Page 1

GP400DDS12

GP400DDS12

Powerline N-Channel Dual Switch IGBT Module

DS5341-1.1 February 2000

The GP400DDS12 is a dual switch 1200V, robust n

channel enhancement mode insulated gate bipolar

transistor (IGBT) module. Designed for low power loss, the

module is suitable for a variety of high voltage applications

in motor drives and power conversion. The high

impedance gate simplifies gate drive considerations

enabling operation directly from low power control

circuitry.

Fast switching times allow high frequency operation

making the device suitable for the latest drive designs

employing pwm and high frequency switching. The IGBT

has a wide reverse bias safe operating area (RBSOA) for

ultimate reliability in demanding applications.

These modules incorporate electrically isolated base

plates and low inductance construction enabling circuit

designers to optimise circuit layouts and utilise earthed

heat sinks for safety.

The powerline range of high power modules includes

dual and single switch configurations with a range of

current and voltage capabilities to match customer system

demands.

Typical applications include dc motor drives, ac pwm

drives, main traction drives and auxiliaries, large ups

systems and resonant inverters.

12

KEY PARAMETERS

V

CES

V

CE(sat)

I

C

I

C(PK)

5

6

7

8

9

11

10

(typ) 2.7V

(max) 400A

(max) 800A

13

24

1200V

FEATURES

■ n - Channel

■ Enhancement Mode

■ High Input Impedance

■ Optimised For High Power High Frequency Operation

■ Isolated Base

■ Full 1200V Capability

■ 400A Per Arm

APPLICATIONS

■ High Power Switching

■ Motor Control

■ Inverters

■ Traction Systems

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

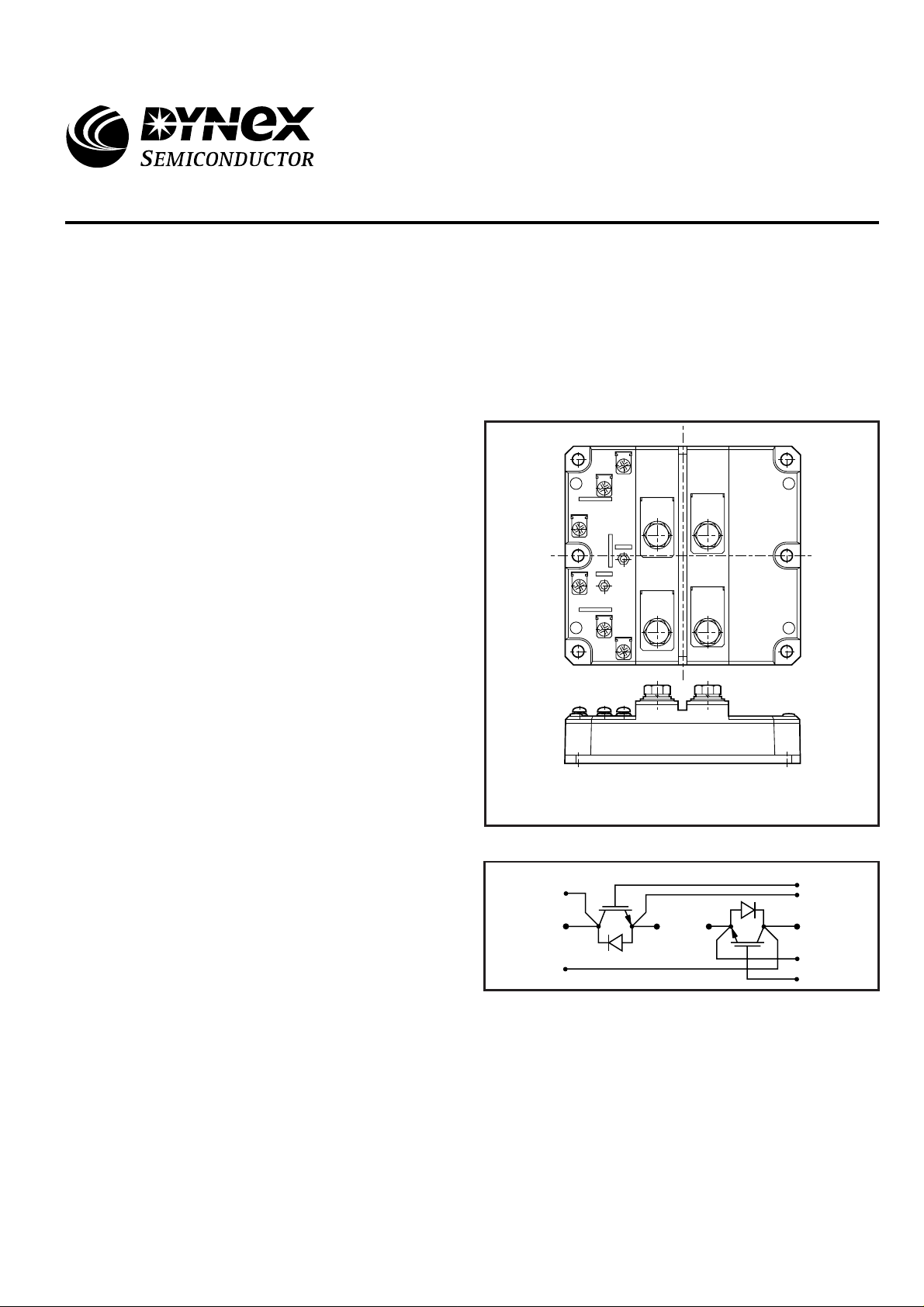

Outline type code: D

(See package details for further information)

