 123.4 20.2 27.3 4.1

60 122.5 20.1 30.3 4.6

100 118.1 19.3 50.0 7.6

250 106.1 17.3 199.5 30.2

500 96.9 15.8 580.1 87.9

1000 84.4 13.7 2435.6 369.0

2000 67.8 11.0 16469.7 2495.4

GAIN = 4

10 125.9 20.6 20.5 3.1

25 123.1 20.1 28.4 4.3

30 121.8 19.9 32.8 5.0

50 119.9 19.6 40.9 6.2

60 119.9 19.6 40.9 6.2

100 116.1 19.0 63.2 9.6

250 105.7 17.3 209.7 31.8

500 96.6 15.8 597.8 90.6

1000 84.3 13.7 2469.5 374.2

2000 68.2 11.0 15656.1 2372.1

GAIN = 8

10 124.7 20.4 23.4 3.5

25 120.6 19.7 37.8 5.7

30 119.2 19.5 44.3 6.7

50 117.5 19.2 53.8 8.2

60 116.8 19.1 58.6 8.9

100 112.1 18.3 100.0 15.2

250 101.4 16.5 345.2 52.3

500 95.3 15.5 691.1 104.7

1000 83.1 13.5 2838.6 430.1

2000 68.3 11.1 15494.7 2347.7

(µV)

RMS NOISE

(µV)

HI7191

GAIN = 16

GAIN = 32

GAIN = 64

GAIN = 128

P-P NOISE

HERTZ SNR ENOB

10 120.1 19.7 39.8 6.0

25 114.8 18.8 73.4 11.1

30 113.5 18.6 85.1 12.9

50 111.0 18.1 114.4 17.3

60 109.6 17.9 134.0 20.3

100 105.5 17.2 214.8 32.5

250 95.2 15.5 699.1 105.9

500 89.1 14.5 1417.7 214.8

1000 83.5 13.6 2686.0 407.0

2000 62.6 10.1 30110.0 4562.1

10 113.2 18.5 88.8 13.5

25 109.0 17.8 142.7 21.6

30 108.2 17.7 157.4 23.8

50 104.7 17.1 235.8 35.7

60 105.0 17.1 227.8 34.5

100 102.3 16.7 310.5 47.0

250 93.4 15.2 861.1 130.5

500 87.1 14.2 1782.7 270.1

1000 78.2 12.7 4990.4 756.1

2000 57.0 9.2 57311.1 8683.5

10 106.7 17.4 186.2 28.2

25 102.9 16.8 288.4 43.7

30 101.9 16.6 325.8 49.4

50 98.5 16.1 479.8 72.7

60 98.9 16.1 459.8 69.7

100 96.3 15.7 620.2 94.0

250 85.5 13.9 2133.5 323.3

500 78.1 12.7 5025.0 761.4

1000 66.7 10.8 18693.5 2832.3

2000 50.5 8.1 120163.0 18206.5

10 101.1 16.5 356.5 54.0

25 96.0 15.7 638.3 96.7

30 95.2 15.5 704.8 106.8

50 93.2 15.2 882.2 133.7

60 92.2 15.0 996.7 151.0

100 91.4 14.9 1086.6 164.6

250 79.4 12.9 4346.4 658.5

500 71.8 11.6 10439.2 1581.7

1000 60.1 9.7 39923.0 6048.9

2000 44.8 7.1 233238.2 35339.1

(µV)

RMS NOISE

(µV)

1903

Page 8

HI7191

Definitions

Integral Non-Linearity, INL, is the maximum deviation of

any digital code from a straight line passing through the endpoints of the transfer function. The endpoints of the transfer

function are zero scale (a point 0.5 LSB below the first code

transition 000...000 and 000...001) and full scale (a point 0.5

LSB above the last code transition 111...110 to 111...111).

Differential Non-Linearity, DNL, is the deviation from the

actual difference between midpoints and the ideal difference

between midpoints (1 LSB) for adjacent codes. If this difference is equal to or more negative than 1 LSB, a code will be

missed.

Offset Error , V

from the ideal input voltage (V

be calibrated to the order of the noise level sho wn in Table 1.

Full Scale Error, FSE, is the deviation of the last code

transition from the ideal input full scale voltage

(V

-+V

IN

REF

to the order of the noise level shown in Table 1.

Input Span, defines the minimum and maximum input

voltages the device can handle while still calibrating properly

for gain.

Noise, e

, Table 1 shows the peak-to-peak and RMS noise

N

for typical notch and -3dB frequencies. The device programming was for bipolar input with a V

the input range is 5V. The analysis was performed on 100

conversions with the peak-to-peak output noise being the

difference between the maximum and minimum readings

over a rolling 10 conversion window . The equation to convert

the peak-to-peak noise data to ENOB is:

ENOB = Log

where: V

FS

CF = 6.6 (Imperical Crest Factor)

The noise from the part comes from two sources, the

quantization noise from the analog-to-digital conversion process and device noise. Device noise (or Wideband Noise) is

independent of gain and essentially flat across the frequency

spectrum. Quantization noise is ratiometric to input full scale

(and hence gain) and its frequency response is shaped by

the modulator.

Looking at Table 1, as the cutoff frequency increases the

output noise increases. This is due to more of the

quantization noise of the part coming through to the output

and, hence, the output noise increases with increasing 3dB frequencies. For the lower notch settings, the output

noise is dominated by the device noise and, hence, altering

the gain has little effect on the output noise. At higher notch

frequencies, the quantization noise dominates the output

noise and, in this case, the output noise tends to decrease

with increasing gain.

Since the output noise comes from two sources, the effectiv e

resolution of the device (i.e., the ratio of the input full scale to

the output RMS noise) does not remain constant with

increasing gain or with increasing bandwidth. It is possible to

, is the deviation of the first code transition

OS

- 0.5 LSB). This error can

IN

/Gain - 1.5 LSB). This error can be calibrated

of +2.5V. This implies

REF

(VFS / V

2

= 5V, V

NRMS

NRMS

= V

)

NP-P

/ CF and

do post-filtering (such as brick wall filtering) on the data to

improve the ov erall resolution for a given -3dB frequency and

also to further reduce the output noise.

Circuit Description

The HI7191 is a monolithic, sigma delta A/D converter which

operates from ±5V supplies and is intended for

measurement of wide dynamic range, low frequency signals.

It contains a Programmable Gain Instrumentation Amplifier

(PGIA), sigma delta ADC, digital filter, bidirectional serial

port (compatible with many industry standard protocols),

clock oscillator, and an on-chip controller.

