CALIFORNIA MICRO DEVICES

n

r

ubes

m

USB Peripheral Power Management

CMPWR160

Features

• 3.3V regulated output up to 500mA

• Quiescent current 35µA (typical)

• Shutdown mode current 7µA (typical)

• 30ms active LOW Power-On Reset (POR) pulse

• Thermal overload protection

• Foldback current limiting protection

• Reverse-current protection

• 8 pin SOIC power package

The SmartORTM CMPWR160 combines a Low Dropout

Regulator (LDO) with a Power-On Reset (POR) pulse

generator, and is intended for Universal Serial Bus

(USB) peripherals. To meet the specification requirements of both USB 1.0 and USB 2.0, the CMPWR160

draws a very low quiescent current (35µA), and delivers

up to 500mA of load current at a fixed 3.3V output.

The POR pulse (active LOW) has a typical duration of

30ms after the output has exceeded and stabilized

above 2.9V. Thus a new POR pulse is developed each

time the regulator power is interrupted and restored,

which occurs often on USB buses when cables are

connected (or disconnected) by the user. It is not

necessary to have a VCC supply for POR to operate,

allowing the CMPWR160 to work in Wired-ORed power

systems.

Applications

• Bus-powered USB peripherals

• Self-powered USB peripherals

• Portable/battery-powered devices

• Critical power monitoring, hot-insertion devices

When VCC is powered down, the device will automatically

enter reverse-current protection mode and maintain

isolation between V

tions that can use power from the USB port in addition to

internal batteries or an AC adapter supply (Wired-ORed

power systems). In the event of V

, the device will automatically enter shutdown mode

V

OUT

and fully isolate the V

A ShutDown input (

powered down on demand. While in shutdown mode the

POR circuitry will remain active, making the device

suitable for systems which contain backup or alternative

power sources.

The CMPWR160 is available in an 8-pin SOIC thermally

enhanced package, ideal for applications where space

is tight.

and VCC. This is useful for applica-

OUT

collapsing below

CC

power source from the output.

