Page 1

HI3318

August 1997

Features

• CMOS Low Power (Typ). . . . . . . . . . . . . . . . . . . 150mW

• Parallel Conversion Technique

• Sampling Rate at 5V Supply . . . . . . . . . . . . . . . . 15MHz

• 8-Bit Latched Three-State Output with Overflow Bit

• Accuracy (Typ). . . . . . . . . . . . . . . . . . . . . . . . . . ±1 LSB

• Single Supply Voltage . . . . . . . . . . . . . . . . . . 4V to 7.5V

• Linearity (INL):

- HI3318JIP . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.5 LSB

- HI3318JIB . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.5 LSB

• Sampling Rate:

- HI3318JIP . . . . . . . . . . . . . . . . . . . . . . . 15MHz (67ns)

- HI3318JIB . . . . . . . . . . . . . . . . . . . . . . . 15MHz (67ns)

• Video Digitizing

• High-Speed A/D Conversion

• Medical Imaging

• Radar Signal Processing

• Digital Communications Systems

8-Bit, 15 MSPS, Flash A/D Converter

Description

The HI3318 is a CMOS parallel (FLASH) analog-to-digital

converter designed for applications demanding both low

power consumption and high speed digitization.

The HI3318 operates over a wide full scale input voltage

range of 4V up to 7.5V with maximum power consumption

depending upon the clock frequency selected. When operated from a 5V supply at a clock frequency of 15MHz, the

typical power consumption of the HI3318 is 150mW.

256 paralleled auto balanced voltage comparators measure

the input voltage with respect to a known reference to produce the parallel bit outputs in the HI3318. 255 comparators

are required to quantize all input voltage levels in this 8-bit

converter, and the additional comparator is required for the

overflow bit.

Ordering Information

TEMP.

PART NUMBER

HI3318JIP -40 to 85 24 Ld PDIP E24.6

HI3318JIB -40 to 85 24 Ld SOIC M24.3

RANGE (oC) PACKAGE

PKG.

NO.

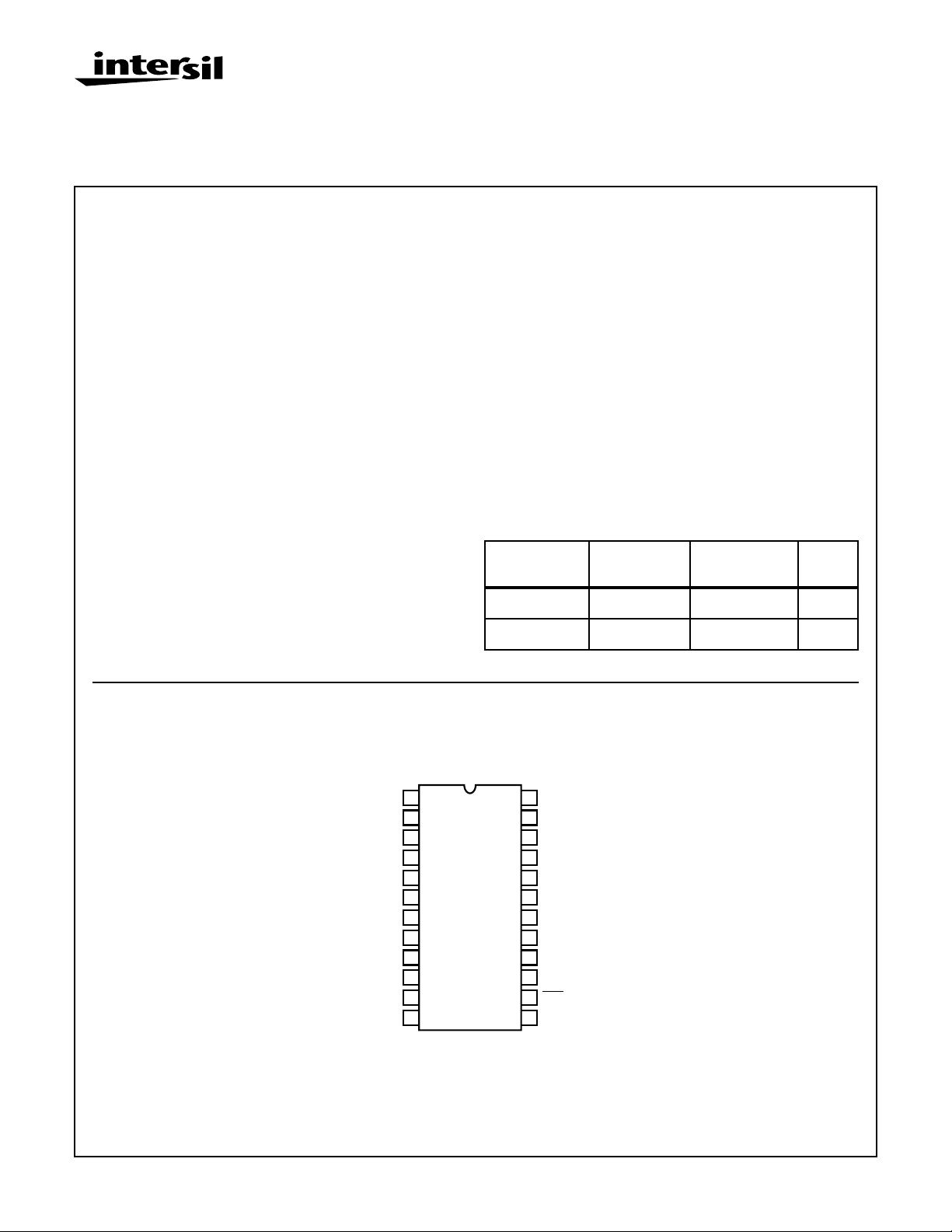

Pinout

(LSB) B1

(MSB) B8

OVERFLOW

(DIG. GND) V

(DIG. SUP.) V

B2

B3

B4

B5

B6

B7

1/4R

SS

DD

1

2

3

4

5

6

7

8

9

10

11

12

HI3318

(PDIP, SOIC)

TOP VIEW

24

VAA+ (ANA. SUP.)

