Page 1

EL400C

200MHz Current Feedback Amplifier

EL400C

Features

• 200MHz -3dB bandwidth, AV=2

• 12ns settling to 0.05%

• VS = ±5V @ 15mA

• Low distortion: HD2, HD3 @

-60dBc at 20MHz

• Differential gain 0.02% at NTSC,

PAL

• Differential phase 0.01° at NTSC,

PAL

• Overload/short-circuit protected

• ±1 to ±8 closed-loop gain range

• Low cost

• Direct replacement for CLC400

Applications

• Video gain block

• Video distribution

• HDTV amplifier

• High-speed A/D conversion

• D/A I-V conversion

• Photodiode, CCD preamps

• IF processors

• High-speed communications

General Description

The EL400C is a wide bandwidth, fast settling monolithic amplifier

built using an advanced complementary bipolar process. This amplifier uses current-mode feedback to achieve more bandwidth at a given

gain than conventional operational amplifiers. Designed for closedloop gains of ±1 to ±8, the EL400C has a 200MHz -3dB bandwidth

(AV = +2), and 12ns settling to 0.05% while consuming only 15mA of

supply current.

The EL400C is an obvious high-performance solution for video distribution and line-driving applications. With low 15mA supply current,

differential gain/phase of 0.02%/0.01°, and a minimum 50mA output

drive, performance in these areas is assured.

The EL400's settling to 0.05% in 12ns, low distortion, and ability to

drive capacitive loads make it an ideal flash A/D driver. The wide

200MHz bandwidth and extremely linear phase allow unmatched signal fidelity. D/A systems can also benefit from the EL400C, especially

if linearity and drive levels are important.

Ordering Information

Part No. Temp. Range Package Outline #

EL400CN -40°C to +85°C 8-Pin P-DIP MDP0031

EL400CS -40°C to +85°C 8-Lead SO MDP0027

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a “controlled document”. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

© 2001 Elantec Semiconductor, Inc.

Connection Diagrams

DIP and SO Package

Top View

Manufactured under U.S. Patent No. 4,893,091

September 26, 2001

Page 2

EL400C

200MHz Current Feedback Amplifier

EL400C

Absolute Maximum Ratings (T

Supply Voltage (VS) ±7V

Output Current

Output is short-circuit protected to ground, however, maximum reliability is obtained if

I

does not exceed 70mA.

OUT

Common-Mode Input Voltage ±V

Differential Input Voltage 5V

Power Dissipation See Curves

= 25°C)

A

Operating Temperature -40°C to +85°C

Lead Temperature (Soldering, 5 Seconds) 300°C

Junction Temperature 175°C

Storage Temperature -60°C to +150°C

S

Thermal Resistance:

θ

= 95°C/W P-DIP

JA

θ

= 175°C/W SO-8

JA

Important Note:

All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: TJ = TC = TA.

