Page 1

March 2012

FDMF6706C – Extra-Small, High-Performance, HighFrequency DrMOS Module

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

Benefits

Ultra-Compact 6x6mm PQFN, 72% Space-Saving

Compared to Conventional Discrete Solutions

Fully Optimized System Efficiency

Clean Switching Waveforms with Minimal Ringing

High-Current Handling

Features

Over 93% Peak-Efficiency

High-Current Handling of 43A

High-Performance PQFN Copper Clip Package

3-State 5V PWM Input Driver

Shorter Propagation Delays than FDMF6704

Shorter Dead Times than FDMF6704

Skip-Mode SMOD# (Low-Side Gate Turn Off) Input

Thermal Warning Flag for Over-Temperature

Condition

Driver Output Disable Function (DISB# Pin)

Internal Pull-Up and Pull-Down for SMOD# and

DISB# Inputs, Respectively

Fairchild PowerTrench® Technology MOSFETs for

Clean Voltage Waveforms and Reduced Ringing

Fairchild SyncFET™ (Integrated Schottky Diode)

Technology in the Low-Side MOSFET

Integrated Bootstrap Schottky Diode

Adaptive Gate Drive Timing for Shoot-through

Protection

Under-Voltage Lockout (UVLO)

Optimized for Switching Frequencies up to 1MHz

Low-Profile SMD Package

Fairchild Green Packaging and RoHS Compliant

Based on the Intel® 4.0 DrMOS Standard

Description

The XS™ DrMOS family is Fairchild’s next-generation,

fully optimized, ultra-compact, integrated MOSFET plus

driver power stage solutions for high-current, highfrequency, synchronous buck DC-DC applications. The

FDMF6706C integrates a driver IC, two power

MOSFETs, and a bootstrap Schottky diode into a

thermally enhanced, ultra-compact 6x6mm PQFN

package.

With an integrated approach, the complete switching

power stage is optimized with regards to driver and

MOSFET dynamic performance, system inductance,

and Power MOSFET R

Fairchild's high-performance PowerTrench® MOSFET

technology, which dramatically reduces switch ringing,

eliminating the need for a snubber circuit in most buck

converter applications.

A new driver IC with reduced dead times and

propagation delays further enhances the performance of

this part. A thermal warning function has been included

to warn of a potential over-temperature situation. The

FDMF6706C also incorporates features, such as Skip

Mode (SMOD), for improved light-load efficiency along

with a 3-state 5V PWM input for compatibility with a

wide range of PWM controllers.

. XS™ DrMOS uses

DS(ON)

Applications

High-Performance Gaming Motherboards

Compact Blade Servers, V-Core and Non-V-Core

DC-DC Converters

Desktop Computers, V-Core and Non-V-Core

DC-DC Converters

Workstations

High-Current DC-DC Point-of-Load (POL)

