Datasheet GMS87C2120Q, GMS87C2120K, GMS87C2120, GMS81C2112Q, GMS81C2112K Datasheet (HYNIX)

...Page 1

JUNE. 2001 Ver 1.00

HYNIX SEMICONDUCTOR

8-BIT SINGLE-CHIP MICROCONTROLLERS

GMS81C2112

GMS81C2120

User’s Manual

Page 2

HYNIX SEMICONDUCTOR

8-BIT SINGLE-CHIP MICROCONTROLLERS

GMS81C2112

GMS81C2120

User’s Manual (Ver. 1.00)

Page 3

Version 1.00

Published by

MCU Application Team

2001 HYNIX Semiconductor All right reserved.

Additional information of this manual may be served by HYNIX Semiconductor offices in Korea or Distributors and Representatives listed at address directory.

HYNIX Semiconductor reserves the right to make changes to any information here in at any time without notice.

The information, diagrams and other data in this manual are correct and reliable; however, HYNIX Semiconductor is in no

way responsible for any violations of patents or other rights of the third party generated by the use of this manual.

Page 4

Page 5

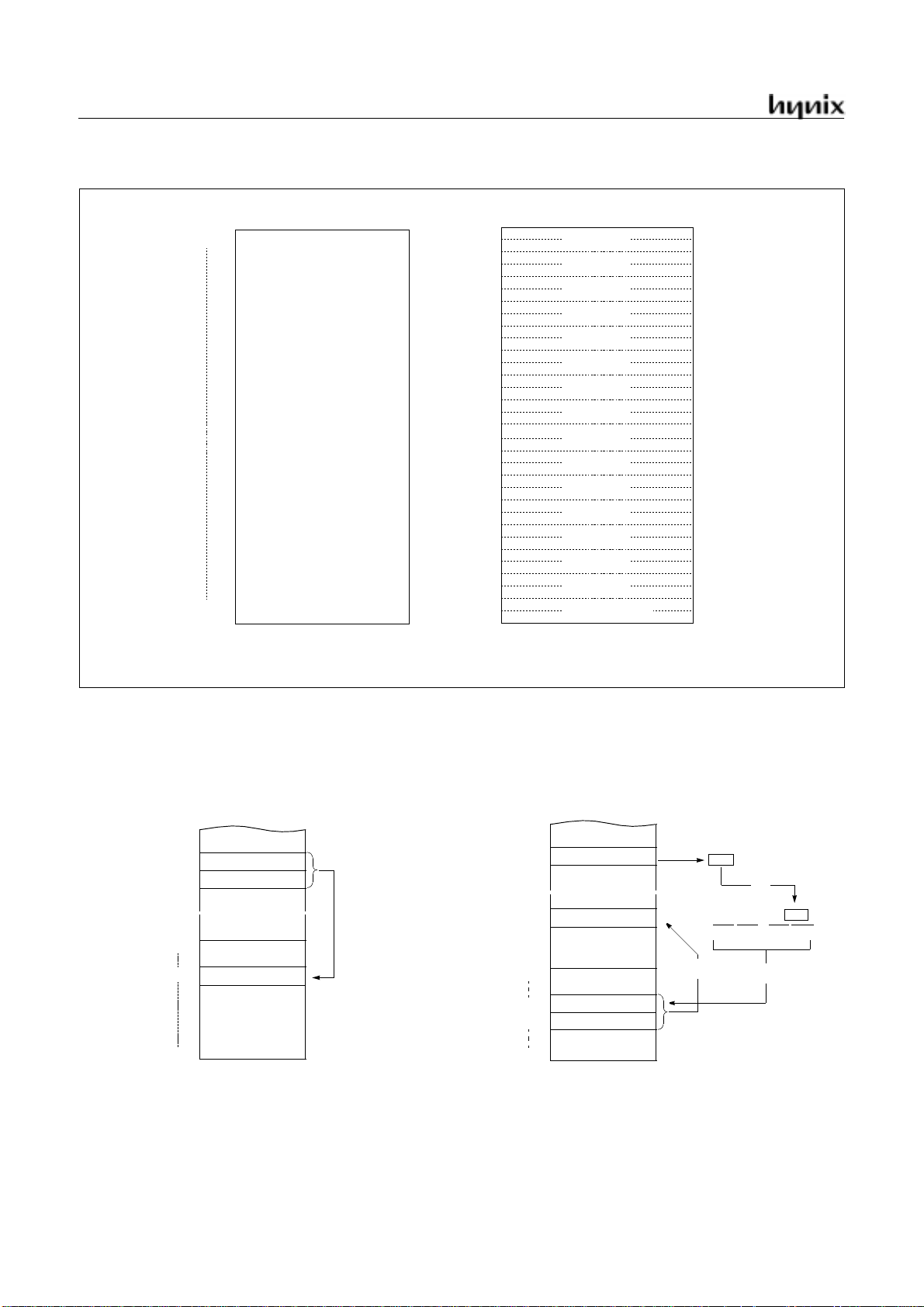

Table of Contents

1. OVERVIEW............................................1

Description .........................................................1

Features ............................... ..............................1

Development Tools ............................................2

Ordering Information

2. BLOCK DIAGRAM.................................3

3. PIN ASSIGNMENT ................................4

4. PACKAGE DIAGRAM............................6

5. PIN FUNCTION......................................8

6. PORT STRUCTURES..........................10

7. ELECTRICAL CHARACTERISTICS....13

Absolute Maximum Ratings .............................13

Recommended Operating Conditions ..............13

A/D Converter Characteristics .........................13

DC Electrical Characteristics for Standard Pins(5V)

14

DC Electrical Characteristics for High-Voltage Pins

15

AC Characteristics ...........................................16

AC Characteristics ...........................................17

Typical Characteristics .....................................18

8. MEMORY ORGANIZATION.................20

Registers ....................... ...................................20

Program Memory ....................... ....... ...............23

Data Memory ...................................................26

Addressing Mode .............................................30

9. I/O PORTS...........................................34

10. BASIC INTERVAL TIMER..................37

11. WATCHDOG TIMER..........................39

12. TIMER/EVENT COUNTER................42

8-bit Timer / Counter Mode ..............................44

16-bit Timer / Counter Mode ............................48

8-bit Compare Output (16-bit) ..........................49

8-bit Capture Mode ......................................... 49

16-bit Capture Mode ....................................... 52

PWM Mode ..................................................... 53

13. ANALOG DIGITAL CONVERTER.....56

14. SERIAL PERIPHERAL INTERFACE.59

Transmission/Recei vi ng Timi ng ........... ........... 61

The method of Serial I/O ................................. 62

The Method to Test Correct Transmission ...... 62

15. BUZZER FUNCTION.........................63

16. INTERRUPTS....................................65

Interrupt Sequence .......................................... 67

Multi Interrupt .................................................. 69

External Interrupt ............................................. 70

17. Power Saving Mode...........................72

Operating Mode .............................................. 73

Stop Mode ....................................................... 74

Wake-up Timer Mode ...................................... 75

Internal RC-Oscillated Watchdog Timer Mode 76

Minimizing Current Consumption .................... 77

18. OSCILLATOR CIRCUIT.....................79

19. RESET...............................................80

External Reset Input ........................................ 80

Watchdog Timer Reset ................................... 80

20. POWER FAIL PROCESSOR.............81

21. OTP PROGRAMMING.......................83

DEVICE CONFIGURATION AREA ...... ...... ..... 83

A. CONTROL REGISTER LIST..................i

B. INSTRUCTION.............. ..... .... ..... ......... iii

Terminology List ................................................iii

Instruction Map ..................................................iv

Instruction Set ....................................................v

C. MASK ORDER SHEET........................xi

Page 6

Page 7

GMS81C2112/GMS81C2120

GMS81C2112/GMS81C2120

CMOS Single-Chip 8-Bit Microcontroller

with A/D Converter & VFD Driver

1. OVERVIEW

1.1 Description

The GMS81C2112 and GMS81C2120 are advanced CMOS 8-b it micro contr oller with 12 K/20K bytes of ROM. Thes e are a

powerful microcontroller which provides a highly flexible and cost effective solution to many VFD applications. These provide the following standard features: 12K/20K bytes of ROM, 448 bytes of RAM, 8-bit timer/counter, 8-bit A/D converter,

10-bit High Speed PWM Output, Programmable Buzzer Driving Port, 8-bit Basic Interval Timer, 7-bit Watch dog Timer,

Serial Peripheral Interface, on-chip oscillator and clo ck circuitry. They also come with h igh voltage I/O p ins that can dir ectl y

drive a VFD (Vacuum Fluores cent Displ ay). I n addit ion, t he GMS81C21 12 and GMS 81C212 0 suppor t po wer saving modes

to reduce power consumption.

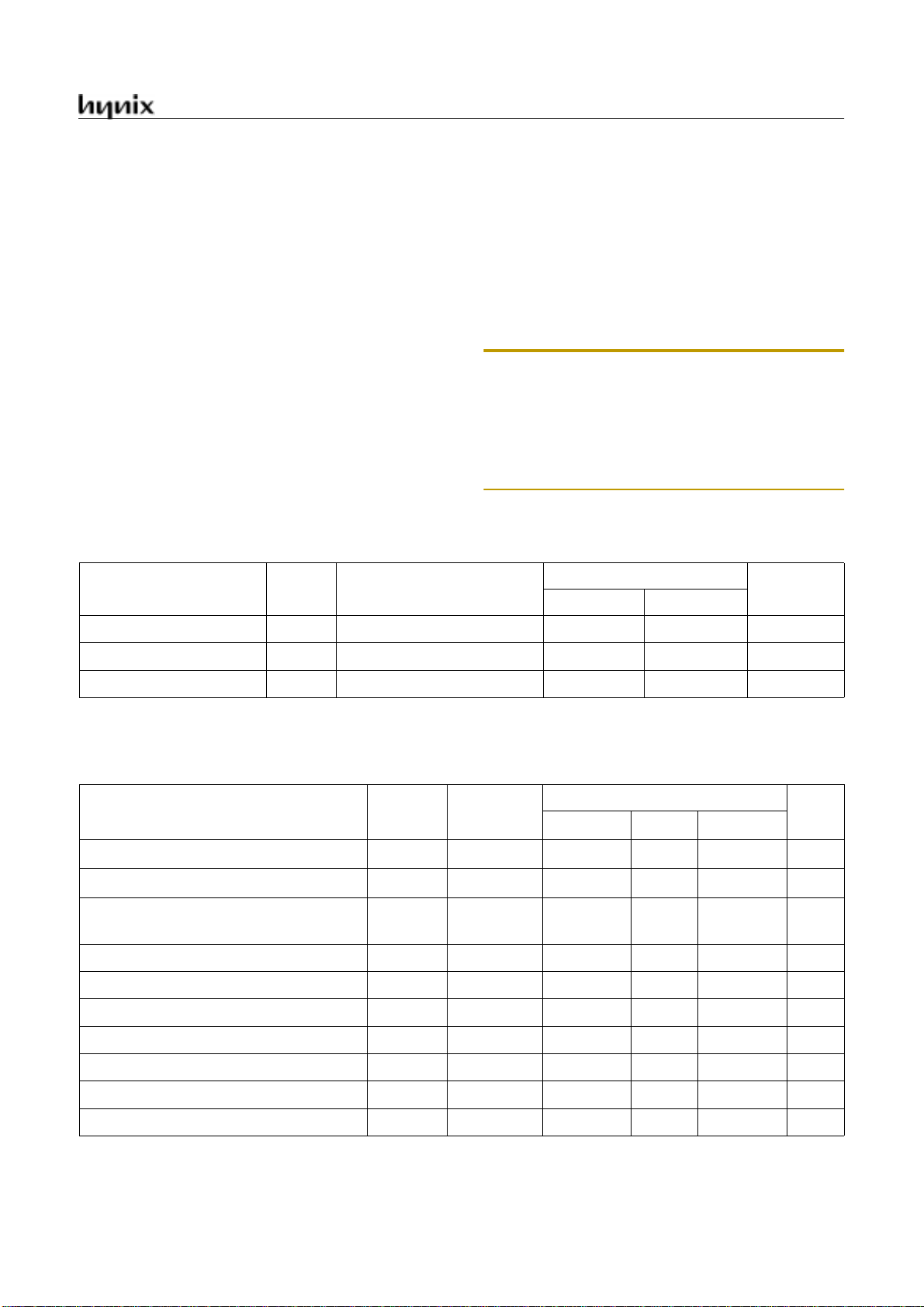

Device name ROM Size RAM Size OTP Package

GMS81C2112 12K bytes

GMS81C2120 20K bytes GMS87C2120

1.2 Features

• 20K/12K bytes ROM(EPROM)

• 448 Bytes of On-Chip Data RAM

(Including STACK Area)

• Minimum Instruction Execution time:

- 1uS at 4MHz (2cycle NOP Instruction)

• One 8-bit Basic Interval Timer

• One 7-bit Watch Dog Timer

• Two 8-bit Timer/Counters

• 10-bit High Speed PWM Output

• One 8-bit Serial Peripheral Interface

• Two External Interrupt Ports

• One Programmable 6-bit Buzzer Driving Port

• 38 I/O Lines

- 34 Programmable I/O pins

(Included 21 high-voltage pins Max. 40V)

- Three Input Only pins: 1 high-voltage pin

- One Output Only pin

448 bytes

-

• 8-Channel 8-bit On-Chip Analog to Digital Converter

• Oscillator:

- Crystal

- Ceramic Resonator

- External R Oscillator

• Low Power Dissipation Modes

- STOP mode

- Wake-up Timer Mode

- Standby Mode

• Operating Voltage: 2.7V ~ 5.5V (at 4.5MHz)

• Operating Frequency: 1MHz ~ 4.5MHz

• Enhanced EMS Improvement

Power Fail Processor

(Noise Immunity Circuit)Enhanced EMS

Improvement

Power Fail Processor

(Noise Immunity Circuit)

42SDIP, 44MQFP,

40PDIP

• Eight Interrupt Sources

- Two External Sources (INT0, INT1)

- Two Timer/Counter Sources (Timer0, Timer1)

- Four Functional Sources (SPI,ADC,WDT,BIT)

JUNE. 2001 Ver 1.00 1

Page 8

GMS81C2112/GMS81C2120

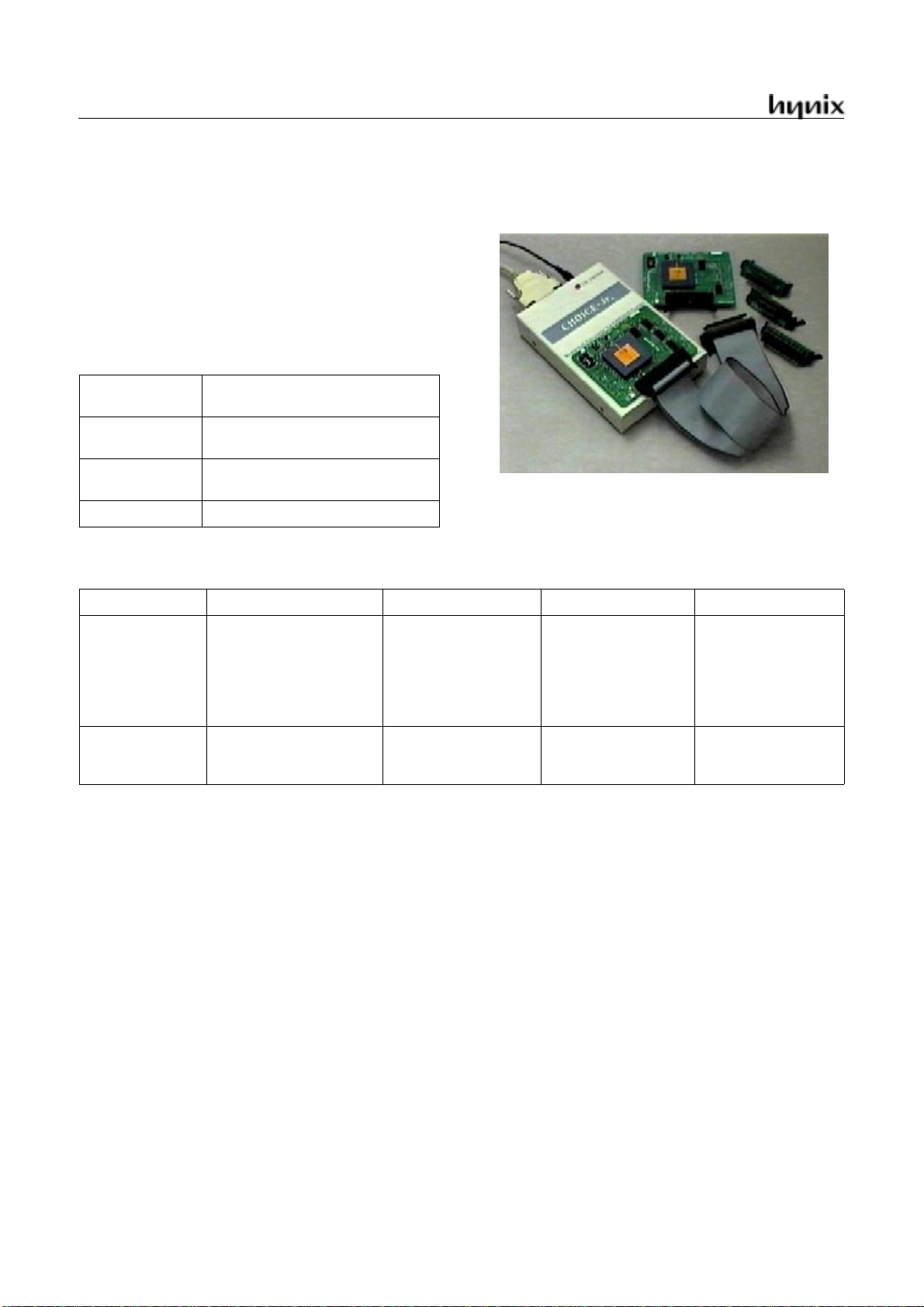

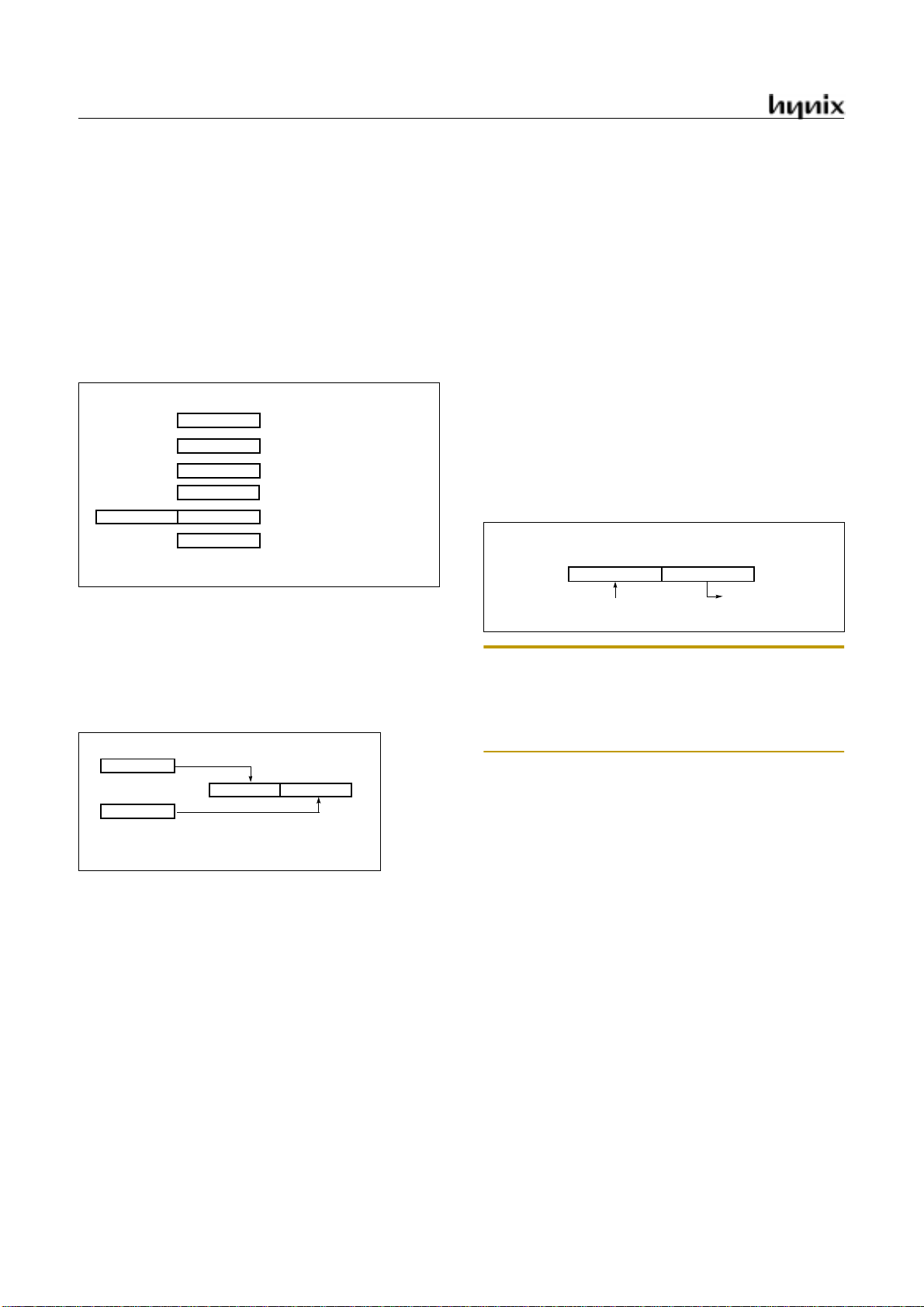

1.3 Development Tools

The GMS81C21xx are supported by a full-featured macro

assembler, an in-circuit emulator CHOICE-Dr.

