HI5634

PRELIMINARY

Data Sheet May 1999

High Performance Programmable

Phase-Locked Loop for LCD Applications

The HI5634 is a low cost but very high-performance

frequency generator for line-locked and genlocked high

resolution video applications. Utilizing an advanced low

voltage CMOS mixed signal technology, the HI5634 is an

effective clock solution for video projectors and displays at

resolutions from VGA to beyond UXGA

The HI5634 offers pixel clock outputs in both differential (to

250MHz) and single-ended (to 150MHz) formats. Digital

phase adjustment circuitry allows user control of the pixel

clock phase relative to the recovered sync signal. A second

differential output at half the pixel clock rate enables

deMUXing of multiplexed A/D converters. The FUNC pin

provides either the regenerated input from the phase-locked

loop (PLL) divider chain output or a re-synchronized and

sharpened input HSYNC.

The advanced PLL utilizes either its internal programmable

feedback divider or an external divider. The device is

programmed by a standard I

2

C-bus® serial interface.

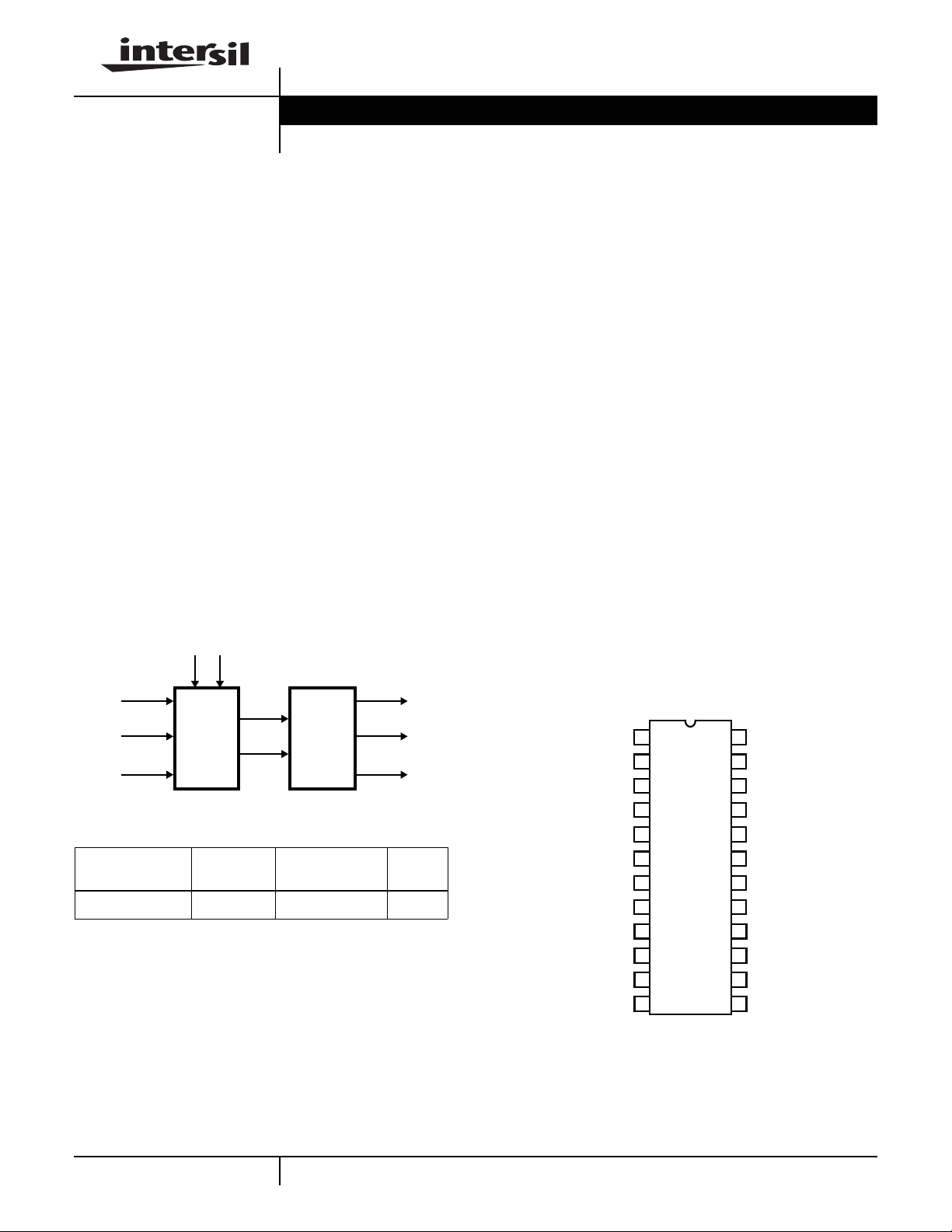

Simplified Block Diagram

File Number

Features

• Pixel Clock Frequencies up to 250MHz

• Very Low Jitter

• Digital Phase Adjustment (DPA) for Clock Outputs

• Balanced PECL Differential Outputs

• Single-Ended SSTL_3 Clock Outputs

• Double-Buffered PLL/DPA Control Registers

• Independent Software Reset for PLL/DPA

• External or Internal Loop Filter Selection

• Uses 3.3V Supply. Inputs are 5V Tolerant.

2

C-bus Serial Interface can Run at Either Low Speed

•I

(100kHz) or High Speed (400kHz)

• Lock Detection

Applications

• LCD Monitors and Video Projectors

• Genlocking Multiple Video Subsystems

• Frequency Synthesis

4745

LOOP FILTER

OSC

HSYNC

2

I

C INTERFACE

PHASE

LOCKED

LOOP

DIGITAL

PHASE

ADJUST

Ordering Information

TEMP.

PART NUMBER

HI5634CB 0 to 70 24 Ld SOIC M24.3

RANGE (oC) PACKAGE

PKG.

CLK

CLK/2

FUNC

NO.

