Page 1

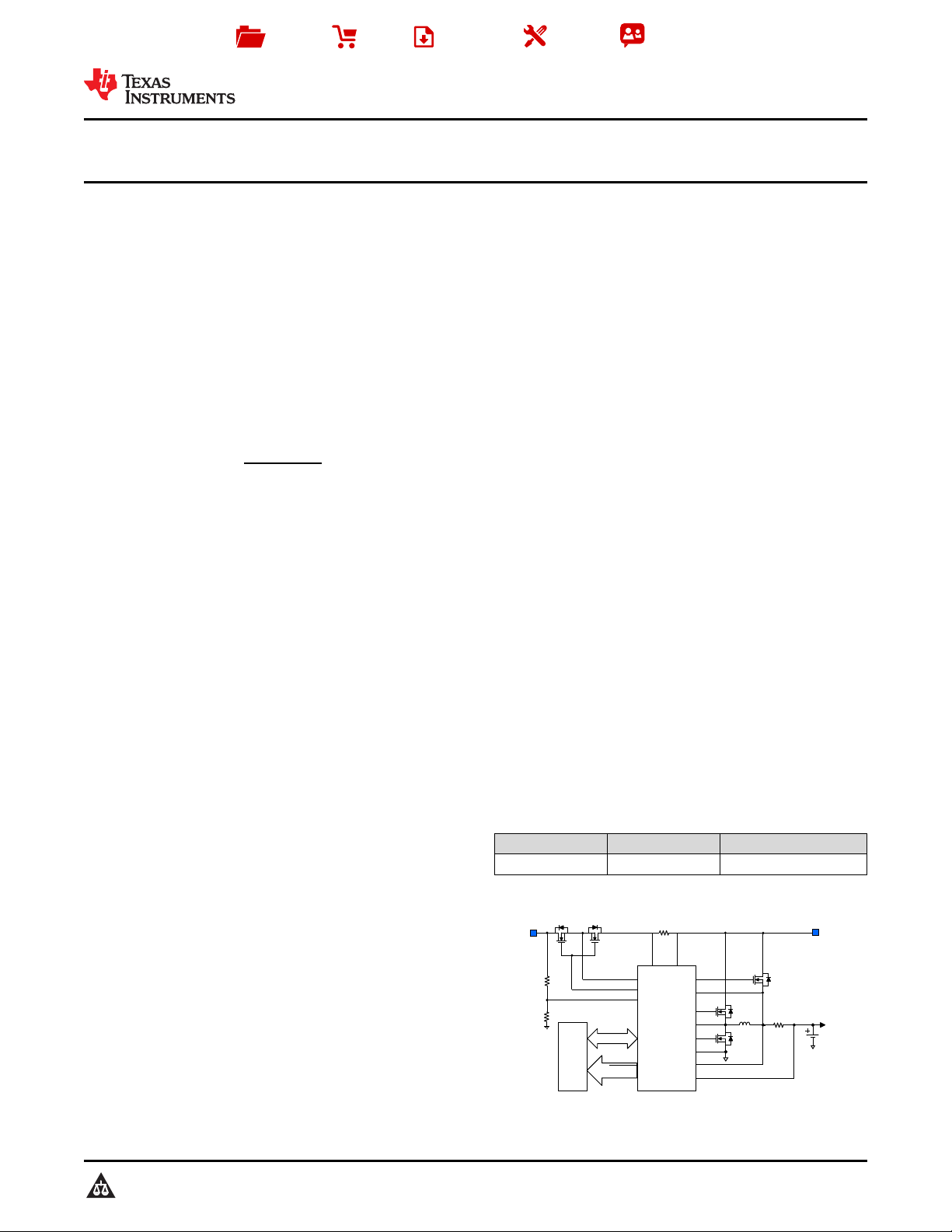

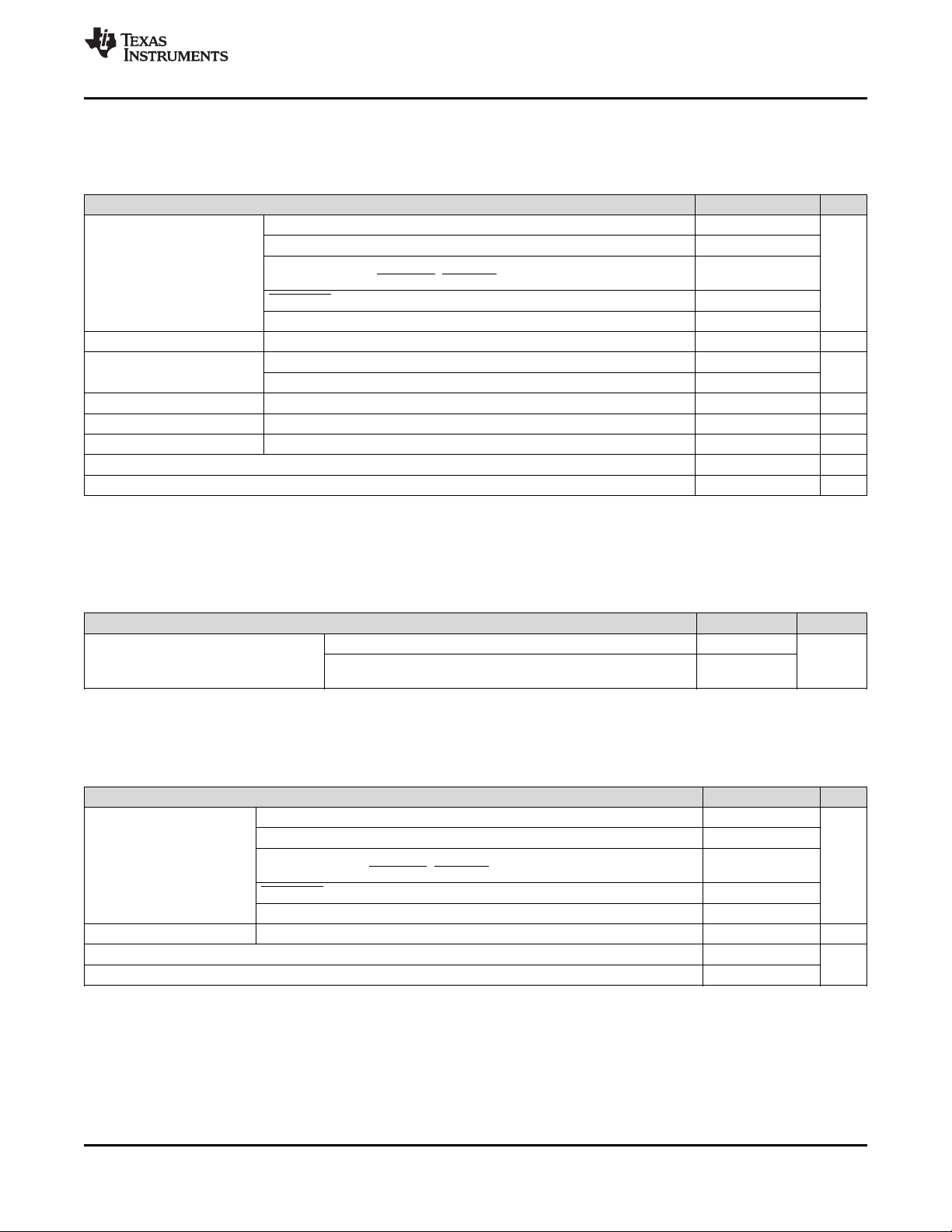

R

SR

Adapter

4.5-24V

HOST

bq24780S

Hybrid Power

Boost Charge

Controller

SYS

Battery

Pack

N-FET Driver

N-FET Driver

1S-4S

SMBus

IADP, ,PROCHOT

PMON, IDCHG

SMBus Controls V & I

with high accuracy

Adapter Detection

Enhanced Safety:

OCP,OVP, FET Short

Integration:

Loop Compensation; Soft-Start

Comparator, BTST Diode

R

AC

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

bq24780S 1- to 4-Cell Hybrid Power Boost Mode Battery Charge Controller

With Power and Processor Hot Monitoring

1 Features

1

• Industrial Innovative Charge Controller With

Hybrid Power Boost Mode

– Adapter and Battery Provides Power to

System Together for Intel®CPU Turbo Mode

– Ultra-Fast Transient Response of 150 µs to

Enter Boost Mode

– Hybrid Power Boost Mode from 4.5- to 24-V

System

– Charge 1- to 4-Cell Battery Pack from 4.5- to

24-V Adapter

• High Accuracy Power and Current Monitoring for

CPU Throttling

– Comprehensive PROCHOT Profile

– ± 2% Current Monitor Accuracy

– ± 5% System Power Monitor Accuracy

(PMON)

• Automatic NMOS Power Source Selection from

Adapter or Battery

– ACFET Fast Turn on in 100 µs

• Programmable Input Current, Charge Voltage,

Charge and Discharge Current Limit

– ±0.4% Charge Voltage (16-mV step)

– ±2% Input Current (128-mA/step)

– ±2% Charge Current (64-mA/step)

– ±2% Discharge Current (512-mA/step)

• High Integration

– Battery LEARN Function

– Battery Present Monitor

– Boost Mode Indicator

– Loop Compensation

– BTST Diode

• Enhanced Safety Features for Overvoltage

Protection, Overcurrent Protection, Battery,

Inductor, and MOSFET Short-Circuit Protection

• Switching Frequency: 600 kHz, 800 kHz, and

1 MHz

• Realtime System Control on ILIM Pin to Limit

Charge and Discharge Current

• 0.65 mA Adapter Standby Quiescent Current for

Energy Star

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

2 Applications

• Notebook, Ultrabook, Detachable, and Tablet PC

• Handheld Terminal

• Industrial and Medical Equipment

• Portable Equipment

3 Description

The bq24780S device is a high-efficiency,

synchronous battery charger, offering low component

count for space-constrained, multi-chemistry battery

charging applications.