CC

SD

) forces the regulator to be

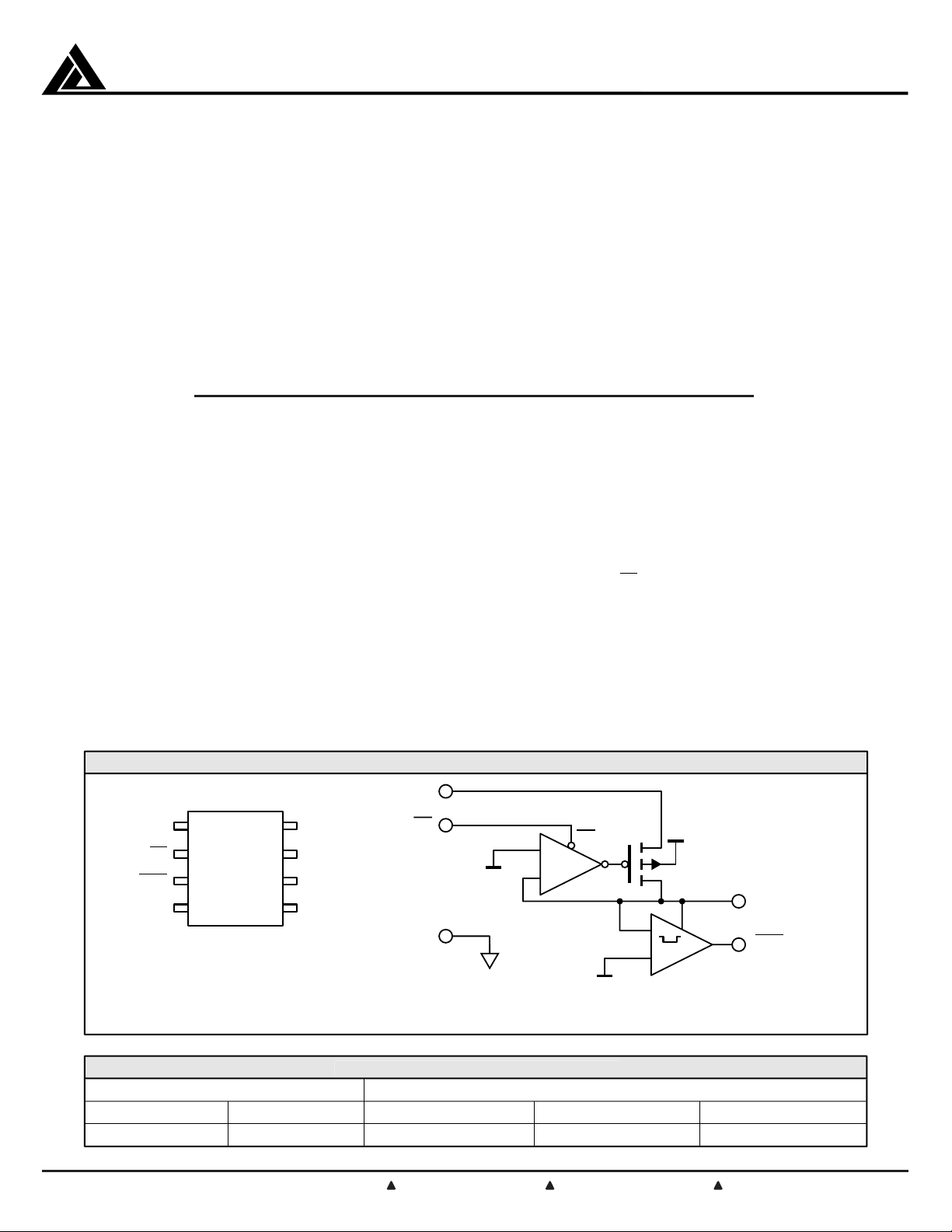

Block Diagra

V

CC

SD

V

GND

V

SD

POR

V

OUT

CC

Top View

1

2

3

4

CMPWR160

8 LEAD SOIC

8

GND

7

GND

6

GND

5

GND

Pin Diagram

Standard Part Ordering Informatio

Package Ordering Part Numbe

8 Power SOIC CMPWR160SA/T CMPWR160SA/R CMPWR160SA

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

12/5/2000

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

Style T

SD

+

REF

3.3V

–

+

30ms

–

2.9V

Simplified Electrical Schematic

Tape & Reel Part Marking

V

OUT

3.3V/500mA

POR

C1571000

1

CALIFORNIA MICRO DEVICES

s

t

5.5

gs

g

t

)

000

s

)