TM

and

OTP programmers. There are third diffe rent type program mers such as emulator add-on board type, single type, gang

type. For mode detail, Refer to “21. OTP PROGRAMMING” on page 83. Macro assembler operates under the

MS-Windows 95/98

TM

.

Please contact sales part of HynixSemiconductor.

In Circuit

Emulators

Socket Adapter

for OTP

POD

Assembler

OA87C21XX-42SD (42SDIP)

OA87C21XX-44QF (44MQFP)

CHPOD81C21D-42SD (42SDIP)

CHPOD81C21D-40PD (40PDIP)

CHOICE-Dr.

HYNIX Macro Assembler

1.4 Ordering Information

Device name ROM Size RAM size Package

Mask version

OTP version

GMS81C2112 K

GMS81C2112 Q

GMS81C2112

GMS81C2120 K

GMS81C2120 Q

GMS81C2120

GMS87C2120 K

GMS87C2120 Q

GMS87C2120

12K bytes

12K bytes

12K bytes

20K bytes

20K bytes

20K bytes

20K bytes OTP

20K bytes OTP

20K bytes OTP

448 bytes

448 bytes

448 bytes

448 bytes

448 bytes

448 bytes

448 bytes

448 bytes

448 bytes

42SDIP

44MQFP

40PDIP

42SDIP

44MQFP

40PDIP

42SDIP

44MQFP

40PDIP

2 JUNE. 2001 Ver 1.00

Page 9

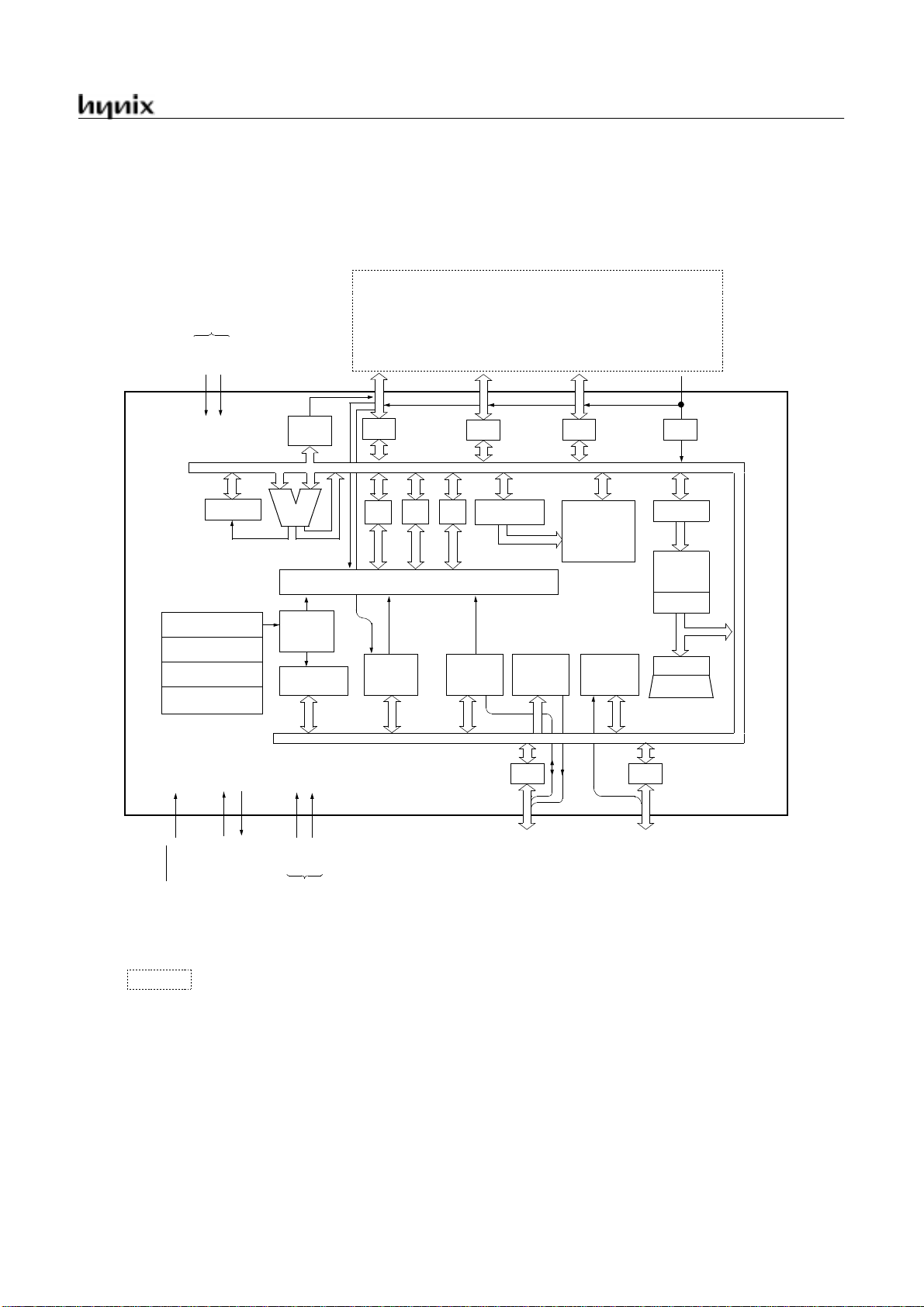

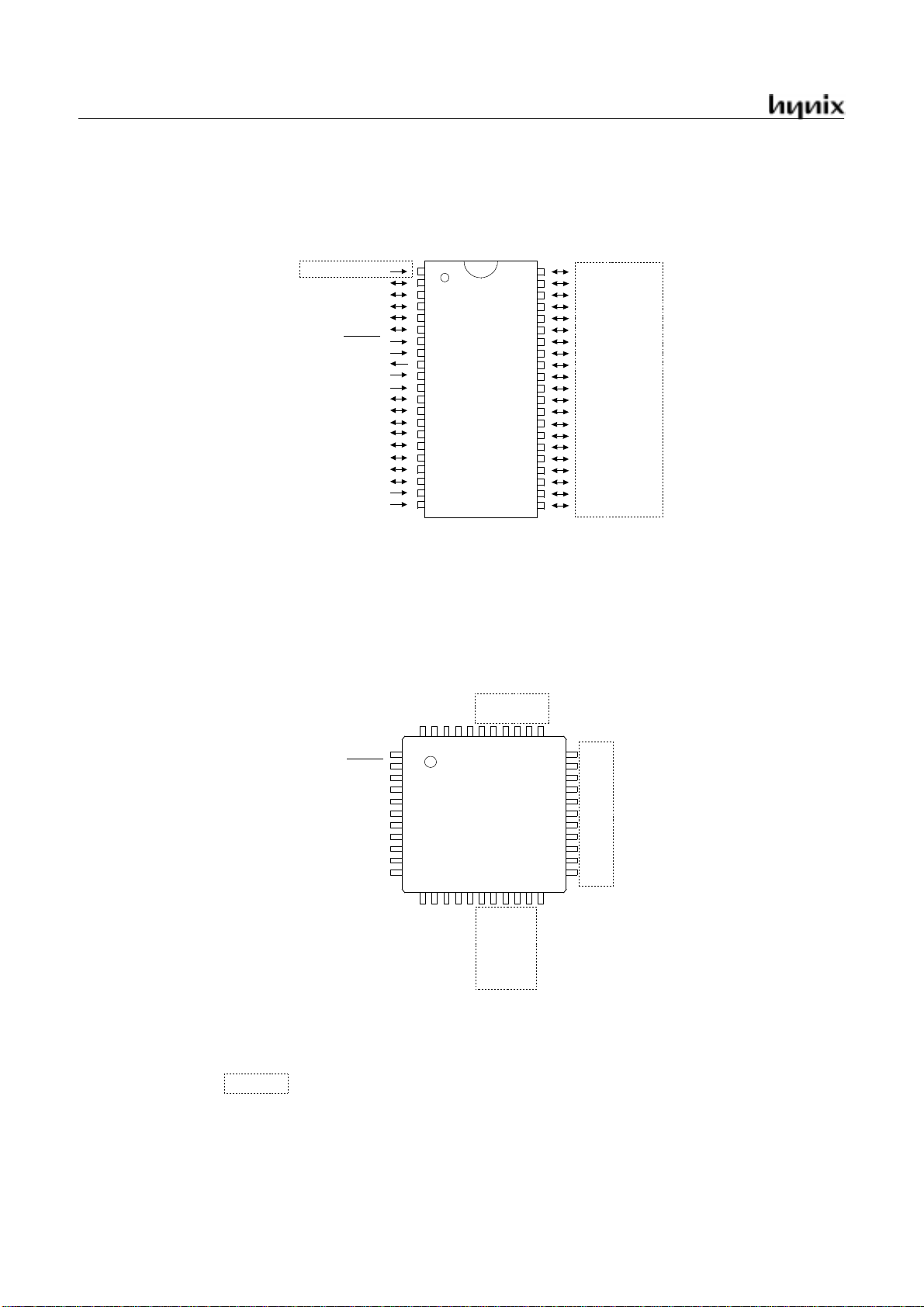

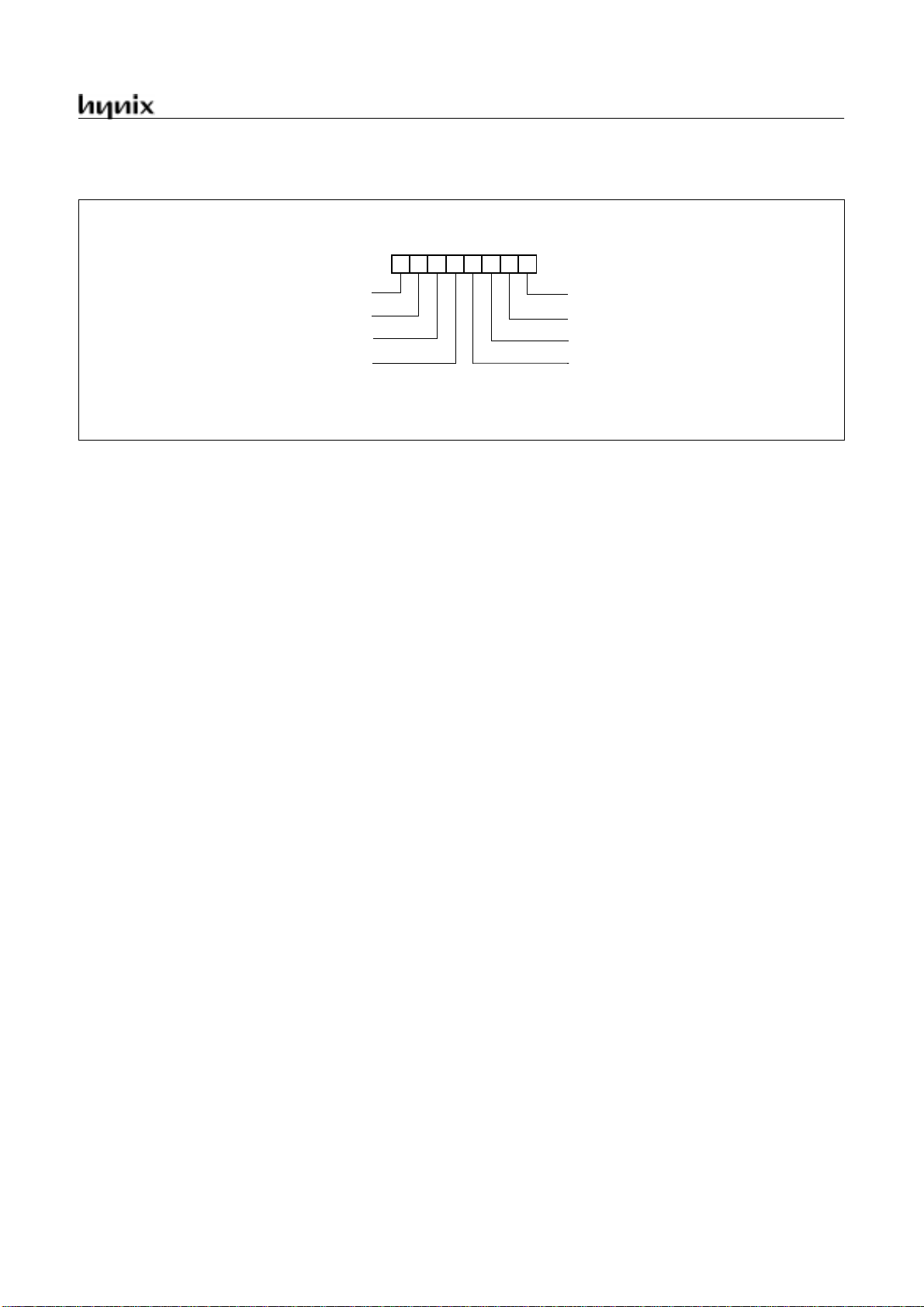

2. BLOCK DIAGRAM

ADC Power

Supply

SS

AVDDAV

R07

R06

R05

R04

R03/BUZO

R02/EC0

R01/INT1

R00/INT0

R20~R27

R30~R34

GMS81C2112/GMS81C2120

Vdisp/RA

PSW

Syst

em controller

System

Clock Controller

Timing generator

Cloc k

Generator

IN

X

RESET

X

OUT

Driver

Buzzer

ALU

8-bit Basic

Interval

Timer

Watchdog

Timer

SS

DD

V

V

Power

Supply

R0

A

X Y

Interrupt Controller

8-bit

Timer/

Counter

R2

Stack Pointer

8-bit serial

Interface

R3

Data Memor y

(448 bytes)