The bq24780S device supports hybrid power boost

mode (previously called "turbo boost mode"). It allows

battery discharge energy to system when system

power demand is temporarily higher than adapter

maximum power level. Therefore, adapter does not

crash.

The bq24780S device uses two charge pumps to

separately drive N-channel MOSFETs (ACFET,

RBFET, and BATFET) for automatic system power

source selection.

Through SMBus, system power management

microcontroller programs input current, charge

current, discharge current, and charge voltage DACs

with high regulation accuracies.

The bq24780S device monitors adapter current

(IADP), battery discharge current (IDCHG), and

system power (PMON) for host to throttle back CPU

speed or reduce system power when needed.

The bq24780S device charges 1-, 2-, 3-, or 4-series

Li+ cells.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

bq24780S WQFN (28) 4.00 × 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

2

Page 2

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 5

6.1 Absolute Maximum Ratings ...................................... 5

6.2 ESD Ratings.............................................................. 5

6.3 Recommended Operating Conditions....................... 5

6.4 Thermal Information.................................................. 6

6.5 Electrical Characteristics........................................... 6

6.6 Timing Requirements.............................................. 11

6.7 Typical Characteristics............................................ 13

7 Detailed Description............................................ 14

7.1 Overview ................................................................. 14

7.2 Functional Block Diagram ....................................... 15

7.3 Feature Description................................................. 16

7.4 Device Functional Modes........................................ 22

7.5 Programming........................................................... 23

7.6 Register Maps......................................................... 25

8 Application and Implementation ........................ 36

8.1 Application Information............................................ 36

8.2 Typical Applications ................................................ 36

9 Power Supply Recommendations...................... 44

10 Layout................................................................... 44

10.1 Layout Guidelines ................................................. 44

10.2 Layout Examples................................................... 45

11 Device and Documentation Support................. 48

11.1 Receiving Notification of Documentation Updates 48

11.2 Community Resources.......................................... 48

11.3 Trademarks........................................................... 48

11.4 Electrostatic Discharge Caution............................ 48

11.5 Glossary................................................................ 48

12 Mechanical, Packaging, and Orderable

Information........................................................... 48

4 Revision History

Changes from Revision B (April 2015) to Revision C Page

• Full data sheet to product folder............................................................................................................................................. 1

Changes from Revision A (April 2015) to Revision B Page

• Changed the Description for pin 22 (GND) in the Pin Functions table................................................................................... 4

• Changed the Thermal Pad to PowerPAD in the Pin Functions table..................................................................................... 4

• Changed 16X to 20X on the SRP and SRN pins of the Functional Block Diagram ............................................................ 15

• Changed C4 From: 0.01 μF To: 0.1 μF in Figure 17 ........................................................................................................... 36

Changes from Original (April 2015) to Revision A Page

• Changed V

in the Electrical Characteristics, MIN From: 190% To: 180%, MAX From: 215% To: 220% ..................... 9

(ACOC)

• Changed "ChargeOption() bit [0] = 0" To: REG0x12[0] in Enable and Disable Charging.................................................... 17

• Changed " (REG0x12[1])" To: (REG0x12[0]=1) in Enable and Disable Charging ............................................................... 17

• Changed " REG0x12" To: "REG0x12[0]" in Battery Charging ............................................................................................ 22

• Changed Bit [10:9] in Table 9 From: 11: 8 ms To: 11: 800 µs ............................................................................................ 30

• Added sentence to Bit [7:6] in Table 9 " If REG0x15() is programmed..." ........................................................................... 30

• Changed text in Bit [5] of Table 9 From: "write 0x3C[2] = 1." To: "write 0x3C[2] = 0."........................................................ 30

• Deleted text from Bit [5] of Table 9 "This function is not available in 1s battery."................................................................ 30

