Page 1

FEATURES

EP7209

EP7209

■ Audio decoder system-on-chip

— Allows for support of multiple audio decompression

algorithms

— Supports MPEG 1, 2, & 2.5 layer 3 audio decoding,

including ISO compliant MPEG 1 & 2 layer 3 support for

all standard sample rates and bit rates

— Supports bit streams with adaptive bit rates

— DAI (Digital Audio Interface) providing glueless interface

to low power DACs, ADCs, and Codecs

■

Ultra low power consumption for MP3 playback

— 87 mW (typical) for 44.1 kHz samples/sec,

128 kbits/s econd

— 50 mW for 22.05 kHz samples/s ec, 64kbits/second

— <1 mW in St andb y State

■

ARM720T processor

— ARM7TDMI CPU

— 8 kbytes of four-way set-associative cache

— MMU with 64-entry TLB (transition look-aside buffer)

— Write Buffer

— Windows

CE enabled

— Thumb code support enabled

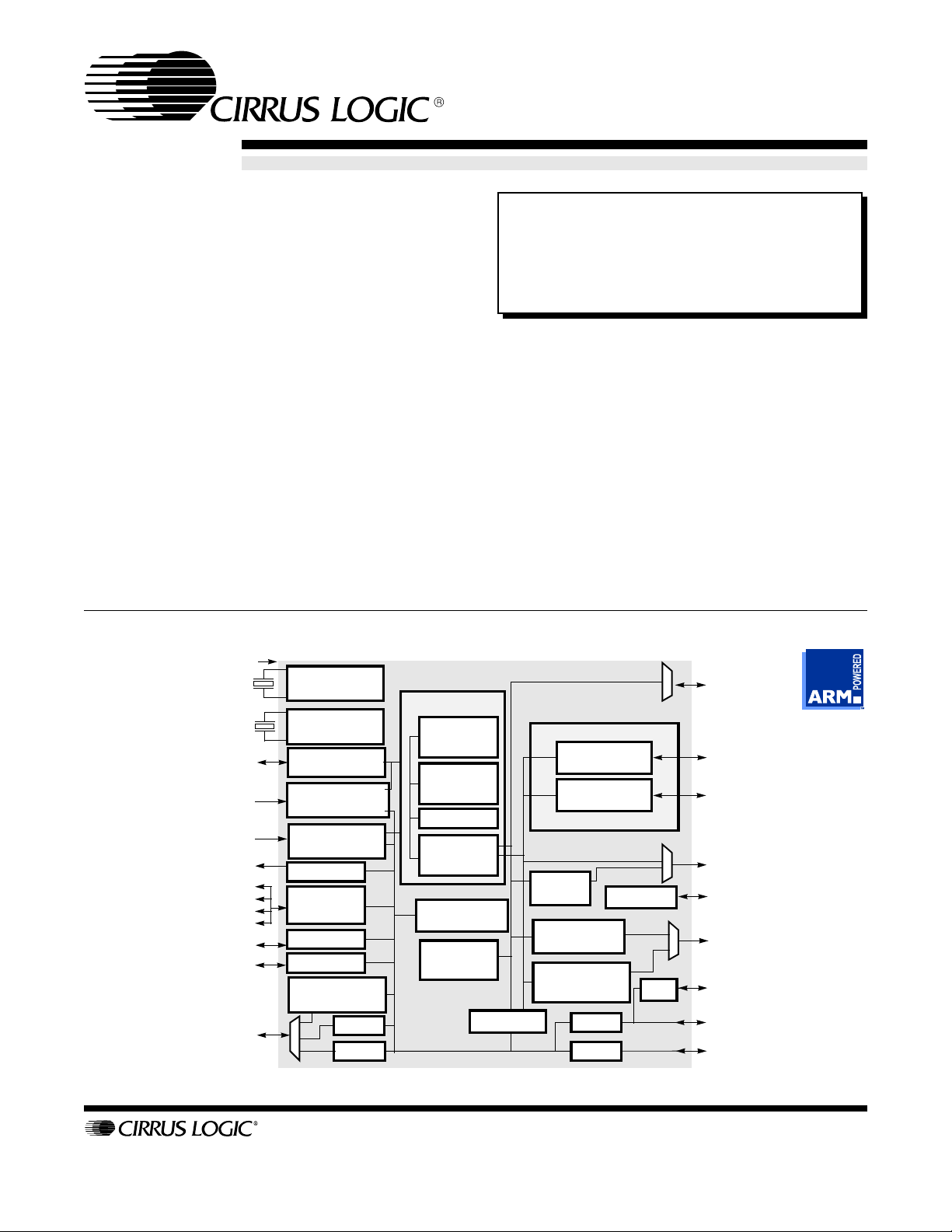

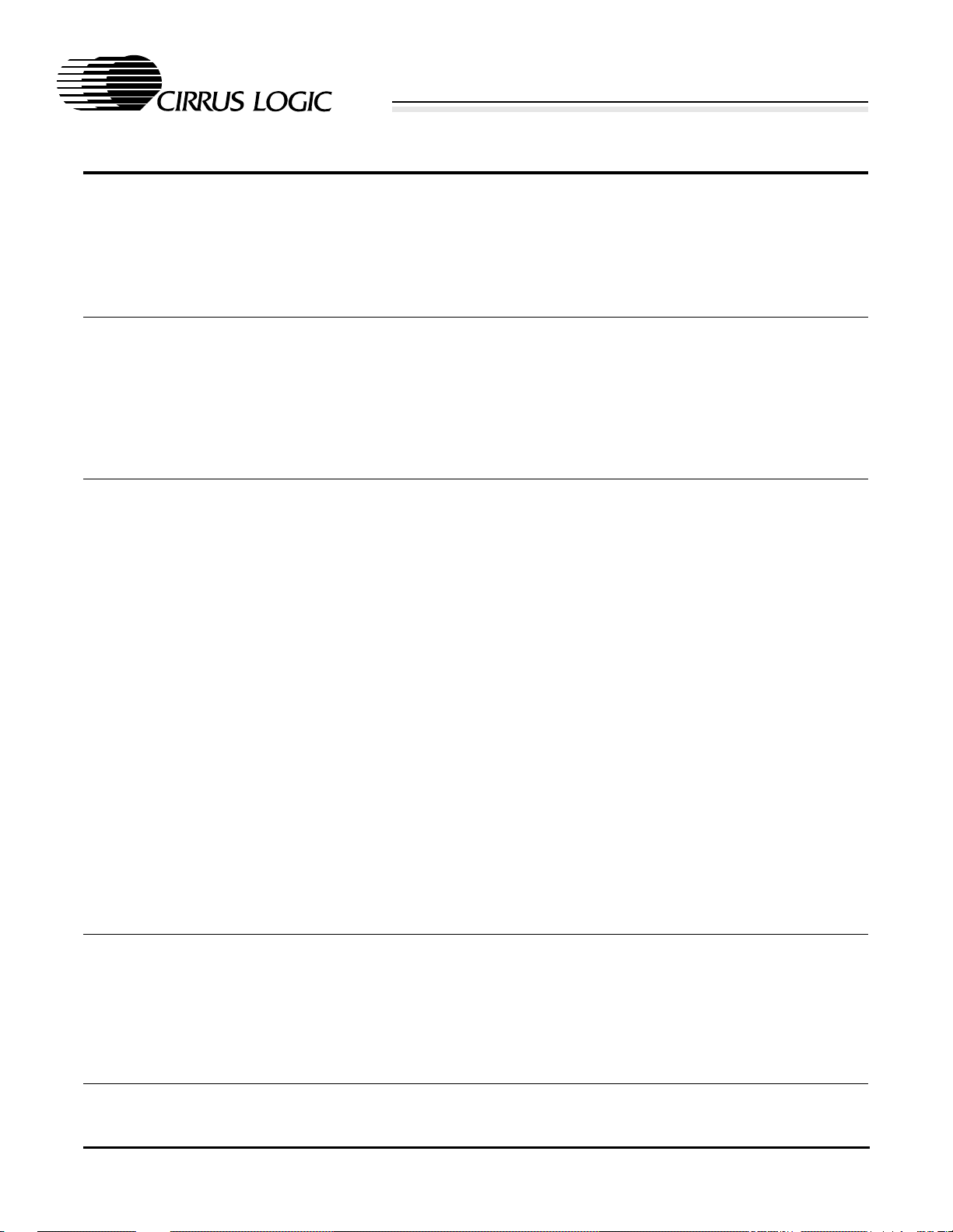

Functional Block Diagram

13-MHZ INPUT

3.6864 MHZ

32.768 KHZ

NPOR, RUN,

RESET, WAKEUP

BAT OK, NEXTPWR

PWRFL, BATCHG

EINT[1:3], FIQ,

MEDCHG

FLASHING LED DRIVE

PORTS A, B, D (8-BIT)

PORT E (3-BIT)

KEYBD DRIVERS (0:7)

BUZZER DRIVE

DC-TO-DC

ADCCLK, ADCIN,

ADCOUT, SMPCLK,

SSICLK, SSITXFR,

SSITXDA, SSIRXDA,

ADCCS

SSIRSFR

PLL

32.768-KHZ

OSCILLA TOR

STATE CONTROL

POWER

MANAGEMENT

INTERRUPT

CONTROLLER

RTC

GPIO

PWM

SSI1 (ADC)

DAI

SSI2

CODEC

Ultra-Low-Power Audio Decoder

System-on-Chip

OVERVIEW

The EP7209 is a complete integrated system on a

chip for enabli ng per sonal di gi tal audio solutions. It

is designed specifica lly for implementing audio

processing algorithms in power sensitive applications. The core-logic functionality of the device is

built around an ARM7 20T embedd ed p r ocessor.

The EP7209 also i ncludes a 32- bit Y2K-comp liant

Real-Time Clock ( RTC) and comp ar ator.

(cont.) (cont.)

ARM720T

ARM7TDMI

CPU CORE

8-KBYTE

CACHE

MMU

WRITE

BUFFER

TIMER

COUNTERS (2)

ON-CHIP

BOOT ROM

EPB BRIDGE

EPB BUS

INTERNAL DATA BUS

MEMORY CONTROLLER

CL-PS6700

INTFC.

EXPANSION

CONTROL

INTERNAL ADDRESS BUS

LCD

DMA

CONTROLLER

ON-CHIP SRAM

38,400 BYTES

ICE-JTAG

LCD

UART1

UART2

IrDA

D[0:31]

PB[0:1], NCS[4:5]

EXPCLK, WORD , NCS[0:3],

EXPRDY, WRITE

A[0:27],

DRA[0:12]

TEST AND

DEVELOPMENT

LCD DRIVE

LED AND

PHOTODIODE

ASYNC

INTERFACE 1

ASYNC

INTERFACE 2

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

DEC ‘99

DS453PP2

1

Page 2

EP7209

FEATURES

■

Dynamically programmable clock speeds of 18,

36, 49, and 74 MHz at 2.5 V

■

Performance matching 100 MHz Intel

Pentium-based PC

■

OEM customization

— Integrated ARM720T RISC processor

— Up to 25 MHz of CPU processing power avai lable (after

digital audio decoding) for custom features such as soft-

ware EQ or tone control, volume control, spectrum

analyzer, random play order, etc.

— Allows for control of digital voice recorder function

■

LCD controller

— Interfaces directly to a single-scan panel monochrome

LCD

— Panel width is programmable from 32 to 1024 pixels in

16-pixel increments

— Video frame buffer size programmable up to 128kbytes

— Bits per pixel of 1, 2, or 4 bits

■

Memory co nt r oller

— Decodes up to 6 separate memory segments of up to

256 Mbytes each

— Each segment can be configured as 8, 16, or 32 bits

wide and supports page-mode access

(cont.)

— Programmable access time for conventional

ROM/SRAM/FLASH memory

— Supports Removable FLASH card interface

— Enables connection to removable FLASH card for addi-

tion of expansion FLASH memory modules

■

38,400 bytes ( 0x9 60 0) of on -ch i p SRA M fo r fast

program execution and/or as a frame buffer

■

On-chip boot ROM for manufacturing support

■

Integrated D AI in te rf ac e

— Connects directly to a Crystal® audio DAC

■

27-bits of general-purpose I/O

— Three 8-bit and one 3-bit GPIO port

— Supports scanning keyboard matrix

■

SIR (up to 115.2 kbps) infrared encoder/decoder

— IrDA (Infrared Data Association) SIR protocol

encoder/decoder

■

DC-to-DC converter interface (PWM)

— Provides two 96 kHz clock outputs with programmable

duty ratio (from 1-in-16 to 15-in-16) that can be used to

drive a DC to DC converter

■

208-pin LQFP or 256-ball PBGA p a ck ag e s

■

Full JTAG boundary scan and Embedded ICE

support

OVERVIEW

(cont.)

The EP7209 also includes a comprehensive set of

integrated peripherals such as an LCD display controller , an audio DAC inter face, and a FLASH memory

interface. Using the EP7209, a portable audio

decoder solution can be built with the addition of an

LCD display, an audio DAC, a FL ASH memo ry subsystem, and a small number of additional low cost

components.

The EP7209 uses its powerful 32-bit RISC processing engine to implement audio decompression algorithms in software. The nature of the on-board RISC

processor and th e avai labi lity of ef fic ient C-comp iler s

and other software dev elopme nt too ls ensure s that a

wide range of audio decompression algorithms can

easily be ported t o an d run o n t he EP 720 9.

The EP7209 uses external memory for storing application code. The use of external memory to support

software audio decompression algorithms ensures

that the audio deco mpression system so lution can be

tailored to the requirements of the application. Software can be place d in a low cost mask ROM f or pri ce

sensitive applicati ons, or can be plac ed in external

FLASH memory to enabl e upgradeable systems. The

EP7209’s 8 kbyte on-board cache and programmable wait state generator ensure that a wide range of

memory options can be uti lize d.

The EP7209 runs a full ISO-compliant MPEG 1, 2, &

2.5 layer 3 audio decompre ssion engine with less

than 50% of its availab le proces sing capab ility. This

leaves significant processin g power available for

product differentiation.

MPEG 1, 2, & 2.5 Layer 3 Object Code Library

Cirrus Logic provides an object code library for

enabling MPEG 1, 2, & 2 .5 layer 3 aud io decomp ression. This library supports the MPEG 1 sample rates

of 48 k, 44.1 k and 32 k bits per second; the MPEG 2

sample rates of 24 k, 22.05 k and 16 k bits per second; and the MPEG 2.5 s ample rates of 12 k,

11.025 k and 8 k bits per second. In addition to all

standard fixed compressed data rates, the MPEG

layer 3 object co de library also supports de compression of variabl e bi t- ra te data streams.

2 DS453PP2

Page 3

EP7209

OVERVIEW

(cont.)

Power Management

The EP7209 is designed for ultra-low-power operation. Its core ope rat es at only 2.5 V, while its I/O has

an operation range of 2.5 V-3.3 V. Through careful

design, Cirrus Logic h as achieved extremely low

power consumption with the EP7209. This is

achieved by using a combination of dynamically

adjustable core clock frequencies, low power states

utilized during periods of inactivity, and fully static

design principles. For example, when decompressing

MPEG 1 layer 3 music data with sample rates of

44.1 kHz and 128 kbits/sec, the EP7209 consumes

less than 87 mW. At sampling frequencies of

22.05 kHz and 64 kbits/sec, power consumption falls

to 50 mW.

Audio Data Memory Interfaces

The EP7209 connects directly to both on-system

FLASH memory and to re movable FLASH m emorycards. The generality of the external interface on the

EP7209 allows for the use of a wide variety of additional memory type s for com press ed audi o dat a storage.

downloading of compressed music or data from a PC

to an EP7209-ba sed po rtable digital aud io p la yer.

The EP7209 can also be connected to industry standard USB slave devices through an external interface. The power of the EP720 9 coupled with the

36 MHz external data bus ensures that the EP7209

can support rapid transfer of compressed audio data

over a USB interface .

