Page 1

GP2W0001YP/GP2W0002YP

IrDA Technical Information

Low Power Infrared Transceiver

FEATURES

• IrDA 1.2a Low Power Option Compatible:

–I

= 27 mA (TYP.) for an operating distance of

F

20 cm

• Small Package Design for IrDA 1.0 Compliant Infra-

red Transceiver 8.7 (W) × 4.2 (D) × 3.15 (H) mm

• Receiver output provides a full output pulse for the

received input signal

• Fits within Mobile Phone Connector Dimensions

• Low Power Consumption and Built-in Shut-Down

Mode (1 µA MAX.)

• Wide Range of Operating Voltages provides power

supply design flexibility (V

• Solder Reflow Compatibility for automated produc-

tion processes

• SMD Package allows both Vertical and Horizontal

mounting on PCBs Description

= 2.7 V to 5.5 V)

CC

The GP2W0002YP is the same module, and adds an

integral Electro-Magnetic Interference (EMI) shield.

While IR energy is inherently immune to EMI, the receiving devices themselves are not. This shield provides an

additional level of protection in electromagnetically noisy

environments such as PCs and other digital products.

The SHARP GP2W0001YP/GP2W0002YP infrared

transceiver modules contain a high speed, high efficiency, low power consumption AlGaAs LED, silicon PIN

photodiode, and a low power bipolar integrated circuit.

The IC contains an LED driver circuit and a receiver, providing the Rx output. IrDA data rates of 2.4 Kbps to

115.2 Kbps are supported at both 20 cm and one-meter

distances. At the one-meter range, emitter current is

approximately I

Option communication mode I

mode communication capability provides wider product

applications, such as a wireless data link with PCs,

PDAs, or any other IrDA compliant application already

on the market.

The GP2W0001YP/GP2W0002YP transceiver

modules may be operated over a power supply range

of 2.7 V to 5.5 V without any performance degradation.

This provides a single part with a wide variety of

design applications.

For power-conscious applications, the transceiver

module has a built-in Shutdown mode. This reduces

the receiver's current consumption to 1 µA (MAX.) during Shutdown. The transmitter and receiver circuits are

separate, allowing the transmitter LED to be driven

when in Shutdown mode.

= 300 mA and in the IrDA Low Power

F

= 27 mA. This dual

F

DESCRIPTION

The SHARP GP2W0001YP is one of the smallest

transceiver modules. Even at low operating voltages,

it provides a reliable interface between logic and IR

signals for through-air, serial, half-duplex IR wireless

data links and is designed to satisfy IrDA physical

layer specifications.

