Page 1

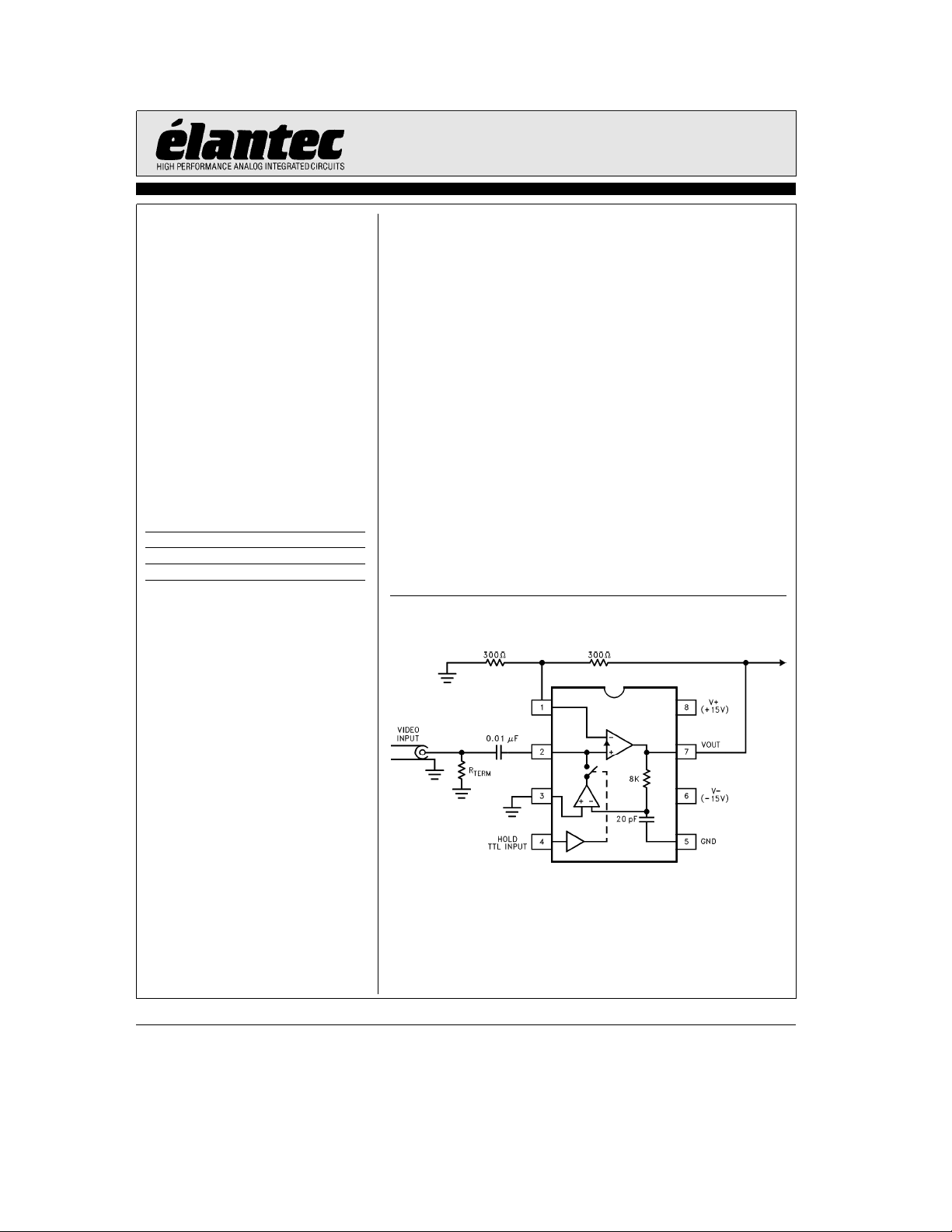

EL4089C

DC Restored Video Amplifier

EL4089C January 1996 Rev B

Features

# Complete video level restoration

system

# 0.02% differential gain and 0.05

differential phase accuracy at

NTSC

# 60 MHz bandwidth

# 0.1 dB flatness to 10 MHz

e

S

g

5V tog15V

# V

# TTL/CMOS hold signal

Applications

# Input amplifier in video

equipment

# Restoration amplifier in video

mixers

Ordering Information

Part No. Temp. Range Package Outline

EL4089CN 0§Ctoa75§C 8-Pin P-DIP MDP0031

EL4089CS 0§Ctoa75§C 8-Lead SO MDP0027

General Description

The EL4089C is an 8-pin complete DC-restored monolithic video amplifier sub-system. It contains a high quality video amplifier and a nulling, sample-and-hold amplifier specifically de-

§

signed to stabilize video performance.

When the HOLD logic input is set to a TTL/CMOS logic 0, the

sample- and-hold amplifier can be used to null the DC offset of

the video amplifer.

When the HOLD input goes to a TTL/CMOS logic l, the correcting voltage is stored on the video amplifier’s input coupling

capacitor. The correction voltage can be further corrected as

need be, on each video line.

The video amplifier is optimized for video performance and low

power. Its current feedback design allows the user to maintain

essentially the same bandwidth over a gain range of nearly 10:1.

The amplifier drives back-terminated 75X lines.

The EL4089C is fabricated in Elantec’s proprietary Comple-

Ý

mentary Bipolar process which produces NPN and PNP transistors with equivalent AC and DC performance. The EL4089C