The EP7209 also includes a built-in 115.2 kbps IrDA

SIR protocol encoder/decoder that can be used to

drive an infrared communication interface to download the dat a.

Digital Audio Interface

The EP7209 integrates an DAI interface to enable a

direct connection to many low cost, low power, high

quality audio converters. In particular, the DAI interface can be used to drive the Crystal CS43L41 / 42 /

43 low power audio DACs and the Crystal CS53L32

low power audio A DC. Some of t hese devices f eature

digital bass and treble boost, digital volume control

and compressor-l imi ter fu ncti ons .

LCD Interface

The EP7209 int erfaces directl y to a singl e-scan pane l

monochrome LCD display. For portable digital audio

Packaging

The EP7209 is available in a 208-pin LQFP package

and a 256-ball PBGA pa cka ge.

player applications that require LCDs, a 128 kbyte

display buf fer is pr ovi ded .

Data Download

System Design

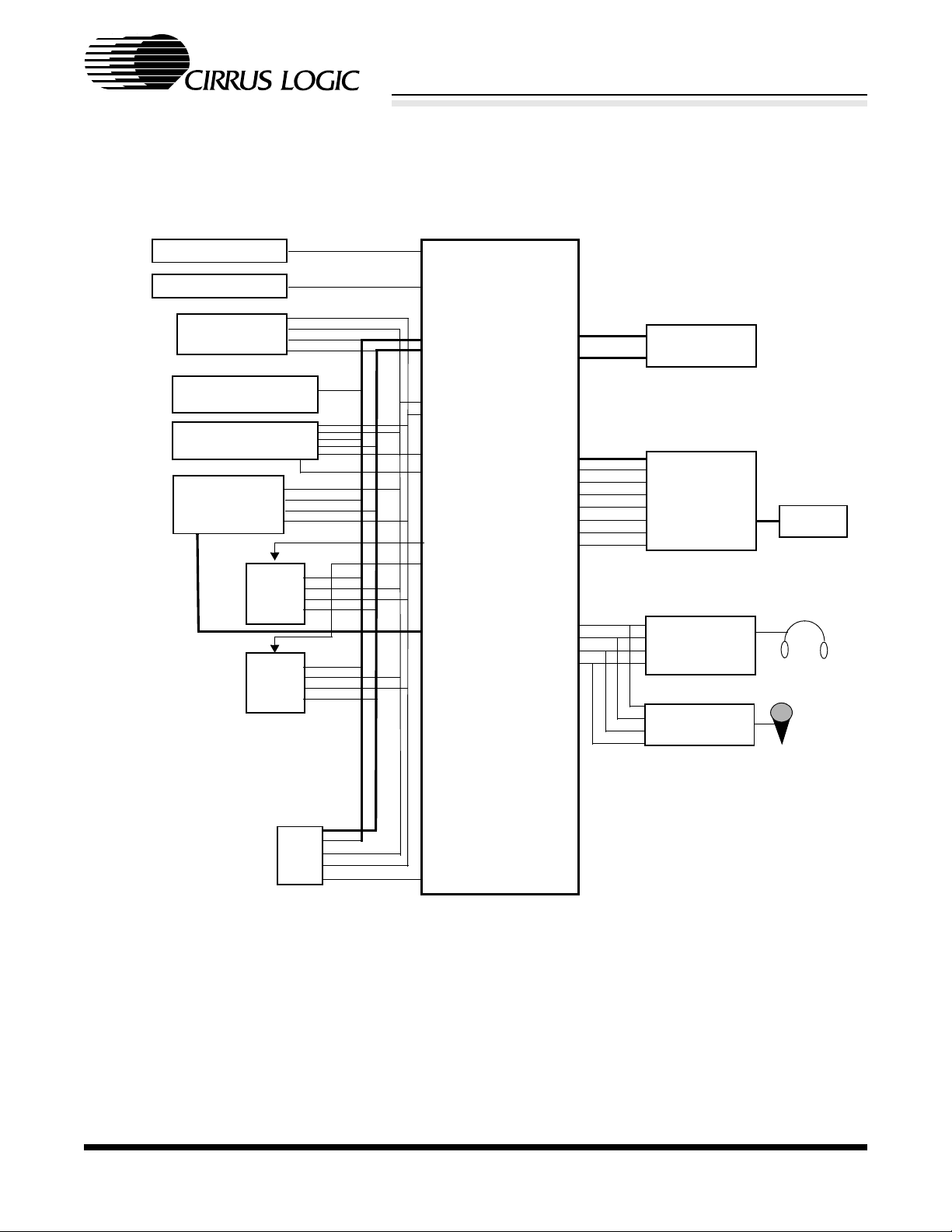

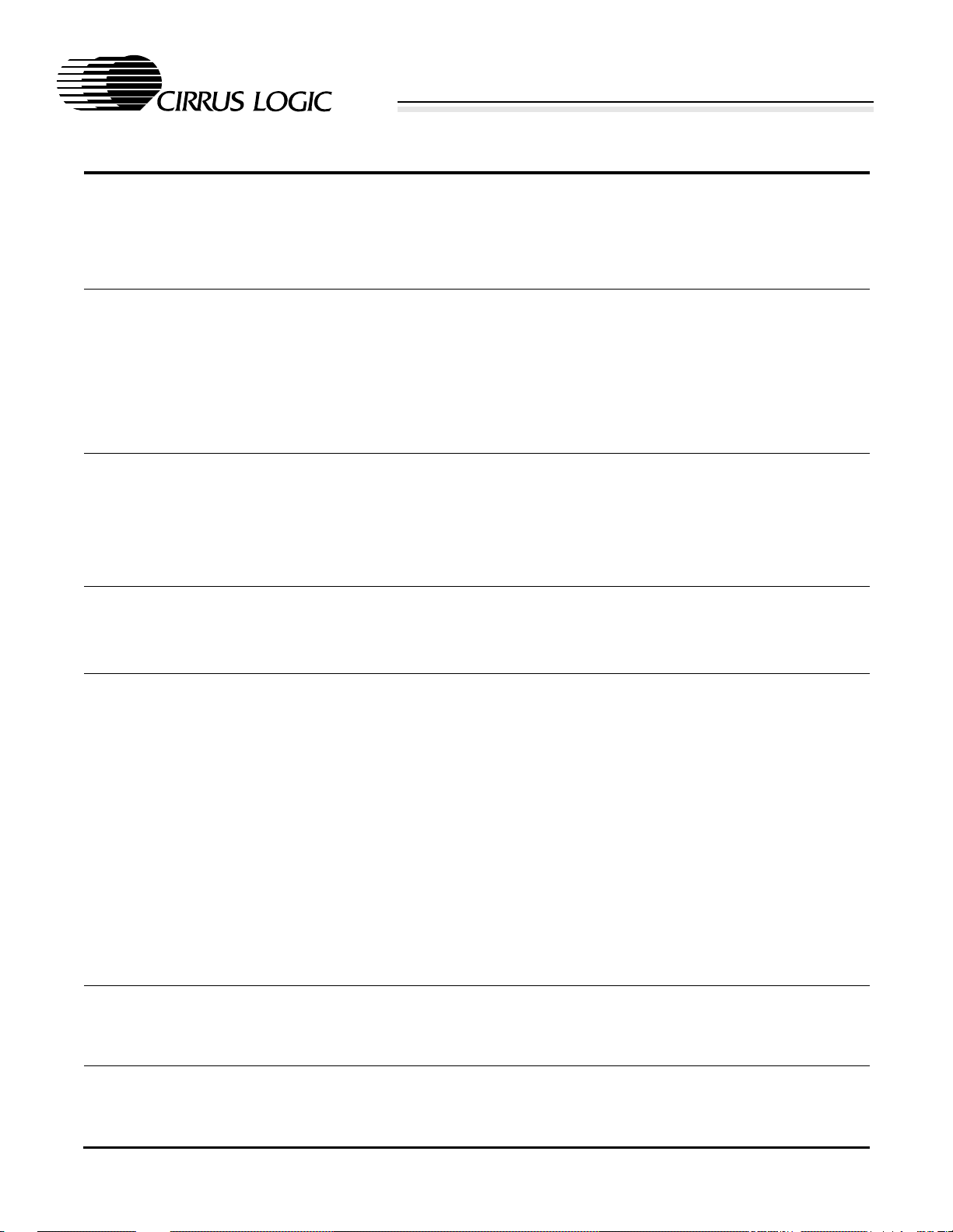

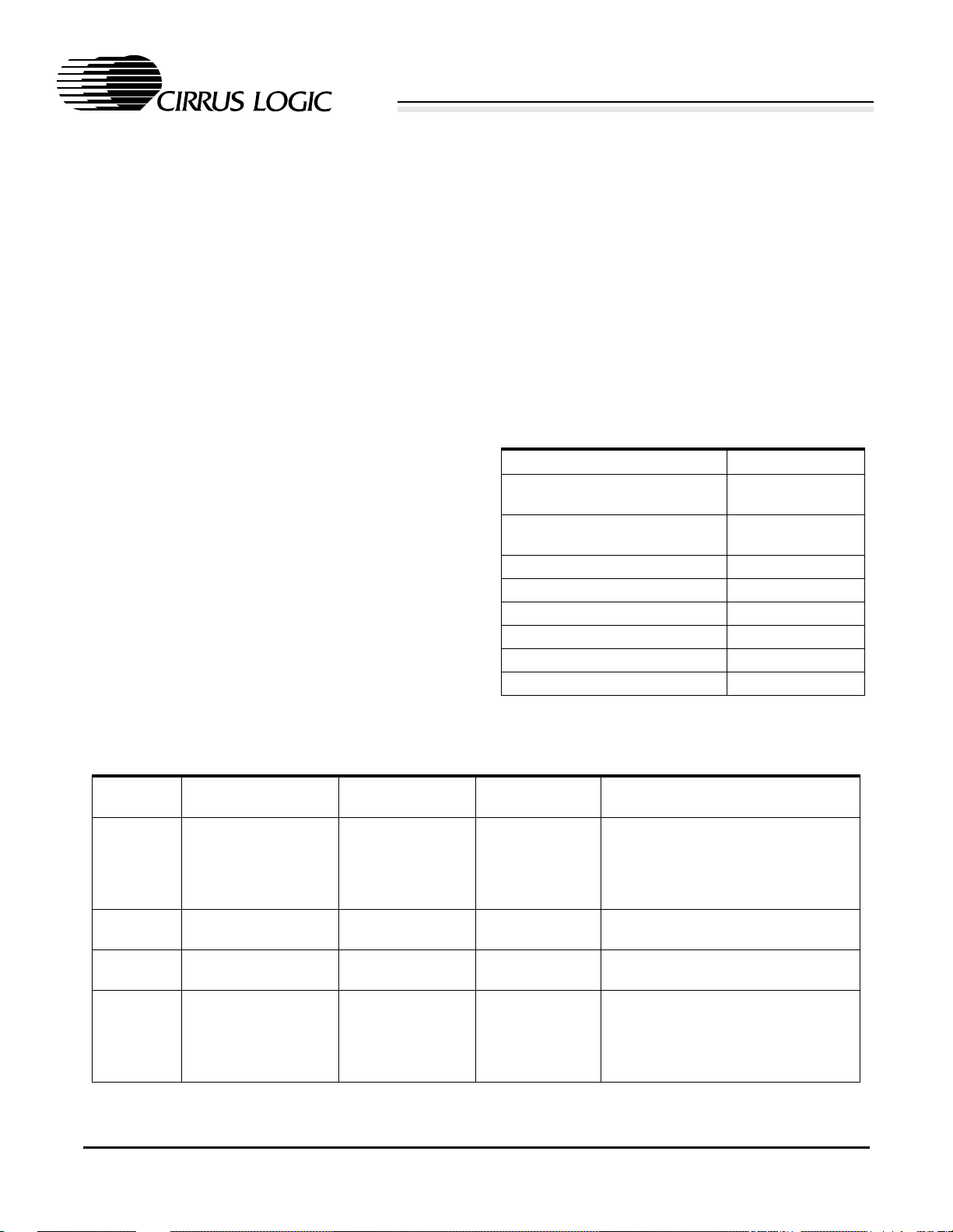

As shown in the system block diagram, simply adding

FLASH memory, an LCD, an audio DAC, and some

The EP7209 along with minimal glue logic can connect to a PC through the parallel port. This enables

discrete components, a complete low power digital

audio player syst em can be made . (See the f ollowing

illustration).

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Preliminary product inf o rmation describes product s whi ch are in production, b ut f or which full character iza t i on da t a i s not yet available. Advance p rodu ct i nformation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document i s accurat e and reli able. However , t he infor mation is subje ct to chang e without noti ce and is provi d ed “AS IS” without warrant y of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights

of third parties. This document is the pro perty of Cirrus Logi c, Inc. and i mplie s no licen se under patents, copyrights, tr ademarks, or trade secre ts. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electro nic, mechanical, photographic, or

otherwise) without the pr i or writ ten consent of Cirrus Logic, Inc. It e ms f rom any Ci rrus Logic website or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

DS453PP2 3

Page 4

EP7209

OVERVIEW

CRYSTAL

CRYSTAL

FLASH MEMORY

PC PARALLEL PORT

SMART MEDIA

INTERFACE

(cont.)

LCD

FLASH CARD/

CARD

NOR

FLASH

× 16

NAND

FLASH

× 8

MOSCIN

RTCIN

D[31:0]

A[27:0]

NMOE

NMWE

EINT[X]

CS[3]

CS[0]

CS[1]

PB[6:7]

NEXTPWR

EP7209

NBATCHG

COL[7:0]

PA[7:0]

PE[2:0]

NPOR

NPWRFL

NBATOK

RUN

WAKEUP

SSICLK

SSITXFR

SSITXDA

SSIRXDA

KEYBOARD/

PUSH BUTTONS

POWER

SUPPLY UNIT

AND

COMPARATORS

STEREO DAC

CS43L41 / 42 /

43

STEREO ADC

CS53L32

BATTERY

HEADPHONES

MIC

USB

CS[4]

Figure 1. A Typical EP7209-Based Digital Audio Player Reference

4 DS453PP2

Page 5

TABLE OF CONTENTS

1. CONVENTIONS ...................................................................................................................... 10

1.1 Acronyms and Abbreviations ............................................................................................ 10

1.2 Units of Measurement ......................................................................................................11

1.3 General Conventions ........................................................................................................11

1.4 Pin Description Conventions ............................................................................................. 11

2. PIN INFORMATION ..... ....... ...... ....... ...... ....... ...... ....... ...... ...... ....................................... .......... 12

2.1 208-Pin LQFP Pin Diagram .............................................................................................. 12

2.2 Pin Descriptions ................................................................................................................ 13

2.2.1 External Signal Functions ................................................................................... 13

2.2.2 SSI/Codec/DAI Pin Multiplexing ............................................................................ 16

2.2.3 Output Bi-Directional Pins .................................................................................... 17

3. FUNCTIONAL DESCRIPTION ............................................................................................... 18

3.1 CPU Core .......................................................................................................................... 19

3.2 State Control ..................................................................................................................... 20

3.2.1 Standby State .......................................................................................................... 20

3.2.1.1 UART in Standby State ............................................................................... 21

3.2.2 Idle State ................................................................................................................. 22

3.2.3 Keyboard Interrupt ................................................................................................... 22

3.3 Resets ............................................................................................................................... 23

3.4 Clocks ............................................................................................................................... 23

3.4.1 On-Chip PLL ............................................................................................................ 23

3.4.1.1 Characteristics of the PLL Interface ............................................................ 24

3.4.2 External Clock Input (13 MHz) ................................................................................ 24

3.4.3 Dynamic Clock Switching When in the PLL Clocking Mode .................................... 26

3.5 Interrupt Controller ............................................................................................................ 26