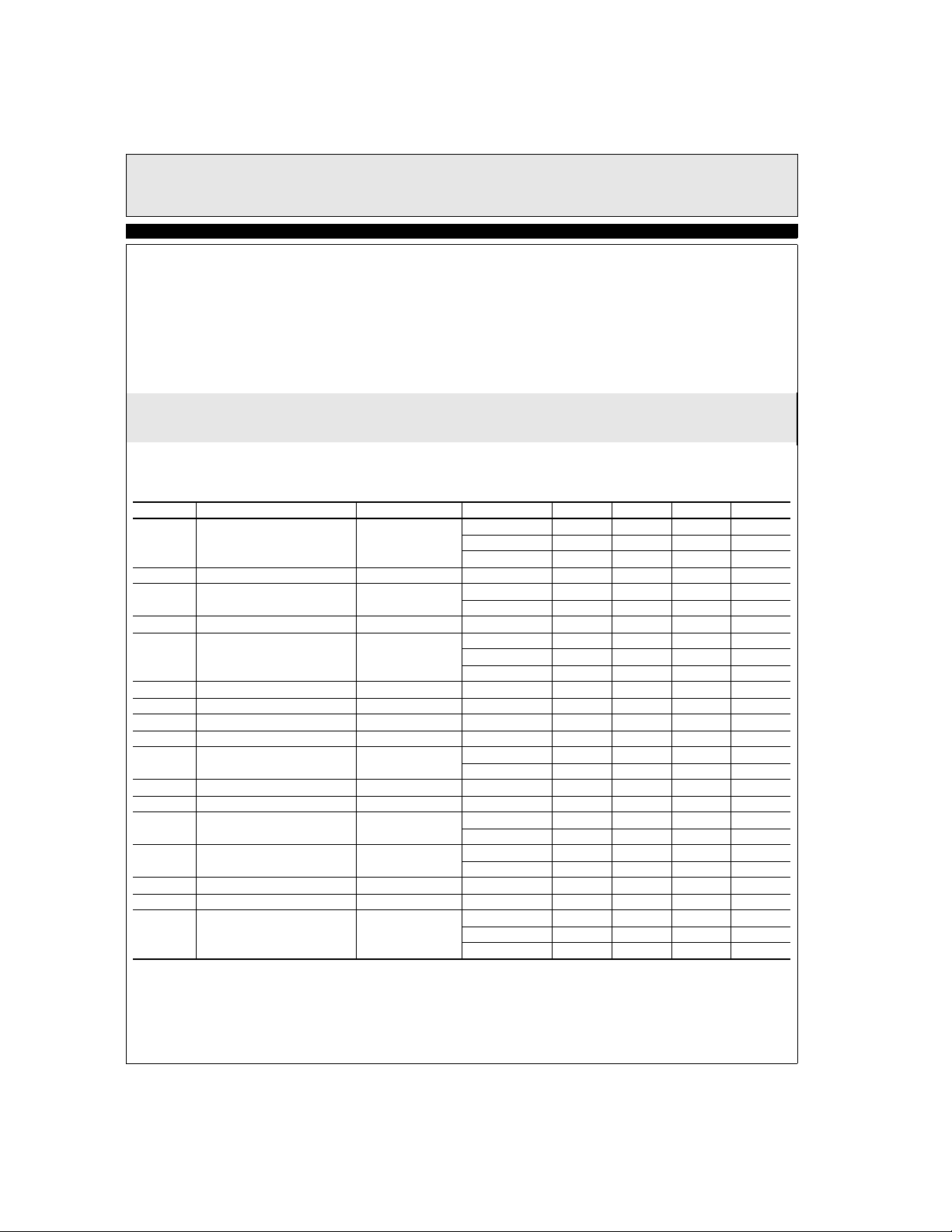

Open Loop DC Electrical Characteristics

VS = ±5V, R

Parameter Description Test Conditions Temp Min Typ Max Unit

V

d(VOS)/dT Average Offset Voltage Drift

+I

d(+IIN)/dT Average +Input Current Drift

-I

d(-IIN)/dT Average -Input Current Drift

PSRR Power Supply Rejection Ratio All 40.0 50.0 dB

CMRR Common-Mode Rejection Ratio All 40.0 50.0 dB

I

S

+R

C

R

CMIR Common-Mode Input Range

I

OUT

V

V

R

= 100Ω unless otherwise specified

L

OS

IN

IN

Input Offset Voltage 25°C 2.0 5.5 mV

[1]

+Input Current 25°C, T

-Input Current 25°C 10.0 25.0 µA

Supply Current—Quiescent No Load All 15.0 23.0 mA

IN

IN

OUT

+Input Resistance 25°C, T

Input Capacitance All 0.5 2.0 pF

Output Impedance (DC) All 0.1 0.2 Ω

[2]

Output Current 25°C, T

OUT

OUTL

OL

1. Measured from T

Output Voltage Swing No Load All 3.2 3.5 V

Output Voltage Swing 100Ω 25°C 3.0 3.4 V

Transimpedance 25°C 30.0 125.0 V/mA

to T

MAX

.

