Page 1

DS1330W

3.3V 256K Nonvolatile SRAM

with Battery Monitor

DS1330W

PRELIMINARY

022598 1/11

FEATURES

• 10 years minimum data retention in the absence of

external power

• Data is automatically protected during power loss

• Power supply monitor resets processor when V

CC

power loss occurs and holds processor in reset during

V

CC

ramp–up

• Battery monitor checks remaining capacity daily

• Read and write access times as fast as 150 ns

• Unlimited write cycle endurance

• Typical standby current 50 µA

• Upgrade for 32K x 8 SRAM, EEPROM or Flash

• Lithium battery is electrically disconnected to retain

freshness until power is applied for the first time

• Optional industrial temperature range of –40°C to

+85°C, designated IND

• New PowerCap Module (PCM) package

– Directly surface–mountable module

– Replaceable snap–on PowerCap provides lith-

ium backup battery

– Standardized pinout for all nonvolatile SRAM

products

– Detachment feature on PowerCap allows easy

removal using a regular screwdriver

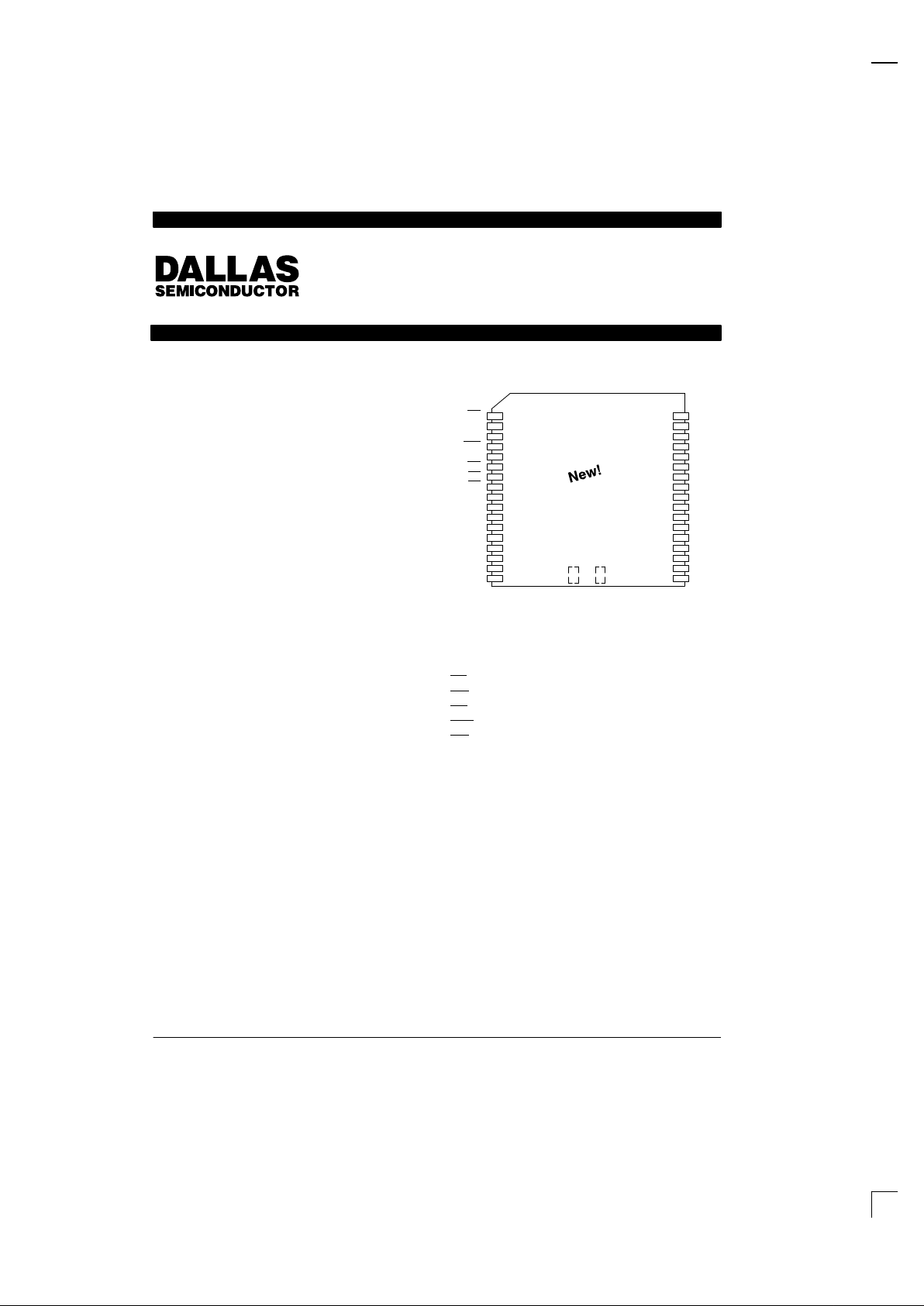

PIN ASSIGNMENT

BW

OE

CE

WE

RST

V

CC

1

2

3

4

5

6

7

8

9

10

11

12

13

34

33

32

31

30

29

28

27

26

25

24

23

22

14

15

16

17

21

20

19

18

NC

NC

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

NC

NC

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

GND

34–PIN POWERCAP MODULE (PCM)

GND V

BAT

(USES DS9034PC POWERCAP)

PIN DESCRIPTION

A0–A14 – Address Inputs

DQ0–DQ7 – Data In/Data Out

CE – Chip Enable

WE – Write Enable

OE – Output Enable

RST

– Reset Output

BW – Battery Warning Output

V

CC

– Power (+3.3 Volts)

GND – Ground

NC – No Connect

DESCRIPTION

The DS1330W 3.3V 256K Nonvolatile SRAM is a

262,144–bit, fully static, nonvolatile SRAM organized

as 32,768 words by eight bits. Each NV SRAM has a

self–contained lithium energy source and control circuitry which constantly monitors V

CC

for an out–of–tolerance condition. When such a condition occurs, the

lithium energy source is automatically switched on and

