Page 1

GP2W0106YP

IrDA Data Sheet

FEATURES

• Built-in Photodiode

• Operating voltage 2.0 V to 3.6 V

• Conforms to eye safety IEC60825-1, without external resistor

• This product shall not contain the following materials, and these materials shall not be used in the production process for this product.

–CFC

– Halon

– Carbon Tetrachloride

– 1.1.1. Trichloroethane (Methylchloroform)

– Specific brominated flame retardants such as the

INTRODUCTION

This specification applies to the outline and charac-

teristics of IrDA 1.2 type (data rate 2.4 kbps to

115.2 kbps, low power option compliant) optical data

communication transceiver.

NOTES

• Caution should be taken to prevent the detector surface from being smeared with dust or dirt, or from

being touched, as it may cause faulty operation.

• Cleaning conditions:

– Solvent cleaning: Solvent temperature 45°C or

– Ultrasonic cleaning: The effect of ultrasonic

– Cleaning solvent: The cleaning shall be carried

• In order to prevent electrostatic damage to the integrated circuit, handle this device in a static-free environment and workstation.

S

PBBO

less. Immersion for 3 minutes or less.

cleaning on the device differs by cleaning bath

size, ultrasonic power output, cleaning time, PCB

size or device mounting condition, etc. Test the

device under actual conditions and confirm that

ultrasonic cleaning does not cause any immediate or potential defects.

out with ethyl alcohol, methyl alcohol, or isopropyl

alcohol.

and PBBS are not used in this device.

S

115 kbps Transceiver

• External force applied to the device after mounting can

cause mounting defects such as the terminal coming

off. Be careful when handling the device and prevent

objects from touching the device after mounting.

• Refer to the ‘Precautions for Soldering’ section.

• When the system (program) is designed, the turn

around time from transmit to receive should be

designed by considering 200 µs or more that is specified by IrDA. This turn around time means the time

that this device does not temporarily detect the

incoming signal, since the transmitted light from the

transmitter side reaches the detector side of the

same transceiver.

• Consider that 200 µs or more (at T

signal) is necessary to return from shut-down mode

to ready-operation mode. In addition, thoroughly

confirm the operation in the actual application.

• When there is considerable external stray light or a

light source is located near the transceiver, or the

detector face receives considerable external stray

light, a pulse other than desired signal output may

be generated as noise on output terminal of the

transceiver. Consider the layout and structure in

your design to minimize disturbing light on the

detector face.

• When the sensor is adopted in an IR communication

system, it should be used according to the signal

method which is specified by ‘Serial Infrared Physical Layer Link Specification’ published by the Infrared Data Association. Faulty operation may occur, if

a signal method other than that specified is used.

• RXD pinout is a pullup (260 kΩ TYP.) to V

down mode. See Table 1 and Figure 2.

• In circuit designs, make allowance for the degradation

of the light emitting diode output that results from

long-term continuous operation (50% degradation/5

years). The light emitting diode output may be

degraded quickly when operated at T

fore it is recommended to operate over T

= 25°C, no input

A

in shut-

DD

= -40°C, there-

A

= -20°C.