MIN

2. Common-Mode Input Range for Rated Performance.

T

T

MIN

MAX

8.7 mV

9.5 mV

All 10.0 40.0 µV/°C

MAX

T

[1]

[1]

MIN

All 50.0 200.0 nA/°C

T

MIN

T

MAX

All 100.0 200.0 nA/°C

100.0 200.0 kΩ

50.0 kΩ

2.0 2.1 V

1.2 V

50.0 70.0 mA

35.0 mA

T

25°C, T

T

T

T

T

MAX

MAX

MIN

MAX

MIN

MAX

MIN

MIN

10.0 25.0 µA

41.0 µA

41.0 µA

35.0 µA

80.0 V/mA

140.0 V/mA

2

Page 3

200MHz Current Feedback Amplifier

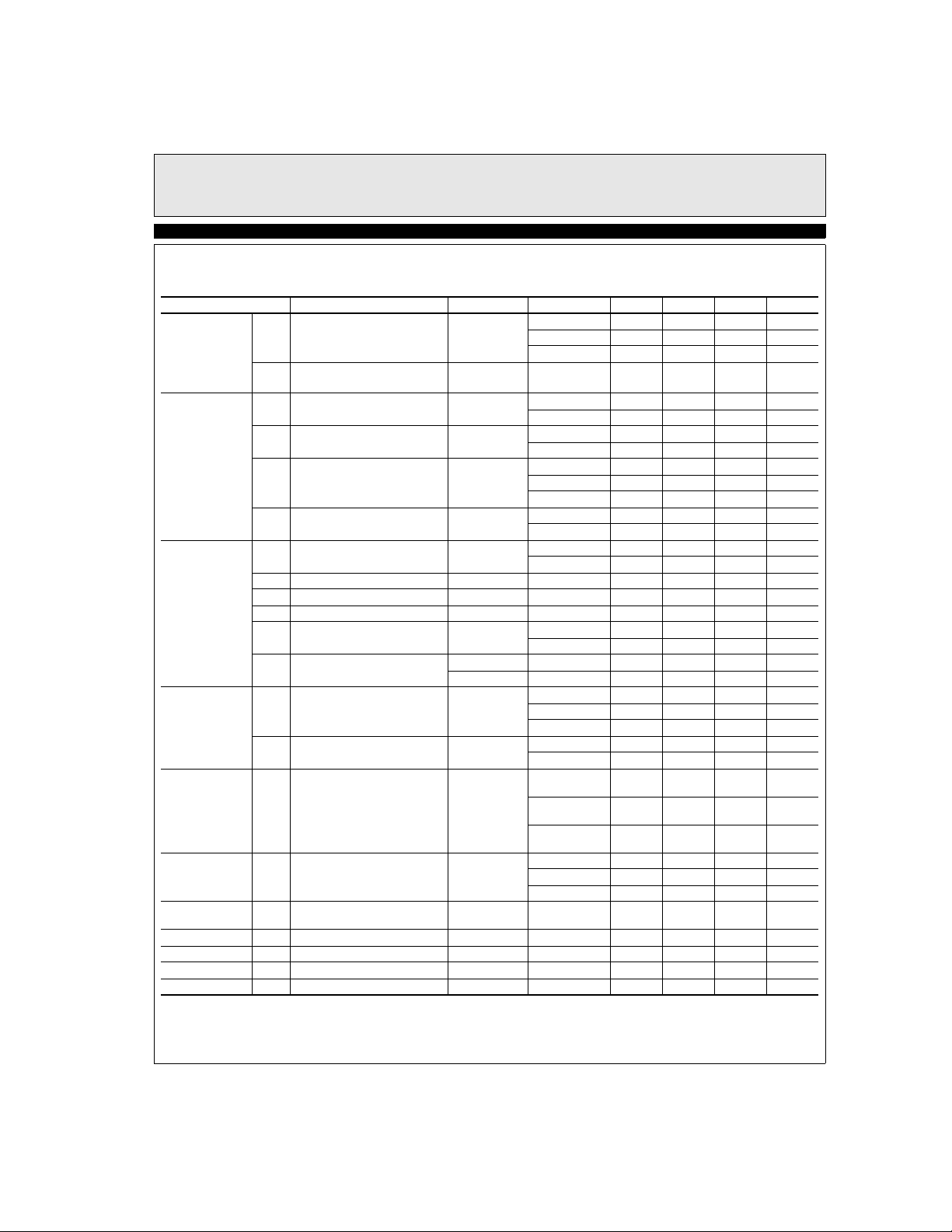

Closed-Loop AC Electrical Characteristics

VS = ±5V, R

Frequency

Response

Gain Flatness GFPL Peaking

Time-Domain

Response

Distortion HD2 2nd Harmonic Distortion at 20MHz 2V

Equivalent Input

Noise

Video

Performance

1. Noise Tests are Performed from 5MHz to 200MHz.

2. Differential Gain/Phase Tests are R

= 250Ω, A

F

= +2, R

= 100Ω unless otherwise specified

V

L

Parameter Description Test Conditions Temp Min Typ Max Unit

SSBW -3dB Bandwidth

(V

< 0.5VPP)

OUT

LSBW -3dB Bandwidth

(V

< 5.0VPP)

OUT

AV = +5 All 35.0 50.0 MHz

25°C 150.0 200.0 MHz

T

T

MIN

MAX

150.0 MHz

120.0 MHz

<40MHz 25°C 0.0 0.3 dB

V

< 0.5V

OUT

GFPH Peaking

V

OUT

GFR Rolloff

V

OUT

LPD Linear Phase Deviation

V

OUT

tr1, tf1Rise Time, Fall Time 0.5V Step 25°C, T