The signal and reference inputs are fully differential for

maximum flexibility and performance. Normally V

V

are tied to +2.5V and AGND respectively. This allows

RLO

for input ranges of 2.5V and 5V when operating in the unipolar and bipolar modes respectively (assuming the PGIA is

configured for a gain of 1). The internal PGIA provides input

gains from 1 to 128 and eliminates the need for external preamplifiers. This means the device will convert signals ranging from 0V to +20mV and 0V to +2.5V when operating in

the unipolar mode or signals in the range of ±20mV to ±2.5V

when operating in the bipolar mode.

The input signal is continuously sampled at the input to the

HI7191 at a clock rate set by the oscillator frequency and the

selected gain. This signal then passes through the sigma

delta modulator (which includes the PGIA) and emerges as

a pulse train whose code density contains the analog signal

information. The output of the modulator is fed into the sinc

digital low pass filter. The filter output passes into the

calibration block where offset and gain errors are removed.

The calibrated data is then coded (2’s complement, offset

binary or binary) before being stored in the Data Output

Register. The Data Output Register update rate is determined by the first notch frequency of the digital filter. This

first notch frequency is programmed into HI7191 via the

Control Register and has a range of 10Hz to 1.953kHz which

corresponds to -3dB frequencies of 2.62Hz and 512Hz

respectively.

Output data coding on the HI7191 is programmable via the

Control Register. When operating in bipolar mode, data output can be either 2’s complement or offset binary. In unipolar

mode output is binary.

The

DRDY signal is used to alert the user that new output

data is available. Converted data is read via the HI7191

serial I/O port which is compatible with most synchronous

transfer formats including both the Motorola 6805/11 series

SPI and Intel 8051 series SSR protocols. Data Integrity is

always maintained at the HI7191 output port. This means

that if a data read of conversion N is begun but not finished

before the next conversion (conversion N + 1) is complete,

the

DRDY line remains active (low) and the data being read

is not overwritten.

The HI7191 provides many calibration modes that can be

initiated at any time by writing to the Control Register. The

device can perform system calibration where external components are included with the HI7191 in the calibration loop

RHI

and

3

1904

Page 9

HI7191

or self-calibration where only the HI7191 itself is in the calibration loop. The On-chip Calibration Registers are

read/write registers which allow the user to read calibration

coefficients as well as write previously determined

calibration coefficients.

Circuit Operation

The analog and digital supplies and grounds are separate

on the HI7191 to minimize digital noise coupling into the

analog circuitry. Nominal supply voltages are AV

DV

= +5V, and AVSS = -5V. If the same supply is used

DD

for AV

rately decoupled to the AV

and DVDD it is imperative that the supply is sepa-

DD

and DVDD pins on the

DD

HI7191. Separate analog and digital ground planes should

be maintained on the system board and the grounds should

be tied together back at the power supply.

When the HI7191 is powered up it needs to be reset by pulling the

RESET line low. The reset sets the internal registers

of the HI7191 as shown in Table 2 and puts the part in the

bipolar mode with a gain of 1 and offset binary coding. The

filter notch of the digital filter is set at 30Hz while the I/O is

set up for bidirectional I/O (data is read and written on the

SDIO line and SDO is three-stated), descending byte order,

and MSB first data format. A self calibration is performed

before the device begins converting.

DRDY goes low when

valid data is available at the output.

TABLE 2. REGISTER RESET VALUES

REGISTER VALUE (HEX)

Data Output Register XXXX (Undefined)

Control Register 28B300

Offset Calibration Register Self Calibration Value

Positive Full Scale Calibration

Register

Negative Full Scale Calibration

Register

Self Calibration Value

Self Calibration Value

The configuration of the HI7191 is changed by writing new

setup data to the Control Register. Whenever data is written

to byte 2 and/or byte 1 of the Control Register the part

assumes that a critical setup parameter is being changed

which means that

DRDY goes high and the device is re-synchronized. If the configuration is changed such that the

device is in any one of the calibration modes, a new calibration is performed before normal conversions continue. If the

device is written to the conversion mode , a new calibration is

NOT performed (A new calibr ation is recommended any time

data is written to the Control Register.). In either case,

goes low when valid data is available at the output.

If a single data byte is written to byte 0 of the Control

Register, the device assumes the gain has NOT been

changed. It is up to the user to re-calibrate the device if the

gain is changed in this manner. For this reason it is

recommended that the entire Control Register be written

when changing the gain of the device. This ensures that the

DD

= +5V,

DRD Y

part is re-calibrated (if in a calibration mode) before the

DRDY output goes low indicating that valid data is available.

The calibration registers can be read via the serial interface

at any time. However, care must be taken when writing data

to the calibration registers. If the HI7191 is internally

updating any calibration register the user can not write to

that calibration register. See the Operational Modes section

for details on which calibration registers are updated for the

various modes.

Since access to the calibration registers is asynchronous to

the conversion process the user is cautioned that new

calibration data may not be used on the very next set of

“valid” data after a calibration register write. It is guaranteed

that the new data will take effect on the second set of output

data. Non-calibrated data can be obtained from the device

by writing 000000 (h) to the Offset Calibration Register,

800000 (h) to the Positive Full Scale Calibration Register,

and 800000 (h) to the Negative Full Scale Calibration Register. This sets the offset correction factor to 0 and the positive

and negative gain slope factors to 1.

If several HI7191s share a system master clock the

SYNC

pin can be used to synchronize their operation. A common

SYNC input to multiple devices will synchronize operation

such that all output registers are updated simultaneously. Of

course the

SYNC pin would normally be activated only after

each HI7191 has been calibrated or has had calibration

coefficients written to it.

The

SYNC pin can also be used to control the HI7191 when

an external multiplexer is used with a single HI7191. The

SYNC pin in this application can be used to guarantee a max-

imum settling time of 3 conversion periods when switching

channels on the multiplexer.

Analog Section Description

Figure 6 shows a simplified block diagram of the analog

modulator front end of a sigma delta A/D Converter. The

input signal V

this case) where the previous modulator output is subtracted

from it. The resulting signal is then integrated and the output

of the integrator goes into the comparator. The output of the

comparator is then fed back via a 1-bit DAC to the summing

junction. The feedback loop forces the average of the fed

back signal to be equal to the input signal V

V

IN

FIGURE 6. SIMPLE MODULATOR BLOCK DIAGRAM

comes into a summing junction (the PGIA in

IN

.