3/4R

23

22

21

20

19

18

17

16

15

14

13

+

V

REF

V

IN

p

PHASE

CLK

- (ANA. GND)

V

AA

V

IN

V

-

REF

CE1

CE2

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

4-1452

File Number 4135.1

Page 2

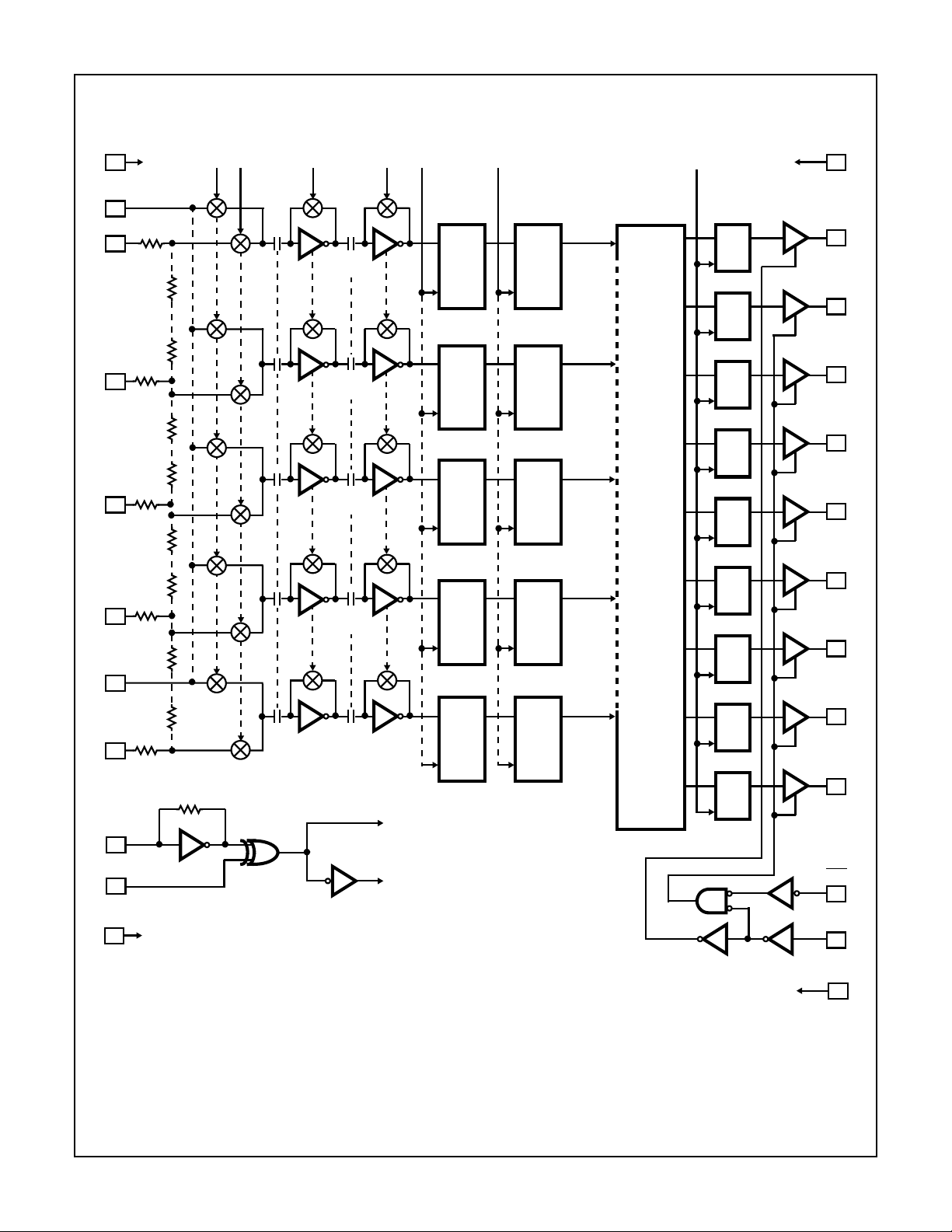

Functional Block Diagram

HI3318

VAA+

24

V

IN

21

V

REF

22

3

/4 REF

23

1

/2 REF

20

1

/4REF

10

V

IN

16

V

REF

15

CLOCK

18

PHASE

19

-

V

AA

17

+

1

/2 R

R = 2Ω

= 7Ω

= 30Ω

= 4Ω

R

≅2K

-

1

/2 R

ANALOG

SUPPLY

R

R

R

R

R

R

≅50K

ANALOG

GND

φ2 φ1 φ1 φ1 φ1 φ2 φ1

COUNT

256

COUNT

193

COUNT

129

COUNT

65

COUNT

1

ENCODER

LOGIC

ARRAY

CAB

# 256

CAB

# 193

CAB

# 129

CAB

# 65

CAB

(NOTE 1)

COMPARATOR #1

DQ

LATCH

256

DQ

LATCH

DQ

LATCH

DQ

LATCH

DQ

LATCH

1

DQ

LATCH

256

DQ

LATCH

DQ

LATCH

DQ

LATCH

DQ

LATCH

11

φ1 (AUTO BALANCE)

φ2 (SAMPLE UNKNOWN)

DIGITAL

SUPPLY

OUTPUT

REGISTER

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

DQ

CLK

THREE-

STATE

DRIVERS

V

DD

12

OVER-

FLOW

9

BIT 8

(MSB)

8

BIT 7

7

BIT 6

6

BIT 5

5

BIT 4

4

BIT 3

3

BIT 2

2

BIT 1

(LSB)

1

CE1

14

CE2

13

NOTE:

1. Cascaded Auto Balance (CAB).

4-1453

DIGITAL

GND

V

SS

11

Page 3

HI3318

Absolute Maximum Ratings T

DC Supply Voltage Range (VDD or VAA+) . . . . . . . . . . -0.5V to +8V

(Referenced to VSS or VAA- Terminal, Whichever is

More Negative)

Input Voltage Range

CE2 and CE1 . . . . . . . . . . . . . . . . . . . . VAA- -0.5V to VDD + 0.5V

Clock, Phase, V

Clock, Phase, V

VIN,3/4 REF, V

-,1/2 Ref. . . . . . . VAA- -0.5V to VAA+ + 0.5V

REF

-,1/4 Ref. . . . . . . . VSS- -0.5V to VDD + 0.5V

REF

+. . . . . . . . . . . . . . .VAA- -0.5V to VAA- + 7.5V

REF

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θJA(oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300oC

(SOIC - Lead Tips Only)

Output Voltage Range, . . . . . . . . . . . . . . . VSS - 0.5V to VDD + 0.5V

Bits 1-8, Overflow (Outputs Off)

DC Input Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±20mA

Clock, Phase, CE1, CE2, VIN, Bits 1-8, Overflow

Recommended VAA+ Operating Range. . . . . . . . . . . . . . . VDD±1V

Recommended VAA- Operating Range . . . . . . . . . . . . . . . VSS±1V

Operating Conditions

Operating Voltage Range (VDD or VAA+). . . 4V (Min) to 7.5V (Max)

Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

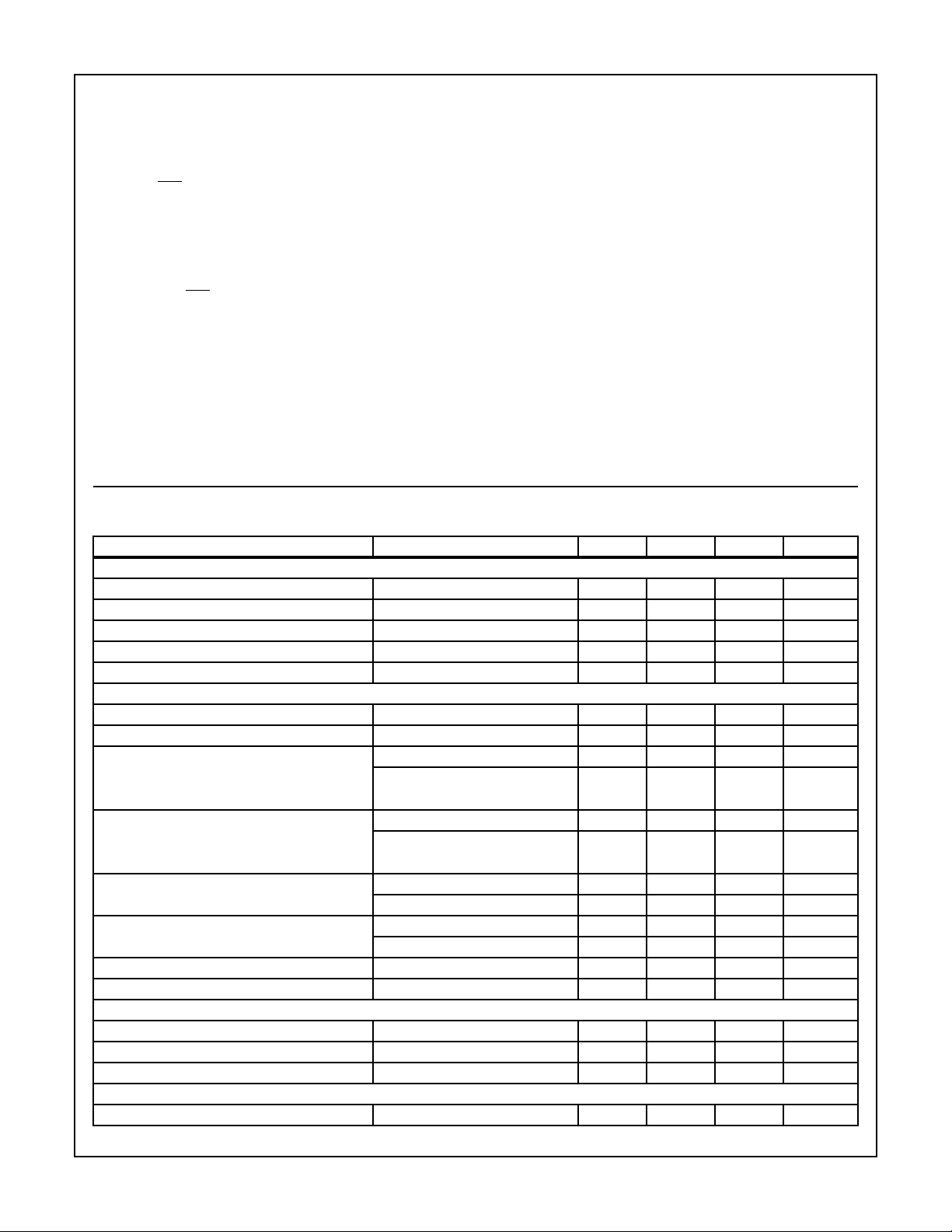

Electrical Specifications At 25

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SYSTEM PERFORMANCE

Resolution 8 - - Bits

Integral Linearity Error - - ± 1.5 LSB

Differential Linearity Error - - +1, -0.8 LSB

Offset Error, Unadjusted V

Gain Error, Unadjusted VIN = V

DYNAMIC CHARACTERISTICS

Maximum Input Bandwidth (Note 1) HI3318 2.5 5.0 - MHz

Maximum Conversion Speed CLK = Square Wave 15 17 - MSPS

Signal to Noise Ratio, SNR fS = 15MHz, fIN = 100kHz - 47 - dB

RMS Signal

----------------------------------

=

RMS Noise

Signal to Noise Ratio, SINAD fS = 15MHz, fIN = 100kHz - 45 - dB

RMS Signal

--------------------------------------------------------------- -

=

RMSNoise + Distortion

o

C, VAA+ = VDD = 5V, V

+ = 6.4V, V

REF

- = VAA- = VSS, CLK = 15MHz,

REF

All Reference Points Adjusted, Unless Otherwise Specified

= V

IN

- +1/2 LSB -0.5 4.5 6.4 LSB

REF

+ -1/2 LSB -1.5 0 1.5 LSB

REF

fS = 15MHz, fIN = 4MHz - 43 - dB

fS = 15MHz, fIN = 4MHz - 35 - dB

Total Harmonic Distortion, THD fS = 15MHz, fIN = 100kHz - -46 - dBc

fS = 15MHz, fIN = 4MHz - -36 - dBc

Effective Number of Bits, ENOB fS = 15MHz, fIN = 100kHz - 7.2 - Bits

fS = 15MHz, fIN = 4MHz - 5.5 - Bits

Differential Gain Error Unadjusted - 2 - %

Differential Phase Error Unadjusted - 1 - %

ANALOG INPUTS

Full Scale Range, VIN and (V

Input Capacitance, V

IN

Input Current, VIN, (See Text) VIN = 5.0V, V

REF

+) - (V

-) Notes 2, 4 4 - 7 V

REF

-30- pF

+ = 5.0V - - 3.5 mA

REF

REFERENCE INPUTS

Ladder Impedance 270 500 800 Ω

4-1454

Page 4

HI3318

Electrical Specifications At 25

o

C, VAA+ = VDD = 5V, V

+ = 6.4V, V

REF

- = VAA- = VSS, CLK = 15MHz,

REF

All Reference Points Adjusted, Unless Otherwise Specified (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

DIGITAL INPUTS

Low Level Input Voltage, V

CE1, CE2 Note 4 - - 0.2V

Phase, CLK Note 4 - - 0.2V

High Level Input Voltage, V

CE1, CE2 Note 4 0.7V

Phase, CLK Note 4 0.7V

OL

DD

AA

IN

DD

AA

--V

--V

V

V

Input Leakage Current, II (Except CLK Input) Note 3 - ±0.2 ±5 µA

Input Capacitance, C

I

-3-pF

DIGITAL OUTPUTS

Output Low (Sink) Current VO = 0.4V 4 10 - mA

Output High (Source) Current VO = 4.5V -4 -6 - mA

Three-State Output Off-State Leakage Current, I

Output Capacitance, C

O

OZ

- ±0.2 ±5 µA

-4-pF

TIMING CHARACTERISTICS

Auto Balance Time, φ133-

∞

ns

Sample Time, φ2 Note 4 25 - 500 ns

Aperture Delay -15- ns

Aperture Jitter - 100 - ps

Data Valid Time, t

Data Hold Time, t

D

H

Output Enable Time, t

Output Disable Time, t

EN

DIS

Note 4 - 50 65 ns

Note 4 25 40 - ns

-18- ns

-18- ns

POWER SUPPLY CHARACTERISTICS

Device Current (IDD + IA) (Excludes I

) Continuous Conversion (Note 4) - 30 60 mA

REF

Auto Balance (φ1) - 30 60 mA

NOTES:

1. A full scale sine wa ve input of greater than f

/2 or the specified input bandwidth (whichever is less) ma y cause an erroneous code. The

CLK

-3dB bandwidth for frequency response purposes is greater than 30MHz.

2. VIN (Full Scale) or V

3. The clock input is a CMOS inverter with a 50kΩ feedback resistor and may be AC coupled with 1V

+ should not exceed VAA+ + 1.5V for accuracy.

REF

minimum source.