< 0.5V

< 0.5V

< 0.5V

PP

T

, T

MIN

MAX

>40MHz 25°C 0.0 0.5 dB

PP

T

, T

MIN

MAX

<75MHz 25°C 0.6 1.0 dB

PP

<75MHz 25°C, T

PP

T

T

T

T

MIN

MAX

MAX

MAX

MIN

MIN

0.2 1.0 °

1.6 2.4 ns

tr2, tf2Rise Time, Fall Time 5.0V Step All 6.5 10.0 ns

t

Settling Time to 0.1% 2.0V Step All 10.0 13.0 ns

s1

t

Settling Time to 0.05% 2.0V Step All 12.0 15.0 ns

s2

OS Overshoot 0.5V Step 25°C 0.0 10.0 %

T

, T

MIN

MAX

SR Slew Rate AV = +2 All 430.0 700.0 V/µs

AV = - 2 All 1600.0 V/µs

25°C -60.0 -45.0 dBc

T

MIN

T

MAX

25°C -60.0 -50.0 dBc

T

, T

MIN

MAX

25°C -157.0 -154.0 dBm

HD3 3rd Harmonic Distortion at 20MHz 2V

NF Noise Floor

PP

PP

[1]

>100kHz

T

MIN

T

MAX

INV Integrated Noise

100kHz to 200MHz

d

Differential Gain

G

d

Differential Phase

P

d

Differential Gain

G

d

Differential Phase

P

VBW -0.1dB Bandwidth

= 100Ω. For other values of R

L

[2]

[2]

[2]

[2]

[2]

[1]

25°C 40.0 57.0 µV

T

MIN

T

MAX

NTSC/PAL 25°C 0.02 % pp

NTSC/PAL 25°C 0.01 ° pp

30MHz 25°C 0.05 % pp

30MHz 25°C 0.05 ° pp

25°C 60.0 MHz

, see curves.

L

EL400C

0.4 dB

0.7 dB

1.0 dB

1.3 dB

1.2 °

2.9 ns

15.0 %

-40.0 dBc

-45.0 dBc

-50.0 dBc

(1Hz)

-154.0 dBm

-153.0 dBm

57.0 µV

63.0 µV

(1Hz)

(1Hz)

