Page 1

IMAGE SENSORS

FTF3020-C

Full Frame CCD Image Sensor

Product specification 1999 November 22

File under Image Sensors

Philips

Semiconductors

Page 2

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

• 35mm film compatible image format (36 x 24 mm2)

• 6M active pixels (3072H x 2048V)

• RGB Bayer pattern

• Progressive scan

• Excellent anti-blooming

• Variable electronic shuttering

• Square pixel structure

• H and V binning

• 80% optical fill factor

• High linear dynamic range (>72dB)

• High sensitivity

• Low dark current and fixed-pattern noise

• Low read-out noise

• Data rate up to 36 MHz

• Mirrored, split and four quadrant read-out

• Perfectly matched to visual spectrum

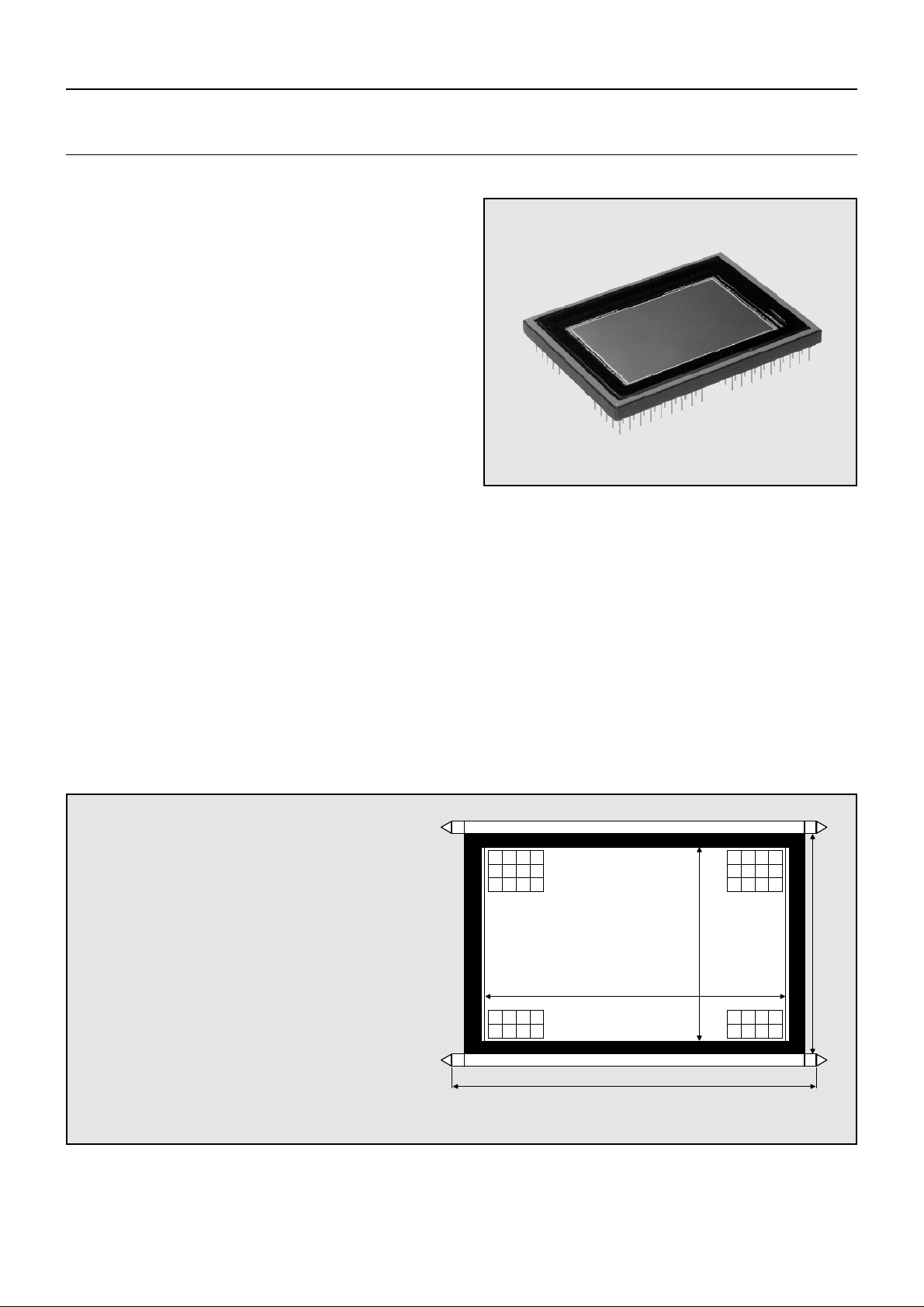

Device structure

Optical size: 36.864 mm (H) x 24.576 mm (V)