10-bit

PWM

R5

R53 / SCLK

R54 / SIN

R55 / SOUT

R56 / PWM1O/T1O

R57

8-bit

ADC

Data Table

R6

R60 / AN0

R61 / AN1

R62 / AN2

R63 / AN3

R64 / AN4

R65 / AN5

R66 / AN6

R67 / AN7

RA

PC

Program

Memory

PC

High Voltage Port

JUNE. 2001 Ver 1.00 3

Page 10

GMS81C2112/GMS81C2120

3. PIN ASSIGNMENT

42SDIP

44MQFP

V

disp

SCLK

SIN

SOUT

PWM1O/T1O

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

RA

R53

R54

R55

R56

R57

RESET

XO

V

AV

R60

R61

R62

R63

R64

R65

R66

R67

AV

V

SS

SS

DD

DD

1

2

3

4

5

6

7

XI

8

9

10

11

12

13

14

15

16

17

18

19

20

21

SOUT

SIN

SCLK

PWM1O/T1O

GMS81C2112/20

Vdisp

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

R34

R33

R32

R31

R30

R27

R26

R25

R24

R23

R22

R21

R20

R07

R06

R05

R04

R03

R02

R01

R00

BUZO

EC0

INT1

INT0

R57

RESET

XO

V

AV

AN0

R60

AN1

R61

R62

AN2

R63

AN3

R64

AN4

High Voltage Port

NC

R55

R54

R53RAR34

R33

R32

R31

R02

EC0

R30

34

R27

33

R26

32

R25

31

R24

30

R23

29

R22

28

R21

27

R20

26

R07

25

R06

24

R05

23

NC

R03

R04

BUZO

R56

41403938373635

444342

1

2

XI

3

4

SS

5

SS

6

GMS81C2112/20

7

8

9

10

11

1213141516171819202122

DDVDD

R00

AN7

AV

R01

INT0

INT1

R65

AN5

R66

AN6

R67

4 JUNE. 2001 Ver 1.00

Page 11

GMS81C2112/GMS81C2120

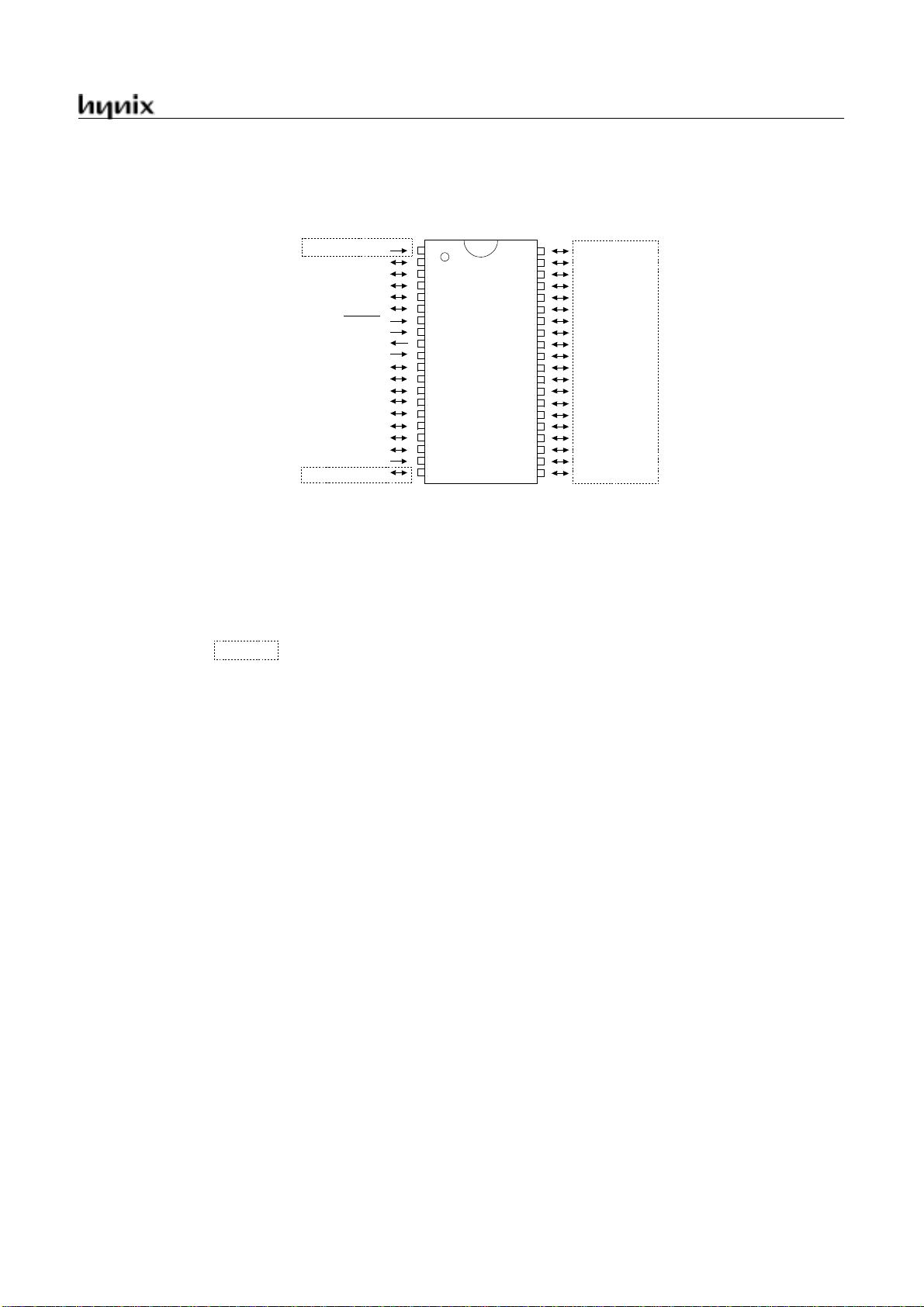

40PDIP

V

disp

SCLK

SIN

SOUT

PWM1O/T1O

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

High Voltage Port

RA

R53

R54

R55

R56

R57

RESET

XO

V

R60

R61

R62

R63

R64

R65

R66

R67

V

SS

DD

1

2

3

4

5

6

7

XI

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

GMS81C2112/20

34

33

32

31

30

29

28

27

26

25

24

23

22

21

R34

R33

R32

R31

R30

R27

R26

R25

R24

R23

R22

R21

R20

R07

R06

R05

R04

R03

R02

R01R00

BUZO

EC0

INT1INT0

JUNE. 2001 Ver 1.00 5

Page 12

GMS81C2112/GMS81C2120

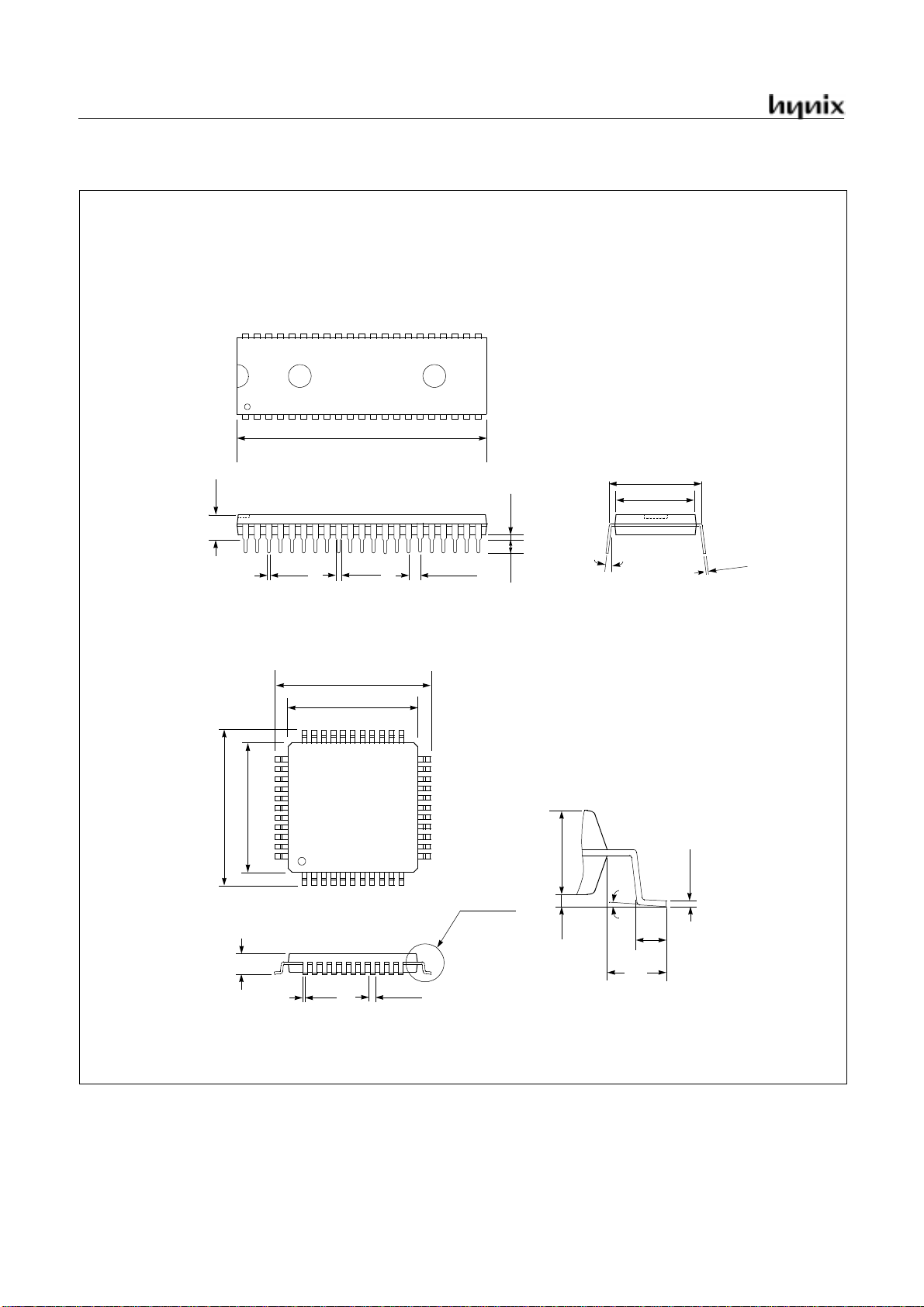

4. PACKAGE DIAGRAM

42SDIP

UNIT: INCH

1.470

1.450

0.600 BSC

0.550

0.190 max.

min. 0.015

0.530

44MQFP

10.10

13.45

12.95

2.35 max.

.012

0.020

0.016

13.45

12.95

10.10

9.90

0.045

0.035

0.070 BSC

0-15

0.140

0.120

°

0

8

0

.0

0

UNIT: MM

9.90

2.10

1.95

0.23

0.13

0.45

0.30

0.80 BSC

SEE DETAIL “A”

0.25

0.10

0-7

°

1.60

BSC

DETAIL “A”

1.03

0.73

6 JUNE. 2001 Ver 1.00

Page 13

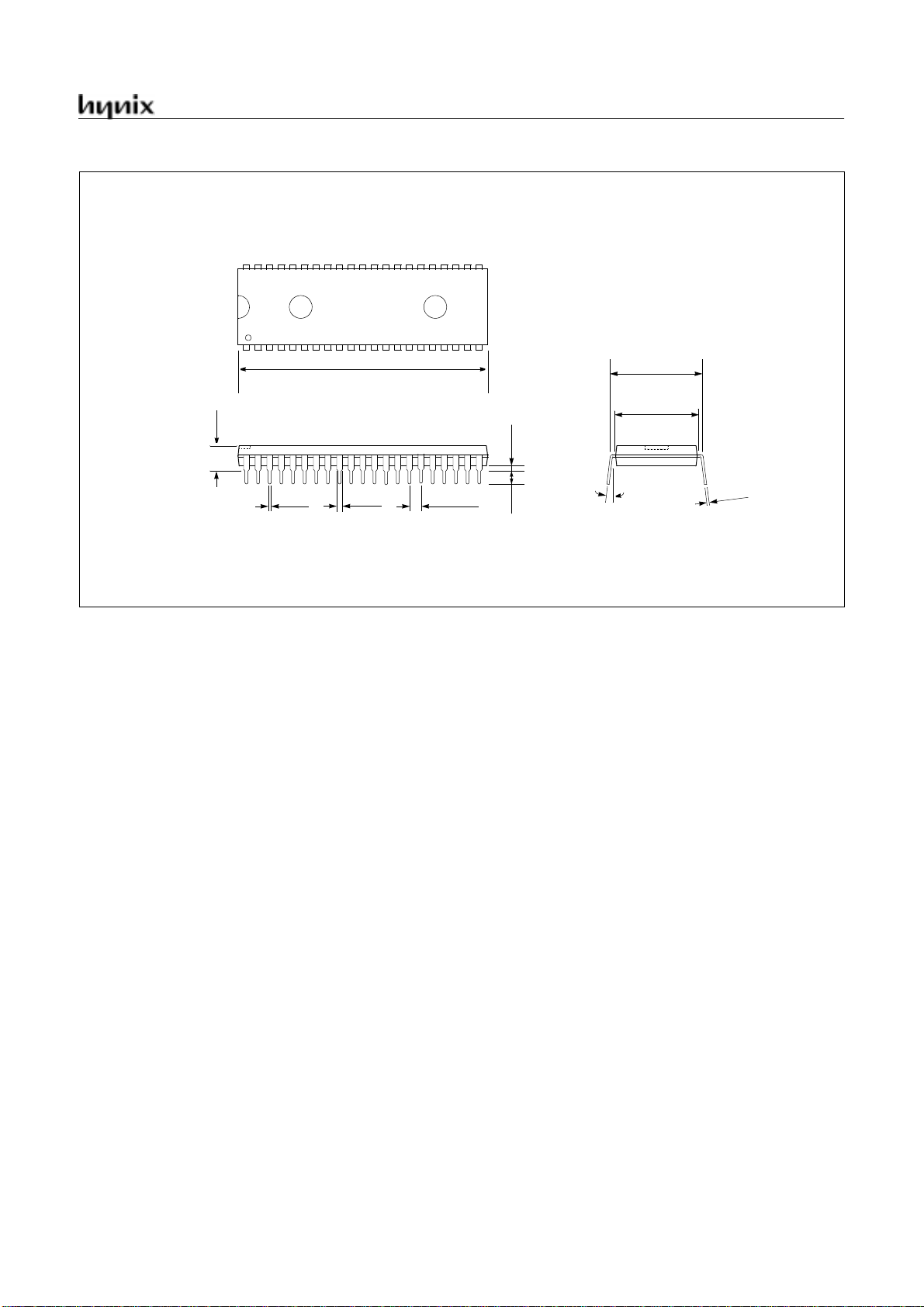

40PDIP

GMS81C2112/GMS81C2120

UNIT: INCH

2.075

2.045

0.200 max.

min. 0.015

0.022

0.015

0.065

0.045

0.100BSC

0.140

0.120

0-15

0.600 BSC

0.550

0.530

°

2

1

.0

0

8

0

.0

0

JUNE. 2001 Ver 1.00 7

Page 14

GMS81C2112/GMS81C2120

5. PIN FUNCTION

DD

V

: Supply voltage.

SS

V

: Circuit ground.

DD

AV

: Supply voltage to the ladder resistor of ADC circuit. To enhance the resolution of analog to digital converter, use independent po wer source as wel l as poss ible, oth er

than digital power source.

SS

AV

: ADC circuit ground.

RESET

X

: Reset the MCU.

IN

: Input to the inverting oscillator amplifier and input to

the internal clock operating circuit.

OUT

X

: Output from the inverting oscillator amplifier.

RA(V

In addition, RA serves the functions of the V

features. V

)

: RA is one-bit high-voltage input only port pin.

disp

is used as a high-voltage i nput power supply

disp

disp

special

pin when selected by the mask option.

Port pin Alternate function

V

RA

R00~R07

: R0 is an 8-bit hi gh-voltage CMOS bidir ectional

(High-voltage input power supply)

disp

I/O port. R0 pins 1 or 0 written to the Port Direction Register can be used as outputs or inputs. In addition, R0

serves the functions of the various following special features.

Port pin Alternate function

R00

R01

R02

R03

INT0 (External interrupt 0)

INT1 (External interrupt 1)

EC0 (Event counter input)

BUZO (Buzzer driver output)

R20~R27

: R2 is an 8-bit high-voltage CMOS bidirectional

I/O port. R2 pins 1 or 0 writt en to th e Port Direction R eg ister can be used as outputs or inputs.

R30~R34

: R3 is a 5-bit high-voltage CMOS bidirectional

I/O port. R3 pins 1 or 0 writt en to th e Port Direction R eg ister can be used as outputs or inputs.

R53~R57

: R5 is an 5-bit CMOS bidirectional I/O port. R5

pins 1 or 0 written to the Port Direction Register can be

used as outputs or inputs. In addition, R5 serves the functions of the various following special features.

Port pin Alternate function

R53

R54

R55

R56

R60~R67

SCLK (Serial clock)

SIN (Serial data input)

SOUT (Serial data output)

PWM1O (PWM1 Output)

T1O (Timer/Counter 1 output)

: R6 is an 8-bit CMOS bidirectional I/O port. R6

pins 1 or 0 written to the Port Direction Register can be

used as outputs or inputs. In addition, R6 is shared with the

ADC input.

Port pin Alternate function

R60

R61

R62

R63

R64

R66

R66

R67

AN0 (Analog Input 0)

AN1 (Analog Input 1)

AN2 (Analog Input 2)

AN3 (Analog Input 3)

AN4 (Analog Input 4)

AN5 (Analog Input 5)

AN6 (Analog Input 6)

AN7 (Analog Input 7)

8 JUNE. 2001 Ver 1.00

Page 15

GMS81C2112/GMS81C2120

PIN NAME In/Out

Function

Basic Alternate

DD

V

SS

V

RA (V

disp

)

- Supply voltage

- Circuit ground

I(I) 1-bit high-voltage Input only port High-voltage input power supply pin

RESET I Reset signal input

XIN I Oscillation input

XOUT O Oscillation output

R00 (INT0) I/O (I)

External interrupt 0 input

R01 (INT1) I/O (I) External interrupt 1 input

R02 (EC0) I/O (I) Timer/Counter 0 external input

8-bit high-voltage I/O ports

R03 (BUZO) I/O (O) Buzzer driving output

R04~R07 I/O

R20~R27 I/O 8-bit high-voltage I/O ports

R30~R34 I/O 5-bit high-voltage I/O ports

R53 (SCLK) I/O (I/O)

Serial clock source

R54 (SIN) I/O (I) Serial data input

R55 (SOUT) I/O (O) Serial data output

R56 (PWM1O/T1O) I/O (O)

5-bit high-voltage I/O ports

PWM 1 pulse output /Timer/Counter 1 out-

put

R57 I/O

R60~R67 (AN0~AN7) I/O (I) 8-bit general I/O ports Analog voltage input

DD

AV

AV

V

V

SS

DD

SS

- Supply voltage input pin for ADC

- Ground level input pin for ADC

- Supply voltage

- Circuit ground

Table 5-1 GMS81C2120 Port Function Description

JUNE. 2001 Ver 1.00 9

Page 16

GMS81C2112/GMS81C2120

Data Bus

V

DD

V

SS

Pin

Data Reg.

Direction

Reg.

Rd

MUX

Selection

SCLK Output

SCLK Input

V

DD

Mask

N-MOS

Open Drain Select

Option

Pull-up

Tr.

Data Bus

V

DD

V

SS

Pin

Data Reg.

Direction

Reg.

Rd

Selection

SIN Input

V

DD

Mask

N-MOS

Open Drain Select

Option

Pull-up

Tr.