2

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

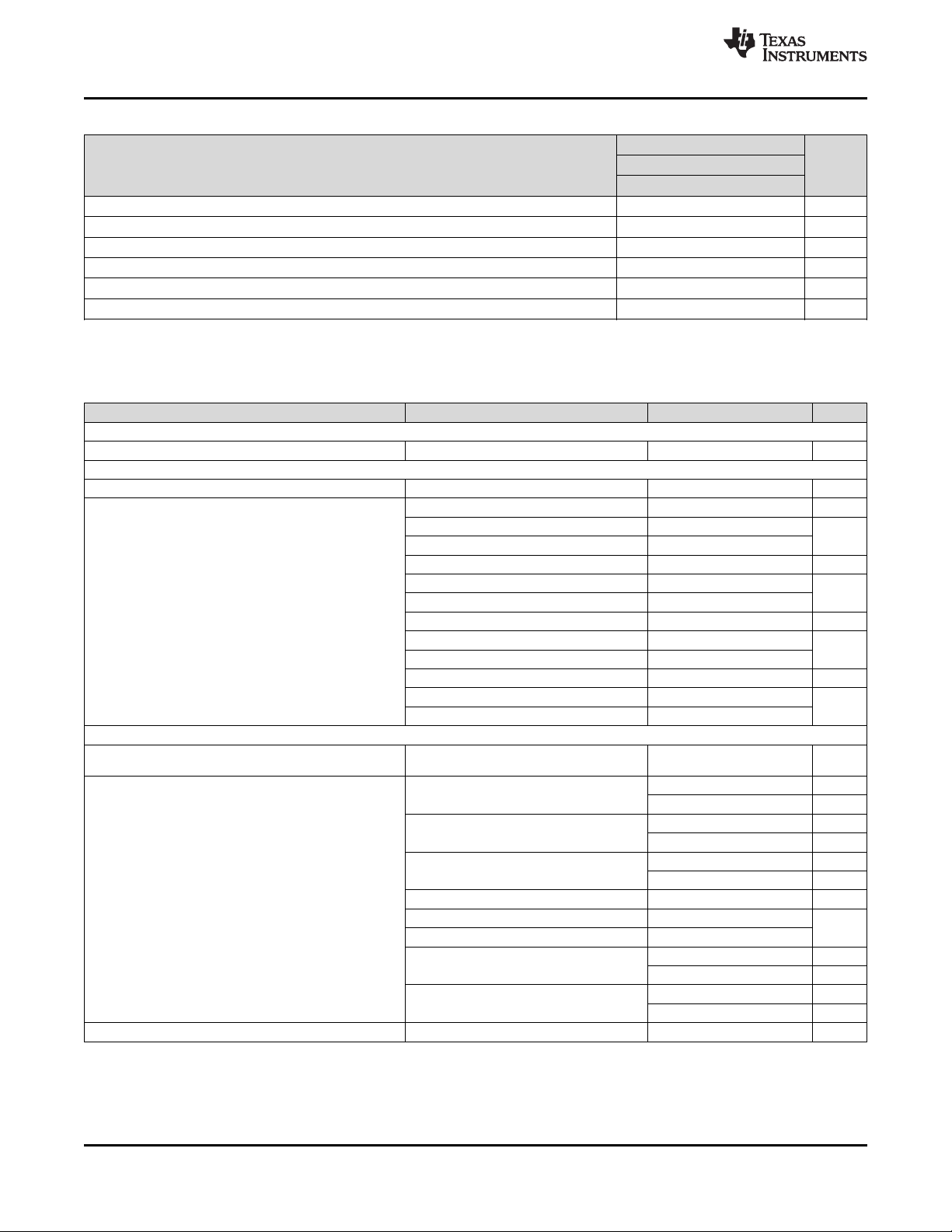

Page 3

Thermal

Pad

28 VCC8IDCHG

1ACN 21 ILIM

27 PHASE9PMON

2ACP 20 SRP

26 HIDRV10PROCHOT

3CMSRC 19 SRN

25 BTST11SDA

4ACDRV 18 BATDRV

24 REGN12SCL

5ACOK 17 BATSRC

23 LODRV13CMPIN

6ACDET 16 TB_STAT

22 GND14CMPOUT

7IADP 15 BATPRES

www.ti.com

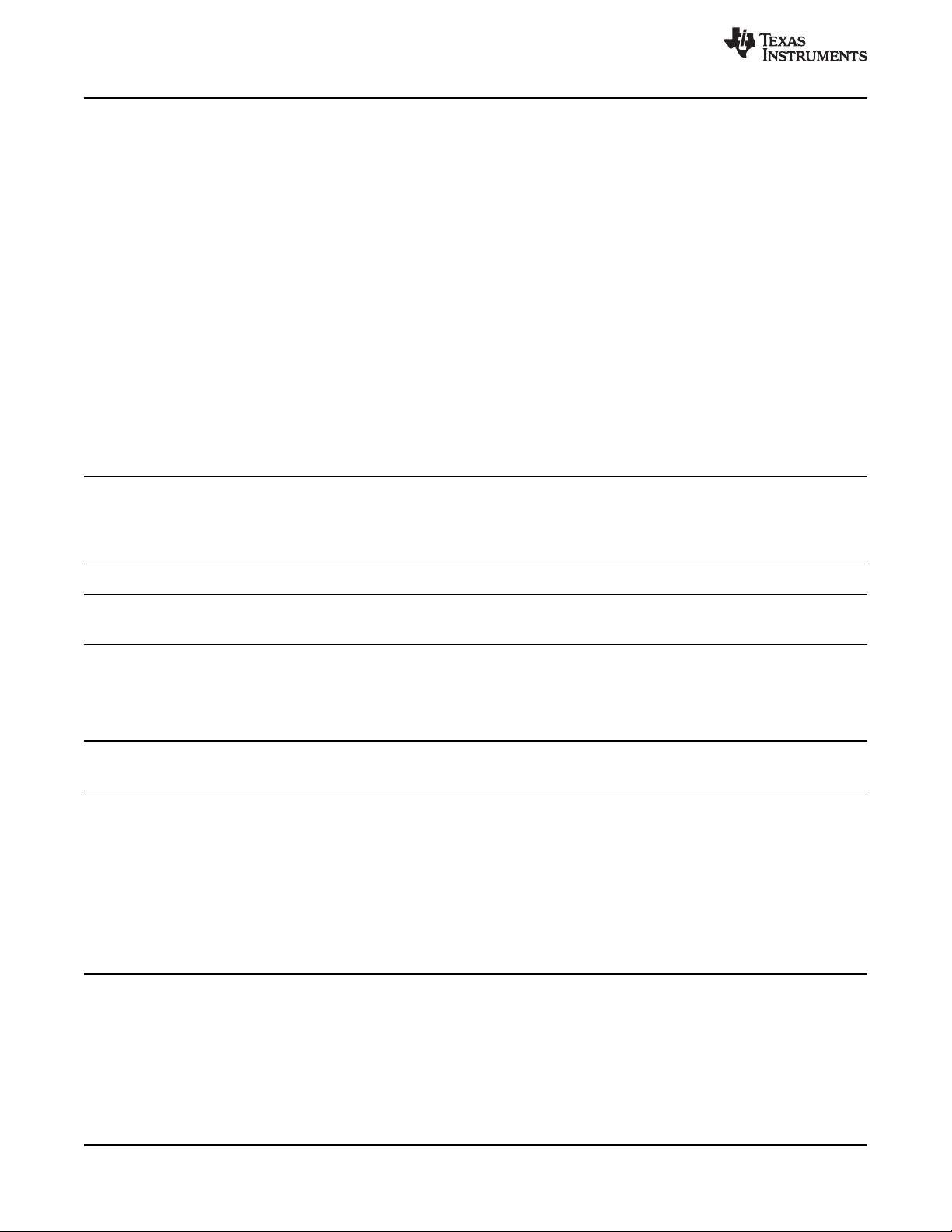

5 Pin Configuration and Functions

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

RUY Package

28-Pin WQFN

Top View

PIN

NAME NUMBER

ACN 1

ACP 2

CMSRC 3

Input current sense resistor negative input. Place an optional 0.01-µF ceramic capacitor from ACN to GND for

common-mode filtering. Place a 0.1-µF ceramic capacitor from ACN to ACP to provide differential mode filtering.

Input current sense resistor positive input. Place a 0.1-µF ceramic capacitor from ACP to GND for commonmode filtering. Place a 0.1-µF ceramic capacitor from ACN to ACP to provide differential-mode filtering.

ACDRV charge pump source input. Place a 4-kΩ resistor from CMSRC to the common source of ACFET (Q1)

and RBFET (Q2) to limit the inrush current on CMSRC pin.

Charge pump output to drive both adapter input N-channel MOSFET (ACFET) and reverse blocking N-channel

ACDRV 4

MOSFET (RBFET). ACDRV voltage is 6 V above CMSRC when ACOK is HIGH. Place a 4-kΩ resistor from

ACDRV to the gate of ACFET and RBFET limits the inrush current on ACDRV pin.

Active HIGH AC adapter detection open drain output. It is pulled HIGH to external pullup supply rail by external

ACOK 5

ACDET 6

IADP 7

IDCHG 8

pullup resistor when a valid adapter is present (ACDET above 2.4 V, VCC above UVLO but below ACOV and

VCC above BAT). If any of the above conditions is not valid, ACOK is pulled LOW by internal MOSFET. Connect

a 10-kΩ pullup resistor from ACOK to the pullup supply rail.

Adapter detection input. Program adapter valid input threshold by connecting a resistor divider from adapter

input to ACDET pin to GND pin. When ACDET pin is above 0.6 V and VCC is above UVLO, REGN LDO is

present, ACOK comparator, input current buffer (IADP), discharge current buffer (IDCHG), independent

comparator, and power monitor buffer (PMON) can be enabled with SMBus. When ACDET is above 2.4V, and

VCC is above SRN but below ACOV, ACOK goes HIGH.

Buffered adapter current output. V

The ratio of 20x and 40x is selectable with SMBus. Place 100-pF (or less) ceramic decoupling capacitor from

IADP pin to GND. This pin can be floating if this output is not in use.

Buffered discharge current. V

The ratio of 8x or 16x is selectable with SMBus. Place 100-pF (or less) ceramic decoupling capacitor from

IDSCHG pin to GND. This pin can be floating if this output is not in use.

Pin Functions

= 20 or 40 × (V

(IADP)

= 8 or 16 × (V

(IDCHG)

DESCRIPTION

– V

(ACP)

– V

(SRN)

(SRP)

(ACN)

)

)

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

3

Page 4

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Pin Functions (continued)

PIN

NAME NUMBER

Buffered total system power. The output current is proportional to the total power from the adapter and battery.

PMON 9

The ratio is selectable through SMBus. Place a resistor from PMON pin to GND to generate PMON voltage.

Place a 100-pF (or less) ceramic decoupling capacitor from PMON pin to GND. This pin can be floating if this

output is not in use.

Active low, open-drain output of the processor hot indicator. The charger IC monitors events like adapter current,

PROCHOT 10

battery discharge current. After any event in the PROCHOT profile is triggered, a minimum 10-ms pulse is

asserted.

SMBus open-drain data I/O. Connect to SMBus data line from the host controller or smart battery. SMBus

SDA 11

communication starts when VCC is above UVLO. Connect a 10-kΩ pullup resistor according to SMBus

specifications.

SMBus open-drain clock input. Connect to SMBus clock line from the host controller or smart battery. SMBus

SCL 12

communication starts when VCC is above UVLO. Connect a 10-kΩ pullup resistor according to SMBus

specifications.

Input of independent comparator. Internal reference, output polarity and deglitch time is selectable by SMBus.

CMPIN 13

Place a resistor between CMPIN and CMPOUT to program hysteresis when the polarity is HIGH. If comparator

is not in use, CMPIN is tied to ground, and CMPOUT is left floating.

Open-drain output of independent comparator. Place 10-kΩ pullup resistor from CMPOUT to pullup supply rail.

CMPOUT 14

Comparator reference, output polarity and deglitch time is selectable by SMBus. If comparator is not in use,

CMPIN is tied to ground, and CMPOUT is left floating.

Active low battery present input signal. Low indicates battery present, high indicates battery absent. The device

BATPRES 15

exits the LEARN function and turns on ACFET/RBFET within 100 µs if BATPRES pin is pulled high. Upon

BATPRES from LOW to HIGH, battery charging and hybrid power boost mode are disabled. The host can

enable charging and hybrid power boost mode by write to REG0x14() and REG0x15() when BATPRES is HIGH

Active low, open-drain output for hybrid power boost mode indication. It is pulled low when the IC is operating in

TB_STAT 16

boost mode. Otherwise, it is pulled high. Connect a 10-kΩ pullup resistor from TB_STAT pin to the pullup supply

rail.

BATSRC 17 Connect to the source of N-channel BATFET. BATDRV voltage is 6 V above BATSRC to turn on BATFET.

Charge pump output to drive N-channel MOSFET between battery and system (BATFET). BATDRV voltage is

BATDRV 18

6 V above BATSRC to turn on BATFET and power system from battery. BATDRV is shorted to BATSRC to turn

off BATFET. Place a 4-kΩ resistor from BATDRV to the gate of BATFET limits the inrush current on BATDRV

pin.

Charge current sense resistor negative input. SRN pin is for battery voltage sensing as well. Connect SRN pin

SRN 19

with a 0.1-µF ceramic capacitor to GND for common-mode filtering. Connect a 0.1-µF ceramic capacitor from

SRP to SRN to provide differential mode filtering.

SRP 20

Charge current sense resistor positive input. Connect a 0.1-µF ceramic capacitor from SRP to SRN to provide

differential mode filtering.

Charge current and discharge current limit.V

V

) for discharge current. Program ILIM voltage by connecting a resistor divider from system reference 3.3-V

ILIM 21

SRP

rail to ILIM pin to GND pin. The lower of ILIM voltage and 0x14() (for charge) or 0x39 (for discharge) reference

sets actual regulation limit. The minimum voltage on ILIM to enable charge or discharge current regulation is 120

mV.

GND 22

IC ground. On PCB layout, connect to analog ground plane, and only connect to power ground plan through pad

underneath IC.

LODRV 23 Low-side power MOSFET driver output. Connect to low-side N-channel MOSFET gate.

6-V linear regulator output supplied from VCC. The LDO is active when ACDET above 0.6 V, VCC above UVLO.

REGN 24

Connect a ≥ 2.2-µF 0603 ceramic capacitor from REGN to GND. The diode between REGN and BTST is

integrated.

BTST 25

High-side power MOSFET driver power supply. Connect a 47-nF capacitor from BTST to PHASE. The diode

between REGN and BTST is integrated inside the IC.

HIDRV 26 High-side power MOSFET driver output. Connect to the high side N-channel MOSFET gate.

PHASE 27 High-side power MOSFET driver source. Connect to the source of the high-side N-channel MOSFET.