Pinout

VDDD

VSSD

SDA

SCL

PDEN

EXTFB

HSYNC

EXTFIL

EXTFILRET

VDDA

VSSA

OSC

1

2

3

4

5

6

7

8

9

10

11

12

HI5634

(SOIC)

TOP VIEW

24

IREF

23

CLK/2+ (PECL)

22

CLK/2- (PECL)

21

CLK+ (PECL)

20

CLK- (PECL)

19

VSSQ

18

VDDQ

17

CLK (SSTL)

16

CLK/2 (SSTL)

15

FUNC (SSTL)

14

LOCK/REF (SSTL)

2

CADR

13

I

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

I2C Bus is a Trademark of Philips Corporation.

| Copyright © Intersil Corporation 1999

HI5634

Pin Descriptions

PIN NO. PIN NAME TYPE DESCRIPTION COMMENTS

1 VDDD PWR Digital Supply 3.3V to Digital Sections

2 VSSD PWR Digital Ground

3 SDA IN/OUT Serial Data I2C-Bus (Note 1)

4 SCL IN Serial Clock I2C-Bus (Note 1)

5 PDEN IN PFD Enable Suspends Charge Pump (Note1)

6 EXTFB IN External Feedback In External Divider Input to PFD (Note1)

7 HSYNC IN Horizontal Sync Clock Input to PLL (Note1)

8 EXTFIL IN External Filter External PLL Loop Filter

9 EXTFILRET IN External Filter Return External PLL Loop Filter Return

10 VDDA PWR Analog Supply 3.3V for Analog Circuitry

11 VSSA PWR Analog Ground Ground for Analog Circuitry

12 OSC IN Oscillator Input From Crystal Oscillator Package (Notes 1, 2)

13 I2CADR IN I2C Address Chip I2C Address Select

Low = 4Dh Read, 4Ch Write

High = 4Fh Read, 4Eh Write

14 LOCK/REF (SSTL) OUT Lock Indicator/Reference Displays PLL or DPA Lock or REF Input

15 FUNC (SSTL) OUT Function Output SSTL_3 Selectable HSYNC Output

16 CLK/2 (SSTL) OUT Pixel Clock/2 Out SSTL_3 Driver to ADC DeMUX Input

17 CLK (SSTL) OUT Pixel Clock Out SSTL_3 Driver to ADC

18 VDDQ PWR Output Driver Supply 3.3V to Output Drivers

19 VSSQ PWR Output Driver Ground Ground for Output Drivers

20 CLK- (PECL) OUT Pixel Clock Out Inverted PECL Driver to ADC. Open Drain Output.

21 CLK+ (PECL) OUT Pixel Clock Out PECL Driver to ADC. Open Drain Output.

22 CLK/2- (PECL) OUT Pixel Clock/2 Out Inverted PECLDriverto ADC DeMUXInput.Open Drain

Output.

23 CLK/2+ (PECL) OUT Pixel Clock/2 Out PECL Driver to ADC DeMUX Input. Open DrainOutput.

24 IREF IN Reference Current Reference Current for PECL Outputs

NOTES:

1. These LVTTL inputs are 5V tolerant.

2. Connect to ground if unused.

2

Block Diagram

HI5634

EN_DLS

REG 0[7]

EXTFIL (8) XFILRET (9)

EN_PLS

REG 0[6]

IREF (24)

BIAS

PECL

VCO

FILTER

SELECT

PUMP

CHARGE

PSD

FIL_SEL

REG 4[7]

OUT_SCL

REG 6[6-7]

REG 1[4-5]

POST

DIVIDER

SCALER

INT FILTER

OE_TCK

CLK (17)

OUTPUT

SCALER

REG 6[1]

CLK+ (21)

+

OE_PCK

REG 6[0]

CLK- (20)

OE_T2

REG 6[3]

CLK/2 (16)

PHASE

DIGITAL

OE_P2

REG 6[2]

CLK/2+ (23)

CLK/2- (22)

+

ADJUST

OE_F

REG 6[4]

FUNC (15)

PDEN (5)

OSC_DIV

REG 7[0-6]

LOCK

LOCK/REF (14)

PDEN

REG 0[0]

PD_POL

REG 0[1]

OSC

DIVIDER

OSC (12)

LOGIC

REG 0[2]

REF_POL

1

FREQ

PHASE/

MUX

0

HSYNC (7)

DETECTOR

IN_SEL

PLL_LOCK

PFD

REG 7[7]

FBK_SEL

REG 12[1]

DPA_LOCK

REG 1[0-2]

REG 0[3]

FBK_POL

REG 0[4]

REG 12[0]

MUX

1

0

EXTFB (6)

FEEDBACK

DIVIDER

FBD1

REG 3[0-3]

FBD0

REG 2[0-7]

DPA_OS

C

2

I

SDA (3)

DPA_RES

REG 4[0-5]

REG 5[0-1]

INTERFACE

SCL (4)

CADR (13)

2

I

CK2_INV

REG 6[5]

POWER

1

ON

MUX

0

RESET

REG 0[5]

FUNC_SEL

3

HI5634

Absolute Maximum Ratings Thermal Information

VDDA, VDDD, VDDQ (Measured to VSS) . . . . . . . . . . . . . . . . . 4.3V

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . .VSSD -0.3V to +5.5V

Analog Outputs . . . . . . . . . . . . . . . . . . VSSA -0.3V to VDDA +0.3V

Digital Pouts. . . . . . . . . . . . . . . . . . . . . VSSQ -0.3V to VDDQ +0.3V

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7). . . >2kV

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . 0oC to 70oC

Voltage Range (VDDA, VDDD, VDDQ to VSS) . . . . . . 3.0V to 3.6V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

3. θJA is measured with the component mounted on an evaluation PC board in free air.

