Datasheet DAC714U, DAC714P, DAC714HL, DAC714HC, DAC714HB Datasheet (Burr Brown Corporation)

Page 1

®

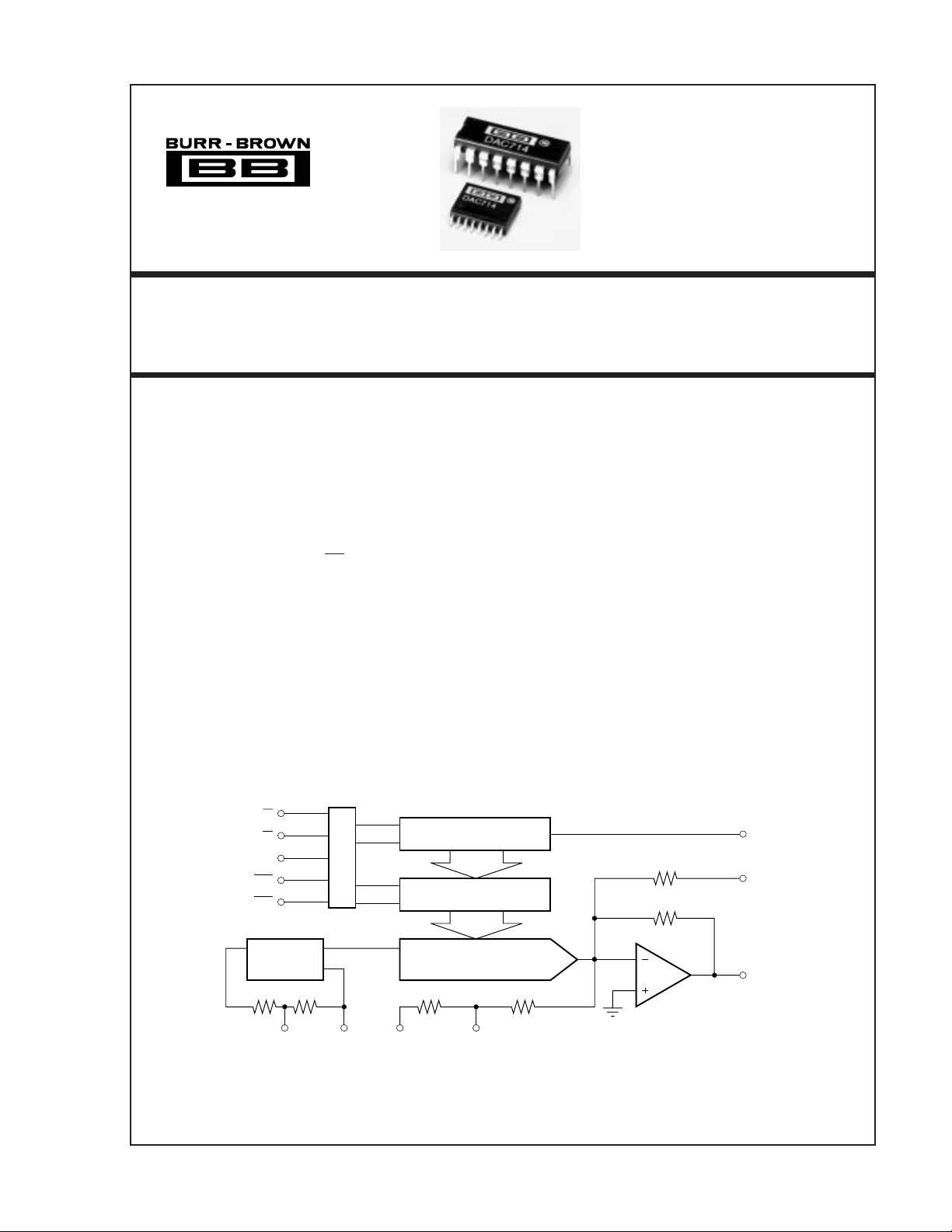

DAC714

16-Bit DIGITAL-TO-ANALOG CONVERTER

With Serial Data Interface

FEATURES:

● SERIAL DIGITAL INTERFACE

● VOLTAGE OUTPUT:

●

±1 LSB INTEGRAL LINEARITY

16-BIT MONOTONIC OVER TEMPERATURE

●

● PRECISION INTERNAL REFERENCE

● LOW NOISE: 120nV/ √Hz Including Reference

● 16-LEAD PLASTIC AND CERAMIC SKINNY

DIP AND PLASTIC SOIC PACKAGES

A

0

A

1

SDI

CLK

CLR

±10V, ±5V, 0 to +10V

Input Shift Register

D/A Latch

DESCRIPTION

The DAC714 is a complete monolithic digital-toanalog converter including a +10V temperature compensated reference, current-to-voltage amplifier, a

high-speed synchronous serial interface, a serial output which allows cascading multiple converters, and

an asynchronous clear function which immediately

sets the output voltage to midscale.

The output voltage range is ±10V, ±5V, or 0 to +10V

while operating from ±12V or ±15V supplies. The

gain and bipolar offset adjustments are designed so

that they can be set via external potentiometers or

external D/A converters. The output amplifier is protected against short circuit to ground.

The 16-pin DAC714 is available in a plastic 0.3" DIP,

ceramic 0.3" CERDIP, and wide-body plastic SOIC

package. The DAC714P, U, HB, and HC are specified

over the –40°C to +85°C temperature range while the

DAC714HL is specified over the 0°C to +70°C range.