Converters

Networking and Telecom Microprocessor Voltage

Regulators

Small Form-Factor Voltage Regulator Modules

Ordering Information

Part

Number

FDMF6706C 40A 12V 1000kHz

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0 2

Current

Rating

Input

Voltage

Switching

Frequency

Package Top Mark

40-Lead, Clipbond PQFN DrMOS,

6.0x6.0mm Package

FDMF6706C

Page 2

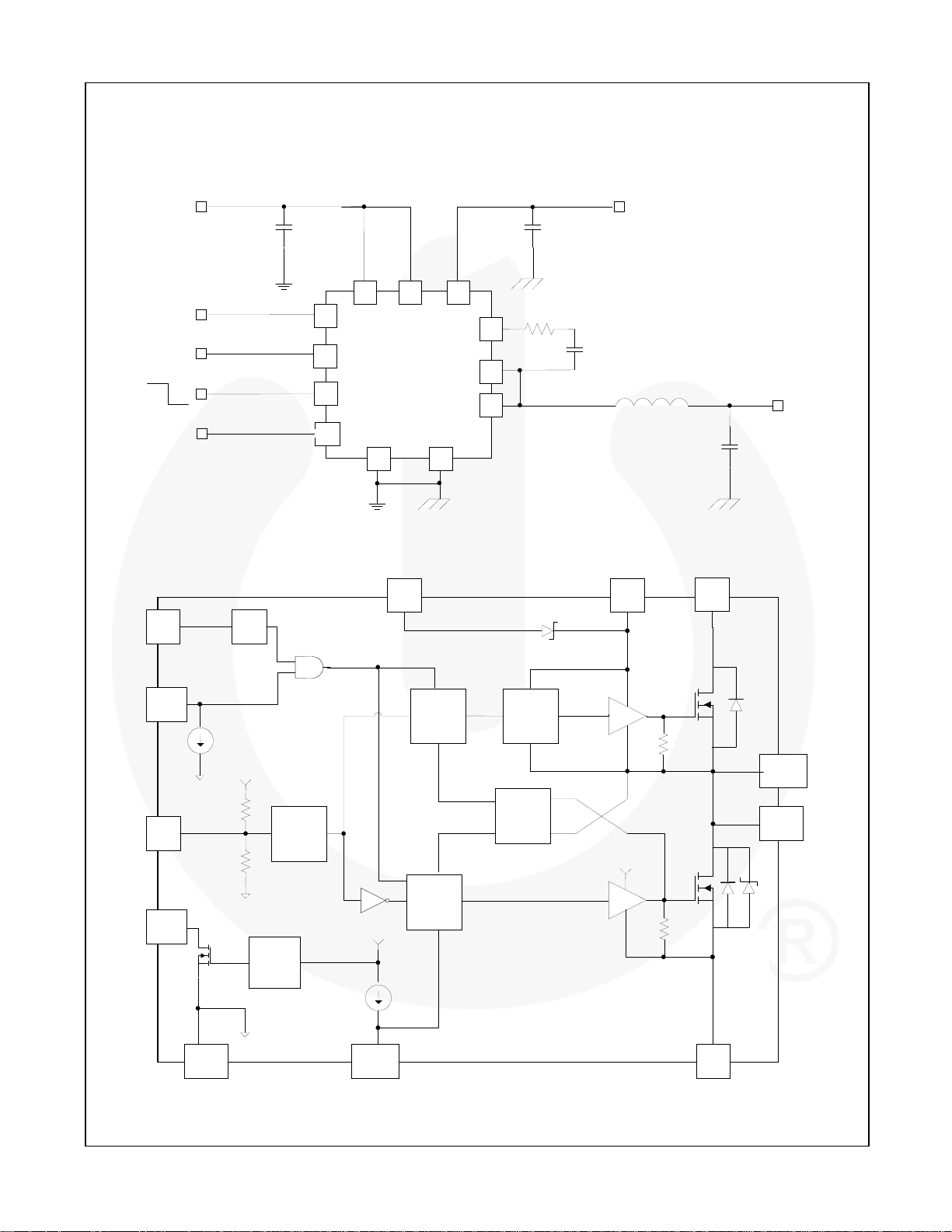

Typical Application Circuit

A

A

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

V5V

C

VDRV

DISB#

PWM Input

OFF

ON

Open Drain

Output

DrMOS Block Diagram

VCIN

UVLO

DISB#

PWM

SMOD#

THWN#

VDRV

VCIN

FDMF6706C

CGND

PGND

VIN

R

BOOT

PHASE

VSWH

BOOT

Figure 1. Typical Application Circuit

VDRV VIN

D

C

VIN

Boot

C

BOOT

BOOT

VIN

3V ~ 15V

L

OUT

C

OUT

Q1

HS Power

MOSFET

V

OUT

DISB#

PWM

THWN#

R

UP_PWM

R

DN_PWM

CGND

10µ

V

CIN

Temp.

Sense

Input

State

3-

Logic

GH

Logic

Level Shift

Dead-Time

Control

GL

Logic

V

CIN

10µ

SMOD#

Figure 2. DrMOS Block Diagram

GH

30kΩ

PHASE

VSWH

V

DRV

GL

30kΩ

Q2

LS Power

MOSFET

PGND

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 2

Page 3

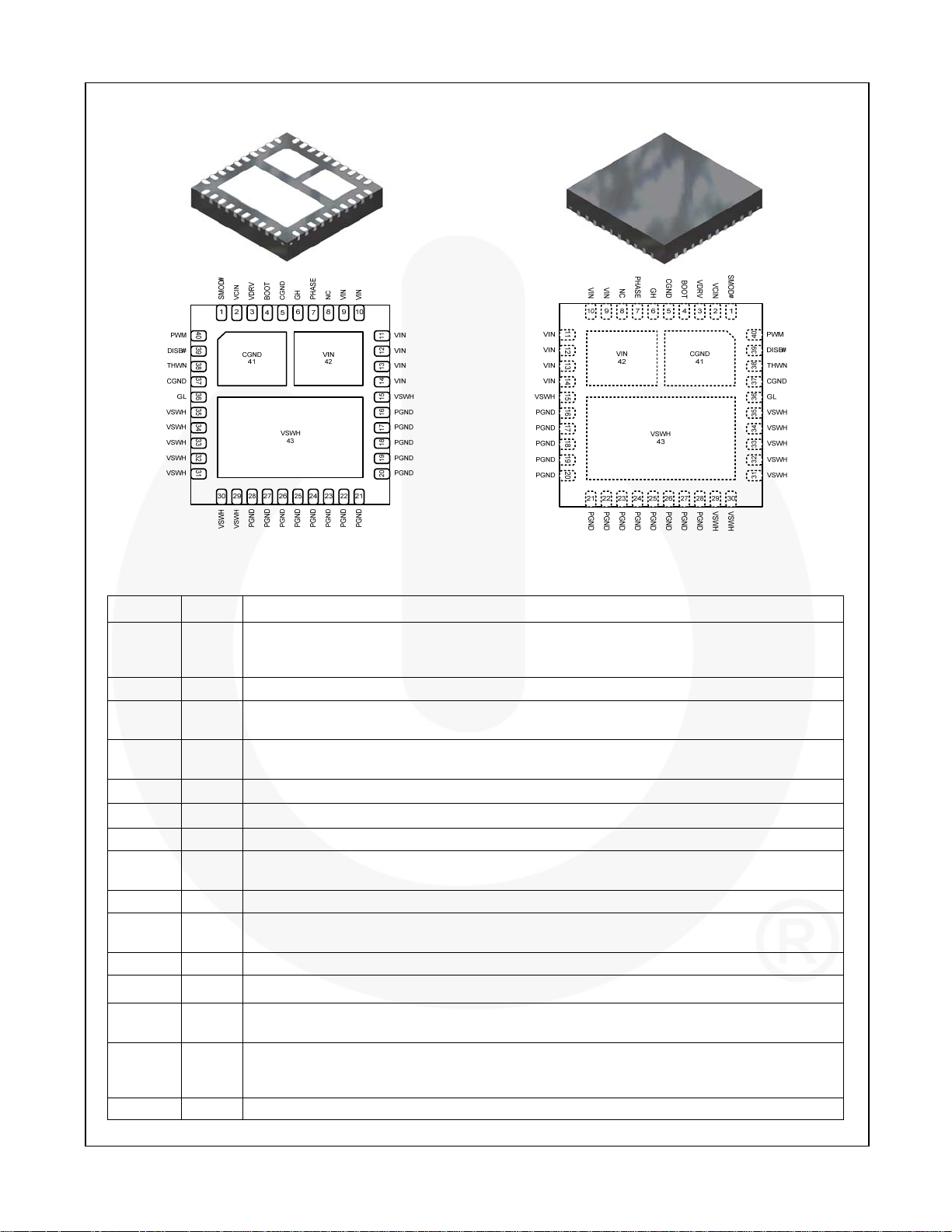

Pin Configuration

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

Figure 3. Bottom View Figure 4. Top View