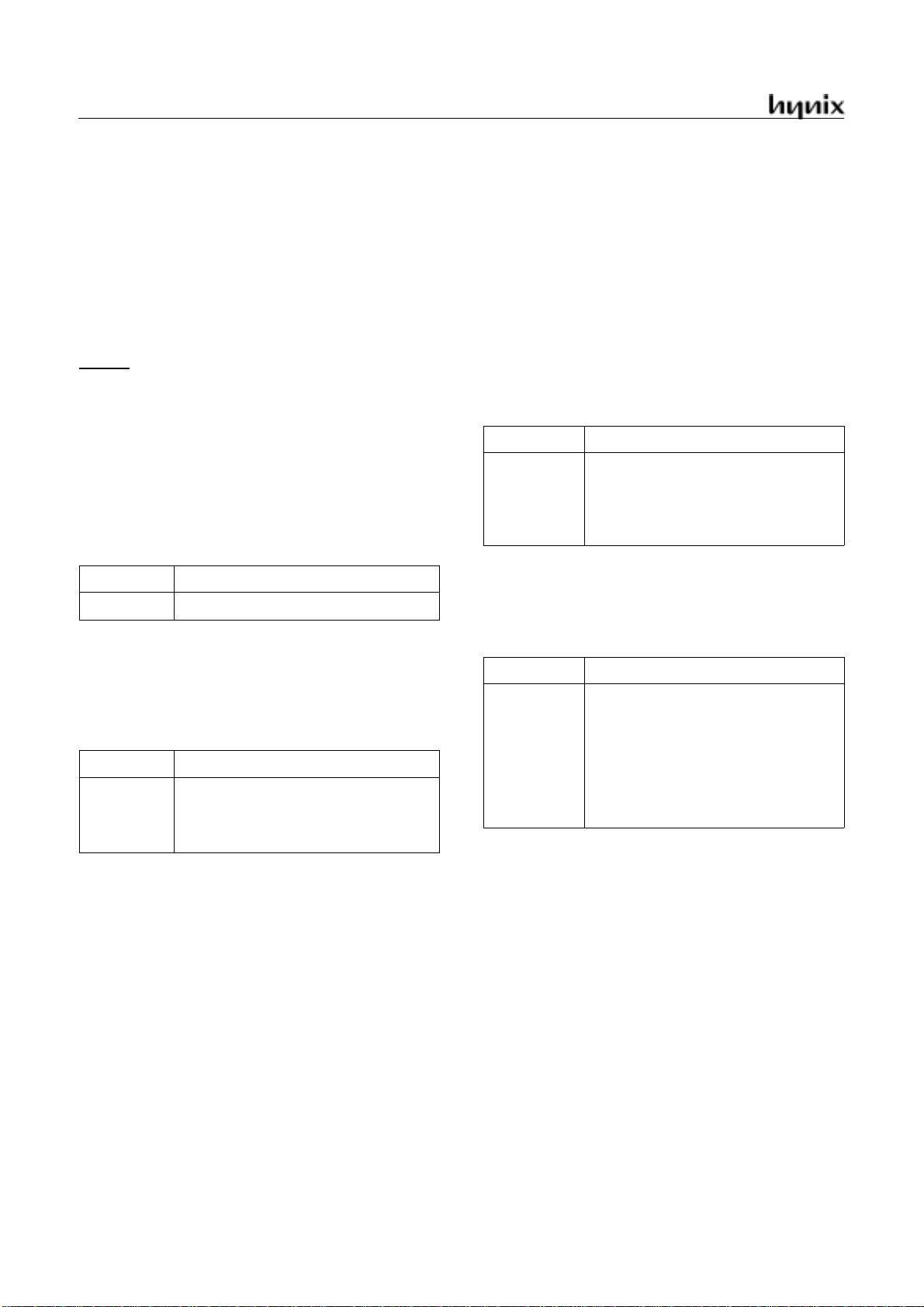

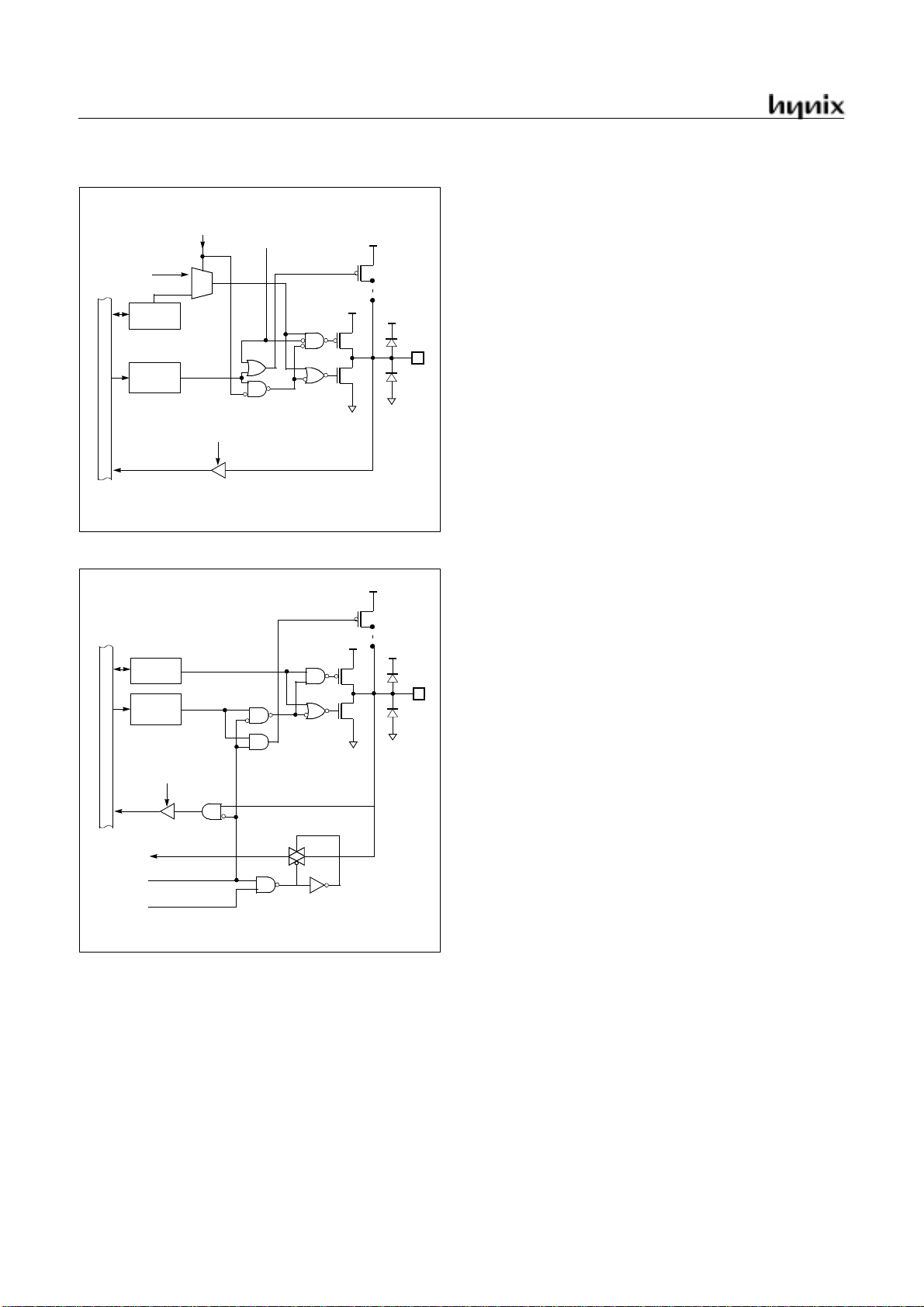

6. PORT STRUCTURES

R57

Data Reg.

Dir.

Reg.

Data Bus

MUX

Rd

R00/INT0, R01/INT1, R02/EC0

Selection

Data Reg.

Data Reg.

Dir.

Reg.

Data Bus

Rd

V

DD

VSS

V

DD

Mask

Option

Pull-up

Tr.

Mask

Option

V

DD

R53/SCLK

Pin

R54/SIN

Pin

EX) INT0

Alternate Function

Vdisp

10 JUNE. 2001 Ver 1.00

Page 17

GMS81C2112/GMS81C2120

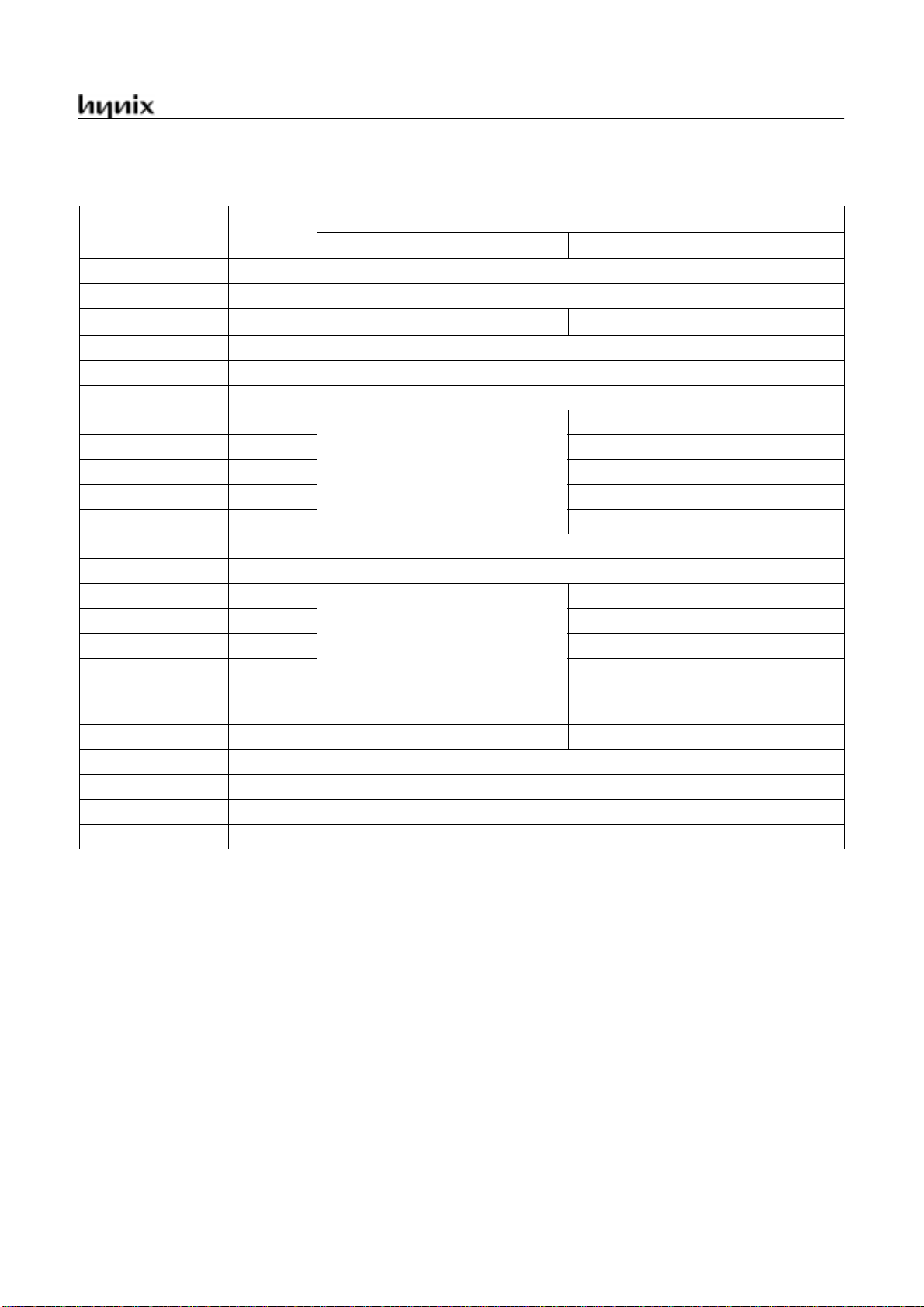

RESET

V

DD

V

SS

OTP :disconnected

Main :connected

XOUT

V

DD

XIN

Stop

Mainclk Off

V

SS

Pin

Data Reg.

Dir.

Rd

V

DD

Vdisp

Reg.

Data Bus

MUX

MUX

Selection

Data Reg.

Secondary

Function

Mask

Option

R55/SOUT

SOUT output

Data Reg.

Direction

Reg.

IOSWB

Data Bus

IOSWIN Input

RA/Vdisp

Rd

Selection

MUX

N-MOS

Open Drain Select

RESET

V

DD

Pull-up

Tr.

Mask

Option

V

DD

Pin

V

SS

V

DD

XIN, XOUT

Data bus

Rd

Vdisp

Mask

Option

R03/BUZO

R04~R07, R20~R27, R30~R34

V

DD

Data Reg.

Mask

Dir.

Reg.

Data Bus

Rd

MUX

Option

Vdisp

Pin

JUNE. 2001 Ver 1.00 11

Page 18

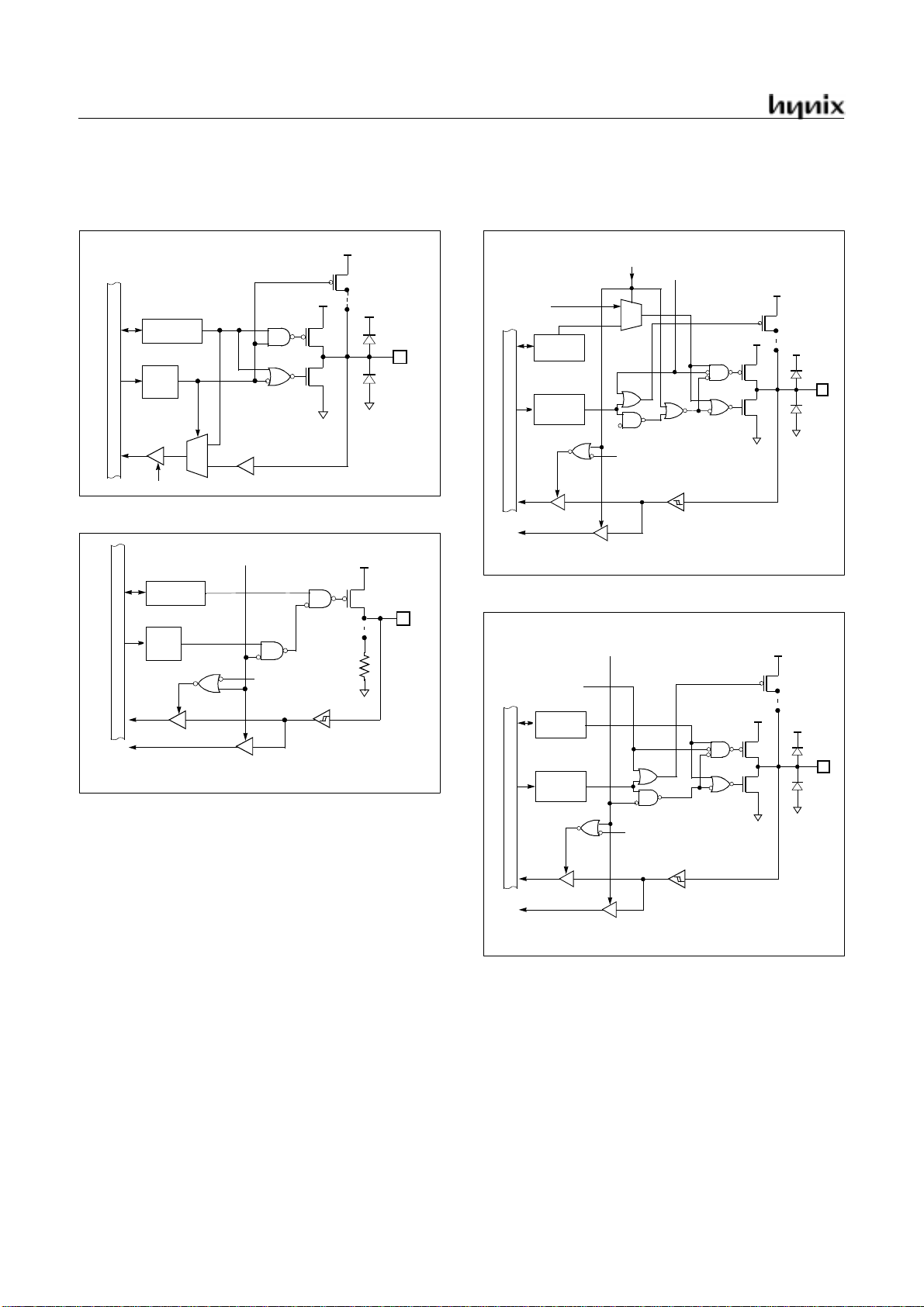

GMS81C2112/GMS81C2120

R56/PWM1O/T1O

Selection

SOUT output

MUX

Data Reg.

Direction

Reg.

Data Bus

R60~R67/AN0~AN7

Data Reg.

N-MOS

Open Drain Select

Rd

V

DD

Pull-up

Tr.

Mask

Option

V

DD

Pin

V

SS

V

DD

Pull-up

Tr.

Mask

V

DD

Option

Direction

Reg.

Data Bus

A/D

Converter

Analog

Input Mode

A/D Ch.

Selection

Rd

Pin

V

SS

12 JUNE. 2001 Ver 1.00

Page 19

7. ELECTRICAL CHARACTERISTICS

7.1 Absolute Maximum Ratings

GMS81C2112/GMS81C2120

Supply voltage.............................................-0.3 to +7.0 V

Storage Temperature ....................................-40 to +85 °C

Voltage on Normal voltage pin

with respect to Ground (V

..............................................................-0.3 to V

SS

)

+0.3 V

DD

Voltage on High voltage pin

with respect to Ground (V

............................................................-45V to V

Maximum current out of V

Maximum current into V

Maximum current sunk by (I

)

SS

DD

pin..........................150 mA

SS

pin ..............................80 mA

DD

per I/O Pin) ..........20 mA

OL

+0.3 V

7.2 Recommended Operating Conditions

Parameter Symbol Condition

Supply Voltage

Operating Frequency

Operating Temperature

T

V

f

DD

XIN

OPR

fXI = 4.5 MHz

VDD = V

Maximum output current sourced by (I

per I/O Pin)

OH

............................. ...... ................................................ 8 mA

Maximum current (ΣI

Maximum current (ΣI

Note:

Stresses above those listed under “Absolute Maximum Ratings” may cause per manent damage to the d evice. This is a stress ra ting only and functional ope r ati on of

the device at any oth er c ond iti ons ab ov e tho se ind ic ated in

the oper ati o na l se c ti ons of this s pecificatio n i s no t i mp l ie d .

Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Min. Max.

2.7 5.5 V

DD

-40 85

)......................................100 mA

OL

)........................................50 mA

OH

Specifications

14.5MHz

Unit

°

C

7.3 A/D Converter Characteristics

(TA=25°C, VDD=5V, VSS=0V, AVDD=5.12V, AVSS=0V @

Parameter Symbol Condition

Analog Power Supply Input Voltage Range

Analog Input Voltage Range

Current Following

Between AV

DD

and

AV

SS

Overall Accuracy

Non-Linearity Error

Differential Non-Linearity Error

Zero Offset Error

Full Scale Error

Gain Error

Conversion Time

1. Data in “T yp” column is at 25°C unless otherwise stated. These parameters are for design guidance only and are not tested.

AV

V

I

AVDD

CA

N

N

DNLE

N

N

N

T

CONV

DD

AN

IN

NLE

ZOE

FSE

NLE

=4MHz)

f

XIN

f

XIN

=4MHz

Specifications

AV

Min.

AV

SS

SS

-0.3

Typ.

1

AV

Max.

AV

DD

DD

+0.3

--200uA

--±2LSB

--±2LSB

--±2LSB

--±2LSB

--±2LSB

--±2LSB

--20us

Unit

V

V

JUNE. 2001 Ver 1.00 13

Page 20

GMS81C2112/GMS81C2120

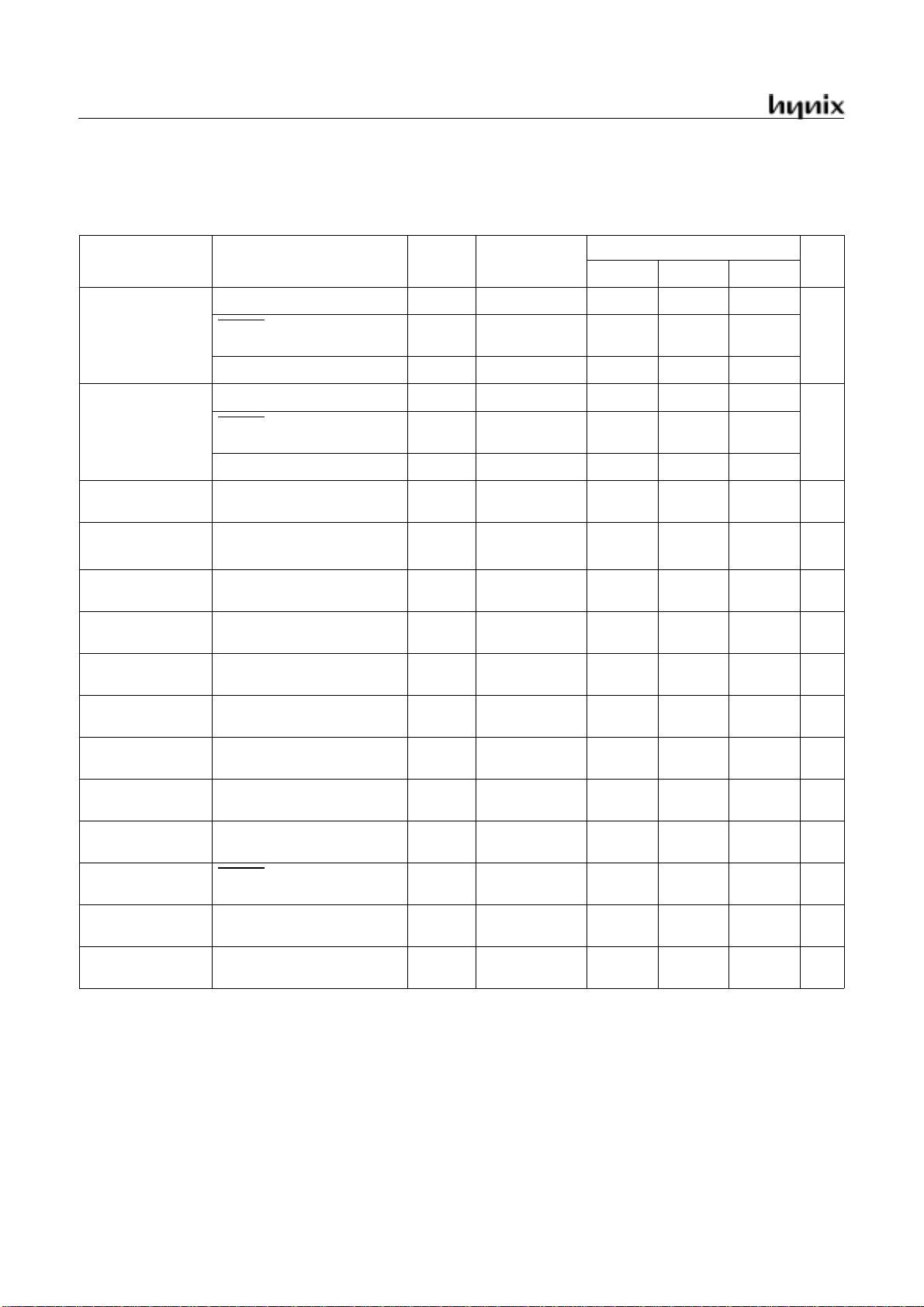

DC Electrical Characteristics for Standard Pins(5V)

7.4

(VDD = 5.0V ± 10%, V

= 0V, TA = -40 ~ 85°C, f

SS

= 4 MHz, Vdisp = VDD-40V to VDD)

XIN

,

Specification

Parameter Pin Symbol Test Condition

Min

XIN

Input High Voltage

RESET,SIN,R55,SCLK,

&

1,EC0

INT0

R53~R57,R6

XIN

,SIN,,R55,SCLK,

Input Low Voltage

RESET

&

INT0

1,EC0

R53~R57,R6

Output High

Voltage

Output Low

Voltage

Input High

Leakage Current

Input Low

Leakage Current

Input Pull-up

Current(*Option)

Power Fa il

Detect Voltage

Current dissipation

in active mode

Current dissipation

in standby mode

Current dissipation

in stop mode

Hysteresis

Internal RC WDT

Frequency

RC Oscillation

Frequency

1. Data in “Typ.” column is at 4.5V, 25°C unless otherwise stated. These parameters are for design guidance only and are not tested.