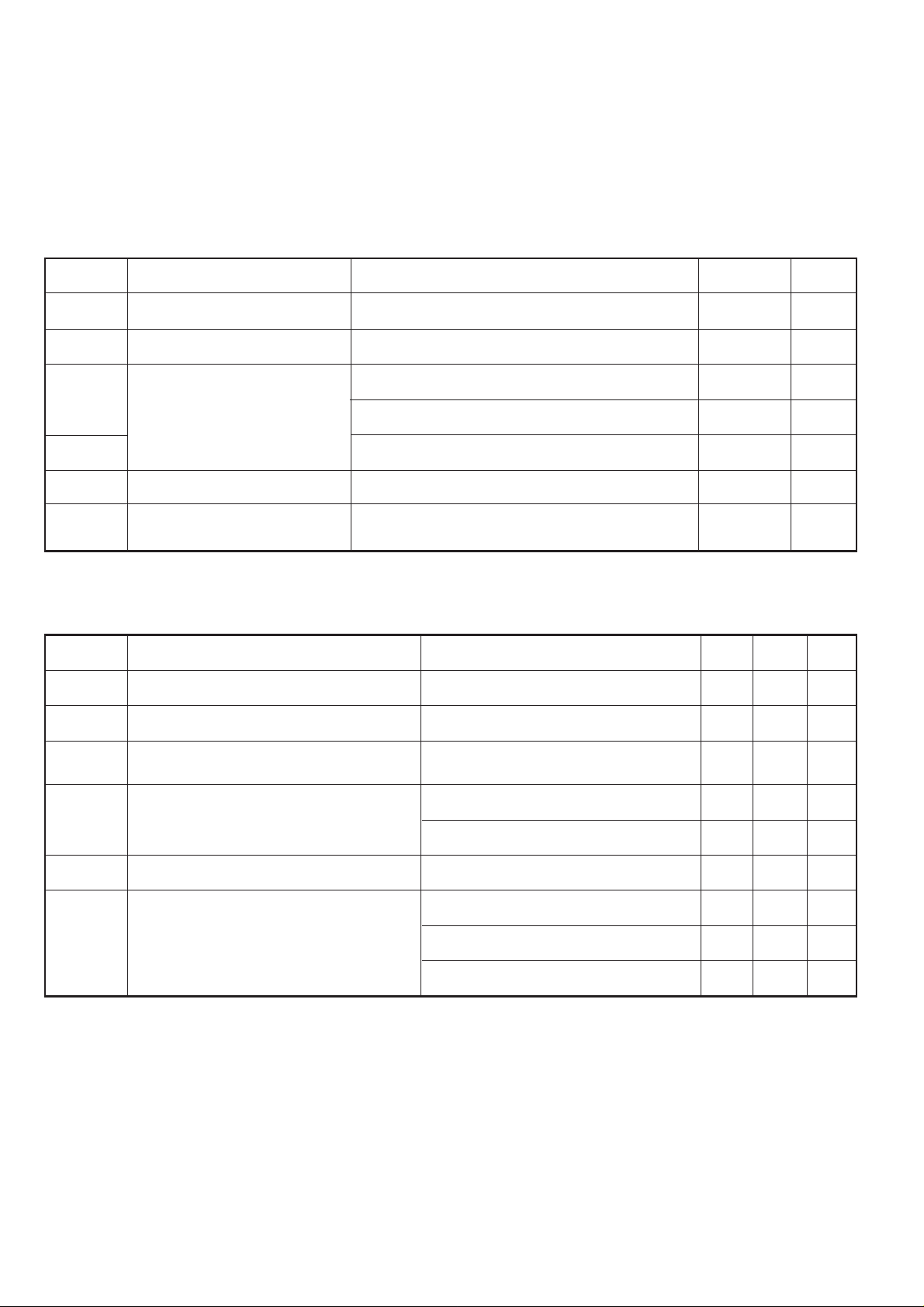

Fig. 1 Electrical connections - (not to scale)

2

)

12(C

2(C

2

2

7(C

)

)

1

)

4(E2)

1(E1)

11(G

10(E

3(C1)

5(E

6(G

2

)

1

)

1

)

Fig.2 Dual switch circuit diagram

ORDERING INFORMATION

Order As: GP400DDS12

Note: When ordering, please use the whole part number.