Pin Definitions

Pin # Name Description

When SMOD#=HIGH, the low-side driver is the inverse of PWM input. When SMOD#=LOW,

1 SMOD#

2 VCIN IC bias supply. Minimum 1µF ceramic capacitor is recommended from this pin to CGND.

3 VDRV

4 BOOT

5, 37, 41 CGND IC ground. Ground return for driver IC.

6 GH For manufacturing test only. This pin must float. Must not be connected to any pin.

7 PHASE Switch node pin for bootstrap capacitor routing. Electrically shorted to VSWH pin.

8 NC

9 - 14, 42 VIN Power input. Output stage supply voltage.

15, 29 -

35, 43

16 – 28 PGND Power ground. Output stage ground. Source pin of low-side MOSFET.

36 GL For manufacturing test only. This pin must float. Must not be connected to any pin.

38 THWN#

39 DISB#

40 PWM PWM signal input. This pin accepts a 3-state 5V PWM signal from the controller.

VSWH

the low-side driver is disabled. This pin has a 10µA internal pull-up current source. Do not add a

noise filter capacitor.

Power for gate driver. Minimum 1µF ceramic capacitor is recommended to be connected as

close as possible from this pin to CGND.

Bootstrap supply input. Provides voltage supply to high-side MOSFET driver. Connect

bootstrap capacitor from this pin to PHASE.

No connect. The pin is not electrically connected internally, but can be connected to VIN for

convenience.