write protection is unconditionally enabled to prevent

data corruption. Additionally, the DS1330W has dedicated circuitry for monitoring the status of VCC and the

status of the internal lithium battery. DS1330W devices

in the PowerCap Module package are directly surface

mountable and are normally paired with a DS9034PC

PowerCap to form a complete Nonvolatile SRAM module. The devices can be used in place of 32K x 8 SRAM,

EEPROM or Flash components.

Page 2

DS1330W

022598 2/11

READ MODE

The DS1330W executes a read cycle whenever WE

(Write Enable) is inactive (high) and CE (Chip Enable)

and OE (Output Enable) are active (low). The unique

address specified by the 15 address inputs (A

0

– A14)

defines which of the 32,768 bytes of data is to be

accessed. Valid data will be available to the eight data

output drivers within t

ACC

(Access Time) after the last

address input signal is stable, providing that CE and OE

(Output Enable) access times are also satisfied. If OE

and CE access times are not satisfied, then data access

must be measured from the later occurring signal (CE or

OE) and the limiting parameter is either tCO for CE or t

OE

for OE rather than address access.

WRITE MODE

The DS1330W excutes a write cycle whenever the WE

and CE signals are in the active (low) state after address

inputs are stable. The later occurring falling edge of CE

or WE will determine the start of the write cycle. The

write cycle is terminated by the earlier rising edge of CE

or WE. All address inputs must be kept valid throughout

the write cycle. WE must return to the high state for a

minimum recovery time (t

WR

) before another cycle can

be initiated. The OE

control signal should be kept inactive (high) during write cycles to avoid bus contention.

However, if the output drivers are enabled (CE

and OE

active) then WE will disable the outputs in t

ODW

from its

falling edge.

DATA RETENTION MODE

The DS1330W provides full functional capability for V

CC

greater than 3.0 volts and write protects by 2.8 volts.