T

I

500

35.30.465

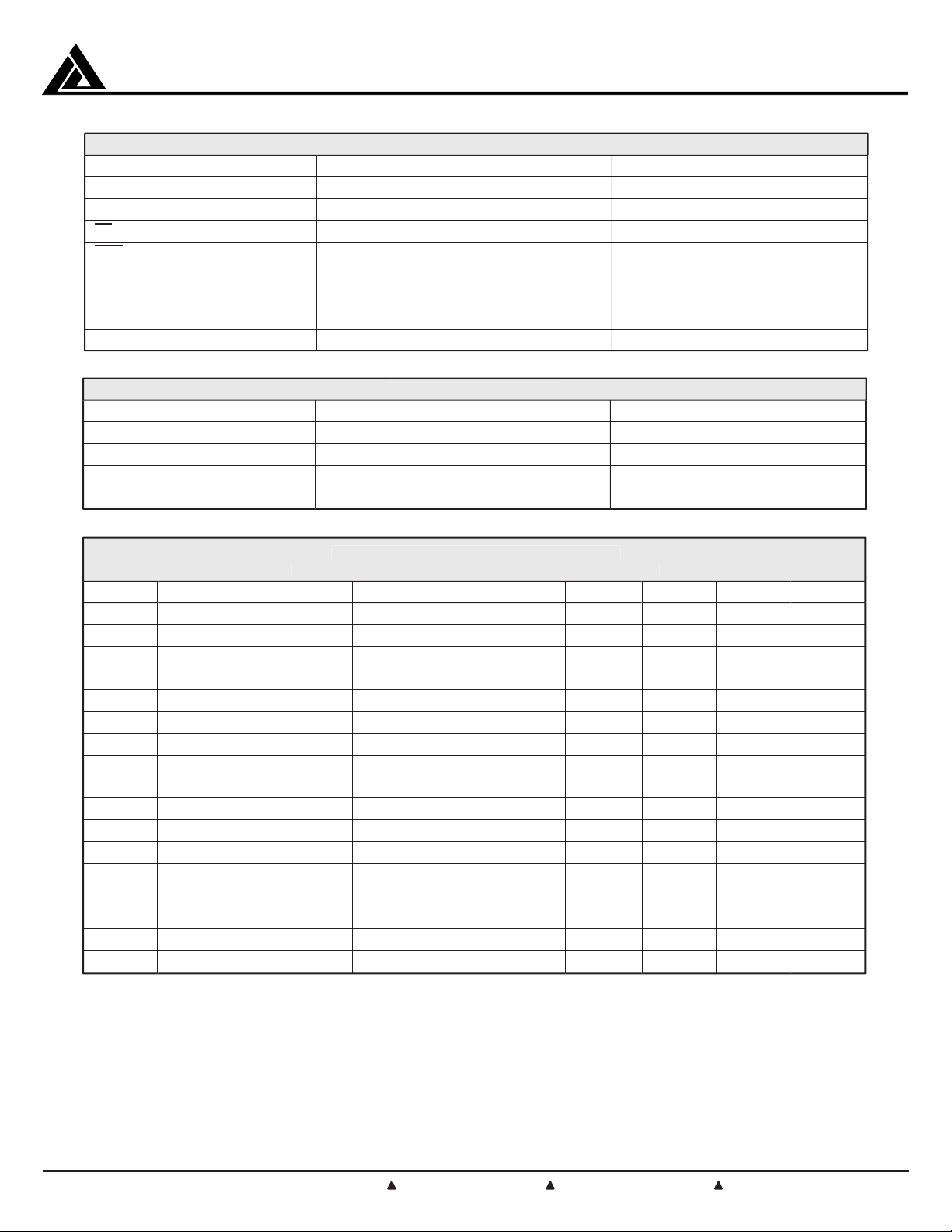

Absolute Maximum Ratin

Parameter Ratin

ESD Protection (HBM

VCC/V

Voltage 6.0, GND –0.5 V

OUT

SD Logic Input Voltage V

POR Logic Output Voltage V

OUT

2

+ 0.5, GND –0.5 V

CC

+ 0.5, GND –0.5

Temperature: Storage –40 to 150

Power Dissipation

Operating Ambient 0 to 70

Operating Junction 0 to 125

Note 1

Internally Limited

Operating Condition

Parameter Range

4.2 to

Temperature (Ambient) 0 to 70

Load Current 0 to 500 mA

10 ± 10% µF

C

EXT

ni

V

˚

ni

C

˚

CMPWR160

C

Electrical Operating Characteristic

(over operating conditions unless specified otherwise

Symbol Parameter

Regulator Output Voltage

OUT

I

Regulator Current Limit 550 mA

LIM

I

S/C

V

R LOAD

V

R LINE

Regulator Dropout Voltage MIN VCC – V

V

DO

Quiescent Supply Current Regulator Enabled (No Load) 35 50 µA

I

Q

Shutdown Supply Current Regulator Disabled 7 10 µA

I

SD

VCC Pin Reverse Leakage V

I

RCC

V

IH SD

V

IL SD

V

POR

T

POR

R

POR

Short-Circuit Current Limit 300 mA

Load Regulation VCC = 5V, I

Line Regulation VCC = 4.2V to 5.5V, I

Shutdown High Detect VCC = 5V 3.0 V

Shutdown Low Detect VCC = 5V 1.0 V

POR Detect Threshold 4.2V < VCC < 5.5V 2.8 2.9 3.0 V

POR Pulse Duration 20 30 40 ms

POR Output Impedance After POR Threshold Detected 0.2 0.5 2 kΩ

T

T

Note 1: The SOIC package used is thermally enhanced through the use of a fused integral leadframe. The power rating is based on a printed