SDO

16

R

FB2

16

Reference

Circuit

V

REF OUT

Adjust

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111 • Twx: 910-952-1111

Internet: http://www.burr-brown.com/ • FAXLine: (800) 548-6133 (US/Canada Only) • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

© 1994 Burr-Brown Corporation PDS-1252D Printed in U.S.A. July, 1997

+10V

16-Bit D/A Converter

R

BPO

V

OUT

Offset AdjustGain

®

1

DAC714

Page 2

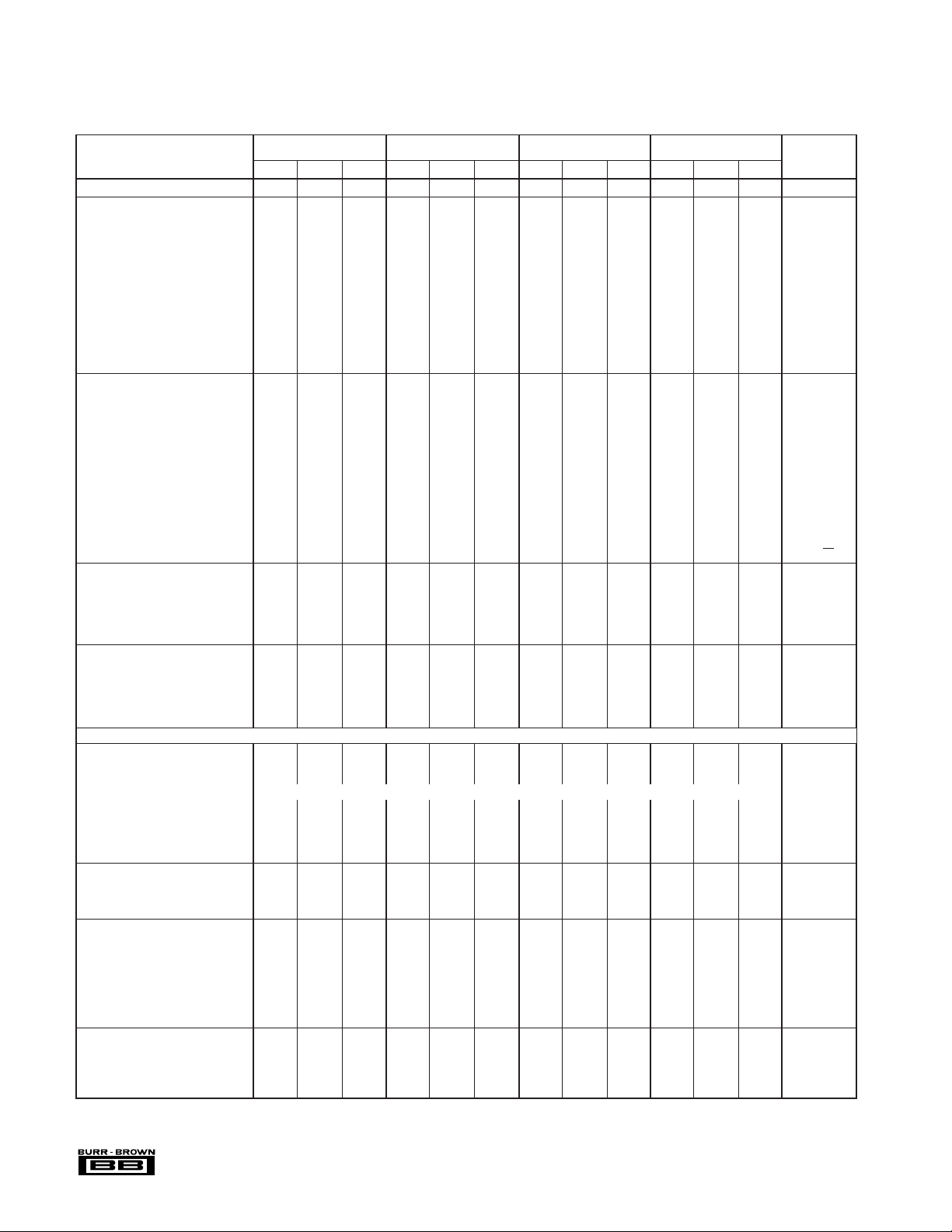

SPECIFICATIONS

At TA = +25°C, +V

PARAMETER MIN TYP MAX MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

TRANSFER CHARACTERISTICS

ACCURACY

Linearity Error ±4 ±2 ±1 ±1 LSB

T

to T

MIN

MAX

Differential Linearity Error ±4 ±2 ±1 ±1 LSB

T

to T

MIN

MAX

Monotonicity 14 15 16 16 Bits

Monotonicity Over Spec Temp Range 13 14 15 16 Bits

Gain Error

T

to T

MIN

MAX

Unipolar/Bipolar Zero Error

T

to T

MIN

MAX

Power Supply Sensitivity of Gain ±0.003 ±0.003 ±0.003 ±0.003 %FSR/%V

DYNAMIC PERFORMANCE

Settling Time

(to ±0.003%FSR, 5kΩ || 500pF Load)

20V Output Step 6 10 6 10 6 10 6 10 µs

1LSB Output Step

Output Slew Rate 10 10 10 10 V/µs

Total Harmonic Distortion

0dB, 1001Hz, f

–20dB, 1001Hz, f

–60dB, 1001Hz, f

SINAD: 1001Hz, f

Digital Feedthrough

Digital-to-Analog Glitch Impulse

Output Noise Voltage (includes reference)

ANALOG OUTPUT

Output Voltage Range

+V

, –VCC = ±11.4V ±10 ±10 ±10 ±10 V

CC

Output Current ±5 ±5 ±5 ±5mA

Output Impedance 0.1 0.1 0.1 0.1 Ω

Short Circuit to ACOM Duration Indefinite Indefinite Indefinite Indefinite

REFERENCE VOLTAGE

Voltage +9.975 +10.000 +10.025 +9.975 +10.000 +10.025 +9.975 +10.000 +10.025 +9.975 +10.000 +10.025 V

T

to T

MIN

MAX

Output Resistance 1 1 1 1 Ω

Source Current 2 2 2 2 mA

Short Circuit to ACOM Duration Indefinite Indefinite Indefinite Indefinite

INTERFACE

RESOLUTION 16 16 16 16 Bits

DIGITAL INPUTS

Serial Data Input Code

Logic Levels

V

IH

V

IL

(VI = +2.7V) ±10 ±10 ±10 ±10 µA

I

IH

(VI = +0.4V) ±10 ±10 ±10 ±10 µA

I

IL

DIGITAL OUTPUT

Serial Data

V

OL (ISINK

V

OH (ISOURCE

POWER SUPPLY REQUIREMENTS

Voltage

+V

CC

–V

CC

Current (No Load, ±15V Supplies)

+V

CC

–V

CC

Power Dissipation

TEMPERATURE RANGES

Specification

All Grades –40 +85 –40 +85 –40 +85 0 +70 °C

Storage –60 +150 –60 +150 –60 +150 –60 +150 °C

Thermal Coefficient,

NOTES: (1) Digital inputs are TTL and +5V CMOS compatible over the specification temperature range. (2) FSR means Full Scale Range. For example, for ±10V output, FSR = 20V. (3) Errors

externally adjustable to zero. (4) Maximum represents the 3σ limit. Not 100% tested for this parameter. (5) For the worst-case Binary Two’s Complement code changes: FFFF

to FFFFH. (6) During power supply turn on, the transient supply current may approach 3x the maximum quiescent specification. (7) Typical (i.e. rated) supply voltages times maximum currents.