EL400C

3

Page 4

EL400C

200MHz Current Feedback Amplifier

EL400C

Typical Performance Curves

Non-Inverting

Frequency Response

Open-Loop Transimpedance

Gain and Phase

Equivalent Input Noise

Inverting Frequency Response Frequency Response for

2nd and 3rd

Harmonic Distortion

Power-Supply

Rejection Ratio

Various RLs

2-Tone 3rd Order

Intermodulation Intercept

Common-Mode

Rejection Ratio

Settling Time Long-Term Settling Time Settling Time vs Load Capacitance

4

Page 5

EL400C

200MHz Current Feedback Amplifier

EL400C

Recommended RS vs

Load Capacitance

Pulse Response AV = +2

Pulse Response AV = +2

Differential Gain and

Phase (3.58MHz)

Differential Gain and

Phase (4.43MHz)

5

Differential Gain and

Phase (30MHz)

Page 6

EL400C

200MHz Current Feedback Amplifier

EL400C

Equivalent Circuit

Burn-In Circuit

All Packages Use The Same Schematic.

6

Page 7

Applications Information

EL400C

EL400C

200MHz Current Feedback Amplifier

Theory of Operation

The EL400C has a unity gain buffer from the non-inverting input to the inverting input. The error signal of the

EL400C is a current flowing into (or out of) the inverting

input. A very small change in current flowing through the

inverting input will cause a large change in the output

voltage. This current amplification is called the transimpedance (ROL) of the EL400C [V

Since ROL is very large, the current flowing into the

inverting input in the steady-state (non-slewing) condition is very small.

Therefore we can still use op-amp assumptions as a firstorder approximation for circuit analysis, namely that:

1. The voltage across the inputs is approximately 0V.

2. The current into the inputs is approximately 0mA.

=(ROL)*(-IIN)].

OUT

Resistor Value Selection and Optimization

The value of the feedback resistor (and an internal

capacitor) sets the AC dynamics of the EL400C. The

nominal value for the feedback resistor is 250Ω, which

is the value used for production testing. This value guarantees stability. For a given closed-loop gain the

bandwidth may be increased by decreasing the feedback

resistor and, conversely, the bandwidth may be

decreased by increasing the feedback resistor.

Reducing the feedback resistor too much will result in

overshoot and ringing, and eventually oscillations.

Increasing the feedback resistor results in a lower -3dB

frequency. Attenuation at high frequency is limited by a

zero in the closed-loop transfer function which results

from stray capacitance between the inverting input and

ground. Consequently, it is very important to keep stray

capacitance to a minimum at the inverting input.

Differential Gain/Phase

An industry-standard method of measuring the distortion of a video component is to measure the amount of

differential gain and phase error it introduces. To measure these, a 40 IREPP reference signal is applied to the

device with 0V DC offset (0IRE) at 3.58MHz for NTSC,

4.43MHz for PAL, and 30MHz for HDTV. A second

measurement is then made with a 0.714V DC offset

(100IRE). Differential Gain is a measure of the change

in amplitude of the sine wave, and is measured in percent. Differential Phase is a measure of the change in

phase, and is measured in degrees. Typically, the maximum positive and negative deviations are summed to

give peak values.

In general, a back terminated cable (75Ω in series at the

drive end and 75Ω to ground at the receiving end) is pre-

ferred since the impedance match at both ends will

absorb any reflections. However, when double-termination is used, the received signal is reduced by half;

therefore a gain of 2 configuration is typically used to

compensate for the attenuation. In a gain of 2 configuration, with output swing of 2VPP, with each back-

terminated load at 150Ω. The EL400C is capable of

driving up to 4 back-terminated loads with excellent

video performance. Please refer to the typical curves for

more information on video performance with respect to

frequency, gain, and loading.

Capacitive Feedback

The EL400C relies on its feedback resistor for proper

compensation. A reduction of the impedance of the feedback element results in less stability, eventually

resulting in oscillation. Therefore, circuit implementations which have capacitive feedback should not be used

because of the capacitor's impedance reduction with frequency. Similarly, oscillations can occur when using the

technique of placing a capacitor in parallel with the feedback resistor to compensate for shunt capacitances from

the inverting input to ground.

Offset Adjustment Pin

Output offset voltage of the EL400C can be nulled by

tying a 10k potentiometer between +VS and -VS with the

slider attached to pin 1. A full-range variation of the

voltage at pin 1 to ±5V results in an offset voltage

adjustment of at least ±10mV. For best settling performance pin 1 should be bypassed to ground with a

ceramic capacitor located near to the package, even if

the offset voltage adjustment feature is not being used.