Switch node input. Provides return for high-side bootstrapped driver and acts as a sense point

for the adaptive shoot-through protection.

Thermal warning flag, open collector output. When temperature exceeds the trip limit, the

output is pulled LOW. THWN# does not disable the module.

Output disable. When LOW, this pin disables Power MOSFET switching (GH and GL are held

LOW). This pin has a 10µA internal pull-down current source. Do not add a noise filter

capacitor.

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 3

Page 4

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

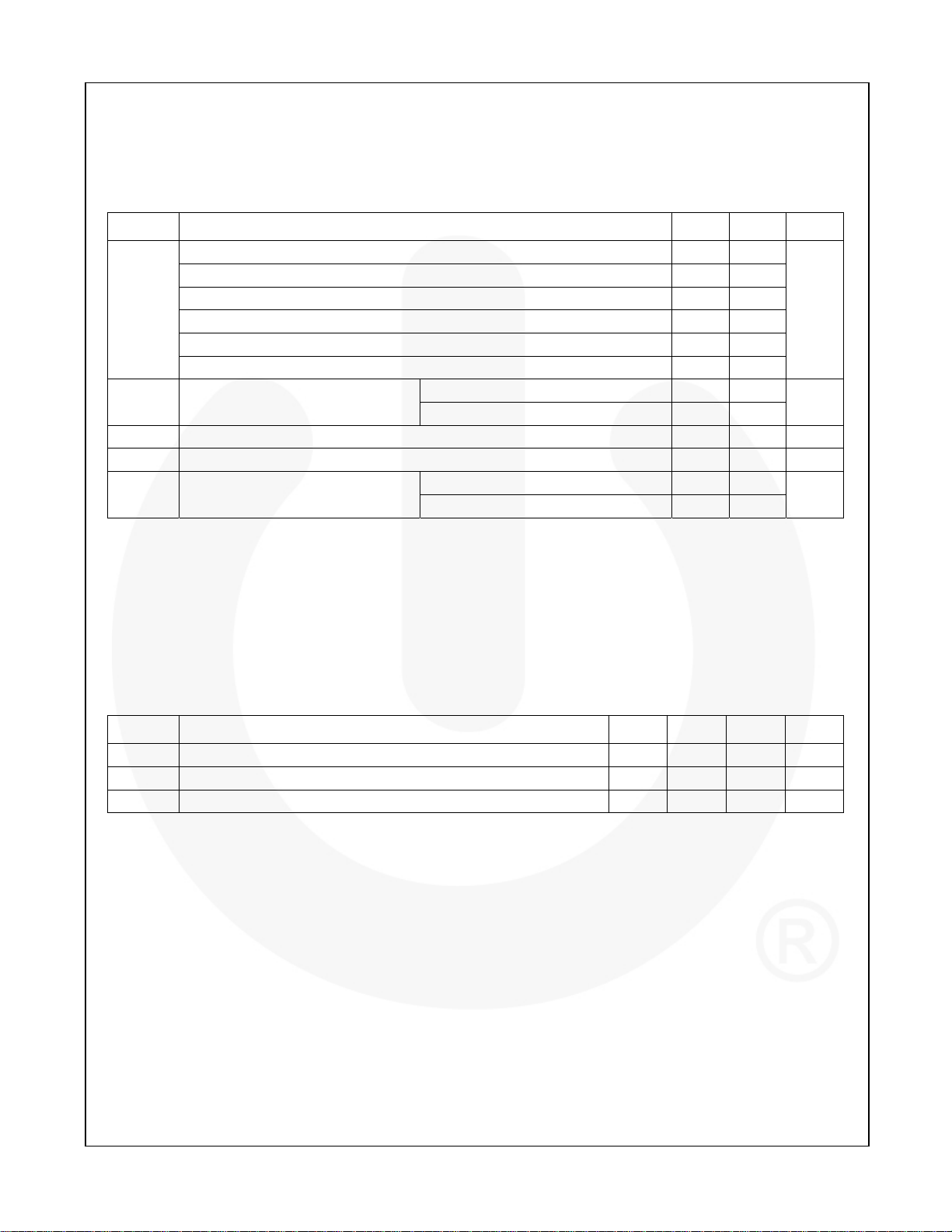

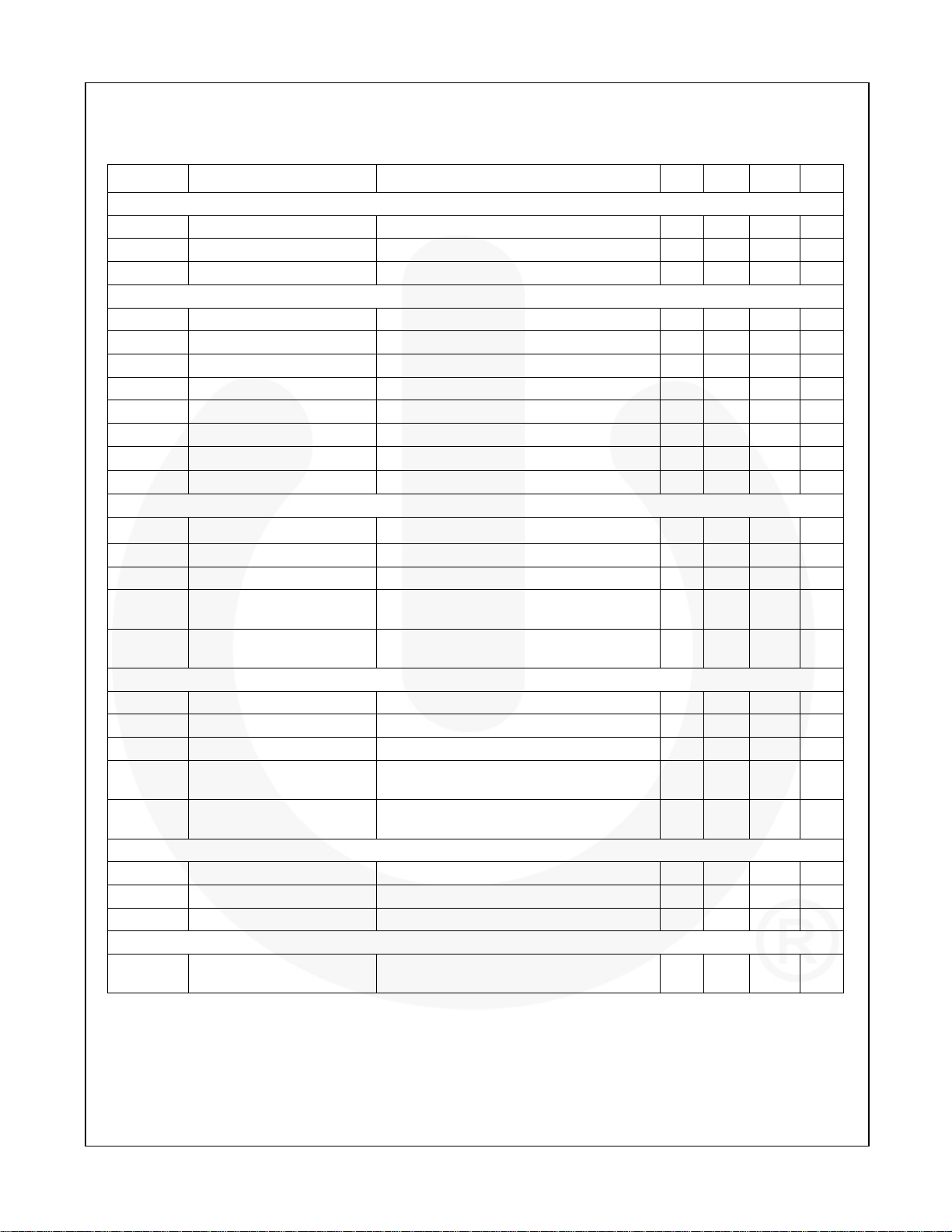

Absolute Maximum Ratings

Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be

operable above the recommended operating conditions and stressing the parts to these levels is not recommended.

In addition, extended exposure to stresses above the recommended operating conditions may affect device reliability.

The absolute maximum ratings are stress ratings only.

Symbol Parameter Min. Max. Unit

VCIN, VDRV, DISB#, PWM, SMOD#, GL, THWN# to CGND Pins 6

VIN to PGND, CGND Pins 25

BOOT, GH to VSWH, PHASE Pins 6

VSWH, PHASE to PGND, CGND Pins 25

BOOT to PGND, CGND Pins 27

BOOT to VDRV 22

f

=300kHz 43

(1)

I

O(AV)

θ

T

JPCB

STG

=12V, VO=1.0V

VIN

Junction-to-PCB Thermal Resistance 3.5 °C/W

Operating and Storage Temperature Range -55 +150 °C

ESD Electrostatic Discharge Protection

SW

fSW=1MHz 40

Human Body Model, JESD22-A114 2000

Charged Device Model, JESD22-C101 2000

Note:

1. I

is rated using Fairchild’s DrMOS evaluation board, at TA = 25°C, with natural convection cooling. This rating

O(AV)

is limited by the peak DrMOS temperature, T

= 150°C, and varies depending on operating conditions and PCB

J

layout. This rating can be changed with different application settings.

V

A

V

Recommended Operating Conditions

The Recommended Operating Conditions table defines the conditions for actual device operation. Recommended

operating conditions are specified to ensure optimal performance to the datasheet specifications. Fairchild does not

recommend exceeding them or designing to Absolute Maximum Ratings.

Symbol Parameter Min. Typ. Max. Unit

V

Control Circuit Supply Voltage 4.5 5.0 5.5 V

CIN

V

Gate Drive Circuit Supply Voltage 4.5 5.0 5.5 V

DRV

VIN Output Stage Supply Voltage

Note:

2. Operating at high V

can create excessive AC overshoots on the VSWH-to-GND and BOOT-to-GND nodes

IN

during MOSFET switching transients. For reliable DrMOS operation, VSWH-to-GND and BOOT-to-GND must

remain at or below the Absolute Maximum Ratings shown in the table above. Refer to the “Application

Information” and “PCB Layout Guidelines” sections of this datasheet for additional information.

(2)