IN

PGIA INTEGRATOR COMPARATOR

+

∑

-

DAC

V

V

RHI

RLO

∫

+

-

1905

Page 10

HI7191

Analog Inputs

The analog input on the HI7191 is a fully differential input

with programmable gain capabilities. The input accepts both

unipolar and bipolar input signals and gains range from 1 to

128. The common mode range of this input is from AVSS to

AV

provided that the absolute value of the analog input

DD

voltage lies within the power supplies. The input impedance

of the HI7191 is dependent upon the modulator input sampling rate and the sampling rate varies with the selected

PGIA gain. Table 3 below shows the sampling rates and

input impedances for the different gain settings of the

HI7191. Note that this table is valid only for a 10MHz master

clock. If the input clock frequency is changed then the input

impedance will change accordingly. The equation used to

calculate the input impedance is:

ZIN = 1/(CIN x fS),

where C

is the nominal input capacitance (8pF) and fS is

in

the modulator sampling rate.

TABLE 3. EFFECTIVE INPUT IMPEDANCE vs GAIN

SAMPLING RATE

GAIN

1 78.125 1.6

2 156.25 0.8

4 312.5 0.4

8, 16, 32, 64, 128 625 0.2

(kHz)

INPUT IMPEDANCE

(MΩ)

Bipolar/Unipolar Input Ranges

The input on the HI7191 can accept either unipolar or bipolar

input voltages. Bipolar or unipolar options are chosen by programming the B/

U bit of the Control Register. Programming

the part for either unipolar or bipolar operation does not

change the input signal conditioning.

The inputs are differential, and as a result are referenced to

the voltage on the V

input. For example, if V

INLO

INLO

is

+1.25V and the HI7191 is configured for unipolar operation

with a gain of 1 and a V

on the V

input is +1.25V to +3.75V. If V

INLO

of +2.5V, the input voltage range

REF

INLO

is +1.25V

and the HI7191 is configured for bipolar mode with gain of 1

and a V

of +2.5V, the analog input range on the V

REF

INHI

input is -1.25V to +3.75V.

Programmable Gain Instrumentation Amplifier

The Programmable Gain Instrumentation Amplifier allows the

user to directly interface low le v el sensors and bridges directly

to the HI7191. The PGIA has 4 selectable gain options of 1, 2,

4, 8 which are implemented by multiple sampling of the input

signal. Input signals can be gained up further to 16, 32, 64 or

128. These higher gains are implemented in the digital section

of the design to maintain a high signal to noise ratio through

the front end amplifiers. The gain is digitally programmable in

the Control Register via the serial interface. For optimum

PGIA performance the V

pin should be tied to the mid point

CM

of the analog supplies.

Differential Reference Input

The reference inputs of the of the HI7191, V

RHI

and V

RLO

provide a differential reference input capability. The nominal

differential voltage (V

common mode voltage cab be anywhere between AV

AV

. Larger values of V

DD

REF

= V

RHI

REF

- V

) is +2.5V and the

RLO

can be used without

SS

and

degradation in performance with the maximum reference

voltage being V

= +5V. Smaller values of V

REF

REF

can also

be used but performance will be degraded since the LSB

size is reduced.

The full scale range of the HI7191 is defined as:

FSR

BIPOLAR

FSR

UNIPOLAR

and V

= 2 x V

= V

must always be greater than V

RHI

REF

REF

/GAIN

/GAIN

for proper

RLO

operation of the device.

The reference inputs provide a high impedance dynamic

load similar to the analog inputs and the effective input

impedance for the reference inputs can be calculated in the

same manner as it is for the analog input impedance. The

only difference in the calculation is that C

for the reference

IN

inputs is 10.67pF. Therefor, the input impedance range for

the reference inputs is from 149kΩ in a gain of 8 or higher

mode to 833kΩ in the gain of 1 mode.

V

Input

CM

The voltage at the V

input is the voltage that the internal

CM

analog circuitry is referenced to and should always be tied to

the midpoint of the AV

and AVSS supplies. This point

DD

provides a common mode input voltage for the internal operational amplifiers and must be driven from a low noise, low

impedance source if it is not tied to analog ground. Failure to

do so will result in degraded HI7191 performance. It is

recommended that V

operating off of AV

V

also determines the headroom at the upper and lower

CM

be tied to analog ground when

CM

= +5V and AVSS = -5V supplies.

DD

ends of the power supplies which is limited by the common

mode input range where the internal operational amplifiers

remain in the linear, high gain region of operation. The

HI7191 is designed to have a range of AV

AV

- 1.8V. Exceeding this range on the VCM pin will

DD

+1.8V < VCM <

SS

compromise the device performance.

Transducer Burn-Out Current Source

The V

input of the HI7191 contains a 500nA (Typ) current

INHI

source which can be turned on/off via the Control Register.

This current source can be used in checking whether a transducer has burnt-out or become open before attempting to take

measurements on that channel. When the current source is

turned on an additional offset will be created indicating the

presence of a transducer. The current source is controlled by

the BO bit (Bit 4) in the Control Register and is disabled on

power up. See Figure 8 for an applications circuit.

,

1906

Page 11

HI7191

HI7191

AV

DD

RATIOMETRIC

CONFIGURATION

LOAD CELL

FIGURE 7. BURN-OUT CURRENT SOURCE CIRCUIT

CURRENT

SOURCE

V

RHI

V

RLO

V

INHI

V

INLO

AV

SS

Digital Section Description

A block diagram of the digital section of the HI7191 is shown

in Figure 9. This section includes a low pass decimation filter, conversion controller, calibration logic, serial interface,

and clock generator.

MODULATOR

CLOCK

CALIBRATION

DIGITAL

FILTER

MODULATOR OUTPUT

FIGURE 8. DIGITAL SECTION BLOCK DIAGRAM

AND CONTROL

CLOCK

GENERATOR

SERIAL I/O

RESETSYNC

Digital Filtering

One advantage of digital filtering is that it occurs after the

conversion process and can remove noise introduced during

the conversion. It can not, however, remove noise present on

the analog signal prior to the ADC (which an analog filter

can).

One problem with the modulator/digital filter combination is

that excursions outside the full scale range of the device

could cause the modulator and digital filter to saturate. This

device has headroom built in to the modulator and digital filter which tolerates signal deviations up to 33% outside of the

full scale range of the device. If noise spikes can drive the

input signal outside of this extended range, it is recommended that an input analog filter is used or the overall input

signal level is reduced.

OSC

OSC

SDO

SDIO

SCLK

CS

DRDY

Low Pass Decimation Filter

The digital low-pass filter is a Hogenauer (sinc

3

) decimating

filter. This filter was chosen because it is a cost effective low

pass decimating filter that minimizes the need for internal

multipliers and extensive storage and is most effective when

used with high sampling or oversampling rates. Figure 10

shows the frequency characteristics of the filter where f

the -3dB frequency of the input signal and f

programmed notch frequency. The analog modulator sends

a one bit data stream to the filter at a rate of that is

determined by:

f

MODULATOR

f

MODULATOR

= f

/128

OSC

= 78.125kHz for f

OSC

= 10MHz.