1/10

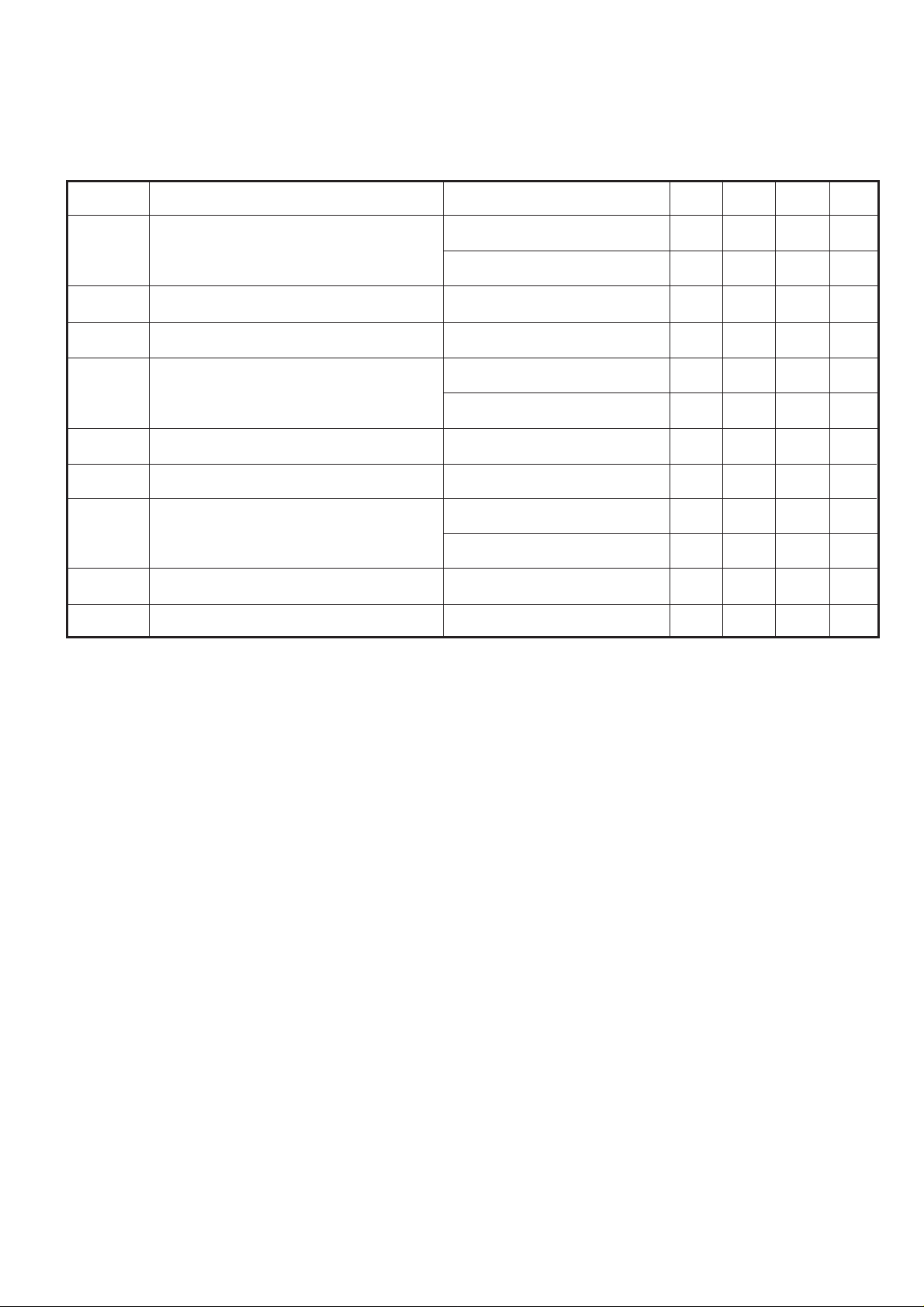

Page 2

GP400DDS12

ABSOLUTE MAXIMUM RATINGS - PER ARM

Stresses above those listed under 'Absolute Maximum Ratings' may cause permanent damage to the device. In

extreme conditions, as with all semiconductors, this may inlcude potentially hazardous rupture of the package.

Appropriate safety precautions should always be followed.

T

= 25˚C unless stated otherwise.

case

Test ConditionsSymbol

V

V

GES

I

I

C(PK)

CES

C

max

isol

Collector-emitter voltage

Gate-emitter voltage

Collector current

Isolation voltageV

VGE = 0V 1200

DC, T

DC, T

1ms, T

T

case

= 25˚C 600

case

= 75˚C 400

case

= 75˚C A800

case

= 25˚C (Transistor)

Commoned terminals to base plate.

AC RMS, 1 min, 50Hz

THERMAL AND MECHANICAL RATINGS

Symbol Conditions

R

R

R

th(j-c)

th(j-c)

th(c-h)

T

j

Thermal resistance - transistor (per arm)

Thermal resistance - diode (per arm) DC junction to case

Thermal resistance - Case to heatsink

(per module)

Junction temperature

DC junction to case

Mounting torque 5Nm

(with mounting grease)

Transistor

Diode

Max.Parameter

3750Maximum power dissipationP

2500

Min.Parameter Units

-

-

-

Max.

8-

Units

V

V±20

A

A

W

V

o

C/kW35

o

C/kW70-

o

C/kW