is specified for operation over 0

Ctoa75§C temperature range.

§

Connection Diagram

DC restoring amplifier with a gain of 2, restoring to ground.

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a ‘‘controlled document’’. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

©

1993 Elantec, Inc.

4089– 1

Page 2

EL4089C

DC Restored Video Amplifier

Absolute Maximum Ratings

a

b

Voltage between V

Voltage between V

and GND pins to (V

Current 60 mA

V

OUT

Current into V

Internal Power Dissipation See Curves

Important Note:

All parameters having Min/Max specifications are guaranteed. The Test Level column indicates the specific device testing actually

performed during production and Quality inspection. Elantec performs most electrical tests using modern high-speed automatic test

equipment, specifically the LTX77 Series system. Unless otherwise noted, all tests are pulsed tests, therefore T

Test Level Test Procedure

I 100% production tested and QA sample tested per QA test plan QCX0002.

II 100% production tested at T

III QA sample tested per QA test plan QCX0002.

IV Parameter is guaranteed (but not tested) by Design and Characterization Data.

V Parameter is typical value at T

and V

, S/H

a

IN

and HOLD Pins 5 mA

b

IN

T

,(V

a

IN

MAX

and T

MIN

A

per QA test plan QCX0002.

e

(T

25§C)

A

33V

a

a

)

0.5V

b)b

0.5V

e

25§C and QA sample tested at T

e

25§C for information purposes only.

A

Operating Ambient

Temperature Range 0

Operating Junction Temperature

Plastic DIP or SOL 150

Storage Temperature Range

Ctoa75§C

§

b

65§Ctoa150§C

e

e

T

TA.