Chip size: 39.148 mm (H) x 26.508 mm (V)

Pixel size: 12 µm x 12 µm

Active pixels: 3072 (H) x 2048 (V)

Total no. of pixels: 3120 (H) x 2060 (V)

Optical black pixels: Left: 20 Right: 20

Timing pixels: Left: 4 Right: 4

Dummy register cells: Left: 7 Right: 7

Optical black lines: Bottom: 6 Top: 6

Description

The FTF3020-C is a full frame CCD colour image sensor designed

for professional digital photography applications, with very low dark

current and a linear dynamic range of over 12 true bits at room

temperature. The four low-noise output amplifiers , one at each corner

of the chip, make the FTF3020-C suitable for a wide range of highend visual light applications. With one output amplifier , a progressiv ely

scanned image can be read out at 5 frames per second. By using

multiple outputs the frame rate increases accordingly. The device

structure is shown in figure 1.

Z Y

GBGB

RGRG

GBGB

Image Area

20

3072 active pixels

6 black lines

2048

active

lines

GBGB

RGRG

GBGB

2060

lines

44

20

W X

Output amplifier

Figure 1 - Device structure

1999 November 2

GBGB

RGRG

77

3120 cells

Output register

3134 cells

6 black lines

GBGB

RGRG

Page 3

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

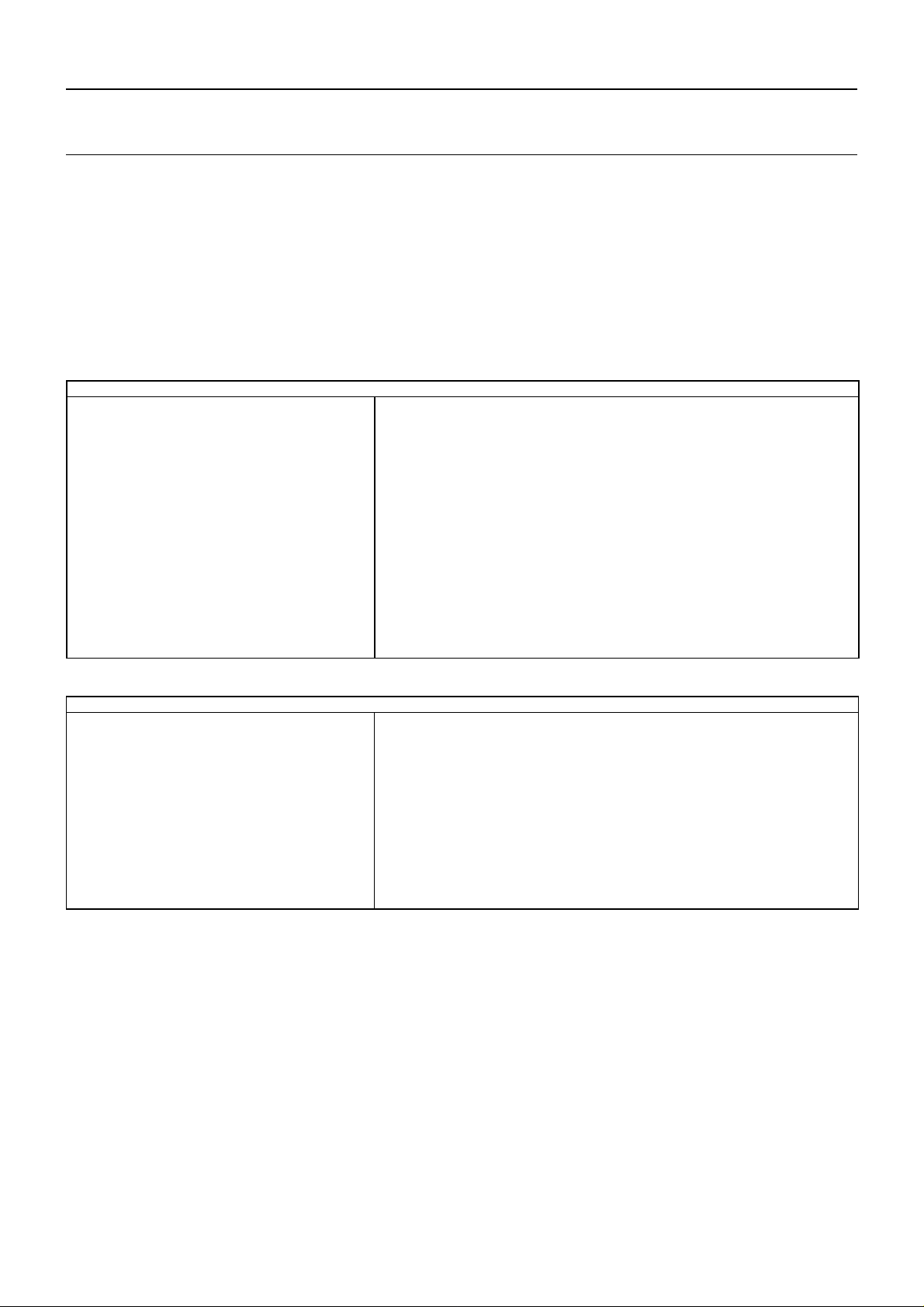

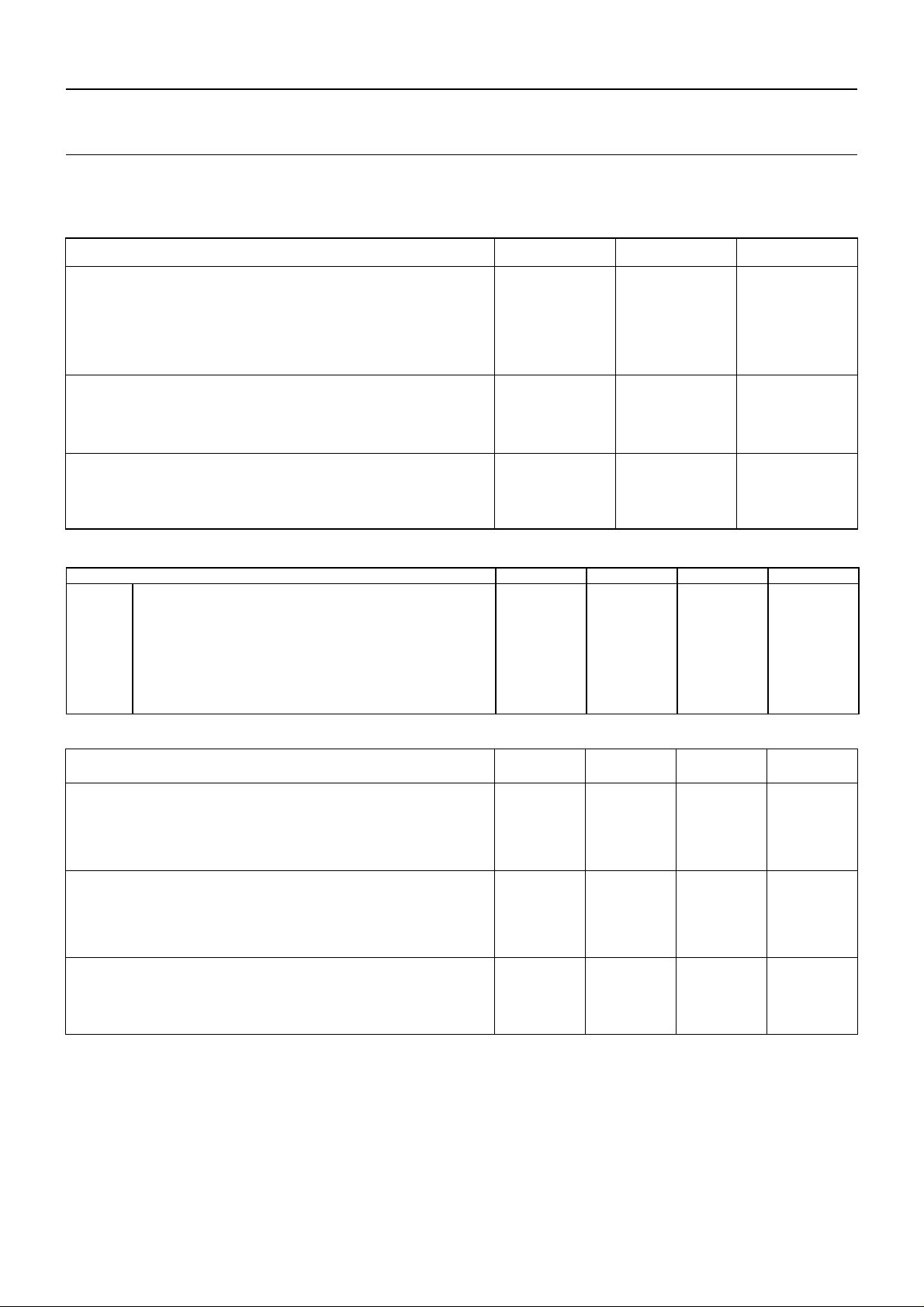

Architecture of the FTF3020-C

The optical centres of all pixels in the image section form a square

grid. The charge is generated and integrated in this section. Output

registers are located below and above the image section for readout. After the integration time, the image charge is shifted one line

at the time to either the upper or lower register or to both

simultaneously, depending on the read-out mode. The left and the

right half of each register can be controlled independently. This

IMAGE SECTION

Image diagonal (active video only)