Shutdown Temperature 160

DISABLE

Thermal Hysteresis 20

HYST

circuit board heat spreading capability equivalent to 2 square inches of copper connected to the GND pins. Typical multi-layer boards

using power plane construction will provide this heat spreading ability without the need for additional dedicated copper area. (Please

consult with factory for thermal evaluation assistance.)

mA <

OUT

Sinking to GND/Sourcing from V

onditions

<

LOAD

LOAD

OUT

mA

= 5mA to 500mA 75 mV

= 5mA 2 mV

LOAD

for I

= 500mA 0.6 0.9 V

LOAD

.1

NI

= 3.3V, VCC = 0V 1 10 µA

CC

˚

˚

C

C

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

2

12/5/2000

CALIFORNIA MICRO DEVICES

s

n

V

.

Interface Signals

CMPWR160

VCC is the input power source for the Low Drop Out

Regulator, capable of delivering 3.3V/500mA output

current even when the input is as low as 4.2V.

Internal loading on this pin is typically 35µA when the

regulator is enabled, which reduces to only 7µA when-

SD

ever the regulator is shutdown (

event of V

collapsing below V

CC

taken Low). In the

, the loading at VCC will

OUT

immediately reduce to less than 0.1µA.

If the V

pin is within a few inches of the main input

CC

filter, a capacitor may not be necessary. Otherwise an

input filter capacitor in the range of 1µF to 10µF will

ensure adequate filtering.

is the regulator shutdown input logic signal which is

SD

Active Low. This is a true CMOS input signal referenced

to V

supply. When the pin is tied High (VCC ) the

CC

regulator operates fully. When the pin is taken to GND,

the device enters shutdown mode and the regulator is

fully disabled. In this mode all critical

POR

circuitry

remains fully powered consuming less than 7µA (typical).

V

is the regulator output voltage used to power the

OUT

load. An output capacitor of 10µF is used to provide the

necessary phase compensation, thereby preventing

oscillation. The capacitor also helps to minimize the peak

output disturbance during line or load transients. Whenever V

collapses below the output the device immedi-

CC

ately enters reverse protection mode to prevent any

current flow back into the regulator pass transistor.

Under these conditions V

will also be used to provide

OUT

the necessary quiescent current for the internal reference and

POR

circuits. This ensures excellent start-up

characteristics for the regulator.

POR

is the Power-On-Reset output pin (Active Low).

When V

rises above the

OUT

POR

threshold voltage

(typically 2.9V), the pin is forced to logic low (GND). The

pin remains logic low for 30ms then it is forced logic high

(3.3V). If V

falls below the

OUT

during this 30ms interval

POR

threshold voltage

POR

will remain logic low. If it

falls below the voltage threshold and then recovers the

30ms time will reset.

If V

falls below the

OUT

POR

threshold voltage

POR

is

immediately forced to logic low.

The power-on reset circuitry is designed to remain active

under all conditions and will produce a valid output even

when V

is not present. A very low quiescent current

CC

(7µA typical) ensures continuous operation of the POR

circuit.

GND is the negative reference for all voltages. This

current that flows in the ground connection is very low

(35µA typical with the regulator enabled and 7µA typical

with the regulator disabled).