= +12V and +15V, –VCC = –12V, and –15V, unless otherwise noted.

CC

DAC714P, U DAC714HB DAC714HC DAC714HL

±8 ±4 ±2 ±2 LSB

±8 ±4 ±2 ±1 LSB

(3)

(3)

±0.1 ±0.1 ±0.1 ±0.1 %

±0.25 ±0.25 ±0.25 ±0.25 %

±0.1 ±0.1 ±0.1 ±0.1 % of FSR

±0.2 ±0.2 ±0.2 ±0.2 % of FSR

±30 ±30 ±30 ±30 ppm FSR/%V

(4)

(5)

= 100kHz 0.005 0.005 0.005 0.005 %

S

= 100kHz 0.03 0.03 0.03 0.03 %

S

= 100kHz 3.0 3.0 3.0 3.0 %

S

= 100kHz 87 87 87 87 dB

S

(5)

(5)

4444µs

2 2 2 2 nV–s

15 15 15 15 nV–s

120 120 120 120 nV/√Hz

+9.960 +10.040 +9.960 +10.040 +9.960 +10.040 +9.960 +10.040 V

(1)

+2.0

(VCC –1.4)

+2.0

Binary Two’s Complement

(VCC –1.4)

+2.0

(VCC –1.4)

+2.0

(VCC –1.4)

0 +0.8 0 +0.8 0 +0.8 0 +0.8 V

= 1.6mA) 0 +0.4 0 +0.4 0 +0.4 0 +0.4 V

= 500µA), T

MIN

to T

+2.4 +5 +2.4 +5 +2.4 +5 +2.4 +5 V

MAX

+11.4 +15 +16.5 +11.4 +15 +16.5 +11.4 +15 +16.5 +11.4 +15 +16.5 V

–11.4 –15 –16.5 –11.4 –15 –16.5 –11.4 –15 –16.5 –11.4 –15 –16.5 V

(6)

13 16 13 16 13 16 13 16 mA

(7)

θ

JA

®

DAC714

22 26 22 26 22 26 22 26 mA

625 625 625 625 mW

75 75 75 75 °C/W

to 0000H and 0000

H

2

(2)

CC

CC

V

H

Page 3

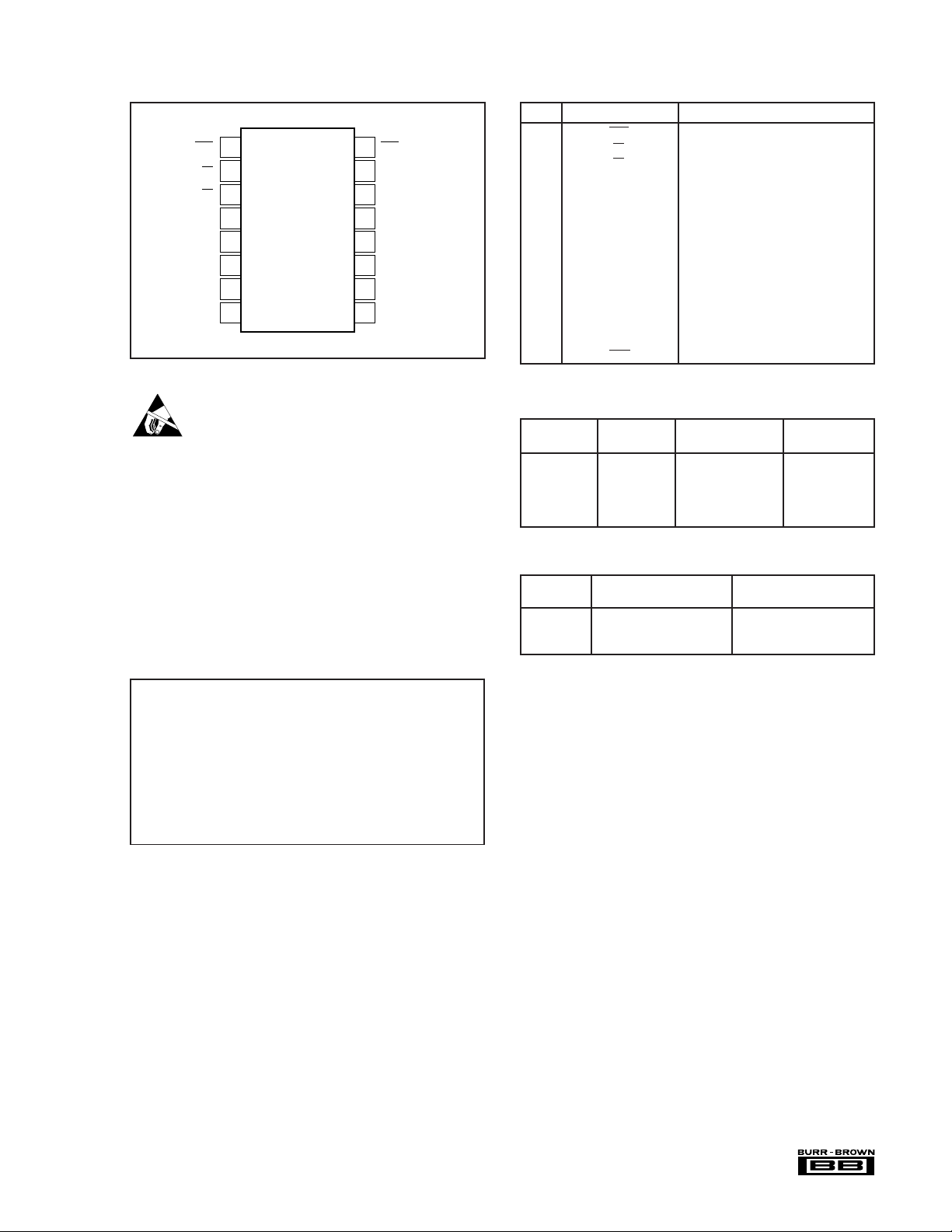

PIN CONFIGURATION

Top View

1

CLK

2

A

0

3

A

1

4

SDI

5

SDO

6

DCOM

7

+V

CC

8

ACOM

DAC714

16

CLR

15

–V

14

Gain Adjust

13

Offset Adjust

12

V

11

R

10

R

9

V

CC

REF OUT

BPO

FB2

OUT

SOIC/DIP

PIN DESCRIPTIONS

PIN LABEL DESCRIPTION

1 CLK Serial Data Clock

2A

3A

4 SDI Serial Data Input

5 SDO Serial Data Output

6 DCOM Digital Ground

7+V

8 ACOM Analog Ground

9V

10 R

11 R

12 V

13 Offset Adjust Offset Adjust

14 Gain Adjust Gain Adjust

15 –V

16 CLR Clear

0

1

CC

OUT

FB2

BPO

REF OUT

CC

Enable for Input Register (Active Low)