The filter then converts the serial modulator data into 40-bit

words for processing by the Hogenauer filter. The data is

decimated in the filter at a rate determined by the CODE

word FP10-FP0 (programed by the user into the Control

Register) and the external clock rate. The equation is:

f

= f

NOTCH

/(512 x CODE).

OSC

The Control Register has 11 bits that select the filter cutoff

frequency and the first notch of the filter. The output data

update rate is equal to the notch frequency. The notch frequency sets the Nyquist sampling rate of the device while

the -3dB point of the filter determines the frequency spectrum of interest (f

through 2047 where 10 yields a 1.953kHz Nyquist rate.

2

1

The Hogenauer filter contains alias components that reflect

). The FP bits have a usable range of 10

S

around the notch frequency. If the spectrum of the frequency

of interest reaches the alias component, the data has been

aliased and therefore undersampled.

Filter Characteristics

Please note: We have recently discovered a performance

anomaly with the HI7191. The problem occurs when the

digital code for the notch filter is programmed within

certain frequencies. We believe the error is caused by

the calibration logic and the digital notch code NOT the

absolute frequency. The error is seen when the user

applies mid-scale (0V input, Bipolar mode). With this

input, the expected digital output should be mid-scale

(800000

erroneous negative full scale (000000

). Instead, there is a small probability, of an

h

)output. Refer to

h

Technical Brief TB348 for complete details.

The FP10 to FP0 bits programmed into the Control Register

determine the cutoff (or notch) frequency of the digital filter.

The allowable code range is 00A

. This corresponds to a

H

maximum and minimum cutoff frequency of 1.953kHz and

10Hz, respectively when operating at a clock frequency of

10MHz. If a 1MHz clock is used then the maximum and minimum cutoff frequencies become 195.3kHz and 1Hz, respectively. A plot of the (sinx/x)

3

digital filter characteristics is

shown in Figure 10. This filter provides greater than 120dB

of 50Hz or 60Hz rejection. Changing the clock frequency or

the programming of the FP bits does not change the shape

of the filter characteristics, it merely shifts the notch frequency. This low pass digital filter at the output of the con-

is the

N

is

C

1907

Page 12

HI7191

verter has an accompanying settling time for step inputs just

as a low pass analog filter does. New data takes between 3

and 4 conversion periods to settle and update on the serial

port with a conversion period t

0

-20

-40

-60

-80

AMPLITUDE (dB)

-100

-120

FIGURE 9. LOW PASS FILTER FREQUENCY CHARACTERISTICS

ALIAS BAND

f

C

fN±f

C

f

N

FREQUENCY (Hz)

being equal to 1/fN.

CONV

2f

N

3f

N

4f

N

Input Filtering

The digital filter does not provide rejection at integer multiples of the modulator sampling frequency. This implies that

there are frequency bands where noise passes to the output

without attenuation. For most cases this is not a problem

because the high oversampling rate and noise shaping characteristics of the modulator cause this noise to become a

small portion of the broadband noise which is filtered. However, if an anti-alias filter is necessar y a single pole RC filter

is usually sufficient.

If an input filter is used the user must be careful that the

source impedance of the filter is low enough not to cause

gain errors in the system. The DC input impedance at the

inputs is > 1GΩ but it is a dynamic load that changes with

clock frequency and selected gain. The input sample rate,

also dependent upon clock frequency and gain, determines

the allotted time for the input capacitor to charge. The addition of external components may cause the charge time of

the capacitor to increase beyond the allotted time. The result

of the input not settling to the proper value is a system gain

error which can be eliminated by system calibration of the

HI7191.

Clocking/Oscillators

The master clock into the HI7191 can be supplied by either a

crystal connected between the OSC

and OSC2 pins as

1

shown in Figure 11A or a CMOS compatible clock signal

connected to the OSC

pin as shown in Figure 11B. The

1

input sampling frequency, modulator sampling frequency, filter -3dB frequency, output update rate, and calibration time

are all directly related to the master clock frequency, f

OSC

For example, if a 1MHz clock is used instead of a 10MHz

clock, what is normally a 10Hz conversion rate becomes a

1Hz conversion rate. Lowering the clock frequency will also

lower the amount of current drawn from the power supplies.

Please note that the HI7191 specifications are written for a

10MHz clock only.

10MHz

1617

OSC

1

HI7191

FIGURE 10A.

10MHz

OSC

1

FIGURE 10B.

FIGURE 10. OSCILLATOR CONFIGURATIONS

OSC

CONNECTION

HI7191

2

NO

OSC

1617

2

Operational Modes

The HI7191 contains several operational modes including

calibration modes for cancelling offset and gain errors of

both internal and external circuitry. A calibration routine

should be initiated whenever there is a change in the ambient operating temperature or supply voltage. Calibration

should also be initiated if there is a change in the gain, filter

notch, bipolar, or unipolar input range. Non-calibrated data

can be obtained from the device by writing 000000 to the

Offset Calibration Register, 800000 (h) to the Positive Full

Scale Calibration Register, and 800000 (h) to the Negative

Full Scale Calibration Register. This sets the offset

correction factor to 0 and both the positive and negative gain

slope factors to 1.

The HI7191 offers several different modes of Self-Calibration

and System Calibration. For calibration to occur, the on-chip

microcontroller must convert the modulator output for three

different input conditions - “zero-scale,” “positive full scale,”

and “negative full scale”. With these readings, the HI7191

can null any offset errors and calculate the gain slope factor

for the transfer function of the converter. It is imperative that

the zero-scale calibration be performed before either of the

gain calibrations. However, the order of the gain calibrations

is not important.

The calibration modes are user selectable in the Control

Register by using the MD bits (MD2-MD0) as shown in

Ta bl e 6 .

DRDY will go low indicating that the calibration is

complete and there is valid data at the output.

.

1908

Page 13

HI7191

TABLE 4. HI7191 OPERATIONAL MODES

MD2 MD1 MD0 OPERATIONAL MODE

0 0 0 Conversion

0 0 1 Self Calibration (Gain of 1 only)

0 1 0 System Offset Calibration

0 1 1 System Positive Full Scale Calibration

1 0 0 System Negative Full Scale Calibration

1 0 1 System Offset/Internal Gain Calibration

(Gain of 1 only)

1 1 0 System Gain Calibration

1 1 1 Reserved

Conversion Mode

For Conversion Mode operation the HI7191 converts the differential voltage between V

into this mode it takes 3 conversion periods (3 x 1/f

INHI

and V

. From switching

INLO

N

) for

DRDY to go low and new data to be valid. No calibration

coefficients are generated when operating in Conversion

Mode as data is calibrated using the existing calibration

coefficients.