Data is maintained in the absence of V

CC

without any

additional support circuitry . The nonvolatile static RAMs

constantly monitor VCC. Should the supply voltage

decay, the NV SRAMs automatically write protect themselves, all inputs become “don’t care,” and all outputs

become high impedance. As V

CC

falls below approximately 2.5 volts, the power switching circuit connects

the lithium energy source to RAM to retain data. During

power–up, when VCC rises above approximately

2.5 volts, the power switching circuit connects external

VCC to the RAM and disconnects the lithium energy

source. Normal RAM operation can resume after V

CC

exceeds 3.0 volts.

SYSTEM POWER MONITORING

The DS1330W has the ability to monitor the external

VCC power supply. When an out–of–tolerance power

supply condition is detected, the NV SRAM warns a processor–based system of impending power failure by

asserting RST

. On power up, RST is held active for 200

ms nominal to prevent system operation during power–on transients and to allow t

REC

to elapse. RST has

an open–drain output driver.

BATTERY MONITORING

The DS1330W automatically performs periodic battery

voltage monitoring on a 24 hour time interval. Such

monitoring begins within t

REC

after VCC rises above V

TP

and is suspended when power failure occurs.

After each 24 hour period has elapsed, the battery is

connected to an internal 1 MΩ test resistor for one

second. During this one second, if battery voltage falls

below the battery voltage trip point (2.6V), the battery

warning output BW

is asserted. Once asserted, BW

remains active until the module is replaced. The battery

is still retested after each VCC power–up, however, even

if BW is active. If the battery voltage is found to be higher

than 2.6V during such testing, BW is de–asserted and

regular 24–hour testing resumes. BW has an open–

drain output driver.

FRESHNESS SEAL

Each DS1330W is shipped from Dallas Semiconductor

with its lithium energy source disconnected, guaranteeing full energy capacity. When VCC is first applied at a

level greater than VTP, the lithium energy source is

enabled for battery backup operation.

PACKAGES

The 34–pin PowerCap Module integrates SRAM

memory and nonvolatile control into a module base

along with contacts for connection to the lithium battery

in the DS9034PC PowerCap. The PowerCap Module

package design allows a DS1330W device to be surface mounted without subjecting its lithium backup battery to destructive high–temperature reflow soldering.

After a DS1330W module base is reflow soldered, a

DS9034PC is snapped on top of the base to form a complete Nonvolatile SRAM module. The DS9034PC is

keyed to prevent improper attachment. DS1330W module bases and DS9034PC PowerCaps are ordered separately and shipped in separate containers. See the

DS9034PC data sheet for further information.

Page 3

DS1330W

022598 3/11

ABSOLUTE MAXIMUM RATINGS*

Voltage On Any Pin Relative To Ground –0.3V to +4.6V

Operating Temperature 0

°C to 70°C, –40°C to +85°C for IND parts

Storage Temperature –40

°C to +70°C, –40°C to +85°C for IND parts

Soldering T emperature 260

°C For 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above those

indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (tA: See Note 10)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Power Supply Voltage V

CC

3.0 3.3 3.6 V

Logic 1 V

IH

2.2 V

CC

V

Logic 0 V

IL

0.0 0.4 V

DC ELECTRICAL CHARACTERISTICS (tA: See Note 10) (VCC=3.3V ±0.3V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage Current I