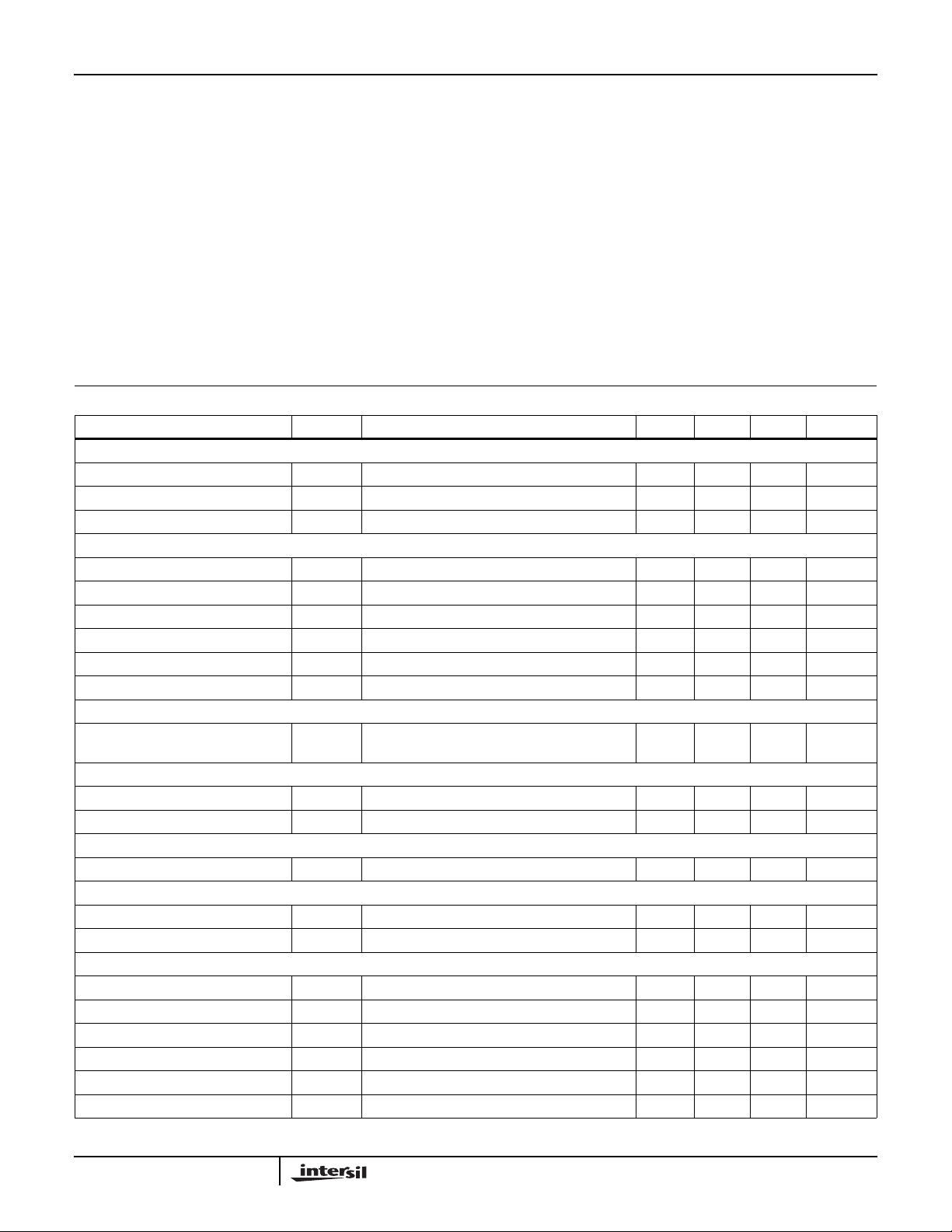

Electrical Specifications Per Operating Conditions Listed Above, Unless Otherwise Specified

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

DC SUPPLY CURRENT

Supply Current, Digital IDDD VDDD = 3.6V - - 25 mA

Supply Current, Output Drivers IDDQ VDDQ = 3.6V, No Output Drivers Enabled - - 6 mA

Supply Current, Analog IDDA VDDA = 3.6V - - 5 mA

DIGITAL INPUTS (SDA, SCL, PDEN, EXTFB, HSYNC, OSC, I

Input High Voltage V

Input Low Voltage V

IH

IL

Input Hysteresis 0.2 - 0.6 V

Input High Current I

Input Low Current I

Input Capacitance C

VIH = VDD - - ±10 µA

IH

VIL = 0 - - ±200 µA

IL

IN

SDA (IN OUTPUT MODE: SDA IS BIDIRECTIONAL)

Output Low Voltage V

OL

I

OUT

Determined by the External Pull-up Resistor.

PECL OUTPUTS (CLK+, CLK-, CLK/2+, CLK/2-)

Output High Voltage V

Output Low Voltage (Note 4) V

OHIOUT

I

OL

OUT

SSTL_3 OUTPUTS (CLK, CLK/2, FUNC, LOCK/REF)

Output Resistance R

1 < VO< 2V - - 80 Ω

O

AC INPUT CHARACTERISTICS

HSYNC Input Frequency f

OSC Input Frequency f

HSYNC

OSC

Reg 7[7] = 0 0.008 - 10 MHz

Reg 7[7] = 1 0.02 - 100 MHz

TIMING CHARACTERISTICS (Note 5)

REF Output Transition Times t

PECL CLK Output Transition Times t

SSTL CLK Output Transition Times t

FUNC Output Transition Times t

HSYNC to REF Delay t

REF to PECL Clock Delay t

Rise Time/Fall Time - 2.8/1.8 - ns

r

Rise Time/Fall Time - 1.0/1.2 - ns

P

Rise Time/Fall Time - 1.6/0.7 - ns

S

Rise Time/Fall Time - 1.2/1.0 - ns

F

0

1

2

CADR)

= 3mA. VOH = 6.0V Maximum, as

= 0 - - VDD V

= Programmed Value 1.0 - - V

Thermal Resistance (Typical, Note 3) θJA (oC/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maximum Junction Temperature (Plastic Package) . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 260oC

(SOIC - Lead Tips Only)