Self-Calibration Mode

Please note: Self-calibration is only valid when operating

in a gain of one. In addition, the offset and gain errors are

not reduced as with the full system calibration.

The Self-Calibration Mode is a three step process that

updates the Offset Calibration Register, the Positive Full

Scale Calibration Register, and the Negative Full Scale Calibration Register. In this mode an internal offset calibration is

done by disconnecting the external inputs and shorting the

inputs of the PGIA together. After 3 conversion periods the

Offset Calibration Register is updated with the value that

corrects any internal offset errors.

After the offset calibration is completed the Positive and

Negative Full Scale Calibration Registers are updated. The

inputs V

INHI

and V

are disconnected and the external

INLO

reference is applied across the modulator inputs. The

HI7191 then takes 3 conversion cycles to sample the data

and update the Positive Full Scale Calibration Register. Next

the polarity of the reference voltage across the modulator

input terminals is reversed and after 3 conversion cycles the

Negative Full Scale Calibration Register is updated. The

values stored in the Positive and Negative Full Scale

Calibration Registers correct for any internal gain errors in

the A/D transfer function. After 3 more conversion cycles the

DRDY line will activate signaling that the calibration is complete and valid data is present in the Data Output Register.

System Offset Calibration Mode

The System Offset Calibration Mode is a single step process

that allows the user to lump offset errors of external circuitry

and the internal errors of the HI7191 together and null them

out. This mode will convert the external differential signal

applied to the V

set Calibration Register.

inputs and then store that value in the Off-

IN

The user must apply the zero point

or offset voltage to the HI7191 analog inputs and allow the

signal to settle before selecting this mode.

sion periods the

DRDY line will activate signaling that the

After 4 conver-

calibration is complete and valid data is present in the Data

Output Register.

System Positive Full Scale Calibration Mode

The System Positive Full Scale Calibration Mode is a single

step process that allows the user to lump gain errors of

external circuitry and the internal errors of the HI7191

together and null them out. This mode will convert the external differential signal applied to the V

inputs and stores the

IN

converted value in the Positive Full Scale Calibration Register.

The user must apply the +Full Scale voltage to the

HI7191 analog inputs and allow the signal to settle before

selecting this mode.

After 4 conversion periods the DRDY

line will activate signaling the calibration is complete and

valid data is present in the Data Output Register.

System Negative Full Scale Calibration Mode

The System Negative Full Scale Calibration Mode is a

single-step process that allows the user to lump gain errors

of external circuitry and the internal errors of the HI7191

together and null them out. This mode will convert the external differential signal applied to the V

inputs and stores the

IN

converted value in the Negative Full Scale Calibration Register.

The user must apply the -Full Scale voltage to the

HI7191 analog inputs and allow the signal to settle before

selecting this mode.

After 4 conversion periods the DRDY

line will activate signaling the calibration is complete and

valid data is present in the Data Output Register.

System Offset/Internal Gain Calibration Mode

Please note: System Offset/Internal Gain is only valid

when operating in a gain of one. In addition, the offset and

gain errors are not reduced as with the full system calibration.

The System Offset/Internal Gain Calibration Mode is a single

step process that updates the Offset Calibration Register,

the Positive Full Scale Calibr ation Register, and the Negative

Full Scale Calibration Register. First the external differential

signal applied to the V

stored in the Offset Calibration Register.

inputs is converted and that value is

IN

The user must

apply the zero point or offset voltage to the HI7191 analog

inputs and allow the signal to settle before selecting this

mode.

After this is completed the Positive and Negative Full Scale

Calibration Registers are updated. The inputs V

INHI

and V

INLO

are disconnected and the external reference is switched in. The

HI7191 then takes 3 conversion cycles to sample the data and

update the Positive Full Scale Calibration Register. Next the

polarity of the reference voltage across the V

INHI

and V

INLO

terminals is reversed and after 3 conversion cycles the

Negative Full Calibration Register is updated. The values

stored in the Positive and Negative Full Scale Calibration

Registers correct for any internal gain errors in the A/D transfer

function. After 3 more conversion cycles, the DRDY line will

activate signaling that the calibration is complete and valid data

is present in the Data Output Register.

1909

Page 14

HI7191

System Gain Calibration Mode

The Gain Calibration Mode is a single step process that

updates the Positive and Negative Full Scale Calibration Registers. This mode will convert the external differential signal

applied to the V

inputs and then store that value in the Nega-

IN

tive Full Scale Calibration Register. Then the polarity of the

input is reversed internally and another conversion is performed. This conversion result is written to the Positive Full

Scale Calibration Register. The user must apply the +Full

Scale voltage to the HI7191 analog inputs and allow the signal

to settle before selecting this mode. After 1 more conversion

period the

DRDY line will activate signaling the calibration is

complete and valid data is present in the data output register.

Reserved

This mode is not used in the HI7191 and should not be

selected. There is no internal detection logic to keep this

condition from being selected and care should be taken not

to assert this bit combination.

Offset and Span Limits

There are limits to the amount of offset and gain which can

be adjusted out for the HI7191. For both bipolar and unipolar

modes the minimum and maximum input spans are

0.2xV

/GAIN and 1.2 x V

REF

/GAIN respectively.

REF

In the unipolar mode the offset plus the span cannot exceed

the 1.2 x V

value of 0.2 x V

V

/ GAIN. In bipolar mode the span is equidistant around

REF

/ GAIN limit. So, if the span is at its minimum

REF

/ GAIN, the offset must be less than 1 x

REF

the voltage used for the zero scale point. For this mode the

offset plus half the span cannot exceed 1.2 x V

the span is at ±0.2 x V

greater than ±2 x V

REF

/ GAIN, then the offset can not be

REF

/GAIN.

REF

/GAIN. If

Serial Interface

The HI7191 has a flexible, synchronous serial communication

port to allow easy interfacing to many industry standard microcontrollers and microprocessors. The serial I/O is compatible

with most synchronous transfer formats, including both the

Motorola 6805/11 SPI and Intel 8051 SSR protocols. The

Serial Interface is a flexible 2-wire or 3-wire hardw are interface

where the HI7191 can be configured to read and write on a

single bidirectional line (SDIO) or configured for writing on

SDIO and reading on the SDO line.