VCC 28

Input supply from adapter or battery. Use 10-Ω resistor and 1-µF capacitor to ground as a low pass filter to limit

inrush current. A diode OR is connected to VCC. It powers charger IC from input adapter and battery.

Exposed pad beneath the IC. Analog ground and power ground star-connected only at the PowerPAD plane.

PowerPAD™

Always solder the PowerPAD to the board and have vias on the PowerPAD plane connecting to analog ground

and power ground planes. It also serves as a thermal pad to dissipate the heat.

DESCRIPTION

= 20 × (V

ILIM

SRP

– V

) for charge current and V

SRN

ILIM

= 5 × (V

www.ti.com

SRN

–

4

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

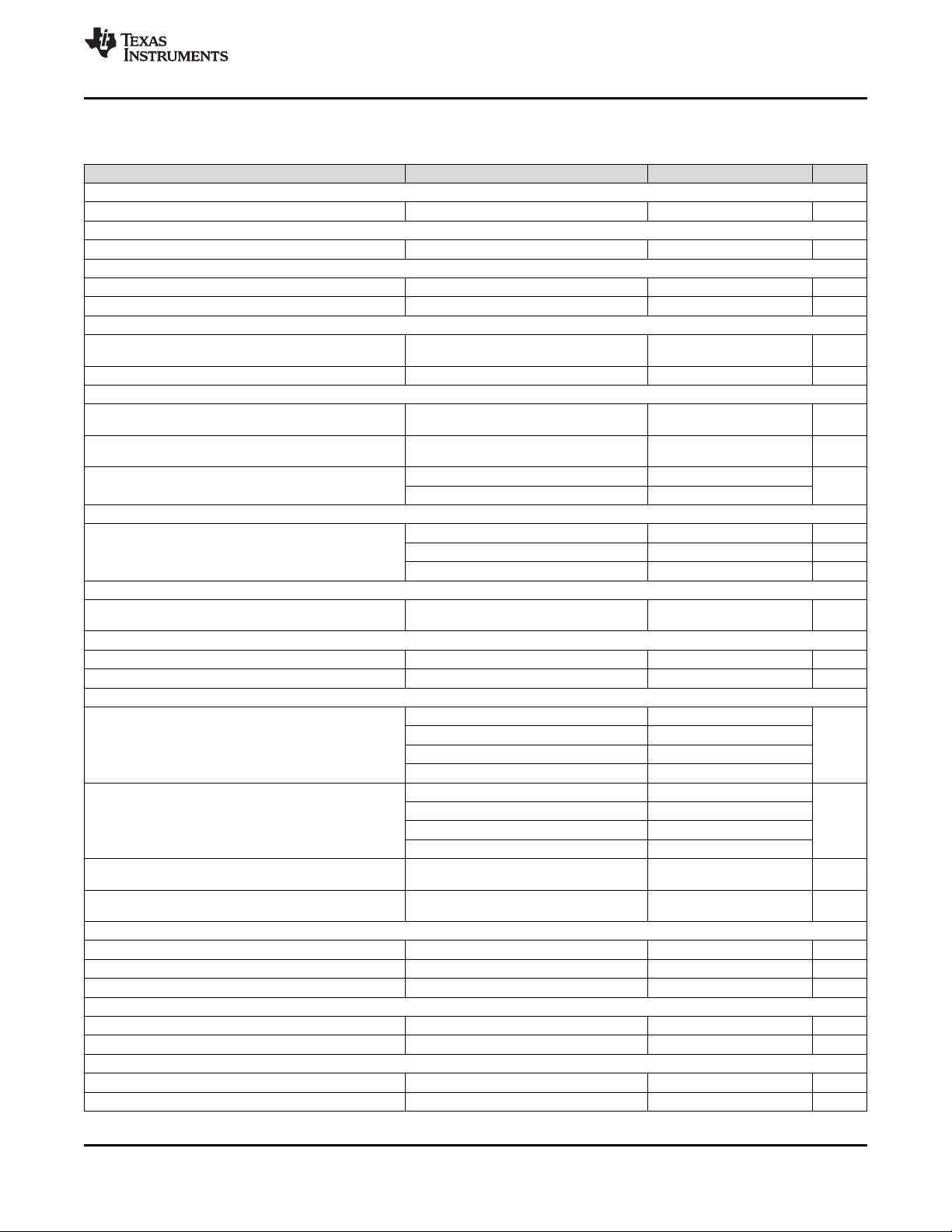

Page 5

bq24780S

www.ti.com

SLUSC27C –APRIL 2015–REVISED MARCH 2017

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

SRN, SRP, ACN, ACP, CMSRC, VCC, BATSRC –0.3 30

PHASE –2 30

Voltage

Differential voltage BTST-PHASE, HIDRV-PHASE ACDRV-CMSRC, BATDRV-BATSRC –0.3 7 V

Voltage

Voltage PHASE (2% duty cycle) –4 30 V

Voltage REGN (5ms) –0.3 9 V

Maximum differential voltage SRP–SRN, ACP–ACN –0.5 +0.5 V

Junction temperature, T

Storage temperature, T

J

stg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND if not specified. Currents are positive into, negative out of the specified pin. Consult Packaging

Section of the data book for thermal limitations and considerations of packages.

ACDET, SDA, SCL, LODRV, REGN, IADP, IDCHG, PMON, ILIM, ACOK,

CMPIN, CMPOUT, BATPRES, TB_STAT

PROCHOT –0.3 5.7

BTST, HIDRV, ACDRV, BATDRV –0.3 36

LODRV (2% duty cycle) –4 7

HIDRV (2% duty cycle) –4 36

(1)(2)

MIN MAX UNIT

–0.3 7

–40 155 °C

–55 155 °C

V

V

6.2 ESD Ratings

VALUE UNIT

(1)

±2000

±500

V

(ESD)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001

Charged device model (CDM), per JEDEC specification JESD22-

(2)

C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

SRN, SRP, ACN, ACP, CMSRC, VCC, BATSRC 0 24

PHASE –2 24

Voltage

Maximum difference SRP–SRN, ACP–ACN –0.4 +0.4 V

Junction temperature, T

Operating free-air temperature, T

ACDET, SDA, SCL, LODRV, REGN, IADP, IDCHG, PMON, ILIM, ACOK,

CMPIN, CMPOUT, BATPRES, TB_STAT

PROCHOT –0.3 5

BTST, HIDRV, ACDRV, BATDRV 0 30

J

A

0 6.5

–20 125

–40 85

V

V

°C

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

5

Page 6

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

6.4 Thermal Information

bq24780S

THERMAL METRIC

(1)

UNITRUY (WQFN)

28 PINS

R

R

R

ψ

ψ

R

θJA

θJCtop

θJB

JT

JB

θJCbot

Junction-to-ambient thermal resistance 33.3 °C/W

Junction-to-case (top) thermal resistance 29.7 °C/W

Junction-to-board thermal resistance 6.5 °C/W

Junction-to-top characterization parameter 0.3 °C/W

Junction-to-board characterization parameter 6.5 °C/W

Junction-to-case (bottom) thermal resistance 1.3 °C/W

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

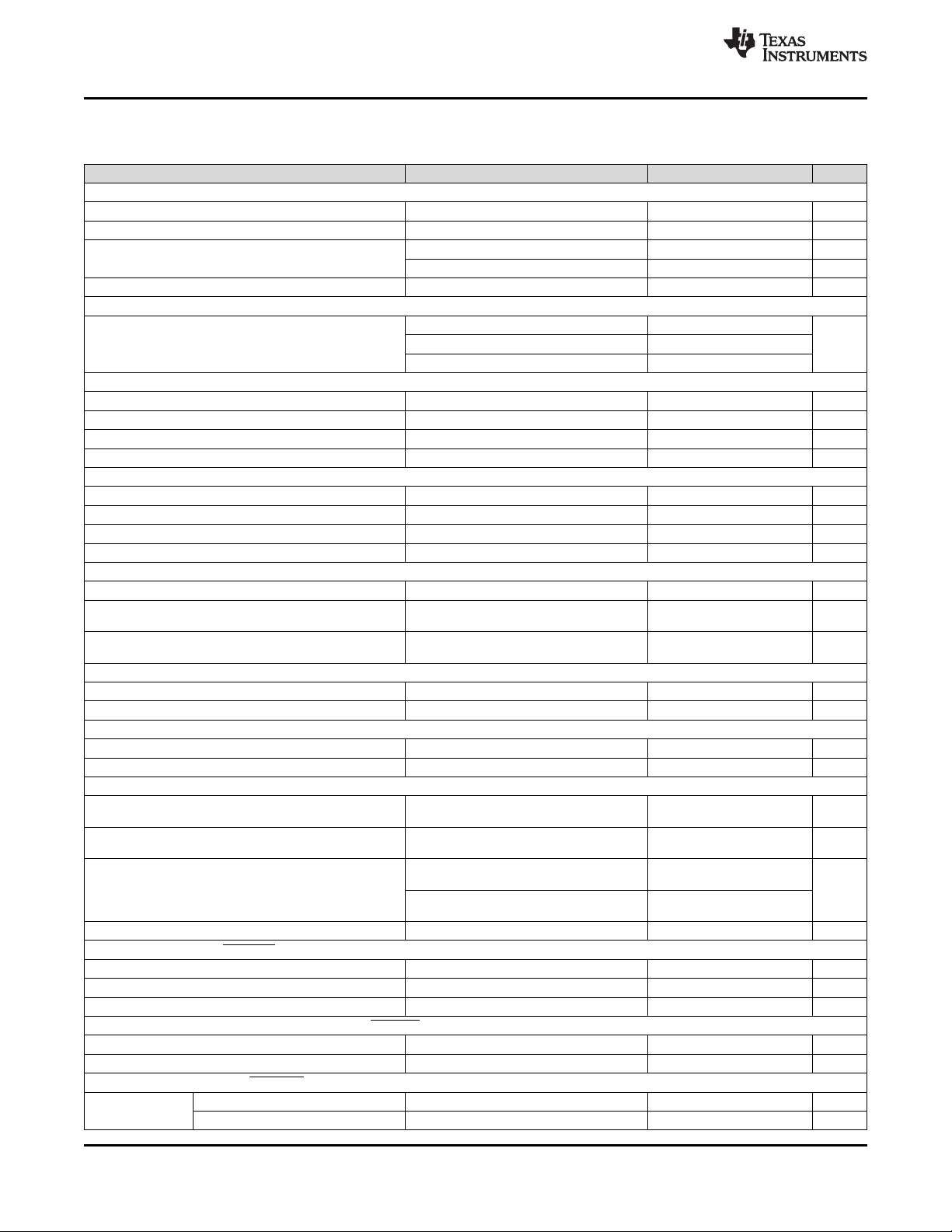

6.5 Electrical Characteristics

4.5 V ≤ V

OPERATING CONDITIONS

V

VCC(OP)