J

C

e

25§C,

A

§

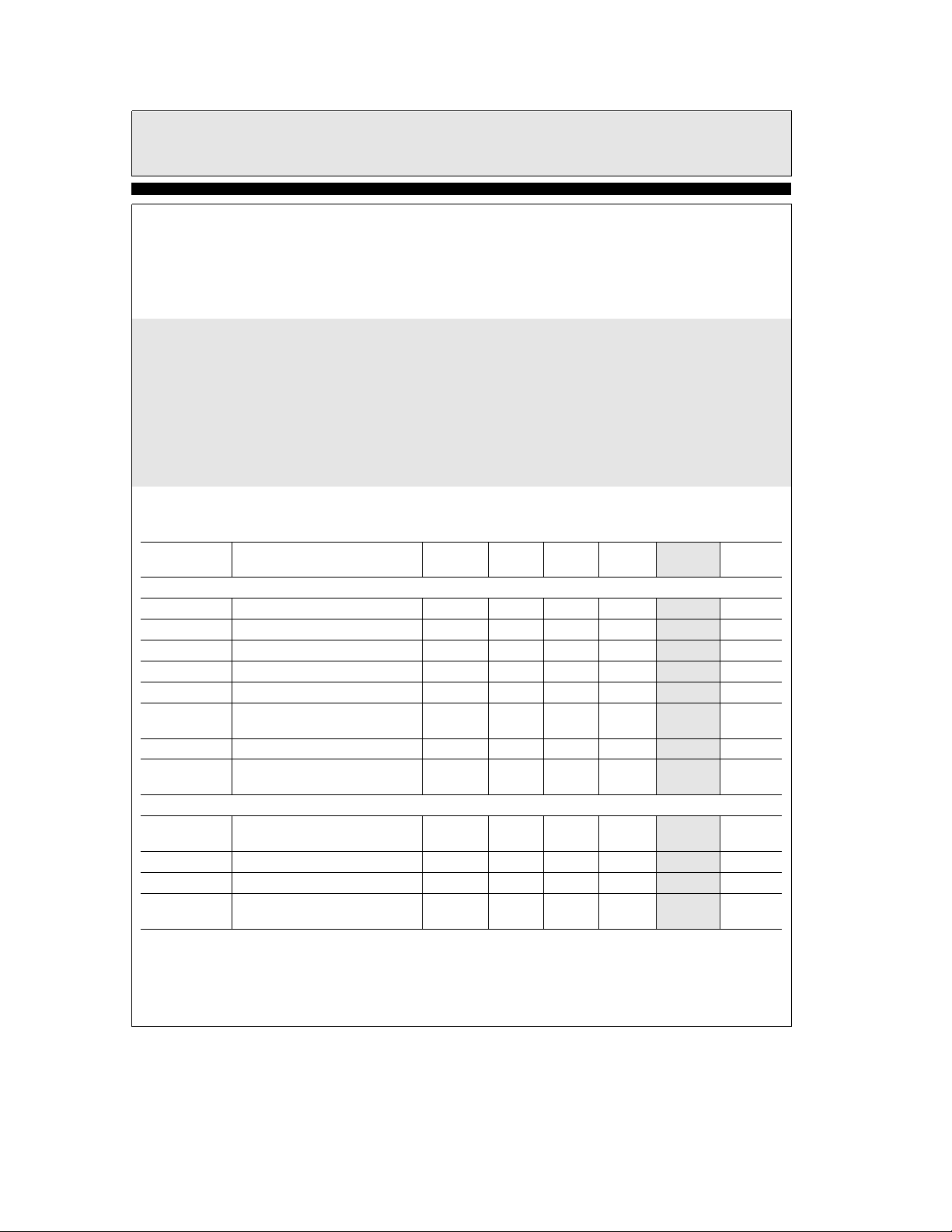

Open Loop DC Electrical Characteristics

Provisional Supplies atg15V, Loade1kX;T

Parameter Description Temp Min Typ Max

Amplifier Section (HOLDe5V)

V

OS

a

Ib

b

Ib

R

OL

R

b

IN

Input Offset Voltage

INaInput Bias Current

INbInput Bias Current

Transimpedance (Note 1)

INbResistance

CMRR Common Mode Rejection Ratio

(Note 2)

V

O

I

SC

Output Voltage Swing

Short Circuit Current

a

Only Driven to 0.5V)

(IN

Restore Section

VOS, Comp Composite Input Offset Voltage

(Note 3)

Iba,r Restore InaInput Bias Current

I

OUT

Restoring Current Available

CMRR Common Mode Rejection Ratio

(Note 2)

A

ea

25§C

Test

Level

a

25§C1225IImV

a

25§C15IImA

a

25§C 18 150 II mA

a

25§C 180 800 II kX

a

25§C20 VX

a

25§C44 60 II dB

a

25§C

a

25§C 45 100 II mA

a

25§C37IImV

a

25§C 3 12 II mA

a

25§C 180 300 II mA

a

25§C60 70 II dB

g

g

12

13 II V

Units

C

TD is 3.5in

2

Page 3

EL4089C

DC Restored Video Amplifier

Open Loop DC Electrical Characteristics

Provisional Supplies atg15V, Loade1kX;T

Parameter Description Temp Min Typ Max

A

ea

25§C

Ð Contd.