A

IrDA Data Sheet 1

Page 2

GP2W0106YP 115 kbps Transceiver

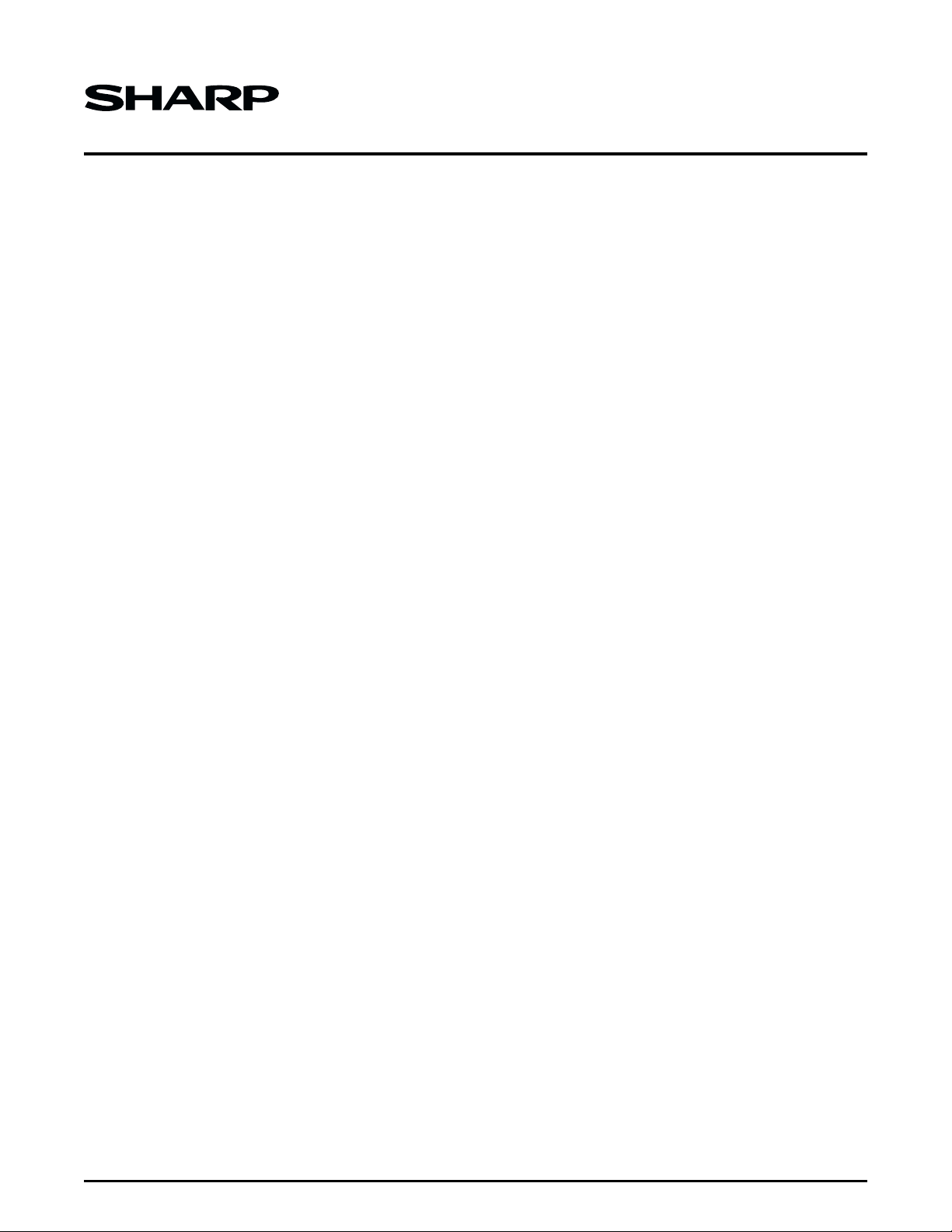

GP2W0106YP-2

TR1

TR2

260 kΩ

TYP.

RXD

Table 1. I/O Truth Table

SD TXD LED RECEIVER TR1 TR2 RXD

Not

Valid

High

Pullup

1NC2NC3

V

+

CX

4

5SD6

GND SD RXD TXD

DD

GND

V

DD

RXD7TXD8LEDA

Low High On Don’t Care ——

Low Low Off IrDA Signal Off On Low

Low Low Off No Signal On Off High

High

Don’t

Care

Off Don’t Care Off Off

COMPONENT

CX 3.3 µF/6.3 V (NOTE 1)

NOTES:

1. Choose the most suitable CX according to the

noise level and noise frequency of power supply.

2. Pin 1 and Pin 2 are not connected internally.

RECOMMENDED VALUE

Figure 1. Recommended External Circuit

1

ENCODER

CIRCUIT

UART

GP2W0106YP-1

Figure 2. RXD Equivalent Circuit

CX

+

LEDA

2

TXD

CONSTANT

CURRENT

CIRCUIT

GP2W0106YP

V

DD

3

3

GP2W0106YP-3

SD INPUT PERFORMANCE

LOW Normal Mode

HIGH

Shutdown

Mode

4

5

NOTES:

1 Transmitting data waveform

2 Encoder circuit output waveform

3 Transmitter output optical signal waveform

4 GP2W0106YP receiver output waveform

Receiving data waveform

5

DECODER

CIRCUIT

RXD

SD

Figure 3. Example of Circuit

GND

2 IrDA Data Sheet

Page 3

115 kbps Transceiver GP2W0106YP

1.425

1.55

0.475

2.375

3.325

1.55

0.1

1.1

2.0

NOTES:

1. Dimensions are in mm.

2. Dimensions are for reference.

3. Soldering paste area

GP2W0106YP-6

0.6

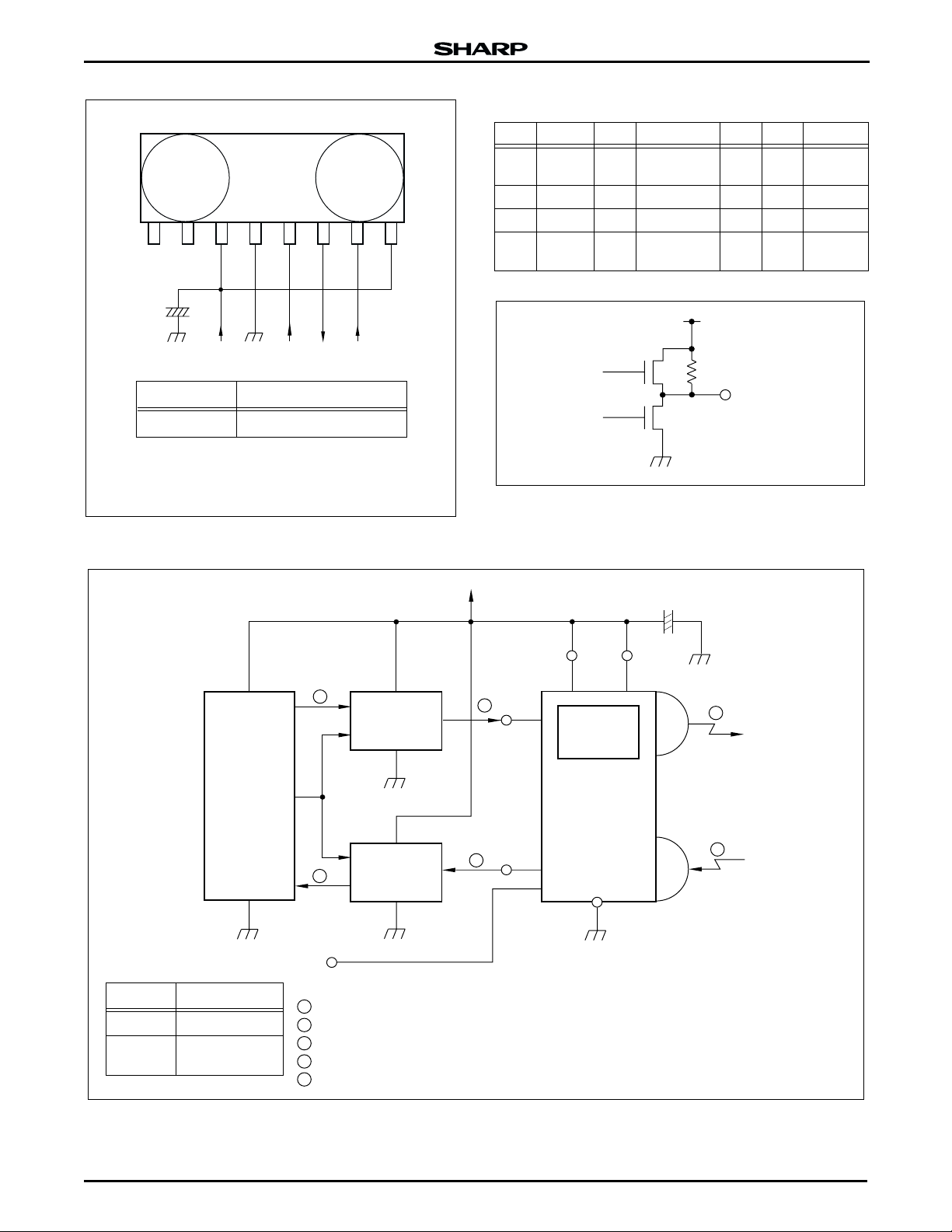

T

1

0

T

10 1

3T/16

2

3

4

5

0

10 1

NOTES:

1 Transmitting data waveform

2 Encoder circuit output waveform

3 Transmitter output optical signal waveform

4 GP2W0106YP receiver output waveform

5 Receiving data waveform

T =

1

Data Rate

Data rate: 2.4 kbps, 9.6 kbps, 19.2 kbps, 38.4 kbps,

57.6 kbps, 115.2 kbps

Figure 4. Example of Signal Waveform

Recommended Size of

Solder Cream Paste

Open the solder mask as shown in Figure 5. The

size of solder cream paste for this device before reflow

soldering must be as large as one of the foot pattern

land, indicated in Figure 6.

GP2W0106YP-4

Figure 5. Solder Cream Paste Size

NOTES:

1. Dimensions are in mm.

2. Dimensions are shown for reference.

3. Connect foot pattern of shield case to GND pattern.

IrDA Data Sheet 3

CENTER OF

MOUNTING AREA

8

0.6

7

6

5

0.475

1.0

1.55

1.425

4

2.375

3

3.325

1.1

2

2.0

0.1

1

Figure 6. Foot Pattern of PCB

1.55

PIN

1

2

3

4

5

6

7

8

PIN NAME SYMBOL

NC

NC

V

DD

Ground

Shutdown

Receiver Data Output

Transmitter Data Input

LED Anode

NC

NC

V

DD

GND

SD

RXD

TXD

LEDA

GP2W0106YP-5

Page 4

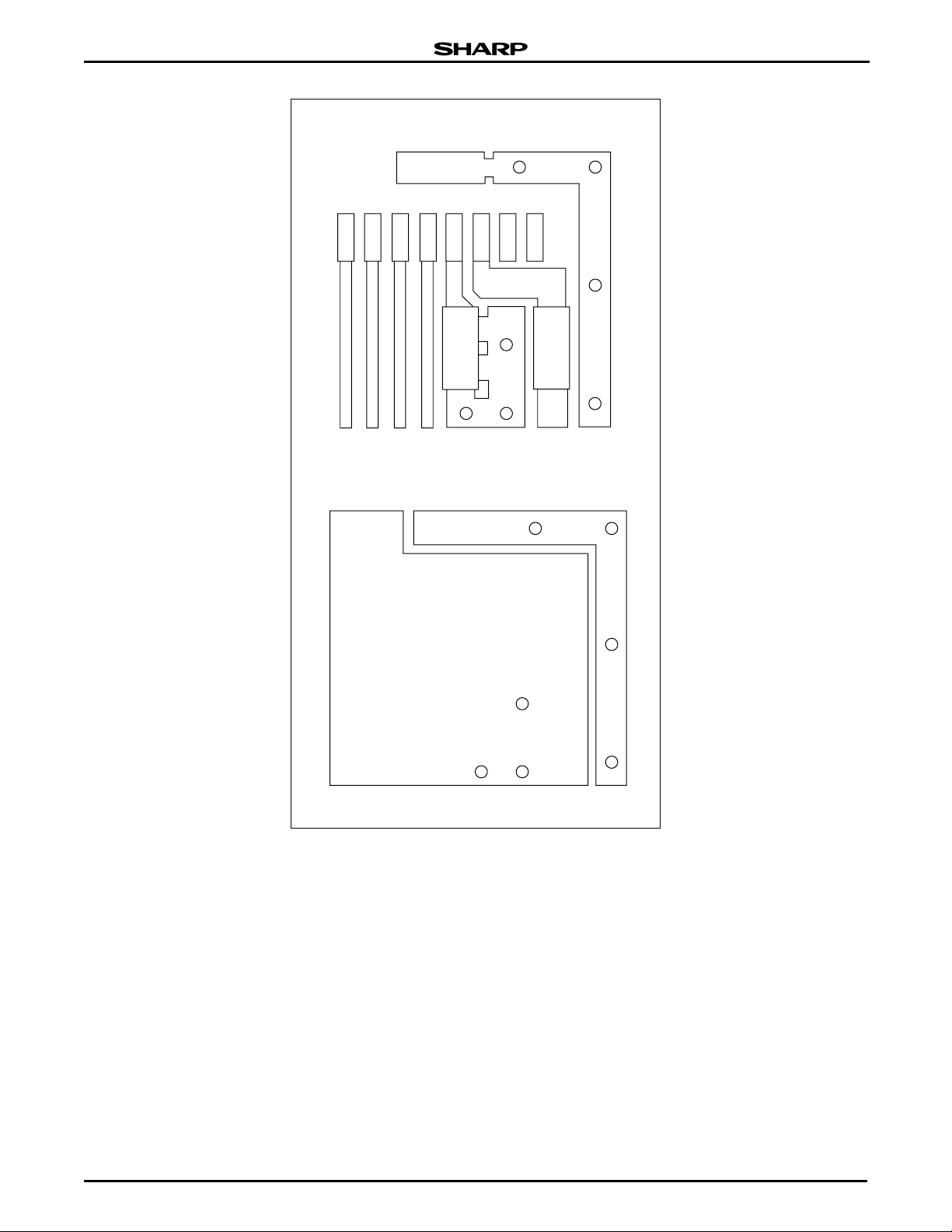

GP2W0106YP 115 kbps Transceiver

COMPONENT SIDE

CX

LEDA

TXD

RXD

SD

GND

CIRCUIT SIDE

Figure 7. PCB Layout Example

DD

V

GND

SHIELD

2W0106-7

4 IrDA Data Sheet

Page 5

115 kbps Transceiver GP2W0106YP

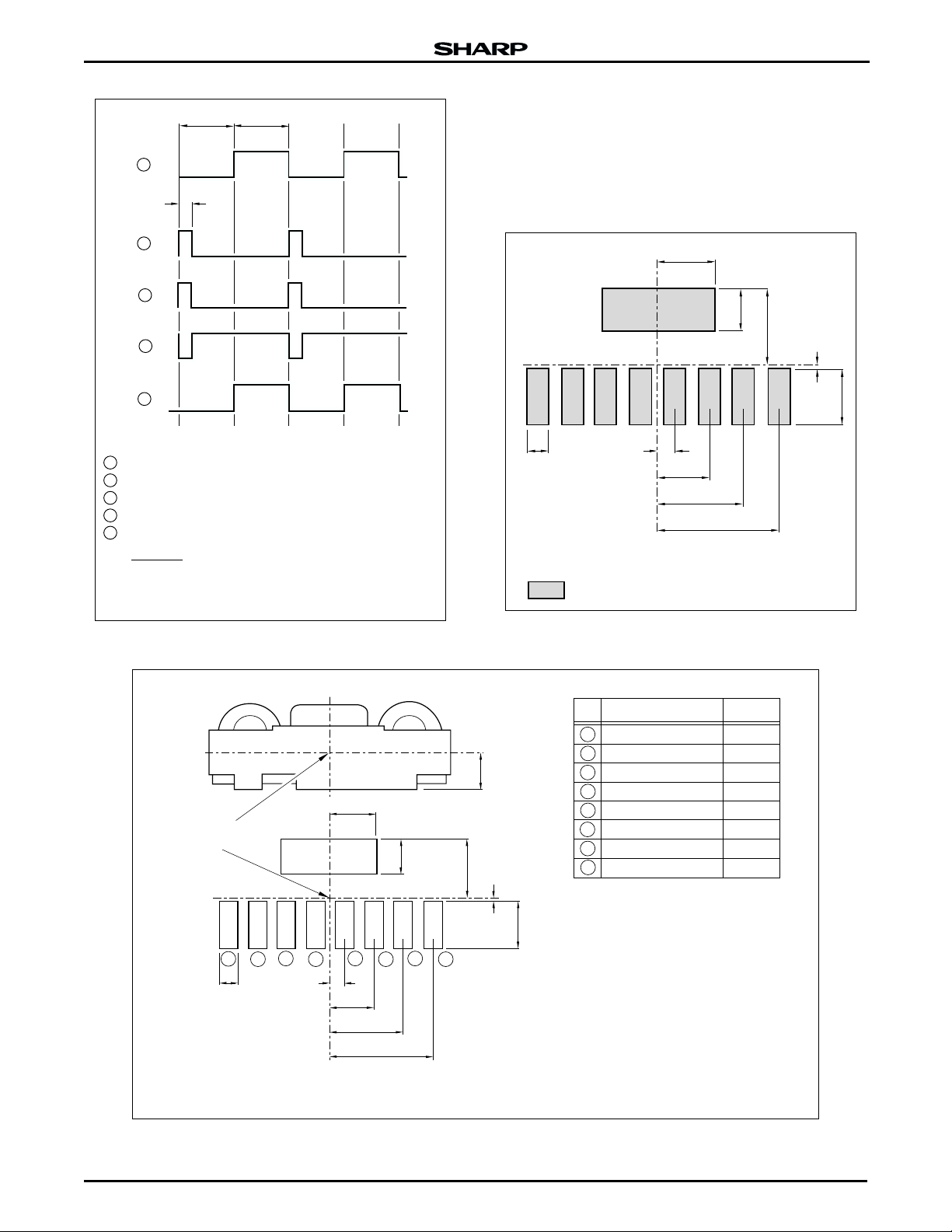

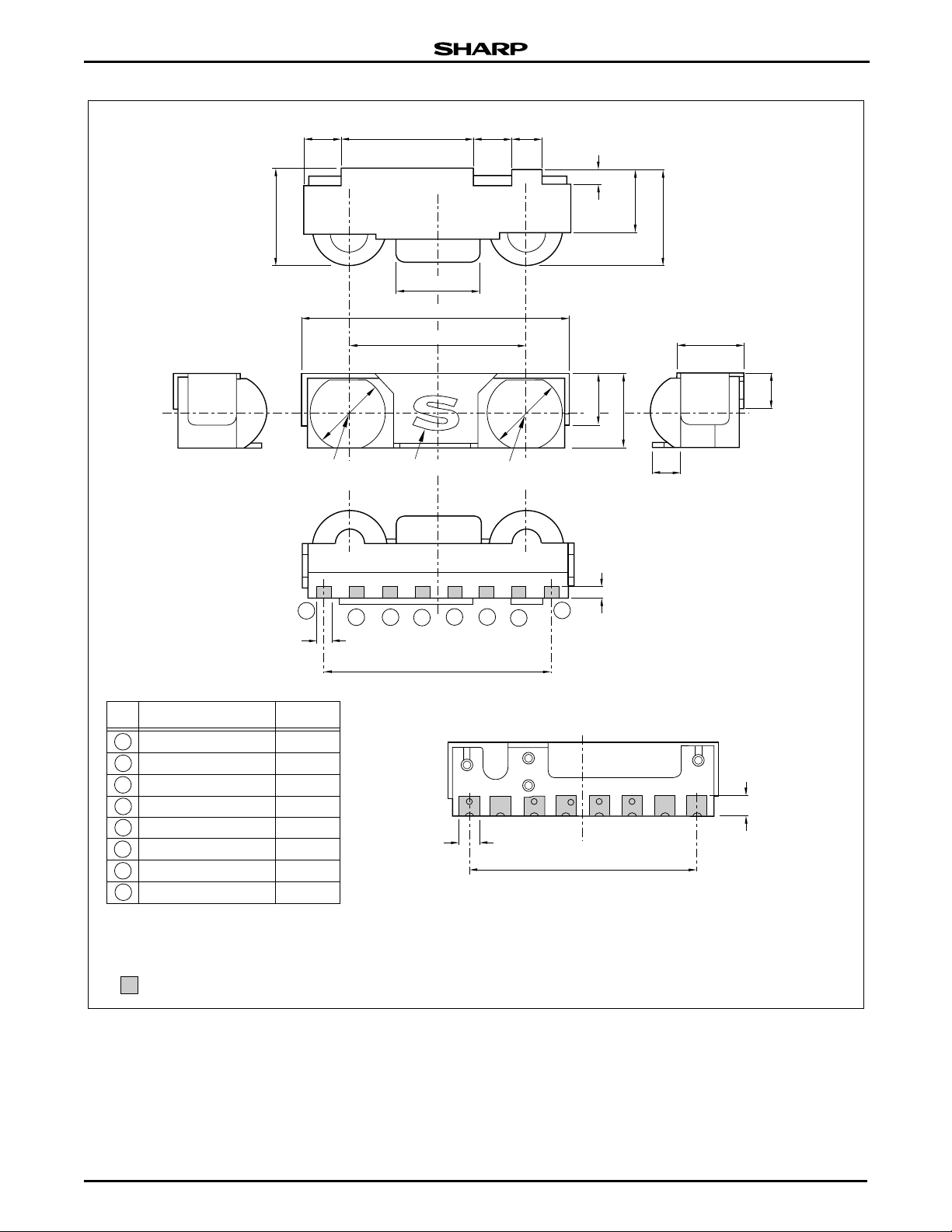

1.15 3.9

2.75 ±0.3

CENTER

OF DETECTOR

2.5

7.9 ±0.3

5.2

EMBOSSED

'S'

1.15 0.9

φ2.2φ2.2

CENTER

OF EMITTER

1.5 ±0.3

0.48

2.15 ±0.3

1.88

0.8

±0.3

2.7

+0.3

-0.2

2 ±0.3

1.05 ±0.3

PIN

1

2

3

4

5

6

7

8

PIN NAME SYMBOL

NC

NC

V

DD

Ground

Shutdown

Receiver Data Output

Transmitter Data Input

LED Anode

1

NC

NC

V

DD

GND

SD

RXD

TXD

LEDA

2 3

+0.2

8 - 0.4

-0.3

PO .95 x 7 = 6.65

8 - 0.6

5 6

4

BOTTOM VIEW

NOTES:

1. Dimensions are in mm.

2. Unspecified tolerances are ±0.2

3.

Adhesion of resin to the terminal area are allowed MAX. 0.2 mm.

area: Au plating

Figure 8. GP2W0106YP Outline Dimensions

8

7

PO .95 x 7 = 6.65

0.35

0.6

±0.3

GP2W0106YP-8

IrDA Data Sheet 5

Page 6

GP2W0106YP 115 kbps Transceiver

RATINGS AND CHARACTERISTICS

Absolute Maximum Ratings

PARAMETER SYMBOL RATINGS UNIT NOTES

Supply voltage V

LED supply voltage V

Peak forward current I

Operating temperature T

Storage temperature T

Soldering temperature T

NOTES:

1. Pulse width: 78.1 µs. Duty ratio: 3/16.

2. Recommended condition: -20°C to +85°C.

3. Soldering reflow time: 5 seconds.

DD

LEDA

FM

OPR

STG

SOL

0 to 6.0 V

0 to VDD +1.0 V

60 mA 1

-20 to +85 °C2

-40 to +85 °C

230 °C3

Recommended Operating Conditions

PARAMETER SYMBOL OPERATING CONDITION UNIT NOTES

Supply voltage V

LED supply voltage V

Operating temperature T

DD

LEDA

OPR

Data rate BR 2.4 to 115.2 kbps

SD terminal high level input voltage V

SD terminal low level input voltage V

TXD high level input voltage V

TXD low level input voltage V

IHSD

ILSD

IHTXD

ILTXD

2.0 to 3.6 V

2.0 to VDD +1.0 V

-20 to +85 °C

VDD × 0.95 to V

DD

V1

0.0 to VDD × 0.1 V 2

VDD × 0.8 to V

DD

V3

0.0 to VDD × 0.2 V 4

NOTES:

1. Shut down mode

2. Normal mode

3. LED ON. See Figure 14.

4. LED OFF. See Figure 14.

6 IrDA Data Sheet

Page 7

115 kbps Transceiver GP2W0106YP

t

W

V

OL

t

R

t

F

V

OH

90%

50%

10%

GP2W0106YP-10

Electrical Characteristics

T

= -40°C to +85°C, VDD = 2.0 V to 3.6 V unless otherwise specified

OPR

PARAMETER SYMBOL MIN. TYP. MAX. UNIT NOTES

Current consumption at no input signal I

Current consumption at shut-down mode I

High level output voltage V

Low level output voltage V

DD

DD-S

OH

OL

V

DD

Rise time tr 0.4 µs 5

Fall time tf 0.4 µs 5

Low level pulse width tw 1.0 3.0 µs 5

Reception distance L 20 cm 5

Input irradiance Ee 9.0 µW/cm

Receiver latency tl 30 500 µs

Receiver wakeup time tsdw 60 500 µs 6

Radiant intensity I

LED peak current I

E

LED

3.6 25 mW/sr 7

16 20 26 mA 7

Rise time tr 0.6 µs 8

Fall time tf 0.6 µs 8

Peak emission wavelength

p 870 nm

λ

100 170 µA 1

0.01 0.2 µA 2

V3

0.5 V 4

2

5

NOTES:

1. No input signal, V

2. No input signal, V

= 20 µA. See Figures 9, 10, and 11.

3. I

OH

4. BR = 115.2 kbps,

5. BR = 115.2 kbps,

6. No input signal.

7. BR = 115.2 kbps,

See Figures 12, 13, and 14.

8. BR = 115.2 kbps. See Figures 12, 13, and 14.

T

1

T

2

NOTE: At BR = 2.4 kbps: T1 = 416.7 µs, T2 = 78.1 µs

At BR = 115.2 kbps: T1 = 8.68 µs, T2 = 1.63 µs

= 0 V. Output terminal open.

ILSD

= VDD. Output terminal open. VDD = 3.3 V.

IHSD

φ ≤

15°, See Figures 9, 10, and 11.

φ ≤

φ ≤

15°, T

15°, T

T

1

= 25°C. See Figures 9, 10, and 11.

OPR

= 25°C. VDD = V

OPR

LEDA

RADIATION

INTENSITY OF

TRANSMITTER

3.6 mW/sr

GP2W0106YP-9

= 3.3 V. V

Figure 9. Input Signal Waveform (Detector Side)

IHTXD

= 2.8 V.

Figure 10. Output Waveform (Detector Side)

IrDA Data Sheet 7

Page 8

GP2W0106YP 115 kbps Transceiver

TRANSMITTER

(NOTE)

NOTE:

1. Transmitter uses GP2W0106YP (λp = 870 nm TYP.)

which is adjusted to a radiation intensity of 3.6 mW/sr.

2. φ Indicates horizontal and vertical directions.

3. Ee: Detector face illuminance < 10 x

Figure 11. Standard Optical System (Detector Side)

90%

I

E

φ

φ

GP2W0106YP

OSCILLOSCOPE

L

GP2W0106YP-11

10%

t

R

t

F

GP2W0106YP-12

Figure 12. Output Waveform Specification

(Emitter Side)

8 IrDA Data Sheet

Page 9

115 kbps Transceiver GP2W0106YP

GP2W0106YP-15

PEAK

FORWARD

CURRENT

I

FM

(mA)

60

40

26

20

-20 85

100755025

AMBIENT TEMPERATURE T

A

(°C)

NOTE: Pulse width ≤ 78.1 µs, Duty ratio 3/16

0-25

0

GP2W0106YP

NOTE: φ indicates horizontal

and vertical directions

1.63 µs

Tx = 2.8 V

V

IN

φ

φ

Figure 13. Standard Optical System (Emitter Side)

= 3.3 V

V

DD

LEDA

TXD

GP2W0106YP

DETECTOR FOR

RADIATION INTENSITY

MEASURING

GP2W0106YP-13

BR = 115.2 kbps

Figure 14. Recommended Circuit (Emitter Side)

IrDA Data Sheet 9

GP2W0106YP-14

Figure 15. Peak Forward Current

Versus Ambient Temperature

Page 10

GP2W0106YP 115 kbps Transceiver

RELIABILITY

TEST ITEMS TEST CONDITIONS

FAILURE JUDGEMENT

CRITERIA

SAMPLES

(n)

DEFECTIVE

(c)

NOTES

1 cycle -20°C to 85°C

Temperature cycling

(30 minutes at each extreme)

n = 22 c = 0 1

20 cycles test

High temperature and high

humidity storage

High temperature storage +85°C, 240 hours n = 22 c = 0 1

Low temperature storage -30°C, 240 hours n = 22 c = 0 1

Operation life 1

Operation life 2

+40°C, 90% RH, 240 hours n = 22 c = 0 1

> Up × 1.2

I

DD

L < Low × 0.8

< Low × 0.8

I

+25°C, V

hours

+25°C, V

240 hours, Pulse width

= 3.3 V, 240

DD

= LEDA = 3.3 V,

DD

E

> Up × 1.2

I

E

Up: Upper

Specification Limint

n = 11 c = 0 1

n = 11 c = 0

78.1 µs, Duty ratio 3/16

Mechanical shock

Variable frequency

vibration

1,000 m/s2, 6 ms,

3 times/±X, ±Y, ±Z direction

2

200 m/s

,

100 to 2,000 to 100 Hz for

approximately 4 minutes

Low: Lower

Specification Limint

n = 11 c = 0

n = 11 c = 0

48 minutes/X, Y, Z direction

Reflow solder head 230°C, 5 s. n = 11 c = 0 2

NOTES:

1. The sample to be tested shall be left at normal temperature and humidity for

2 hours after it is taken out of the chamber. No dew point.