Technical Information 1

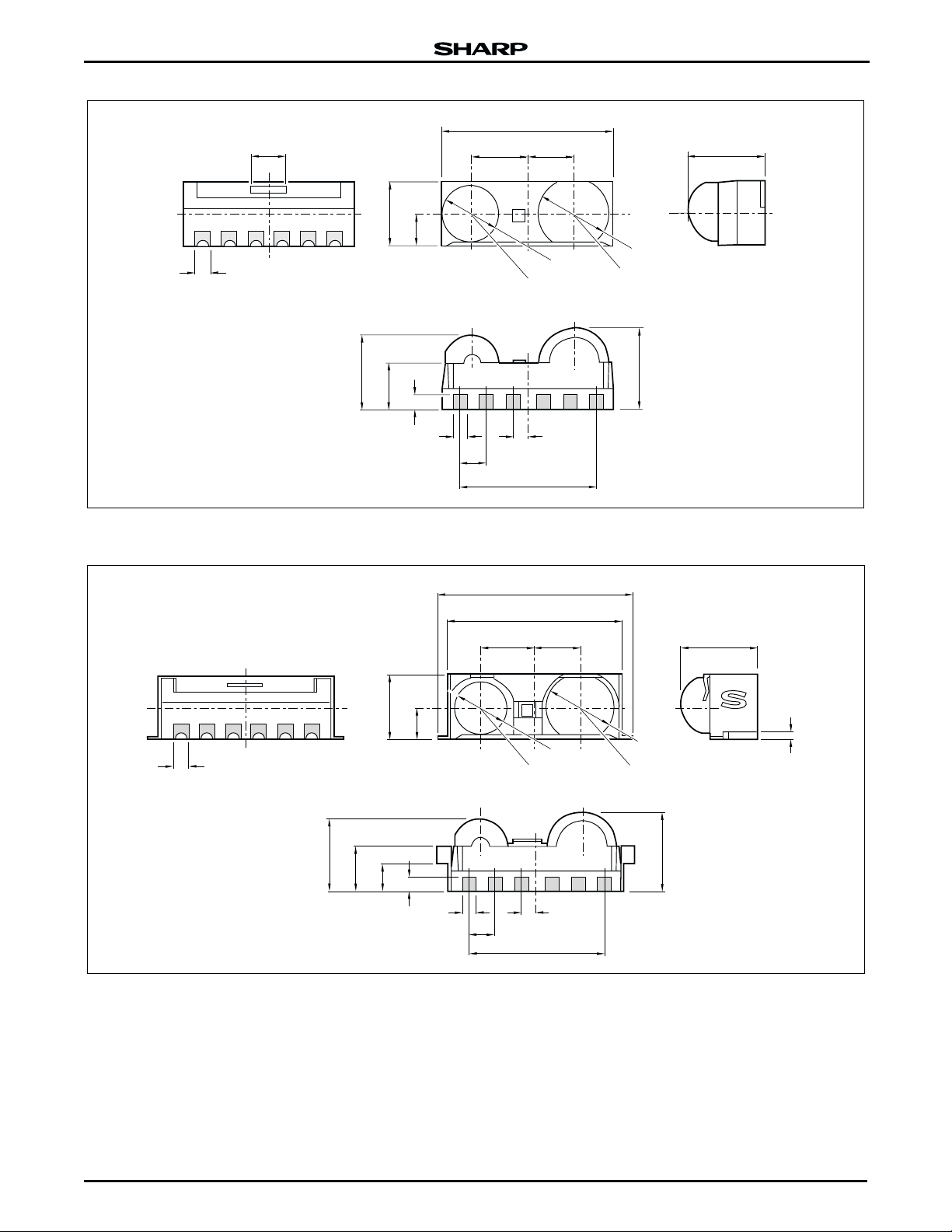

OUTLINE DIMENSIONS

The dimensions shown in Figure 1 and Figure 2 are

only for design reference, and are subject to change

without notice. The metal shield case version

GP2W0002YP, (for excellent noise immunity) is shown

in Figure 2. Contact your local SHARP office for the latest device specifications.

Page 2

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

8.7

4.2

1.1

2.0

3.15

1.7

2.95

TRANSMITTER

CENTER

2.325

φ2.8

φ3.6

RECEIVER

CENTER

NOTES:

1. Dimensions are in mm.

2. Unspecified tolerances are ±0.3 mm.

3. Resin burrs are not included in this

outline dimension drawing.

4. Package material: Visible light

cut-off resin (Color: black)

5. Weight: Approximately 0.12 g

6. Pin assignment: See Figure 5 and Table 1.

Figure 1. GP2W0001YP Outline Dimensions

1.1

3.5

2.2

3.4

0.8

1.7

0.8

1.4

0.7

7.0

10.2

9.2

2.95

2.325

TRANSMITTER

CENTER

φ2.8

4.2

φ3.6

RECEIVER

CENTER

GP2W0001YP-20

4.2

0.7

NOTES:

1. Dimensions are in mm.

2. Unspecified tolerances are ±0.3 mm.

3. Resin burrs are not included in this

outline dimension drawing.

4. Package material: Visible light

cut-off resin (Color: black)