Aspect ratio

Active image width x height

Pixel width x height

Geometric fill factor

Image clock pins

Capacity of each clock phase

Number of active lines

Number of black reference lines

Number of dummy black lines

Total number of lines

Number of active pixels per line

Number of overscan (timing) pixels per line

Number of black reference pixels per line

Total number of pixels per line

44.30 mm

3:2

36.864 x 24.576 mm

12x12 µm

80%

16 pins (A1..A4)

7.5nF per pin

2048

4 (=2x2)

8 (=2x4)

2060

3072

8 (2x4)

40 (2x20)

3120

enables either single or multiple read-out. During vertical transport,

the C3 gates separate the pixels in the register . The central C3 gates

of the lower and upper registers are part of the left half of the sensor

(W and Z quadrants respectively). Each register can be used for

vertical binning. Each register contains a summing gate at both ends

that can be used for horizontal binning (see figure 2).

2

2

Output buffers on each corner

Number of registers

Number of dummy cells per register

Number of register cells per register

Output register horizontal transport clock pins

Capacity of each C-clock phase

Overlap capacity between neighbouring C-clocks

Output register Summing Gates

Capacity of each SG

Reset Gate clock phases

Capacity of each RG

OUTPUT REGISTERS

Three-stage source follower

2

14 (2x7)

3134 (3120+14)

6 pins per register (C1..C3)

200 pF per pin

40pF

4 pins (SG)

15pF

4 pins (RG)

15pF

1999 November 3

Page 4

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

RGRG

OG

C3 C3 C3 C3 C3 C3 C3 C3 C3C3 C3

7 dummy pixels

RD

OUT_Z

One Pixel

SG: summing gate

OG: output gate

RG: reset gate

RD: reset drain

OUT_W

OG C1 OG

RG

RD

C3 C3 C3C3 C3 C3 C3 C3 C3 C3 C3

SG

20 black &4 timing

columns

C1C1SG C2 C2 C2 C1 C2 C1 C2 C1 C2 C1 C2 C2C1 C1 C2 C1 C2 C1 C2 C1 C2 C1 SG OGC1 C3

A1 A1

A2

A3

A4

A1

A1

A2

A3

A4

A1

A2

A3

A4

A1

A1

A2

A3A3

A4

A1

A2

A3

A4

A1

A1

A2

A3

A4

C1C1C2 C2 C2 C1 C2 C1 C2C1

6 black

lines

2K active

images

lines

6 black

lines

C2 C1 C2 C1 C2 C2C1 C1 C2 C1 C2 C1 C2

column

1

column

24 + 1

3K image

pixels

IMAGE

3K x 2K

FF CCD

C3

column

24 + 3K

20 black & 4 timing

columns

column

24 +3K +24

7 dummy pixels

A2

A3

A4

A1

A1

A2

A3

A4

A1

A2

A3

A4

A1

A1

A2

A3

A4

A1

A2

A3

A4

A1

A1A1

A2

A3

A4

A1A1

A1, A2, A3, A4: clocks of image section C1, C2, C3: clocks of hor izontal registers

C1 SG

RD

OUT_Y

OUT_X

RD

RG

RG

Figure 2 - Detailed internal structure

1999 November 4

Page 5

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Specifications

ABSOLUTE MAXIMUM RATINGS

GENERAL:

storage temperature

ambient temperature during operation

voltage between any two gates

DC current through any clock phase (absolute value)

OUT current (no short circuit protection)

VOLTAGES IN RELAT ION TO VPS:

VNS, SFD, RD

VCS, SFS

all other pins

VOLTAGES IN RELAT ION TO VNS:

SFD, RD

VCS, SFS, VPS

all other pins

2

VNS

VPS

SFD

SFS

VCS

OG

RD

3

N substrate

P substrate

Source Follower Drain

Source Follower Source

Current Source

Output Gate

Reset Drain

DC CONDITIONS

1

MIN. MAX. UNIT

-55

-40

-20

-0.2

0

-0.5

-8

-5

-15

-30

-30

+80

+60

+20

+2.0

10

+30

+5

+25

+0.5

+0.5

+0.5

°C

°C

V

µA

mA

V

V

V

V

V

V

MIN. [V] TYPICAL [V] MAX. [V] MAX. [mA]

18

1

16

0

-5

4

13

24

3

20

0

0

6.5

15.5

28

7

24

0

3

8

18

15

15

4.5

1

-

-

-

AC CLOCK LEVEL CONDITIONS

2

MIN. TYPICAL MAX. UNIT

IMAGE CLOCKS:

A-clock amplitude during integration and hold

A-clock amplitude during vertical trans port (duty cycle=5/8)

A-clock low level

Charge Reset (CR) level on A-clock

5

4

8

10

-5

10

14

0

-5

V

V

V

V

OUTPUT REGISTER CLOCKS:

C-clock amplitude (duty cycle during hor. trans port = 3/6)

C-clock low level

Summing Gate (SG) amplitude

Summing Gate (SG) low level

4.75

2

5

3.5

10

3.5

5.25

10

V

V

V

V

OTHER CLOCKS:

Reset Gate (RG) amplitude

Reset Gate (RG) low level

Charge Reset (CR) pulse on Nsub

1

During Charge Reset it is allowed to exceed maximum rating levels (see note 5).

2

All voltages in relation to SFS.

3

To set the VNS voltage for optimal Ver tical Anti-Blooming (VAB), it should be adjustable between minimum and maximum values.

4

Three-level cloc k is preferred for maximum charge; the swing during vertical transport should be 4V higher than the voltage during integration.

A two level clock (typically 10V) can be used if a lower maximum charge handling capacity is allowed.

5

Charge Reset can be achieved in two ways:

5

5

0

10

3

10

10

10

V

V

V

• The typical A-clock low level is applied to all image clocks; for proper CR, an additional Charge Reset pulse on VNS is required (preferred).

• The typical CR level is applied to all image clocks simultaneously.

1999 November 5

Page 6

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Timing diagrams (for default operation)

AC CHARACTERISTICS MIN. TYPICAL MAX. UNIT

Horizontal frequency (1/Tp)

Vertical frequency

Charge Reset (CR) time

Rise and fall times: image clocks (A)

1

Tp = 1 clock period

2

Duty cycle = 50% and phase shift of the C clocks is 120 degrees.

1

register clocks (C)

summing gate (SG)

reset gate (RG)

18

50

10

2

10

3

3

3

193.7

20

5

5

5

36

100

1/6 Tp

1/6 Tp

1/6 Tp

MHz

kHz

µs

ns

ns

ns

ns

Frame Timing

Sensor Output

SSC

A1

A2, A3, A4

CR

Ahigh

VD

BLC

EXT. SHUTTER

H

L

H

L

H

L

H

L

H

*

L

H

L

H

L

H

L

Line Timing

SSC

A1

A2

A3

A4

CR

AHigh

VD

BLC

H

L

H

L

H

L

H

L

H

L

H

L

H

*

L

H

L

H

L

Tp30

20472046 2048

Tp20

BlackDummy

D

Tp66

Tp112

BBD123

BBBB BBBB

Integration Time

Tp360

Tp138

Tp204

Tp230

Tp138

Tp138

Tp360

Tp396

Pixel Timing

SSC

C1

C2

C3

SG

RG

Tp = 1 / 18MHz = 55.56ns

Pixel output sequence: 7 dummy, 20 black, 4 timing, 3072 active, 4 timing, 20 black Line Time: 3487 x Tp = 193.7µs

* During AHigh = H the phiA high level is increased from 10V to 14V (This is necessary during readout only)

VD: Frame pulse

CR: Charge Reset

BLC: Black Level Clamp

A1 to A4: Vertical image clocks

1999 November 6

H

L

H

L

H

L

H

L

H

L

H

L

1Tp

Figure 3 - Timing diagrams

3127 pixels

Tp / 6

C1 to C3: Horizontal register clocks

SSC: Start-Stop C-clocks

SG: Summing gate

RG: Reset gate

Page 7

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Line timing

SSC

A1

A2

A3

Pixel timing

A4

—> time

Y / Div.: 10V (A1, A2, A3, A 4); 5V (SSC)

Figure 4 - Vertical readout

C1

C2

C3

SG

RG

Y / Div. : 5V (C1, C2, C3); 10V (SG, RG)

Figure 5 - Start horizontal readout

1999 November 7

—> time

Page 8

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Performance

The test conditions for the perfo rmance characteristics are as follows:

• All values are measured using typical operating conditions.

• VNS is adjusted as low as possible while maintaining proper

Ver tical Anti-Blooming.

• Sensor temperature = 60°C (333K).

• Horizontal transport frequency = 18MHz.

• Integration time = 10ms (unless specified otherwise).

• The light source is a lamp of 3200K in conjunction with neutral

density filters and a 1.7mm thick BG40 infrared cut-off filter. For

Linear Operation measurements, a temperature conversion filter

(Melles Griot type no. 03FCG261, -120 mired, thickness: 2.5mm)

is applied.