3.5.1 Interrupt Latencies in Different States ..................................................................... 28

3.5.1.1 Operating State ........................................................................................... 28

3.5.1.2 Standby State .............................................................................................. 28

3.6 EP7209 Boot ROM .......................................................................................................... 29

3.7 Memory and I/O Expansion Interface ............................................................................... 30

3.8 CL-PS6700 PC Card Controller Interface ......................................................................... 31

3.9 Endianness ....................................................................................................................... 33

3.10 Internal UARTs (Two) and SIR Encoder ......................................................................... 34

3.11 Serial Interfaces .............................................................................................................. 34

3.11.1 Codec Sound Interface .......................................................................................... 36

3.11.2 Digital Audio Interface ........................................................................................... 37

3.11.2.1 DAI Operation ............................................................................................ 38

3.11.2.2 DAI Frame Format ..................................................................................... 38

3.11.2.3 DAI Signals ................................................................................................ 38

3.11.3 ADC Interface — Master Mode Only SSI1 (Synchronous Serial Interface) .......... 39

3.11.4 Master/Slave SSI2 (Syn chro nou s Serial Interfa ce 2) .................... ....... ...... ....... ... 39

3.11.4.1 Read Back of Residual Data ..................................................................... 42

3.11.4.2 Support for Asymmetric Traffic .................................................................. 42

3.11.4.3 Continuous Data Transfer ......................................................................... 43

3.11.4.4 Discontinuous Clock .................................................................................. 43

3.11.4.5 Error Conditions ........................................................................................ 43

3.11.4.6 Clock Polarity ............................................................................................ 43

3.12 LCD Controller with Support for On-Chip Frame Buffer .................................................. 43

3.13 Timer Counters ............................................................................................................... 45

3.13.1 Free Running Mode ............................................................................................... 46

3.13.2 Prescale Mode ............................ ...... ....... ...... ...... ....... ....................................... ... 46

3.14 Real Time Clock .............................................................................................................. 46

EP7209

EP7209

DS453PP2

DS453PP2

5

Page 6

EP7209

3.14.1 Characteristics of the Real Time Clock Interface ................................................... 46

3.15 Dedicated LED Flasher ...................................................................................................47

3.16 Two PWM Interfaces .......................................................................................................47

3.17 Boundary Scan ................................................................................................................47

3.18 In-Circuit Emulation .........................................................................................................48

3.18.1 Introduction ............................................... ...... ...... ....... ...... ....................................48

3.18.2 Functionality .................................................... ...... ....... ...... ....... ...... ....... ...... ..........48

3.19 Maximum EP7209-Based System ..................................................................................48

4. MEMORY MAP ................................ ...................................... ....... ...... ....... ...... ....... ...... ..........50

5. REGISTER DESCRIPTIONS ..................................................................................................51

5.1 Internal Registers ..............................................................................................................51

5.1.1 PADR Port A Data Register .....................................................................................54

5.1.2 PBDR Port B Data Register .....................................................................................54

5.1.3 PDDR Port D Data Register ....................................................................................54

5.1.4 PADDR Port A Data Direction Register ................................................................... 54

5.1.5 PBDDR Port B Data Direction Register ................................................................... 54

5.1.6 PDDDR Port D Data Direction Register ...................................................................55

5.1.7 PEDR Port E Data Register .....................................................................................55

5.1.8 PEDDR Port E Data Direction Register ................................................................... 55

5.2 SYSTEM Control Registers ...............................................................................................56

5.2.1 SYSCON1 The System Control Register 1 ............................................................. 56

5.2.2 SYSCON2 System Control Register 2 .....................................................................59

5.2.3 SYSCON3 System Control Register 3 .....................................................................61

5.2.4 SYSFLG1 — The System Status Flags Register .................................................... 62

5.2.5 SYSFLG2 System Status Register 2 ....................................................................... 64

5.3 Interrupt Registers .............................................................................................................65

5.3.1 INTSR1 Interrupt Status Register 1 ......................................................................... 65

5.3.2 INTMR1 Interrupt Mask Register 1 ..........................................................................67

5.3.3 INTSR2 Interrupt Status Register 2 ......................................................................... 67

5.3.4 INTMR2 Interrupt Mask Register 2 ..........................................................................68

5.3.5 INTSR3 Interrupt Status Register 3 ......................................................................... 68

5.3.6 INTMR3 Interrupt Mask Register 3 ..........................................................................68

5.4 Memory Configuration Registers .......................................................................................69

5.4.1 MEMCFG1 Memory Configuration Register 1 .........................................................69

5.4.2 MEMCFG2 Memory Configuration Register 2 .........................................................69

5.5 Timer/Counter Registers ...................................................................................................71

5.5.1 TC1D Timer Counter 1 Data Register ..................................................................... 71

5.5.2 TC2D Timer Counter 2 Data Register ..................................................................... 71

5.5.3 RTCDR Real Time Clock Data Register ..................................................................71

5.5.4 RTCMR Real Time Clock Match Register ...............................................................71

5.6 LEDFLSH Register ............................................................................................................72

5.7 PMPCON Pump Control Register .....................................................................................73

5.8 CODR — The CODEC Interface Data Register ................................................................74

5.9 UART Registers ................................................................................................................74

5.9.1 UARTDR1–2 UART1–2 Data Registers ..................................................................74

5.9.2 UBRLCR1–2 UART1–2 Bit Rate and Line Control Registers ..................................75

5.10 LCD Registers .................................................................................................................77

5.10.1 LCDCON — The LCD Control Register ................................................................. 77

5.10.2 PALLSW Least Signi fic an t Word — LCD Palette Register ....................................78

5.10.3 PALMSW Most Significant Word — LCD Palette Register ....................................78

5.10.4 FBADDR LCD Frame Buffer Start Address ...........................................................79

5.11 SSI Register ....................................................................................................................79

5.11.1 SYNCIO Synchronous Serial ADC Interface Data Register ..................................79

5.12 STFCLR Clear all ‘Start Up Reason’ flags location ........ ....... ...... ....... ...... ....... ...... ....... ... 8 0

6 DS453PP2

Page 7

EP7209

5.13 ‘End Of Interrupt’ Locations ............................................................................................ 81

5.13.1 BLEOI Battery Low End of Interrupt ...................................................................... 81

5.13.2 MCEOI Media Changed End of Interrupt .............................................................. 81

5.13.3 TEOI Tick End of Interrupt Location ...................................................................... 81

5.13.4 TC1EOI TC1 End of Interrupt Location ................................................................. 81

5.13.5 TC2EOI TC2 End of Interrupt Location ................................................................. 82

5.13.6 RTCEOI RTC Match End of Interrupt .......................................................... ....... ... 82

5.13.7 UMSEOI UART1 Modem Status Changed End of Interrupt .................................. 82

5.13.8 COEOI Codec End of Interrupt Location ............................................................... 82

5.13.9 KBDEOI Keyboard End of Interrupt Location ........................................................ 82

5.13.10 SRXEOF End of Interrupt Location ..................................................................... 82

5.14 State Control Registers ...................................................................................................82

5.14.1 STDBY Enter the Standby State Location ............................................................. 82

5.14.2 HALT Enter the Idle State Location ....................................................................... 82

5.15 SS2 Registers ................................................................................................................. 83

5.15.1 SS2DR Synchronous Serial Interface 2 Data Register ......................................... 83

5.15.2 SS2POP Synchronous Serial Interface 2 Pop Residual Byte ............................... 83

5.16 DAI Register Definitions ..................................................................................................83

5.16.1 DAI Control Register ............................................................................................. 84

5.16.1.1 DAI Enable (DAIEN) .................................................................................. 85

5.16.1.2 DAI Interrupt Generation ........................................................................... 85

5.16.1.3 Left Channel Transmit FIFO Interrupt Mask (LCTM) ................................. 85

5.16.1.4 Left Channel Receive FIFO Interrupt Mask (LARM) ................................. 85

5.16.1.5 Right Channel Transmit FIFO Interrupt Mask (RCTM) .............................. 86

5.16.1.6 Right Channel Receive FIFO Interrupt Mask (RCRM) .............................. 86

5.16.1.7 Loop Back Mode (LBM) ............................................................................. 86

5.16.2 DAI Data Registers .. ....... ...... ....... ...... ....... ...... ....................................... ...... ....... ... 87

5.16.2.1 DAI Data Register 0 .................................................................................. 87

5.16.2.2 DAI Data Register 1 .................................................................................. 88

5.16.2.3 DAI Data Register 2 .................................................................................. 88

5.16.3 DAI Status Register ............................................................................................... 89

5.16.3.1 Right Channel Transmit FIFO Service Request Flag (RCTS) ................... 89

5.16.3.2 Right Channel Receive FIFO Service Request Flag (RCRS) ................... 89

5.16.3.3 Left Channel Transmit FIFO Service Request Flag (LCTS) ...................... 89

5.16.3.4 Left Channel Receive FIFO Service Request Flag (LCRS) ...................... 90

5.16.3.5 Right Channel Transmit FIFO Underrun Status (RCTU) ........................... 90

5.16.3.6 Right Channel Receive FIFO Overrun Status (RCRO) ............................. 90

5.16.3.7 Left Channel Transmit FIFO Underrun Status (LCTU) .............................. 90

5.16.3.8 Left Channel Receive FIFO Overrun Status (LCRO) ................................ 90

5.16.3.9 Right Channel Transmit FIFO Not Full Flag (RCNF) ................................. 90

5.16.3.10 Right Channel Receive FIFO Not Empty Flag (RCNE) ........................... 90

5.16.3.11 Left Channel Transmit FIFO Not Full Flag (LCNF) .................................. 91

5.16.3.12 Left Channel Receive FIFO Not Empty Flag (LCNE) .............................. 91

5.16.3.13 FIFO Operation Completed Flag (FIFO) ................................................. 91

6. ELECTRICAL SPECIFICATIONS .......................................................................................... 93

6.1 Absolute Maximum Ratings .............................................................................................. 93

6.2 Recommended Operating Conditions .............................................................................. 93

6.3 DC Characteristics ............................................................................................................ 93

6.4 AC Characteristics ............................................................................................................ 95

6.5 I/O Buffer Characteristics ................................................................................................ 102

6.6 JTAG Bandary Scan Signal Ordering ............................................................................. 102

7. TEST MODES ........ ...... ....................................... ....... ...... ...... ....... ...... ....... ...... ....... .............. 106

7.1 Oscillator and PLL Bypass Mode .................................................................................... 106

7.2 Oscillator and PLL Test Mode ......................................................................................... 106

DS453PP2

7

Page 8

7.3 Debug/ICE Test Mode ....................................................................................................107

7.4 Hi-Z (System) Test Mode ...............................................................................................107

7.5 Software Selectable Test Functionality ..........................................................................107

8. PIN INFORMATION ..... ....... ...... ....... ...................................... ....... ...... ....... ...... ....... ...... ........ 108

8.1 208-Pin LQFP Pin Diagram .............................................................................................108

8.2 208-Pin LQFP Numeric Pin Listing .................................................................................109

8.3 256-Pin PBGA Pin Diagram ............................................................................................112

8.4 256-Ball PBGA Ball Listing ..............................................................................................113

8.4.1 PBGA Ground Connections ...................................................................................116

9. PACKAGE SPECIFICATIONS .............................................................................................117

9.1 208-Pin LQFP Package Outline Drawing .......................................................................117

9.2 EP7209 256-Ball PBGA (17

10. ORDERING INFORMATION ...............................................................................................119

11. APPENDIX A: BOOT CODE ..............................................................................................120

12. INDEX ................................................................................................................................. 125

LIST OF FIGURES

Figure 1. 208-Pin LQFP (Low Profile Quad Flat Pack) Pin Diagram.............................................12

Figure 2. EP7209 Block Diagram..................................................................................................19

Figure 3. State Diagram ................................................................................................................ 20

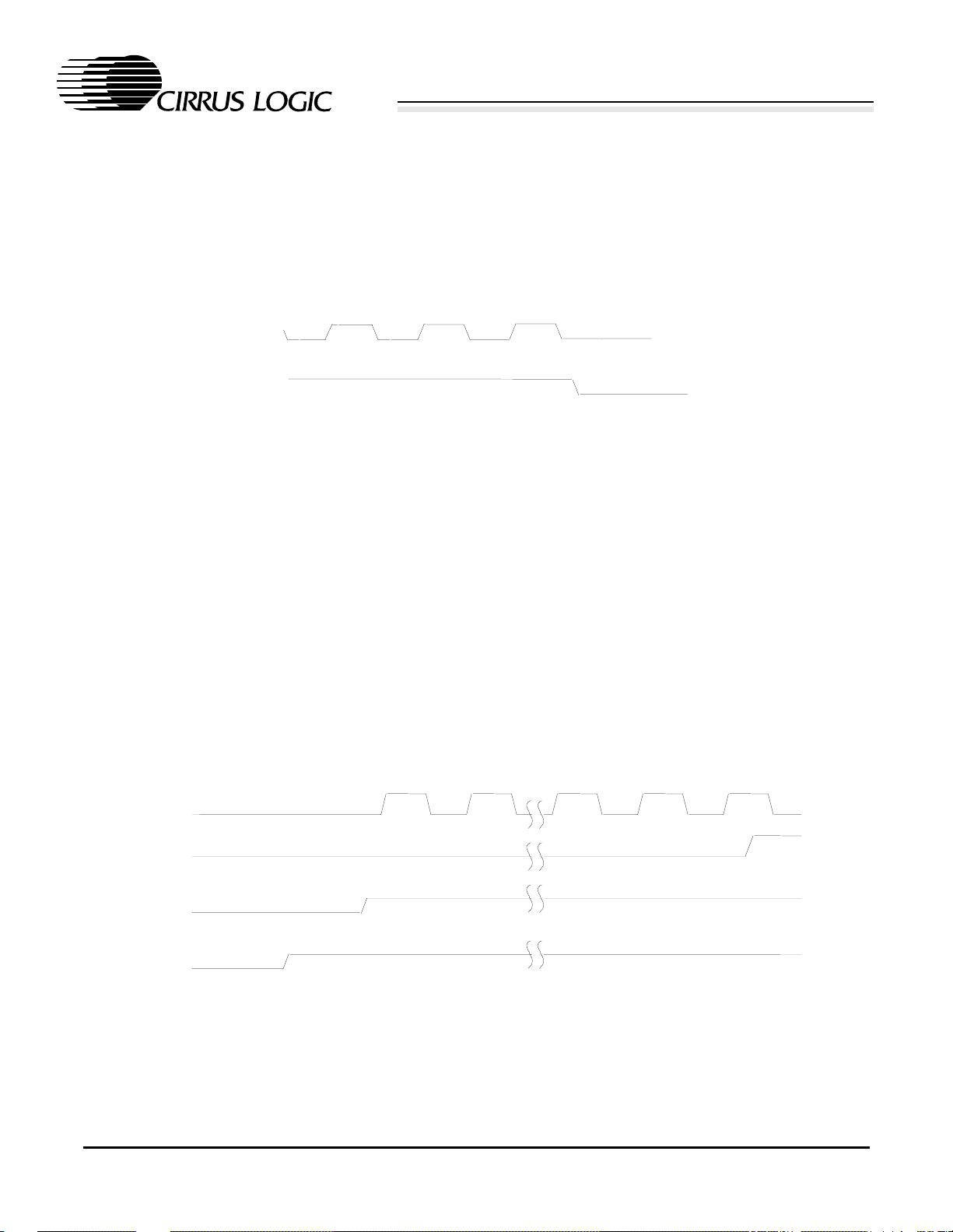

Figure 4. CLKEN Timing Entering the Standby State ...................................................................25

Figure 5. CLKEN Timing Entering the Standby State ...................................................................25

Figure 6. Codec Interrupt Timing...................................................................................................36

Figure 7. DAI Interface .............. ...... ....................................... ...... ....... ...... ....... ...... ....... ...... ..........37

Figure 8. EP7209 Rev C - Digital Audio Interface Timing – MSB/Left Justified format................ 38