3.0 12.0 15.0 V

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 4

Page 5

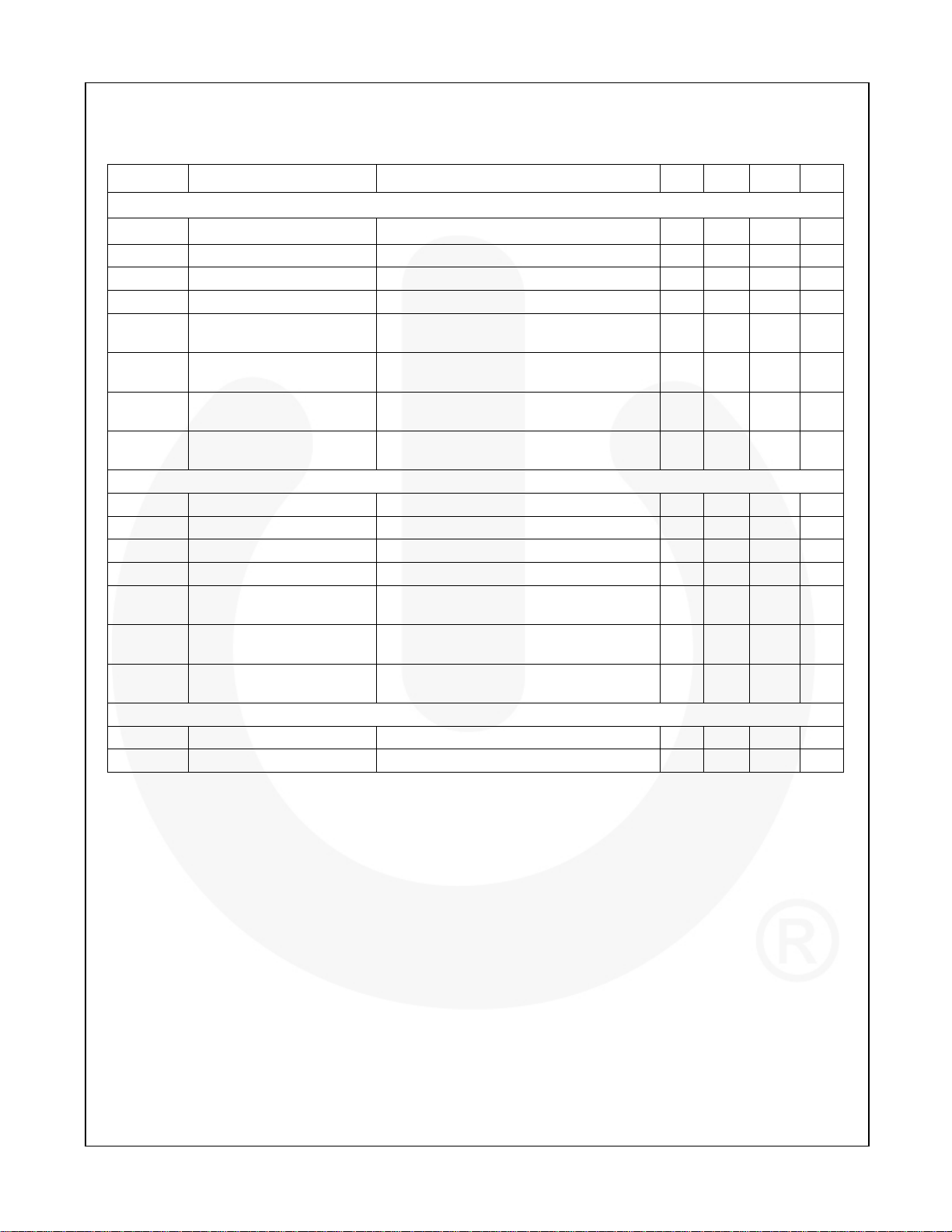

Electrical Characteristics

Typical values are VIN = 12V, V

Symbol Parameter Condition Min. Typ. Max. Unit

Basic Operation

IQ Quiescent Current IQ=I

UVLO UVLO Threshold V

UVLO

PWM Input

R

R

V

V

V

V

t

D_HOLD-OFF

V

HiZ_PWM

DISB# Input

V

V

t

PD_DISBL

t

PD_DISBH

SMOD# Input

V

IH_SMOD

V

t

PD_SLGLL

t

PD_SHGLH

Thermal Warning Flag

R

250ns Timeout Circuit

t

D_TIMEOUT

UVLO Hysteresis 0.4 V

_Hyst

Pull-Up Impedance 10 kΩ

UP_PWM

Pull-Down Impedance 10 kΩ

DN_PWM

PWM High Level Voltage

IH_PWM

3-State Rising Threshold

TRI_HI

3-State Falling Threshold

TRI_LO

PWM Low Level Voltage

IL_PWM

3-State Shutoff Time 160 200 ns

3-State Open Voltage 2.3 2.5 2.7 V

High-Level Input Voltage 2 V

IH_DISB

Low-Level Input Voltage 0.8 V

IL_DISB

I

Pull-Down Current 10 µA

PLD

Propagation Delay

Propagation Delay

High-Level Input Voltage 2 V

Low-Level Input Voltage 0.8 V

IL_SMOD

I

Pull-Up Current 10 µA

PLM

Propagation Delay

Propagation Delay

T

Activation Temperature 150 °C

ACT

T

Reset Temperature 135 °C

RST

Pull-Down Resistance I

THWN

Timeout Delay

= 5V, V

CIN

= 5V, and T

DRV

VCIN+IVDRV

Rising 2.9 3.1 3.3 V

CIN

= +25°C unless otherwise noted.

A

, PWM=LOW or HIGH or Float 2 mA

3.30 3.55 3.80

3.20 3.45 3.70

1.00 1.25 1.50

0.85 1.15 1.40

PWM=GND, Delay Between DISB# from

HIGH to LOW to GL from HIGH to LOW

PWM=GND, Delay Between DISB# from

LOW to HIGH to GL from LOW to HIGH

PWM=GND, Delay Between SMOD# from

HIGH to LOW to GL from HIGH to LOW

PWM=GND, Delay Between SMOD# from

LOW to HIGH to GL from LOW to HIGH

=5mA 30 Ω

PLD

SW=0V, Delay Between GH from HIGH to

LOW and GL from LOW to HIGH

25 ns

25 ns

10 ns

10 ns

250 ns

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

V

V

V

V

Continued on the following page…

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 5

Page 6

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

Electrical Characteristics

Typical values are VIN = 12V, V

Symbol Parameter Condition Min. Typ. Max. Unit

High-Side Driver

R

SOURCE_GH

R

SINK_GH

t

t

t

D_DEADON

t

PD_PLGHL

t

PD_PHGHH

t

PD_TSGHH

Low-Side Driver

R

SOURCE_GL

R

SINK_GL

t

t

t

D_DEADOFF

t

PD_PHGLL

t

PD_TSGLH

Boot Diode

Output Impedance, Sourcing Source Current=100mA 1 Ω

Output Impedance, Sinking Sink Current=100mA 0.8 Ω

Rise Time GH=10% to 90%, C

R_GH

Fall Time GH=90% to 10%, C

F_GH

LS to HS Deadband Time

PWM LOW Propagation

Delay

PWM HIGH Propagation

Delay (SMOD Held LOW)

Exiting 3-State Propagation

Delay

Output Impedance, Sourcing Source Current=100mA 1 Ω

Output Impedance, Sinking Sink Current=100mA 0.5 Ω

Rise Time GL=10% to 90%, C

R_GL

Fall Time GL=90% to 10%, C

F_GL

HS to LS Deadband Time

PWM-HIGH Propagation

Delay

Exiting 3-State Propagation

Delay

VF Forward-Voltage Drop IF=10mA 0.35 V

VR Breakdown Voltage IR=1mA 22 V

= 5V, V

CIN

= 5V, and T

DRV

= +25°C unless otherwise noted.

A

=1.1nF 12 ns

LOAD

=1.1nF 11 ns

LOAD

GL going LOW to GH going HIGH,

2V GL to 10 % GH

PWM going LOW to GH going LOW,

V

IL_PWM

to 90% GH

PWM going HIGH to GH going HIGH,

V

to 10% GH (SMOD=LOW)

IH_PWM

PWM (from 3-State) going HIGH to GH

going HIGH, V

IH_PWM

to 10% GH

=2.7nF 12 ns

LOAD

=2.7nF 8 ns

LOAD

SW going LOW to GL going HIGH,

2.2V SW to 10% GL

PWM going HIGH to GL going LOW,

V

IH_PWM

to 90% GL

PWM (from 3-State) going LOW to GL

going HIGH, V

IL_PWM

to 10% GL

10 ns

16 30 ns

30 ns

30 ns

12 ns

9 25 ns

20 ns

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 6

Page 7

PWM

VSW

V

IH_PWM

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

V

IL_PWM

GL

GH

to

VSWH

H

t

PD PHGLL

90%

2.0V

t D_DEADON

Figure 5. PWM Timing Diagram

10%

t

PD PLGHL

90%

10%

1.2V

t

D_DEADOFF

t

D_TIMEOUT

( 250ns Timeout)

2.2V

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 7

Page 8

Typical Performance Character istics

Test Conditions: VIN=12V, V

unless otherwise specified.

Figure 6. Safe Operating Area Figure 7. Module Power Loss vs. Output Current

=1.0V, V

OUT

300kHz

1MHz

CIN

=5V, V

DRV

=5V, L

=320nH, TA=25°C, and natural convection cooling,

OUT

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

I

= 30A

OUT

fSW = 300kHz

I

= 30A

OUT

Figure 8. Power Loss vs. Switching Frequency Figure 9. Power Loss vs. Input Voltage

fSW = 300kHz

= 30A

I

OUT

fSW = 300kHz

= 30A

I

OUT

Figure 10. Power Loss vs. Driver Supply Voltage Figure 11. Power Loss vs. Output Voltage

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 8

Page 9

Typical Performance Characteristics (Continued)

Test Conditions: VIN=12V, V

unless otherwise specified.