• Vertical transport frequency = 50kHz (unless specified otherwise).

LINEAR OPERATION MIN. TYPICAL MAX. UNIT

Linear dynamic range

1

Charge Transfer Efficiency 2 vertical

Charge Transfer Efficiency

2

horizontal

Image lag

Resolution (MTF) @ 42 lp/mm

Responsivity

Quantum efficiency @ 530 nm

Low Pass Shading

Random Non-Uniformity (RNU)

3

4

VNS required for good Vertical Anti-Blooming (VAB)

Power dissipation at 2.5 frames/s

1

Linear dynamic range is defined as the ratio of Q

2

Charge Transfer Efficiency values are tested by evaluation and expressed as the value per gate transfer.

3

Low Pass Shading is defined as the ratio of the one-σ value of an 8x8 pixels blurred image (low-pass) to the mean signal value.

4

RNU is defined as the ratio of the one-σ value of the highpass image to the mean signal value at nominal light.

to read-out noise (the latter reduced by Correlated Double Sampling).

lin

4200:1(12bit)

65

60

20

18

0.999995

0.999999

70

26

2.0

0.3

24

610

0

5

5

28

%

%

kel/lux·s

%

%

%

V

mW

Linear Dynamic Range

14,000

35°C

45°C

55°C

LDR

12,000

10,000

8,000

6,000

4,000

2,000

0

0 5 10 15 20 25 30 35 40

Hor. Frequency (MHz)

Figure 6 - Typical Linear dynamic range vs. horizontal read-out frequency and sensor temperature

1999 November 8

Page 9

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Maximum Read-out Speed

20

18

16

14

12

10

8

Images/sec.

6

4

2

0

0 102030405060708090100

4 outputs

2 outputs

1 output

Integration time (ms)

Figure 7 - Maximum number of images/second versus integration time

Quantum Efficiency

25

R

20

G

15

B

10

Quantum efficiency (%)

5

0

400 450 500 550 600 650 700

Wavelength (nm)

Figure 8 - Quantum efficiency versus wavelength

1999 November 9

Page 10

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

LINEAR/SATURATION MIN. TYPICAL MAX. UNIT

Full-well capacity saturation level (Qmax )

Full-well capacity shading (Qmax, shading )

Full-well capacity linear operation (Qlin )

Charge handling capacity

4

1

2

3

Overexposure 5 handling

1

Qmax is determined from the lowpass filtered image.

2

Qmax, shading is the maximum difference of the full-well charges of all pixels, relative to Qmax.

3

The linear full-well capacity Qlin is calculated from linearity test (see dynamic range). The evaluation test guarantees 97% linearity.

4

Charge handling capacity is the largest charge packet that can be transported through the register and read-out through the output buffer.

5

Overexposure over entire area while maintaining good Ver tical Anti-Blooming (VAB). It is tested by measuring the dar k line.

240

180

500

10

350

600

200

600

50

kel.

%

kel.

kel.

x Qmax level

Charge Handling vs. Integration/Transport Volta ge

600

10V/14V

500

400

9V/13V

Output Signal (kel.)

300

200

100

8V/12V

0

123456

Exposure (arbitrary units)

Figure 9 - Charge handling versus integration/transport voltage

1999 November 10

Page 11

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

OUTPUT BUFFERS MIN. TYPICAL MAX. UNIT

Conversion factor

Mutual conversion factor matching (∆ACF)

1

Supply current

Bandwidth

Output impedance buffer (R

1

Matching of the four outputs is specified as ∆ACF with respect to reference measured at the operating point (Q

= 3.3kΩ, C

load

= 2pF)

load

57.5

0

4.5

110

400

DARK CONDITION MIN. TYPICAL MAX. UNIT

Dark current level @ 30° C

Dark current level @ 60° C

Fixed Pattern Noise

1

(FPN) @ 60° C

RMS readout noise @ 9MHz bandwidth after CDS

1

FPN is the one-σ value of the highpass image.

20

0.3

15

25

10

2

30

0.6

25

30

µV/el.

µV/el.

mA

MHz

Ω

/2).

lin

2

pA/cm

2

nA/cm

el.

el.

1000

)

2

100

10

Dark Current (pA/cm

1

0 102030405060

Dark Current

Temp. (oC)

Figure 10 - Dark current versus temperature

1999 November 11

Page 12

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Application information

Current handling

One of the purposes of VPS is to drain the holes that are generated

during exposure of the sensor to light. Free electrons are either

transported to the VRD connection and, if excessive (from overexposure), free electrons are drained to VNS. No current should

flow into any VPS connection of the sensor . During high ov erexposure

a total current 10 to 15mA through all VPS connections together

may be expected. The PNP emitter follower in the circuit diagram

(figure 11) serves these current requirements.