IL

–1.0 +1.0 µA

I/O Leakage Current

CE

≥ VIH ≤ V

CC

I

IO

–1.0 +1.0 µA

Output Current @ 2.2V I

OH

–1.0 mA 14

Output Current @ 0.4V I

OL

2.0 mA 14

Standby Current CE = 2.2V I

CCS1

50 250 µA

Standby Current CE = VCC–0.2V I

CCS2

30 150 µA

Operating Current I

CCO1

50 mA

Write Protection Voltage V

TP

2.8 2.9 3.0 V

CAPACITANCE (tA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

IN

5 10 pF

Input/Output Capacitance C

I/O

5 10 pF

Page 4

DS1330W

022598 4/11

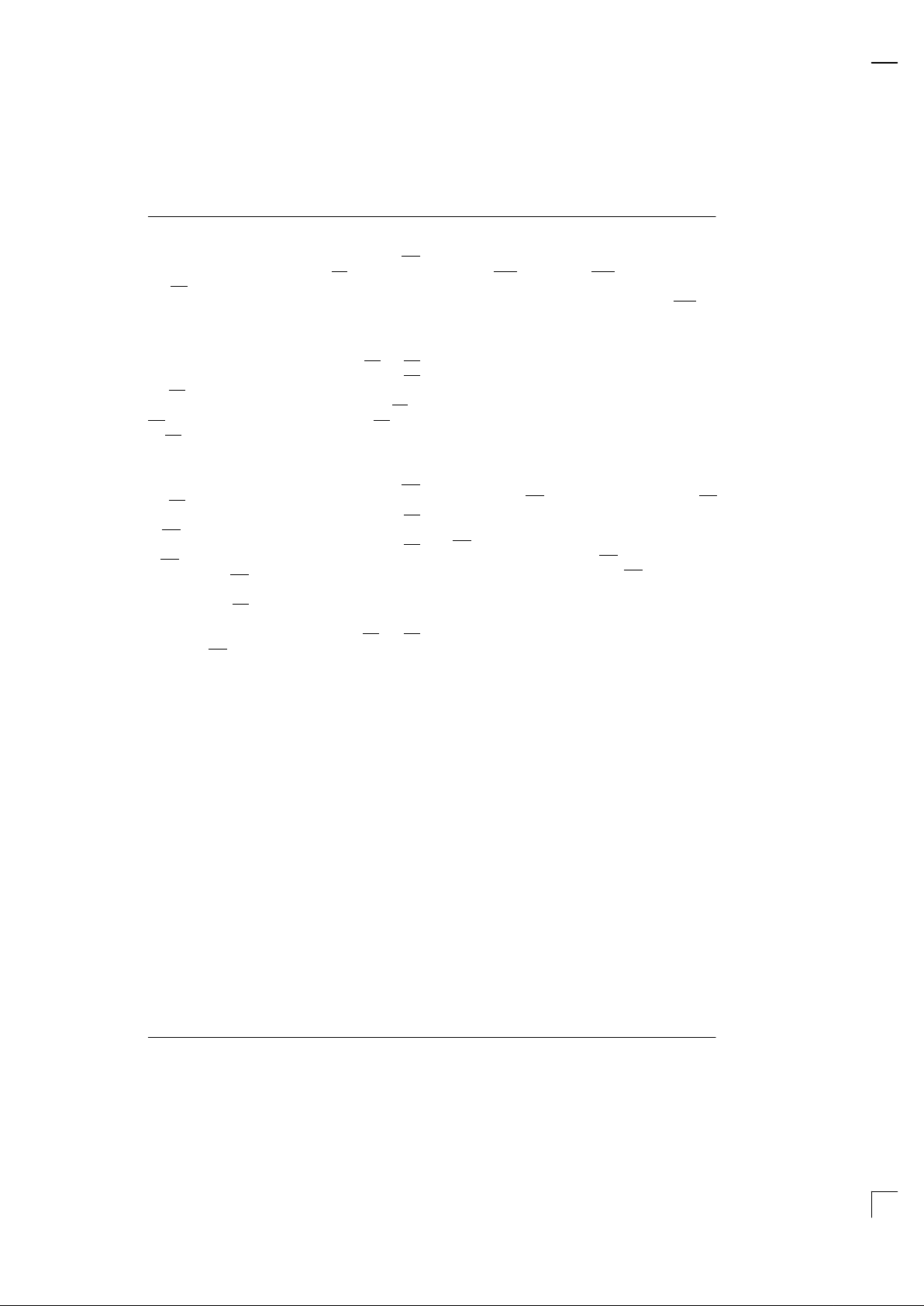

AC ELECTRICAL CHARACTERISTICS (tA: See Note 10) (VCC=3.3V ±0.3V)