5. Weight: Approximately 0.12 g

6. Pin assignment: See Figure 5 and Table 1.

3.5

2.2

1.55

0.8

0.8

1.4

0.7

7.0

4.2

GP2W0001YP-21

Figure 2. GP2W0002YP (with Shielding Case) Outline Dimensions

2 Technical Information

Page 3

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

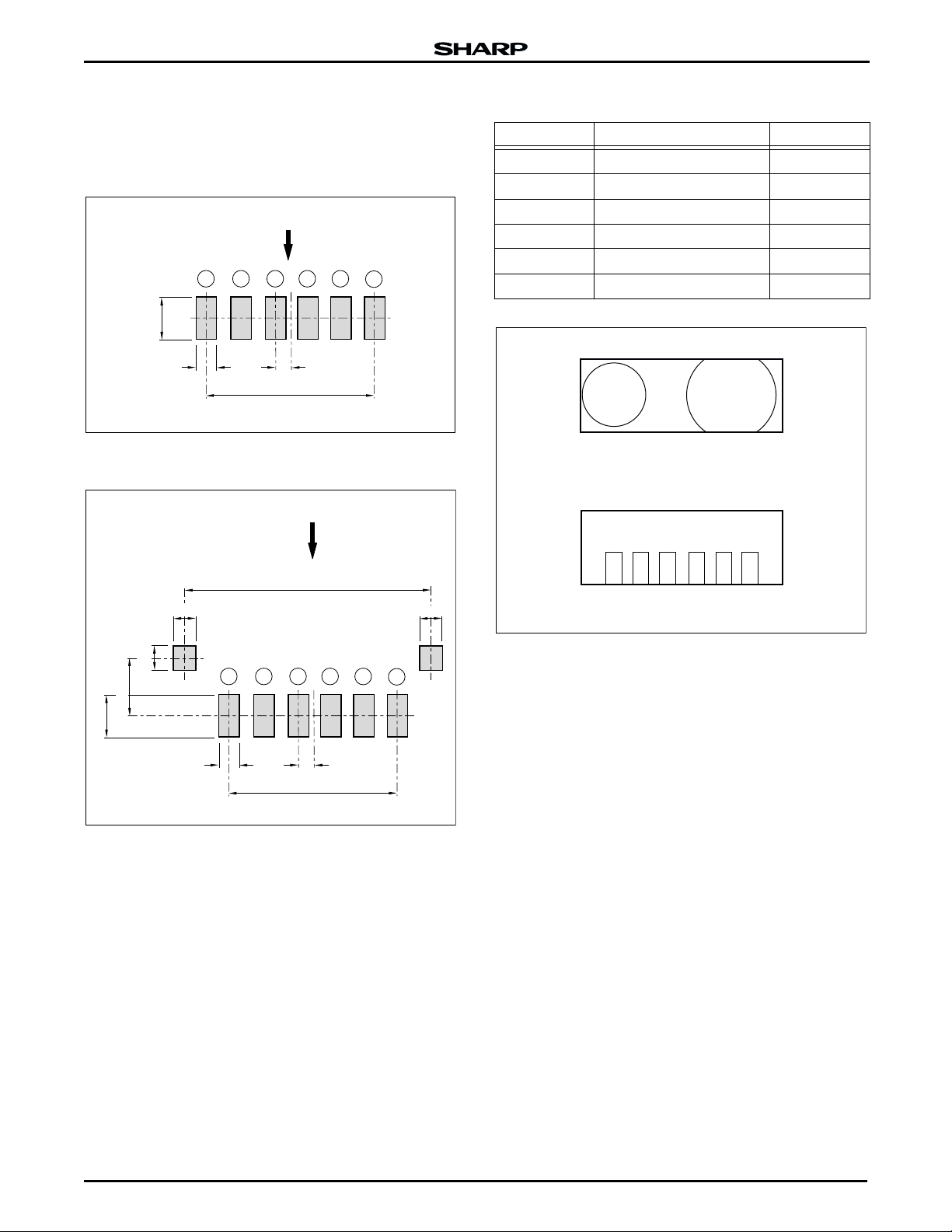

Solder Paste Footprints

Figure 3 and Figure 4 are the Solder Paste footprint

drawings for both parts. Note that the GP2W0002YP

footprint in Figure 4 is compatible with both parts.

LENS (PD/LED) SIDE

23456

1

1.7

0.9

P 1.4 × 5 = 7

NOTE: Viewed from the parts side of PCB.

Figure 3. GP2W0001YP Soldering Footprint

LENS (PD/LED) SIDE

0.7

GP2W0001YP-22

Table 1. Pinouts

PIN NO. DESCRIPTION SYMBOL

1 LED Anode LEDA

2 Transmitter Data Input TxD

3 Shut Down Circuit Input SD

4 Receiver Data Output RxD

5 Ground GND

6 Supply Voltage V

PIN 1 PIN 6

CC

10

0.8

1.05

2.025

1.7

0.9

P 1.4 × 5 = 7

NOTE: Viewed from the parts side of PCB.