2 - 5.5 V

VSS-0.3 - 0.8 V

- - 10 pF

- - 0.4 V

11.3 11.5 12 ns

-1.0 0.8 2.2 ns

4

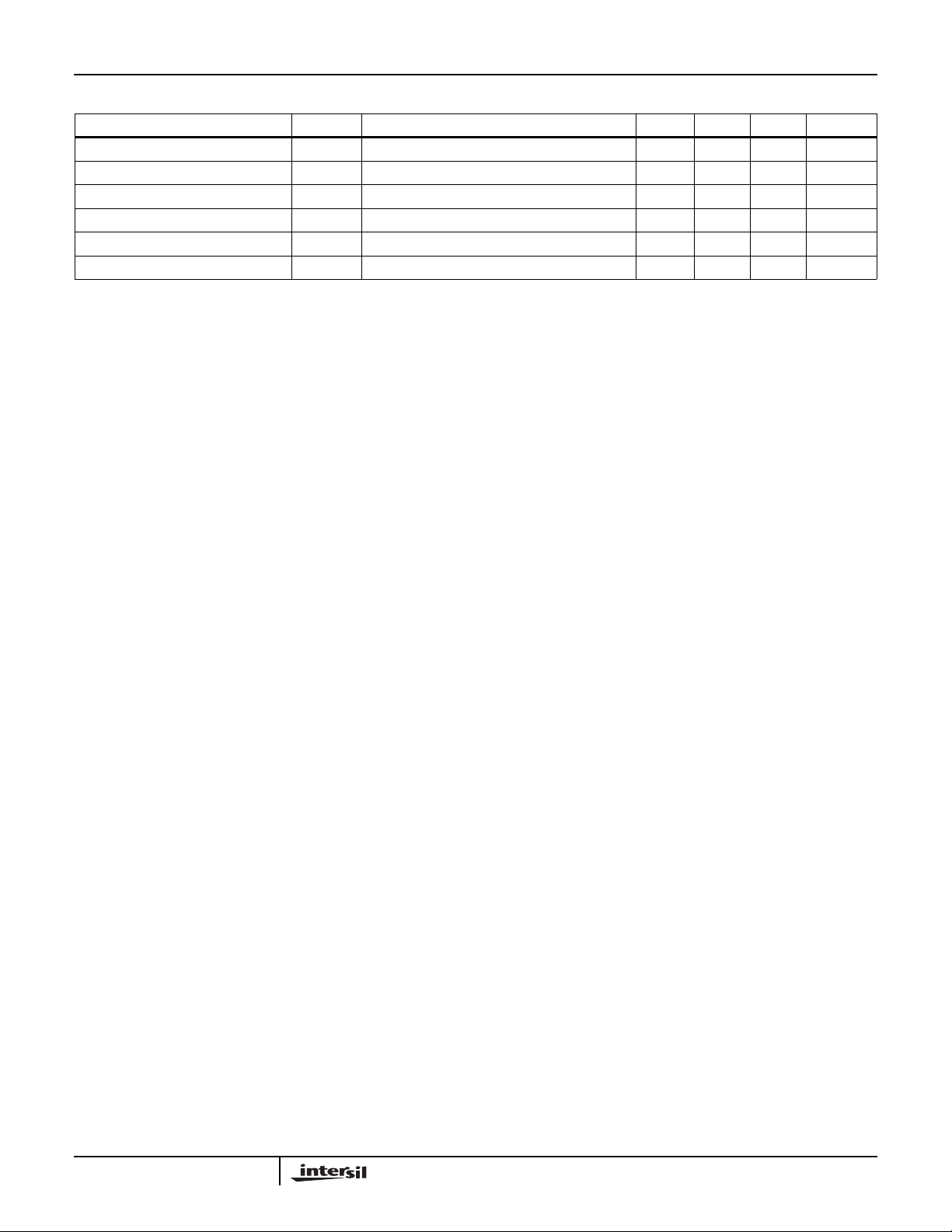

HI5634

Electrical Specifications Per Operating Conditions Listed Above, Unless Otherwise Specified (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

PECL Clock Duty Cycle t2, t

PECL Clock to SSTL Clock Delay t

PECL Clock to FUNC Delay t

PECL Clock to PECL Clock/2 Delay t

PECL Clock to SSTL Clock/2 Delay t

SSTL Clock Duty Cycle t

NOTES:

must not fall below the minimum specified level or the I

4. V

OL

5. Measured at 3.6V 0oC, 135MHzoutput frequency, PECLClock lines to 75Ω termination, SSTL Clock lines unterminated, 20pF load. Transition

times vary based on termination. See the “Output Timing Diagram” for details.

3

4

5

6

7

, t

8

9

value may not be maintained.

OUT

45 50 55 %

0.2 0.75 1.2 ns

1.5 1.9 2.3 ns

1.0 1.3 1.5 ns

1.1 1.4 1.8 ns

45 50 55 %

Application Information

Overview

The HI5634 addresses stringent graphics system line locked

and genlocked applications and provides the clock signals

required by high-performance video A/D converters. Included

are a phase locked loop (PLL) with a 500MHz voltage

controlled oscillator (VCO), a digital phase adjustment to

provide a user programmed pixel cloc k dela y, the means for

deMUXing multiplexed A/D Con v erters, and both balanced

programmable(PECL) and single-ended (SSTL_3)high-speed

clock outputs.

Phase-Locked Loop

The phase-locked loop is optimized for line-locked

applications, forwhich the inputs are horizontal syncsignals.

A high-performance Schmitt trigger preconditions the

HSYNC input, whose pulses can be degraded if they are

from a remote source. This preconditioned HSYNC signal is

provided as a clean reference signal with a short transition

time (in contrast, the signal that a typical PC graphics card

provides has a transition time of tens of nanoseconds).

A second high frequency input such as a crystal oscillator

and a 7-bit programmable divider can be selected. This

selection allows the loop to operate from a local source and

is also useful for evaluating intrinsic jitter.

A 12-bit programmable feedback divider completes the loop.

Designers can substitute an external divider.

Either the conditioned HSYNC input or the loop output

(recovered HSYNC) is available at the FUNC pin, aligned to

the edge of the pixel clock.

Automatic Power-On-Reset Detection

The HI5634has automatic power-on-resetdetection circuitry

and itresets itself if the supplyvoltage drops belowthreshold

values. No external connection to a reset signal is required.