VNS drains superfluous electrons as a result of overexposure. In

other words, it only sinks current. During high overexposure a total

current of 10 to 15mA through all VNS connections together ma y be

expected. The NPN emitter follower in the circuit diagram meets

these current requirements. The clamp circuit, consisting of the diode

and electrolytic capacitor, enables the addition of a Charge Reset

(CR) pulse on top of an otherwise stable VNS v oltage . To protect the

CCD, the current resulting from this pulse should be limited. This

can be accomplished by designing a pulse generator with a rather

high output impedance.

Decoupling of DC voltages

All DC voltages (not VNS, which has additional CR pulses as

described above) should be decoupled with a 100nF decoupling

capacitor. This capacitor must be mounted as close as possible to

the sensor pin. Further noise reduction (by bandwidth limiting) is

achieved by the resistors in the connections between the sensor

and its voltage supplies. The electrons that build up the charge

packets that will reach the floating diffusions only add up to a small

current, which will flow through VRD . Theref ore a large series resistor

in the VRD connection may be used.

Outputs

T o limit the on-chip po wer dissipation, the output buff ers are designed

with open source outputs. Outputs to be used should therefore be

loaded with a current source or more simply with a resistance to

GND. In order to prevent the output (which typically has an output

impedance of about 400Ω) from bandwidth limitation as a result of

capacitive loading, load the output with an emitter follo wer b uilt from

a high-frequency transistor. Mount the base of this transistor as close

as possible to the sensor and keep the connection between the

emitter and the next stage short. The CCD output buffer can easily

be destroyed by ESD. By using this emitter follower, this danger is

suppressed; do NOT reintroduce this danger by measuring directly

on the output pin of the sensor with an oscilloscope probe. Instead,

measure on the output of the emitter follower. Slew rate limitation is

avoided by avoiding a too-small quiescent current in the emitter

follower; about 10mA should do the job. The collector of the emitter

follower should be decoupled properly to suppress the Miller effect

from the base-collector capacitance.

A CCD output load resistor of 3.3kΩ typically results in a bandwidth

of 110MHz. The bandwidth can be enlarged to about 130MHz by

using a resistor of 2.2kΩ instead, which, however, also enlarges the

on-chip power dissipation.

Device protection

The output buffers of the FTF3020-C are likely to be damaged if

VPS rises above SFD or RD at any time. This danger is most realistic

during power-on or power-off of the camera. The RD voltage should

always be lower than the SFD voltage.

Never exceed the maximum output current. This may damage the

device permanently. The maximum output current should be limited

to 10mA.

Be especially aware that the output buffers of these image sensors

are very sensitive to ESD damage.

Because of the fact that our CCDs are built on an n-type substrate,

we are dealing with some parasitic npn transistors. To avoid activ ation

of these transistors during switch-on and switch-off of the camera,

we recommend the application diagram of figure 11.

Unused sections

To reduce power consumption the following steps can be taken.

Connect unused output register pins (C1...C3, SG, OG) and unused

SFS pins to zero Volts.

Colour processing

In order to guarantee true colours, always use an external IR filter

type CM500(0)s, 1mm or similar. The cover glass itself is not an IR

filter.

More information

Detailed application information is provided in the application note

AN01 entitled ‘Camera Electronics for the mK x nK CCD Image

Sensor Family’.

1999 November 12

Page 13

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Device Handling

An image sensor is a MOS device which can be destroy ed by electrostatic discharge (ESD). Therefore, the device should be handled

with care.

Always store the de vice with short-circuiting clamps or on conductive

foam. Alwa ys s witch off all electric signals when inserting or removing

the sensor into or from a camera (the ESD protection in the CCD

image sensor process is less effective than the ESD protection of

standard CMOS circuits).

Being a high quality optical device, it is important that the cover

glass remain undamaged. When handling the sensor , use fingercots.

VSFD

CR pulse

0

27

Ω

BAT74

Schottky!

Ω

15

BAT74

Schottky!

10k

Ω

100nF

-

+

BAT74

BAT74

BC

850C

0.5-1mA

BC

850C

0.5-1mA

0.5-1mA

BC

860C

1uF 100nF

2mA

100nF

100nF

When cleaning the glass we recommend using ethanol (or possibly

water). Use of other liquids is strongly discouraged:

• if the cleaning liquid evaporates too quickly, rubbing is likely to

cause ESD damage.

• the cover glass and its coating can be damaged by other liquids.

Rub the window carefully and slowly.

Dry rubbing of the window may cause electro-static charges or

scratches which can destroy the device.

keep short

VNS

SFD

VPS

VRD

<10mm! keep short!