Figure 9. SSI2 Port Directions in Slave and Master Mode............................................................ 40

Figure 10. Residual Byte Reading.................................................................................................42

Figure 11. Video Buffer Mapping...................................................................................................45

Figure 12. A Maximum EP7209 Based System ............................................................................ 49

Figure 13. Consecutive Memory Read Cycles with Minimum Wait States....................................97

Figure 14. Sequential Page Mode Read Cycles with Minimum Wait States.................................98

Figure 15. Consecutive Memory Write Cycles with Minimum Wait States.................................... 99

Figure 16. LCD Controller Timings..............................................................................................100

Figure 17. SSI Interface for AD7811/2 ........................................................................................100

Figure 18. SSI Timing Interface for MAX148/9............................................................................101

Figure 19. SSI2 Interface Timings...............................................................................................101

Figure 20. 208-Pin LQFP (Low Profile Quad Flat Pack) Pin Diagram.........................................108

Figure 21. 256-Ball Plastic Ball Grid Array Diagram ...................................................................112

EP7209

× 17 × 1.53-mm Body) Dimensions ..................................118

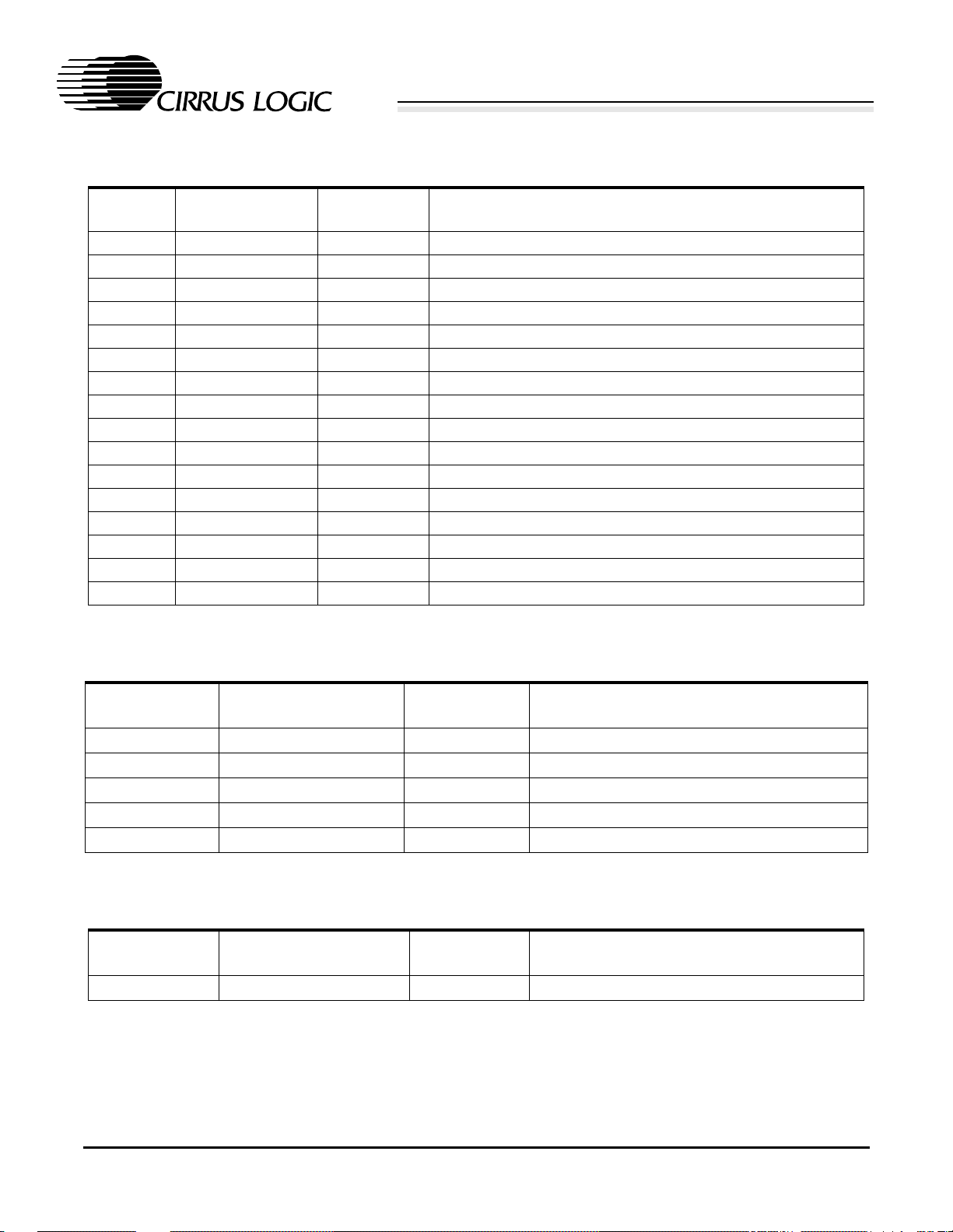

LIST OF TABLES

Table 1. Acronyms and Abbreviations...........................................................................................10

Table 2. Unit of Measurement.......................................................................................................11

Table 3. Pin Description Conventions ...........................................................................................11

Table 4. External Signal Functions................................................................................................13

Table 5. SSI/Codec/DAI Pin Multiplexing......................................................................................16

Table 6. Output Bi-Directional Pins ...............................................................................................17

Table 7. Peripheral Status in Different Power Management States.............................................. 21

Table 8. Exception Priority Handling .............................................................................................26

Table 9. Interrupt Allocation in the First Interrupt Register............................................................ 27

Table 10. Interrupt Allocation in the Second Interrupt Register.....................................................27

Table 11. Interrupt Allocation in the Third Interrupt Register.........................................................27

Table 12. External Interrupt Source Latencies..............................................................................29

Table 13. Chip Select Address Ranges After Boot From On-Chip Boot ROM..............................29

8 DS453PP2

Page 9

EP7209

Table 14. Boot Options ................................................................................................................. 30

Table 15. CL-PS6700 Memory Map.............................................................................................. 31

Table 16. Space Field Decoding................................................................................................... 32

Table 19. Serial Interface Options................................................................................................. 35

Table 20. Serial-Pin Assignments................................................................................................. 35

Table 21. ADC Interface Operation Frequencies.......................................................................... 39

Table 17. Effect of Endianness on Read Operations.................................................................... 41

Table 18. Effect of Endianness on Write Operations .................................................................... 41

Table 22. Instructions Supported in JTAG Mode .......................................................................... 47

Table 23. Device ID Register ........................................................................................................ 48

Table 24. EP7209 Memory Map in External Boot Mode............................................................... 50

Table 25. EP7209 Internal Registers Compatible with CL-PS7111 (Little Endian Mode)............. 52

Table 26. EP7209 Internal Registers (Big Endian Mode) ............................................................. 54

Table 27. SYSCON1..................................................................................................................... 56

Table 28. SYSCON2..................................................................................................................... 59

Table 29. SYSCON3..................................................................................................................... 61

Table 30. SYSFLG........................................................................................................................ 62

Table 31. SYSFLG2...................................................................................................................... 64

Table 32. INTSR1 ......................................................................................................................... 65

Table 34. INTSR3 ......................................................................................................................... 68

Table 35. Values of the Bus Width Field....................................................................................... 70

Table 36. Values of the Wait State Field at 13 MHz and 18 MHz................................................. 70

Table 37. Values of the Wait State Field at 36 MHz ..................................................................... 70

Table 38. MEMCFG ...................................................................................................................... 71

Table 39. LED Flash Rates........................................................................................................... 72

Table 40. LED Duty Ratio ............................................................................................................. 72

Table 41. PMPCON ...................................................................................................................... 73

Table 42. Sense of PWM control lines.......................................................................................... 73

Table 43. UARTDR1-2 UART1-2.................................................................................................. 74

Table 44. UBRLCR1-2 UART1-2 .................................................................................................. 75

Table 45. LCDCON....................................................................................................................... 77

Table 46. Gray Scale Value to Color Mapping.............................................................................. 79

Table 47. SYNCIO ........................................................................................................................ 80

Table 48. DAI Control Register ..................................................................................................... 84

Table 49. DAI Data Register 0...................................................................................................... 87

Table 50. DAI Data Register 1...................................................................................................... 88

Table 51. DAI Control, Data and Status Register Locations......................................................... 91

Table 52. absolute Maximum Ratings........................................................................................... 93

Table 53. Recommended Operating Conditions........................................................................... 93

Table 54. DC Characteristics........................................................................................................ 93

Table 55. AC Timing Characteristics.............................................................................................95

Table 56. Timing Characteristics................................................................................................... 96

Table 57. I/O Buffer Output Characteristics ................................................................................ 102

Table 58. 208-Pin LQFP Numeric Pin Listing ............................................................................. 102

Table 59. EP7209 Hardware Test Modes................................................................................... 106

Table 60. Oscillator and PLL Test Mode Signals........................................................................ 107

Table 61. Software Selectable Test Functionality....................................................................... 107

Table 62. 208-Pin LQFP Numeric Pin Listing ............................................................................. 109

Table 63. 256-Ball PBGA Ball Listing.......................................................................................... 113

Table 64. PBGA Balls to Connect to Ground (V

) .................................................................... 116

SS

DS453PP2

9

Page 10

EP7209

1. CONVENTIONS

This section presents acronyms, abbreviations,

units of measurement, and conventions used in this

data sheet.

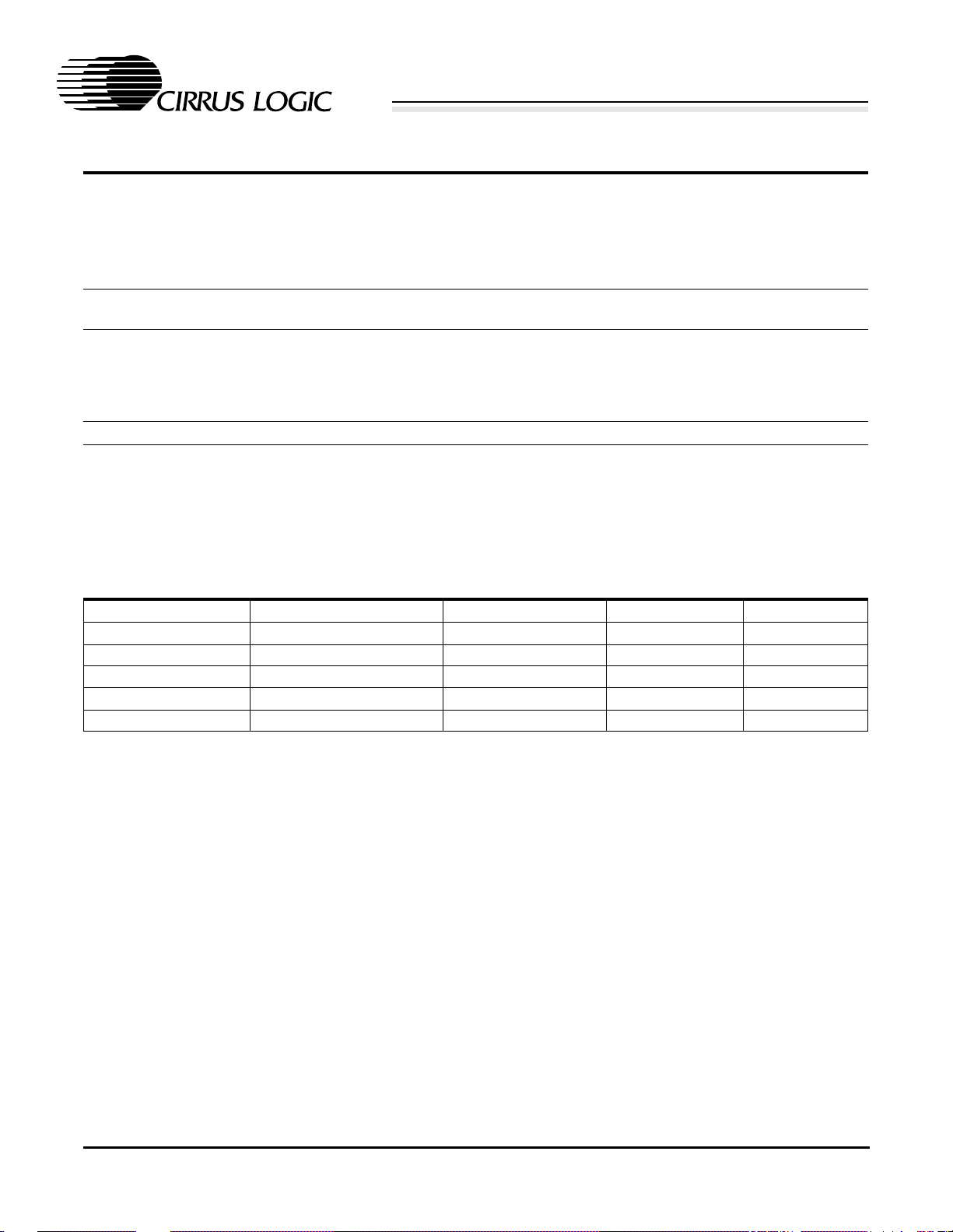

1.1 Acronyms and Abbreviations

Table 1 lists abbreviations and acronyms used in

this data sheet.

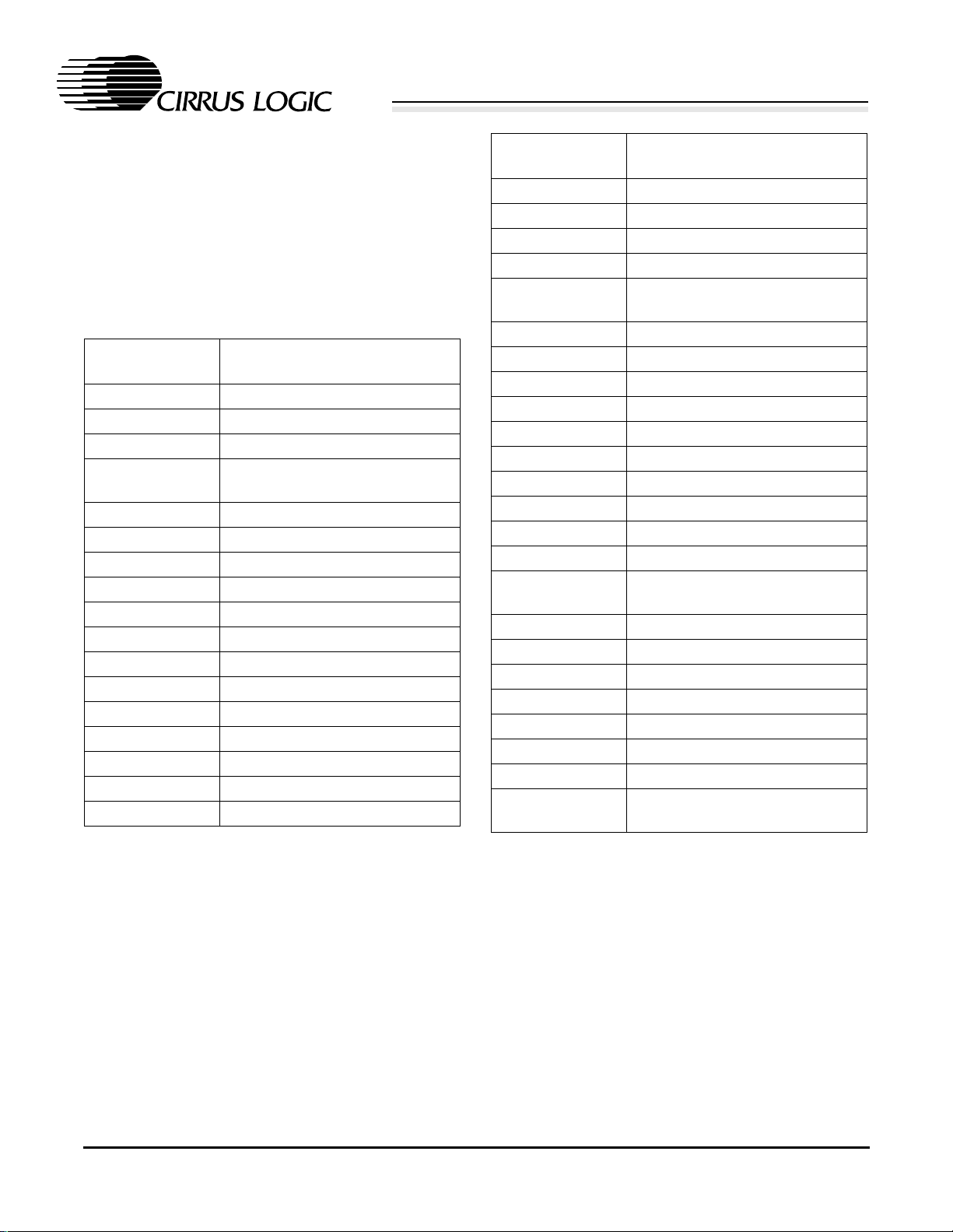

Acronym/

Abbreviation

AC alternating current.