P-P

4. Parameter not tested, but guaranteed by design or characterization.

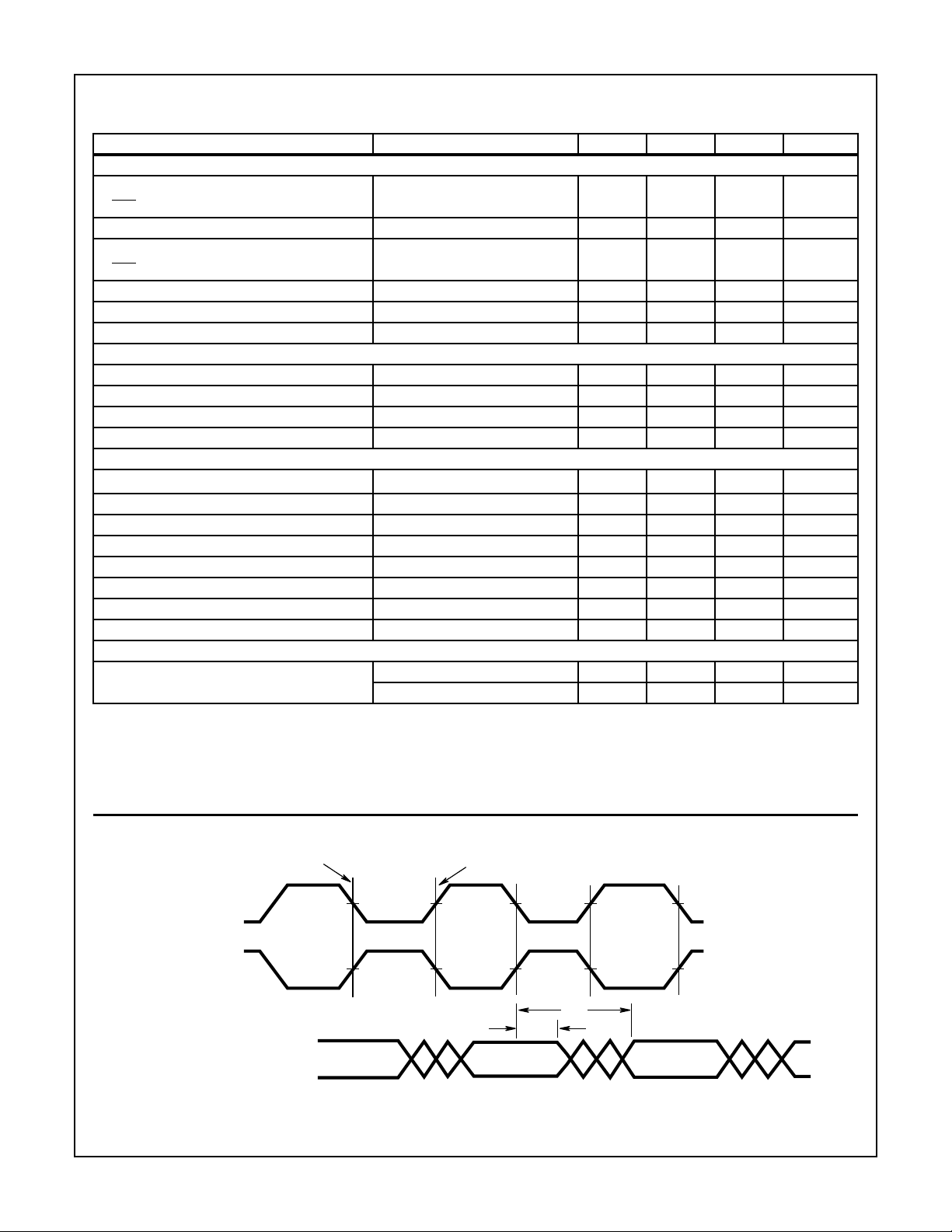

Timing Waveforms

COMPARATOR DATA IS LATCHED

CLOCK (PIN 18)

IF PHASE (PIN 19)

IS LOW

CLOCK IF

PHASE IS HIGH

DECODED DATA IS SHIFTED

TO OUTPUT REGISTERS

φ2

SAMPLE

N

DAT A

N - 2

AUTO

BALANCE

φ2 φ1φ1 φ2

SAMPLE

N + 1

DAT A

N - 1

FIGURE 1. INPUT TO OUTPUT TIMING DIAGRAM

4-1455

AUTO

BALANCE

t

H

SAMPLE

N + 2

t

D

DAT A

N

Page 5

Timing Waveforms (Continued)

CE1

CE2

t

DIS

t

EN

HI3318

t

DIS

t

EN

BITS 1 - 8

OF

DAT A

HIGH

IMPEDANCE

DAT A

DAT A DATA

HIGH

IMPEDANCE

HIGH

IMPEDANCE

FIGURE 2. OUTPUT ENABLE TIMING DIAGRAM

AUTO

BALANCE

33ns

MIN

SAMPLE

N + 1

25ns

MIN

50ns

MIN

CLOCK

DAT A

AUTO

BALANCE

NO MAX

LIMIT

SAMPLE

N

25ns

MIN

FIGURE 3A. STANDBY IN INDEFINITE AUTO BALANCE (SHOWN WITH PHASE = LOW)

CLOCK

DAT A

SAMPLE

N

500ns 33ns

MAX

BALANCE

AUTO

MIN

SAMPLE

N + 1

25ns

MIN

AUTO

BALANCE

50ns

TYP

DAT A

N - 1

SAMPLE

FIGURE 3B. STANDBY IN SAMPLE (SHOWN WITH PHASE = LOW)

FIGURE 3. PULSE MODE OPERATION

4-1456

N + 2

DAT A

N

Page 6

Typical Performance Curves

HI3318

(mA)

DD

I

40

35

30

25

20

15

10

0

fS (MHz)

302010

28

27

26

(mA)

DD

I

25

24

23

-50

-25 25 75

TEMPERATURE (oC)

FIGURE 4. DEVICE CURRENT vs SAMPLE FREQUENCY FIGURE 5. DEVICE CURRENT vs TEMPERATURE

8.0

fS = 15MHz, fI = 1MHz

7.8

7.6

7.4

7.2

7.0

6.8

ENOB (LSB)

6.6

6.4

6.2

6.0

30

40 60 8020100-10-20-30-40

TEMPERATURE (oC)

FIGURE 6. ENOB vs TEMPERATURE

907050

1.00

fS = 15MHz

0.90

0.80

0.70

0.60

0.50

0.40

0.30

NON-LINEARITY (LSB)

0.20

0.10

0

TEMPERATURE (oC)

30

40 60 8020100-10-20-30-40

FIGURE 7. NON-LINEARITY vs TEMPERATURE

INL

DNL

100500

907050

1.20

1.08

0.96

0.84

0.72

0.60

0.48

0.36

NON-LINEARITY (LSB)

0.24

0.12

0

10 200

INL

DNL

25155

fS (MHz)

1.00

fS = 15MHz

1.80

1.60

1.40

1.20

1.00

0.80

0.60

NON-LINEARITY (LSB)

0.40

0.20

0

1

INL

DNL

2460

V

(V)

REF

FIGURE 8. NON-LINEARITY vs SAMPLE FREQUENCY FIGURE 9. NON-LINEARITY vs REFERENCE VOLTAGE

4-1457

753

Page 7

Typical Performance Curves (Continued)

8.0

7.6

7.2

6.8

6.4

6.0

5.6

ENOB (BITS)

5.2

4.8

4.4

4.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

FIGURE 10. ENOB vs INPUT FREQUENCY

HI3318

fS = 15MHz

5.0

fI (MHz)

Pin Descriptions

PIN NAME DESCRIPTION

1 B1 Bit 1 (LSB) Output Data Bits

2 B2 Bit 2

3 B3 Bit 3

4 B4 Bit 4

5 B5 Bit 5

6 B6 Bit 6

7 B7 Bit 7

8 B8 Bit 8 (MSB)

9 OF Overflow

1

10

11 V

12 V

13 CE2 Three-State Output Enable Input,

14

15 V

16 V

17 V

18 CLK Clock Input

19 PHASE Sample clock phase control input.

20

21 V

22 V

23

24 V

/4 R Reference Ladder1/4 Point

SS

DD

CE1 Three-State Output Enable Input

REF

IN

AA

1

/2 R Reference Ladder Midpoint

IN

REF

3

/4 R Reference Ladder3/4 Point

AA

Digital Ground

Digital Power Supply, +5V

Active Low, See Truth Table.