DS1330W–150

PARAMETER SYMBOL

MIN MAX

TYPE UNITS NOTES

Read Cycle Time t

RC

150 ns

Access Time t

ACC

150 ns

OE to Output Valid t

OE

70 ns

CE to Output Valid t

CO

150 ns

OE or CE to Output Active t

COE

5 ns 5

Output High Z from Deselection t

OD

35 ns 5

Output Hold from Address

Change

t

OH

5 ns

Write Cycle Time t

WC

150 ns

Write Pulse Width t

WP

100 ns 3

Address Setup Time t

AW

0 ns

Write Recovery Time t

WR1

t

WR2

5

20

ns 12

13

Output High Z from WE t

ODW

35 ns 5

Output Active from WE t

OEW

5 ns 5

Data Setup Time t

DS

60 ns 4

Data Hold Time t

DH1

t

DH2

0

20

ns 12

13

READ CYCLE

t

RC

t

ACC

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

t

OH

V

IH

t

OD

t

OD

V

IH

V

OH

V

OL

V

OH

V

OL

t

COE

t

COE

OUTPUT

DATA VALID

D

OUT

OE

ADDRESSES

V

IH

V

IH

t

OE

V

IL

V

IL

CE t

CO

SEE NOTE 1

Page 5

t

WC

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

ADDRESSES

CE

WE

D

OUT

D

IN

DATA IN STABLE

t

AW

t

WP

t

WR2

V

IH

V

IL

V

IL

V

IL

V

IH

V

IH

V

IL

V

IL

t

COE

t

ODW

t

DS

t

DH2

V

IL

V

IH

V

IL

V

IH

SEE NOTES 2, 3, 4, 6, 7, 8 AND 13

DS1330W

022598 5/11

WRITE CYCLE 1

t

WC

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

ADDRESSES

t

AW

DATA IN STABLE

HIGH

IMPEDANCE

V

IL

V

IL

V

IL

V

IL

V

IH

V

IH

t

WP

t

WR1

t

ODW

t

OEW

t

DS

t

DH1

V

IH

V

IL

V

IH

V

IL

CE

WE

D

OUT

D

IN

SEE NOTES 2, 3, 4, 6, 7, 8 AND 12

WRITE CYCLE 2

Page 6

DS1330W

022598 6/11

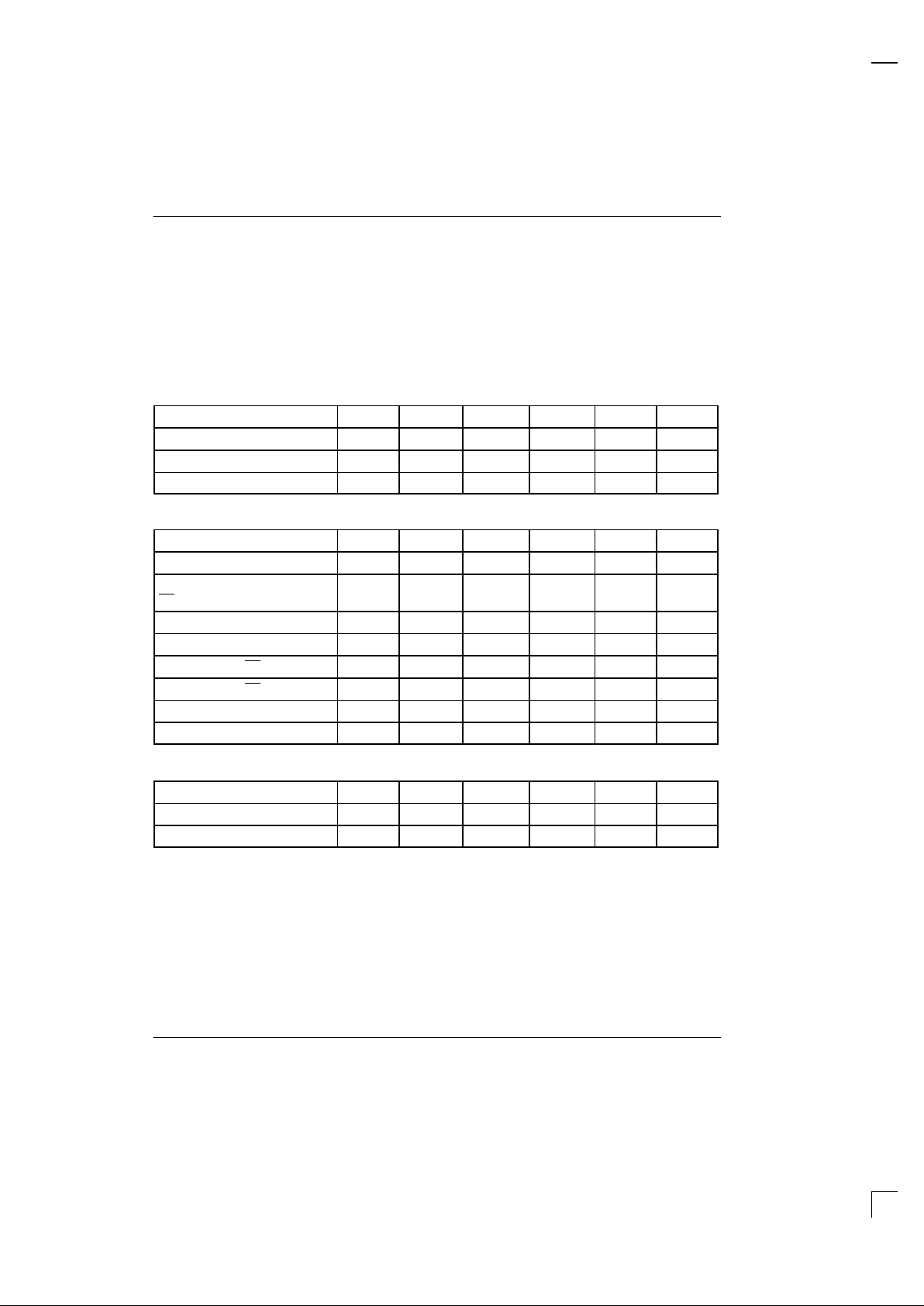

POWER–DOWN/POWER–UP CONDITION

V

CC

2.7V

t

F

t

PD

t

R

t

REC

BACKUP CURRENTSUPPLIED FROM

LITHIUM BATTERY

CE

,

WE

V

TP

t

BPU

t

RPU

t

RPD

RST

BW

V

IL

V

IH

SLEWS WITH

V

CC

V

IL

SEE NOTES 11 AND 14

t

DR

SLEWS WITH

V

CC

t