Enable for D/A Latch (Active Low)

Positive Power Supply

D/A Output

±10V Range Feedback Output

Bipolar Offset

Voltage Reference Output

Negative Power Supply

ELECTROSTATIC

DISCHARGE SENSITIVITY

Electrostatic discharge can cause damage ranging from performance degradation to complete device failure. BurrBrown Corporation recommends that all integrated circuits

be handled and stored using appropriate ESD protection

methods.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet

published specifications.

ABSOLUTE MAXIMUM RATINGS

to Common .................................................................... 0V to +17V

+V

CC

–V

to Common .................................................................... 0V to –17V

CC

+V

to –VCC....................................................................................... 34V

CC

ACOM to DCOM ............................................................................... ±0.5V

Digital Inputs to Common............................................. –1V to (V

External Voltage Applied to BPO and Range Resistors..................... ±V

V

......................................................... Indefinite Short to Common

REF OUT

V

............................................................... Indefinite Short to Common

OUT

SDO ............................................................... Indefinite Short to Common

Power Dissipation .......................................................................... 750mW

Storage Temperature ...................................................... –60°C to +150°C

Lead Temperature (soldering, 10s)................................................ +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

(1)

CC

–0.7V)

CC

ORDERING INFORMATION

PRODUCT PACKAGE max at +25

DAC714P Plastic DIP ±4 LSB –40°C to +85°C

DAC714U Plastic SOIC ±4 LSB –40°C to +85°C

DAC714HB Ceramic DIP ±2 LSB –40°C to +85°C

DAC714HC Ceramic DIP ±1 LSB –40°C to +85°C

DAC714HL Ceramic DIP ±1 LSB 0°C to +70°C

LINEARITY ERROR TEMPERATURE

°C RANGE

PACKAGE INFORMATION

PRODUCT PACKAGE NUMBER

PACKAGE DRAWING

DAC714P Plastic DIP 180

DAC714U Plastic SOIC 211

DAC714H Ceramic DIP 129

NOTE: (1) For detailed drawing and dimension table, please see end of data sheet,

or Appendix C of Burr-Brown IC Data Book.

(1)

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

3

DAC714

®

Page 4

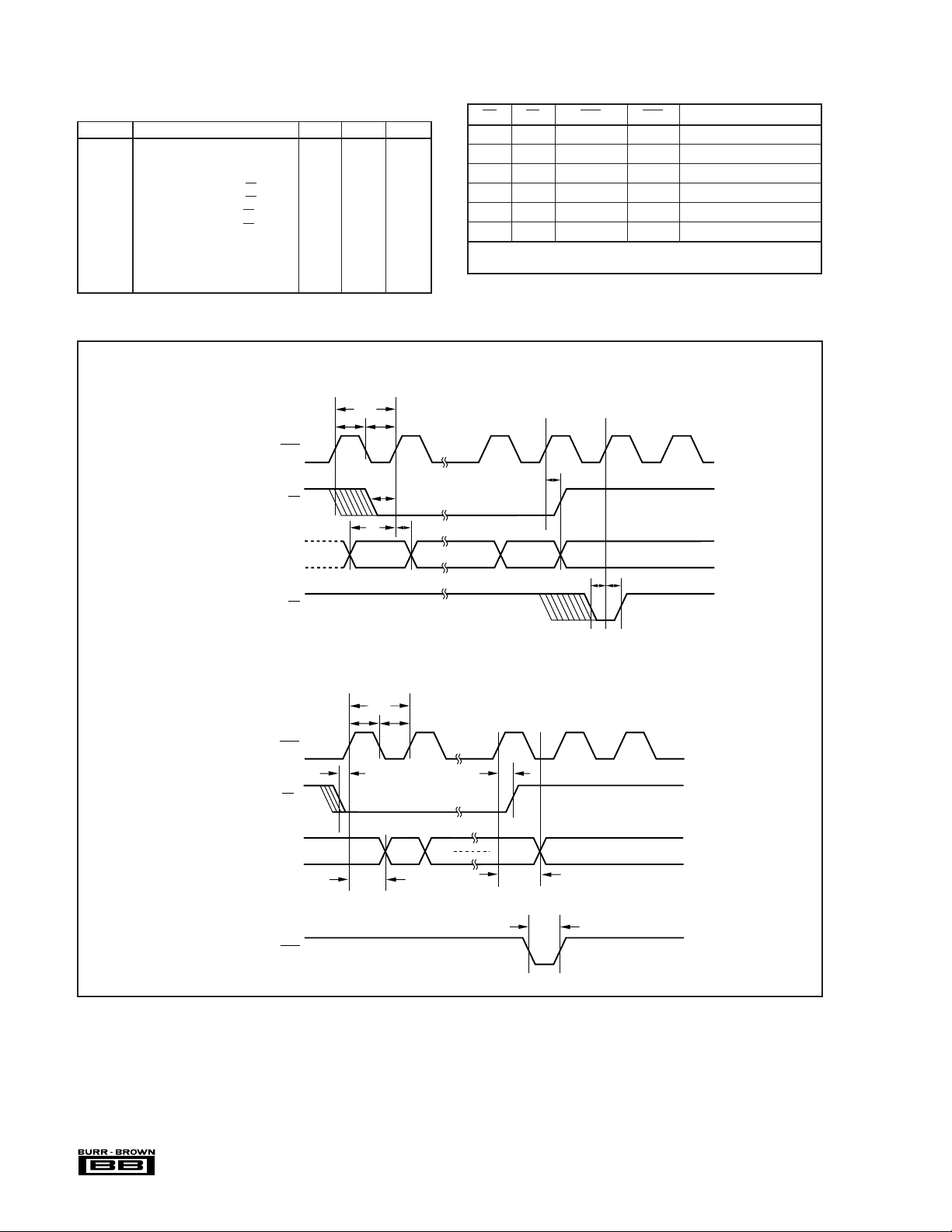

TIMING SPECIFICATIONS

TA = –40°C to +85°C, +VCC = +12V or +15V, –VCC = –12V or –15V.