A/D analog-to-digital.

ADC analog-to-digi tal conve r ter.

CMOS

CODEC coder/decoder.

CPU central processing unit.

D/A digital-to-analog.

DC direct current.

DMA direct-memory access.

EPB embedded peripheral bus.

FCS frame check sequence.

FIFO first in/first out.

GPIO general purpose I/O.

ICT in circuit test.

IR infrared.

IrDA Infrared Data Association.

JTAG Joint Test Action Group.

complementary metal oxide

semiconductor.

Definition

Acronym/

Abbreviation

LCD liquid crystal display.

LED light-emitting diode.

LQFP low profile quad flat pack.

LSB least significant bit.

MIPS

MMU memory management unit.

MSB most significant bit.

PBGA plastic ball grid array.

PCB printed circuit board.

PDA personal digital assistant.

PIA peripheral inter face a dapt er.

PLL phase locked loop.

PSU power supply unit.

p/u pull-up resistor.

RAM random access memory.

RISC

ROM read-only memory.

RTC Real Time Clock.

SIR slow (9600–115.2 kbps) infrared.

SRAM static random access memory.

SSI synchronous serial interface.

TAP te st acces s port.

TLB tran slati on loo ka side buffer.

UART

millions of instructions per second.

reduced instruction set computer.

universal asynchro n ous

receiver.

Definition

Table 1. Acronyms and Abbreviations

10 DS453PP2

Table 1. Acronyms and Abbreviations (cont.)

Page 11

1.2 Units of Measurement 1.3 General Conventions

EP7209

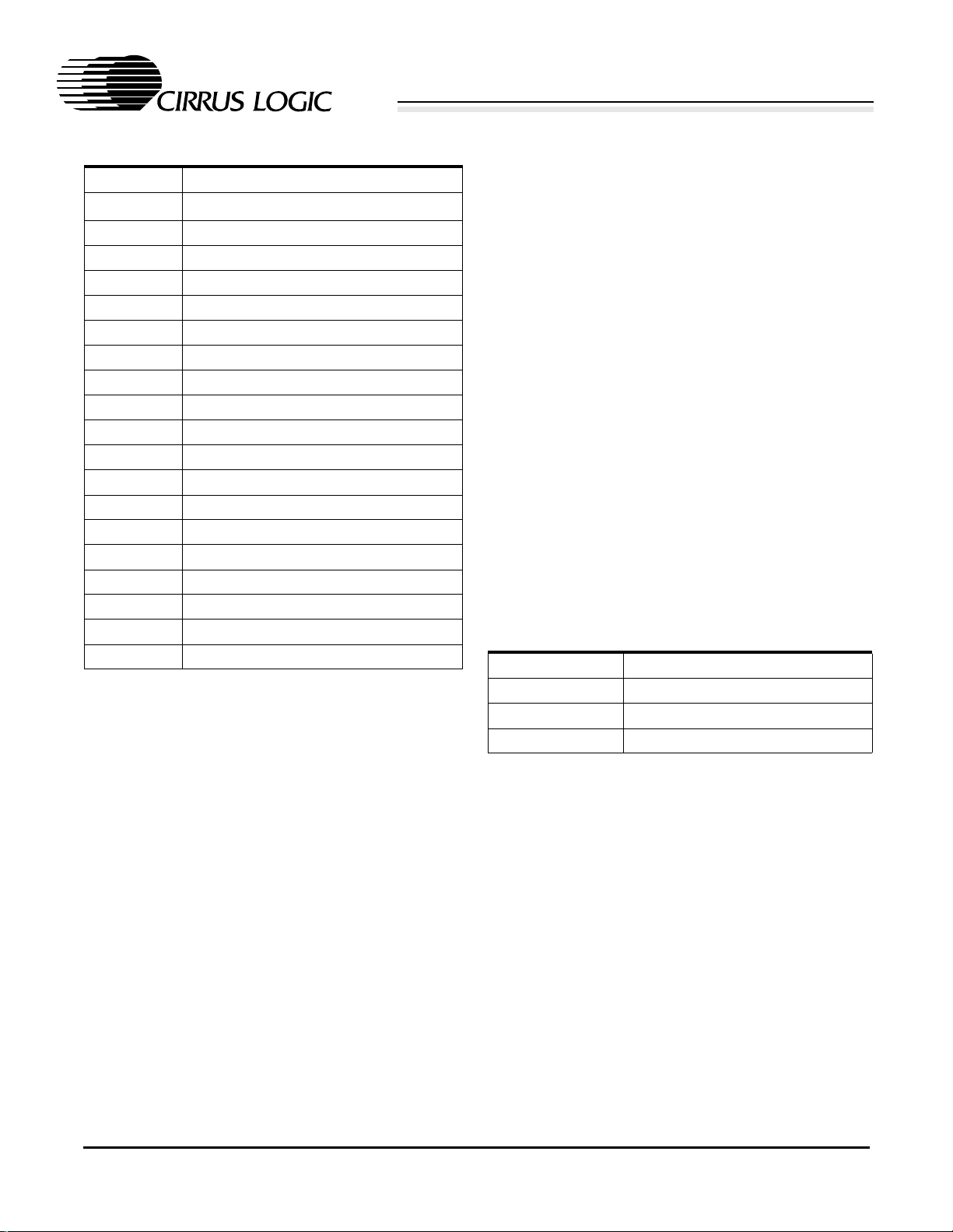

Symbol Unit of Measure

°C

Hz hertz (cycle per second)

kbits/s kilobits per second

kbyte kilobyte (1,024 bytes)

kHz kilohertz

Ω kilohm

k

Mbps megabits (1,048,576 bits) per second

Mbyte megabyte (1,048,576 bytes)

MHz megahertz (1,000 kilohertz)

µAmicroampere

µFmicrofarad

µWmicrowatt

µs microsecond (1,000 nanoseconds)

mA milliampere

mW milliwatt

ms millisecond (1,000 microseconds)

ns nanosecond

Vvolt

Wwatt

degree Celsius

Table 2. Unit of Measurement

Hexadecimal numbers are presen ted with all l etters

in uppercase and a lowercase ‘h’ appended or with

a 0x at the beginning. For example, 0x14 and

03CAh are hexadecimal numbers. Binary numbers

are enclosed in single quotation marks when in text

(for example, ‘11’ designates a binary number).

Numbers not indicated by an ‘h’, 0x or quotation

marks are decimal.

Registers are referred to by acronym, as listed in

the tables on the previous page, with bits listed in

brackets MSB-to-LSB separated by a colon (:) (for

example, CODR[7:0]), or LSB-to-MSB separated

by a hyphen (for example, CODR[0–2]).

The use of ‘tbd’ indicates values that are ‘to be determined’, ‘n/a’ designates ‘not available’, and

‘n/c’ indicates a pin that is a ‘no connect’.

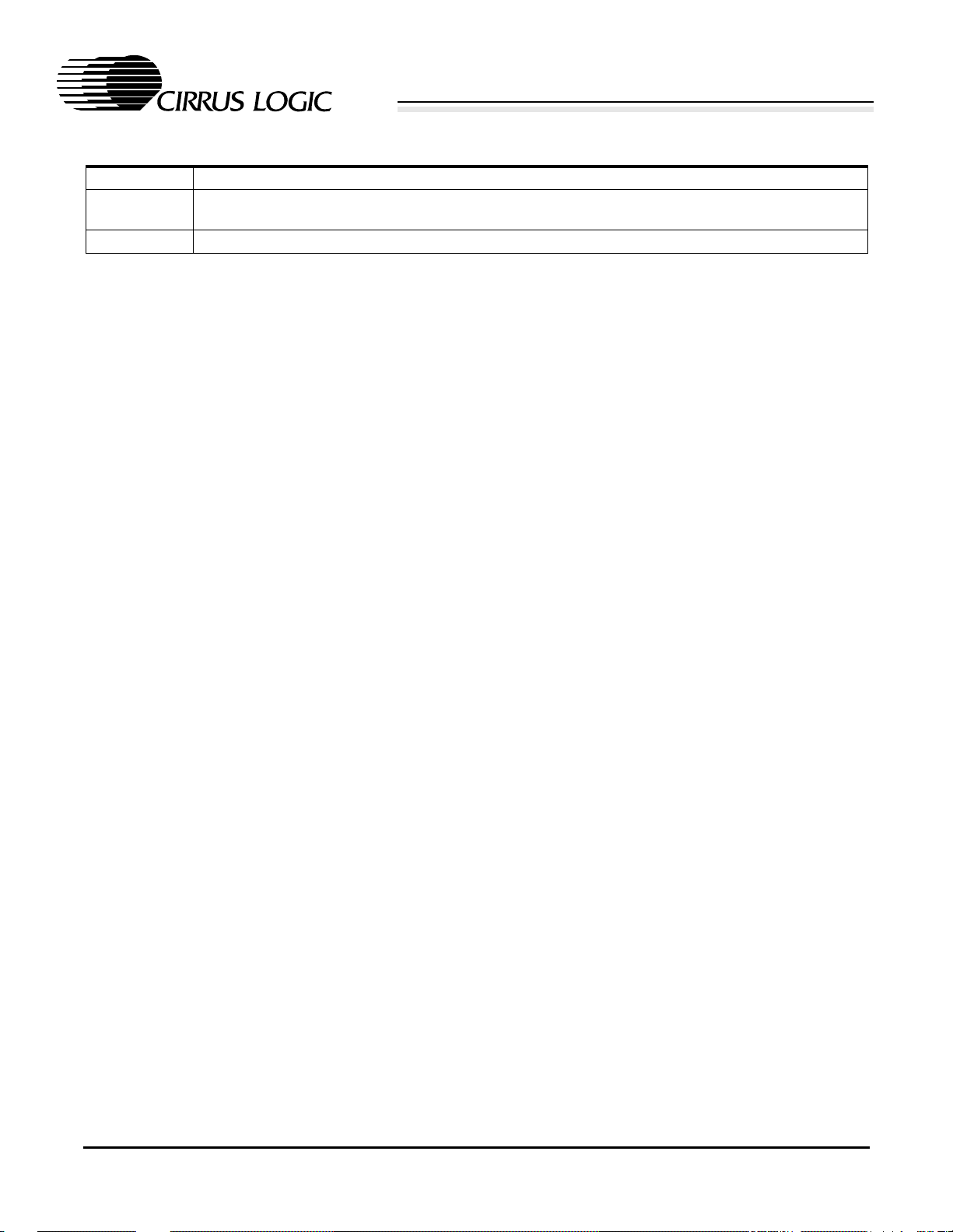

1.4 Pin Description Conventions

Abbreviations used for signal directions are listed

in Table 3.

Abbreviation Direction

I Input

OOutput

I/O Input or Output

DS453PP2

Table 3. Pin Description Conventions

11

Page 12

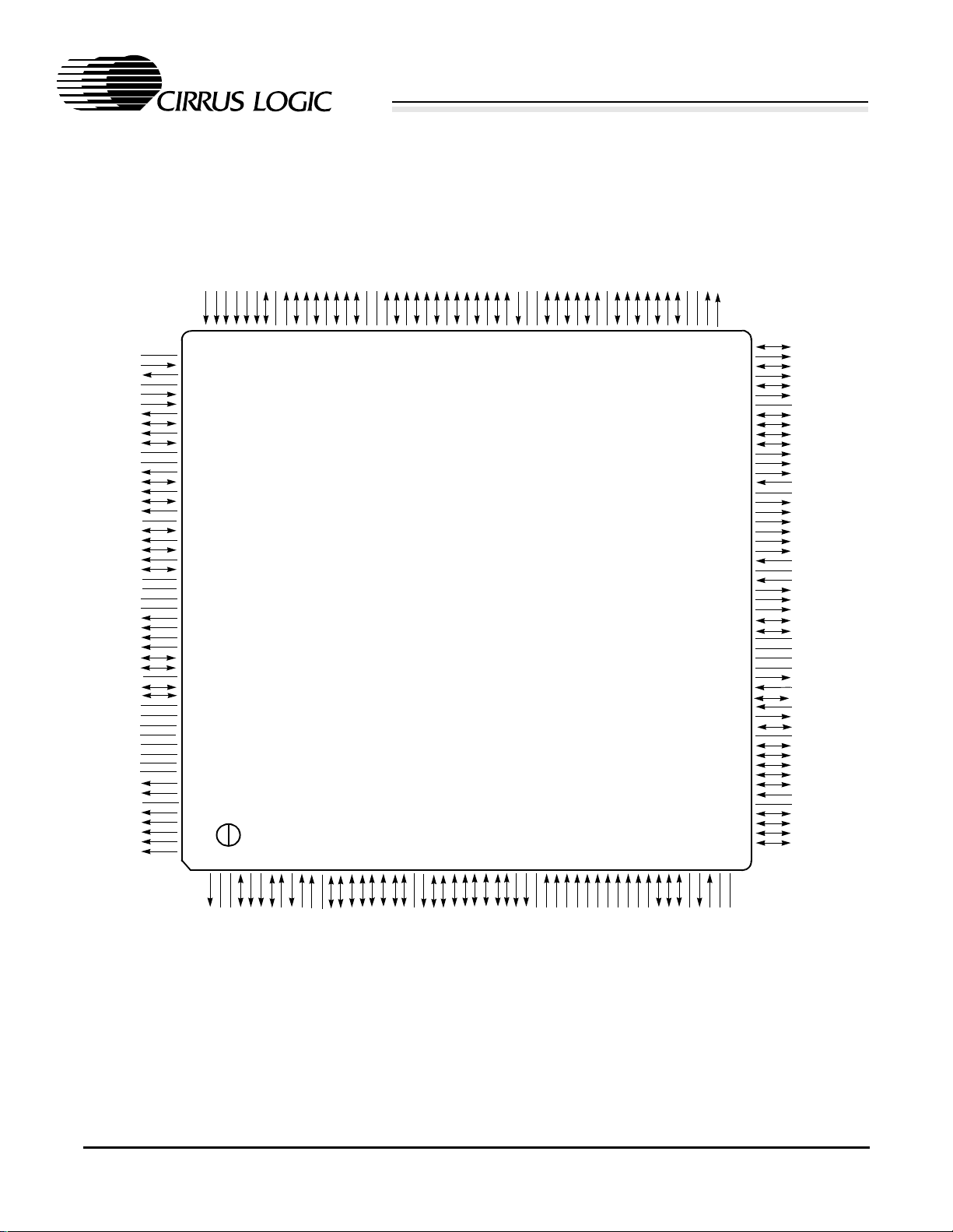

2. PIN INFORMATION

2.1 208-Pin LQFP Pin Diagram

NEXTPWR

BATOK

NPOR

VDDOSC

MOSCIN

MOSCOUT

VSSOSC

WAKEUP

NPWRFL

A[6]