o

C150

o

C125-

T

stg

- Mounting - M6 Nm5-

Storage temperature range

Screw torque

-

Electrical connections - M4 Nm2Electrical connections - M8 Nm10-

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

2/10

–40

125

o

C

Page 3

ELECTRICAL CHARACTERISTICS

T

= 25˚C unless stated otherwise.

case

GP400DDS12

Symbol

I

CES

I

GES

V

GE(TH)

V

CE(SAT)

I

F

I

FM

V

F

C

ies

L

M

Parameter

Collector cut-off current

Gate leakage current

Gate threshold voltage

Conditions

VGE = 0V, VCE = V

VGE = 0V, VCE = V

CES

CES

, T

VGE = ±20V, VCE = 0V

= 125˚C mA50--

case

CE

Min.

VGE = 15V, IC = 400A

Collector-emitter saturation voltage

= 125˚C V

case

Diode forward current

Diode maximum forward current

DC

tp = 1ms A

Diode forward voltage IF = 400A 3.02.5-

Input capacitance

Module inductance

IF = 400A, T

VCE = 25V, VGE = 0V, f = 1MHz

= 125˚C 2.92.4-

case

-

Typ.

-

-

Max.

-

-

-4IC = 120mA, VGE = V

±4

3.52.7-

Units

mA1

µA

V7.5

V

4.03.2-VGE = 15V, IC = 400A, T

400

-

-

800

-

A

V

V

45

-

-

-

nF

nH

-20

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

3/10

Page 4

GP400DDS12

INDUCTIVE SWITCHING CHARACTERISTICS

For definition of switching waveforms, refer to figure 3 and 4.