SYMBOL PARAMETER MIN MAX UNITS

t

CLK

t

CL

t

CH

t

A0S

t

A1S

t

AOH

t

A1H

t

DS

t

DH

t

DSOP

t

CP

Data Clock Period 100 ns

Clock LOW 50 ns

Clock HIGH 50 ns

Setup Time for A

Setup Time for A

Hold Time for A

Hold Time for A

Setup Time for DATA 50 ns

0

1

0

1

50 ns

50 ns

0ns

0ns

Hold Time for DATA 10 ns

Output Propagation Delay 140 ns

Clear Pulsewidth 200 ns

TIMING DIAGRAMS

Serial Data In

t

CLK

Serial Data Input

MSB First

Latch Data

In D/A Latch

CLK

SDI

t

CH

A

0

A

1

t

CL

t

A0S

t

DS

D

15

TRUTH TABLE

A

A

0

011 → 0 → 1 1 Shift Serial Data into SDI

101 → 0 → 1 1 Load D/A Latch

111 → 0 → 1 1 No Change

001 → 0 → 1 1 Two Wire Operation

X X 1 1 No Change

X X X 0 Reset D/A Latch

NOTES: X = Don’t Care. (1) All digital input changes will appear at the

output.

t

A0H

t

DH

D

14

D

0

CLK CLR DESCRIPTION

1

t

A1S

t

A1H

(1)

Serial Data

Out

CLK

A

SDO

CLR

Serial Data Out

t

CLK

t

CH

0

t

DSOP

t

CL

t

A0S

D

15

D

14

Clear

t

A0H

D

0

t

DSOP

t

CP

®

DAC714

4

Page 5

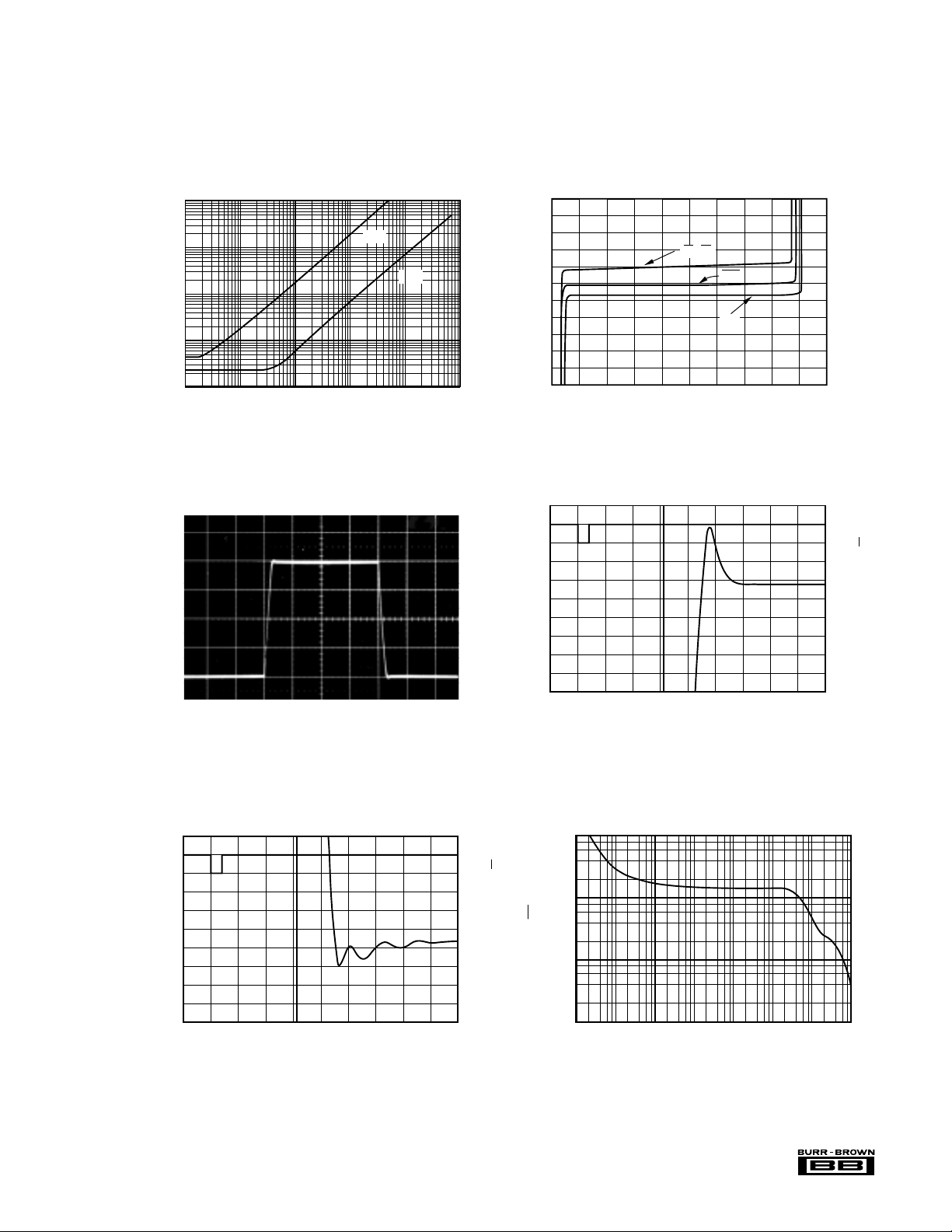

TYPICAL PERFORMANCE CURVES

1000

100

10

1

1 10 100 1k 10k 100k 1M 10M

Frequency (Hz)

nV/√Hz

V

OUT

SPECTRAL NOISE DENSITY

At TA = +25°C, VCC = ±15V, unless otherwise noted.