CHARGE VOLTAGE REGULATION

V

BAT(REG_RNG)

V

BAT(REG_ACC)

CHARGE CURRENT REGULATION

V

IREG(CHG_RNG)

I

CHRG(REG_ACC)

I

LGK(SRP-SRN)

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VCC/ACP/ACN operating voltage 4.5 24 V

Battery voltage 1.024 19.2 V

ChargeVoltage() = 0x41A0 16.8 V

–10°C-85°C –0.4% 0.4%

–40°C-125°C –0.5% 0.5%

ChargeVoltage() = 0x3130 12.592 V

–10°C-85°C –0.4% 0.4%

Charge voltage regulation accuracy

Charge current regulation differential

voltage

Charge current regulation accuracy

(SRN > 2.8 V)

SRP and SRN leakage mismatch –8 8 µA

–40°C-125°C –0.5% 0.5%

ChargeVoltage() = 0x20D0 8.4 V

–10°C-85°C –0.4% 0.4%

–40°C-125°C –0.6% 0.6%

ChargeVoltage() = 0x1060 4.192 V

–10°C-85°C –0.5% 0.8%

–40°C-125°C –0.7% 0.8%

V

ChargeCurrent() = 0x1000

ChargeCurrent() = 0x0800

ChargeCurrent() = 0x0200

ChargeCurrent() = 0x0100 256 mA

ChargeVoltage() = 0x20D0, 0x3031, 0x41A0 –16% 16%

ChargeVoltage() = 0x1060 –20% 20%

ChargeCurrent() = 0x00C0

ChargeCurrent() = 0x0080

IREG(CHG)

= V

SRP

– V

SRN

0 81.28 mV

4096 mA

–2% 2%

2048 mA

–3% 3%

512 mA

–10% 10%

192 mA

–20% 20%

128 mA

–30% 30%

6

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 7

www.ti.com

Electrical Characteristics (continued)

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

4.5 V ≤ V

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DISCHARGE CURRENT REGULATION

V

(IREG_CHG_RNG)

I

(DCHRG_REG_ACC)

Charge current regulation differential

voltage

Discharge current regulation accuracy

INPUT CURRENT REGULATION

V

(IREG_DPM_RNG)

I

(DPM_REG_ACC)

I

LGK(ACP-ARN)

Input current regulation differential

voltage

Input current regulation accuracy

ACP and ACN leakage mismatch –5 5 µA

INPUT CURRENT SENSE AMPLIFIER

V

(IADP)

I

(IADP)

A

(IADP)

V

(IADP_ACC)

V

(IADP_CLAMP)

C

(IADP)

IADP output voltage 0 3.3 V

IADPT output current 0 1 mA

IADP sense amplifier gain V

Current sense amplifier gain accuracy

IADP clamp voltage 3 3.3 V

IADP output load capacitance With 0 to 1mA load 100 pF

DISCHARGE CURRENT SENSE AMPLIFIER

V

(IDCHG)

I

(IDCHG)

A

(IDCHG)

V

(IDCHG_ACC)

V

(IDCHG_CLAMP)

C

(IDCHG)

IDCHG output voltage 0 3.3 V

IDCHG output current 0 1 mA

Current sense amplifier gain V

Current sense output accuracy

IDCHG clamp voltage 3 3.3 V

IDCHG output load capacitance With 0 to 1mA load 100 pF

V

IREG(IDISCHG)

= V

SRN

– V

ChargeCurrent() = 0x2000

ChargeCurrent() = 0x1000

ChargeCurrent() = 0x0800

ChargeCurrent() = 0x0400

ChargeCurrent() = 0x0400

V

(IREG_DPM)

= V

(ACP)

– V

(ACN)

InputCurrent() = 0x1000

InputCurrent() = 0x0800

InputCurrent() = 0x0400

InputCurrent() = 0x0200

/ V

(IADP)

V

(ACP-ACN)

V

(ACP-ACN)

V

(ACP-ACN)

V

(ACP-ACN)

V

(ACP-ACN)

V

(ACP-ACN)

(IDCHG)/V(SRN-SRP)

V

(SRN-SRP)

V

(SRN-SRP)

V

(SRN-SRP)

V

(SRN-SRP)

, REG0x12[4] = 0 20 V/V

(ACP-ACN)

= 40 mV –2% 2%

= 20 mV –4% 4%

≥ 10 mV –7% 7%

≥ 5 mV –20% 20%

≥ 2.5 mV –30% 30%

≥ 1.5 mV –40% 40%

, REG0x12[3] = 1 16 V/V

= 40 mV –5% 5%

= 20 mV –9% 9%

= 10 mV –17% 17%

= 5 mV –34% 34%

SRP

0 322.56 mV

8192 mA

–2% 2%

4096 mA

–3% 3%

2048 mA

–5% 5%

1024 mA

–8% 8%

512 mA

–10% 10%

0 80.64 mV

4096 mA

–2% 2%

2048 mA

–3% 3%

1024 mA

–5% 5%

512 mA

–12% 12%

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

7

Page 8

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Electrical Characteristics (continued)

www.ti.com

4.5 V ≤ V

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SYSTEM POWER SENSE AMPLIFIER

V

(PMON)

I

(PMON)

A

(PMON)

V

PMON_ACC

V

PMON_CLAMP

C

PMON

PMON output voltage 0 3.3 V

PMON output current 0 160 µA

PMON system gain V

PMON Gain Accuracy

(REG0x3B[9]=1)

PMON clamp voltage 3% 3.3% V

Maximum output load capacitance With 0 to 1 mA 100 pF

REGN REGULATOR

V

(REGN_REG)

I

(REGN_LIM_Charging)

V

LDO(DROPOUT)

I

(REGN_LIM)

I

(REGN_TSHUT)

C

(REGN)

REGN regulator voltage V

REGN current limit when in charging

mode

REGN output voltage in dropout V

REGN current limit when not in charging

REGN output under thermal shutdown V

REGN output capacitor I

VCCUNDER VOLTAGE LOCKOUT COMPARATOR

V

VCC(UVLO)

V

VCC(UVLO_HYS)

Input undervoltage rising threshold VCCrising 2.4 2.6 2.8 V

Input undervoltage falling hysteresis 200 mV

QUIESCENT CURRENT

Current with battery only,

I

BAT

I

AC

TJ= 0 to 85°C,

I

+ I

+ I

SRP

ACN

+ I

I

SRN

ACP

Adapter current,

I

+ I

ACP

+ I

VCC

BATSRC

ACN

+ I

+ I

ACDRV

PHASE

ACOK COMPARATOR

V

(ACOK_RISE)

V

(ACOK_FALL)

V

(WAKEUP_RISE)

V

(WAKEUP_FALL)

ACOK rising threshold V

ACOK falling threshold V

WAKEUP detect rising threshold V

WAKEUP detect falling threshold V

VCC to SRN COMPARATOR (VCC_SRN)

V

(VCC-SRN_FALL)

V

(VCC-SRN _RISE)

VCC-SRN falling threshold to turn off

ACFET

VCC-SRN rising threshold to turn on

ACFET

ACN to SRN COMPARATOR (ACN_SRN)

V

(ACN-SRN_FALL)

V

(ACN- SRN _RISE)

ACN to BAT falling threshold VCC ramps

up above SRN

ACN to BAT rising threshold to turn on

BATFET

+ I

+ I

VCC

CMSRC

(PMON)

/(PIN+ P

, REG0x3B[9] = 1 1 µA/W

BAT

Adapter Only with System Power = 19.5V/45W –4% 4%

Adapter Only with System Power = 12V/24W –6% 6%

Adapter Only with System Power = 5V/9W –10% 10%

Battery Only with System Power 11V/44W –4.5% 4.5%

Battery Only with System Power 7.4V/29.8W –7% 7%

Battery Only with System Power 3.7V/14.4W –10% 10%

> V

VCC

V

(REGN)

VCC

V

REGN

mode

REGN

LOAD

V

BAT

REG0x12[15] = 1

V

BAT

REG0x12[15] = 1

+

V

BAT

BATFET on, REG0x12[15] = 0, REGN = 0 V,

, V

(UVLO)