Digital Phase Adjustment

The digital phase adjustment allows addition of a

programmable delay to the pixel clock output, relative to the

recovered HSYNC signal. The ability to add delays is

particularly useful when multiple video sources must be

synchronized. A delay of up to one pixel clock period is

selectable in the following increments:

1/64 period for pixel clock rates to 40MHz

1/32 period for pixel clock rates to 80MHz

1/16 period for pixel clock rates to 160MHz

Output Drivers and Logic Inputs

The HI5634 utilizes low voltage TTL (LVTTL) inputs as well

as SSTL_3 (EIA/JESD8-8) and low voltage PECL (pseudoECL) outputs, operating at 3.3V supply voltage. The LVTTL

inputs are 5V tolerant. The SSTL_3 and differential PECL

output drivers drive resistive terminations or transmission

lines. Atlower clock frequencies,the SSTL_3 outputs can be

operated unterminated.

I2C-busSerial Interface

The HI5634 utilizes the industry standard I2C-bus serial

interface. The interface uses 12 registers: one write-only,

eight read/write, and three read-only. Two HI5634 devices

can be addressed,according to the state ofthe I

2

CADR pin.

When the pin is low, the read address is 4Dh, and the write

address is 4Ch. When the pin is high, the read address is

4Fh, and the write address is 4Eh. The I

2

C-bus serial

interface canrunat either low speed (100kHz) or highspeed

(400kHz) and provides 5V tolerant input.

PC Board Layout

Use a PC board with at least four layers: one power, one

ground, and two signal. No special cutouts are required for

power and ground planes. All supply voltages must be

suppliedfrom a commonsource andmust rampup together.

Flux and other board surface debris can degrade the

performance of the external loop filter. Ensure that the

HI5634 area of the board is free of contaminants.

5

HI5634

Specific Layout Guidelines

1. Digital Supply (VDDD) - Bypass pin 1 (VDDD) to pin 2

(VSSD) with 4.7µF and 0.1µF capacitors, located as

close as possible to the pins. Traces must be maximally

wide and include multiple surface-etched vias to the appropriate plane.

2. External Loop Filter - Theuse ofan external loop filter

is stronglyrecommended in all designs. Locate loop filter components as close to pins 8 and 9 (EXTFIL and EXTFILRET) as possible. Typical loop filter values are 6.8kΩ

forthe seriesresistor,3300pF RF-type capacitorforthe series capacitor, and 150pF for the shunt capacitor.

3. Analog PLL Supply (VDDA) - Decouple pin 10 (VDDA)

with a series ferrite bead. Bypass the supply end of the

bead with 4.7µF and 0.1µF capacitors. Bypass pin 10 to

pin 11 (VSSA) with a 0.1µF capacitor.Locate these components as close as possible tothe pins. Traces must be

maximally wide and havemultiple surface-etched vias to

the power or ground planes.

4. PECL Current Set Resistor - Locate PECL current set

resistor asclose as possibleto pin 24(IREF). Bypass pin

24 to ground with a 0.1µF capacitor.

5. PECL Outputs - Implement these outputs asmicrostrip

transmission lines. The trace widths shown are for 75Ω

characteristic impedance, presuming 0.067 in. between

layers.Locate the optional series “snubbing” resistorsas

close as possible to the pins. If the termination resistors

are included on-board, locate them as close as possible

to the load and connect directly to the powerand ground

planes (thesetermination resistors areomitted if theload

device implements them internally).

6. Output Driver Supply (VDDQ) - Bypass pin 18(VDDQ)

to pin 19 (VSSQ) with 4.7µF and 0.1µF capacitors, located as close as possible to the pins. Traces must be maximally wide and include multiple surface-etched vias to

the appropriate plane.

7. SSTL_3 Outputs- SSTL_3outputs can beused likeconventional CMOSrail-to-rail logic or as a terminated transmission line system at higher-output frequencies. With

terminated outputs, the considerations of item 5, “PECL

Outputs” apply. See JEDEC documents JESD8-A and

JESD8-8.

Power Supply Considerations

The HI5634 incorporates special internal power-on-reset

circuitry that requires no external reset signal connection.

The supply voltage (VDD) must remain within the

recommended operatingconditions during normaloperation.

To reset the HI5634, the supply voltage at the part must be

reduced below the threshold voltage (V

reset circuit. The supply voltage must remain below that

threshold voltage such that board power conditioning

capacitors are drained and the proper reset state is latched.

The amount of time (t

) to hold the voltage in a reset state

D

varies with the design. However, a typical value of 10ms

should be sufficient.

) of the power-on-

TH

VDD

V

MIN

VTH = 1.8V

t

D

SSTL_3 Outputs

Unterminated Outputs

In the HI5634, unterminated SSTL output pins display

exponential transitions similar to those of rectangular pulses

presented to RC loads. The 10-90% rise time is typically

1.6ns, and the corresponding fall time is typically 700ps. In

turn, this asymmetry contributes to duty cycle asymmetry at

higher output frequencies. In the absence of significant load

capacitance (which can further increase rise and fall time),

this asymmetry is the dominant factor determining high

frequency performance of these single-ended outputs.

Typically, no termination is required for the LOCK/REF,

FUNC, and CLK/2 outputs nor for CLK outputs up to

approximately 135MHz.

Terminated Outputs

SSTL_3 outputs are intended to terminate in low

impedances to reduce the effect of external circuit

capacitance. Use of transmission line techniques enables

use of longer traces between source and driver without

increasing ringing due to reflections. Where external

capacitance is minimal and substantial voltage swing is

required to meet LVTTL V

intrinsic rise and fall times of HI5634 SSTL outputs are only

slightly improved by termination in a low impedance.

The HI5634 SSTL output source impedance is typically less

than 60Ω. Termination impedance of 100Ω reduces output

swing by less than 30% which is more than enough to drive

a single load of LVTTL inputs.