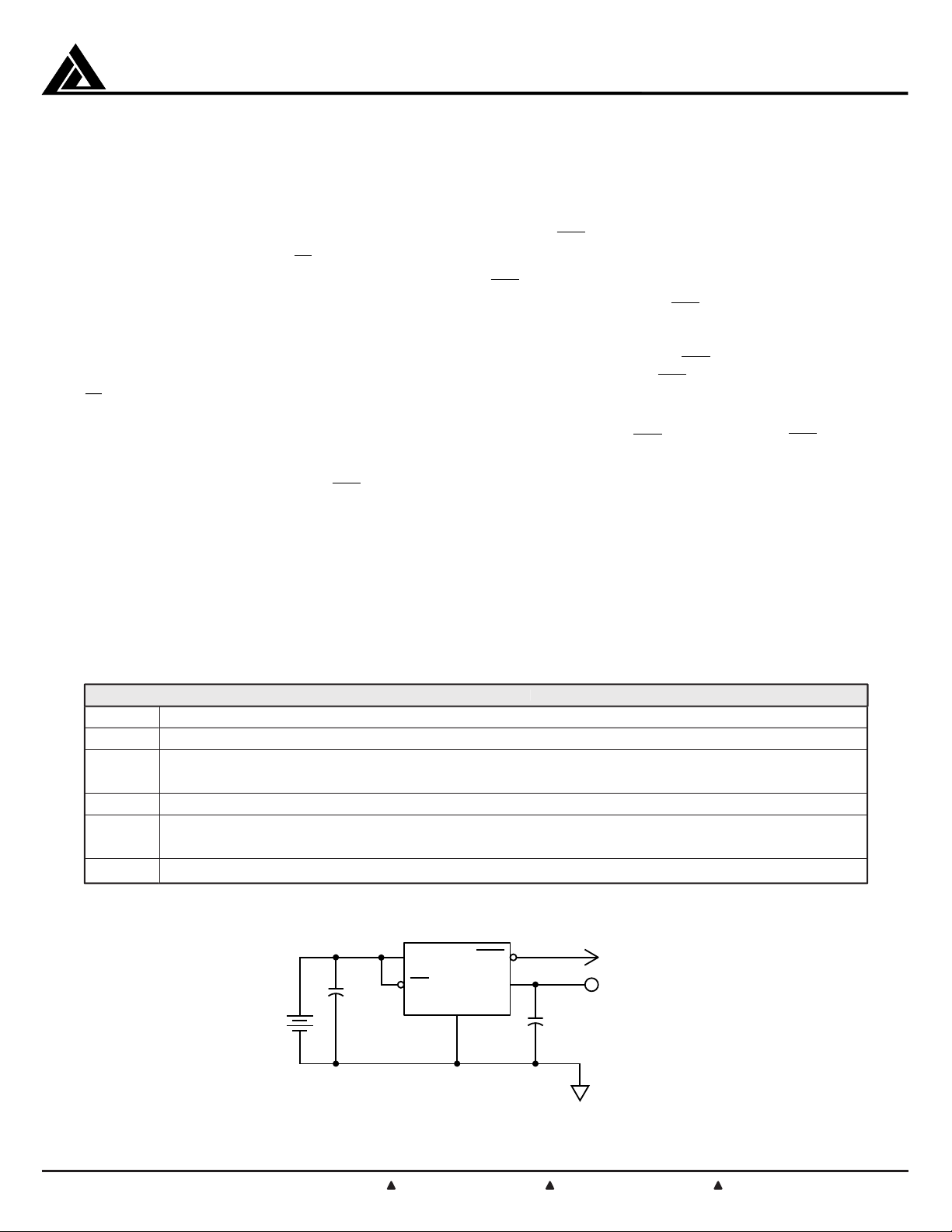

Pin Function

Symbol Descriptio

Positive supply input for regulator. When V falls below

the regulator is disabled

T

SD Shutdown control input signal (Active Low) to disable internal voltage regulator and current supply

to less than 7µA.

POR Power-On-Reset output signal is held Low until the output has been stable (>2.9V) for at least 30ms.

V

Regulator voltage ouput (3.3V) capable of delivering 500mA when device is enabled (SD is High).

OUT

Whenever the output exceeds 2.9V (TYP) the POR pulse is triggered.

GND Negative reference for all voltages

CMPWR160

V

CC

C

+

V

CC

5V

+

–

IN

1µF

SD

GND

POR

V

OUT

+

C

OUT

10µF

uP Reset

V

OUT

3.3V/500mA

GND

Typical Application Circuit

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

12/5/2000

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

3

CALIFORNIA MICRO DEVICES

Typical DC Characteristics

Unless stated otherwise, all DC characteristics were

measured at room temperature with a nominal V

supply voltage of 5V and an output capacitance of 10µF.

Resistive load conditions were used.