Active High. See Truth Table.

- Reference Voltage Negative Input

Analog Signal Input

- Analog Ground

When PHASE is low, “Sample Unknown” occurs when the clock is low

and “Auto Balance” occurs when the

clock is high (see text).

Analog Signal Input

+ Reference Voltage Positive Input

+ Analog Power Supply, +5V

(High = True)

CHIP ENABLE TRUTH TABLE

CE1 CE2 B1 - B8 OF

0 1 Valid Valid

1 1 Three-State Valid

X 0 Three-State Three-State

X = Don’t Care

Theory of Operation

A sequential parallel technique is used by the HI3318 converter to obtain its high speed operation. The sequence consists of the “Auto-Balance” phase, φ1, and the “Sample

Unknown” phase, φ2. (Refer to the circuit diagram.) Each conversion takes one clock cycle(see Note). With the phase control (pin 19) high, the “Auto-Balance” (φ1) occurs during the

high period of the clock cycle, and the “Sample Unknown” (φ2)

occurs during the low period of the clock cycle.

NOTE: The device requires only a single phase clock The terminology of φ1 andφ2 ref ers to the high and low periods of the same clock.

During the “Auto-Balance” phase, a transmission switch is

used to connect each of the first set of 256 commutating

capacitors to their associated ladder reference tap. Those

tap voltages will be as follows:

V

(N) = [(N/256) V

TAP

= [(2N - 1)/512] V

Where:

(n) = reference ladder tap voltage at point n,

V

TAP

V

= voltage across V

REF

N = tap number (1 through 256).

The other side of these capacitors are connected to singlestage amplifiers whose outputs are shorted to their inputs by

switches. This balances the amplifiers at their intrinsic trip

points, which is approximately (V

of capacitors now charges to their associated tap voltages.

At the same time a second set of commutating capacitors and

amplifiers is also auto-balanced. The balancing of the second-

] - (1/512) V

REF

REF

]

REF

,

REF

- to V

AA

+,

REF

+ - VAA-)/2. The first set

4-1458

Page 8

HI3318

stage amplifier at its intrinsic trip point removes any tracking

differences between the first and second amplifier stages. The

cascaded auto-balance (CAB) technique, used here,

increases comparator sensitivity and temperature tracking.

In the “Sample Unknown” phase, all ladder tap switches and

comparator shorting switches are opened. At the same time

V

is switched to the first set of commutating capacitors. Since

lN

the other end of the capacitors are now looking into an effectively open circuit, any input voltage that differs from the previous tap voltage will appear as a voltage shift at the comparator

amplifiers. All comparators that had tap voltages greater than

V

will go to a “high” state at their outputs. All comparators that

lN

had tap voltages lower than V

will go to a “low” state.

lN

The status of all these comparator amplifiers is AC coupled

through the second-stage comparator and stored at the end

of this phase (φ2) by a latching amplifier stage. The latch

feeds a second latching stage, triggered at the end of φ1.

This delay allows comparators extra settling time. The status

of the comparators is decoded by a 256 to 9-bit decoder

array, and the results are clocked into a storage register at

the end of the next φ2.

A 3-stage buffer is used at the output of the 9 storage

registers which are controlled by two chip-enable signals.

CE1 will independently disable B1 through B6 when it is in a

high state. CE2 will independently disable B1 through B8

and the OF buffers when it is in the low state.

To facilitate usage of this device, a phase control input is

provided which can effectively complement the clock as it

enters the chip.

Continuous-Clock Operation

One complete conversion cycle can be traced through the

HI3318 via the following steps. (Refer to timing diagram.) With

the phase control in a “low” state, the rising edge of the clock

input will start a “sample” phase. During this entire “high” state

of the clock, the comparators will track the input v oltage and the

first-stage latches will track the comparator outputs. At the falling edge of the clock, all 256 comparator outputs are captured

by the 256 latches. This ends the “sample” phase and starts the

“auto-balance” phase for the comparators. During this “low”

state of the clock, the output of the latches settles and is captured by a second row of latches when the clock returns high.

The second-stage latch output propagates through the decode

array, and a 9-bit code appears at the D inputs of the output

registers. On the next f alling edge of the cloc k, this 9-bit code is

shifted into the output registers and appears with time delay t

as valid data at the output of the three-state drivers. This also

marks the end of the next “sample” phase, thereby repeating

the conversion process f or this ne xt cycle .

Pulse-Mode Operation

The HI3318 needs two of the same polarity clock edges to

complete a conversion cycle: If, for instance, a negative

going clock edge ends sample “N”, then data “N” will appear

after the next negative going edge. Because of this requirement, and because there is a maximum sample time of

500ns (due to capacitor droop), most pulse or intermittent

sample applications will require double clock pulsing.

If an indefinite standby state is desired, standby should be in

auto-balance, and the operation would be as in Figure 3A.

If the standby state is known to last less than 500ns and lowest average power is desired, then operation could be as in

Figure 3B.

Increased Accuracy

In most cases the accuracy of the HI3318 should be sufficient without any adjustments. In applications where accuracy is of utmost importance, five adjustments can be made

to obtain better accuracy, i.e., offset trim; gain trim; and

1

/2 and3/4 point trim.