HI5634

SSTL_3 OUTPUT

and VIL requirements, the

IH

VDD

330Ω

150Ω

SINGLE

LVTTL

LOAD

6

I 2C Register Map Summary

HI5634

REGISTER

NUMBER NAME ACCESS BIT NAME BIT #

0h Input Control R / W PDEN 0 1 Phase Detector Enable (0 = External Enable, 1 = Always Enabled)

PD_POL 1 0 Phase Detector Enable Polarity (0 = Not Inverted, 1 = Inverted)

REF_POL 2 0 External Reference Polarity (0 = Positive Edge, 1 = Negative Edge)

FBK_POL 3 0 External Feedback Polarity (0 = Positive Edge, 1 = Negative Edge)

FBK_SEL 4 0 External Feedback Select (0 = Internal Feedback, 1 = External)

FUNC_SEL 5 0 Function Out Select (0 = Recovered HSYNC, 1 = Input HSYNC)

EN_PLS 6 1 Enable PLL Lock/Ref Status Output (0 = Disable, 1 = Enable)

EN_DLS 7 0 Enable DPA Lock/Ref Status Output (0 = Disable, 1 = Enable)

1h Loop Control R / W † PFD0-2 0-2 0 Phase Detector Gain

Reserved 3 0 Reserved

PSD0-1 4-5 0 Post Scaler Divider (0 = ÷2, 1 = ÷4, 2 = ÷8, 3 = ÷16)

Reserved 6-7 0 Reserved

2h FDBK Div 0 R / W † FDB0-7 0-7 FF PLL Feedback Divider LSBs (Bits 0-7)

3h FDBK Div 1 R / W † FDB8-11 0-3 F PLL Feedback Divider MSBs (Bits 8-11)

Reserved 4-7 0 Reserved

4h DPA Offset R / W DPA_OS0-5 0-5 0 Digital Phase Adjustment Offset

Reserved 6 0 Reserved

FIL_SEL 7 0 Loop Filter Select (0 = External, 1 = Internal)

5h DPA Control R / W †† DPA_RES0-1 0-1 3 DPA Resolution(0 =16 Delay Elements, 1 =32, 2= Reserved,3=64)

METAL_REV 2-7 0 Metal Mask Revision Number

6h Output Enables R / W OE_PCK 0 0 Output Enable for PECL PCLK Outputs (0 = High Z, 1 = Enabled)

OE_TCK 1 0 Output Enable for STTL_3 CLK Output (0 = High Z, 1 = Enabled)

OE_P2 2 0 Output Enable for PECL CLK/2 Outputs (0 = High Z, 1 = Enabled)

OE_T2 3 0 Output Enable for STTL_3 CLK/2 Output (0 = High Z, 1 = Enabled)

OE_F 4 0 Output Enable for STTL_3 FUNC Output (0 = High Z, 1 = Enabled)

CK2_INV 5 0 CLK/2 Invert (0 = Not Inverted, 1 = Inverted)

OUT_SCL 6-7 0 SSTL Clock Scaler (0 = ÷1, 1 = ÷2, 2 = ÷4, 3 = ÷8)

7h OSC_DIV R / W OSC_DIV 0-6 0-6 0 Osc Divider Modulus

IN_SEL 7 1 Input Select (0 = HSYNC Input, 1 = Osc Divider)

8h Reset Write DPA 0-3 x Writing xAh Resets DPA and Loads Working Register 5

PLL 4-7 x Writing 5xh Resets PLL and Loads Working Registers 1-3

10h Chip Ver Read CHIP VER 0-7 17 Chip Version 23 Decimal (17 Hex)

11h Chip Rev Read CHIP REV 0-7 01 Initial Value 01h. Value Increments With Each All Layer Change.

12h RD_REG Read DPA_LOCK 0 N/A DPA Lock Status (0 = Unlocked, 1 = Locked)

PLL_LOCK 1 N/A PLL Lock Status (0 = Unlocked, 1 = Locked)

Reserved 2-7 0 Reserved

RESET

VALUE DESCRIPTION

† Identifies Double Buffered Registers. Working Registers are Loaded During Software PLL Reset.

†† Identifies Double Buffered Registers. Working Registers are Loaded During Software DPA Reset.

7

Software Programming Flow

HI5634

INITIALIZE

REGISTERS 0, 6, 7

CHANGE PLL AND/OR

DPA SETTINGS

SET DPA OUTPUT

DELAY TO 0

NO

CHANGE

PLL FREQ.

REG4[0-5] = 0

YES

?

SET INPUT, PFD GAIN, POST

SCALER, AND FEEDBACK DIVIDER

PLL SOFTWARE RESET

WAIT ~ 1ms

NO

PLL

LOCKED

?

REG12[1] = 1?

REGS 0, 1, 2, 3

REG8 = 50h

(NOTE 6)

REG5

NOTES:

6. Updates working Registers 1-3.

7. Updates working Resister 5.

SET DPA

RESOLUTION

DPA SOFTWARE RESET

WAIT ~ 1ms

8

YES

REG8 = 0Ah

(NOTE 7)

SELECT DESIRED

DPA OUTPUT DELAY

DONE

REG4[0-5]

HI5634

Detailed Register Description

Register: 0h Name: Input Control Access: Read/Write

BIT NAME BIT # RESET VALUE DESCRIPTION

PDEN 0 1 Phase/FrequencyDetector Enable -0 = ExternalEnable (Phase/Frequency Detectorcontrolled by PDEN

(pin 5) only), 1 = Always Enabled (default).

PD_POL 1 0 Phase/Frequency Detector Enable Polarity - Used only when (Reg0 [0]=0).

0 = Not inverted (default, PDEN input (pin 5) isactive high),1= Inverted(PDEN input(pin 5)is activelow).

REF_POL 2 0 Phase/Frequency Detector External Reference Polarity - Edge of input signal on which Phase Detector

triggers. 0 = Rising Edge (default), 1 = Falling Edge.

FBK_POL 3 0 External Feedback Polarity - Edge of EXTFB (pin6) signal on whichPhase/Frequency Detector triggers

when external feedback is used (Reg0 [4]=1). 0 = Positive Edge (default), 1 = Negative Edge.

FBK_SEL 4 0 External Feedback Select - 0 = Internal Feedback (default), 1 = External Feedback.

FUNC_SEL 5 0 Function Output Select - Selects re-clocked output to FUNC (pin 15).