R53~R57,R6,BUZO,

PWM1O/T1O,SCLK,SOUT

R53~R57,R6,BUZO,

PWM1O/T1O,SCLK,SOUT

R53~R57,R6

R53~R57,R6

R53~R57,R6

V

DD

V

DD

V

DD

V

DD

,SIN,R55,SCLK,

RESET

,

INT1,EC0

INT0

XOUT

XOUT

V

V

V

V

V

V

V

V

OL1

V

OL2

I

IH1

I

IL1

I

PU

V

PFD

I

DD

I

STBY

I

STOP

V

T+~VT-

T

RCWDT

f

RCOSC

IH1

IH2

IH3

IL1

IL2

IL3

OH

External Clock

External Clock -0.3

I

= -0.5mA VDD-0.5

OH

I

= 1.6mA

OL

I

= 10mA

OL

XIN

f

=4.5MHz 8 mA

XIN

f

=4.5MHz 3 mA

XIN

f

=Off

SXIN

=32.7KHz

f

R= 120K

0.9V

DD

0.8V

DD

0.7V

DD

-0.3

-0.3

-1 uA

50 100 180 uA

0.4 V

830KHz

Ω

1.522.5MHz

1

Typ.

Max

VDD+0.3

VDD+0.3

VDD+0.3

0.1V

DD

0.2V

DD

0.3V

DD

0.4

2

1uA

2.7 V

10 uA

Unit

V

V

V

V

14 JUNE. 2001 Ver 1.00

Page 21

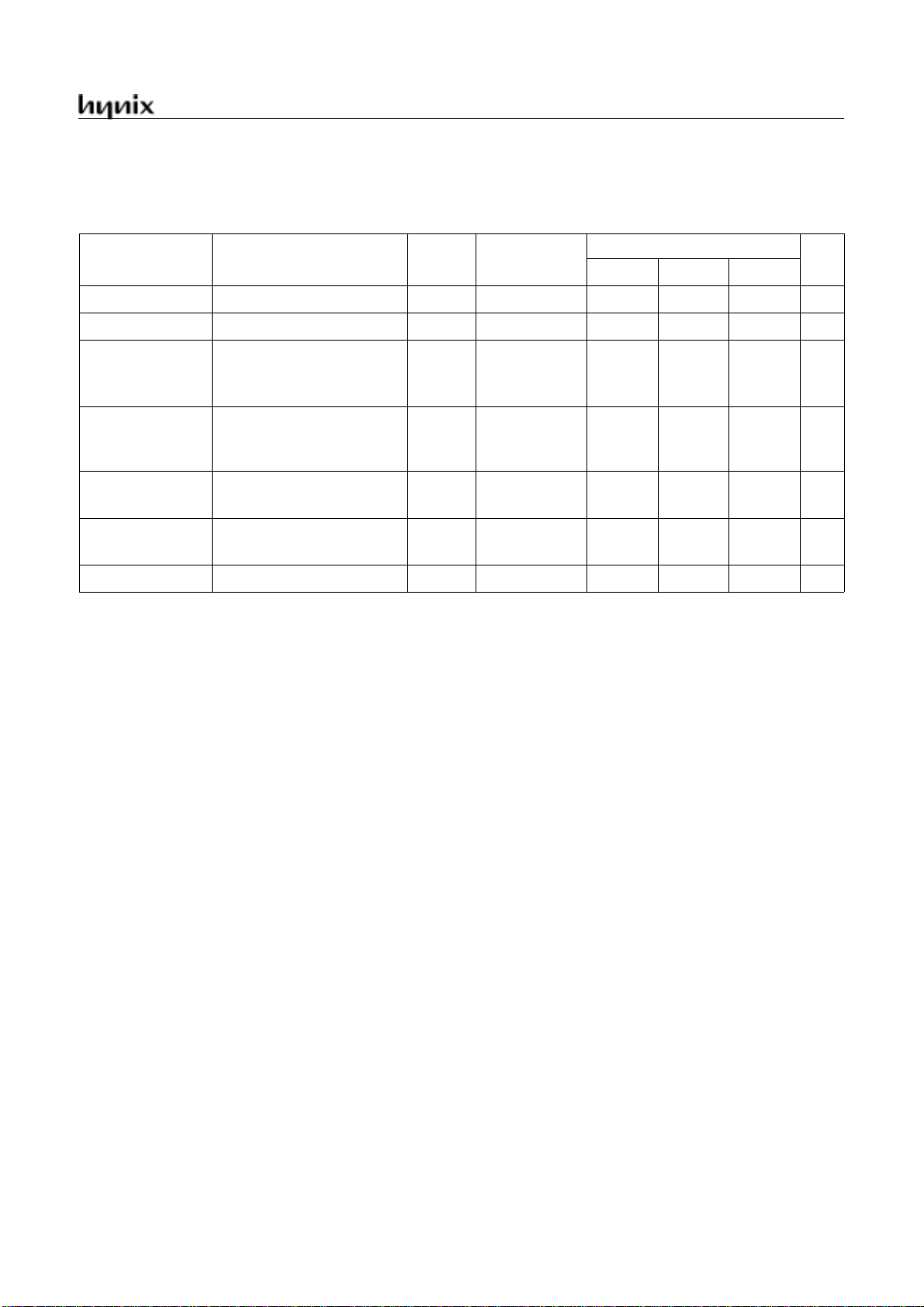

7.5 DC Electrical Characteristics for High-Voltage Pins

GMS81C2112/GMS81C2120

(VDD = 5.0V ± 10%, V

= 0V, TA = -40 ~ 85°C, f

SS

= 4 MHz, Vdisp = VDD-40V to VDD)

XIN

Specification

Parameter Pin Symbol Test Condition

Input High Voltage R0,R2,R30~R34,RA

Input Low Voltage R0,R2,R30~R34,RA

Output High

Voltage

Output Low

Voltage

Input High

Leakage Current

Input Pull-down

Current(*Option)

R0,R2,R30~R34

R0,R2,R30~R34

R0,R2,R30~R34,RA

R0,R2,R30~R34

Input High Voltage R0,R2,R30~R34,RA

1. Data in “Typ.” column is at 4.5V, 25°C unless otherwise stated. These parameters are for design guidance only and are not tested.

V

IH

V

IL

I

= -15mA

OH

I

V

OH

OH

I

OH

= -10mA

= - 4mA

Vdisp = VDD-40

V

OL

150KΩ atVDD-

40

I

IH

I

PD

V

IH

VIN=VDD-40V

to V

DD

Vdisp=VDD-35V

VIN=V

DD

Min

0.7V

DD

VDD-40 0.3V

-3.0

V

DD

VDD-2.0

V

-1.0

DD

200 600 1000 uA

0.7V

DD

Typ.

1

Max

VDD+0.3

DD

V

-37

DD

VDD-37

20 uA

VDD+0.3

Unit

V

V

V

V

V

JUNE. 2001 Ver 1.00 15

Page 22

GMS81C2112/GMS81C2120

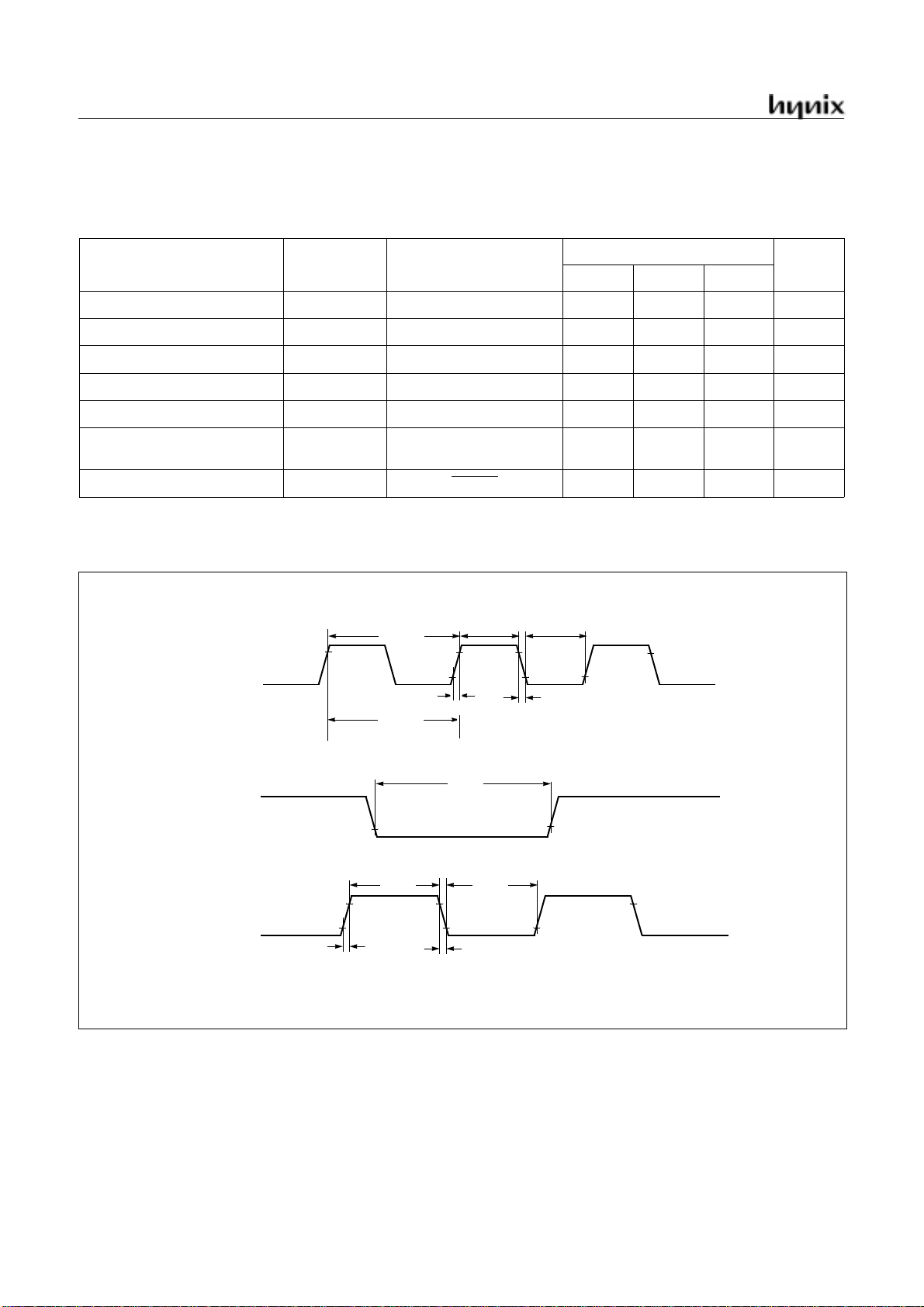

7.6 AC Characteristics

(TA=-40~ 85°C, VDD=5V±10%, VSS=0V)

Parameter Symbol Pins

Operating Frequency

External Clock Pulse Width

External Clock Transition Time

Oscillation Stabilizing Time

External Input Pulse Width

External Input Pulse Transi-

tion Time

RESET Input Width

XI

f

CP

t

CPW

t

RCP,tFCP

t

ST

t

EPW

t

REP,tFEP

t

RST

Specifications

Min. Typ. Max.

XIN 1 - 8 MHz

XIN 80 - - nS

XIN - - 20 nS

XIN, XOUT - - 20 mS

INT0, INT1, EC0 2 - -

INT0, INT1, EC0 - - 20 nS

RESET 8--

t

1/f

CP

CPW

t

CPW

0.5V

-0.5V

V

DD

Unit

t

SYS

t

SYS

RESETB

INT0, INT1

EC0

t

REP

t

SYS

t

EPW

t

FEP

t

t

RCP

RST

t

EPW

t

FCP

Figure 7-1 Timing Chart

0.2V

0.2V

DD

0.8V

DD

DD

16 JUNE. 2001 Ver 1.00

Page 23

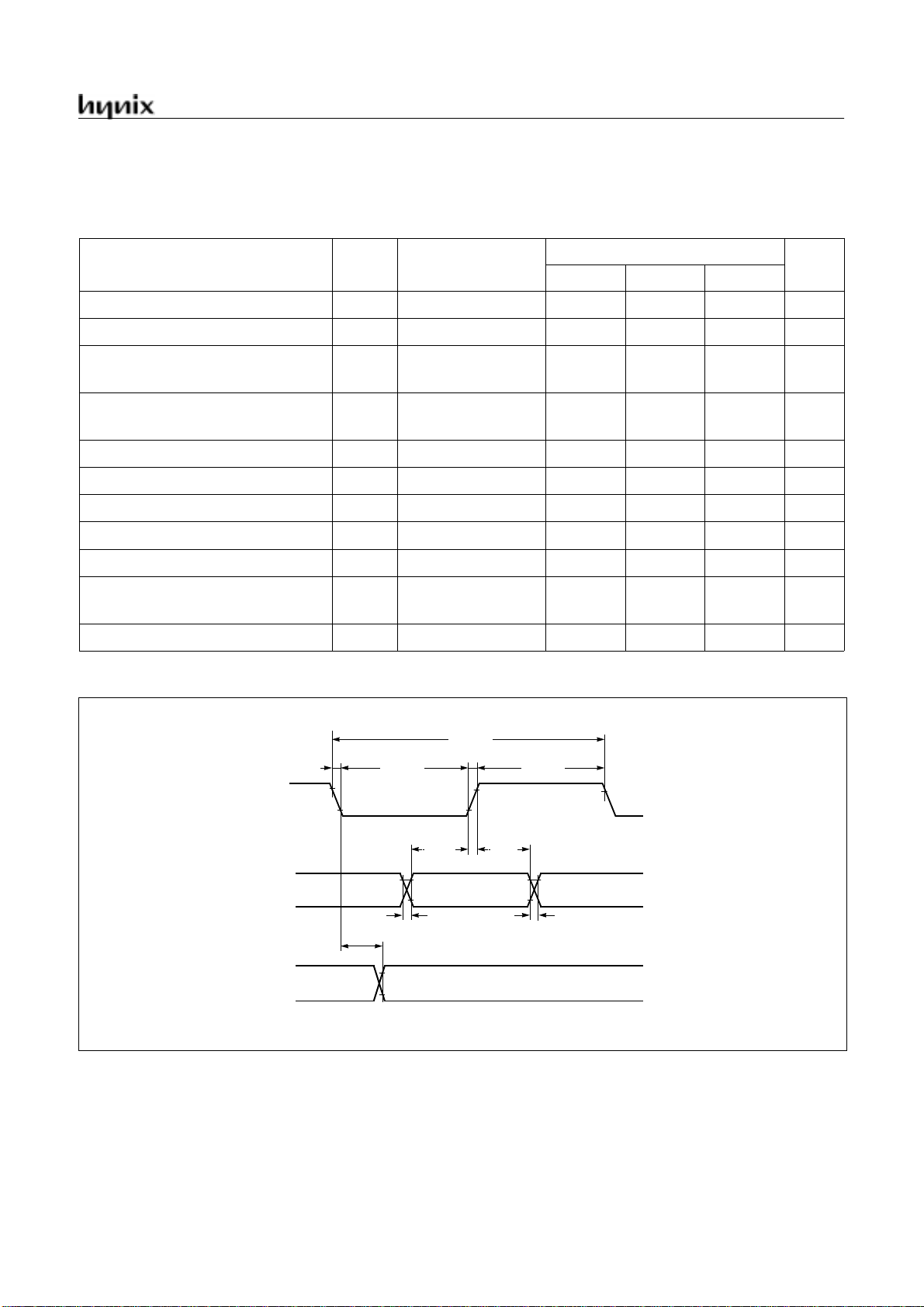

7.7 AC Characteristics

GMS81C2112/GMS81C2120

(TA=-40~+85°C, VDD=5V±10%, VSS=0V, f

Parameter Symbol Pins

Serial Input Clock Pulse

Serial Input Clock Pulse Width

Serial Input Clock Pulse Transition

Time

SIN Input Pulse Transition Time

SIN Input Setup Time (External SCLK)

SIN Input Setup Time (Internal SCLK)

SIN Input Hold Time

Serial Output Clock Cycle Time

Serial Output Clock Pulse Width

Serial Output Clock Pulse Transition

Time

Serial Output Delay Time

XIN

t

SCYC

t

SCKW

t

FSCK

t

RSCK

t

FSIN

t

RSIN

t

SUS

t

SUS

t

HS

t

SCYC

t

SCKW

t

FSCK

t

RSCK

s

OUT

=4MHz)

Specifications

Unit

Min. Typ. Max.