PU

V

IH

BATTERY WARNING DETECTION

BATTERY

t

BPU

V

TP

V

BAT

TEST

ACTIVE

BW

t

BTC

t

BW

t

BTPW

V

CC

V

IL

SEE NOTE 14

2.6V

Page 7

DS1330W

022598 7/11

POWER–DOWN/POWER–UP TIMING (tA: See Note 10)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

VCC Fail Detect to CE and WE

Inactive

t

PD

1.5 µs 11

VCC slew from VTP to 0V t

F

150 µs

VCC Fail Detect to RST Active t

RPD

15 µs

14

VCC slew from 0V to V

TP

t

R

150 µs

VCC Valid to CE and WE

Inactive

t

PU

2 ms

VCC Valid to End of Write

Protection

t

REC

125 ms

VCC Valid to RST Inactive t

RPU

150 200 350 ms 14

VCC Valid to BW Valid t

BPU

1 s 14

BATTERY WARNING TIMING (tA: See Note 10)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Battery Test Cycle t

BTC

24 hr

Battery Test Pulse Width t

BTPW

1 s

Battery Test to BW Active t

BW

1 s

(tA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Expected Data Retention Time t

DR

10 years 9

WARNING:

Under no circumstance are negative undershoots, of any amplitude, allowed when device is in battery backup mode.

NOTES:

1. WE is high for a Read Cycle.

2. OE

= VIH or VIL. If OE = VIH during write cycle, the output buffers remain in a high impedance state.

3. t

WP

is specified as the logical AND of CE and WE. tWP is measured from the latter of CE or WE going low to the

earlier of CE or WE going high.

4. t

DS

is measured from the earlier of CE or WE going high.

5. These parameters are sampled with a 5 pF load and are not 100% tested.

6. If the CE

low transition occurs simultaneously with or latter than the WE low transition, the output buffers remain

in a high impedance state during this period.

7. If the CE

high transition occurs prior to or simultaneously with the WE high transition, the output buffers remain

in high impedance state during this period.