D[6]

A[5]

D[5]

VDDIO

VSSIO

A[4]

D[4]

A[3]

D[3]

A[2]

VSSIO

D[2]

A[1]

D[1]

A[0]

D[0]

VSSCORE

VDDCORE

VSSIO

VDDIO

CL[2]

CL[1]

FRM

DD[3]

DD[2]

VSSIO

DD[1]

DD[0]

N/C

N/C

N/C

N/C

VDDIO

VSSIO

N/C

N/C

NMWE

NMOE

VSSIO

NCS[0]

NCS[1]

NCS[2]

NCS[3]

NCS[4]

NURESET

NMEDCHG/NBROM

156

155

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

M

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

1

D[7]

A[7]

D[8]

A[8]

D[9]

D[10]

154

153

152

NBATCHG

151

150

VSSIO

149

148

147

146

145

A[9]

144

143

A[10]

142

D[11]

141

2345678910111213141516171819202122232425262728293031323334353637383940414243444546474849515052

VSSIO

VDDIO

A[11]

D[12]

A[12]

D[13]

A[13]

140

139

138

137

136

134

135

EP7209

208-Pin LQFP

(Top View)

D[14]

133

A[14]

132

D[15]

131

A[15]

130

D[16]

129

A[16]

128

D[17]

127

A[17]

126

NTRST

125

VSSIO

124

VDDIO

D[18]

122

123

A[18]

121

D[19]

120

EP7209

A[19]

D[20]

VSSIO

A[21]

D[22]

D[23]

A[23]

D[24]

VSSIO

VDDIO

A[24]

109

108

107

106

HALFWORD

105

104

103

102

101

100

D[25]

A[25]

D[26]

A[26]

D[27]

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

A[27]

VSSIO

D[28]

D[29]

D[30]

D[31]

BUZ

COL[0]

COL[1]

TCLK

VDDIO

COL[2]

COL[3]

COL[4]

COL[5]

COL[6]

COL[7]

FB[0]

VSSIO

FB[1]

SMPCLK

ADCOUT

ADCCLK

DRIVE[0]

DRIVE[1]

VDDIO

VSSIO

VDDCORE

VSSCORE

NADCCS

ADCIN

SSIRXFR

SSIRXDA

SSITXDA

SSITXFR

VSSIO

SSICLK

PD[0]/LEDFL SH

PD[1]

PD[2]

PD[3]

TMS

VDDIO

PD[4]

PD[5]

PD[6]

PD[7]

A[22]

D[21]

A[20]

111

110

112

113

114

115

116

117

118

119

NCS[5]

VSSIO

VDDIO

TDI

PB[7]

PB[6]

PB[5]

PB[4]

TXD[2]

WORD

WRITE

EXPCLK

VSSIO

RXD[2]

EXPRDY

PB[3]

RUN/CLKEN

TDO

PA[6]

PA[5]

PA[3]

PA[2]

PA[1]

PB[2]

PA[7]

VDDIO

PB[1]/PRDY[2]

PB[0]/PRDY[1]

PA[0]

PA[4]

TXD[1]

LEDDRV

CTS

DSR

DCD

VSSIO

PHDIN

RXD[1]

EINT[3]

NEINT[2]

NEINT[1]

NTEST[1]

NEXTFIQ

NTEST[0]

PE[2]/CLKSEL

PE[1]BOOTSEL[1]

PE[0]BOOTSEL[0]

N/C

RTCIN

VDDRTC

VSSRTC

RTCOUT

Notes: 1)For package specifications, please see 208--Pin LQFP Package Outline Drawing on page 117

2)N/C should not be grounded but left as no connects

Figure 1. 208-Pin LQFP (Low Profile Quad Flat Pack) Pin Diagram

12 DS453PP2

Page 13

EP7209

2.2 Pin Descriptions

Table 4 describes the function of all the external signals to the EP7209. Note that all output signals are tri-

stateable to enable the Hi-Z test modes to be supported.

2.2.1 External Signal Functions

Function Signal

Signal Description

Name

Data bus D[0:31] I/O 32-bit system data bus for memory and I/O interface

A[0:27] O 28 bits of system byte address during memory and expansion cycles

Whenever the EP7209 is in the Standby State, the external address and data

Address bus

nMOE O Memory output enable, active low

nMWE O Memory write enable, active low

nCS[0:3] O Chip select; active low, SRAM-like chip selects for expansion

nCS[4:5] O Chip select; active low, CS for expansion or for CL-PS6700 select

EXPRDY I

WRITE O Write strobe, low during reads, high during writes from the EP7209

buses are driven low. The RUN signal is used internally to force these buses to

be driven low. This is done to p reve nt perip herals that are powe red-d own from

draining current. Also, the internal peripheral’s signals get set to their Reset

State.

Expansion port ready; external expansion devices drive this low to extend the

bus cycle. This is used to insert wait states for an external bus cycle.

To do write accesses of dif fere nt siz es W ord and Hal f-W ord mus t be extern ally

decoded. The encoding of these signals is as follows:

Access Size Word Half-Word

Word 1 0

Memory

Interface

Half-Word * 1

Byte 0 0

DS453PP2

WORD/

HALFWORD

EXPCLK I/O

O

The core will generate an address. When doing a read, the ARM core will

select the appropriate byte channels. When doing a write, the correct bytes

will have to be enabled depending on the above signals and the least significant bits of the address bus.

The ARM architecture does no t sup port un ali gne d ac ces s es. For a read using

x 32 memory, it is assumed tha t y ou w ill i gno re b it s 1 an d 0 of the address bus

and perform a word rea d (or i n po wer c ritical systems decode the relevan t bits

depending on the size of the access). If an unaligned read takes place, the

core will rotate the resulting data in the register. For more information on this

behavior see the LDR instruction in the ARM7TDMI data sheet.

Expansion cl oc k ra te i s t he s am e a s the CP U clock for 13 MHz and 18MHz. It

runs at 36.864 MHz for 36,49 and 74 MHz modes; in 13 MHz mode this pin is

used as the clock input.

Table 4. External Signal Functions

13

Page 14

EP7209

Function Signal

Name

nMEDCHG/

nBROM

Interrupts

Power

Management

nEXTFIQ I External active low fast interrupt request input

EINT[3] I External active high interrupt request input

nEINT[1:2] I Two general purpose, active low interrupt inputs

nPWRFL

BATOK

nEXTPWR I

nBATCHG

nPOR I

Signal Description

Media changed input; active low, deglitched. Used as a general purpose FIQ

interrupt during normal ope r ati on. It is also us ed on pow er up to co nfi gure the

I

processor to either boot from the internal Boot ROM, or from external memory.

When low, the chip will boot from the internal Boot ROM.

1

1

1

Power fail input; active low, deglitched input to force system into the Standby

I

State

Main battery OK input; fallin g edge gen erates a FIQ, a low lev el in th e Standby

I

State inhibits system start up; deglitched input

External power sense; must be driven low if the system is powered by an

external source

New battery sense; driven low if battery voltage falls below the "no-battery"

I

threshold; it is a deglitched input

Power-on reset input. This signal is not deglitched. When active it completely

resets the entire system, including all the RTC registers. Upon power-up, the

signal must be held active low for a minimum of 100 µsec after Vdd has settled. During normal operation, nPOR needs to be held low for at least one

clock cycle of the selected clock speed (i.e., when running at 13 MHz, the

pulse width of nPOR needs to be > 77 nsec).

State Control

DAI, Codec or

SSI2

Interface

(See Table 5 for

SSI2/Codec/DAI

Pin Multiplexing)

Note that nURESET, RUN/CLKEN, TEST(0), TEST(1), PE(0), PE(1), PE(2),

DRIVE(0), DRIVE(1), DD(0), DD(1), DD(2), and DD(3) are al l latched on rising

edge of nPOR.

This pin is programmed to either output the RUN signal or the CLKEN signal.

The CLKENSL bit is used to configure this pin. When RUN is selected, the pin

RUN/CLKEN I/O

WAKEUP

nURESET

SSICLK I/O DAI/Codec/SSI2 clock signal

SSITXFR I/O DAI/Codec/SSI2 serial data output frame/synchronization pulse output

SSITXDA O DAI/Codec/SSI2 serial data output

SSIRXDA I

SSIRXFR I/O

1

1

will be high when the system is active or idle, low while in the Standby State.

When CLKEN is selected, the pin will only be driven low when in the Standby

State (For RUN, see Table 6).

Wake up deglitched input signal; rising edge forces system into the Operating

State from the Standby State; active after an nPOR reset. The wakeup signa l

can not be used to exit Idle, only Standby. Wakeup must wait at least 2 sec-

I

onds before it goes high for it to be detected by the CPU. It must also be held

high for at least 125

first detection has no effect (i.e., it is ignored).

User reset input; active low deglitched input from user reset button.

This pin is also latched upon the rising edge of nPOR and read along with the

I

input pins nTEST[0:1] to force the device into special test modes. nURESET

does not reset the RTC.

DAI/Codec/SSI2 seri al data input

SSI2 serial data input frame/synchronizati on pulse

DAI external clock input

µsec to guarantee its detection. Toggling wakeup after its

Table 4. External Signal Functions (cont.)

14 DS453PP2

Page 15

EP7209

Function Signal

Name

ADCCLK O Serial clock output

ADC

Interface

(SSI1)

IrDA and

RS232

Interfaces

LCD

Keyboard &

Buzzer drive

LED Flasher

General

Purpose I/O

PWM

Drives

nADCCS O Chip select for ADC interface

ADCOUT O Seria l data output

ADCIN I Serial data input

SMPCLK O Sample cloc k output

LEDDRV O Infrared LED drive output (UART1)

PHDIN I Photo diode input (UART1)

TXD[1:2] O RS232 UART1 and 2 TX outputs

RXD[1:2] I RS232 UART1 and 2 RX inputs

DSR I RS232 DSR input

DCD I RS232 DCD input

CTS I RS232 CTS input

DD[0:3] I/O

CL[1] O LCD line clock

CL[2] O LCD pixel clock

FRM O LCD frame synchronization pulse output

M O LCD AC bias drive

COL[0:7] O Keyboard column drives (SYSCON1)

BUZ O Buzzer drive output (SYSCON1)

PD[0]/

LEDFLSH

PA[0:7] I/O

PB[0]/PRDY1

PB[1]/PRDY2

PB[2:7]

PD[0:7] I/O Port D I/O

PE[0]/

BOOTSEL[0]

PE[1]/

BOOTSEL[1]

PE[2]/

CLKSEL

DRIVE[0:1] I/O

FB[0:1] I PWM feedback inputs

Signal Description

LCD serial display data; pins can be used on power up to read the ID of some

LCD modules (See Table 6).

LED flasher driver — multiplexed with Port D bit 0. This pin can provide up to

O

4 mA of drive current.

Port A I/O (bit 6 for boot clock option, bit 7 for CL-PS6700 PRDY input); also

used as keyboard row inputs

Port B I/O. All eight Port B bits can be used as GPIOs.

When the PC CARD1 or 2 control bits in the SYSCON2 register are de-

I/O

asserted, PB[0] and PB[1] are available for GPIO. When asserted, these port

bits are used as the PRDY signals for connected CL-PS6700 PC Card Host

Adapter devices.

Port E I/O (3 bits only). Can be used as general purpose I/O during normal

I/O

operation.

During power-on reset, PE[0] and PE[1] are inputs and are latched by the ris-

I/O

ing edge of nPOR to s el ect the me mo ry wi d th tha t th e EP7209 will use to read

from the boot code storage device (i.e., external 8-bit-wide FLASH bank).

During power-on reset, PE[2] is latched by the rising edge of nPOR to select

I/O

the clock mode of operation (i.e., either the PLL or external 13 MHz clock

mode).

PWM drive ou tputs. These pins are inputs on power up to determine what

polarity the output of the PWM should be when active. Otherwise, these pins

are always an output (See Table 6).

DS453PP2

Table 4. External Signal Functions (cont.)

15

Page 16

EP7209

Function Signal

Signal Description

Name

TDI I JTAG data in

Boundary

Scan

Test nTEST[0:1] I

Oscillators

No connects N/C No connects should be left as no connects; do not connect to ground

TDO O JTAG data out

TMS I JTAG mode select

TCLK I JTAG clock

nTRST I JTAG async reset

Test mode select input s. Th ese pi ns are u sed in conju nction with t he power-o n

latched state of nURESET to select between the various device test models.

MOSCIN

MOSCOUT

RTCIN

RTCOUT

I

Main 3.6864 MHz oscillator for 18.432 MHz–73.728 MHz PLL

O

I

Real Time Clock 32.768 kHz oscillator

O

Table 4. External Signal Functions (cont.)

1. All deglitched inputs are via the 16.384 kHz clock. Each deglitched signal must be held active for at least two clock periods. Therefore, the

input signal must be active for at least ~125

µs to be detected cleanly.

NOTE: The RTC crystal must be populated for the device to function properly.

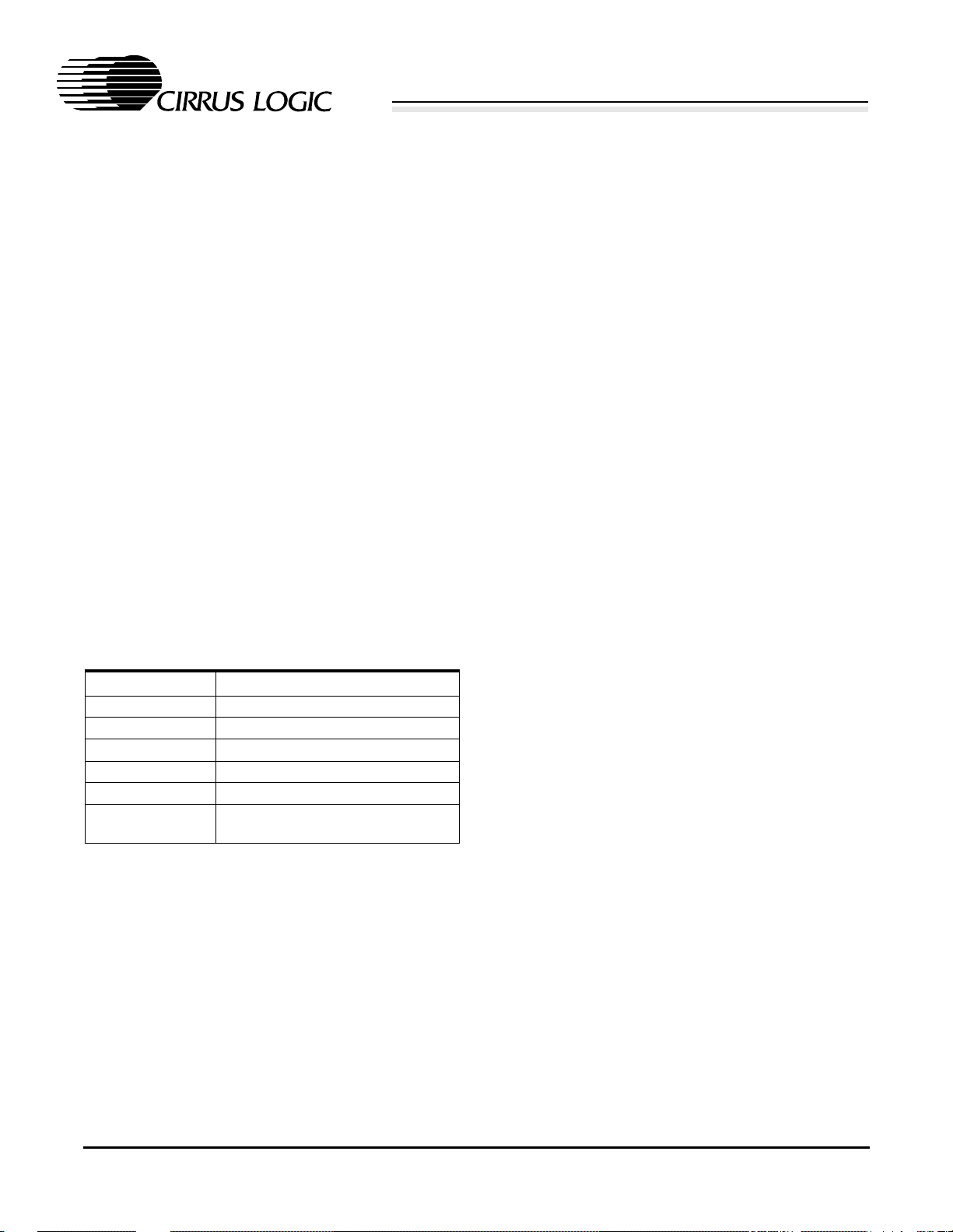

2.2.2 SSI/Codec/DAI Pin Multiplexing

SSI2 Codec DAI Direction Strength

SSICLK PCMCLK SCLK I/O 1

SSITXFR PCMSYNC LRCK I/O 1

SSITXDA PCMOUT SDOUT Output 1

SSIRXDA PCMIN SDIN Input

SSIRXFR p/u* MCLK I/O 1

* p/u = use an ~10 k pull-up

The selection between SSI2 and the codec is controlled by the state of the SERSEL bit in SYSCON2 (See

SYSCON2 System Control Register 2). The choice between the SSI2, codec, and the DAI is controlled by

the DAISEL bit in SYSCON3 (See SYSCON3 System Control Register 3).