SCLK

SCLK

2t

SYS

+70

t

SYS

-8ns

-8ns

+200

SCLK - - 30 ns

SIN - - 30 ns

SIN 100 - - ns

SIN 200 - ns

SIN

SCLK

SCLK

t

SYS

t

4t

SYS

SYS

-30

-ns

-

16t

SYS

ns

ns

+70

SCLK 30 ns

SOUT 100 ns

SCLK

SIN

SOUT

t

0.8V

0.2V

t

SCYC

FSCK

DD

DD

t

SCKW

t

SUS

t

FSIN

t

DS

0.8V

DD

0.2V

DD

Figure 7-2 Serial I/O Timing Chart

t

RSCK

t

SCKW

t

HS

0.8V

DD

0.2V

DD

t

RSIN

JUNE. 2001 Ver 1.00 17

Page 24

GMS81C2112/GMS81C2120

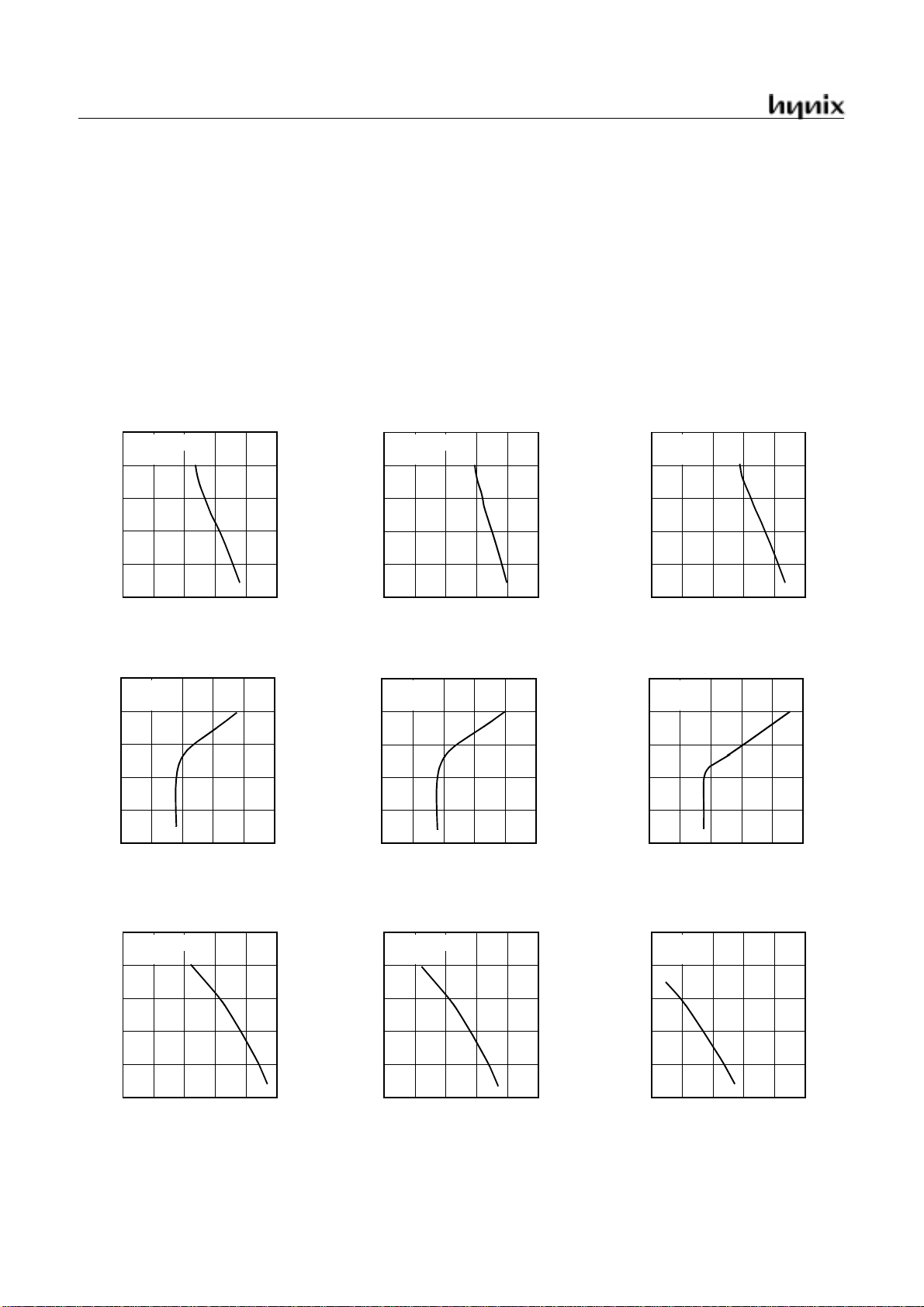

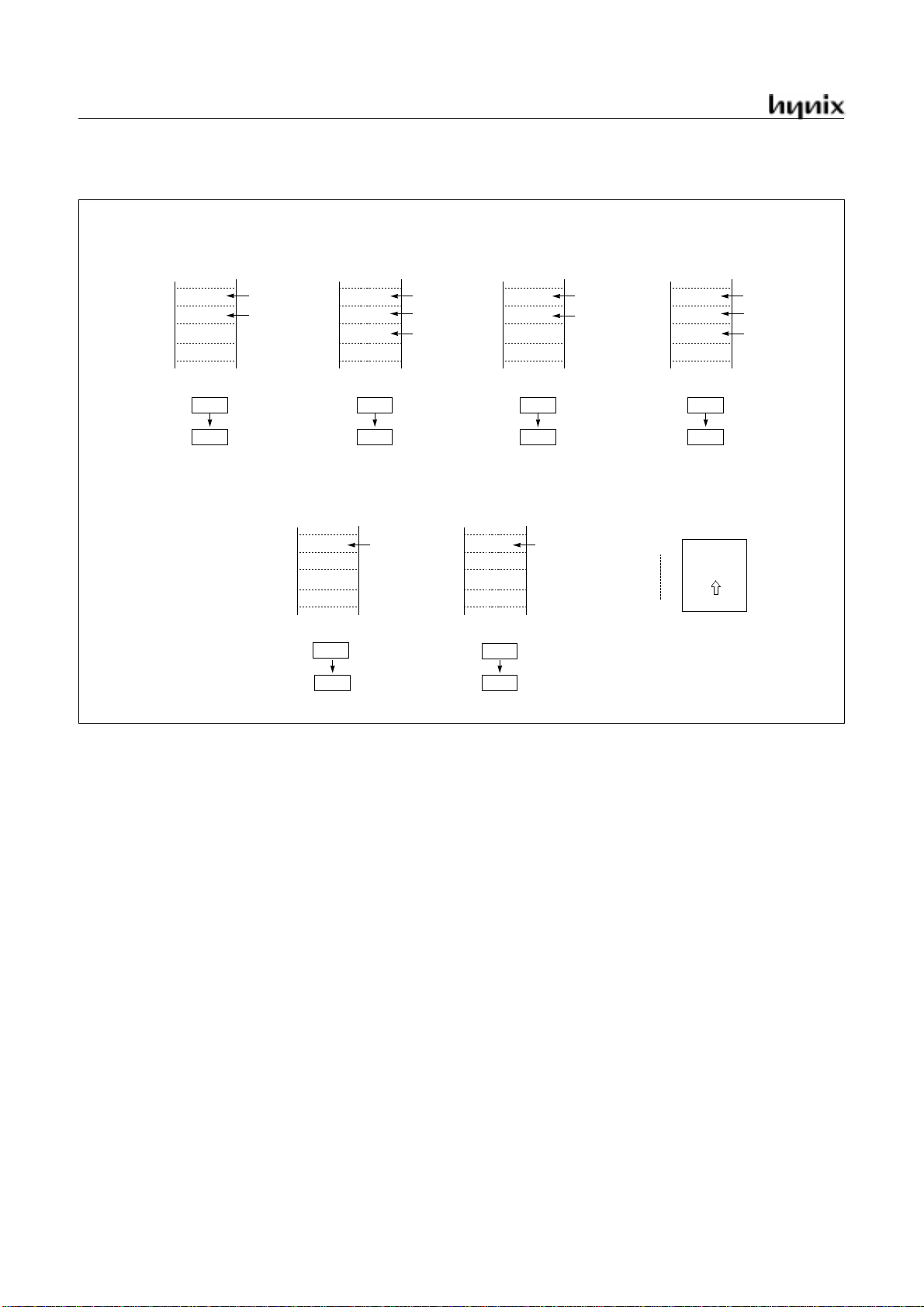

7.8 Typical Characteristics

This graphs and tables provided in this section are for design guidance only and are not tested or guaranteed.

In some graphs or tables the data presented are outside specified operating range (e.g. outside specified

VDD range). This is for information only and devices

are guaranteed to operate properly only within the

specified range.

R40~R43, R6, R53~R57

BUZO, PWM1O/T1O

V

SCLK, SOUT pins

OH

4.8 4.9

R40~R43, R6, R53~R57

BUZO, PWM1O/T1O

OL

SCLK, SOUT pins

5.0

V

(V)

OH

I

OH

(mA)

-1.6

-1.2

-0.8

-0.4

I

OL

(mA)

16

I

OH

VDD=4.0V

Ta=25°C

0

I

OL

VDD=4.0V

Ta=25°C

−

V

OH

3.6 3.7

−

V

OL

I

OH

(mA)

-1.6

-1.2

-0.8

-0.4

I

OL

(mA)

16

I

OH

VDD=5.0V

Ta=25°C

0

I

OL

VDD=5.0V

Ta=25°C

−

4.6 4.7

−

V

The data presented in this s ection is a statistical s ummary

of data collected on units from different lots over a period

of time. “Typical” represents the mean of the distribution

while “max” or “min” represents (mean + 3σ) and (mean −

3σ) respectively where σ is standard deviation

−

I

V

OH

VDD=3.0V

Ta=25°C

2.6 2.7

−

I

V

OL

VDD=3.0V

Ta=25°C

OL

OH

2.8 2.9

3.0

3.8 3.9

4.0

V

(V)

OH

I

OH

(mA)

-1.6

-1.2

-0.8

-0.4

I

OL

(mA)

16

0

V

(V)

OH

12

8

4

0

I

OH

(mA)

-16

-12

-8

-4

I

OH

VDD=5.0V

Ta=25°C

0

0.6 0.8

−

V

OH

1.0 2.0

1.0 1.2

R0, R2,RA

R30~R34 pins

3.0 4.0

1.4

5.0

V

(V)

V

(V)

12

8

4

1.4

5.0

V

(V)

V

(V)

OL

OH

I

OH

(mA)

-16

-12

-8

-4

0

I

0

0.6 0.8

−

V

OH

VDD=4.0V

Ta=25°C

1.0 2.0

1.0 1.2

OH

3.0 4.0

OL

OH

12

I

OH

(mA)

-16

-12

-8

-4

8

4

0

I

0

0.6 0.8

−

V

OH

VDD=3.0V

Ta=25°C

1.0 2.0

OH

1.0 1.2

3.0 4.0

1.4

5.0

V

(V)

V

(V)

OL

OH

18 JUNE. 2001 Ver 1.00

Page 25

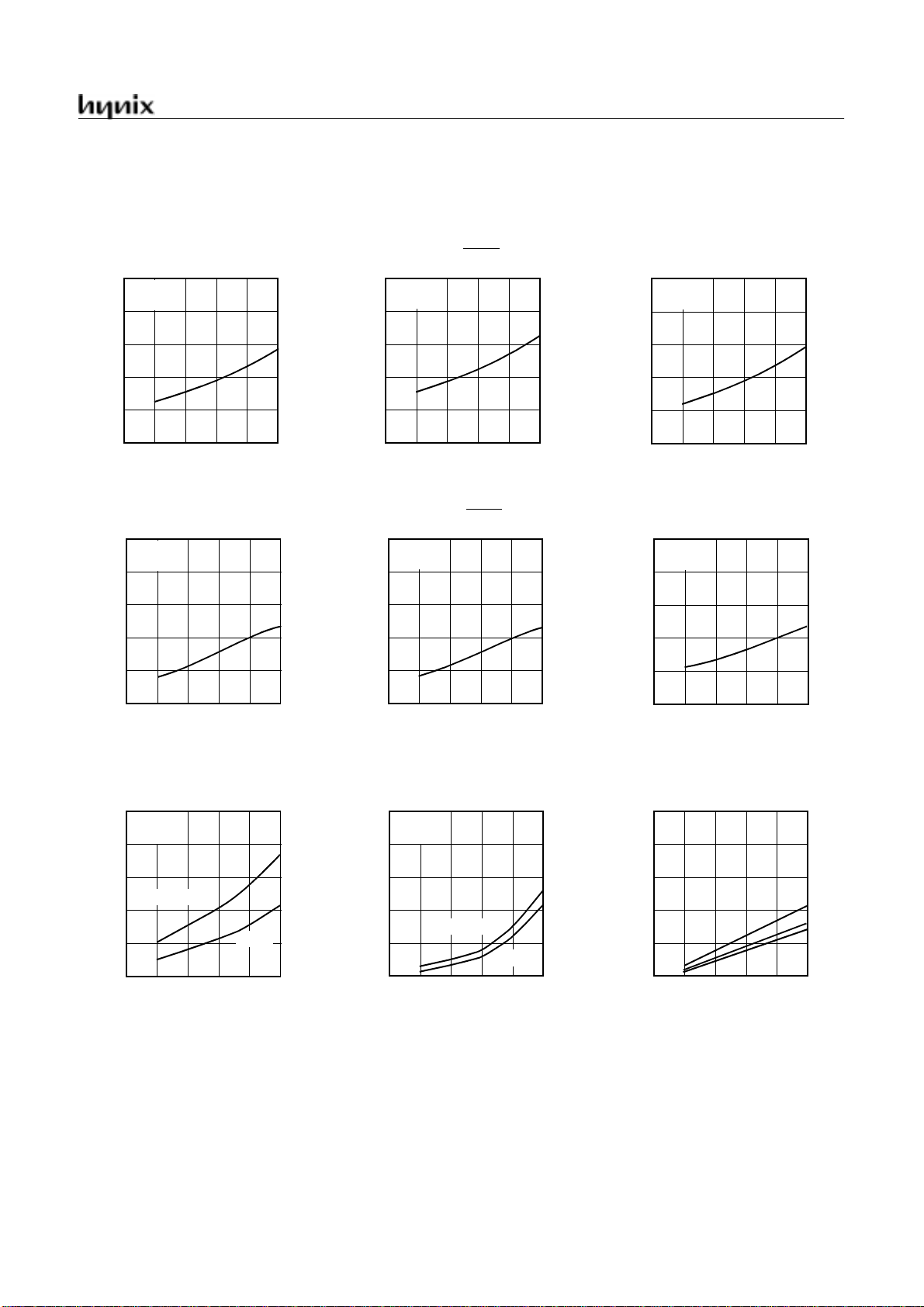

GMS81C2112/GMS81C2120

RESET, R55, SIN, SCLK

V

IH2

INT0, INT1, EC0 pinsXIN pins

45

RESET, R55, SIN, SCLK

V

IL2

INT0, INT1, EC0 pinsXIN pins

23

45

−

V

V

DD

V

IH3

f

=4.5MHz

XIN

(V)

Ta=25°C

4

3

2

1

V

DD

(V)

6

V

DD

(V)

6

0

1

23

−

V

V

DD

V

IL3

f

=4.5MHz

XIN

(V)

Ta=25°C

4

3

2

1

0

1

23

IH3

IL3

R53~R57, R6 pins

V

(V)

45

R53~R57, R6 pins

45

6

V

6

DD

(V)

DD

4

3

2

1

0

IL2

4

3

2

1

0

V

DD

f

XIN

Ta=25°C

1

V

DD

f

XIN

Ta=25°C

1

−

=4.5MHz

23

−

=4.5MHz

−

V

V

DD

f

=4.5MHz

XIN

Ta=25°C

23

V

DD

f

=4.5MHz

XIN

Ta=25°C

IH1

−

V

IL1

23

45

45

V

DD

(V)

6

V

DD

(V)

6

V

IH1

(V)

4

3

2

1

0

V

IL1

(V)

4

3

2

1

0

V

IH2

(V)

V

(V)

I

DD

(mA)

4.0

3.0

2.0

1.0

0

I

DD

Ta=25°C

−

V

DD

f

= 4.5MHz

XIN

23

Normal Operation

2.5MHz

45

−

V

I

SBY

DD

= 4.5MHz

XIN

Stand-by Mode

2.5MHz

45

V

DD

(V)

6

I

DD

Ta=25°C

(mA)

4.0

3.0

2.0

1.0

V

DD

(V)

6

0

f

23

I

DD

(µA)

2.0

1.5

1.0

0.5

0

I

STOP

−

V

DD

23

Stop Mode

45

6

85°C

25°C

-20°C

V

DD

(V)

JUNE. 2001 Ver 1.00 19

Page 26

GMS81C2112/GMS81C2120

SP

01

H

Stack Address ( 100H ~ 1FEH )

Bit 15 Bit 087

Hardware fixed

00H~FF

H

8. MEMORY ORGANIZATION

The GMS81C2112 and GMS81C2120 have separate address spaces for Program memory and Data Memory. Pro gram memory can only be read, not written to. It can be up

8.1 Registers

This device has six registers that are the Program Counter

(PC), a Accumulator (A), two index registers (X, Y), the

Stack Pointer (SP), and the Program Status Word (PSW).

The Program Counter consists of 16-bit register.

A

X

Y

SP

PCH

Figure 8-1 Configuration of Registers

Accumulator:

PCL

PSW

The Accumulator is the 8-bit general purpose register, used for data operation such as transfer, temporary saving, and conditional judgement, etc.

The Accumulator can be used as a 16-bit register with Y

Register as shown below.

ACCUMULATOR

X REGISTER

Y REGISTER

STACK POINTER

PROGRAM COUNTER

PROGRAM STATUS

WORD

to 12K/20K bytes of Program memory. Data memory can

be read and written to up to 448 by tes includ ing the s tack

area.

Generally, SP is automatically updated when a subrout ine

call is executed or an interrupt is accepted. However, if it

is used in excess of the stack area permitted by the data

memory allocating configuration, the user-processed data

may be lost.

The stack can be located at any position within 100

1FF

of the internal data memory. The SP is not initialized

H

to

H

by hardware, requiring to write the initial v alue (the lo cation with which the use of the stack starts) by using the initialization routine. Normally, the initial value of “FF

” is

H

used.

Note:

The Stack Pointer must be initi alized by softwa re be-

cause its value is undefined after RESET.

Example: To initialize the SP

LDX #0FFH

TXSP ; SP ← FFH

Y

Y A

A

Two 8-bit Registers can be used as a "YA" 16-bit Register

Figure 8-2 Configuration of YA 16-bit Register

X, Y Registers

: In the addressing mode which uses these

index registers, the register conten ts a re added to the specified address, which becomes the actual address. These

modes are extremely effective for referencing subroutine

tables and memory tables . The index regi sters also h ave increment, decrement, comparison and data transfer functions, and they can be used as simple accumulators.

Stack Pointer

: The Stack Pointer is an 8-bit register used

for occurrence interrupts and calling out subroutines. Stack

Pointer identifies the location in the stack to be access

(save or restore).

Program Counter

: The Program Counter is a 16-bit wide

which consists of two 8-bit registers, PCH and PCL. This

counter indicates the address of the next instruction to be

executed. In reset state, the program counter has reset routine address (PC

Program Status Word

:0FFH, PCL:0FEH).

H

: The Program Status Word (PSW)

contains several bits that reflect the current state of the

CPU. The PSW is described in Figure 8-3. It contains the

Negative flag, the Overflow flag, the Break flag the Half

Carry (for BCD operation), the Interrupt enable flag, the

Zero flag, and the Carry flag.

[Carry flag C]

This flag stores any carry or borrow from the ALU of CPU

after an arithmetic operation and is also changed by the

Shift Instruction or Rotate Instruction.

[Zero flag Z]

This flag is set when the result of an arithmetic operation

or data transfer is "0" and is cleared by any other result.

20 JUNE. 2001 Ver 1.00

Page 27

NEGATIVE FLAG

OVERFLOW FLAG

when G=1, page is selected to “page 1”

SELECT DIRECT PAGE

BRK FLAG

Figure 8-3 PSW (Program Status Word) Register

MSB LSB

N

PSW

V G B H I Z C

GMS81C2112/GMS81C2120

RESET VALUE : 00

CARRY FLAG RECEIVES

CARRY OUT

ZERO FLAG

INTERRUPT ENABLE FLAG

HALF CARRY FLAG RECEIVES

CARRY OUT FROM BIT 1 OF

ADDITION OPERLANDS

H

[Interrupt disable flag I]

This flag enables/disables all interrupts except interrupt

caused by Reset or software BRK instruction. All interrupts are disabled when cleared to “0”. This flag immediately becomes “0” when an interrupt is served. It is set by

the EI instruction and cleared by the DI instruction.

[Half carry flag H]

After operation, this is set when there is a carry from bit 3

of ALU or there is no borrow from bit 4 of ALU. This bit

can not be set or cleared except CLRV instruction with

Overflow flag (V).

[Break flag B]

This flag is set by software BRK instruction to distinguish

BRK from TCALL instruction with the same vector address.

[Direct page flag G]

This flag assigns RAM page for direct addressing mode. In

the direct addressing mode, addressing area is from zero

page 00

addressing area is assigned 100

to 0FFH when this flag is "0". If it is set to "1",

H

to 1FFH. It is set by

H

SETG instruction and cleared by CLRG.

[Overflow flag V]

This flag is set to “1” when an overflow occurs as the result

of an arithmetic operation involving signs. An overflow

occurs when the result of an addition or subtraction exceeds +127(7F

) or -128(80H). The CLRV instruction

H

clears the overflow flag. There is no set instruction. When

the BIT instruction is executed, bit 6 of memory is copied

to this flag.

[Negative flag N]

This flag is set to match the sign bit (bit 7) status of the re-

sult of a data or arithmetic operation. When the BIT instruction is executed, bit 7 of memory is copied to this flag.