The interface is byte organized with each register byte

having a specific address and single or multiple byte transfers are supported. In addition, the interface allows flexibility

as to the byte and bit access order. That is, the user can

specify MSB/LSB first bit positioning and can access bytes

in ascending/descending order from any byte position.

The serial interface allows the user to communicate with 5

registers that control the operation of the device.

Data Output Register - a 24-bit, read only register

containing the conversion results.

Control Register - a 24-bit, read/write register containing

the setup and operating modes of the device.

Offset Calibration Register - a 24-bit, read/write register

used for calibrating the zero point of the converter or system.

Positive Full Scale Calibration Register - a 24-bit,

read/write register used for calibrating the Positive Full Scale

point of the converter or system.

Negative Full Scale Calibration Register - a 24-bit,

read/write register used for calibrating the Negative Full

Scale point of the converter or system.

Two clock modes are supported. The HI7191 can accept the

serial interface clock (SCLK) as an input from the system or

generate the SCLK signal as an output. If the MODE pin is

logic low the HI7191 is in external clocking mode and the

SCLK pin is configured as an input. In this mode the user

supplies the serial interface clock and all interface timing

specifications are synchronous to this input. If the MODE pin

is logic high the HI7191 is in self-clocking mode and the

SCLK pin is configured as an output. In self-clocking mode,

SCLK runs at F

= OSC1/8 and stalls high at byte

SCLK

boundaries. SCLK does NOT have the capability to stall low

in this mode. All interface timing specifications are

synchronous to the SCLK output.

Normal operation in self-clocking mode is as follows (See

Figure 13):

first SCLK transition output is delayed 29 OSC

the next rising OSC

stalls high for 28 OSC

CS is sampled low on falling OSC1 edges. The

cycles from

. SCLK transitions eight times and then

1

cycles. After this stall period is com-

1

1

pleted SCLK will again transition eight times and stall high.

This sequence will repeat continuously while

The extra OSC

cycle required when coming out of the CS

1

CS is active.

inactive state is a one clock cycle latency required to properly sample the

boundaries is 28 OSC

rising edge stall period of 32 OSC

The affects of

CS input. Note that the normal stall at byte

cycles thus giving a SCLK rising to

1

cycles.

1

CS on the I/O are different for self-clocking

mode (MODE = 1) than for external mode (MODE = 0). For

external clocking mode

CS inactive disables the I/O state

machine, effectively freezing the state of the I/O cycle. That

is, an I/O cycle can be interrupted using chip select and the

HI7191 will continue with that I/O cycle when re-enabled via

CS. SCLK can continue toggling while CS is inactive. If CS

goes inactive during an I/O cycle, it is up to the user to

ensure that the state of SCLK is identical when reactivating

CS as to what it was when CS went inactive. For read operations in external clocking mode, the output will go three-state

immediately upon deactivation of

CS.

For self-clocking mode (MODE = 1), the affects of CS are

different. If CS transitions high (inactive) during the period

when data is being transferred (any non stall time) the HI7191

will complete the data transfer to the byte boundary. That is,

once SCLK begins the eight transition sequence, it will always

complete the eight cycles. If CS remains inactive after the byte

has been transferred it will be sampled and SCLK will remain

stalled high indefinitely . If CS has returned to active lo w bef ore

the data byte transfer period is completed the HI7191 acts as

if CS was active during the entire transfer period.

1910

Page 15

HI7191

It is important to realize that the user can interrupt a data

transfer on byte boundaries. That is, if the Instruction Register calls for a 3 byte transf er and

CS is inactive after only one

byte has been transferred, the HI7191, when reactiv ated, will

continue with the remaining two bytes before looking for the

next Instruction Register write cycle.

Note that the outputs will NOT go three-state immediately upon

CS inactive for read operations in self-clocking mode. In the

case of CS going inactive during a read cycle the outputs

remain driving until after the last data bit is transferred. In the

case of CS inactive during the clock stall time it takes 1 OSC

cycle plus prop delay (Max) for the outputs to be disab led.

I/O Port Pin Descriptions

The serial I/O port is a bidirectional por t which is used to

read the data register and read or write the control register

and calibration registers. The port contains two data lines, a

synchronous clock, and a status flag. Figure 12 shows a

diagram of the serial interface lines.

DATA OUT

BIDIRECTIONAL DATA

PORT CLOCK

CHIP SELECT

DEVICE STATUS

SDO

SDIO

SCLK

CS

DRDY

MODECLOCK MODE

HI7191

CS - Chip select. This signal is an active low input that

allows more than one device on the same serial communication lines. The SDO and SDIO will go to a high impedance

state when this signal is high. If driven high during any

communication cycle, that cycle will be suspended until

reactivation. Chip select can be tied low in systems that

maintain control of SCLK.

DRDY - Data Ready. This is an output status flag from the

device to signal that the Data Output Register has been

updated with the new conversion result. DRDY is useful as an

edge or level sensitive interrupt signal to a microprocessor or

1

microcontroller. DRDY low indicates that new data is available

at the Data Output Register. DRDY will return high upon

completion of a complete Data Output Register read cycle.

MODE - Mode. This input is used to select between Synchronous Self Clocking Mode (‘1’) or the Synchronous External

Clocking Mode (‘0’). When this pin is tied to V

the serial

DD

port is configured in the Synchronous Self Clocking mode

where the synchronous shift clock (SCLK) for the serial port is

generated by the HI7191 and has a frequency of OSC

When the pin is tied to DGND the serial port is configured for

the Synchronous External Clocking Mode where the synchronous shift clock for the serial port is generated by an external

device up to a maximum frequency of 5MHz.

Programming the Serial Interface

CS

1

/8.

FIGURE 11. HI7191 SERIAL INTERFACE

SDO - Serial Data out. Data is read from this line using those

protocols with separate lines for transmitting and receiving

data. An example of such a standard is the Motorola Serial

Peripheral Interface (SPI) using the 68HC05 and 68HC11

family of microcontrollers, or other similar processors. In the

case of using bidirectional data transfer on SDIO, SDO does

not output data and is set in a high impedance state.

SDIO - Serial Data in or out. Data is always written to the

device on this line. However, this line can be used as a bidirectional data line. This is done by properly setting up the

Control Register. Bidirectional data transfer on this line can

be used with Intel standard serial interfaces (SSR, Mode 0)

in MCS51 and MCS96 family of microcontrollers, or other

similar processors.