POWER SUPPLY REJECTION vs

POWER SUPPLY RIPPLE FREQUENCY

1k

–V

100

10

(ppm of FSR/ %)

1

0.1

[Change in FSR]/[Change in Supply Voltage]

10 100 1k 10k 100k 1M

Frequency (Hz)

± FULL SCALE OUTPUT SWING

10

OUT

0

V (V)

–10

Time (10µs/div)

LOGIC vs V LEVEL

2.0

CC

+V

CC

1.0

A

, A

0

1

CLR

0

I Digital Input (µA)

–1.0

SDI

–2.0

–0.85 0 2.55 4.25 5.95 6.8

0.85 1.7 3.4 5.1

V Digital Input

SETTLING TIME, +10V TO –10V

2500

2000

1500

+5V

0V

(V)

1

A

1000

500

0

–500

–1000

∆ Around –10V (µV)

–1500

–2000

–2500

Time (1µs/div)

2500

SETTLING TIME, –10V TO +10V

2000

1500

1000

500

0

–500

–1000

∆ Around +10V (µV)

–1500

–2000

–2500

Time (1µs/div)

+5V

0V

1

A

®

5

DAC714

Page 6

DISCUSSION OF

SPECIFICATIONS

LINEARITY ERROR

Linearity error is defined as the deviation of the analog

output from a straight line drawn between the end points of

the transfer characteristic.

DIFFERENTIAL LINEARITY ERROR

Differential linearity error (DLE) is the deviation from

1LSB of an output change from one adjacent state to the

next. A DLE specification of ±1/2LSB means that the output

step size can range from 1/2LSB to 3/2LSB when the digital

input code changes from one code word to the adjacent code

word. If the DLE is more positive than –1LSB, the D/A is

said to be monotonic.

MONOTONICITY

A D/A converter is monotonic if the output either increases

or remains the same for increasing digital input values.

Monotonicity of the C and L grades is guaranteed over the

specification temperature range to 16 bits.

SETTLING TIME

Settling time is the total time (including slew time) for the

D/A output to settle to within an error band around its final

value after a change in input. Settling times are specified to

within ±0.003% of Full Scale Range (FSR) for an output

step change of 20V and 1LSB. The 1LSB change is measured at the Major Carry (FFFFH to 0000H, and 0000H to

FFFFH: BTC codes), the input transition at which worst-case

settling time occurs.

TOTAL HARMONIC DISTORTION

Total harmonic distortion is defined as the ratio of the

square root of the sum of the squares of the values of the

harmonics to the value of the fundamental frequency. It is

expressed in % of the fundamental frequency amplitude at

sampling rate f

SIGNAL-TO-NOISE

AND DISTORTION RATIO (SINAD)

SINAD includes all the harmonic and outstanding spurious

components in the definition of output noise power in

addition to quantizing and internal random noise power.

SINAD is expressed in dB at a specified input frequency and

sampling rate, f

DIGITAL-TO-ANALOG GLITCH IMPULSE

The amount of charge injected into the analog output from

the digital inputs when the inputs change state. It is measured at half scale at the input codes where as many as

possible switches change state—from 0000

.

S

.

S

to FFFFH.

H

DIGITAL FEEDTHROUGH

When the A/D is not selected, high frequency logic activity

on the digital inputs is coupled through the device and shows

up as output noise. This noise is digital feedthrough.

OPERATION

The DAC714 is a monolithic integrated-circuit 16-bit D/A

converter complete with 16-bit D/A switches and ladder

network, voltage reference, output amplifier and a serial

interface.

INTERFACE LOGIC

The DAC714 has double-buffered data latches. The input

data latch holds a 16-bit data word before loading it into the

second latch, the D/A latch. This double-buffered organization permits simultaneous update of several D/A converters.

All digital control inputs are active low. Refer to the block

diagram shown in Figure 1.

All latches are level-triggered. Data present when the enable

inputs are logic “0” will enter the latch. When the enable

inputs return to logic “1”, the data is latched.

The CLR input resets both the input latch and the D/A latch

to 0000

LOGIC INPUT COMPATIBILITY

The DAC714 digital inputs are TTL compatible (1.4V switching level), low leakage, and high impedance. Thus the inputs

are suitable for being driven by any type of 5V logic Family,

such as CMOS. An equivalent circuit for the digital inputs

is shown in Figure 2.

The inputs will float to logic “0” if left unconnected. It is

recommended that any unused inputs be connected to DCOM

to improve noise immunity.

Digital inputs remain high impedance when power is off.

INPUT CODING

The DAC714 is designed to accept binary two’s complement (BTC) input codes with the MSB first which are

compatible with bipolar analog output operation. For this

configuration, a digital input of 7FFF

scale output, 8000H produces a minus full scale output, and

0000H produces bipolar zero output.

INTERNAL REFERENCE

The DAC714 contains a +10V reference. The reference

output may be used to drive external loads, sourcing up to

2mA. The load current should be constant, otherwise the

gain and bipolar offset of the converter will vary.

(midscale).

H

produces a plus full

H

®

DAC714

6

Page 7

Gain Adjust

+ Full Scale

All Bits

Logic 0

Range of

Offset Adjust

Offset Adj.

Translates

the Line

Digital Input

All Bits

Logic 1

Analog Output

Full Scale

Range

Gain Adjust

Rotates the Line

– Full Scale

MSB on All

Others Off

Bipolar

Offset

Range of

Gain Adjust

≈ ±0.3%

≈ ±0.3%

14 12

V

REF OUT

+V

– V

CC

7

CC

15

CLK

CLR

180Ω

15kΩ

+2.5V

1

3A

1

16

2A

0

4SDI

5SDO

–V

CC

+10V

Reference

D/A Switches

Shift Register

DAC Latch

16

10kΩ

8 6

ACOM

250Ω

9750Ω

10kΩ

DCOM

R

10

FB2

R

11

BPO

Offset

13

Adjust

V

9

OUT

FIGURE 1. DAC714 Block Diagram.

+V

CC

ESD Protection Circuit

Digital

Input

–V

1kΩ

6.8V 5pF

CC

FIGURE 2. Equivalent Circuit of Digital Inputs.

OUTPUT VOLTAGE SWING

The output amplifier of the DAC714 is designed to achieve

a ±10V output range while operating on ±11.4V or higher

power supplies.