23456

0.7

GP2W0001YP-23

Figure 4. GP2W0002YP Soldering Footprint

0.8

PIN 1 PIN 6

GP2W0001YP-28

Figure 5. Pin Locations

1

Technical Information 3

Page 4

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

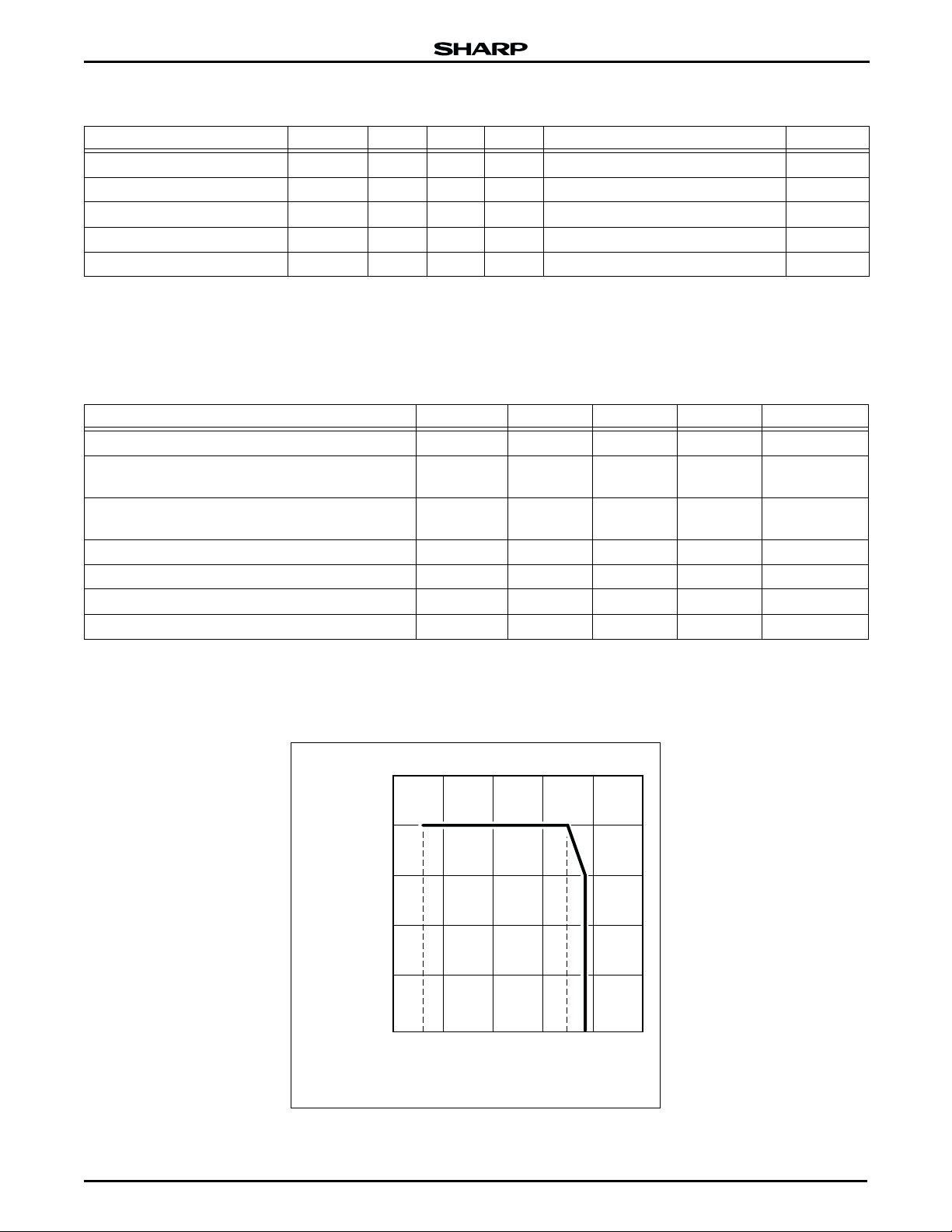

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL MIN. MAX. UNIT CONDITIONS NOTE

Supply Voltage V

Peak Forward LED Current I

Operating Temperature T

Soldering Temperature T

Storage Temperature T

CC

FM

OPR

SOL

STG

06.0V

500 mA Pulse 78.1 ms, 3/16-duty cycle 1, 2, 3

-10 +70 °C3

230 °C Solder reflow time: 5 seconds

-20 +85 °C

NOTES:

1. An in-band optical signal is a pulse/sequence where the peak

wavelength,

pulse characteristics are compliant with the IrDA Physical Layer

λp, is defined as 850 nm < λp < 900 nm, and the

2. See ‘IrDA Physical Layer Link Specification, Appendix A’ for

ambient light conditions.

3. See Figure 6.

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN. MAX. UNIT NOTE

Supply Voltage V

Logic High Transmitter Input

Voltage (TxIN)

Logic Low Transmitter Input

Voltage (TxIN)

Shutdown Circuit High Level Input Voltage V

Shutdown Circuit Low Level Input Voltage V

V

IHTXD

V

ILTXD

CC

IHSD

ILSD

Data Rate BR 2.4 115.2 Kbps

Operating Temperature T

NOTES:

1. Measured at the input circuit, not the device pin. Tx input should

not exceed 0.8 V

2. 0.4 or Open

CC.

OPR

2.7 5.5 V

2.4 V

CC

0.4 V

VCC – 0.6 V

CC

0.0 0.4 V 2

-10 70 °C

V1

V

400

(mA)

300

200

100

0

-10 60 70

0

AMBIENT TEMPERATURE T

(°C)