SCLK - Serial clock. The serial clock pin is used to synchronize data to and from the HI7191 and to run the port state

machines. In Synchronous External Clock Mode, SCLK is

configured as an input, is supplied by the user, and can run

up to a 5MHz rate. In Synchronous Self Clocking Mode,

SCLK is configured as an output and runs at OSC

29 33 37 41

OSC

1

/8.

1

It is useful to think of the HI7191 interface in terms of

communication cycles. Each communication cycle happens

in 2 phases. The first phase of every communication cycle

is the writing of an instruction byte. The second phase is

the data transfer as described by the instruction byte. It is

important to note that phase 2 of the communication cycle

can be a single byte or a multi-byte transfer of data. For

example, the 3-byte Data Output Register can be read

using one multi-byte communication cycle rather than three

single-byte communication cycles. It is up to the user to

maintain synchronism with respect to data transfers. If the

system processor “gets lost” the only way to recover is to

reset the HI7191. Figure 14 shows both a 2-wire and a

3-wire data transfer.

Several for mats are available for reading from and writing to

the HI7191 registers in both the 2-wire and 3-wire protocols.

A portion of these formats is controlled by the CR<2:1> (BD

and

MSB) bits which control the byte direction and bit order

of a data transfer respectively. These two bits can be written

in any combination but only the two most useful will be discussed here.

45

89

121 125

CS

SCLK

FIGURE 12. SCLK OUTPUT IN SELF-CLOCKING MODE

1911

Page 16

HI7191

The first combination is to reset both the BD and MSB bits

(BD = 0, MSB = 0). This sets up the interface for descending

byte order and MSB first format. When this combination is

used the user should always write the Instruction Register

such that the starting byte is the most significant byte address.

For example, read three b ytes of DR starting with the most significant byte. The first byte read will be the most significant in

MSB to LSB format. The next byte will be the next least significant (recall descending byte order) again in MSB to LSB order.

The last byte will be the next lesser significant byte in MSB to

LSB order. The entire word was read MSB to LSB f ormat.

The second combination is to set both the BD and

MSB bits to

1. This sets up the interface for ascending b yte order and LSB

first format. When this combination is used the user should

always write the Instruction Register such that the starting

byte is the least significant byte address. For example, read

three bytes of DR starting with the least significant byte. The

first byte read will be the least significant in LSB to MSB format. The next byte will be the next greater significant (recall

ascending byte order) again in LSB to MSB order. The last

byte will be the next greater significant byte in LSB to MSB

order.

The entire word was read MSB to LSB format.

After completion of each communication cycle, The HI7191

interface enters a standby mode while waiting to receive a

new instruction byte.

Instruction Byte Phase

The instruction byte phase initiates a data transfer

sequence. The processor writes an 8-bit byte (Instruction

Byte) to the Instruction Register. The instruction byte informs

the HI7191 about the Data transfer phase activities and

includes the following information:

- Read or Write cycle

- Number of Bytes to be transferred

- Which register and starting byte to be accessed

Data Transfer Phase

In the data transfer phase, data transfer takes place as set

by the Instruction Register contents. See Write Operation

and Read Operation sections for detailed descriptions.

Instruction Register

The Instruction Register is an 8-bit register which is used

during a communications cycle for setting up read/write

operations.

INSTRUCTION REGISTER

MSB654321LSB

R/W MB1 MB0 FSC A3 A2 A1 A0

CS

INSTRUCTION

BYTE

SDIO

INSTRUCTION

CYCLE

FIGURE 13A. 2-WIRE, 3-BYTE READ OR WRITE TRANSFER

CS

INSTRUCTION

BYTE

SDIO

INSTRUCTION

SDO

CYCLE

FIGURE 13B. 3-WIRE, 3-BYTE READ TRANSFER

DATA

BYTE 1

DAT A

BYTE 1

DAT A

BYTE 2

DATA TRANSFER

DAT A

BYTE 2

DATA TRANSFER

DAT A

BYTE 3

DAT A

BYTE 3

R/W - Bit 7 of the Instruction Register determines whether a

read or write operation will be done following the instruction

byte load. 0 = READ, 1 = WRITE.

MB1, MB0 - Bits 6 and 5 of the Instruction Register determine the number of bytes that will be accessed following the

instruction byte load. See Table 5 for the number of bytes to

transfer in the transfer cycle.

TABLE 5. MULTIPLE BYTE ACCESS BITS

MB1 MB0 DESCRIPTION

0 0 Transfer 1 Byte

0 1 Transfer 2 Bytes

1 0 Transfer 3 Bytes

1 1 Transfer 4 Bytes

FSC - Bit 4 is used to determine whether a Positive Full

Scale Calibration Register I/O transfer (FSC = 0) or a Negative Full Scale Calibration Register I/O transfer (FSC = 1) is

being performed (see Table 6).

A3, A2, A1, A0 - Bits 3 and 2 (A3 and A2) of the Instruction

Register determine which internal register will be accessed

while bits 1 and 0 (A1 and A0) determine which byte of that

register will be accessed first. See Table 6 for the address

decode.

1912

Page 17

HI7191

TABLE 6. INTERNAL DATA ACCESS DECODE STARTING BYTE

FSC A3 A2 A1 A0 DESCRIPTION

X0000Data Output Register, Byte 0

X0001Data Output Register, Byte 1

X0010Data Output Register, Byte 2

X0100Control Register, Byte 0

X0101Control Register, Byte 1

X0110Control Register, Byte 2

X1000Offset Cal Register, Byte 0

X1001Offset Cal Register, Byte 1

X1010Offset Cal Register, Byte 2

0 1100Positive Full Scale Cal Register, Byte 0

0 1101Positive Full Scale Cal Register, Byte 1

0 1110Positive Full Scale Cal Register, Byte 2

1 1100Negative Full Scale Cal Register, Byte 0

1 1101Negative Full Scale Cal Register, Byte 1

1 1110Negative Full Scale Cal Register, Byte 2

Write Operation

Data can be written to the Control Register, Offset Calibration Register, Positive Full Scale Calibration Register, and

the Negative Full Scale Calibration Register. Write operations are done using the SDIO,

CS and SCLK lines only, as

all data is written into the HI7191 via the SDIO line even

when using the 3-wire configuration. Figures 15 and 16

show typical write timing diagrams.

The communication cycle is started by asserting the

CS line

low and starting the clock from its idle state. To assert a write

cycle, during the instruction phase of the communication

cycle, the Instruction Byte should be set to a write transfer

(

R/W = 1).

When writing to the serial port, data is latched into the

HI7191 on the rising edge of SCLK. Data can then be

changed on the falling edge of SCLK. Data can also be

changed on the rising edge of SCLK due to the 0ns hold

time required on the data. This is useful in pipelined applications where the data is latched on the rising edge of the

clock.