Table 5. SSI/Codec/DAI Pin Multiplex ing

16 DS453PP2

Page 17

EP7209

2.2.3 Output Bi-Directional Pins

RUN The RUN pin is looped back in to skew the address and data bus from each other.

Drive [0:1] Drive 0 and 1 are looped back in on power up to determine what polarity the output of the PWM should be

when active.

DD[3:0] DD[3:0] are looped back in on power up to enable the reading of the ID of some LCD modules.

NOTE: The above output pins ar e implemen ted as b i-direction al pins to enable the out put side of the pad to

be monitored and hence provide more accurate control of timing or duration:

Table 6. Output Bi-Directional Pins

DS453PP2

17

Page 18

EP7209

3. FUNCTIONAL DESCRIPTION

The EP7209 device is a single-chip embedded controller designed to be used in low cost and ultralow-power digital audio players. Operating at

74 MHz, the EP7209 delivers approximately

66 Dhrystone 2.1 MIPS of sustained performance

(74 MIPS peak). This is approximately the same as

a 100 MHz Pentium-based PC.

The EP7209 contains the following functional

blocks:

• ARM720T processor which consists of the fol-

lowing functional sub-blocks:

- ARM7TDMI CPU core (which supports

the logic for the Thumb instruction set, core

debug, enhanced multiplier, JTAG, and the

Embedded ICE) running at a dynamically

programmable clock speed of 18 MHz,

36 MHz, 49 MHz, or 74 MHz.

- Memory Management Unit (MMU) compatible with the ARM710 core (providing

address translation and a 64 entry translation lookaside buffer) with added support

for Windows CE.

- 8 kbytes of unified instruction and data

cache with a four-way set associative cache

controller.

- Write buffer

• 38,400 bytes (0x9600) of on-chip SRAM that

can be shared between the LCD controller and

general application use.

• Memory interfaces for up to 6 independent

256 Mbyte expansion segments with programming wait states.

• 27 bits of general purpose I/O - multiplexed to

provide additional functionality where necessary.

• Digital Audio Interface (DAI) for connection to

CD-quality DACs and codecs.

• Interrupt controller

• Advanced system state control and power man-

agement.

• Two full-duplex 16550A compatible UARTs

with 16-byte transmit and receive FIFOs.

• IrDA SIR protocol controller capable of speeds

up to 115.2 kbps.

• Programmable 1-, 2-, or 4-bit-per-pixel LCD

controller with 16-level gray scaler.

• Programmable frame buffer start address, allowing a system to be built using only internal

SRAM for memory.

• On-chip boot ROM programmed with serial

load boot sequence.

• Two 16-bit general purpose timer counters.

• A 32-bit Real Time Clock (RTC) and compar-

ator.

• Dedicated LED flasher pin driven from the

RTC with programmable duty ratio (multiplexed with a GPIO pin).

• Two synchronous serial interfaces for Microwire or SPI peripherals such as ADCs, one supporting both the master and slave mode and the

other supporting only the master mode.

• Full JTAG boundary scan and Embedded ICE

support.

• Two programmable pulse-width modulation

interfaces.

• An interface to one or two Cirrus Logic CLPS6700 PC Card controller devices to support

two PC Card slots.

18 DS453PP2

Page 19

EP7209

• Oscillator and phase locked loop (PLL) to generate the core clock speeds of 18.432 MHz,

36.864 MHz, 49.152 MHz, and 73.728 MHz

from an external 3.6864 MHz crystal, with an

alternative external clock input (used in

13 MHz mode).

• A low power 32.768 kHz oscillator.

The EP7209 design is optimized for low power dissipation and is fabricated on a fully static

0.25 micron CMOS process. It is available in a

256-ball PBGA or a 208-pin LQFP package.

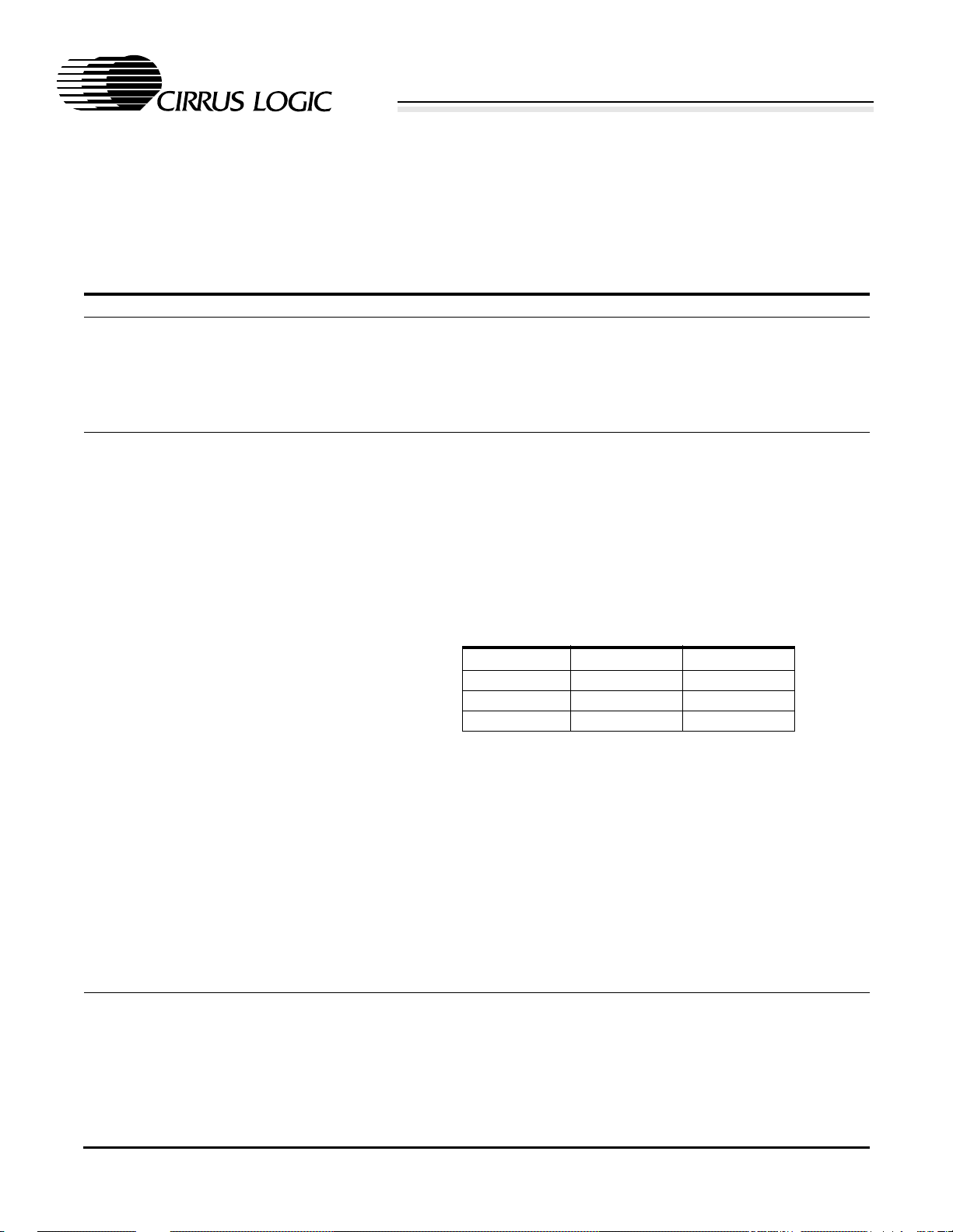

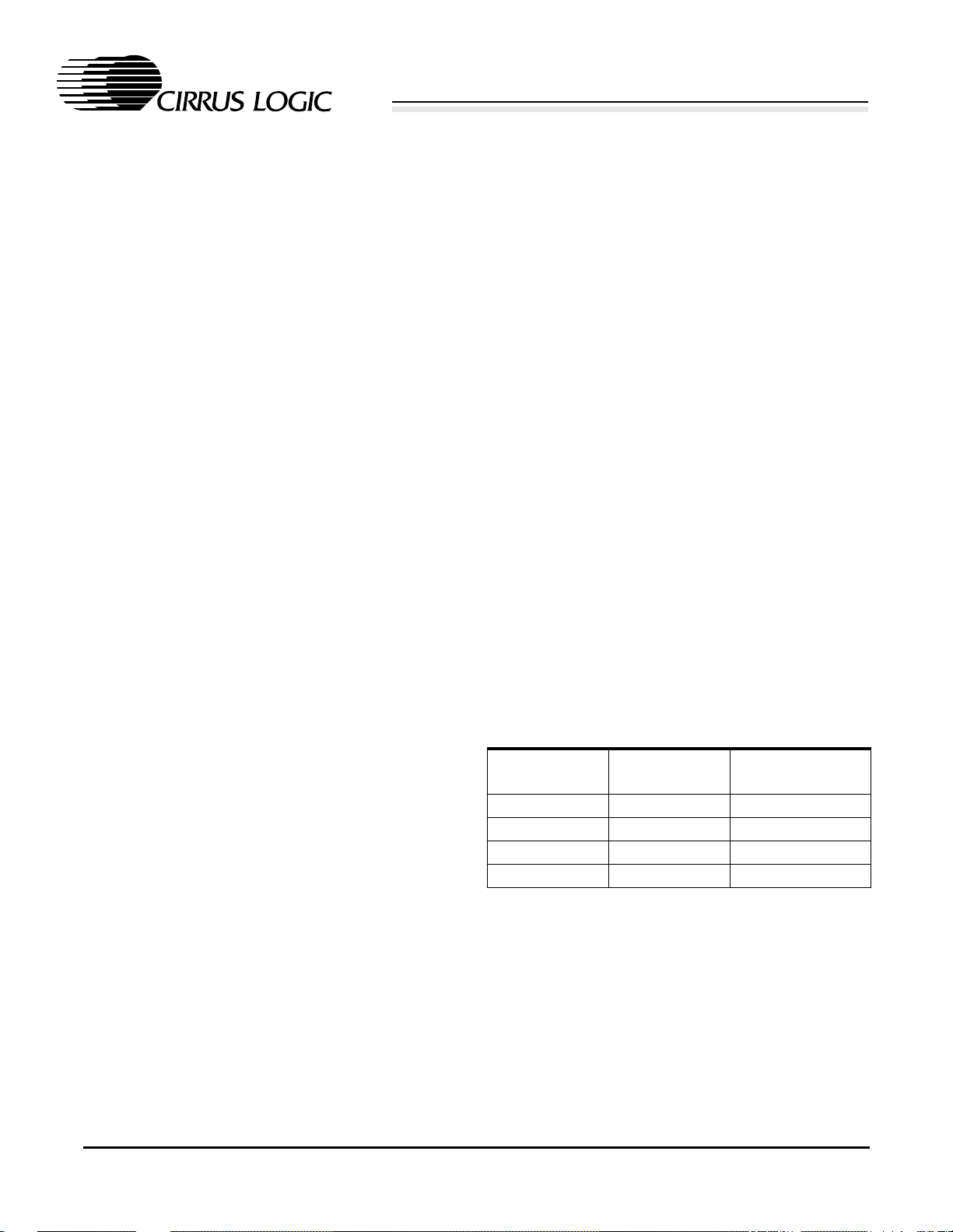

Figure 2 shows a simplified block diagram of the

EP7209. All external memory and peripheral devices are connected to the 32-bit data bus using the

external 28-bit address bus and control signals.

3.1 CPU Core

The ARM720T consists of an ARM7TDMI 32-bit

RISC processor, a unified cache, and a memory

management unit (MMU). The cache is four-way

set associative with 8-kbytes organized as 512 lines

of 4 words. The cache is directly connected to the

ARM7TDMI, and therefore caches the virtual address from the CPU. When the cache misses, the

MMU translates the virtual address into a physical

address. A 64-entry translation lookaside buffer

(TLB) is utilized to speed the address translation

process and reduce bus traffic necessary to read the

page table. The MMU saves power by only translating the cache misses.

See the ARM720T Data sheet for a complete description of the various logic blocks that make up

the processor, as well as all internal registe r information.

13-MHZ INPUT

3.6864 MHZ

32.768 KHZ

NPOR, RUN,

RESET, WAKEUP

BAT OK, NEXTPWR

PWRFL, BATCHG

EINT[1:3], FIQ,

MEDCHG

FLASHING LED DRIVE

PORTS A, B, D (8-B IT)

PORT E (3-BIT)

KEYBD DRIVERS (0:7)

BUZZER DRIVE

DC-TO-DC

ADCCLK, ADCIN,

ADCOUT, SMPCLK,

SSICLK, SSITXFR,

SSITXDA, SSIRXDA,

ADCCS

SSIRSFR

PLL

32.768-KHZ

OSCILLATOR

STATE CONTRO L

POWER

MANAGEMENT

INTERRUPT

CONTROLLER

RTC

GPIO

PWM

SSI1 (ADC)

DAI

SSI2

CODEC

INTERNAL DATA BUS

ARM720T

ARM7TDMI

CPU CORE

8-KBYTE

CACHE

MMU

WRITE

BUFFER

TIMER

COUNTERS (2)

ON-CHIP

BOOT ROM

EPB BRIDGE

EPB BUS

MEMORY CONTROLLER

CL-PS6700

INTFC.