Test

Level

Restore Section ÐContd.

PSRR Power Supply Rejection Ratio (Note 4)

V

THRESHOLD

HOLD Logic Threshold

IIH, Hold HOLD Input Current@Logic High

I

, Hold HOLD Input Current@Logic Low

IL

a

25§C60 90 II dB

a

25§C 0.8 2.0 II V

a

25§C15IImA

a

25§C 5 15 II mA

Supply Current

Isy, Hold Supply Current (HOLDe5V)

Isy, Sampling Supply Current (HOLDe0V)

a

25§C 4.8 6.0 9.0 II mA

a

25§C 5.0 6.5 11.0 II mA

Closed Loop AC Electrical Characteristics

Provisional Supplies atg15V, Loade150X and 15 pF. Rfand R

g

e

300X;A

Parameter Description Min Typ Max

Amplifier Section

SR Slew Rate (Note 5) 500 V V/ms

SR Slew Rate withg5V Supplies

(Note 5)

BW Bandwidth

g

5V Supplies

BW Bandwidth

g

5V Supplies

dG Differential Gain V

at 3.58 MHz (Note 6) V

dPh Differential Phase V

at 3.58 MHz (Note 6) V

b

3 dB 60 V MHz

b

3 dB 55 V MHz

g

0.1 dB 25 V MHz

g

0.1 dB 23 V MHz

e

g

15V 0.02 V %

S

e

g

5V 0.03 V %

S

e

g

15V 0.05 V

S

e

g

5V 0.06 V

S

Restore Section

SR Restore Amplifier Slew Rate

(Test Circuit) 20% –80%

T

HE

T

HD

Note 1: For current feedback amplifiers, A

Note 2: V

Note 3: Measured from S/H Input to amplifier output, while restoring.

Note 4: V

Note 5: SR measured at 20% to 80% of a 4V pk-pk square wave.

CM

is measured at V

OS

Note 6: DC offset from

Note 7: Test fixture was designed to minimize capacitance at the IN

capacitance to ground at this very sensitive pin. See application notes for further details.

Time to Enable Hold 25 V ns

Time to Disable Hold 40 V ns

e

e

g

10V for V

g

15V.

g

4.5V and V

VOL

e

S

e

S

e

S

b

0.714V througha0.714V, ac amplitude is 286 mVp-p, equivalent to 40 ire.

ROL/R

.

b

IN

g

16V, both supplies are changed simultaneously.

b

e

e

2, T

V

25§C. (See Note 7 about Test Fixture)