A

GP2W0001YP-27

100755025

PEAK

FORWARD

CURRENT

I

FM

Figure 6. Peak Forward Current vs. Temperature

4 Technical Information

Page 5

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

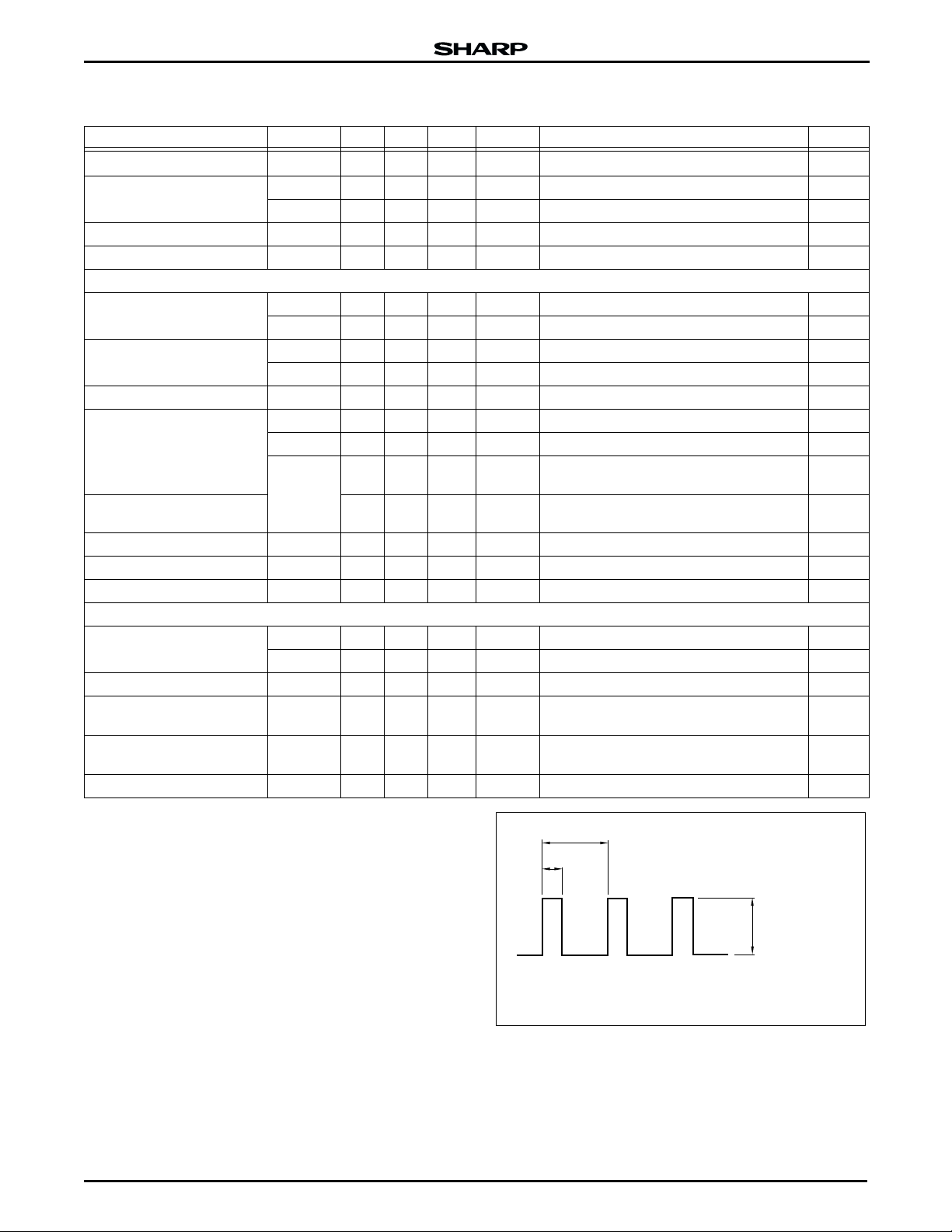

ELECTRICAL AND OPTICAL SPECIFICATIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT CONDITIONS NOTES

Supply Voltage V

Maximum Reception

Distance

CC

L1 ≥ 0.2 m 2Θ

L2 ≥ 1.0 m 2Θ

2.7 5.5 V

Data Rate BR 2.4 115.2 Kbps

Operating Temperature T

OPR

-10 70 °C

RECEIVER

High Level Output Voltage

Low Level Output Voltage

V

OH

V

OH

V

OL1

V

OL2

4.5 V VCC = 5 V

2.5 V VCC = 3 V

0.6 V VCC = 5 V, IOL = 400 mA RxD = ON 3

0.6 V VCC = 3 V, IOL = 400 mA RxD = ON 3

Viewing Angle 2Θ 30 degrees

Low Level Pulse Width

t

t

W1

W2

0.8 16 µs BR = 2.4 Kbps (pulse width 78.12 µs)

0.8 8 µs BR = 115.2 Kb/s (pulse width 1.63 µs)

1.0 1.4 mA

I

CC1

Current Consumption 0.7 1.0 mA

1.0 µA Shut-down Mode

1.2 µs 3

0.2 µs 3

Rise Time t

Fall Time t

I

CC2

R

F

TRANSMITTER

Radiant Intensity

I

E1

I

E2

3.6 28.8 mW/sr IF = 27 mA, 2Θ

40 350 mW/sr IF = 300 mA, 2Θ

Peak Emission Wavelength λp 850 870 900 nm I

Peak LED Current I

LEDA

High Level Input Voltage V

Low Level Input Voltage V

IH

IL

500 mA

2.4 V

CC

0.0 0.4 V

V

≤ 15°, IE = 3.6 mW/sr

1/2

≤ 15°, IE = 40 mW/sr

1/2

No input signal, VCC = 5.0 V, output open,

= VCC - 0.6 V

V

IHSD

No input signal, V

V

= VCC - 0.6 V

IHSD

= 20 mA

F

= 3.0 V, output open,

CC

≤ 15°

1/2

≤ 15°

1/2

All modes, PW = 78.1 µs or less,

3/16 duty cycle

Measured at input circuit. Device pin will

usually not exceed 0.8 V

NOTES:

1. These specifications reflect the Recommended Operating Conditions, unless otherwise noted.

2. All typical values are at 25°C and 3.3 V, ambient light on the

receiver surface under 10 Lux, unless otherwise noted.