Offset Trim

In general, offset correction can be done in the preamp circuitry by introducing a dc shift to V

the op amp. When this is not possible the V

be adjusted to produce an offset trim. The theoretical input

voltage to produce the first transition is

or by the offset trim of

lN

1

/2 LSB. The equa-

- input can

REF

tion is as follows:

(0 to 1 transition) =1/2 LSB =1/2 (V

V

lN

for the first transition is less than the theoretical, then a

If V

lN

= V

REF

/512.

single-turn 50Ω pot connected between V

will accomplish the adjustment. Set V

/256)

REF

- and ground

REF

to1/2 LSB and trim

lN

the pot until the 0-to-1 transition occurs.

for the first transition is greater than the theoretical,

If V

lN

then the 50Ω pot should be connected between V

REF

negative voltage of about 2 LSBs. The trim procedure is as

stated previously.

Gain Trim

In general, the gain trim can also be done in the preamp

circuitry by introducing a gain adjustment for the op amp.

When this is not possible, then a gain adjustment circuit

should be made to adjust the reference voltage. To perform

this trim, V

That voltage is

should be set to the 255 to overflow transition.

lN

1

/3 LSB less than V

+ and is calculated as

REF

follows:

VlN (255 to 256 transition) = V

= V

REF

REF

- V

/512

REF

(511/512).

To perform the gain trim, first do the offset trim and then

apply the required V

adjust V

+10V TO 30V

D

NOTE: Bypass V

cap. Parts noted should have low temperature drift.

FIGURE 11. TYPICAL VOLTAGE REFERENCE SOURCE FOR

+ until that transition occurs on the outputs.

REF

INPUT

CA3085E

DRIVING V

for the 255 to overflow transition. Now

lN

+

3

2

1

6

7

4

10µF, TAN

+ to analog GND near A/D with 0.1µF ceramic

REF

+ INPUT

REF

8

(NOTE 1)

5K

IOT

18Ω

CW

(NOTE 1)

1.5K

+

- and a

V

REF

(PIN 22)

4.7µF,

TAN/IOV

1

/4,

+

4-1459

Page 9

HI3318

1

/4 Point Trims

1

/4,1/2 and3/4 points on the reference ladder are

The

brought out for linearity adjusting or if the user wishes to

create a nonlinear transfer function. The

driven by the reference drivers shown (Figure 12) or by 2-K

pots connected between V

REF

+ and V

point should be set first by applying an input of 257/512 x

(V

) and adjusting for an output changing from 128 to

REF

129. Similarly the

129/512 and 385/512 x (V

192 to 193 and 64 to 65. (Note that the points are actually

1

/4,1/2 and3/4 of full scale +1 LSB.)

V

+

REF

(PIN 22)

1

/4 and3/4points can be set with inputs of

) and adjusting for counts of

REF

510Ω

510Ω

1K

POT

1K

POT

1K

POT

CW

CW

CW

4

11

3

+

2

-

5

+

6

-

10

+

9

-

+10V TO +30V

1

/4 points can be

-. The1/2 (mid-)

REF

10Ω

1

10Ω

7

10Ω

8

3

/4 REF

(PIN 23)

1

/2 REF

(PIN 20)

1

/4 REF

(PIN 10)

supply should be bypassed at the A/D to the analog side of

the ground. See Figure 15 for a block diagram of this concept. All capacitors shown should be low impedance 0.1µF

ceramics and should be mounted as close to the A/D as possible. If V

+ is derived from VDD, a small (10Ω resistor or

AA

inductor and additional filtering (4.7µF tantalum) may be

used to keep digital noise out of the analog system.

Input Loading

The HI3318 outputs a current pulse to the V

terminal at the

lN

start of every sample period. This is due to capacitor charging and switch feedthrough and varies with input voltage and

sampling rate. The signal source must be capable of recovering from the pulse before the end of the sample period to

guarantee a valid signal for the A/D to convert. Suitable high

speed amplifiers include the HA-5033, HA-2542; and

CA3450. Figure 16 is an example of an amplifier which

recovers fast enough for sampling at 15MHz.

Output Loading

The CMOS digital output stage, although capable of driving

large loads, will reflect these loads into the local ground. It is

recommended that a local QMOS buffer such as

CD74HC541 E be used to isolate capacitive loads.

NOTES:

1. All Op Amps =3/4 CA324E.

2. Bypass all reference points to analog ground near A/D with 0.1µF

ceramic caps.

3. Adjust V

FIGURE 12. TYPICAL1/4 POINT DRIVERS FOR ADJUSTING

first, then1/3,3/4 and1/4 points.

REF+

LINEARITY (USE FOR MAXIMUM LINEARITY)

9-Bit Resolution

To obtain 9-bit resolution, two HI3318s can be wired together.

Necessary ingredients include an open-ended ladder network, an overflow indicator, three-state outputs, and chipenable controls, all of which are av ailable on the HI3318.

The first step for connecting a 9-bit circuit is to totem-pole

the ladder networks, as illustrated in Figure 13. Since the

absolute resistance value of each ladder may var y, external

trim of the mid-reference voltage may be required.

The overflow output of the lower device now becomes the

ninth bit. When it goes high, all counts must come from the

upper device. When it goes low, all counts must come from

the lower device. This is done simply by connecting the lower

overflow signal to the CE1 control of the lower A/D converter

and the CE2 control of the upper A/D converter. The threestate outputs of the two devices (bits 1 through 8) are now

connected in parallel to complete the circuitry. The complete

circuit for a 9-bit A/D conv erter is shown in Figure 14.

Grounding/Bypassing

The analog and digital supply grounds of a system should be

kept separate and only connected at the A/D. This keeps

digital ground noise out of the analog data to be converted.

Reference drivers, input amps, reference taps, and the V

AA

Definitions

Dynamic Performance Definitions

Fast Fourier Transform (FFT) techniques are used to evaluate

the dynamic performance of the converter. A low distortion sine

wave is applied to the input, it is sampled, and the output is

stored in RAM. The data is then transformed into the frequency

domain with a 4096 point FFT and analyzed to evaluate the

dynamic performance of the A/D. The sine wave input to the

part is -0.5dB down from full scale for all these tests.