A

Test

Level

275 V V/ms

25 V V/ms

input. A ‘‘good’’ fixture should have less than 2 pF of stray

Units

Units

§

§

TD is 3.2in TD is 3.2in

3

Page 4

EL4089C

DC Restored Video Amplifier

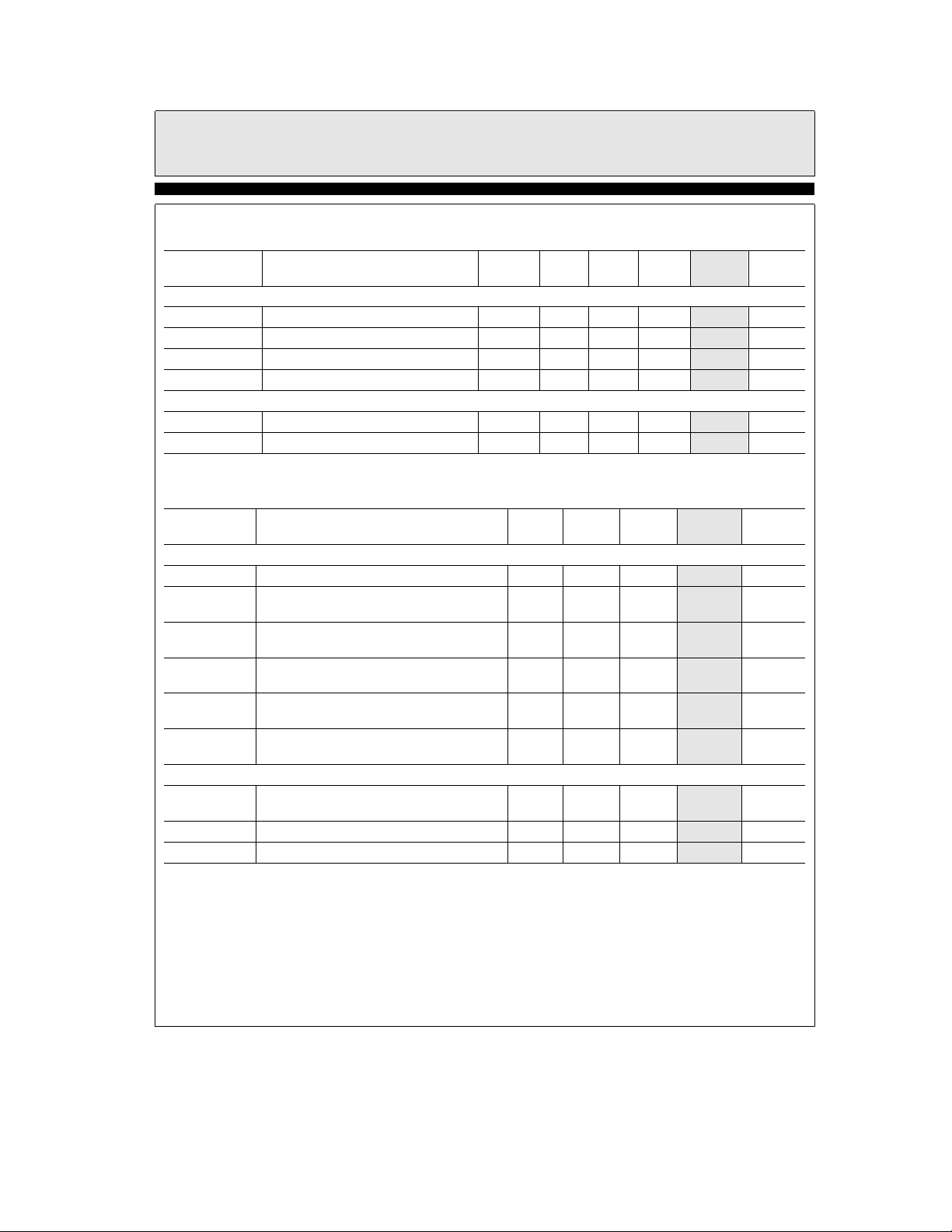

Typical Performance Curves

Supply Current vs Temperature

e

g

15V

V

S

Supply Current

vs Supply Voltage

Restoring Current

vs Temperature

Amplifier Output Voltage

vs Die Temperature;

e

g

15V

V

S

4089– 2

4089– 4

Amplifier Input Current

vs Die Temperature

Amplifier Offset Voltage

vs Die Temperature

4089– 3

4089– 5

4089– 6

4089– 7

4

Page 5

EL4089C

DC Restored Video Amplifier

Typical Performance Curves

CMRR for Amplifier and

Restore Section

vs Die Temperature

Relative Frequency Response

for Various Gains, R

e

300X

F

Ð Contd.