T

= 25˚C unless stated otherwise

case

Symbol

t

d(off)

t

E

OFF

t

d(on)

E

Q

Q

T

= 125˚C unless stated otherwise.

case

t

d(off)

t

E

OFF

t

d(on)

r

ON

r

Turn-off delay time

Fall time

f

Turn-off energy loss

Turn-on delay time ns

Rise time

Turn-on energy loss

Diode reverse recovery charge

rr

Diode reverse recovery charge

rr

Turn-off delay time

Fall time

f

Turn-off energy loss

Turn-on delay time ns

Rise time

Parameter Min. Typ. Max. Units

Conditions

IC = 400A

VGE = ±15V

VCE = 600V

R

= R

G(ON)

G(OFF)

L ~ 100nH

IF = 400A

VR = 50%V

dIF/dt = 2000A/µs

IC = 400A

VGE = ±15V

VCE = 600V

R

= R

G(ON)

G(OFF)

L ~ 100nH

= 3.3Ω

,

CES

= 3.3Ω

-

1100

150

130

-

1300

200

170

ns

ns

mJ

900- 800

320

-t

90

-

30-

-

1300

200

170

-

400

130

50

1500

250

250

ns

mJ

µC

-170-

µC

ns

ns

mJ

1200- 950

350

-t

450

ns

4/10

E

Q

Q

Turn-on energy loss

ON

Diode reverse recovery charge

rr

Diode reverse recovery charge µC-225-

rr

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

IF = 400A

VR = 50%V

CES

,

dIF/dt = 2000A/µs

150

-

200

mJ

µC7050-

Page 5

SWITCHING DEFINITIONS

t

5

t

6

t

7

I

C

V

ce

V

ge

90%

0V

-15V

+15V

90%

10%

+15V

GP400DDS12

t4 + 5µs

E

= ∫ V

on

t

t

= t2 - t

d(on)

tr = t3 - t

10%

0V

V

ge

-15V

I

dt

ce.Ic

1

1

2

90%

10%

t

t

1

2

t

3

t

4

C

V

ce

Fig.3 Definition of turn-on switching times

t7 + 5µs

E

= ∫ V

off

t

t

= t6 - t

d(off)

tf = t7 - t

dt

ce.Ic

5

5

6

Fig.4 Definition of turn-off switching times

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

5/10

Page 6

GP400DDS12

CURVES

Vge = 20/15/12/10V

800

Common emitter

T

= 25˚C

case

700

600

- (A)

500

C

400

300

Collector current, I

200

100

0

0 1.0 2.0 3.0 4.0 5.0

Collector-emitter voltage, V

ce

- (V)

Fig.5 Typical output characteristics Fig.6 Typical output characteristics

Vge = 20/15/12/10V

800

Common emitter

T

= 125˚C

case

700

600

- (A)

500

C

400

300

Collector current, I

200

100

0

0 1.0 2.0 3.0 4.0 5.0

Collector-emitter voltage, V

ce

- (V)

80

70

60

50

- (mJ)

on

Conditions:

= 25˚C,

T

case

V

= 600V,

CE

V

= ±15V

GE

A

B

110

100

90

80

70

- (mJ)

on

Conditions:

T

= 125˚C,

case

V

= 600V,

CE

V

= ±15V

GE

60

40

30

Turn-on energy, E

20

10

0

0 50 100 150 200 250 300 350 400

Collector current, I

- (A)

C

C

A : Rg = 15Ω

B : R

= 10Ω

g

C : R

= 5Ω

g

50

40

Turn-on energy, E

30

20

10

A : Rg = 15Ω

B : R

C : R

0

0 50 100 150 200 250 300 350 400

Collector current, I

- (A)

C

Fig.7 Typical turn-on energy vs collector current Fig.8 Typical turn-on energy vs collector current

A

B

C

= 10Ω

g

= 5Ω

g

6/10

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

Page 7

90

0

25

50

75

100

125

0 50 100 150 200 250 300 350 400

Collector current, I

C

- (A)

Turn-off energy, E

off

- (mJ)

A : Rg = 15Ω

B : R

g

= 10Ω

C : R

g

= 5Ω

A

B

C

Conditions:

T

case

= 125˚C,

V

CE

= 600V,

V

GE

= ±15V

Conditions:

T

= 25˚C,

case

80

V

= 600V,

CE

V

= ±15V

GE

70

60

- (mJ)

off

50

40

30

Turn-off energy, E

20

A : Rg = 15Ω

10

B : R

C : R

0

0 100 200 300 400 500 600 700 800

Collector current, I

- (A)

C

A

B

C

= 10Ω

g

= 5Ω

g

GP400DDS12

Fig.9 Typical turn-off energy vs collector current Fig.10 Typical turn-off energy vs collector current