= 0 V, V

= 5 V, I

LOAD

= 0 V, V

= 5V 13 23 mA

= 100 µA to 50 mA 2.2 μF

= 16.8 V, VCC disconnected from battery,

= 16.8 V, VCC connected from battery,

= 16.8 V, VCC connect to battery,

Comparator and PROCHOT enabled, PMON

(ACDET)

VCC

> V

(wakeup_RISE)

> V

, in charging mode 80 100 mA

(UVLO)

5.7 6 6.3 V

= 20 mA 4.4 4.6 4.75 V

> V

VCC

, Not in charging

(UVLO)

13 mA

25 44

700 800

disabled, TJ= 0 to 85°C

V

(VCC_ULVO)

charge disabled

V

(VCC_ULVO)

charge enabled, no switching

V

(VCC_ULVO)

charge enabled, switching, MOSFET Qg 4nC

VCC

VCC

VCC

VCC

> V

(VCC_UVLO)

> V

(VCC_UVLO)

> V

(VCC_UVLO)

> V

(VCC_UVLO)

< V

< V

< V

VCC

VCC

VCC

< V

< V

< V

(ACOVP)

(ACOVP)

(ACOVP)

, V

, V

, V

(ACDET)

(ACDET)

(ACDET)

> 2.4 V,

> 2.4 V,

> 2.4 V,

0.65 0.8

1.6 3

10

, ACDET ramps up 2.375 2.4 2.425 V

, ACDET ramps down 2.3 2.345 2.395 V

, ACDET ramps up 0.57 0.8 V

, ACDET ramps down 0.3 0.51 V

VCC ramps down to SRN –20 60 140 mV

VCC ramps up above SRN 170 260 360 mV

ACN ramps down towards SRN 120 200 280 mV

ACN ramps above SRN 220 290 360 mV

5

μA

mA

8

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 9

www.ti.com

Electrical Characteristics (continued)

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

4.5 V ≤ V

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

HIGH SIDE IFAULT COMPARATOR (IFAULT_HI)

V

(ACN_PH_RISE)

ACN to PH rising threshold reg0x37 bit [7] = 0 450 750 1200 mV

LOW SIDE IFAULT COMPARATOR (IFAULT_LOW)

V

(IFAULT_LO_RISE)

PHASE to GND rising threshold reg0x37 bit [6] = 1 180 250 340 mV

INPUT OVERVOLTAGE COMPARATOR (ACOVP)

V

(ACOV)

V

(ACOV_HYS)

VCC overvoltage rising threshold VCC ramps up 24 26 28 V

VCC overvoltage falling hysteresis VCC ramps down 1 V

INPUT OVERCURRENT COMPARATOR (ACOC)

V

(ACOC)

V

(ACOC_CLAMP)

Rising threshold w.r.t. ICRIT input current

limit

ACOC threshold V

BAT OVERVOLTAGE COMPARATOR (BAT_OVP)

V

OVP(RISE)

V

OVP(FALL)

I

OVP

Overvoltage rising threshold as

percentage of V

BAT(REG)

Overvoltage falling threshold as

percentage of V

BAT(REG)

Discharge resistor on SRP

CHARGE OVERCURRENT COMPARATOR (CHG_OCP)

Cycle-by-cycle overcurrent limit,

V

OCP(limit)

measured voltage between SRP and

SRN

CHARGE UNDERCURRENT COMPARATOR (CHG_UCP)

V

UCP(FALL)

Cycle-by-cycle undercurrent falling

threshold

LIGHT LOAD COMPARATOR (LIGHT_LOAD)

V

LL(FALL)

V

LL(RISE_HYST)

Light load falling threshold SRP ramps down towards SRN 1.25 mV

Light load rising hysteresis SRP ramps above SRN 1.25 mV

BATTERY DEPLETION COMPARATOR (BAT_DEPL)

V

BAT(DEPL_FALL)

V

BAT(DEPL_RISE_ HYST)

V

BAT(DEPL_RDEG)

V

BAT(DEPL_FDEG)

Battery depletion falling threshold, as

percentage of voltage regulation limit

Battery depletion rising hysteresis

Battery depletion rising deglitch

Battery depletion falling deglitch

BATTERY LOWV COMPARATOR (BAT_LOWV)

V

BAT(LV_FALL)

V

BAT(LV_RHYST)

I

BAT(LV_RESET)

Battery LOWV falling threshold SRN ramps down 2.3 2.5 2.8 V

Battery LOWV rising hysteresis SRN ramps up 200 mV

Battery LOWV charge current limit Measure across SRP and SRN 5 mV

THERMAL SHUTDOWN COMPARATOR (TSHUT)

T

SHUT

T

SHUT(HYS)

Thermal shutdown rising temperature Temperature ramps up 155 °C

Thermal shutdown hysteresis, falling Temperature ramps down 20 °C

ILIM COMPARATOR

V

ILIM(FALL)

V

ILIM(RISE)

ILIM as converter enable falling threshold V

ILIM as converter enable rising threshold V

REG0x37[9] = 1 180% 200% 220%

(ACP)

– V

(ACN)

50 190 mV

SRN ramps up 103% 104% 106%

SRN ramps down 102%

VSRN > 6 V 6

VSRN = 4.5 V 2.5

mA

ChargeCurrent() = 0x0xxxH 54 60 66 mV

ChargeCurrent() = 0x1000H – 0x17C0H 80 90 100 mV

ChargeCurrent() = 0x1800H – 0x1FC0H 110 120 130 mV

SRP ramps down towards SRN 1 5 9 mV

REG0x3B[15:14] = 00 56% 60% 64%

REG0x3B[15:14] = 01 60% 64% 68%

REG0x3B[15:14] = 10 64% 68% 72%

REG0x3B[15:14] = 11 68% 72% 78%

REG0x3B[15:14] = 00 225 305 400

REG0x3B[15:14] = 01 240 325 430

REG0x3B[15:14] = 10 255 345 450

mV

REG0x3B[15:14] = 11 280 370 490

Delay to turn on BATFET and turn off ACFET

during LEARN cycle

Delay to turn off BATFET and turn on ACFET

during LEARN cycle

falling 60 75 90 mV

ILIM

rising 90 105 120 mV

ILIM

600 ms

10 µs

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

9

Page 10

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Electrical Characteristics (continued)

www.ti.com

4.5 V ≤ V

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INDEPENDENT COMPARATOR

V

(CMPOS)

V

(CMPCM)

V

(CMPREF)

V

(CMPRISE)

Comparator input offset –4 4 mV

Comparator input common-mode 0 6.5 V

Comparator reference voltage (CMPIN

falling)

Comparator reference hysteresis REG0x3B[6] = 0 100 mV

PWM OSCILLATOR

F

SW

PWM switching frequency

BATFET GATE DRIVER (BATDRV)

I

BAT(FET)

BATDRV charge pump current limit V

Gate drive voltage on BATFET V

R

BAT(DRV_OFF)

R

BAT(DRV_LOAD)

BATDRV turn-off resistance 5 6.2 7.4 kΩ

Minimum Load between gate and source 500 kΩ

ACFET GATE DRIVER (ACDRV)

I

(ACFET)

ACDRV charge pump current limit V

Gate drive voltage on ACFET V

R

(ACDRV_OFF)

R

(ACDRV_LOAD)

ACDRV turn-off resistance 5 6.2 7.4 kΩ

Minimum load between gate and source 500 kΩ

PWM HIGH SIDE DRIVER (HIDRV)

R

DS(HI_ON)

R

DS(HI_OFF)

V

(BTST_REFRESH)

High-side driver (HSD) turn-on resistance V

High-side driver (HSD) turn-off

Resistance

Bootstrap refresh comparator threshold

voltage

PWM LOW SIDE DRIVER (LODRV)

R

DS(LO_ON)

R

DS(LO_OFF)

Low-side driver (LSD) turn-on resistance 7.5 12 Ω

Low-side driver (LSD) turn-off resistance 0.75 1.25 Ω

INTERNAL SOFT START

I

STEP

t

STEP

Soft start step size 64 mA

Soft start step time 400 µs

PROCHOT

V

(ICRIT)

V

(INOM)

V

(IDCHG)

V

(VSYS)

ICRIT comparator threshold

INOM comparator threshold

IDCHG comparator threshold

VSYS comparator threshold REG0x3C[7:6] = 01 5.88 6 6.12 V

LOGIC INPUT (SDA, SCL, BATPRES)

V

IN(LO)

V

IN(HI)

V

IN(LEAK)

Input low threshold 0.8 V

Input high threshold 2.1 V

Input bias current V = 7 V –1 µA

LOGIC OUTPUT OPEN DRAIN (ACOK, SDA, CMPOUT, TB_STAT)

V

O(LO)

V

O(LEAK)

Output saturation voltage 5-mA drain current 500 mV

Leakage current V = 7 V –1 1 µA

LOGIC OUTPUT OPEN DRAIN (PROCHOT)

V

O(LEAK_PROCHOT)

Output saturation voltage 17-mA drain current 300 mV

Leakage current V = 5.5 V –1 1 µA

REG0x3B[7] = 0 2.28 2.3 2.32 V

REG0x3B[7] = 1 1.18 1.2 1.22 V

REG0x12[9:8] = 00 510 600 690

kHzREG0x12[9:8] = 01 680 800 920

REG0x12[9:8] = 10 850 1000 1150

– V

BAT(DRV)

– V

BAT(DRV)

– V

(ACDRV)

– V

(ACDRV)

– V

(BTST)

(PH)

V

– V

(BTST)

(PH)

V

– V

(BTST)

requested

(PH)