GAIN AND OFFSET ADJUSTMENTS

Figure 3 illustrates the relationship of offset and gain adjustments for a bipolar connected D/A converter. Offset should

be adjusted first to avoid interaction of adjustments. See

Table I for calibration values and codes. These adjustments

have a minimum range of ±0.3%.

FIGURE 3. Relationship of Offset and Gain Adjustments.

Offset Adjustment

Apply the digital input code, 8000

, that produces the maxi-

H

mum negative output voltage and adjust the offset potentiometer

or the offset adjust D/A converter for –10V (or 0V unipolar).

7

DAC714

®

Page 8

DAC714 CALIBRATION VALUES

DIGITAL INPUT CODE ANALOG OUTPUT (V)

BINARY TWO’S BIPOLAR UNIPOLAR

COMPLEMENT, BTC 20V RANGE 10V RANGE DESCRIPTION

7FFF

|

4000

|

0001

0000

FFFF

|

C000

|

8000

H

H

H

H

H

H

H

+9.999695 +9.999847 + Full Scale –1LSB

+5.000000 +7.500000 3/4 Scale

+0.000305 +5.000153 BPZ + 1LSB

0.000000 +5.000000 Bipolar Zero (BPZ)

–0.000305 +4.999847 BPZ – 1LSB

–5.000000 +2.500000 1/4 Scale

–10.00000 0.000000 Minus Full Scale

TABLE I. Digital Input and Analog Output Voltage Calibra-

tion Values.

Gain Adjustment

Apply the digital input that gives the maximum positive

voltage output. Adjust the gain potentiometer or the gain

adjust D/A converter for this positive full scale voltage.

INSTALLATION

GENERAL CONSIDERATIONS

Due to the high-accuracy of the DAC714 system design

problems such as grounding and contact resistance become

very important. A 16-bit converter with a 20V full-scale

range has a 1LSB value of 305µV. With a load current of

5mA, series wiring and connector resistance of only 60mΩ

will cause a voltage drop of 300µV. To understand what this

means in terms of a system layout, the resistivity of a typical

1 ounce copper-clad printed circuit board is 1/2 mΩ per

square. For a 5mA load, a 10 milliinch wide printed circuit

conductor 60 milliinches long will result in a voltage drop of

150µV.

The analog output of DAC714 has an LSB size of 305µV

(–96dB) in the bipolar mode. The rms noise floor of the D/A

should remain below this level in the frequency range of

interest. The DAC714’s output noise spectral density (which

includes the noise contributed by the internal reference,) is

shown in the Typical Performance Curves section.

Wiring to high-resolution D/A converters should be routed

to provide optimum isolation from sources of RFI and EMI.

The key to elimination of RF radiation or pickup is small

loop area. Signal leads and their return conductors should be

kept close together such that they present a small capture

cross-section for any external field. Wire-wrap construction

is not recommended.

POWER SUPPLY AND

REFERENCE CONNECTIONS

Power supply decoupling capacitors should be added as

shown in Figure 4. Best performance occurs using a 1 to

10µF tantalum capacitor at –V

. Applications with less

CC

+12V to +15V

1µF

1

2

3

4

DAC714

5

6

DCOM

7

+V

CC

+

8

ACOM

–V

16

–12V to –15V

15

CC

14

13

12

11

10

1µF

+

9

FIGURE 4. Power Supply Connections.

critical settling time may be able to use 0.01µF at –V

CC

as well as at +VCC. The capacitors should be located

close to the package.

The DAC714 has separate ANALOG COMMON and DIGITAL COMMON pins. The current through DCOM is mostly

switching transients and are up to 1mA peak in amplitude.

The current through ACOM is typically 5µA for all codes.

Use separate analog and digital ground planes with a single

interconnection point to minimize ground loops. The analog

pins are located adjacent to each other to help isolate analog

from digital signals. Analog signals should be routed as far

as possible from digital signals and should cross them at

right angles. A solid analog ground plane around the D/A

package, as well as under it in the vicinity of the analog and

power supply pins, will isolate the D/A from switching

currents. It is recommended that DCOM and ACOM be

connected directly to the ground planes under the package.

If several DAC714s are used or if DAC714 shares supplies

with other components, connecting the ACOM and DCOM

lines to together once at the power supplies rather than at

each chip may give better results.

LOAD CONNECTIONS

Since the reference point for V

OUT

and V

REF OUT

is the

ACOM pin, it is important to connect the D/A converter load

directly to the ACOM pin. Refer to Figure 5.

Lead and contact resistances are represented by R

through

1

R3. As long as the load resistance RL is constant, R1 simply

introduces a gain error and can be removed by gain adjustment of the D/A or system-wide gain calibration. R2 is part

of RL if the output voltage is sensed at ACOM.

In some applications it is impractical to return the load to the

ACOM pin of the D/A converter. Sensing the output voltage

at the SYSTEM GROUND point is reasonable, because there

is no change in DAC714 ACOM current, provided that R

is

3

a low-resistance ground plane or conductor. In this case you

may wish to connect DCOM to SYSTEM GROUND as well.

®

DAC714

8

Page 9

GAIN AND OFFSET ADJUST

Connections Using Potentiometers

GAIN and OFFSET adjust pins provide for trim using

external potentiometers. 15-turn potentiometers provide sufficient resolution. Range of adjustment of these trims is at

least ±0.3% of Full Scale Range. Refer to Figure 6.

Using D/A Converters

The GAIN ADJUST and OFFSET ADJUST circuits of

the DAC714 have been arranged so that these points may

be easily driven by external D/A converters. Refer to

Figure 7. 12-bit D/A converters provide an OFFSET

adjust resolution and a GAIN adjust resolution of 30µV

to 50µV per LSB step.

Nominal values of GAIN and OFFSET occur when the D/A

converters outputs are at approximately half scale, +5V.

OUTPUT VOLTAGE RANGE CONNECTIONS

The DAC714 output amplifier is connected internally to

provide a 20V output range. For other ranges and configurations, see Figures 6 and 7.

DIGITAL INTERFACE

SERIAL INTERFACE

The DAC714 has a serial interface with two data buffers

which can be used for either synchronous or asynchronous

updating of multiple D/A converters. A0 is the enable control

for the input shift register. A1 is the enable for the D/A Latch.

CLK is used to strobe data into the latches enabled by A0 and

A1. A CLR function is also provided and when enabled it sets

the shift register and the D/A Latch to 0000

is midscale).