The communication cycle is started by asserting the CS line

and starting the clock from its idle state. To asser t a read

cycle, during the instruction phase of the communication

cycle, the Instruction Byte should be set to a read transfer

(

R/W = 0).

When reading the serial port, data is driven out of the

HI7191 on the falling edge of SCLK. Data can be registered

externally on the next rising edge of SCLK.

Read Operation - 2-Wire Transfer

Data can be read from the Data Output Register, Control

Register, Offset Calibration Register, Positive Full Scale Calibration Register, and the Negative Full Scale Calibration

Register. When configured in two-wire transfer mode, read

operations are done using the SDIO,

CS and SCLK lines. All

data is read via the SDIO line. Figures 19 and 20 show

typical 2-wire read timing diagrams.

The communication cycle is started by asserting the CS line

and starting the clock from its idle state. To assert a read cycle,

during the instruction phase of the communication cycle, the

Instruction Byte should be set to a read transfer (R/W = 0).

When reading the serial port, data is driven out of the

HI7191 on the falling edge of SCLK. Data can be registered

externally on the next rising edge of SCLK.

Detailed Register Descriptions

Data Output Register

The Data Output Register contains 24 bits of converted data.

This register is a read only register.

BYTE 2

MSB 22 21 20 19 18 17 16

D23 D22 D21 D20 D19 D18 D17 D16

BYTE 1

15 14 13 12 11 10 9 8

D15 D14 D13 D12 D11 D10 D9 D8

BYTE 0

7654321LSB

D7 D6 D5 D4 D3 D2 D1 D0

Read Operation - 3-Wire Transfer

Data can be read from the Data Output Register, Control

Register, Offset Calibration Register, Positive Full Scale

Calibration Register, and the Negative Full Scale Calibration

Register. When configured in 3-wire transfer mode, read

operations are done using the SDIO, SDO,

CS and SCLK

lines. All data is read via the SDO line. Figures 17 and 18

show typical 3-wire read timing diagrams.

1913

Page 18

HI7191

CS

SCLK

SDIO

SDO

CS

SCLK

DIO

SDO

SCLK

IR WRITE PHASE DATA TRANSFER PHASE - TWO-BYTE WRITE

I0 I1 I2 I3 I4 I5 I6 I7 B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14 B15

THREE-STATETHREE-STATE

FIGURE 14. DATA WRITE CYCLE, SCLK IDLE LOW

IR WRITE PHASE DATA TRANSFER PHASE - TWO-BYTE WRITE

I0 I1 I2 I3 I4 I5 I6 I7

THREE-STATE

B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14

THREE-STATE

FIGURE 15. DATA WRITE CYCLE, SCLK IDLE HIGH

CS

IR WRITE PHASE

DATA TRANSFER PHASE - TWO-BYTE READ

B15

SDIO

SDO

I0 I1 I2 I3 I4 I5 I6 I7

B1 B2 B3 B4 B5

B0

B6 B7

B8

B9 B10 B11 B12 B13 B14

FIGURE 16. DATA READ CYCLE, 3-WIRE CONFIGURATION, SCLK IDLE LOW

CS

SCLK

SDIO

SDO

IR WRITE PHASE DATA TRANSFER PHASE - TWO-BYTE READ

I0 I1 I2 I3 I4 I5 I6 I7

B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14

FIGURE 17. DATA READ CYCLE, 3-WIRE CONFIGURATION, SCLK IDLE HIGH

CS

SCLK

I0 I1 I2 I3 I4 I5 I6 I7 B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14

SDIO

IR WRITE PHASE DATA TRANSFER PHASE - TWO-BYTE READ

B15

B15

B15

SDO

THREE-STATETHREE-STATE

FIGURE 18. DATA READ CYCLE, 2-WIRE CONFIGURATION, SCLK IDLE LOW

1914

Page 19

HI7191

CS

SCLK

SDIO

SDO

IR WRITE PHASE DATA TRANSFER PHASE - TWO-BYTE READ

I0 I1 I2 I3 I4 I5 I6 I7 B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14

FIGURE 19. DATA READ CYCLE, 2-WIRE CONFIGURATION, SCLK IDLE HIGH

Control Register

The Control Register contains 24-bits to control the various

sections of the HI7191. This register is a read/write

register.

BYTE 2

MSB 22 21 20 19 18 17 16

DC FP10 FP9 FP8 FP7 FP6 FP5 FP4

BYTE 1

15 14 13 12 11 10 9 8

FP3 FP2 FP1 FP0 MD2 MD1 MD0 B/U

BYTE 0

7654321LSB

G2 G1 G0 BO SB BD MSB SDL

DC - Bit 23 is the Data Coding Bit used to select between

two’s complementary and offset binary data coding. When

this bit is set (DC = 1) the data in the Data Output Register

will be two’s complement. When cleared (DC = 0) this data

will be offset binary. When operating in the unipolar mode

the output data is available in straight binary only (the DC bit

is ignored). This bit is cleared after a

RESET is applied to

the part.

FP10 through FP0 - Bits 22 through 12 are the Filter pro-

gramming bits that determine the frequency response of the

digital filter. These bits determine the filter cutoff frequency,

the position of the first notch and the data rate of the HI7191.

The first notch of the filter is equal to the decimation rate and

can be determined by the formula:

f

= f

NOTCH

/(512 x CODE)

OSC

where CODE is the decimal equivalent of the value in FP10

through FP0. The values that can be programmed into these

bits are 10 to 2047 decimal, which allows a conversion rate

range of 9.54Hz to 1.953kHz when using a 10MHz clock.

Changing the filter notch frequency, as well as the selected

gain, impacts resolution. The output data rate (or effective

conversion time) for the device is equal to the frequency

selected for the first notch to the filter. For example, if the first

notch of the filter is selected at 50Hz then a new word is available at a 50Hz rate or every 20ms. If the first notch is at 1kHz

a new word is available every 1ms.

B15

THREE-STATETHREE-STATE

The settling-time of the converter to a full scale step input

change is between 3 and 4 times the data rate. For example,

with the first filter notch at 50Hz, the worst case settling time to

a full scale step input change is 80ms. If the first notch is 1kHz,

the settling time to a full scale input step is 4ms maximum.

The -3dB frequency is determined by the programmed first

notch frequency according to the relationship:

f

-3dB

= 0.262 x f

NOTCH

.

MD2 through MD0 - Bits 11 through 9 are the Operational

Modes of the converter. See Table 4 for the Operational

Modes description. After a

RESET is applied to the part these