REG0x3C[15:11] = 01001, as percentage of

input current limit, InputCurrent() = 0x1000

as percentage of input current limit,

InputCurrent()=0x0800

REG0x3D[15:11] = 10000, as voltage between

SRN and SRP

REG0x3D[15:11] = 00100, as voltage between

SRN and SRP

= 5 V 40 60 µA

BAT(SRC)

when V

BAT(SRC)

= 5 V 40 60 µA

(CMSRC)

when V

(CMSRC)

VCC

(SRN)

> V

> V

(UVLO)

BAT(UVLO)

5.5 6.1 6.8 V

5.5 6.1 6.8 V

= 5.5 V 6 10 Ω

= 5.5 V 0.9 1.4 Ω

when low side refresh pulse is

3.85 4.3 4.7 V

147% 150% 153%

107% 110% 112%

160 163.84 167

38 40.96 44

mV

10

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 11

bq24780S

www.ti.com

SLUSC27C –APRIL 2015–REVISED MARCH 2017

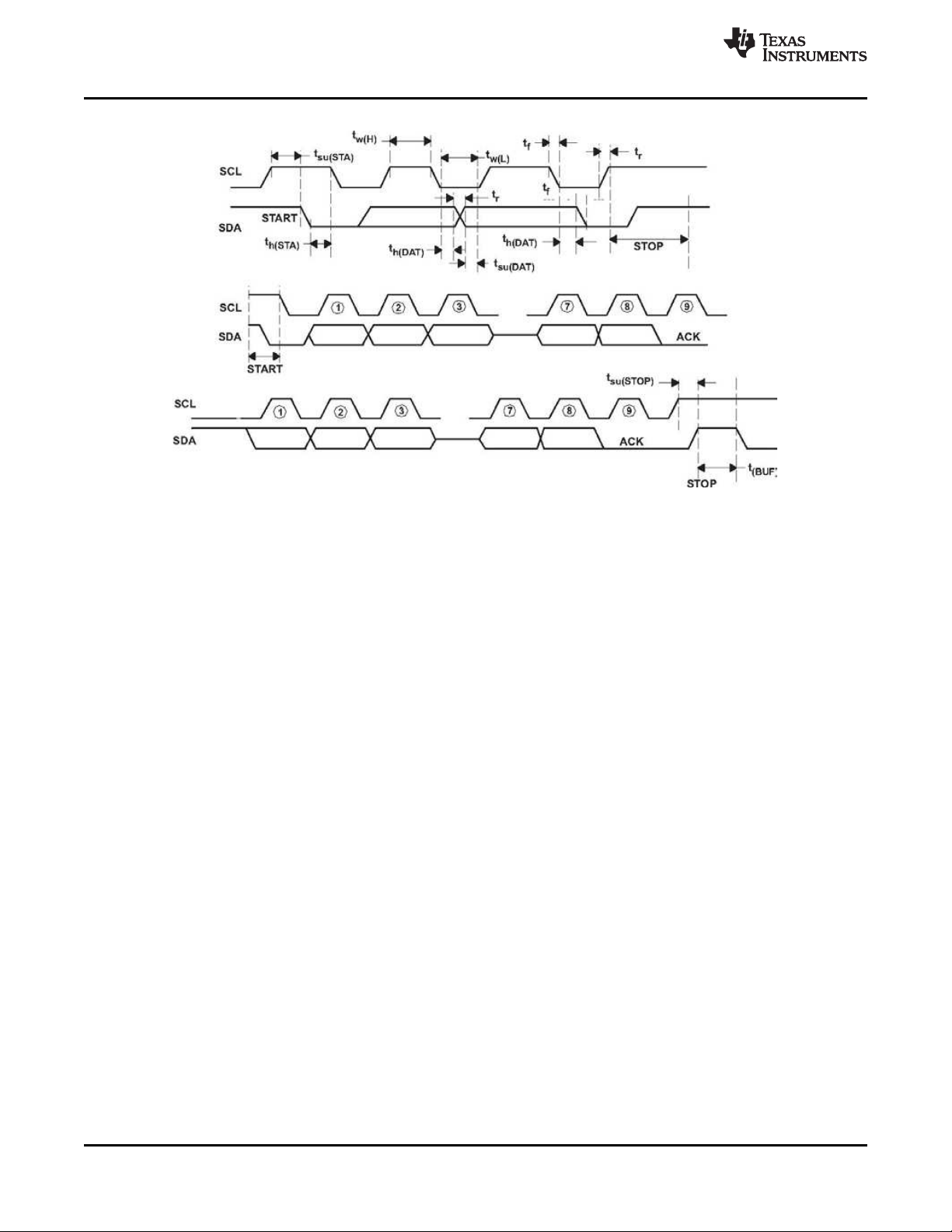

6.6 Timing Requirements

4.5 V ≤ V

ACOK COMPARATOR

t

ACOK_RISE_DEG

t

ACOK_FALL_DEG

INPUT OVERCURRENT COMPARATOR (ACOC)

t

ACOC_DEG

SMBus TIMING CHARACTERISTICS

t

R

t

F

t

W(H)

t

W(L)

t

SU(STA)

t

H(STA)

t

SU(DAT)

t

H(DAT)

t

SU(STOP)

t

(BUF)

F

S(CL)

HOST COMMUNICATION FAILURE

t

timeout

t

BOOT

t

WDI

WDI

t

WDI

PWM DRIVER TIMING

t

DEADTIME_RISE

t

DEADTIME_FALL

(1) Devices participating in a transfer timeout when any clock low exceeds the 25-ms minimum timeout period. Devices that have detected

a timeout condition must reset the communication no later than the 35-ms maximum timeout period. Both a master and a slave must

adhere to the maximum value specified because it incorporates the cumulative stretch limit for both a master (10 ms) and a slave (25

ms).

(2) User can adjust threshold through SMBus ChargeOption() REG0x12.

≤ 24 V, –40°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER MIN TYP MAX UNIT

ACOK rising deglitch to turn on

ACFET; V

ACOK falling deglitch to turn off

ACFET

ACDET

[GBD]

> 2.4V

[GBD]

> V

VCC

1st time or REG0x12[12] = 0

V

> V

VCC

Not 1st time or REG0x12[12] = 1

V

> V

VCC

, ACDET ramps up,

VCC_UVLO

, ACDET ramps up,

VCC_UVLO

, ACDET ramps down 3 µs

VCC_UVLO

100 150 200 ms

0.9 1.3 1.7 s

V

Deglitch time to latch off ACFET 9 12 15 ms

SCLK/SDATA rise time 1 µs

SCLK/SDATA fall time 300 ns

SCLK pulse width high 4 50 µs

SCLK pulse width low 4.7 µs

Setup time for start condition 4.7 µs

Start condition hold time after which first clock pulse is generated 4 µs

Data setup time 250 ns

Data hold time 300 ns

Setup time for stop condition 4 µs

Bus free time between start and stop condition 4.7 µs

Clock frequency 10 100 kHz

SMBus bus release timeout

(1)

25 35 ms

Deglitch for watchdog reset signal 10 ms

Watchdog timeout period, REG0x12 [14:13] = 01

Watchdog timeout period, REG0x12 [14:13] = 10

Watchdog timeout period, REG0x12 [14:13] = 11

(2)

(2)

(2)

(default) 140 175 210

4 5 6

70 88 105

Driver dead time from low side to high side 20 ns

Driver dead time from high side to low side 20 ns

st

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

11

Page 12

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Figure 1. SMBus Communication Timing Waveforms

