Page 1

SOFT RECOVERY

VERY HIGH VOLT AGE

SMALL RECOVERY CHARGE

BYT 11-600 →1000

FAST RECOVERY RECTIFIER DIODES

APPLICATIONS

ANTISATURATION DIODES FOR TRANSIS-

F 126

(Plastic)

TOR BASE DRIVE

SNUBBER DIODES

ABSOL UT E RATINGS (limiting values)

Symbol Parameter Value Unit

I

FRM

I

F (AV)

I

FSM

P

tot

T

stg

T

T

L

Symbol Parameter

Repetive Peak Forward Current

Average Forward Current * T

Surge non Repetitive Forward Current tp = 10ms

Power Dissipation *

Storage and Junction Temperature Range - 55 to + 150

j

Maximum Lead Temperature for Soldering during 10s at 4mm

from Case

≤ 20µs

t

p

75°C

a =

δ = 0.5

Sinusoidal

55°C

T

a =

BYT 11-

600 800 1000

20 A

1A

35 A

1.25 W

- 55 to + 150

230

°C

°C

Unit

V

RRM

Repetitive Peak Reverse Voltage 600 800 1000 V

THERMAL RESISTANCE

Symbol Parameter Value Unit

R

th (j - a)

* On infinite heatsink with 10mm lead length.