Line Regulation Characteristics of the regulator are

shown in Figure 1. At maximum rated load conditions

(500mA), a 100mV drop in regulation occurs when the

line voltage has collapses below 3.8V. For light load

conditions (5mA), regulation is maintained for line

voltages as low as 3.3V.

CC

3.35

3.30

3.25

3.20

(V)

OUT

3.15

V

3.10

3.05

3.0 3.5 4.0

Figure 1. Line Regulation

5mA Load

VCC (V)

CMPWR160

500mA Load

4.5

5.0

Load Regulation performance is shown from zero to

maximum rated load in Figure 2. A 10% to 100% change

of rated load, results in an output voltage change of less

than 10mV. This translates into an effective output

impedance of approximately 0.02Ω.

Ground Current is shown across the entire range of

load conditions in Figure 3. The ground current increases

by 40µA across the range of load conditions. This

increase is due to the current limiting protective circuitry

becoming active.

(V)

OUT

V

3.40

3.35

3.30

3.25

3.20

0 200 400

Load Current (mA)

Figure 2. Load Regulation

100

80

60

40

600

Ground Current (µA)

20

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

4

0

0 200 400

Load Current (mA)

Figure 3. Ground Current

600

12/5/2000

CALIFORNIA MICRO DEVICES

Typical DC Characteristics continued

CMPWR160

VCC Operating Current (no load, SD high) is shown

across a range of V

supply voltages with the regulator

CC

enabled in Figure 4. The graph shows that the operating

current is 35µA typical and changes by less than 1µA

across this range.

VCC Shutdown Current variation with the VCC supply

voltage is shown in Figure 5.

60

50

40

30

20

Supply Current (µA)

10

0

3.5 4.5 5.5

V

(V)

CC

Figure 4. VCC Operating Current (no load)

10

8

6

4

Supply Current (µA)

2

0

1.5 2.5 3.5

(V)

V

CC

Figure 5. VCC Shutdown Current

5.54.5

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

12/5/2000

5

CALIFORNIA MICRO DEVICES

Typical Transient Characteristics

CMPWR160

The transient characterization test setup is shown in

Figure 6. It was the setup used for the transient tests

unless specified otherwise.

A maximum rated load current of 6.6Ω (500mA @ 3.3V)

was used during characterization along with a nominal

V

supply voltage of 5V DC, unless specified otherwise.

CC

The load transient characterization was done by switching between 6.6 and 660Ω load resistors. This switched

the load between 500 and 5mA respectively.

For the V

V

supply was ramped between 0 and 5V. Both the rise

CC

and fall times for the V

power-up and power-down characterizations

CC

power-up/down pulses were

CC

controlled to be 15ms.

CMPWR160

V

CC

V

CC

+

C1

10µF

C2

0.1µF

SD

In the line transient characterizations the V

voltage was controlled to step between 4.5 to 5.5V.

For the

tied to ground and the V

response characterization VCC and SD were

POR

voltage was directly driven

OUT

between 2.7 and 3.1V. This was done by connecting a

function generator directly to the output of the device.

These voltage values were picked because it drove V

directly across the typical

V

was tied to ground to show that the

CC

operate even when the V

threshold voltage of 2.9V.

POR

POR

supply voltage is not present.

CC

The oscilloscope traces show the full bandwidth response at the

SD

,

POR

, V

CC

and V

pins depending on

OUT

the characterization.

POR

V

OUT

GND

+

C3

0.1µF

C4

10µF

(500mA)

6.6Ω

supply

CC

circuitry will

POR

V

OUT

OUT

GND

Figure 6. Transient Characterization Test Setup

power-up Cold Start

V

CC

Figure 7 shows the output response during an initial V

power up with SD tied to VCC. When VCC reaches a

particular threshold, the regulator turns on. The uncharged output capacitor causes maximum inrush

current to flow. At this point the device sees the output

as a short circuit and the device enters a protective

current limiting mode. The output capacitor quickly

charges and V

below V

the inrush current stops flowing and the output

CC

rises with the input. V

rises. Once this voltage rises to just

OUT

continues to rise with the input

OUT

until it reaches 3.3V.