2. Refer to the ‘Precautions for Soldering’ section for temperature profile.

10 IrDA Data Sheet

Page 11

115 kbps Transceiver GP2W0106YP

OUTGOING INSPECTION

• Inspection lot: Inspection shall be carried out per

each delivery lot.

• Inspection method: A single sampling plan, normal

inspection level two based on ISO 2859 shall be

adopted.

Table 2. Outgoing Inspection

PARAMETER

Major defect

Minor defect

INSPECTION ITEMS AND

TEST METHOD

Disconnection, short 0.1

Inverse polarity on terminal 0.1

Soldering defect (obstacle to

use)

Electrical characteristic defect 0.1

Appearance defect which

affects the electrical characteristics such as, split, chip,

scratch, stain, or blur

AQL(%)

0.1

0.25

PRECAUTIONS FOR SOLDERING

Solder Reflow

Solder only once at the temperature and the time

within the temperature profile as shown in Figure 16.

Other Precautions

An infrared lamp used to heat up for soldering may

cause a localized temperature rise in the resin. Keep the

package temperature within that specified in Figure 16.

Also avoid immersing the resin part in the solder. Even if

within the temperature profile shown in Figure 16, there

is the possibility that the gold wire in the package may

break if the deformation of the PCB affects the lead pins.

Use after fully confirming the conditions of actual solder

reflow machine.

Soldering

• Soldering iron shall be less than 25 W, and temper-

ature of soldering iron point shall be used at less

than 260°C.

• Soldering time shall be within 5 seconds.

• Soldered product shall treat at normal temperature.

• Solder: 6/4 solder or included Ag solder.

230°C

MAX.

200°C

165°C

MAX.

25°C

1 - 4°C/s

1 - 4°C/s

1 - 4°C/s

5 s MAX.

60 s MAX.

120 s MAX. 90 s MAX.

GP2W0106YP-16

Figure 16. Temperature Profile

IrDA Data Sheet 11

Page 12

GP2W0106YP 115 kbps Transceiver

TAPING SPECIFICATIONS

Taping Method

• Taping structure and dimensions: The tape should

have a structure in which a cover tape is sealed heatpressed on the carrier tape of conductive PET. See

Figure 17.

• Reel structure and dimensions: The taping reel

should be conductive plastic with its dimensions as

shown in Figure 18.

• Direction of product insertion: Product direction in

carrier tape should be such that electrode side of

product is placed on the cover tape side and lens

side of product is placed on the hold side of the tape.

See Figure 19.

2.0 ±0.1

4.0 ±0.1

8.0 ±0.1

• Taped device repair: To repair taped device failure,

cut the bottom of carrier tape with a cutter, and after

replacing with good devices, seal the cut portion with

adhesive tape.

• Adhesiveness of cover tape: The exfoliation force

between carrier tape and cover tape should be 0.2 N

to 1 N for the angle from 160° to 180°.

• Rolling method and quantity: Wind the tape back on

the reel so that the cover tape is on the outside.

Attach more than 20 cm of blank tape to the trailer

and the leader of the tape and fix both ends with

adhesive tape. One reel shall contain 2,000 pieces.

• Safety protection during shipping: There should be

no deformation of component or degradation of electrical characteristics due to shipping.

φ1.5

+0.1

-0.0

0.3 ±0.05

2.65 ±0.1

NOTE: Dimensions are in mm.

1.75 ±0.1

7.5 ±0.1

16.0 ±0.3

3.25 ±0.1

Figure 17. Tape Structure and Dimensions

8.5 ±0.1

GP2W0106YP-17

12 IrDA Data Sheet

Page 13

115 kbps Transceiver GP2W0106YP

21 ±0.8

13 ±0.2

2 ±0.5

22.4 MAX.

100 ±1

NOTE: Dimensions are in mm.

330 ±2

17.5 ±0.5

GP2W0106YP-18

Figure 18. Reel Structure and Dimensions

PULL-OUT DIRECTION

LENS

SIDE

GP2W0106YP-19

Figure 19. Direction of Product Insertion

IrDA Data Sheet 13

Page 14

GP2W0106YP 115 kbps Transceiver

TAPING MOISTURE-PROOF PACKING

Packaging Specifications

Table 3. Packaging Material

NAME MATERIAL

Aluminum laminate bag Aluminum polyethylene

Label Paper

Siccative

Outer case Paper

Pads Paper

Packaging Method

• Seal the aluminum laminated bag containing the

tape reel (2,000 pieces per reel) and siccative.

• Fill out necessary information on the label and paste

it on the aluminum laminate bag.

• Pack four aluminum laminated bags (containing one

reel each) into the designated outer case, where

paper pads are placed on the bottom and top of the

outer case, as well as between each layer of the aluminum laminated bags. Minimum order/shipment

quantity should be one laminated bag.