JUNE. 2001 Ver 1.00 21

Page 28

GMS81C2112/GMS81C2120

At execution of

a CALL/TCALL/PCALL

01FE

01FD

01FC

01FB

SP before

execution

SP after

execution

PCH

PCL

01FE

01FC

Push

down

01FE

01FD

01FC

01FB

SP before

execution

SP after

execution

At acceptance

of interrupt

01FE

01FD

01FC

01FB

At execution

of PUSH instruction

PUSH A (X,Y,PSW)

A

01FE

01FD

PCH

PCL

PSW

01FE

01FB

Push

down

Push

down

01FE

01FD

01FC

01FB

At execution

of RET instruction

01FE

01FD

01FC

01FB

At execution

of POP instruction

POP A (X,Y,PSW)

PCH

PCL

01FC

01FE

A

01FD

01FE

Pop

up

Pop

up

At execution

of RET instruction

01FE

01FD

01FC

01FB

0100H

01FEH

PCH

PCL

PSW

01FB

01FE

Stack

depth

Pop

up

Figure 8-4 Stack Operation

22 JUNE. 2001 Ver 1.00

Page 29

8.2 Program Memory

0FFE0H

E2

Address Vector Area Memory

E4

E6

E8

EA

EC

EE

F0

F2

F4

F6

F8

FA

FC

FE

-

-

Serial Communication Interface

Basic Interval Timer

-

-

-

Timer/Counter 0 Interrupt

-

External Interrupt 0

-

RESET Vector Area

External Interrupt 1

Watchdog Timer Interrupt

"-" means reserved area.

NOTE:

Timer/Counter 1 Interrupt

-

A/D Converter

GMS81C2112/GMS81C2120

A 16-bit program counter is capable of addressing up to

64K bytes, but this device has 2 0K bytes program memory

space only physically implemented. Accessing a location

above FFFF

will cause a wrap-around to 0000H.

H

Figure 8-5, shows a map of Pr ogram Memory. After reset,

the CPU begins execution from reset vector which is stored

in address FFFE

and FFFFH as shown in Figure 8-6.

H

As shown in Figure 8-5, each area is assigned a fix ed location in Program Memory. Program Memory area contains

the user program.

B000

H

D000

H

FEFF

H

FF00

FFC0

FFDF

FFE0

FFFF

H

H

TCALL area

H

H

Vector Area

H

Interrupt

PCALL area

GMS81C2120, 20K ROM

GMS81C2112, 12K ROM

Example: Usage of TCALL

LDA #5

TCALL 0FH ;

:;

:;

;

;TABLE CALL ROUTINE

;

FUNC_A: LDA LRG0

RET

;

FUNC_B: LDA LRG1

RET

;

;TABLE CALL ADD. AREA

;

ORG 0FFC0H ;

DW FUNC_A

DW FUNC_B

1BYTE INSTRUCTION

IN STEAD OF 3 BYTES

NORMAL CALL

1

2

TCALL ADDRESS AREA

The interrupt causes the CPU to jum p to specific location,

where it commences the execution of the service routine.

The External interrupt 0, for example, is assigned to location 0FFFA

interval: 0FFF8

0FFFA

Any area from 0FF00

. The interrupt service locations spaces 2-byte

H

and 0FFF9H for External Interru pt 1,

and 0FFFBH for External Interrupt 0, etc.

H

H

to 0FFFFH, if it is not going to be

H

used, its service location is available as general purpose

Program Memory.

Figure 8-5 Program Memory Map

Page Call (PCALL) area contains subroutine program to

reduce program byte length by using 2 bytes PCALL instead of 3 bytes CALL instruction. If it is frequently called,

it is more useful to save program byte length .

Table Call (TCALL) c auses the CPU to jump to each

TCALL address, where it commences the execution of the

service routine. The Table Call service area spaces 2-byte

for every TCALL: 0FFC0

TCALL14, etc., as shown in Figure 8-7.

JUNE. 2001 Ver 1.00 23

for TCALL15, 0FFC2H for

H

Figure 8-6 Interrupt Vector Area

Page 30

GMS81C2112/GMS81C2120

11111111 11010110

01001010

PC:

FH FH DH 6H

4A

~

~

~

~

25

0FFD6

H

0FF00

H

0FFFF

H

D1

NEXT

0FFD7

H

➊

➋

➌

0D125

H

Reverse

Address

0FF00

0FFFF

PCALL Area Memory

H

PCALL Area

(256 Bytes)

H

Address P ro gra m Mem o r y

0FFC0

H

C1

C2

C3

C4

C5

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

DA

DB

DC

DD

DE

DF

NOTE:

* means that the BRK software interrupt is using

same address with TCALL0.

TCALL 15

TCALL 14

TCALL 13

TCALL 12

TCALL 11

TCALL 10

TCALL 9

TCALL 8

TCALL 7

TCALL 6

TCALL 5

TCALL 4

TCALL 3

TCALL 2

TCALL 1

TCALL 0 / BRK *

PCALL

→

→

→ →

rel

4F35 PCALL 35H

0FF00

0FF35

0FFFF

Figure 8-7 PCALL and TCALL Memory Area

TCALL

→

→

→ →

n

4A TCALL 4

4F

35

~

~

H

H

NEXT

H

~

~

24 JUNE. 2001 Ver 1.00

Page 31

Example: The usage software example of Vector address for GMS81C2120.

ORG 0FFE0H

DW NOT_USED

DW NOT_USED

DW SIO ; Serial Interface

DW BIT_TIMER ; Basic Interval Timer

DW WD_TIMER ; Watchdog Timer

DW ADC ; ADC

DW NOT_USED

DW NOT_USED

DW NOT_USED

DW NOT_USED

DW TIMER1 ; Timer-1

DW TIMER0 ; Timer-0

DW INT1 ; Int.1

DW INT0 ; Int.0

DW NOT_USED ; DW RESET ; Reset

GMS81C2112/GMS81C2120

; ORG 0D000H ; GMS81C2112(12K)ROM Start address

;*******************************************

; MAIN PROGRAM *

;*******************************************

;

RESET: DI ;Disable All Interrupts

RAM_CLR: LDA #0 ;RAM Clear(!0000H->!00BFH)

;

;

ORG 0B000H ; GMS81C2120(20K)ROM Start address

CLRG

LDX #0

STA {X}+

CMPX #0C0H

BNE RAM_CLR

LDX #0FFH ;Stack Pointer Initialize

TXSP

LDM R0, #0 ;Normal Port 0

LDM R0IO,#82H ;Normal Port Direction

:

:

:

LDM TDR0,#125 ;8us x 125 = 1mS

LDM TM0,#0FH ;Start Timer0, 8us at 4MHz

LDM IRQH,#0

LDM IRQL,#0

LDM IENH,#0E0H ;Enable Timer0, INT0, INT1

LDM IENL,#0

LDM IEDS,#05H ;Select falling edge detect on INT pin

LDM R0FUNC,#03H ;Set external interrupt pin(INT0, INT1)

EI ;Enable master interrupt

:

:

:

:

NOT_USED :NOP

:

RETI

JUNE. 2001 Ver 1.00 25

Page 32

GMS81C2112/GMS81C2120

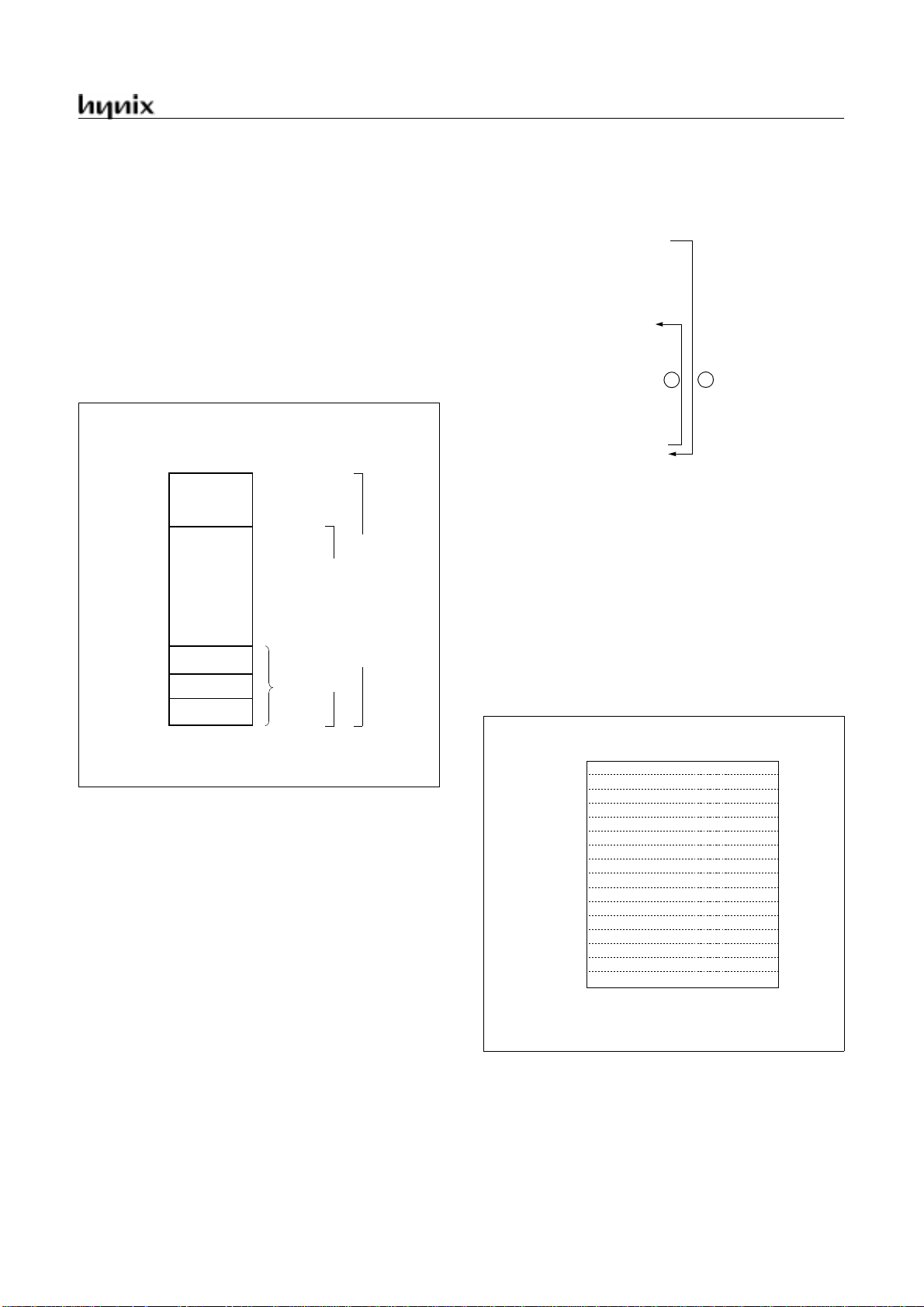

8.3 Data Memory

Figure 8-8 shows the internal Data Memory space available. Data Memory is divi d ed i nto two groups, a user RAM

(including Stack) and control registers.

0000

H

digital converters and I/O ports. The control registers are in

address range of 0C0

to 0FFH.

H

Note that unoccupied addresses may not be implemented

on the chip. Read accesses to these addresses will in general return random data, and write accesses will have an indeterminate effect.

User Memory

00BF

00C0

00FF

0100

01FF

H

H

H

H

H

Control

Registers

User Memory

or Stack Area

PAGE0

PAGE1

When “G-flag=0”,

this page is selected

When “G-flag=1”

Figure 8-8 Data Memory Map

User Memory

The GMS81C21xx have 448 × 8 bits for the user me mo ry

(RAM).

Control Registers

The control registers are used by the CPU and Peripheral

function blocks for controlling the desired operation of the

device. Therefore these registers contain control and status

bits for the interrupt system, the timer/ counters, analog to

More detailed informations of each register are explained

in each peripheral section.

Note:

Write only registers can not be accessed by bit manipulation instruction. Do not use read-modify-write instruction. Use byte manipulation instruction, for example “LDM”.

Example; To write at CKCTLR

LDM CLCTLR,#09H

;Divide ratio(

÷16

)

Stack Area

The stack provides the area where the return address is

saved before a jump is performed during the processing

routine at the execution of a subroutine call instruction or

the acceptance of an interrupt.

When returning from the processing routine, execu ting the

subroutine return instruction [RET] restores the contents of

the program counter from the stack; ex ecuting the interrupt

return instruction [RETI] restores the contents of the program counter and flags.

The save/restore locations in the stack are determined by

the stack pointed (SP). The SP is automatically decreased

after the saving, and increased before the restoring. This

means the value of the SP indicates the stack location

number for the next save. Refer to Figure 8-4 on page 22.

26 JUNE. 2001 Ver 1.00

Page 33

GMS81C2112/GMS81C2120

Address

0C0H

0C1H

0C4H

0C5H

0C6H

0C7H

0CAH

0CBH

0CCH

0CDH

0D0H

0D1H

0D1H

0D1H

0D2H

0D3H

0D3H

0D4H

0D4H

0D4H

0D5H

0DEH

0E0H

0E1H

0E2H

0E3H

0E4H

0E5H

0E6H

0EAH

0EBH

0ECH

0ECH

0EDH

0EDH

0EFH

0F4H

0F6H

0F7H

0F9H

0FAH

0FBH

Symbol R/W

R0

R0IO

R2

R2IO

R3

R3IO

R5

R5IO

R6

R6IO

TM0

T0

TDR0

CDR0

TM1

TDR1

T1PPR

T1

CDR1

T1PDR

PWM1HR

BUR

SIOM

SIOR

IENH

IENL

IRQH

IRQL

IEDS

ADCM

ADCR

BITR

CKCTLR

WDTR

WDTR

PFDR

R0FUNC

R5FUNC

R6FUNC

R5NODR

SCMR

RA

R/W

W

R/W

W

R/W

W

R/W

W

R/W

W

R/W

R

W

R

R/W

W

W

R

R

R/W

W

W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

R

W

R

W

R/W

W

W

W

W

R/W

R

RESET

Value

Undefined

0000_0000

Undefined

0000_0000

Undefined

---0_0000

Undefined

0000_0--Undefined

0000_0000

--00_0000

0000_0000

1111_1111

0000_0000

0000_0000

1111_1111

1111_1111

0000_0000

0000_0000

0000_0000

----_0000

1111_1111

0000_0001

Undefined

0000_---0000_---0000_---0000_----

----_0000

-000_0001

Undefined

0000_0000

-001_0111

0000_0000

0111_1111

----_-100

----_0000

-0--_---0000_0000

0000_0---

---0_0000

Undefined

Addressing

mode

byte

1

2

byte, bit

byte, bit

byte

byte, bit

byte

byte, bit

byte

byte, bit

byte

byte, bit

byte

byte

byte

byte, bit

byte

byte

byte

byte

byte, bit

byte

byte

byte, bit

byte, bit

byte, bit

byte, bit

byte, bit

byte, bit

byte, bit

byte, bit

byte

byte

byte

byte

byte

byte, bit

byte

byte

byte

byte

byte

3

-

Note:

Several names are given at same address. Refer to

below table.

When read When write

Addr.

Timer

Mode

Capture

Mode

PWM

Mode

Timer

Mode

PWM

Mode

D1H T0 CDR0 - TDR0 D3H - TDR1 T1PPR

D4H T1 CDR1 T1PDR - T1PDR

ECH BITR CKCTLR

Table 8-2 Various Register Name in Same Address

Table 8-1 Control Registers

1. "byte, bit" means that register can be addressed by not only bit

but byte manipulation instruction.

2. "byte" means that register can be addressed by only byte

manipulation instruction. On the other hand, do not use any

read-modify-write instruction such as bit manipulation for

clearing bit.

3. RA is one-bit high-voltage input only port pin. In addition, RA

serves the functions of the Vdisp special features. Vdisp is

used as a high-voltage input power supply pin when selected

by the mask option.

JUNE. 2001 Ver 1.00 27

Page 34

GMS81C2112/GMS81C2120

Address Name

Bit 7

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

C0H R0 R0 Port Data Register (Bit[7:0])

C1H R0IO R0 Port Direction Register (Bit[7:0])

C4H R2 R2 Port Data Register (Bit[7:0])

C5H R2IO R2 Port Direction Register (Bit[7:0])

C6H R3 R3 Port Data Register

C7H R3IO R3 Port Direction Register

(Bit[4:0])

(Bit[4:0])

CAH R5 R5 Port Data Register (Bit[7:3])

CBH R5IO R5 Port Direction Register (Bit[7:3])

CCH R6 R6 Port Data Register (Bit[7:0])

CDH R6IO R6 Port Direction Register (Bit[7:0])

D0H TM0 - - CAP0 T0CK2 T0CK1 T0CK0 T0CN T0ST

D1H

T0/TDR0/

CDR0

Timer0 Register / Timer0 Data Register / Capture0 Data Register

D2H TM1 POL 16BIT PWM1E CAP1 T1CK1 T1CK0 T1CN T1ST

D3H

D4H

D5H PWM1HR PWM1 Hig h Register

TDR1/

T1PPR

T1/CDR1/

T1PDR

Timer1 Data Register / PWM1 Period Register

Timer1 Register / Capture1 Data Register / PWM1 Duty Register

(Bit[3:0])

DEH BUR BUCK1 BUCK0 BUR5 BUR4 BUR3 BUR2 BUR1 BUR0

E0H SIOM POL IOSW SM1 SM0 SCK1 SCK0 SIOST SIOSF

E1H SIOR SPI DATA REGISTER

E2H IENH INT0E INT1E T0E T1E

E3H IENL ADE WDTE BITE SPIE - - - E4H IRQH INT0IF INT1IF T0IF T1IF

E5H IRQL ADIF WDTIF BITIF SPIIF - - - -

E6H IEDS IED1H IED1L IED0H IED0L

EAH ADCM - ADEN ADS3 ADS2 ADS1 ADS0 ADST ADSF

EBH ADCR ADC Result Data Register

ECH

ECH

1

BITR

CKCTLR

Basic Interval Timer Data Register

1

- WAKEUP RCWDT WDTON BTCL BTS2 BTS1 BTS0

EDH WDTR WDTCL 7-bit Watchdog Counter Register

EFH

PFDR

2

-----PFDISPFDMPFDS

F4H R0FUNC - - - - BUZO EC0 INT1 INT0

Table 8-3 Control Registers of GMS81C2120

These registers of shaded area can not be access by bit manipulation instruction as " SET1, CLR1 ", but should be access by register operation instruction as " LDM dp,#imm ".

28 JUNE. 2001 Ver 1.00

Page 35

GMS81C2112/GMS81C2120

Address Name

F6H R5FUNC F7H R6FUNC AN7 AN6 AN5 AN4 AN3 AN2 AN1 AN0

F9H R5NODR NODR7 NODR6 NODR5 NODR4 NODR3 - - FAH SCMR - - - CS1 CS0 - - MAINOFF

FBHRA -------RA0

These registers of shaded area can not be access by bit manipulation instruction as " SET1, CLR1 ", but should be access by register operation instruction as " LDM dp,#imm ".

1.The register BITR and CKCTLR are located at same address. Address ECH is read as BITR, written to CKCTLR.

2.The register PFDR only be implemented on devices, not on In-circuit Emulator.

Bit 7

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PWM1O/

T1O

Table 8-3 Control Registers of GMS81C2120

- - - - - -

JUNE. 2001 Ver 1.00 29

Page 36

GMS81C2112/GMS81C2120

8.4 Addressing Mode

The GMS800 series MCU uses six addressing modes;

• Register addressing

• Immediate addressing

• Direct page addressing

• Absolute addressing

• Indexed addressing

• Register-indirect addressing

(1) Register Addressing

Register addressing accesses the A, X, Y, C and PSW.

(2) Immediate Addressing

→

→

→ →

#imm

In this mode, second byte (operand) is accessed as a data

immediate ly.