4089– 8

Transimpedance (ROL)

vs Die Temperature

Frequency Response vs Supply

e

e

2; R

A

V

300

F

4089– 9

Frequency Response Flatness vs Supply

e

e

2; R

A

V

300

F

4089– 10

4089– 12

4089– 11

Frequency Response Flatness for Various

Load and Supply Conditions

e

e

2; R

A

V

300

F

4089– 13

5

Page 6

EL4089C

DC Restored Video Amplifier

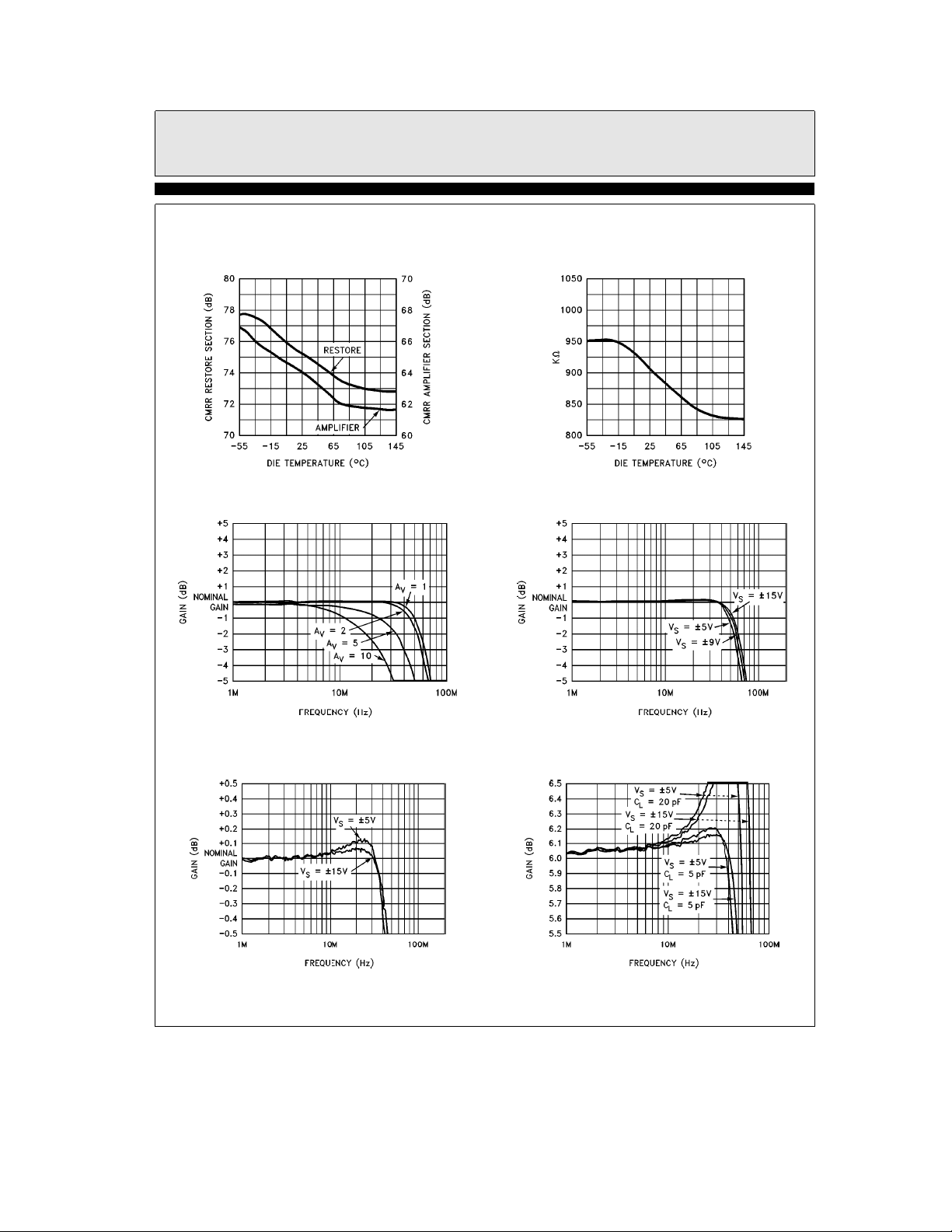

Typical Performance Curves

Frequency Response Flatness

vs C

e

2; R

e

300

F

;A

b

IN

V

Ð Contd.