• The outer case should then be sealed with packaing

tape, with indicating the model name, quantity, and

outgoing inspection data on the case. Total of 8,000

pieces per carton.

Table 4. Packaging Method Specifications

Storage and Treatment After Unsealing

• Storage conditions: The product should be stored

with these conditions:

– Storage temperature: 10°C to 30°C

– Humidity: below 60% RH

• Treatment after opening:

– After unsealing, devices should be mounted un-

der the temperature condition of 10°C to 30°C, at

the humidity conditions of below 60% RH, within

two days.

– In case long term storage is needed, devices

should either be stored in dry box or re-sealed in

a moisture-proof bag with siccative and kept in an

environment where the temperature is 10°C to

30°C, at the humidity condition of below 60% RH.

Devices must be mounted within two weeks.

• Baking before mounting:

– In the event that the devices are not maintained

in the recommended storage conditions or the

enclosed siccative indicator has turned pink,

baking must be done before devices are mounted. Please also note that baking should only be

done once.

– Recommended condition: 100°C, 12 to 24 hours.

– Baking will not be properly done with the devices

in their shipping package. To complete the baking

properly, devices should either be temporarily

mounted to PCB with adhesive, or placed in a

metal tray. The temporary mounting should be

done using adhesive, not by soldering.

PACKAGE

SHAPE

Tape reel

(φ 330 mm)

PRODUCT QUANTITY

2,000

1 model

pieces

per reel

SACK

QUANTITY

1 reel per

moisture-proof

laminated bag

14 IrDA Data Sheet

Page 15

115 kbps Transceiver GP2W0106YP

DESICCANT

EXAMPLE 1

LABEL

(MODEL NUMBER

QUANTITY

DATE)

PRODUCTS

IN TAPE-REEL

ALUMINUM

LAMINATED BAG

TAPE-REEL IN

ALUMINUM LAMINATED BAG

PADS

(TOTAL 5 SHEETS)

440 mm TYP.

TAPE-REEL IN

ALUMINUM

LAMINATED BAG

(TOTAL 4 SETS)

PACKING CASE

EXAMPLE 3

370 mm TYP.

PACKING

TAPE

EXAMPLE 2

PACKAGE METHOD EXAMPLES:

1. Seal the aluminum laminated bag, including the tape reel

with 2,000 pieces and desiccant.

2. Fill out the model name, quantity etc. in the blank area of label

and paste on the bag.

3. Put the four moisture-proof laminated bags in the ruled case.

Put the pad between the bags, and top and bottom.

4. Seal the case with packing tape, and indicate model name

and quantity. (8,000 pieces/package)

Total Packaged mass: Approximately 3.3 kg.

NOTE: Dimensions are in mm.

Figure 20. Packing Specification

150 mm TYP.

MODEL NUMBER

QUANTITY

DATE

EXAMPLE 4

GP2W0106YP-20

IrDA Data Sheet 15

Page 16

GP2W0106YP 115 kbps Transceiver

LIFE SUPPORT POLICY

SHARP components should not be used in medical devices with life support functions or in safety equipment (or similiar applications where

component failure would result in loss of life or physical harm) without the written approval of an officer of the SHARP Corporation.

LIMITED WARRANTY

SHARP warrants to its Customer that the Products will be free from defects in material and workmanship under normal use and service for a

period of one year from the date of invoice. Customer's exclusive remedy for breach of this warranty is that SHARP will either (i) repair or

replace, at its option, any Product which fails during the warranty period because of such defect (if Customer promptly reported the failure to

SHARP in writing) or, (ii) if SHARP is unable to repair or replace, refund the purchase price of the Product upon its return to SHARP. This

warranty does not apply to any Product which has been subjected to misuse, abnormal service or handling, or which has been altered or

modified in design or construction, or which has been serviced or repaired by anyone other than Sharp. The warranties set forth herein are in

lieu of, and exclusive of, all other warranties, express or implied. ALL EXPRESS AND IMPLIED WARRANTIES, INCLUDING THE

WARRANTIES OF MERCHANTABILITY, FITNESS FOR USE AND FITNESS FOR A PARTICULAR PURPOSE, ARE SPECIFICALLY

EXCLUDED. In no event will Sharp be liable, or in any way responsible, for any incidental or consequential economic or property damage.

The above warranty is also extended to Customers of Sharp authorized distributors with the following exception: reports of failures of Products

during the warranty period and return of Products that were purchased from an authorized distributor must be made through the distributor.

In case Sharp is unable to repair or replace such Products, refunds will be issued to the distributor in the amount of distributor cost.

SHARP reserves the right to make changes in specifications at any time and without notice. SHARP does not assume any responsibility

for the use of any circuitry described; no circuit patent licenses are implied.

NORTH AMERICA

SHARP Microelectronics

of the Americas

5700 NW Pacific Rim Blvd.

Camas, WA 98607, U.S.A.

Phone: (360) 834-2500

Telex: 49608472 (SHARPCAM)

Facsimile: (360) 834-8903

EUROPE

SHARP Electronics (Europe) GmbH

Microelectronics Division

Sonninstraße 3

20097 Hamburg, Germany

Phone: (49) 40 2376-2286

Facsimile: (49) 40 2376-2232

http://www.sharpmed.com

ASIA

SHARP Corporation

Integrated Circuits Group

2613-1 Ichinomoto-Cho

Tenri-City, Nara, 632, Japan

Phone: +81-743-65-1321

Facsimile: +81-743-65-1532

http://www.sharp.co.jp

http://www.sharpsma.com

©2000 by SHARP Corporation Reference Code SMA00007

Loading...

Loading...