8. If WE

is low or the WE low transition occurs prior to or simultaneously with the CE low transition, the output buffers

remain in a high impedance state during this period.

Page 8

DS1330W

022598 8/11

9. Each DS1330W has a built–in switch that disconnects the lithium source until VCC is first applied by the user. The

expected t

DR

is defined as accumulative time in the absence of VCC starting from the time power is first applied

by the user.

10.All AC and DC electrical characteristics are valid over the full operating temperature range. For commercial products, this range is 0°C to 70°C. For industrial products (IND), this range is –40°C to +85°C.

11.In a power down condition the voltage on any pin may not exceed the voltage on V

CC

.

12.t

WR1

and t

DH1

are measured from WE going high.

13.t

WR2

and t

DH2

are measured from CE going high.

14.RST

and BW are open–drain outputs and cannot source current. External pull–up resistors should be connected

to these pins for proper operation. Both pins will sink 10 mA.

DC TEST CONDITIONS

Outputs Open

Cycle = 200 ns for operating current

All voltages are referenced to ground

AC TEST CONDITIONS

Output Load: 100 pF + 1TTL Gate

Input Pulse Levels: 0 – 3.0V

Timing Measurement Reference Levels

Input: 1.5V

Output: 1.5V

Input pulse Rise and Fall Times: 5 ns

ORDERING INFORMATION

DS1330 W P –

SSS –

III

Operating Temperature Range

blank: 0° to 70°

IND: –40° to +85°C

Access

150:

Speed

150 ns

Package Type

blank: 28–pin 600 mil DIP

P: 34–pin PowerCap Module

Page 9

DS1330W

022598 9/11

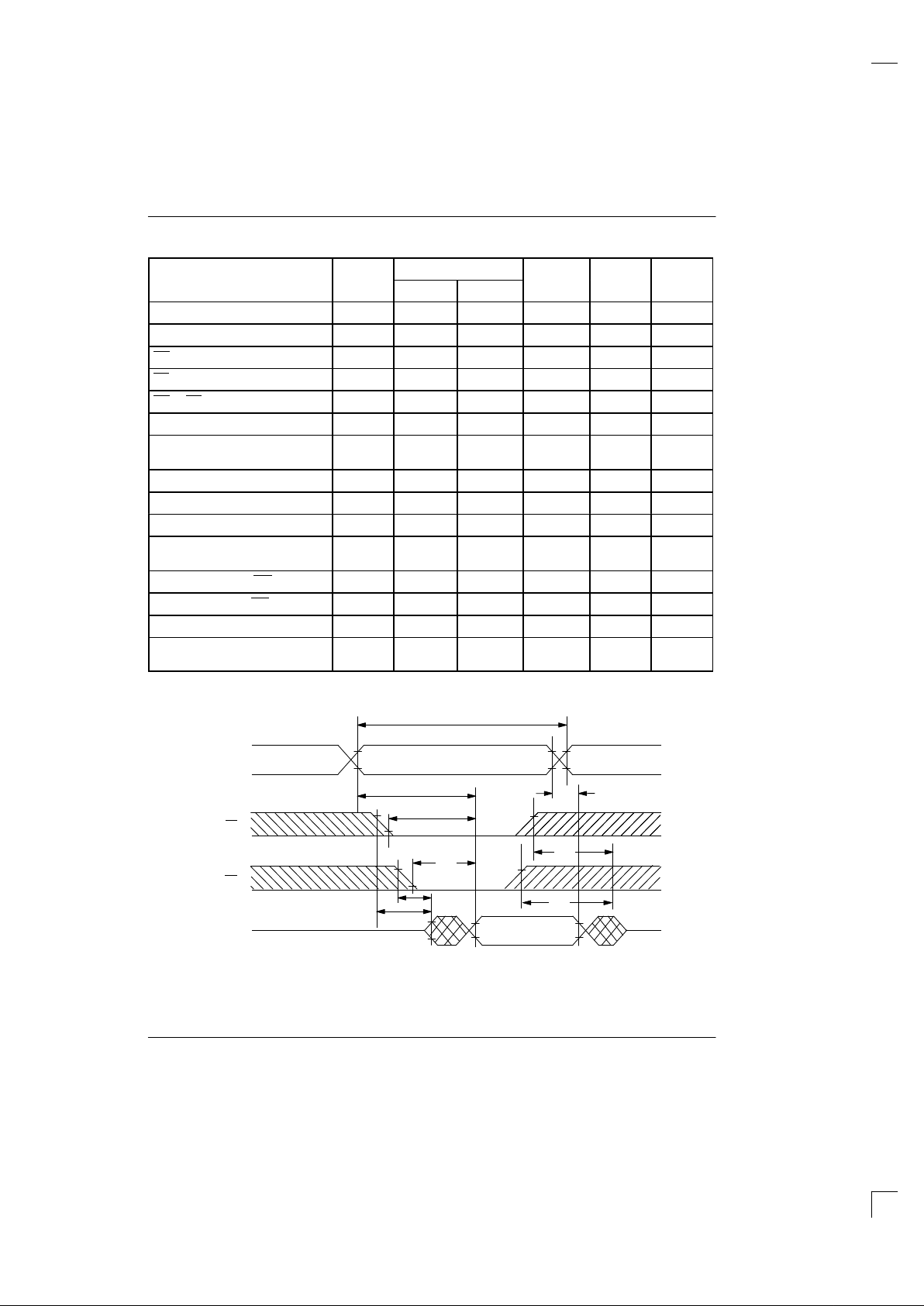

DS1330W NONVOLATILE SRAM, 34–PIN POWERCAP MODULE

PKG

DIM

INCHES

MIN NOM MAX

A 0.920 0.925 0.930

B 0.980 0.985 0.990

C – – 0.080

D 0.052 0.055 0.058

E 0.048 0.050 0.052

F 0.015 0.020 0.025

G 0.020 0.025 0.030

TOP VIEW

SIDE VIEW

BOTTOM VIEW: REFERENCE ONLY

COMPONENTS AND PLACEMENTS

MAY DIFFER FROM THOSE SHOWN

Page 10

DS1330W

022598 10/11

DS1330W NONVOLATILE SRAM, 34–PIN POWERCAP MODULE WITH POWERCAP

PKG

DIM

INCHES

MIN NOM MAX

A 0.920 0.925 0.930

B 0.955 0.960 0.965

C 0.240 0.245 0.250

D 0.052 0.055 0.058

E 0.048 0.050 0.052

F 0.015 0.020 0.025

G 0.020 0.025 0.030

TOP VIEW

SIDE VIEW

BOTTOM VIEW: REFERENCE ONLY

COMPONENTS AND PLACEMENTS

MAY DIFFER FROM THOSE SHOWN

ASSEMBLY AND USE

Reflow soldering

Dallas Semiconductor recommends that

PowerCap Module bases experience

one pass through solder reflow oriented

label–side up (live–bug).

Hand soldering and touch–up

Do not touch soldering iron to leads for

more than 3 seconds. To solder, apply

flux to the pad, heat the lead frame pad

and apply solder. To remove part, apply

flux, heat pad until solder reflows, and

use a solder wick.

LPM replacement in a socket

To replace a Low Profile Module in a

68–pin PLCC socket, attach a

DS9034PC PowerCap to a module base

then insert the complete module into the

socket one row of leads at a time, pushing only on the corners of the cap. Never

apply force to the center of the device.

To remove from a socket, use a PLCC

extraction tool and ensure that it does

not hit or damage any of the module IC

components. Do not use any other tool

for extraction.

Page 11

DS1330W

022598 11/11

RECOMMENDED POWERCAP MODULE LAND PATTERN

PKG

DIM

INCHES

MIN NOM MAX

A – 1.050 –

B – 0.826 –

C – 0.050 –

D – 0.030 –

E – 0.112 –

A

D

B

C

E

16 PL

RECOMMENDED POWERCAP MODULE SOLDER STENCIL

PKG

DIM

INCHES

MIN NOM MAX

A – 1.050 –

B – 0.890 –

C – 0.050 –

D – 0.030 –

E – 0.080 –

A

D

B

C

E

16 PL

Loading...

Loading...