EXPANSION

CONTROL

INTERNAL ADDRESS BUS

LCD

DMA

LCD

CONTROLLER

ON-CHIP SRAM

38,400 BYTES

UART1

UART2

Figure 2. EP7209 Block Diagram

ICE-JTAG

IrDA

D[0:31]

PB[0:1], NCS[4:5]

EXPCLK, WORD, NCS[0:3],

EXPRDY, WRITE

A[0:27],

DRA[0:12]

TEST AND

DEVELOPMENT

LCD DRIVE

LED AND

PHOTODIODE

ASYNC

INTERFACE 1

ASYNC

INTERFACE 2

DS453PP2

19

Page 20

EP7209

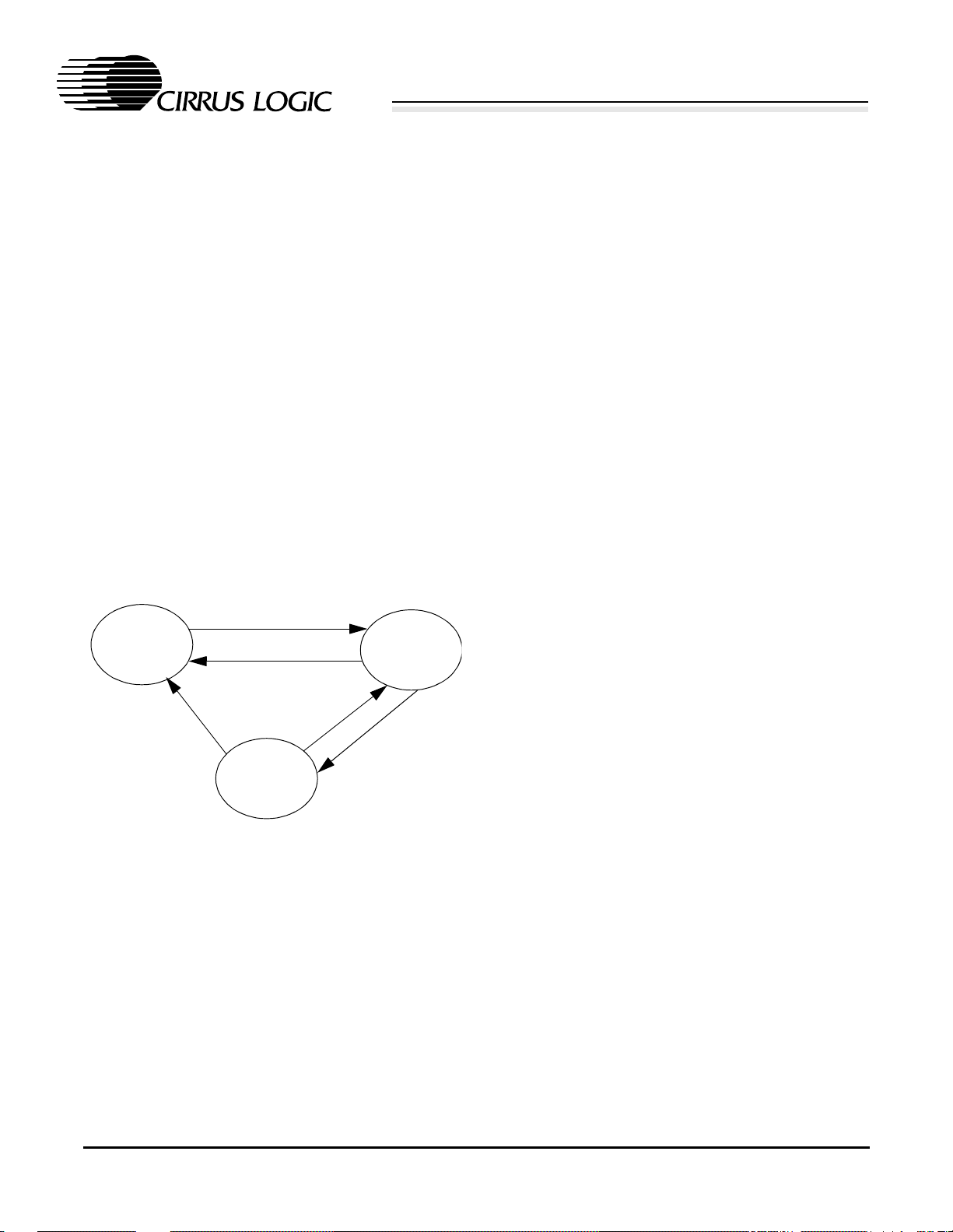

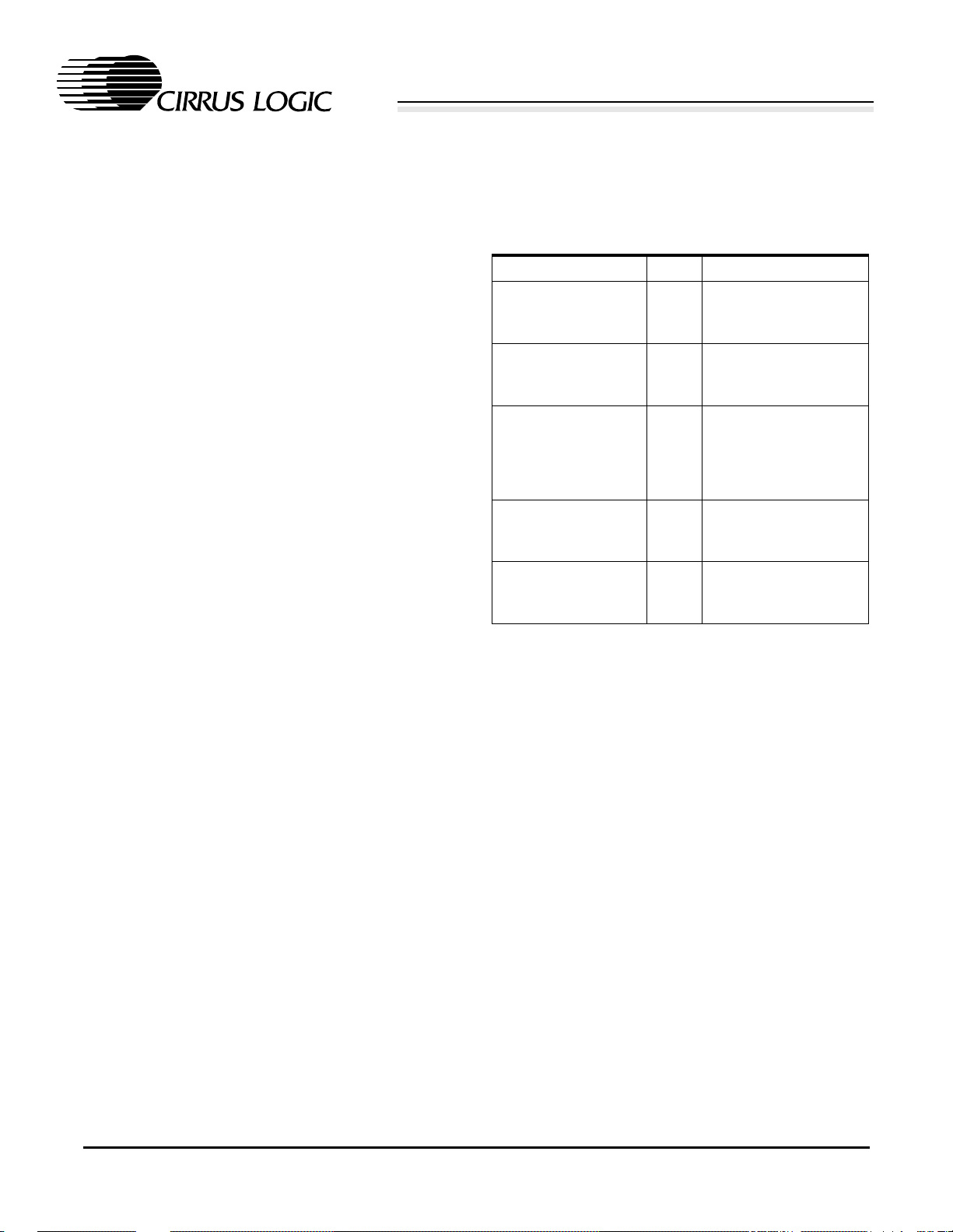

Figure 3. State Diagram

Standby

Operating

Idle

Interrupt or r ising wakeup

Write to standby location,

power fail, or user reset

I

n

t

e

r

r

u

p

t

Write to halt location

nPOR, power fail,

or user reset

3.2 State Control

The EP7209 supports the following Power Management States: Operating, Idle, and Standby (see

Figure 3). The normal program execution state is

the Operating State; this is a full performance state

where all of the clocks and peripheral logic are enabled. The Idle State is the same as the Operating

State with the exception of the CPU clock being

halted, and an interrupt or wakeup will return it

back to the Operating State. The Standby State has

the lowest power consumption, selecting this mode

shuts down the main oscillator, leaving only the

Real Time Clock and its associated logic powered.

It is important when the EP7209 is in Standby that

all power and ground pins remain connected to

power and ground in order to have a proper system

wake-up. The only state that Standby can transition

to is the Operating State.

3.2.1 Standby State

The Standby State equates to the system being

switched "off" (i.e., no display, and the main oscillator is shut down). When the 18.432–73.72 MHz

mode is selected, the PLL will be shut down. In the

13 MHz mode, if the CLKENSL bit is set low, then

the CLKEN signal will be forced low and can, if required, be used to disable an external oscillator.

In the Standby State, all the system memory and

state is maintained and the system time is kept upto-date. The PLL/on-chip oscillator or external oscillator is disabled and the system is static, except

for the low power watch crystal (32 kHz) oscillator

and divider chain to the RTC and LED flasher. The

RUN signal is driven low and this signal can be

used externally in the system to power down other

system modules.

Whenever the EP7209 is in the Standby State, the

external address and data buses are forced low internally by the RUN signal. Thi s i s do ne to preve nt

peripherals that are powered-down from draining

current. Also, the internal peripheral’s signals get

set to their Reset State.

In the description below, the RUN/CLKEN pin can

be used either for the RUN functionality, or the

CLKEN functionality to allow an external oscillator to be disabled in the 13 MHz mode. Either RUN

or CLKEN functionality can be selected according

to the state of the CLKENSL bit in the SYSCON2

register. Table 7 on the following page shows peripheral status in various power management

states.

When first powered, or reset by the nPOR (Power

On Reset, active low) signal, the EP7209 is forced

into the Standby State. This is known as a cold reset, and when leaving the Standby State after a cold

reset, external wake up is the only way to wake up

the device. When leaving the Standby State after

non-cold reset conditions (i.e., the software has

forced the device into the Standby State), the transition to the Operating State can be caused by a rising edge on the WAKEUP input signal or by an

enabled interrupt. Normally, when entering the

Standby State from the Operating State, the software will leave some interrupt sources enabled.

NOTE: The CPU cannot be awakened by the T INT,

WEINT, and BLINT interrupts when in the

Standby State.

20 DS453PP2

Page 21

EP7209

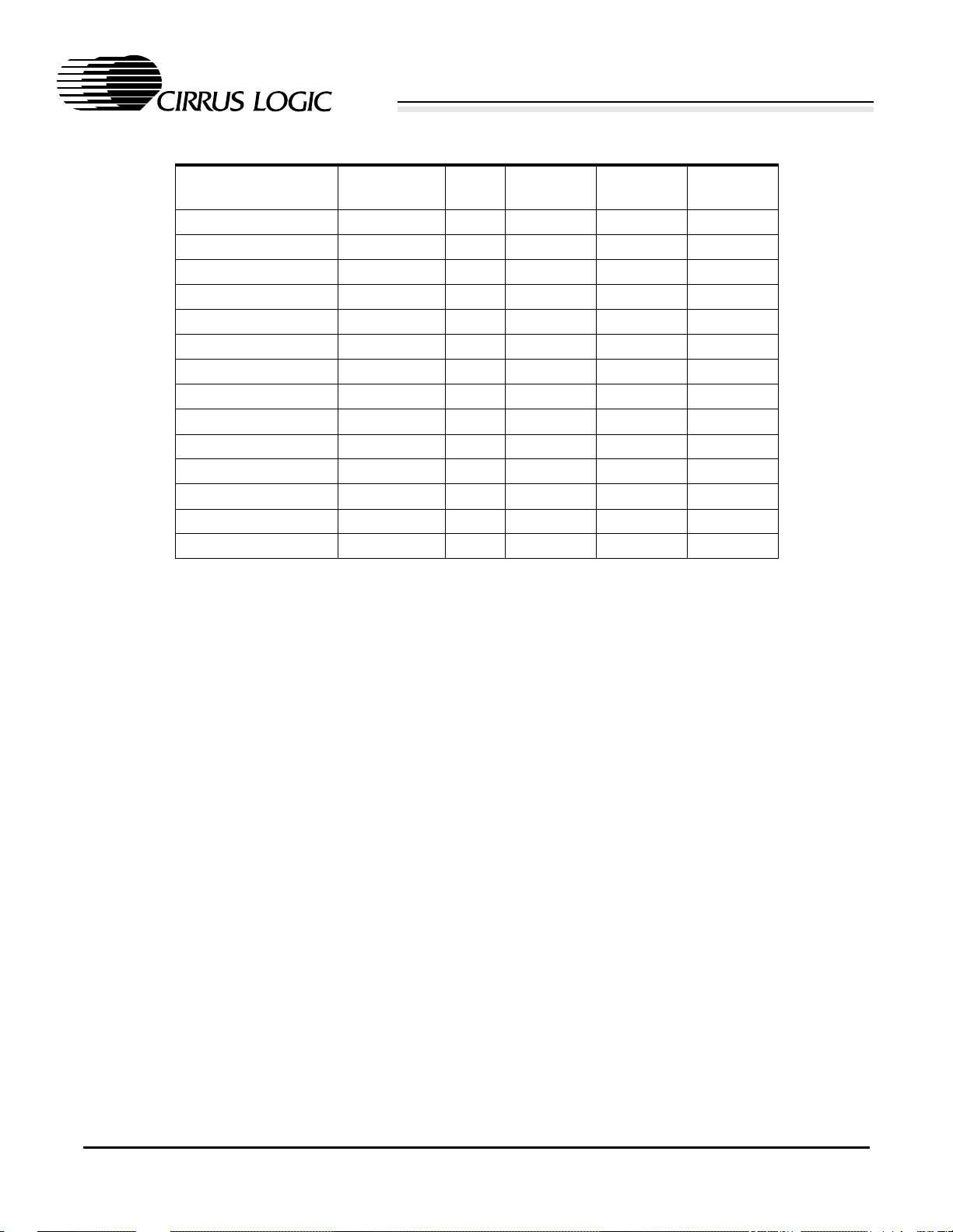

Address (W/B) Operating Idle Standby nPOR

UARTs

LCD FIFO

LCD

ADC Interface

SSI2 Interface

DAI Interface

Codec

Timers

RTC

LED Flasher

DC-to-DC

CPU

Interrupt Control

PLL/CLKEN Signal

Table 7. Peripheral Status in Different Power Management States

On On Off Reset Reset

On On Reset Reset Reset

On On Off Reset Reset

On On Off Reset Reset

On On Off Reset Reset

On On Off Reset Reset

On On Off Reset Reset

On On Off Reset Reset

On On On On On

On On On Reset Reset

On On Off Reset Reset

On Off Off Reset Reset

On On On Reset Reset

On On Off Off Off

Typically, software writes to the Standby internal

memory location to cause the transition from the

Operating State to the Standby State. Before entering the Standby State, if external I/O devices (such

as the CL-PS6700s connected to nCS[4] or nCS[5])

are in use, the software must c heck to ensure that

they are idle before issuing the write to the Standby

State location.

Before entering the Standby State, the software

must properly disable the DAI. Failing to do so will

result in higher than expected power consumption

in the Standby State, as well as unpredictable operation of the DAI. The DAI ca n be r e-enabled afte r

transitioning back to the Operating State.

nURESET

RESET

RESET

and either the nEXTPWR input pin is low or the

BATOK input pin is high. This prevents the system

from starting when the power supply is inadequate

(i.e., the main batteries are low), corresponding to

a low level on nPWRFL or BATOK.

From the Standby State, if the WAKEUP signal is

applied with no clock except the 32 kHz clock running, the EP7209 will be initialized into a state

where it is ready to start and is waiting for the CPU

to start receiving its clock. The CPU will still be

held in reset at this point. After the first clock is applied, there will be a delay of about eight clock cycles before the CPU is enabled. This delay is to

allow the clock to the CPU time to settle.

The system can also be forced into the Standby

State by hardware if the nPWRFL or nURESET inputs are forced low. The only exit from the Standby

State is to the Operating State.

The system will only transition to the Operating

State from the Standby State under the following

conditions: when the nPWRFL input pin is high

DS453PP2

3.2.1.1 UART in Standby State

During the Standby State, the UARTs are disabled

and cannot detect any activity (i.e., start bit) on the

receiver. If this functionality is required then this

can be accomplished in software by the following