35

Conditions:

V

= 600V,

30

- (mJ)

25

off(Diode)

20

15

V

R

CE

= 15V,

GE

= 5Ω

g

T

T

case

case

= 125˚C

= 25˚C

10

Diode turn-off energy, E

5

0

0 100 200 300 400

Collector current, I

C

(A)

Fig.11 Typical diode reverse recovery charge vs collector current Fig.12 Typical switching characteristics

2000

1800

t

1600

1400

- (ns)

s

1200

1000

d(off)

t

f

t

d(on)

800

Switching times, t

600

400

200

t

r

0

0 50 100 150 200 250 300 350 400

Collector currrent, I

- (A)

C

Conditions:

= 125˚C,

T

case

V

= 600V

CE

V

= 15V

GE

R

= 5Ω

g

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

7/10

Page 8

GP400DDS12

800

700

1000

900

800

600

700

- (A)

C

600

500

400

Collector current, I

300

- (A)

500

F

400

300

Forward current, I

Tj = 25˚C

Tj = 125˚C

200

200

T

= 125˚C

case

V

100

0

0 0.5 1 1.5 2 2.5 3 3.5

Forward voltage, VF - (V)

100

= ±15V

ge

R

= 5Ω*

g

*Recommended minimum value

0

0 200 400

Collector-emitter voltage, V

600

Fig.13 Diode typical forward characteristics Fig.14 Reverse bias safe operating area

800

ce

- (V)

1000 1200

10000

IC max. (single pulse)

1000

- (A)

C

I

C

max. DC (continuous)

t

p

= 1ms

50µs

100µs

100

Collector current, I

10

1

1 10 100 1000 10000

Collector-emitter voltage, V

ce

- (V)

Fig.15 Forward bias safe operating area Fig.16 Transient thermal impedance

100

- (°C/kW )

th (j-c)

10

1

Transient thermal impedance, Z

0.1

1 10 1000100

Pulse width, t

- (ms)

p

Diode

Transistor

10000

8/10

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

Page 9

GP400DDS12

PACKAGE DETAILS

For further package information, please contact your local Customer Service Centre. All dimensions in mm, unless stated

otherwise. DO NOT SCALE.

13

24

16

18

26

13

6x M4

7

9

12

11

10

11.5 35

14

62

15

15

5

6

8

20

62

65

13

24

4x M8

57

43.3 11.85

57

6x Ø7

65

38

28

5

140

Nominal weight: 1600g

Module outline type code: D

ASSOCIATED PUBLICATIONS

Title Application Note

Number

Electrostatic handling precautions AN4502

An introduction to IGBTs AN4503

IGBT ratings and characteristics AN4504

Heatsink requirements for IGBT modules AN4505

Calculating the junction temperature of power semiconductors AN4506

Gate drive considerations to maximise IGBT efficiency AN4507

Parallel operation of IGBTs – punch through vs non-punch through characteristics AN4508

Guidance notes for formulating technical enquiries AN4869

Principle of rating parallel connected IGBT modules AN5000

Short circuit withstand capability in IGBTs AN5167

Driving high power IGBTs with concept gate drivers AN5190

31.5

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

9/10

Page 10

GP400DDS12

POWER ASSEMBLY CAPABILITY

The Power Assembly group was set up to provide a support service for those customers requiring more than the basic

semiconductor, and has developed a flexible range of heatsink / clamping systems in line with advances in device types and the

voltage and current capability of our semiconductors.

We offer an extensive range of air and liquid cooled assemblies covering the full range of circuit designs in general use today. The

Assembly group continues to offer high quality engineering support dedicated to designing new units to satisfy the growing needs of

our customers.

Using the up to date CAD methods our team of design and applications engineers aim to provide the Power Assembly Complete

solution (PACs).

HEATSINKS

Power Assembly has it’s own proprietary range of extruded aluminium heatsinks. They have been designed to optimise the

performance or our semiconductors. Data with respect to air natural, forced air and liquid cooling (with flow rates) is available on

request.

For further information on device clamps, heatsinks and assemblies, please contact your nearest Sales Representative or the

factory.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded as

a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company reserves

the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such

methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication

or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS5341-1 Issue No. 1.1 February 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

10/10

Caution: This device is sensitive to electrostatic discharge. Users should follow ESD handling procedures.

Loading...

Loading...