Figure 12. Power Loss vs. Output Inductance Figure 13. Driver Supply Current vs. Frequency

=1.0V, V

OUT

fSW = 300kHz

I

= 30A

OUT

=5V, V

CIN

DRV

=5V, L

=320nH, TA=25°C, and natural convection cooling,

OUT

I

= 0A

OUT

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

fSW = 300kHz

= 0A

I

OUT

Figure 14. Driver Supply Current vs. Driver

Supply Voltage

Figure 15. Driver Supply Current vs. Output Current

Figure 16. PWM Thresholds vs. Temperature Figure 17. DISB# Thresholds vs. Temperature

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 9

Page 10

Typical Performance Characteristics (Continued)

Test Conditions: VIN=12V, V

unless otherwise specified.

=1.0V, V

OUT

=5V, V

CIN

=5V, L

DRV

OUT

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

=320nH, TA=25°C, and natural convection cooling,

Figure 18. SMOD# Thresholds vs. Temperature Figure 19. BOOT Diode V

vs. Temperature

F

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 10

Page 11

Functional Description

A

p

t

The FDMF6706C is a driver-plus-FET module optimized

for the synchronous buck converter topology. A single

PWM input signal is all that is required to properly drive

the high-side and the low-side MOSFETs. Each part is

capable of driving speeds up to 1MHz.

VCIN and Disable

The VCIN pin is monitored by an under-voltage lockout

(UVLO) circuit. When V

is enabled for operation. When V

the driver is disabled (GH, GL=0). The driver can also

be disabled by pulling the DISB# pin LOW (DISB# <

), which holds both GL and GH LOW regardless

V

IL_DISB

of the PWM input state. The driver can be enabled by

raising the DISB# pin voltage HIGH (DISB# > V

Table 1. UVLO and Disable Logic

UVLO DISB# Driver State

0 X Disabled (GH, GL=0)

1 0 Disabled (GH, GL=0)

1 1 Enabled (See T able 2)

1 Open Disabled (GH, GL=0)

Note:

3. DISB# has an internal pull-down current source of

10µA.

Thermal Warning Flag

The FDMF6706C provides a thermal warning flag

(THWN) to warn of over-temperature conditions. The

thermal warning flag uses an open-drain output that

pulls to CGND when the activation temperature (150°C)

is reached. The THWN output returns to a highimpedance state once the temperature falls to the reset

temperature (135°C). For use, the THWN output

requires a pull-up resistor, which can be connected to

VCIN. THWN does NOT disable the DrMOS module.

HIGH

THWN

Logic

State

Normal

Operation

LOW

Figure 20. THWN Operation

rises above ~3.1V, the driver

CIN

135°C Rese

Temperature

T

J_driver IC

falls below ~2.7V,

CIN

150°C

ctivation

erature

Tem

IH_DISB

Thermal

Warning

).

3-State PWM Input

The FDMF6706C incorporates a 3-state 5V PWM input

gate drive design. The 3-state gate drive has both logic

HIGH level and LOW level, along with a 3-state

shutdown window. When the PWM input signal enters

and remains within the 3-state window for a defined

hold-off time (t

D_HOLD-OFF

), both GL and GH are pulled

LOW. This feature enables the gate drive to shut down

both high-and low-side MOSFETs to support features

such as phase shedding, which is a common feature on

multiphase voltage regulators.

Operation when Exiting 3-State Condition

When exiting a valid 3-state condition, the FDMF6706C

design follows the PWM input command. If the PWM

input goes from 3-state to LOW, the low side MOSFET

is turned on. If the PWM input goes from 3-state to

HIGH, the high-side MOSFET is turned on. This is

illustrated in Figure 21. The FDMF6706C design allows

for short propagation delays when exiting the 3-state

window (see Electrical Characteristics).

Low-Side Driver

The low-side driver (GL) is designed to drive a groundreferenced low R

N-channel MOSFET. The bias

DS(ON)

for GL is internally connected between VDRV and

CGND. When the driver is enabled, the driver's output is

180° out of phase with the PWM input. When the driver

is disabled (DISB#=0V), GL is held LOW.

High-Side Driver

The high-side driver is designed to drive a floating Nchannel MOSFET. The bias voltage for the high-side

driver is developed by a bootstrap supply circuit,

consisting of the internal Schottky diode and external

bootstrap capacitor (C

held at PGND, allowing C

through the internal diode. When the PWM input goes

HIGH, GH begins to charge the gate of the high-side

MOSFET (Q1). During this transition, the charge is

removed from C

Q1 turns on, V

V

+ V

IN

BOOT

BOOT

rises to VIN, forcing the BOOT pin to

SWH

, which provides sufficient VGS enhancement

for Q1. To complete the switching cycle, Q1 is turned off

by pulling GH to VSWH. C

VDRV when VSWH falls to PGND. GH output is inphase with the PWM input. The high-side gate is held

LOW when the driver is disabled or the PWM signal is

held within the 3-state window for longer than the 3state hold-off time, t

D_HOLD-OFF

). During startup, VSWH is

BOOT

to charge to VDRV

BOOT

and delivered to the gate of Q1. As

is then recharged to

BOOT

.

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 11

Page 12

Adaptive Gate Drive Circuit

_

V

The driver IC advanced design ensures minimum

MOSFET dead-time while eliminating potential shoot

through (cross-conduction) currents. It senses the state

of the MOSFETs and adjusts the gate drive adaptively

to ensure they do not conduct simultaneously. Figure 21

provides the relevant timing waveforms. To prevent

overlap during the LOW-to-HIGH switching transition

(Q2 off to Q1 on), the adaptive circuitry monitors the

voltage at the GL pin. When the PWM signal goes

HIGH, Q2 begins to turn off after some propagation

delay (t

PD_PHGLL

~2V, Q1 begins to turn on after adaptive delay t

V

IH_PWM

PWM

). Once the GL pin is discharged below

D_DEADON

V

IH_PWM

V

IL_PWM

t

R_GH

.