Multiple DAC714s can be connected to the same CLK and

data lines in two ways. The output of the serial shift register

is available as SDO so that any number of DAC714s can be

cascaded on the same input bit stream as shown in Figures

8 and 9. This configuration allows all D/A converters to be

updated simultaneously and requires a minimum number of

control signals. These configurations do require 16N CLK

cycles to load any given D/A converter, where N is the

number of D/A converters.

The DAC714 can also be connected in parallel as shown in

Figure 10. This configuration allows any D/A converter in

the system to be updated in a maximum of 16 CLK cycles.

(output voltage

H

SDI

CLR

A

A

0

1

DAC714

Bus

Interface

System Ground

V

REFRBPO

10kΩ

V

REF

ACOMDCOM

Alternate Ground

3

Sense Connection

To +V

CC

(1)

0.01µF

0.01µF

To –V

CC

NOTE: (1) Locate close to DAC714 package.

R

10kΩ10kΩ

Analog

Power

Supply

R

FB2

R

1

V

OUT

R

L

R

2

Sense

Output

FIGURE 5. System Ground Considerations for High-Resolution D/A Converters.

9

®

DAC714

Page 10

Internal

+10V Reference

180Ω

15kΩ

IDAC

0-2mA

8

Offset Adjust

9.75kΩ

ACOM

V

REF OUT

Gain Adjust

10kΩ

10kΩ

12

P

1

1kΩ

R

1

100Ω

14

R

2MΩ

13

V

27kΩ

OUT

R

3

10

R

FB2

9

2

+V

CC

10kΩ to 100kΩ

–V

CC

For no external adjustments, pins 13 and 14 are not

connected. External resistors R

values. Range of adjustment at least ±0.3% FSR.

- R3 are standard ±1%

1

FIGURE 6a. Manual Offset and Gain Adjust Circuits; Unipolar Mode (0V to +10V output range).

Internal

+10V Reference

180Ω 250Ω

15kΩ

IDAC

0-2mA

8

Bipolar Offset

Gain Adjust

Offset Adjust

9.75kΩ

ACOM

V

10kΩ

REF OUT

10kΩ

12

11

P

1

1kΩ

R

100Ω

P

2

1kΩ

1

R

100Ω

2

14

13

R

10

R

FB2

9

3

27kΩ

V

OUT

R

10kΩ

4

For no external adjustments, pins 13 and 14 are not

connected. External resistors R

values. Range of adjustment at least ±0.3% FSR.

- R4 are standard ±1%

1

FIGURE 6b. Manual Offset and Gain Adjust Circuits; Bipolar Mode (–5V to +5V output range).

®

DAC714

10

Page 11

Internal

+10V Reference

180Ω 250Ω

V

REF OUT

Bipolar Offset

Gain Adjust

Offset Adjust

12

11

R

200Ω

1

R

1.3kΩ

+10V

2

10kΩ

14

10kΩ

–10V

Suggested Op Amps

OPA177GP, GS or

13

5kΩ

OPA604AP, AU

15kΩ

9.75kΩ

10kΩ

10kΩ

R

FB2

10

R

3

11.8kΩ

R

4

24.3kΩ

RFBV

REF A

0 to +10V

Suggested Op Amps

OPA177GP, GS: Single or

OPA2604AP, AU: Dual

0 to +10V

RFBV

REF B

IDAC

0-2mA

±10V V

DAC714

9

OUT

For no external adjustments, pins 13 and 14 are not

connected. External resistors R

Range of adjustment at least ±0.3% FSR.

- R4 tolerance: ±1%.

1

Suggested D/As

CMOS

DAC7800: Dual: Serial Input, 12-bit Resolution

DAC7801: Dual: 8-bit Port Input, 12-bit Resolution

DAC7802: Dual: 12-bit Port Input, 12-bit Resolution

DAC7528: Dual: 8-bit Port Input, 8-bit Resolution

DAC7545: Dual: 12-bit Port Input, 12-bit Resolution

DAC8043: Single: Serial Input, 12-bit Resolution

BIPOLAR (complete)

DAC813 (Use 11-bit resolution for 0V to +10V output. No op amps required).

FIGURE 7. Gain and Offset Adjustment in the Bipolar Mode Using D/A Converters (–10V to +10V output range).

11

®

DAC714

Page 12

Data

Data Latch

Update

CLK

+5V

+5V

+5V

4

SDI

2

A0

3

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

DAC714

DAC714

DAC714

SDO

SDO

SDO

5

5

5

To other DACs

1

16

4

2

3

1

16

4

2

3

1

16

FIGURE 8a. Cascaded Serial Bus Connection with Synchronous Update.

DAC3 DAC2 DAC1

(1)

Clock

FEDCBA9876543210FEDCBA9876543210FEDCBA9876543210

Data

Data Latch

Update

NOTE: (1) Maximum Clock Frequency is 5.26MHz.

FIGURE 8b. Timing Diagram For Figure 8a.

®

DAC714

12

Page 13

Data

Data Latch

Update

+5V

+5V

+5V

4

SDI

2

A0

3

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

DAC714

DAC714

DAC714

SDO

SDO

SDO

5

5

5

To other DACs

1

16

4

2

3

1

16

4

2

3

1

16

FIGURE 9a. Cascaded Serial Bus Connection with Asynchronous Update.

DAC3 DAC2 DAC1

Data

Update

(1)

FEDCBA9876543210FEDCBA9876543210FEDCBA9876543210

Data Latch

NOTE: (1) Maximum Data Latch Frequency is 5.26MHz.

FIGURE 9b. Timing Diagram For Figure 9a.

13

®

DAC714

Page 14

Data

Data Latch 1

Update

CLK

CLR

Data Latch 2

Data Latch 3

4

SDI

2

A0

3

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

SDI

A0

A1

CLK

CLR

DAC714

DAC714

DAC714

SDO

SDO

SDO

5

5

5

1

16

4

2

3

1

16

4

2

3

1

16

FIGURE 10a. Parallel Bus Connection.

DAC1 DAC2 DAC3

(1)

Clock

FEDCBA9876543210FEDCBA9876543210FEDCBA9876543210

Data

Data Latch 1

Data Latch 2

Data Latch 3

Update

NOTE: (1) Maximum Clock Frequency is 10MHz.

FIGURE 10b. Timing Diagram For Figure 10a.

®

DAC714

14

Loading...

Loading...