GND

CC

Tek Run Sample

25.0kS/s

1.00V

Ch2

V

CC

V

OUT

1.00V

M 2.00ms

(500mA Load)

280mV

Ch2

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

6

Figure 7. VCC Power-up Cold Start

12/5/2000

CALIFORNIA MICRO DEVICES

CMPWR160

Typical Transient Characteristics continued

VCC Power down

Figure 8 shows the output response of the regulator

during a complete power down situation under full load

conditions with

Shutdown Transient Response

The transient response of the output voltage to the

pin is shown in Figure 9. The graph shows that a rising

edge on the

edge disables the regulator.

The rise and fall time for the output voltages are 100µs

and 200µs respectively.

SD

tied to VCC.

SD

pin enables the regulator and a falling

SD

Tek Run Sample

25.0kS/s

V

OUT

1.00V

Ch2

V

CC

1.00V

Figure 8. VCC Power Down

Tek 3 Acqs

2

25.0kS/s

SD

M 2.00ms

(500mA Load)

3.50V

Ch2

POR

Response

The transient response of the active low POR pin to V

is shown in Figure 10. When V

POR

threshold voltage (typically 2.9V), the pin is forced

rises above the

OUT

OUT

to logic low (0V). The pin remains at logic low for 30ms

then it is forced to logic high (3.3V). If V

threshold voltage during this 30ms interval

POR

falls below the

OUT

POR

will remain logic low. If it falls below the voltage threshold

and then recovers the 30ms time will reset.

When V

falls below the

OUT

POR

threshold voltage

POR

is

immediately forced to logic low.

V

is tied to ground to show that the

CC

work without V

present.

CC

POR

circuitry will

(500mA Load)

V

OUT

1.00V

Ch2

5.00V

M 200µs

Ch2

Figure 9. Shutdown Transient Response

V

POR

5.0kS/s

3.1V

OUT

2.7V

Tek Run Sample

2

3.0V

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

12/5/2000

1.00V

Figure 10.

Ch2

200mV

POR

M 10.0ms

Ch2

Response

2.90V

7

CALIFORNIA MICRO DEVICES

Typical Transient Characteristics continued

Load Step response

Figure 11 shows the output voltage (Ch1) response of

the regulator during a step load change between 5mA

and 500mA (represented on Ch2). For the 5mA to

500mA transition an initial transient overshoot of 60mV

occurs and then the output settles to its final voltage

within 20µs. For the 500mA to 5mA transition there is

also an initial overshoot of 60mV however it takes

approximately 250µs to settle to its final voltage.

The overall DC voltage disturbance on the output is

approximately 25mV, which demonstrates the regulator

output impedance of 50mΩ.

V

offset = 3.3V

OUT

Tek Run Sample

1

250kS/s

500mA

Load

5mA

VOUT (offset = 3.3V)

CMPWR160

Line Step Response

Figure 12 shows the output response of the regulator to

a V

line voltage transient between 4.5V and 5.5V

CC

(1Vpp as shown on Ch2). The load condition during this

test is 5mA. The output response produces less than

10mV of disturbance on both edges indicating a line

rejection of better than 40dB at high frequencies.

V

offset = 3.3V

OUT

Reset response time with overdrive

Figure 13 shows the time it takes for the

reset when the output voltage is driven below the

POR

signal to

POR

trigger threshold by varying amounts. The amount the

voltage is driven below the POR trigger threshold is the

overdrive voltage.

Ch1

50.0mV

2.00V

Figure 11. Load Step Response

V

CC

4.5V

20.0mV

250kS/s

5.5V

(5mA Load)

V

OUT(offset = 3.3V)

M 200µs

500mV

Ch2

Tek 2 Acqs

2

Figure 12. Line Step Response

1000

100

Ch2

Ch2

1.60VM 200µs

5.00V

10

Turn Off Delay (µs)

Figure 13. Reset Response Time with Overdrive

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

8

1

0 50 100 150 200

Overdrive (mV)

250 300

12/5/2000

CALIFORNIA MICRO DEVICES

Typical Thermal Characteristics

CMPWR160

Thermal dissipation of junction heat consists primarily of

two paths in series. The first path is the junction to the

case (θJC) thermal resistance which is defined by the

package style, and the second path is the case to

ambient (θ

) thermal resistance, which is dependent on

CA

board layout.