7

Page 8

EL400C

200MHz Current Feedback Amplifier

EL400C

Printed Circuit Layout

As with any high frequency device, good PCB layout is

necessary for optimum performance. Ground plane construction is a requirement, as is good power-supply and

Offset Adjust bypassing close to the package. The

inverting input is sensitive to stray capacitance, therefore connections at the inverting input should be

minimal, close to the package, and constructed with as

little coupling the ground plane as possible.

Capacitance at the output node will reduce stability,

eventually resulting in peaking, and finally oscillation if

the capacitance is large enough. The design of the

EL400C allows a larger capacitive load than comparable

products, yet there are occasions when a series resistor

before the capacitance may be needed. Please refer to

the graphs to determine the proper resistor value needed.

8

Page 9

EL400C Macromodel

* Revision A. March 1992

* Enhancements include PSRR, CMRR, and Slew Rate Limiting

* Connections: +input

* | -input

* | | +Vsupply

* | | | -Vsupply

* | | | | output

* | | | | |

.subckt M400 3 2 7 4 6

*

* Input Stage

*

e1 10 0 3 0 1.0

vis 10 9 0V

h2 9 12 vxx 1.0

r1 2 11 50

l1 11 12 48nH

iinp 3 0 8µA

iinm 2 0 8µA

*

* Slew Rate Limiting

*

h1 13 0 vis 600

r2 13 14 1K

d1 14 0 dclamp

d2 0 14 dclamp

*

* High Frequency Pole

*

*e2 30 0 14 0 0.00166666666

l3 30 17 0.1µH

c5 17 0 0.1pF

r5 17 0 500

*

* Transimpedance Stage

*

g1 0 18 17 0 1.0

rol 18 0 150K

cdp 18 0 2.8pF

*

* Output Stage

*

q1 4 18 19 qp

q2 7 18 20 qn

q3 7 19 21 qn

q4 4 20 22 qp

r7 21 6 2

r8 22 6 2

ios1 7 19 2.5mA

ios2 20 4 2.5mA

*

* Supply Current

*

ips 7 4 9mA

*

* Error Terms

*

ivos 0 23 5mA

vxx 23 0 0V

e4 24 0 3 0 1.0

e5 25 0 7 0 1.0

EL400C

EL400C

200MHz Current Feedback Amplifier

9

Page 10

EL400C

200MHz Current Feedback Amplifier

EL400C

e6 26 0 4 0 1.0

r9 24 23 3K

r10 25 23 1K

r11 26 23 1K

*

* Models

*

.model qn npn (is=5e-15 bf=200 tf=0.5nS)

.model qp pnp (is=5e-15 bf=200 tf=0.5nS)

.model dclamp d(is=1e-30 ibv=0.266 bv=1.3 n=4)

.ends

EL400C Macromodel

10

Page 11

EL400C

200MHz Current Feedback Amplifier

EL400C

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any circuits described

herein and makes no representations that they are free from patent infringement.

WARNING - Life Support Policy

Elantec, Inc. products are not authorized for and should not be used

within Life Support Systems without the specific written consent of

Elantec, Inc. Life Support systems are equipment intended to sup-

Elantec Semiconductor, Inc.

675 Trade Zone Blvd.

Milpitas, CA 95035

Telephone: (408) 945-1323

(888) ELANTEC

Fax: (408) 945-9305

European Office: +44-118-977-6020

Japan Technical Center: +81-45-682-5820

port or sustain life and whose failure to perform when properly used

in accordance with instructions provided can be reasonably

expected to result in significant personal injury or death. Users contemplating application of Elantec, Inc. Products in Life Support

Systems are requested to contact Elantec, Inc. factory headquarters

to establish suitable terms & conditions for these applications. Elantec, Inc.’s warranty is limited to replacement of defective

components and does not cover injury to persons or property or

other consequential damages.

September 26, 2001

11

Printed in U.S.A.

Loading...

Loading...