3. See Figure 7, Figure 8, and Figure 9

NOTE: At BR = 2.4 Kbps: t1 = 416.7 µs, t2 = 78.1 µs

At BR = 115.2 Kbps: t

t

1

t

2

RADIATION

INTENSITY OF

TRANSMITTER

3.6 mW/Sr MIN.

= 8.68 µs, t2 = 1.63 µs

1

GP2W0001YP-24

Figure 7. Detector Input Signal Waveform

Technical Information 5

Page 6

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

t

R

V

OH

90%

t

F

50%

10%

t

W

V

OL

GP2W0001YP-7

Figure 8. Output Waveform Specification

= 3 V,

V

CC

= 2.2 Ω

R

L

= 1,500 pF

1.63 µs

Tx = 2.7 V

V

IN

CX

2

Tx TxD

= 1 kΩ

R

2

GP2W0001YP

BR = 115.2 Kbps

Figure 9. Recommended Emitter Circuit

GP2W0001YP-26

TRANSMITTER

(NOTE 1)

NOTES:

1. Transmitter uses GP2W0001YP (λp = 870 nm TYP.)

adjusted to a radiation intensity of 3.6 mW/Sr.

2. φ Indicates horizontal and vertical directions.

3. Ee: Detector face illuminance < 10 lx

Figure 10. Standard Optical Detector System

E

e

φ

φ

GP2W0001YP

OSCILLOSCOPE

L

GP2W0001YP-25

6 Technical Information

Page 7

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

ELECTRICAL DESIGN APPLICATION TIPS

Figure 11 shows a circuit application and passive

component values for a GP2W0001YP. The values

shown are only for reference. Contact your local Sharp

office concerning technical reference data for optical/

electrical characteristics.

Circuit Application and

External Passive Components

The circuit application and the external passive com-

ponents shown in Figure 11 enable the GP2W0001YP

to operate at both one-meter and 20 cm low power

option communication modes at V

= 3.0 V.

CC

SHUTDOWN MODE

The ‘Shutdown’ pin is an active LOW terminal.

Shutdown mode only affects the power consumption

of the receiver circuits. The transmitter LED can still be

operated when SD is asserted. The two circuits are

independent and not internally connected. The transmitter circuit does not consume current unless a drive

signal is applied.

Table 2. SD Pin Functions

INPUT PERFORMANCE

HIGH Normal Mode

LOW Shutdown Mode

OPEN Shutdown Mode

6 54321

CX

1

R

R

1

V

CC

COMPONENTS

CX

1

CX

2

R

1

R

2

R

L

NOTE: All recommended values are for V

RxD TxDSD

RECOMMENDED VALUES

47 µF, 6.3 V or as appropriate

1,500 pF, 25 V

47 Ω, ±5%, 1/10 W

1 kΩ, ±5%, 1/10 W

2.2 Ω ±5%, 1/2 W,1 meter

33 Ω ±1%, 1/8 W, 20 cm

(low power)

2

Figure 11. External Components

CX

CC

2

= 3.0 V

R

L

GP2W0001YP-29

V

SD

RxD

OPERATABLE

40 ms

IH

V

IL

(or OPEN)

HIGH

LOW

GP2W0001YP-30

Figure 12. Receiver Activation

Technical Information 7

Page 8

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

Signal Waveform Example

Figure 14 shows examples of each waveform when

operating a GP2W0001YP to IrDA standards. Note that

the IrDA bitstream is inverted in the encoder and

decoder circuits, and the output pulse is sent during a

‘0’ bit. The examples are for reference only, to help

understand the GP2W0001YP hardware, and device

signal measurements. The receiver output is not gated,

and will send output for the entire period of the received

IR input signal. Refer to Figure 14 for waveform reference points.

T

1

2

3

0

3/16T

T

10 1

3

2

4

ENCODER

CIRCUIT

DECODER

CIRCUIT

1

5

GP2W0001YP-31

Figure 13. GP2W0001YP Block Diagram

4

5

NOTES:

1 Transmit data waveform

2

Encoder circuit output waveform

3 Transmitter output optical signal waveform

4 GP2W0001YP receiver output waveform

5

Receive data waveform

T =

Data rate: 2.4 Kbps, 9.6 Kbps, 19.2 Kbps, 38.4 Kbps,

1

Data Rate

0

57.6 Kbps, 115.2 Kbps

10 1

Figure 14. Signal Waveform Example

GP2W0001YP-32

8 Technical Information

Page 9

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

MECHANICAL DESIGN

APPLICATION TIPS

Recommended Footprint

Figure 15 shows the basic recommended footprint

for PCB design using the SHARP GP2W0001YP infrared transceiver module. All values shown here are for

reference, and are in mm.