0 = Recovered HSYNC (default, regenerated HSYNC output), 1 = External HSYNC (Schmitt-trigger

conditioned input from HSYNC (pin 7)).

EN_PLS 6 1 OutputsPLLLockStatus (Reg12[1])

on LOCK/REF pin.

EN_DLS 7 0 Outputs DPA Lock Status

(Reg12[0]) on LOCK/REF pin.

Bits6, 7enable multiple functionsat

LOCK/REF output (pin 14), as

shown in table at right.

EN_PLS EN_DLS IN_SEL LOCK/REF (14)

0 0 N/A 0

0 1 N/A 1 if DPA Locked, 0 Otherwise

1 0 N/A 1 if PLL Locked, 0 Otherwise

1 1 0 Post Schmitt TriggerHSYNC(7)

XOR REF_POL

111 F

OSC

÷ OSC_DIV

Register: 1h Name: Loop Control Register Access: Read/Write (Note 8)

BIT NAME BIT # RESET VALUE DESCRIPTION

PFD0-2 0-2 0 Phase/Frequency Detector Gain. BIT 2 BIT 1 BIT 0 PFD GAIN (µA/2π RAD)

000 1

001 2

010 4

011 8

100 16

101 32

110 64

111 128

Reserved 3 0 Reserved

PSD0-1 4-5 0 Post-Scaler Divider - Divides the output of the

VCO prior to the DPA and Feedback Divider.

Reserved 6-7 0 Reserved

BIT 5 BIT 4 PSD DIVIDER

0 0 2 (Default)

01 4

10 8

11 16

9

HI5634

Register: 2h, 3h Name: Feedback Divider Registers Access: Read/Write (Note 8, 9)

REG # BIT NAME BIT # RESET VALUE DESCRIPTION

2h FBD0-7 0-7 FF PLL Feedback Divider LSBs (0-7). When Bit 0 = 0, the total number of pixels is even.

When Bit 0 = 1, the total number of pixels is odd.

3h FBD8-11 0-3 F PLL Feedback Divider MSBs (8-11).

3h Reserved 4-7 Reserved

REG 3 REG 2

321076543210

Feedback Divider Modulus = +8

12 ≤ Feedback Divider Modulus ≤ 4103

Register: 4h Name: DPA Offset Register Access: Read/Write

BIT NAME BIT # RESET VALUE DESCRIPTION

DPA_OS0-5 0-5 0 Digital Phase Adjustment Offset - Selects clock edge offset in discrete steps from zero to one clock

period minus one step. Resolution (number of delay elements per clock cycle) is selected by

DPA_RES0-1 (Reg 5[0-1]). Note: Offsets equal to or greater than one clock period are neither

recommended nor supported. Example: For DPA_RES0-1=01h, theclock canbe delayedfrom 0to 31

steps.

Reserved 6 0 Reserved

FIL_SEL 7 0 Selects external loop filter (0) or internal loop filter (1).

The use of an external loop filter is strongly recommended for all designs.

Register: 5h Name: DPA Control Register Access: Read/Write (Note 10)

BIT NAME BIT # RESET VALUE DESCRIPTION

DPA_RES0-1 0-1 3 Digital Phase Adjustment

(DPA) Resolution Select.

Use of the DPA above

160MHz is not

recommended.

METAL_REV 2-7 0 Metal Mask Revision

Number - After power-up,

register bits 2-7 must be

written with 111111.

After this write, a read indicates the metal mask revision, as shown in the

table at right.

NOTES:

8. Double buffered registers. Actual working registers are loaded during software PLL reset. See Register 8h for details.

9. The value that is programmed into these two registers, plus a value of 8, defines the total number of clock periods that the HI5634 generates

between HSYNCs. Program these registers with the total number of horizontal pixels per line minus 8.

10. Double buffered register. Actual working registers are loaded during software DPA reset. See Register 8h for details.

BIT 1 BIT 0

00 16

01 32

1 0 Reserved

11 64

REVISION BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2

A111111

B011111

C1 1 0 1 1 1 1

C2 0 0 1 1 1 1

D1101 11

E111011

F111101

G1111 10

DELAY

ELEMENTS CLK RANGE (MHz)

8024

4012

16048

10

HI5634

Register: 6h Name: Output Enable Register Access: Read/Write

BIT NAME BIT # RESET VALUE DESCRIPTION

OE_PCK 0 0 Output Enable for CLK Outputs (PECL) - 0 = High Z (default), 1 = Enabled.

OE_TCK 1 0 Output Enable for CLK Output (SSTL_3) - 0 = High Z (default), 1 = Enabled.

OE_P2 2 0 Output Enable for CLK/2 Outputs (PECL) - 0 = High Z (default), 1 = Enabled.

OE_T2 3 0 Output Enable for CLK/2 Output (SSTL_3) - 0 = High Z (default), 1 = Enabled.

OE_F 4 0 Output Enable for FUNC Output (SSTL_3) - 0 = High Z (default), 1 = Enabled.

CK2_INV 5 0 CLK/2 Invert - 0 = Not Inverted (default), 1 = Inverted.

OUT_SCL 6-7 0 Clock (CLK) Scaler. BIT 7 BIT 6 CLK DIVIDER

00 1

01 2

10 4

11 8

Register: 7h Name: Oscillator Divider Register Access: Read/Write

BIT NAME BIT # RESET VALUE DESCRIPTION

OSC_DIV0- 6 0-6 0 Oscillator Divider Modulus - Divides the input from OSC (pin 12) by the set modulus.

The modulus equals the programmed value, plus2. Therefore,the modulusrange isfrom 3to 129.

IN_SEL 7 1 Input Select - Selects the input to the Phase/Frequency Detector

0 = HSYNC, 1 = Osc Divider (default).

Register: 8h Name: Reset Register Access: Write Only

BIT NAME BIT # RESET VALUE DESCRIPTION

DPA Reset 0-3 X Writing XAh to this register resets DPA working

Register 5.

PLL Reset 4-7 X Writing 5Xh to this register resets PLL working

Registers 1-3.