Signal-to-Noise (SNR)

SNR is the measured RMS signal to RMS noise at a specified input and sampling frequency. The noise is the RMS

sum of all of the spectral components except the fundamental and the first five harmonics.

Signal-to-Noise + Distortion Ratio (SINAD)

SINAD is the measured RMS signal to RMS sum of all

other spectral components below the Nyquist frequency

excluding DC.

Effective Number of Bits (ENOB)

The effective number of bits (ENOB) is derived from the

SINAD data. ENOB is calculated from:

ENOB = (SINAD - 1.76 + V

where: V

CORR

= 0.5dB.

Total Harmonic Distortion (THD)

THD is the ratio of the RMS sum of the first 5 harmonic components to the RMS value of the measured input signal.

CORR

)/6.02,

4-1460

Page 10

HI3318

6.4V REF

A

+6.4V REF

+5V

V

IN1

0V TO 6.4V

MID-POINT

DRIVER

+5V

V

+

REF

+

V

AA

-

V

AA

OF

V

DD

BIT 8

NC

+5V

A

V

IN

V

IN

BIT 1

CL

PH

CE2

CE1

V

REF

V

REF

V

-

+

SS

V

DD

D

+5V

CE2

V

IN

V

IN

VAA+

-

V

AA

V

A

REF

A

CE1

OF

BIT 8

BIT 1

CL

PH

-

V

SS

D

BIT 9

BIT 8

BIT 1

CLOCK

PHASE

+4V TO +6.5V

REFERENCE

CLOCK

SOURCE

INPUT SIGNAL

FIGURE 13. USING TWO HI3318s FOR 9-BIT RESOLUTION

4.7µF/10V TANTALUM

A

OPTIONAL CAP

(SEE TEXT)

0.01µF

AMPLIFIER/BUFFER

(SEE TEXT)

+

AD

+5V (ANALOG SUPPLY)

V

+

AA

3/4 REF

V

+

REF

V

IN

1/2 REF

PHASE

CLK

V

-

AA

V

IN

V

-

REF

CE1

CE2

BIT 1

BIT 2

BIT 3

BIT 4

BIT 5

BIT 6

BIT 7

BIT 8

OVF

1/4 REF

V

SS

V

DD

HI3318

DIGITAL

OUTPUT

D

+

4.7µF

TANTALUM/10V

A

+5V (DIGITAL SUPPLY)

FIGURE 14. TYPICAL CIRCUIT CONFIGURATION FOR THE HI3318 WITH NO LINEARITY ADJUST

4-1461

Page 11

SIGNAL

SOURCE

SIGNAL

GROUND

HI3318

V

AMP

REF

-

ANALOG

SUPPLIES

+

V

AA

SUPPLY

FIGURE 15. TYPICAL SYSTEM GROUNDING/BYPASSING

IN

IN

REF

AA

REF

V

+

+

AA

DRIVERS

-

-

OUTPUT

V

V

REFERENCE

TAPS

V

V

V

DD

V

SS

TO

DIGITAL

SYSTEM

V

DD

SUPPLY

SYSTEM

DIGITAL

GROUND

75Ω

1V

P-P

VIDEO

INPUT

75Ω

5pF

14

11

CA3450

9

3

5

4

-4V

NOTE: Ground-planing and tight layout are extremely important.

FIGURE 16. TYPICAL HIGH BANDWIDTH AMPLIFIER FOR DRIVING THE HI3318

10Ω

7

8

13

12

+8V

0.001µF

6

0.001µF

75010Ω

0.1

10Ω

390Ω

110Ω

16

A/D FLASH

INPUT

21

0V TO -10V

OFFSET SOURCE

< 10Ω

R

S

4-1462

Page 12

HI3318

TABLE 1. OUTPUT CODE TABLE

(NOTE 1)

INPUT VOLTAGE BINARY OUTPUT CODE

CODE

DESCRIPTION

Zero 0.00 0.00 000000000 0

1 LSB 0.025 0.02 000000001 1

2 LSB 0.05 0.04 000000010 2

•

•

•

1

/4 Full Scale 1.60 1.28 001000000 64

•

•

•

1

/2 Full Scale - 1 LSB 3.175 2.54 001111111 127

1

/2 Full Scale 3.20 2.56 010000000 128

1

/2 Full Scale + 1 LSB 3.225 2.58 010000001 129

•

•

•

3

/4 Full Scale 4.80 3.84 011000000 192

V

REF

6.40V (V)

•

•

•

•

•

•

•

•

•

V

REF

5.12V (V) OF

•

•

•

•

•

•

•

•

•

MSB

B8 B7 B6 B5 B4 B3 B2

•

•

•

•

•

•

•

•

•

LSB

B1

DECIMAL

COUNT

•

•

•

•

•

•

•

•

•

•

•

•

Full Scale - 1 LSB 6.35 5.08 011111110 254

Full Scale 6.375 5.10 011111111 255

Over Flow 6.40 5.12 111111111 511

NOTE: 1. The voltages listed above are the ideal centers of each output code shown as a function of its associated reference voltage.

Reducing Power

Most power is consumed while in the auto-balance state.

When operating at lower than 15MHz clock speed, power

can be reduced by stretching the sample (φ2) time. The constraints are a minimum balance time (φ1) of 33ns, and a

maximum sample time of 500ns. Longer sample times cause

droop in the auto-balance capacitors. Power can also be

•

•

•

•

•

•

•

•

•

•

•

•

Clock Input

The Clock and Phase inputs feed buffers referenced to V

and V

-. Phase should be tied to one of these two poten-

AA

AA

tials, while the clock (if DC coupled) should be driven at least

from 0.2 to 0.7 x (V

coupled with at least a 1V

levels or 5V QMOS levels when V

+ - VAA-). The clock may also be AC

AA

swing. This allows TTL drive

P-P

+ is greater than 5V.

AA

reduced in the reference string by switching the reference on

only during auto-balance.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reser ves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

+

4-1463

Loading...

Loading...