The overall junction to ambient (θ

) thermal resistance is

JA

equal to:

θ

= θJC + θ

JA

CA

For a given package style and board layout, the operating junction temperature is a function of junction power

dissipation P

, and the ambient temperature, resulting

JUNC

in the following thermal equation:

T

= T

JUNC

= T

AMB

AMB

+ P

+ P

JUNC

JUNC

(θ

(θJA)

JC

) + P

JUNC

(θCA )

The CMPWR160SA is housed in a thermally enhanced

package where all the GND pins (5 through 8) are

integral to the leadframe (fused leadframe). When the

device is mounted on a double sided printed circuit

board with two square inches of copper allocated for

“heat spreading”, the resulting θ

is 50°C/W.

JA

Based on a maximum power dissipation of

1.0W (2Vx500mA) with an ambient of 70°C the resulting

junction temperature will be:

T

JUNC

= T

AMB

+ P

JUNC

(θ

)

JA

= 70°C + 1.0W (50°C/W)

= 70°C + 50°C = 120°C

All thermal characteristics of the CMPWR160SA were

measured using a double sided board with two square

inches of copper area connected to the GND pins for

“heat spreading”.

Measurements showing performance up to junction

temperature of 125°C were performed under light load

conditions (5mA). This allows the ambient temperature to

be representative of the internal junction temperature.

Note: The use of multi-layer board construction with

power planes will further enhance the thermal performance of the package. In the event of no copper area

being dedicated for heat spreading, a multi-layer board

construction, using only the minimum size pad layout,

will typically provide the CMPWR160SA with an overall

θ

of 70°C/W which allows up to 780mW to be safely

JA

dissipated.

Output Voltage vs. Temperature

Figure 14 shows the regulator V

performance up to

OUT

the maximum rated junction temperature. A 125°C

variation in junction temperature from –25°C causes an

output voltage variation of about 50mV, reflecting

a voltage temperature coefficient of approximately

±50ppm/°C.

3.35

3.33

3.31

(v)

OUT

V

3.29

3.27

3.25

–25 25075

Figure 14. V

Temperature Variation (5mA)

OUT

50 100 125

Temperature (˚C)

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

12/5/2000

9

CALIFORNIA MICRO DEVICES

Typical Thermal Characteristics continued

CMPWR160

Output Voltage (Rated) vs. Temperature

Figure 15 shows the regulator steady state performance

when fully loaded (500mA) from –25°C up to the rated

maximum temperature of 70°C. The output variation at

maximum load is approximately 20mV across the shown

operating temperature. This translates to a temperature

coefficient of approximately ±30ppm/°C.

POR

Voltage Threshold Temperature Variation

Figure 16 shows the

POR

threshold voltage variation

from –25°C up to the maximum rated junction temperature. The overall 150°C change in junction temperature

causes less than a 5mV variation in the

POR

threshold

voltage. This translates to a temperature coefficient of

±6ppm/°C.

The POR pulse duration does not vary with temperature.

3.34

3.32

3.30

(v)

OUT

V

3.28

3.26

3.24

–25 250

Figure 15. V

3.00

2.95

2.90

POR Threshold (v)

2.85

50

Temperature (˚C)

Temperature Variation (500mA)

OUT

3.24

VCC Supply Current Temperature Variation

Figure 17 shows the VCC supply current variation with

temperature from –25°C to the maximum rated junction

temperature with no load on the device. The supply

current changes less than 1µA over the entire 150°C

range shown in the plot.

Current (µA)

©2000 California Micro Devices Corp. All rights reserved. SmartOR™ is a trademark of California Micro Devices Corporation.

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

10

–25 25075

Figure 16.

50 100 125

Temperature (˚C)

POR

Threshold

Temperature Variation

40

38

36

34

32

30

–25 25075

Figure 17. V

50 100 125

Temperature (˚C)

Supply Current

CC

vs. Temperature

12/5/2000

Loading...

Loading...