VALUE RESETS

XA DPA

5X PLL

5A DPA and PLL

Register: 10h Name: Chip Version Register Access: Read Only

BIT NAME BIT # RESET VALUE DESCRIPTION

CHIP VER 0-7 17 Chip Version 23 (17h).

Register: 11h Name: Chip Revision Register Access: Read Only

BIT NAME BIT # RESET VALUE DESCRIPTION

CHIP REV 0-7 01+ Initial value 01h.

+Value increments with each all-layer change.

Register: 12h Name: Status Register Access: Read Only

BIT NAME BIT # RESET VALUE DESCRIPTION

DPA_LOCK 0 N/A DPA Lock Status (Refer to Register 0h, bits 6 and 7). 0 = Unlocked, 1 = Locked.

PLL_LOCK 1 N/A PLL Lock Status (Refer to Register 0h, bits 6 and 7). 0 = Unlocked, 1 = Locked.

Reserved 2-7 0 Reserved

11

HI5634

I 2C Data Format

(Notes 11-14)

RANDOM REGISTER WRITE PROCEDURE

S010011XW

AAA

P

7 Bit Address Register Address Data

RANDOM REGISTER READ PROCEDURE

S010011XW S010011XR AP

AA A

7 Bit Address Register Address 7 Bit Address Data

SEQUENTIAL REGISTER WRITE PROCEDURE

S010011XW P

AAAAA

7 Bit Address Register Address Data Data

SEQUENTIAL REGISTER READ PROCEDURE

S010011XW S010011XR A AP

AA A

7 Bit Address Register Address 7 Bit Address Data Data

Direction: = Bus Host to Device = Device to Bus Host

NOTES:

11. All values are transmitted with the most significant bit first and the least significant bit last.

2

12. The value of the X-bit equals the logic state of pin 13 (I

CADR).

13. R = Read Command = 1, W = Write Command = 0.

14. S = Start Condition, A = Acknowledge,

A = No Acknowledge, P = Stop Condition. See “I2C Data Characteristics” for description.

I 2C Data Characteristics

SDA

SCL

DATA LINE STABLE:

DATA VALID

BIT TRANSFER ON THE I

SDA

SCL

DATA OUTPUT BY

TRANSMITTER

DATA OUTPUT BY

RECEIVER

SCL FROM MASTER

S

START

CONDITION

S

START

CONDITION

START AND STOP CONDITIONS

12 7 89

ACKNOWLEDGE ON THE I

NOTE: These waveforms are from “The I2C bus and how to use it,” published by Philips Semiconductor. The document can be obtained from:

http://www-us2.semiconductors.philips.com/acrobat/various/i2c_bus_specification_1995.pdf.

CHANGE

OF DATA

ALLOWED

2

C BUS

2

C BUS

P

STOP

CONDITION

CLOCK PULSE FOR

ACKNOWLEDGMENT

12

AC Timing Characteristics Overview

HSYNC

REF

13

EVEN TOTAL PIXELS

ODD TOTAL PIXELS ††

PECL CLK-

PECL CLK+

SSTL CLK

FUNC

HI5634

†

PECL CLK/2+

PECL CLK/2-

SSTL CLK/2

PECL CLK-

PECL CLK+

SSTL CLK/2

† Timing when Register 2[0] = 0 (Total Number of Pixels is Even).

†† Timing when Register 2[0] = 1 (Total Number of Pixels is Odd).

Output Timing Diagram

HI5634

HSYNC

REF

PECL CLK-

PECL CLK+

SSTL CLK

FUNC

EVEN TOTAL PIXELS †

PECL CLK/2+

PECL CLK/2-

SSTL CLK/2

t

R

t

0

t

1

t

S

†Timing when Register 2[0] = 0 (Total Number of Pixels is Even).

t

2

t

4

t

F

t

5

t

6

t

7

t

3

t

8

t

9

t

P

14

Typical Performance Curves

HI5634

700

FREQUENCY (SLOW: 3.0V AT 70oC)

FREQUENCY (NOMINAL: 3.3V AT 30

600

FREQUENCY (FAST: 3.6V AT 0

JITTER (3.0V AT 70

JITTER (3.3V AT 30

500

JITTER (3.6V AT 0

400

300

200

VCO FREQUENCY (MHz)

100

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3 3.2

o

C)

o

C)

o

C)

VCO VOLTAGE (V)

o

C)

o

C)

JITTER (ps)

100

0

20

DPA_RES 0-1 = 00h

18

50MHz - SVGA AT 72Hz

157.5MHz - SXGA AT 85Hz

16

14

12

10

8

6

DELAY RANGE (ns)

4

2

0

0481216

DPA OFFSET SETTING (# OF STEPS)

FIGURE 1. VCO FREQUENCY AND JITTER vs VCO VOLTAGE FIGURE 2. DPA DELAY vs OFFSET SETTING (16 ELEMENTS)

45

DPA_RES 0-1 = 01h

25.175MHz - VGA AT 60Hz

40

78.75MHz - XGA AT 75Hz

35

30

25

20

15

DELAY RANGE (ns)

10

5

0

0 4 8 121620242832

DPA OFFSET SETTING (# OF STEPS)

90

DPA_RES 0-1 = 03h

12.27MHz - NTSC

80

39.8MHz - SVGA AT 60Hz

70

60

50

40

30

DELAY RANGE (ns)

20

10

0

0 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64

DPA OFFSET SETTING (# OF STEPS)

FIGURE 3. DPA DELAY vs OFFSET SETTING (32 ELEMENTS) FIGURE 4. DPA DELAY vs OFFSET SETTING (64 ELEMENTS)

15

Small Outline Plastic Packages (SOIC)

HI5634

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbolsare defined in the “MOSeries Symbol List” in Section2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension“D” doesnot includemold flash, protrusions or gateburrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. Thechamfer onthe bodyis optional.If itis notpresent, avisual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controllingdimension: MILLIMETER. Convertedinch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M24.3 (JEDEC MS-013-AD ISSUE C)

24 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.020 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.5985 0.6141 15.20 15.60 3

E 0.2914 0.2992 7.40 7.60 4

e 0.05 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N24 247

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only .Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

16

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...