1.5 1.1

2

0.75

6 - 0.9

P1.4

Electro-Mechanical Design Tip

Figure 16 gives a recommended set of locations for

resistors and capacitors for better performance, particularly for the power supply (V

shown in Figure 16, should be mounted near the

GP2W0001YP transceiver module for best performance. All values in Figure 16 are for reference and

are in mm.

1.1

1.5

) line. R1 and CX1, as

CC

6 - 2.6

NOTE: Dimensions are in mm.

7.0

GP2W0001YP-33

Figure 15. Recommended Footprint

Technical Information 9

Page 10

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

2

0.75

1.5 1.1

6 - 0.9

P1.4

7.0

1.1

1.5

6 - 2.6

NOTE: Dimensions are in mm.

Capacitor and resistor on the power

trace should be located as close as

possible to the GP2W0001YP

transceiver module.

V

CC

GND

GP2W0001YP-34

Figure 16. PCB Design Tip

10 Technical Information

Page 11

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

Cabinet and IR Cosmetic

Window Design Tips

Figure 17 with its calculations illustrates the design

tips for a cabinet and an IR cosmetic window with ±18°

viewing angles in the vertical and horizontal axes. All

transceiver dimension values are for reference, and

are in mm.

The optical window size should be the minimum size

of W × H, either rectangular or elliptical, to maintain

w

(8.475)

18

˚

W

18

˚

IrDA data transfer performance. The dimensions for W

can be calculated by the formula:

W = 2 × L × tan(18 + w)

And the dimensions for H can be calculated by the

formula:

H = 2 × L × tan(18 +h)

In the case where the viewing angle is +18°, which

conforms to or exceeds the IrDA Serial Infrared Physical Layer Link Specifications. Values to be calculated

with above the formula must be given in mm.

L

L

h

(3.15)

18

18

˚

H

˚

NOTE: Dimensions are in mm.

GP2W0001YP-35

Figure 17. Optical Window Tips

Technical Information 11

Page 12

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

Evaluation Board

Figure 18 shows the recommended evaluation circuit for the GP2W0001YP/GP2W0002YP devices. This

circuit is provided on an evaluation board for test and

evaluation purposes. Samples are available through

your Sharp support office or Sales Representative.

The resistor value for RL is based on the supply voltage. For the one-meter range, the parallel combination

of the three values should be adjusted to approximately

Ω when V

2.2

300 mA with approximately 200 mW being dissipated in

the resistors. For the 20 cm (reduced) range, the value is

adjusted to 33

and the resistive power dissipation will be approximately

31 mW.

= 3.3 V, yielding a forward current of

CC

Ω, the nominal forward current is 27 mA,

When the 33

Ω value and a forward current of 27 mA

is used, a total of 31.3 mW is dissipated during LED ontime. This dissipation is within the rating of the SR1206

package. When used at a data rate of 115 Kbps, the

maximum on time is 18.75% of a bit time when the LED

is ‘ON.’ Since only the logical ‘0’ values of a data string

are sent, the overall duty cycle is below this value.

The board carries three positions to allow the use of

a combination of standard resistor values. To create

the 2.2

parallel. For the 43

used or three parallel resistors of 130

Ω value, three 6.6 Ω resistors are connected in

Ω value, one 43 Ω resistor can be

Ω. The resistor

positions on the board are in the SR1206 footprint,

which supports one-quarter Watt resistors.

This test and evaluation board is not intended for

production applications, and should not be subjected to

long periods at elevated temperature. Operation of the

board should be limited to free-air test conditions.

RL 2.2 Ω - 33 Ω

R

5

R

4

R

3

GND

V

CC

J1

+

+

+

+

+

2 × 5

+

+

+

+

+

2 V

CC

4 TxD

6 RxD

8

10

R

47 Ω

1

1

3

5

7

9

C2 1,500 pF 25 V

R

2

1K

Figure 18. GP2W0001YP Test Circuit

C

1

47 µF TANT

1

LEDA

2

TxD

3

SD

4

RxD

5

GND

6

V

CC

GP2W0001YP

GP2W0001YP-36

12 Technical Information

Page 13

Low Power Infrared Transceiver GP2W0001YP/GP2W0002YP

MOISTURE-PROOF PACKING

INFORMATION

Scope

This section describes the specifications of

GP2W0001YP/GP2W0002YP moisture-proof packing,

and is only for reference. The official specifications

should be consulted for packing information.

Packing Material Specifications

The GP2W0001YP/GP2W0002YP reel is moistureproof packed for shipment. Table 3 describes the materials used for each item of the moisture-proof packing.

Packing Method

1. Seal the aluminum laminate bag that contains the

tape reel (2,000 devices/reel) and desiccant.