4089– 14

Differential Phase vs DC Input

Offset; A

R

e

e

2; F

O

3.58 MHz;

V

e

150X

L

Differential Gain vs DC Input

Offset; A

R

e

e

2, F

O

3.58 MHz,

V

e

150X

L

4089– 15

8-Pin Plastic DIP

Maximum Power Dissipation

vs Ambient Temperature

4089– 17

4089– 16

8-Lead SO

Maximum Power Dissipation

vs Ambient Temperature

4089– 18

6

Page 7

EL4089C

DC Restored Video Amplifier

Typical Application

The EL4089 can be used to DC-restore a video

waveform (see Fig. 1). The above circuit forces

the cable driving video amplifier’s output to

ground when the HOLD pin is at a logic low.

The ‘‘correction voltage’’ is stored on capacitor

CX1, an external ceramic capacitor. The capacitor value is chosen from the system requirements. The typical input bias current to the video amplifier is 1 mA, so for a 62 ms hold time, and

a 0.01 mF capacitor, the output voltage drift is

6.2 mV in one line.

The S/H amplifier can provide a typical current

of 300 mA to charge capacitor CX1, so with a

1.2 ms sampling time, the output can be corrected

by 36 mV in each line.

Using a smaller value of CX1 increases both the

voltage that can be corrected, and the drift while

being held, likewise, using a larger value of CX1,

reduces the voltages.

The RX1 resistor is in the circuit purely to simulate some external source impedance, and is not

needed as a real component. Likewise for RX2.

The 75X back terminating resistor RXT is recommended when driving 75X cables.

The board layout should have a ground plane underneath the EL4089, with the ground plane cut

away from the vicinity of the V

This helps to minimize the stray capacitance on

pin 1.

Power supply bypassing is important, and a

0.1 mF ceramic capacitor, from each power pin to

ground, placed very close to the power pins, together with a 4.7 mF tantalum bead capacitor, is

recommended.

When both digital and Analog grounds are on the

same board, the EL4089 should be on the Analog

ground. The digital ground can be connected to

the Analog ground through a 100X – 300X resistor, near the EL4089. This allows the digital signal a return path, while preventing the digital

noise from corrupting the analog ground.

IN

b

pin, (pin 1).

Figure 1

7

4089– 19

Page 8

EL4089C

DC Restored Video Amplifier

EL4089CJanuary 1996 Rev B

Table of Charge Storage Capacitor vs Droop Charging Rates

Cap Value Droop in 60 ms Charge in 1.2 ms Charge in 4 ms

nF mV mV mV

10 6 36 120

33 1.8 11 36

100 0.6 3.6 12

Basic formulae are:

V (droop)

and V (charge)

eIba

* (Line timebSample time) / Capacitor

e

I

* Sample time / Capacitor

OUT

For best results the source impedance should be

kept low, using a buffer for example.

pled during active video. Typically the sample is

made during the back porch period of horizontal

blanking. For this reason color composite signals,

Because the S/H effectively shorts the input signal during Sample, the input should not be sam-

which have color burst on the back porch, can

not be passed. See EL2090 or EL4093 for this ap-

plication.

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes

in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any

circuits described herein and makes no representations that they are free from patent infringement.

WARNING Ð Life Support Policy

Elantec, Inc. products are not authorized for and should not be

used within Life Support Systems without the specific written

consent of Elantec, Inc. Life Support systems are equipment in-

Elantec, Inc.

1996 Tarob Court

Milpitas, CA 95035

Telephone: (408) 945-1323

(800) 333-6314

Fax: (408) 945-9305

European Office: 44-71-482-4596

tended to support or sustain life and whose failure to perform

when properly used in accordance with instructions provided can

be reasonably expected to result in significant personal injury or

death. Users contemplating application of Elantec, Inc. products

in Life Support Systems are requested to contact Elantec, Inc.

factory headquarters to establish suitable terms & conditions for

these applications. Elantec, Inc.’s warranty is limited to replace-

ment of defective components and does not cover injury to per-

sons or property or other consequential damages.

Printed in U.S.A.8

Loading...

Loading...