To preclude overlap during the HIGH-to-LOW transition

(Q1 off to Q2 on), the adaptive circuitry monitors the

voltage at the VSWH pin. When the PWM signal goes

LOW, Q1 begins to turn off after some propagation

delay (t

PD_PLGHL

Q2 begins to turn on after adaptive delay t

Additionally, V

). Once the VSWH pin falls below ~2.2V,

is monitored. When V

GS(Q1)

D_DEADOFF

GS(Q1)

discharged below ~1.2V, a secondary adaptive delay is

initiated, which results in Q2 being driven on after

t

D_TIMEOUT

implemented to ensure C

, regardless of SW state. This function is

is recharged each

BOOT

switching cycle in the event that the SW voltage does

not fall below the 2.2V adaptive threshold. Secondary

delay t

V

TRI_HI

D_TIMEOUT

t

F_GH

is longer than t

V

IH_PWM

D_DEADOFF

.

V

V

TRI_HI

V

TRI_LO

IL_PWM

V

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

.

is

GH

to

VSWH

VSWH

GL

CCM

t

PD_PHGLL

90%

2.0V

t

D_DEADON

less than

t

2.2

10%

t

PD

PLGHL

t

D_DEADOFF

t

R_GL

D_HOLD

t

OFF

D_HOLD -

OFF

-

DCM

t

Enter

3

F_GL

State

-

t

Exit

3-State

PD_TSGHH

t

D_HOLD -OFF

Notes:

= propagation delay from external sign al (PWM, SMOD#, etc.) to IC generated signal. Example (t

t

PD_xxx

t

= delay from IC generated signal to IC generated signal. Example (t

D_xxx

PWM Exiting 3-state

t

= PWM rise to LS VGS fall, V

PD_PHGLL

t

= PWM fall to HS VGS fall, V

PD_PLGHL

= PWM rise to HS VGS rise, V

t

PD_PHGHH

SMOD# Dead Times

t

= SMOD# fall to LS VGS fall, V

PD_SLGLL

= SMOD# rise to LS VGS rise, V

t

PD_SHGLH

to 90% LS VGS t

IH_PWM

to 90% HS VGS t

IL_PWM

to 10% HS VGS (SMOD# held LOW)

IH_PWM

to 90% LS VGS t

IL_SMOD

to 10% LS VGS t

IH_SMOD

– LS VGS (GL) LOW to HS VGS (GH) HIGH)

D_DEADON

PD_TSGHH

PD_TSGLH

D_DEADON

D_DEADOFF

Figure 21. PWM and 3-StateTiming Diagram

DCM

t

PD_TSGHH

Enter

3

-State

PD_PHGLL

= PWM 3-state to HIGH to HS VGS rise, V

= PWM 3-state to LOW to LS VGS rise, V

= LS VGS fall to HS VGS rise, LS-comp trip value (~2.0V GL) to 10% HS VGS

= VSWH fall to LS VGS rise, SW-comp trip value (~2.2V VSWH) to 10% LS VGS

Exit

3 S t at e

– PWM going HIGH to LS VGS (GL) going LOW)

less than

t

D_HOLD -

IH_PWM

IL_PWM

t

D_HOLD

OFF

Enter

3 -State

to 10% HS VGS

to 10% LS VGS

-

OFF

t

PD_TSGLH

Exit

State

3-

90%

10%

V

V

90%

1

IN

OUT

0%

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 12

Page 13

Skip Mode (SMOD)

V

V

#

The SMOD function allows for higher converter

efficiency under light-load conditions. During SMOD, the

low-side FET gate signal is disabled (held LOW),

preventing discharging of the output capacitors as the

filter inductor current attempts reverse current flow –

also known as “Diode Emulation” Mode.

When the SMOD pin is pulled HIGH, the synchronous

buck converter works in Synchronous Mode, gating on

the low-side FET. When the SMOD pin is pulled LOW,

the low-side FET is gated off. The SMOD pin is

connected to the PWM controller, which enables or

disables the SMOD automatically when the controller

detects light-load condition from output current sensing.

Normally this pin is active LOW. See Figure 22 for

timing delays.

SMOD

V

IH_PWM

V

PWM

GH

to

SWH

IL_PWM

90%

10%

Table 2. SMOD Logic

DISB# PWM SMOD# GH GL

0 X X 0 0

1 3-State X 0 0

1 0 0 0 0

1 1 0 1 0

1 0 1 0 1

1 1 1 1 0

Note:

4. The SMOD feature is intended to have low

propagation delay between the SMOD signal and

the low-side FET VGS response time to control

diode emulation on a cycle-by-cycle basis.

V

V

IL_SMOD

V

IH_PWM

10%

IH_SMOD

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

SWH

GL

t

PD_PHGLL

t

D_DEADON

90%

2.0V

t

PD_PLGHL

2.2V

t

D_DEADOFF

10%

CCM

CCM

t

PD_SLGLL

Delay from SMOD# going

LOW to LS VGSLOW

HS turn -on with SMOD# LOW

t

PD_PHGHH

DCM

t

Delay from SMOD# going

HIGH to LS VGSHIGH

PD_SHGLH

10%

V

OUT

Figure 22. SMOD Timing Diagram

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 13

Page 14

Application Information

A

A

A

Supply Capacitor Selection

For the supply input (V

capacitor is recommended to reduce noise and to

supply the peak current. Use at least a 1µF X7R or X5R

capacitor. Keep this capacitor close to the VCIN pin and

connect it to the GND plane with vias.

Bootstrap Circuit

The bootstrap circuit uses a charge storage capacitor

(C

), as shown in Figure 23. A bootstrap capacitance

BOOT

of 100nF X7R or X5R capacitor is adequate. A series

bootstrap resistor would be needed for specific

applications to improve switching noise immunity.

VCIN Filter

The VDRV pin provides power to the gate drive of the

high-side and low-side power FET. In most cases, it can

be connected directly to VCIN, the pin that provides

power to the logic section of the driver. For additional

V5V

I

5V

), a local ceramic bypass

CIN

C

VDR

noise immunity, an RC filter can be inserted between

VDRV and VCIN. Recommended values would be 10Ω

and 1µF.

Power Loss and Efficiency

Measurement and Calculation

Refer to Figure 23 for power loss testing method. Power

loss calculations are:

P

=(VIN x IIN) + (V5V x I5V) (W)

IN

P

P

P

P

EFF

EFF

C

x I

SW=VSW

OUT=VOUT

LOSS_MODULE=PIN

LOSS_BOARD=PIN

MODULE

BOARD

VIN

OUT

x I

OUT

=100 x PSW/PIN (%)

=100 x P

I

IN

(W)

(W)

- PSW (W)

- P

(W)

OUT

OUT/PIN

V

IN

(%)

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

DISB

PWM

Input

OFF

ON

OpenDrain

Output

VCIN

DISB#

PWM

SMOD

THWN

VDRV

FDMF6706C

CGND

PGND

VIN

R

BOOT

BOOT

C

VSWH

PHASE

BOOT

VV

SW

L

OUT

Figure 23. Power Loss Measurem ent B lock Diagram

I

OUT

C

OUT

V

OUT

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 14

Page 15

PCB Layout Guidelines

Figure 24 provides an example of a proper layout for the

FDMF6706C and critical components. All of the highcurrent paths, such as VIN, V

SWH

, V

OUT

, and GND

copper, should be short and wide for low inductance

and resistance. This technique aids in achieving a more

stable and evenly distributed current flow, along with

enhanced heat radiation and system performance.