2. Fill in the necessary information on the label and

paste it on the aluminum laminate bag.

3. Pack 4 aluminum laminated bags (1 reel each) into

the designated outer case, placing paper pads on

the bottom and top of the outer case, as well as be-

tween each layer of the aluminum laminated bags.

See Table 4.

4. Seal the outer case with craft tape, indicating the

model name, quantity, and out-going inspection date

on the case. (8,000 pieces total per carton)

TREATMENT AFTER UNSEALING

1. After unsealing, devices should be mounted at a

temperature of 10°C to 30°C, humidity below 60%

RH, within 3 days.

2. For long term storage, devices should either be

stored in a dry box, or re-sealed in a moisture-proof

bag with desiccant and stored in an environment

where the temperature is 10°C to 30°C, humidity below 60% RH. Devices must be mounted within 2

weeks.

BAKING BEFORE MOUNTING

If the devices are not kept in the storage conditions

described above, or the desiccant indicator has turned

pink, baking must be performed before devices are

mounted: baking may only be done once.

• Recommended Baking Conditions: 100°C

12 to 24 hours

NOTE: Do not bake the devices while they are still on the reel — the

reel will melt. Parts should be either temporarily mounted to

a PCB with adhesive, or placed in a metal tray. Any device

that has been out of its dry pack for more than 72 hours

should be dried in some manner prior to any automated surface mount reflow process. Otherwise these devices should

be mounted and soldered by hand.

Table 3. Packing Materials

Storage and Treatment

ITEM MATERIAL

Aluminum Laminate Bag Aluminum Polyethylene

STORAGE CONDITIONS

The product should be stored under these conditions:

• Storage temperature: 10°C to 30°C

• Humidity: below 60% RH

Label Paper

Desiccant

Outer Case Paper

Pads Paper

Table 4. Packing Quantities

PACKING SHAPE PRODUCT QUANTITY PER REEL QUANTITY PER BAG

Tape reel (

NOTE: Minimum order/shipment quantity should be one laminated bag (1 reel of 2,000 pieces).

∅ 330 mm) 1 model 2,000 pieces 1 reel

Technical Information 13

Page 14

GP2W0001YP/GP2W0002YP Low Power Infrared Transceiver

LIFE SUPPORT POLICY

SHARP components should not be used in medical devices with life support functions or in safety equipment (or similiar applications where

component failure would result in loss of life or physical harm) without the written approval of an officer of the SHARP Corporation.

LIMITED WARRANTY

SHARP warrants to its Customer that the Products will be free from defects in material and workmanship under normal use and service for a

period of one year from the date of invoice. Customer's exclusive remedy for breach of this warranty is that SHARP will either (i) repair or

replace, at its option, any Product which fails during the warranty period because of such defect (if Customer promptly reported the failure to

SHARP in writing) or, (ii) if SHARP is unable to repair or replace, refund the purchase price of the Product upon its return to SHARP. This

warranty does not apply to any Product which has been subjected to misuse, abnormal service or handling, or which has been altered or

modified in design or construction, or which has been serviced or repaired by anyone other than Sharp. The warranties set forth herein are in

lieu of, and exclusive of, all other warranties, express or implied. ALL EXPRESS AND IMPLIED WARRANTIES, INCLUDING THE

WARRANTIES OF MERCHANTABILITY, FITNESS FOR USE AND FITNESS FOR A PARTICULAR PURPOSE, ARE SPECIFICALLY

EXCLUDED. In no event will Sharp be liable, or in any way responsible, for any incidental or consequential economic or property damage.

The above warranty is also extended to Customers of Sharp authorized distributors with the following exception: reports of failures of Products

during the warranty period and return of Products that were purchased from an authorized distributor must be made through the distributor.

In case Sharp is unable to repair or replace such Products, refunds will be issued to the distributor in the amount of distributor cost.

SHARP reserves the right to make changes in specifications at any time and without notice. SHARP does not assume any responsibility

for the use of any circuitry described; no circuit patent licenses are implied.

NORTH AMERICA

SHARP Microelectronics

of the Americas

5700 NW Pacific Rim Blvd.

Camas, WA 98607, U.S.A.

Phone: (360) 834-2500

Telex: 49608472 (SHARPCAM)

Facsimile: (360) 834-8903

EUROPE

SHARP Electronics (Europe) GmbH

Microelectronics Division

Sonninstraße 3

20097 Hamburg, Germany

Phone: (49) 40 2376-2286

Facsimile: (49) 40 2376-2232

http://www.sharpmed.com

ASIA

SHARP Corporation

Integrated Circuits Group

2613-1 Ichinomoto-Cho

Tenri-City, Nara, 632, Japan

Phone: +81-743-65-1321

Facsimile: +81-743-65-1532

http://www.sharp.co.jp

http://www.sharpsma.com

©2000 by SHARP Corporation Reference Code SMA00060

Loading...

Loading...