10k

Ω

Ω

BFR

92A

output for

preprocessing

10mA

OUT

VCS

VOG

100 Ω

3.3k

Ω

100nF

10k

100nF

100nF

1k

Ω

<7pF!

Figure 11 - Application diagram to protect the FTF3020-C

1999 November 13

Page 14

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Pin configuration

The FTF3020-C is mounted in a Pin Grid Array (PGA) package with

96 pins in a 20x15 grid of 52.70 x 40.00 mm2. The position of pin A1

(quadrant W) is marked with a gold dot on top of the package.

Symbol Name Pin # W Pin # X Pin # Y Pin # Z

VNS

VNS

VNS

VNS

VPS

SFD

SFS

VCS

OG

RD

A1

A2

A3

A4

C1

C2

C3

SG

RG

OUT

NC

NC

NC

NC

N substrate

N substrate

N substrate

N substrate

P substrate

Source Follower Drain

Source Follower Source

Current Source

Output Gate

Reset Drain

Image Clock (Phase 1)

Image Clock (Phase 2)

Image Clock (Phase 3)

Image Clock (Phase 4)

Register Clock (Phase 1)

Register Clock (Phase 2)

Register Clock (Phase 3)

Summing Gate

Reset Gate

Output

Not Connected

Not Connected

Not Connected

Not Connected

The image clock phases of quadrant W are internally connected to

X, and Y is connected to Z.

A1

A5

C2

G1

A2

B2

D2

C1

B3

D1

B5

A3

A4

B4

F2

F1

G2

E1

E2

B1

I1

I2

H1

H2

U1

U5

S2

M1

U2

T2

R2

S1

T3

R1

T5

U3

U4

T4

N2

N1

M2

P1

P2

T1

K1

K2

L1

L2

U10

U6

S9

M10

U9

T9

R9

S10

T8

R10

T6

U8

U7

T7

N9

N10

M9

E10

P9

T10

K10

K9

L10

L9

A10

A6

C9

G10

A9

B9

D9

C10

B8

D10

B6

A8

A7

B7

F9

F10

G9

P10

E9

B10

I10

I9

H10

H9

ABCDEFGHJ

10

9

8

7

6

5

4

3

2

1

Figure 12 - FTF3020-C pin configuration (top view)

TOP

Z

W

FTF3020-C

KLMNPRSTU

Y

X

1999 November 14

Page 15

Philips Semiconductors Product specification

Full Frame CCD Image Sensor FTF3020-C

Pack age inf ormation

Top cover glass to top chip 2.4 ±0.25

Chip - bottom package 1.7 ±0.15

INDEX

MARK

PIN 1

SENSOR CRYSTAL

COVER GLASS

±

0.15

26.35

52.7

A

±

0.53

EPOXY GLUE

TOP VIEW

0.15

±

20

0.15

±

1.27

Chip - cover glass 1.3 ±0.20

Cover glass 1.0 ±0.05

Image sensor chip

1.4 / 100

0.40

±

40

COVER GLASS

0.15

±

4.57

STAND-OFF PIN

(2.54)

0.46

BOTTOM VIEW

±

48.26

Figure 13 - Mechanical drawing of the PGA package of the FTF3020-C

1999 November 15

0.27

±

0.05

0.20

±

35.56

A is the center of the image area.

Position of A:

26.35 ± 0.15 to left edge of package

20.00 ± 0.15 to upper edge of package

1.7 ± 0.15 to bottom of package

Angle of rotation: less than ± 1°

Sensor flatness: < 20 µm (P-V)

Cover glass: Cor ning 7059

Thickness of cover glass: 1 ± 0.05

Refractive index: nd = 1.53

Double sided AR coating < 1% (430-660 nm) reflection

All drawing units are in mm

Page 16

Order codes

The sensors can be ordered using the following codes:

FTF3020-C sensors

Description Quality Grade Order Code

FTF3020-C/TG

FTF3020-C/EG

FTF3020-C/IG

FTF3020-C/HG

You can contact the Image Sensors division of Philips

Semiconductors at the following address:

Philips Semiconductors

Image Sensors

Internal Postbox WAG-05

Prof. Holstlaan 4

5656 AA Eindhoven

The Netherlands

phone +31 - 40 - 27 44 400

fax +31 - 40 - 27 44 090

www.semiconductors.philips.com/imagers/

Test grade

Economy grade

Industrial grade

High grade

9922 157 37431

9922 157 37451

9922 157 37421

9922 157 37411

Philips

Semiconductors

Philips reserves the right to change any information contained herein without notice. All information furnished by Philips is believed to be accurate. © Philips Electronics N.V. 1999

9922 157 37411

Loading...

Loading...