November 1994

Junction-ambient* 60

°C/W

1/4

Page 2

BYT11-600 → 1000

ELECTRICAL CHARACTERISTICS

STATIC CHARACTERISTICS

Synbol Test Conditions Min. Typ. Max. Unit

I

R

V

F

Tj = 25°C

Tj = 25°C

V

= V

R

RRM

I

= 1A 1.3 V

F

20

RECOVERY CHARACTERISTICS

Symbol Test Conditions Min. Typ. Max. Unit

t

rr

Tj = 25°C IF = 0.5A IR = 1A I

= 0.25A

rr

100 ns

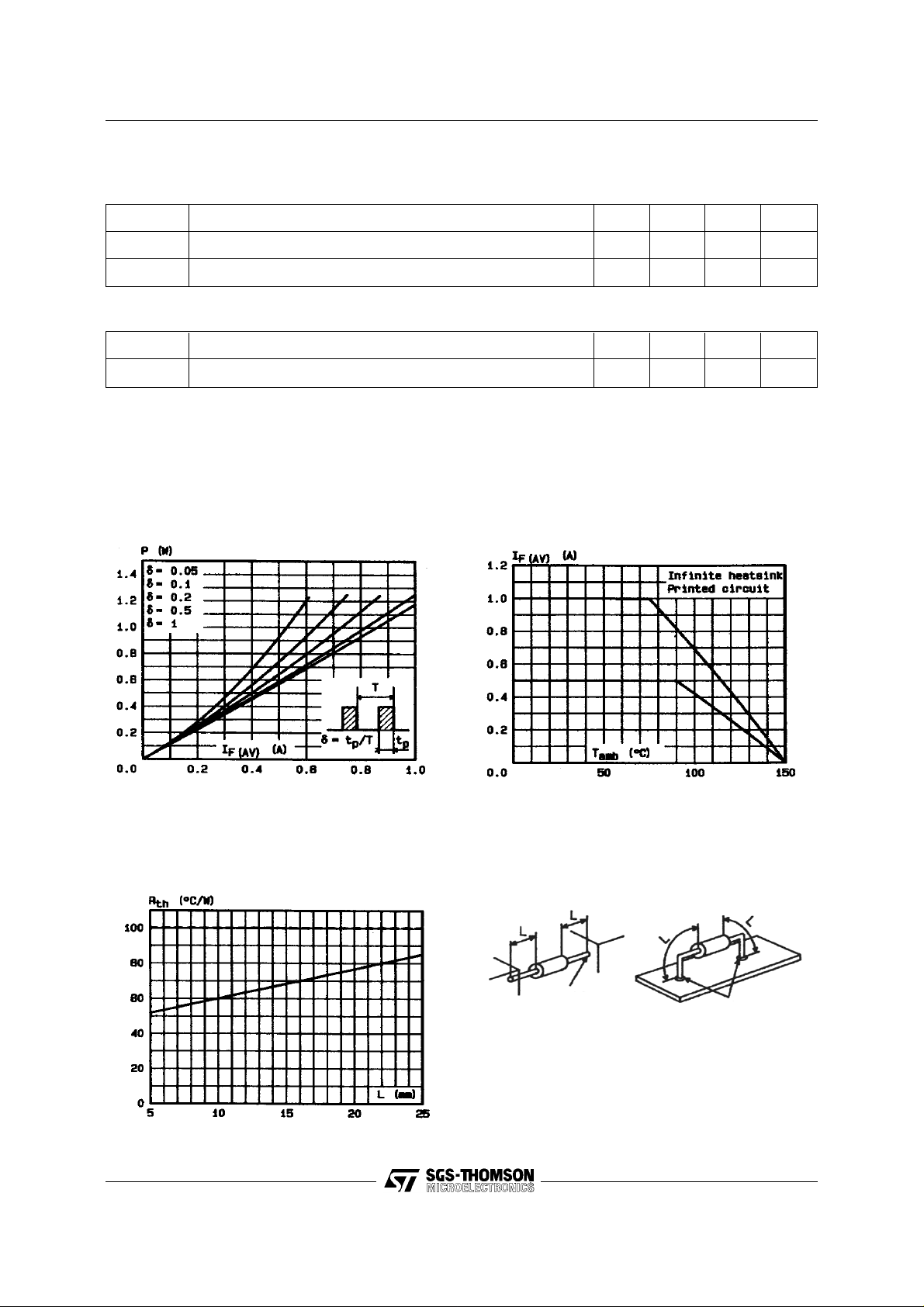

To evaluate the conduction losses use the following equations:

V

= 1.1 + 0.075 IF P = 1.1 x I

F

Figure 1. Maximum average power

dissipation versus average forward curr ent .

F(AV)

+ 0.075 I

F2(RMS)

Figure 2. Average forward current versus

ambient temperature.

µA

Figure 3. Thermal resistance versus lead

length.

2/4

Moun ting n°1

INFINIT E HE ATSIN K

Test point of

t

lead

Moun ting n°2

PRINTED CIRCUIT

Soldering

Page 3

Figure 4. Transient thermal impedance

junction-ambient for mounting n°2 versus

pulse duration (L = 10 mm) .

BYT 11-600 → 1000

Figure 5. Peak forward current

versus peak forward voltage drop

(maximum values).

Figure 6. Capacitance versus reverse applied

voltage

Figure 7. Non repetitive surge peak current

versus number of cycles

3/4

Page 4

BYT11-600 → 1000

PACKAGE MECHANICAL DATA

F 126 (Plastic)

DIMENSIONS

REF.

Millimeters Inches

Min. Max. Min. Max.

A 6.05 6.35 0.238 0.250

B 26 1.024

∅ C

∅ D

2.95 3.05 0.116 0.120

0.76 0.86 0.029 0.034

E 1.27 0.050

Cooling method: by convection (method A)

Marking: type number ring at cathode end

Weight: 0.4g

BA B

note 1

E

/

O

D

note 2

E

note 1

O

/

D

NOTES

1 - The lead diameter ∅ D is not controlled over zone E

2 - The minimum axia l lengh within which the device may be

placed with its leads bent at right angles is 0.59"(15 mm)

/

O

C

Information furnished is b elieved to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsability for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent o r patent rights of SGS-THOMSON Microelectronics. Specif ications mentioned

in this publication are subject to change without notice. This publication supersedes an d replaces all information previously supplied.

SGS-THOMSON Microelect ronics product s are not auth orized for use as critical components in life su pport devic es or s ystems wi thout express

written approval of SGS-THOMSON Microelectronics.

© 1994 SGS-THOMSON Microelectronics - Printed in Italy - All rights reserved.

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - United Kingdom - U.S.A.

4/4

Loading...

Loading...