Example:

0435 ADC #35H

MEMORY

04

35

A+35H+C → A

(3) Direct Page Addressing

→

→

→ →

dp

In this mode, a address is specified within direct page.

Example; G=0

C535 LDA 35H ;A ←RAM[35H]

35H

data

➋

~

~

0E550H

0E551H

C5

35

(4) Absolute Addressing

~

~

→

→

→ →

➊

!abs

data → A

Absolute addressing sets corresponding memory data to

Data, i.e. second byte (Operand I) of command bec omes

lower level address and third byte (Operand II) becomes

upper level address.

With 3 bytes command, it is possible to access to whole

memory area.

ADC, AND, CMP, CMPX, CMPY, EOR, LDA, LDX,

LDY, OR, SBC, STA, STX, STY

When G-flag is 1, then RAM address is defined by 16-bit

address which is composed of 8-bit RAM paging register

(RPR) and 8-bit immediate data.

Example: G=1

E45535 LDM 35H,#55H

0135H

➊

0F100H

0F101H

0F102H

data

~

~

~

~

data ¨ 55H

➋

E4

55

35

Example;

0735F0 ADC !0F035H ;A ←ROM[0F035H]

0F035H

0F100H

0F101H

0F102H

data

~

~

07

35

F0

~

~

➋

A+data+C → A

➊

address: 0F035

The operation within data memory (RAM)

ASL, BIT, DEC, INC, LSR, ROL, ROR

Example; Addressing accesses the address 0135

regard-

H

less of G-flag.

30 JUNE. 2001 Ver 1.00

Page 37

983501 INC !0135H ;A ←ROM[135H]

GMS81C2112/GMS81C2120

135H

0F100H

0F101H

0F102H

data

~

~

98

35

01

~

~

➌

➋

data+1 → data

➊

address: 0135

(5) Indexed Addressing

X indexed direct page (no offset)

→

→

→ →

{X}

In this mode, a address is specified by the X register.

ADC, AND, CMP, EOR, LDA, OR, SBC, STA, XMA

Example; X=15

D4 LDA {X} ;ACC←RAM[X].

115H

~

~

H

data

, G=1

➋

~

~

data → A

➊

0E550H

D4

35H

X indexed direct page (8 bit offset)

data

~

~

DB

~

~

➊

➋

data Æ A

36H Æ X

→

→

→ →

dp+X

This address value is the second byte (Operand) of command plus the data of -register. And it assigns the memory in Direct page.

ADC, AND, CMP, EOR, LDA, LDY, OR, SBC, STA

STY, XMA, ASL, DEC, INC, LSR, ROL, ROR

Example; G=0, X=0F5

C645 LDA 45H+X

3AH

data

H

➌

0E550H

0E551H

~

~

C6

45

~

~

➋

➊

45H+0F5H=13AH

data → A

X indexed direct page, auto increment

In this mode, a address is specified within direct page by

the X register and the content of X is increased by 1.

LDA, STA

Example; G=0, X=35

DB LDA {X}+

H

→

→

→ →

{X}+

Y indexed direct page (8 bit offset)

→

→

→ →

dp+Y

This address value is the second byte (Operand) of command plus the data of Y-register, which assign s Memory in

Direct page.

This is same with above (2). Use Y register instead of X.

Y indexed absolute

→

→

→ →

!abs+Y

Sets the value of 16-bit absolute address plus Y-register

data as Memory.This addressing mode can specify memory in whole area.

Example; Y=55

H

JUNE. 2001 Ver 1.00 31

Page 38

GMS81C2112/GMS81C2120

H

D500FA LDA !0FA00H+Y

0F100H

0F101H

0F102H

0FA55H

~

~

D5

00

FA

data

➊

0FA00H+55H=0FA55H

~

~

➋

data → A

➌

(6) Indirect Addressing

Direct page indirect

→

→

→ →

[dp]

Assigns data address to use for accomplishing command

which sets memory data (or pair memory) by Operand.

Also index can be used with Index register X,Y.

JMP, CALL

Example; G=0

3F35 JMP [35H]

1625 ADC [25H+X]

35H

36H

~

~

0E005H

~

~

0FA00H

Y indexed indirect

05

E0

data

16

25

→

→

→ →

~

~

~

~

0E005H

➋

[dp]+Y

25 + X(10) = 35

➊

A + data + C → A

➌

Processes memory data as Data, assigned by the data

[dp+1][dp] of 16-bit pair memory paired by Operan d in Direct pageplus Y-register data.

ADC, AND, CMP, EOR, LDA, OR, SBC, STA

Example; G=0, Y=10

1725 ADC [25H]+Y

H

35H

36H

~

~

0E30AH

~

~

0FA00H

X indexed indirect

0A

E3

NEXT

3F

35

→

→

→ →

~

~

~

~

[dp+X]

➋

➊

jump to

address 0E30AH

Processes memory data as Data, assigned by 16-bit pair

memory which is determined by pair data

[dp+X+1][dp+X] Operand plusX-register dat a in Direct

page.

ADC, AND, CMP, EOR, LDA, OR, SBC, STA

Example; G=0, X=10

H

25H

26H

~

~

0E015H

~

~

0FA00H

Absolute indirect

05

E0

data

17

25

→

→

→ →

~

~

~

~

[!abs]

➋

➊

0E005H + Y(10)

= 0E015H

➌

A + data + C

A

→

The program jumps to address specified by 16-bit absolute

address.

JMP

Example; G=0

32 JUNE. 2001 Ver 1.00

Page 39

1F25E0 JMP [!0C025H]

PROGRAM MEMORY

GMS81C2112/GMS81C2120

➊

0E025H

0E026H

0E725H

0FA00H

25

E7

~

~

NEXT

~

~

1F

25

E0

➋

~

~

jump to

address 0E30AH

~

~

JUNE. 2001 Ver 1.00 33

Page 40

GMS81C2112/GMS81C2120

R0 Data Register

R0

ADDRESS: 0C0

H

RESET VALUE: Undefined

R07 R06 R05 R04 R03

R02 R01

R00

Port Direction

R0 Direction Register

R0IO

ADDRESS : 0C1

H

RESET VALUE : 00

H

0: Input

1: Output

Input / Output data

R0 Function Selection Register

R0FUNC

ADDRESS : 0F4

H

RESET VALUE : ----0000

B

0: R00

1: INT0

0

0: R01

1: INT1

0: R02

1: BUZO

0: R03

1: EC0

123----

9. I/O PORTS

The GMS81C21xx has five ports (R0, R2, R3, R5, and

R6).These ports pins may be multiplexed with an alternate

function for the peripheral features on the device.

All pins have data direction registers which can define

these ports as output or input. A “1” in the port direction

register configure the corresponding port pin as output.

Conversely, write “0” to the corresponding bit to specif y it

as input pin. For example, to use the even numbered bit of

R0 as output ports and the odd numbe red bits as input

ports, write “55

” to address 0C1H (R0 port direction reg-

H

ister) during initial setting as shown in Figure 9-1.

All the port direction registers in the GMS81C2120 have 0

written to them by reset function. On the other hand, its initial status is input.

0C0

0C1

0C2

0C3

WRITE "55

H

R0 direction

H

H

R1 direction

H

R0 data

R1 data

" TO PORT R0 DIRECTION REGISTER

H

0 1 0 1 0 1 0 1

76543210

I O I O I O I O

76543210

I : INPUT PORT

O : OUTPUT PORT

BIT

PORT

R0 and R0IO register:

bidirectional I/O port (address 0C0

R0 is an 8-bit high-voltage CMOS

). Each port can be set

H

individually as input and output through the R0IO register

(address 0C1

). Each port can directly drive a vacuum flu-

H

orescent display. R03 port is multiplexed with Buzzer Output Port(BUZO), R02 port is multiplexed with Event

Counter Input Port (EC0), and R01~R00 are multiplexed

with External Interrupt Input Port(INT1, INT0)

Port Pin

R00

R01

R02

R03

INT0 (External interrupt 0 Input Port)

INT1 (External interrupt 1 Input Port)

EC0 (Event Counter Input Port)

BUZO (Buzzer Output Port)

.The control register R0FUNC (address F4

Alternate Function

H

) controls to

select alternate function. After reset, this value is "0", port

may be used as general I/O ports. To select alter nate function such as Buzzer Output, External Event Counter Input

and External Interrupt Input, write "1" to the corresponding bit of R0FUNC. Regardless of the direction register

R0IO, R0FUNC is sel ected to use as alterna te functions,

port pin can be used as a corresponding alternate features

(BUZO, EC0, INT1, INT0)

Figure 9-1 Example of Port I/O Assignment

RA(Vdisp) register:

only port pin. In addition, RA se rves the funct ions of the

special features. V

V

disp

power supply pin when selected by the mask option.

RA Data Register

RA

Port pin Alternate function

RA

RA is one-bit high-voltage input

is used as a high-voltage input

disp

ADDRESS: 0FB

RESET VALUE: Undefined

RA0

Input data

V

(High-voltage input power supply)

disp

H

34 JUNE. 2001 Ver 1.00

Page 41

GMS81C2112/GMS81C2120

R5 Data Register

R5

ADDRESS: 0CA

H

RESET VALUE: Undefined

R57

R56 R55 R54 R53

- - -

R5 Direction Register

R5IO

ADDRESS : 0CB

H

RESET VALUE : 00000---

B

Input / Output data

R5 Function Selection Register

R5FUNC

ADDRESS : 0F6

H

RESET VALUE : -0------

B

0: R56

1:

- -----6-

R5 N-MOS Open Drain

R5NODR

ADDRESS: 0F9

H

RESET VALUE: 00000---

B

N-MOS Open Drain Selection

Selection Register

0: Disable

1: Enable

Port Direction

0: Input

1: Output

PWM1O/T1O

R2 and R2IO register:

bidirectional I/O port (address 0C4

R2 is an 8-bit high-volta ge CMOS

). Each port can be set

H

individually as input and output th rou gh t he R2IO regis t er

(address 0C5

). Each port can directly drive a vacuum flu-

H

orescent display.

R2 Data Register

R2

R27 R26 R25 R24 R23 R22 R21 R20

Input / Output data

R2 Direction Register

R2IO

R3 and R3IO register:

R3 is a 5-bit high-voltage CMOS

bidirectional I/O port (address 0C6

ADDRESS: 0C4

RESET VALUE: Undefined

ADDRESS : 0C5

RESET VALUE : 00

Port Direction

0: Input

1: Output

). Each port can be set

H

H

H

H

individually as input and output th rou gh t he R3IO regis t er

(address 0C7

).

H

R5FUNC.

The control register R5NODR (address 0F9

) controls to

H

select N-MOS open drain port. To select N -MOS open

drain port, write "1" to the corresponding bit of R5 FUNC.

R3 Data Register

-

R3

- - R34 R33

R3 Direction Register

R3IO

- -

R5 and R5IO register:

port (address 0CA

input and output through the R5IO register (address

0CB

).In addition, Po rt R5 is multiplexed wi th Pulse

H

Width Modulator (PWM).

Port Pin

R56

The control register R5FUNC (address 0F6

select PWM function.After reset, the R5IO register value

is "0", port may be used as general I/O ports. To select

). Each pin can be set individually as

H

PWM1 Data Output

Timer 1 Data Output

PWM function, write "1" to the corresponding bit of

-

ADDRESS: 0C6

RESET VALUE: Undefined

R32 R31 R30

ADDRESS : 0C7

RESET VALUE : ---00000

H

Input / Output data

H

Port Direction

0: Input

1: Output

R5 is an 5-bit bidirectional I/O

Alternate Function

) controls to

H

B

R6 and R6IO register:

port (address 0CC

H

R6 is an 8-bit bidirectional I/O

). Each port can be set individually as

input and output through the R6IO register (address

0CD

). R67~R60 ports are multiplexed with Analog Inpu t

H

Port.

Port Pin

R60

R61

R62

R63

R64

R65

R66

R67

AN0 (ADC input 0)

AN1 (ADC input 1)

AN2 (ADC input 2)

AN3 (ADC input 3)

AN4 (ADC input 4)

AN5 (ADC input 5)

AN6 (ADC input 6)

AN7 (ADC input 7)

The control register R6FUNC (address 0F7

Alternate Function

H

) controls to

select alternate function. After reset, this value is "0", port

may be used as general I/O ports. To select alter nate func-

JUNE. 2001 Ver 1.00 35

Page 42

GMS81C2112/GMS81C2120

tion such as Analog Input, write "1" to the corresponding

bit of R6FUNC. Regardless of the direction register R6IO,

R6FUNC is selected to use as alternate functions, port pin

can be used as a corresponding alternate features

(AN7~AN0)

R6 Data Register

R6

R67 R66 R65 R64 R63

R6 Direction Register

ADDRESS: 0CC

RESET VALUE: Undefined

R62 R61

Input / Output data

ADDRESS : 0CD

RESET VALUE : 00

R6IO

Port Direction

0: Input

1: Output

R6 Function Selection Register

R6FUNC

0: R67

1: AN7

0: R66

1: AN6

0: R65

1: AN5

0: R64

1: AN4

H

R60

H

ADDRESS : 0F7

RESET VALUE : 00

1234567

0

0: R61

1: AN1

0: R62

1: AN2

0: R63

1: AN3

H

H

0: R60

1: AN0

H

36 JUNE. 2001 Ver 1.00

Page 43

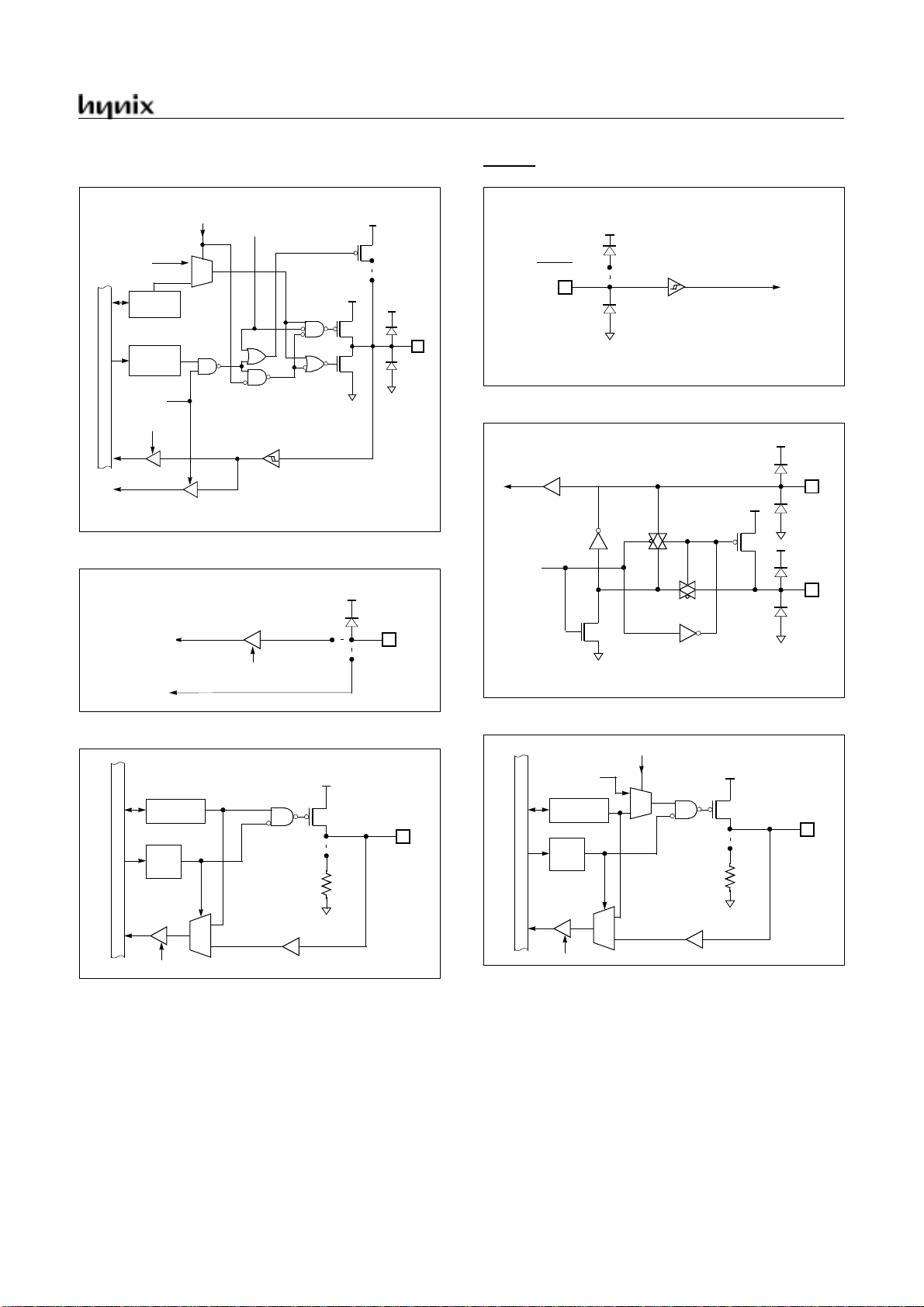

10. BASIC INTERVAL TIMER

GMS81C2112/GMS81C2120

The GMS81C21xx has one 8-bit Basic Interval Timer that

is free-run, can not stop. Block di agram is shown in Figure

10-1. In addition, the Basic Interval Tim er generates the

time base for watchdog timer counting. It also provides a

Basic interval timer interrupt (BITIF).

The 8-bit Basic interval timer register (BITR) is increased

every internal count pulse which is divided by prescaler.

Since prescaler has divided ratio by 8 to 1024, the count

rate is 1/8 to 1/1024 of the oscillator frequency. As the

count overfl ows fr om FF

to 00H, this overflow causes to

H

generate the Basic interval timer interrupt. The BITIF is interrupt request flag of Basic interval timer. The Basic Interval Timer is controlled by the clock control register

(CKCTLR) shown in Figure 10-2.

When write "1 " to bi t BTCL of CKCTLR, BITR reg ister is

cleared to "0" and restart to count-up. The bit BTCL be-

Internal RC OSC

WAKEUP

STOP

comes "0" after one machine cycle by hardware.

If the STOP instruction executed after writing "1" to bit

WAKEUP of CKCTLR, it goes into the wake-up timer

mode. In this mode, all of the block is halted except the o scillator, prescaler (only fXIN÷2048) and Timer0.

If the STOP instruction executed after writing "1" to bit

RCWDT of CKCTLR, it goes into the internal RC oscillated watchdog timer mode. In this mode, all of the block is

halted except the internal RC oscillator, Basic Interval

Timer and Watchdog Timer. More detail informations are

explained in Power Saving Function. The bit WDTON decides Watchdog Timer or the normal 7-bit timer.

Source clock can be selected by lower 3 bits of CKCTLR.

BITR and CKCTLR are located at same address, and address 0EC

is read as a BITR, and written to CKCTLR.

H

8

÷

16

÷

32

÷

64

X

PIN

IN

÷

MUX

128

÷

256

÷

Prescaler

512

÷

1024

÷

Select Input clock

]

[0EC

Basic Interval Timer

clock control register

H

3

BTS[2:0]

CKCTLR

1

0

RCWDT

source

clock

[0EC

Internal bus line

8-bit up-counter

BITR

]

H

clear

BTCL

Read

overflow

Basic Interval

BITIF

To Watchdog timer (WDTCK)

Timer Interrupt

Figure 10-1 Block Diagram of Basic Interval Timer

JUNE. 2001 Ver 1.00 37

Page 44

GMS81C2112/GMS81C2120

CKCTLR

[2:0]

000

001

010

011

100

101

110

111

76543210

CKCTLR

-

Caution:

Both register are in same address,

when write, to be a CKCTLR,

when read, to be a BITR.

Source clock

÷