The following guidelines are recommendations for the

PCB designer:

1. Input ceramic bypass capacitors must be placed

close to the VIN and PGND pins. This helps

reduce the high-current power loop inductance

and the input current ripple induced by the power

MOSFET switching operation.

2. The V

copper trace serves two purposes. In

SWH

addition to being the high-frequency current path

from the DrMOS package to the output inductor, it

also serves as a heat sink for the low-side

MOSFET in the DrMOS package. The trace

should be short and wide enough to present a lowimpedance path for the high-frequency, highcurrent flow between the DrMOS and inductor to

minimize losses and temperature rise. Note that

the VSWH node is a high voltage and highfrequency switching node with high noise

potential. Care should be taken to minimize

coupling to adjacent traces. Since this copper

trace also acts as a heat sink for the lower FET,

balance using the largest area possible to improve

DrMOS cooling while maintaining acceptable

noise emission.

3. An output inductor should be located close to the

FDMF6706C to minimize the power loss due to the

VSWH copper trace. Care should also be taken so

the inductor dissipation does not heat the DrMOS.

4. PowerTrench® MOSFETs are used in the output

stage. The Power MOSFETs are effective at

minimizing ringing due to fast switching. In most

cases, no VSWH snubber is required. If a snubber

is used, it should be placed close to the VSWH and

PGND pins. The resistor and capacitor need to be

of proper size for the power dissipation.

5. VCIN, VDRV, and BOOT capacitors should be

placed as close as possible to the VCIN to CGND,

VDRV to CGND, and BOOT to PHASE pins to

ensure clean and stable power. Routing width and

length should be considered as well.

6. Include a trace from PHASE to VSWH to improve

noise margin. Keep the trace as short as possible.

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 15

7. The layout should include the option to insert a

small-value series boot resistor between the boot

capacitor and BOOT pin. The boot-loop size,

including R

BOOT

and C

, should be as small as

BOOT

possible. The boot resistor is normally not

required, but is effective at controlling the highside MOSFET turn-on slew rate. This can improve

noise operating margin in synchronous buck

designs that may have noise issues due to ground

bounce or high positive and negative VSWH

ringing. Inserting a boot resistance lowers the

DrMOS efficiency. Efficiency versus noise tradeoffs must be considered.

The VIN and PGND pins handle large current

transients with frequency components greater than

100MHz. If possible, these pins should be

connected directly to the VIN and board GND

planes. The use of thermal relief traces in series

with these pins is discouraged since this adds

inductance to the power path. This added

inductance in series with either the VIN or PGND

pin degrades system noise immunity by increasing

positive and negative VSWH ringing.

8. CGND pad and PGND pins should be connected

by plane GND copper with multiple vias for stable

grounding. Poor grounding can create a noise

transient offset voltage level between CGND and

PGND. This could lead to faulty operation of gate

driver and MOSFET.

9. Ringing at the BOOT pin is most effectively

controlled by close placement of the boot

capacitor. Do not add an additional BOOT to the

PGND capacitor. This may lead to excess current

flow through the BOOT diode.

10. The SMOD# and DISB# pins have weak internal

pull-up and pull-down current sources,

respectively. These pins should not have any

noise filter capacitors. Do not to float these pins

unless absolutely necessary.

11. Use multiple vias on each copper area to

interconnect top, inner, and bottom layers to help

distribute current flow and heat conduction. Vias

should be relatively large and of reasonably low

inductance. Critical high-frequency components,

such as R

BOOT

, C

, the RC snubber, and

BOOT

bypass capacitors should be located as close to

the respective DrMOS module pins as possible

on the top layer of the PCB. If this is not feasible,

they should be connected from the backside

through a network of low-inductance vias.

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

Page 16

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

Bottom View Top View

Figure 24. PCB Layout Example

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 16

Page 17

Physical Dimensions

0.10 C

2X

6.00

B

A

6.00

PIN#1

INDICATOR

2.50

31

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

5.80

4.50

2130

20

0.40

0.65

11

0.35

0.50

(0.70)

0.40

2.00±0.10

0.10

0.08 C

0.40

C

FRONT VIEW

(2.20)

21

20

11

10

(0.20)

BOTTOM VIEW

1.10

0.90

0.30

0.20

TOP VIEW

4.40±0.10

(0.20)

0.05

0.00

DETAIL 'A'

SCALE: 2:1

0.10

2X

SEE

DETAIL 'A'

0.10 CAB

0.05

0.30

(40X)

0.20

30

31

2.40±0.10

1.50±0.10

40

1

2.00±0.10

0.50

C

SEATING

PLANE

0.25

1.60

C

40

0.60

0.50 TYP

C

0.20

0.50

0.30

NOTES: UNLESS OTHERWISE SPECIFIED

A) DOES NOT FULLY CONFORM TO JEDEC

REGISTRATION MO-220, DATED

MAY/2005.

B) ALL DIMENSIONS ARE IN MILLIMETERS.

C) DIMENSIONS DO NOT INCLUDE BURRS

OR MOLD FLASH. MOLD FLASH OR

BURRS DOES NOT EXCEED 0.10MM.

D) DIMENSIONING AND TOLERANCING PER

ASME Y14.5M-1994.

E) DRAWING FILE NAME: PQFN40AREV2

1

2.10

LAND PATTERN

RECOMMENDATION

PIN #1 INDICATOR

(40X)

10

0.15

2.10

Figure 25. 40-Lead, Cli pbond PQFN D rMOS, 6.0x6.0mm Package

Package drawings are provided as a service to customers considering Fairchild components. Drawings may change in any manner

without notice. Please note the revision and/or date on the drawing and contact a Fairchild Semiconductor representative to verify or

obtain the most recent revision. Package specifications do not expand the terms of Fairchild’s worldwide terms and conditions, specifically the

warranty therein, which covers Fairchild products.

Always visit Fairchild Semiconductor’s online packaging area for the most recent package drawings:

http://www.fairchildsemi.com/packaging/

.

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 17

Page 18

FDMF6706C - Extra-Small High-Performance, High-Frequency DrMOS Module

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FDMF6706C • Rev. 1.0.2 18

Loading...

Loading...