www.ti.com

12

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

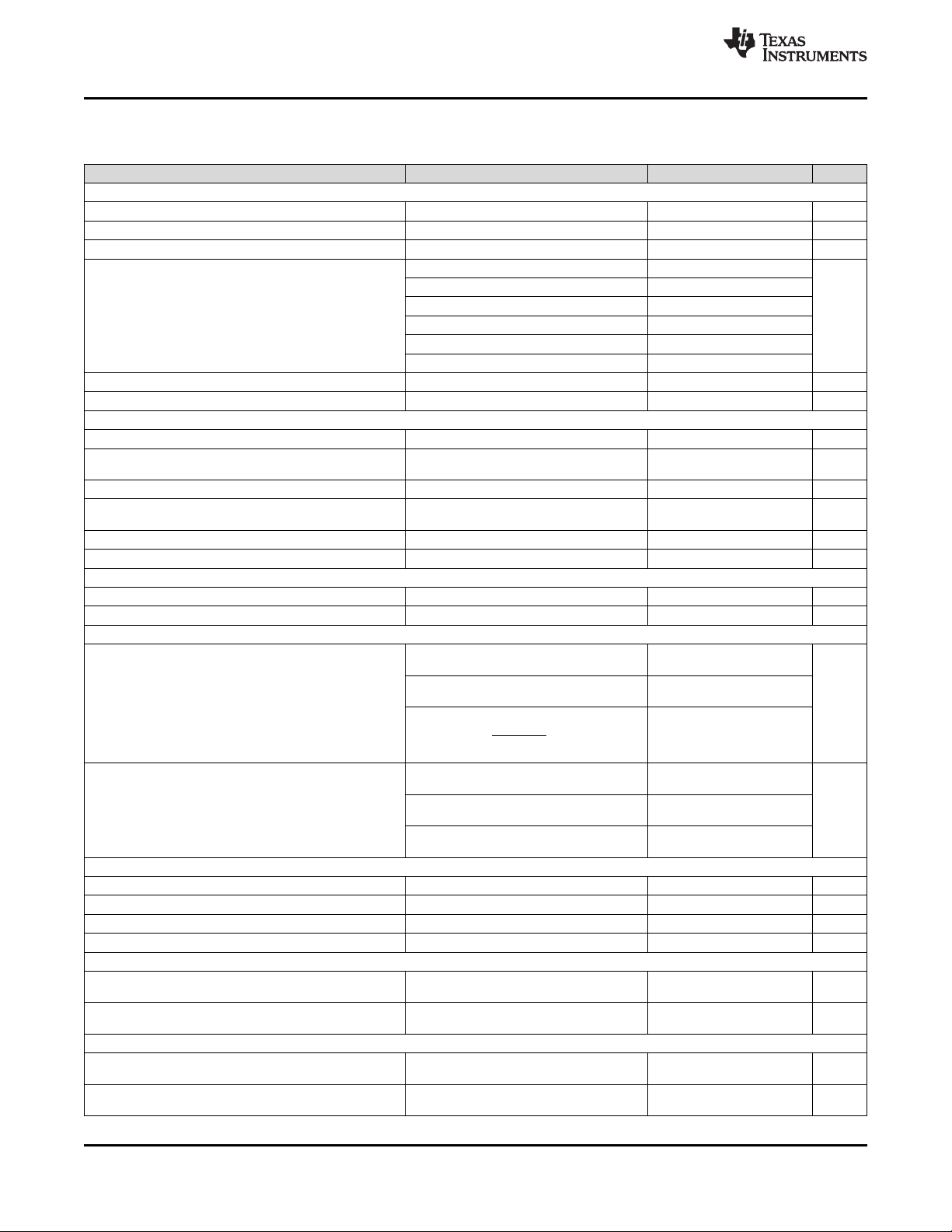

Page 13

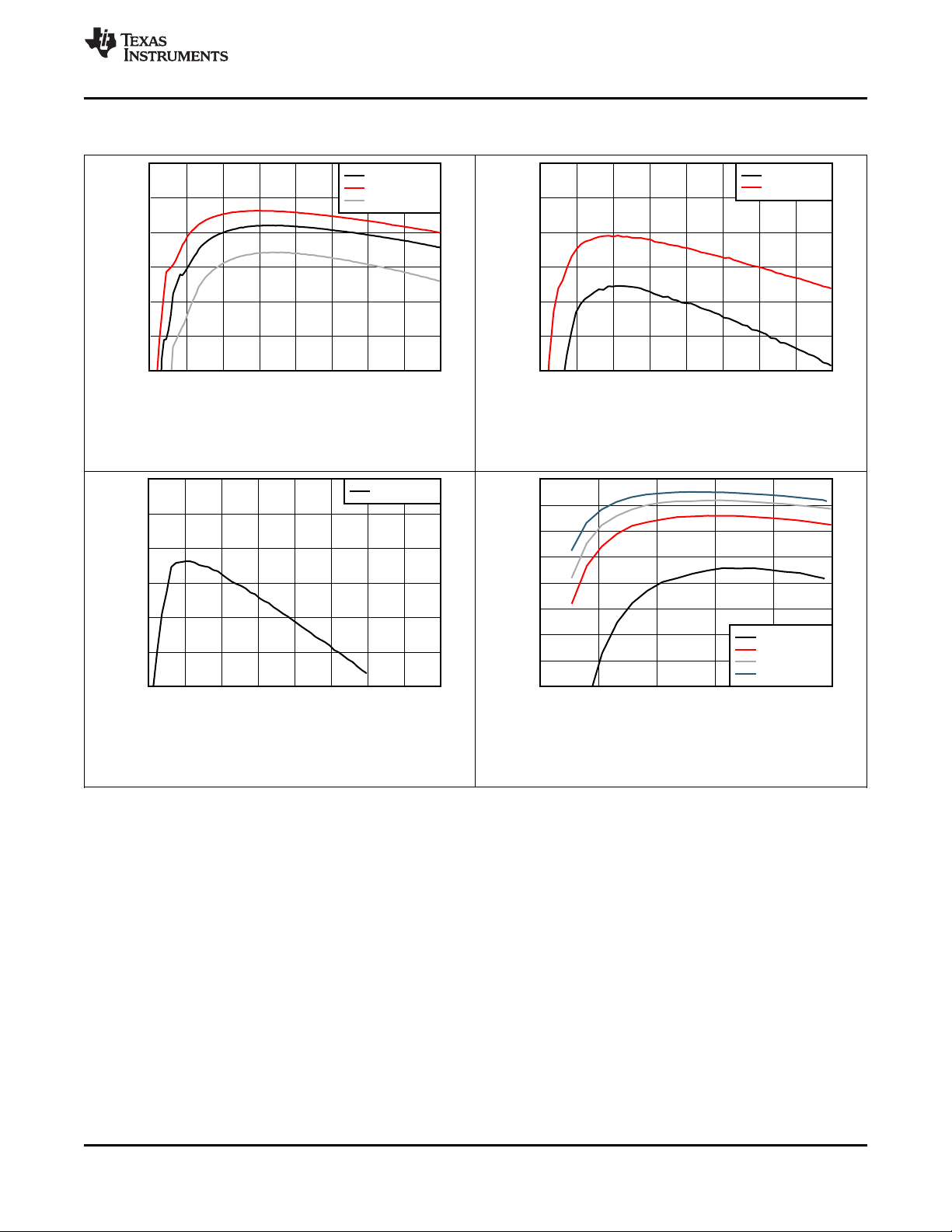

Charge Current (A)

Efficiency

0 1 2 3 4 5 6 7 8

88%

90%

92%

94%

96%

98%

100%

D003

V

BAT

= 3.7 V

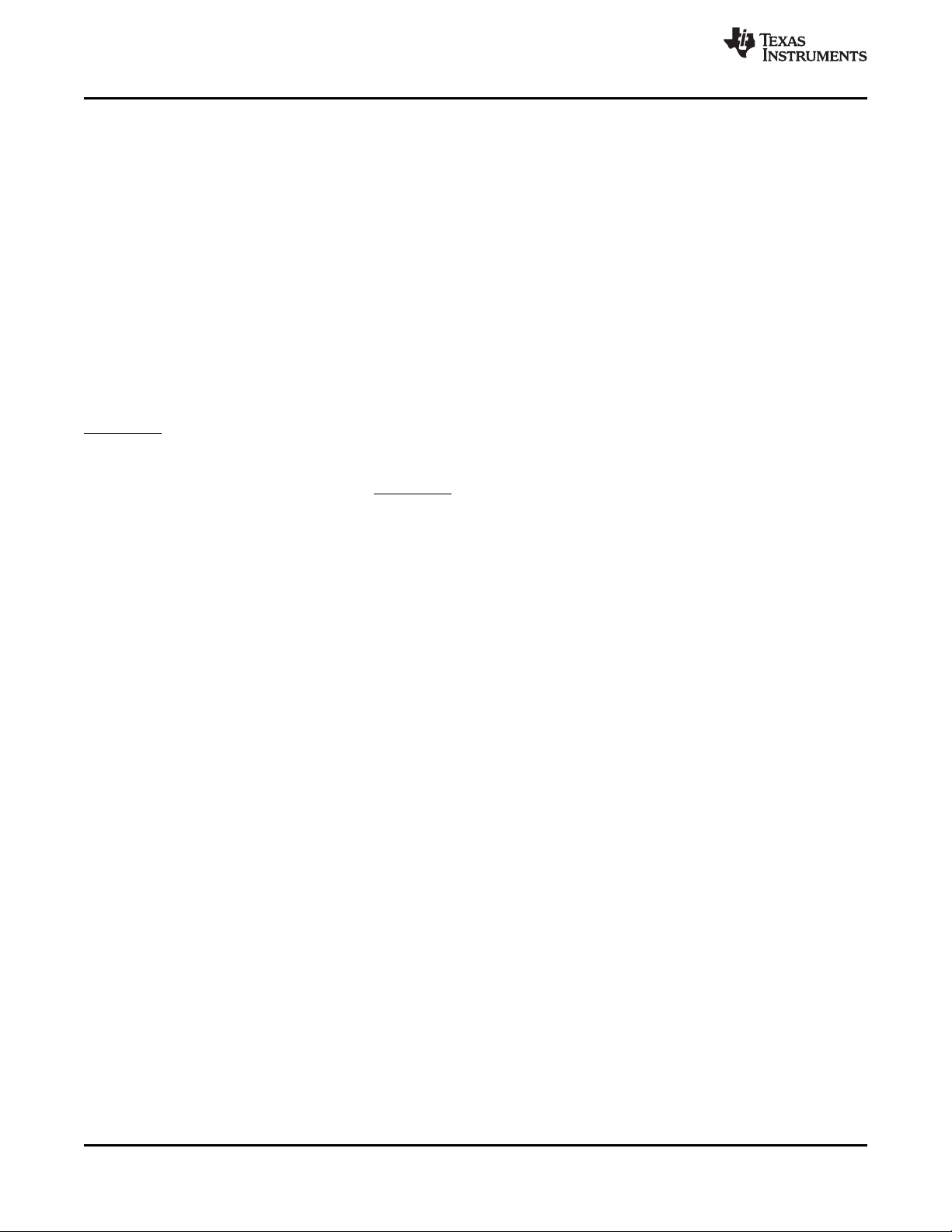

Discharge Current (A)

Efficiency

0 2 4 6 8 10

60%

65%

70%

75%

80%

85%

90%

95%

100%

D004

V

BAT

= 3.7 V

V

BAT

= 7.4 V

V

BAT

= 11.1 V

V

BAT

= 14.8 V

Charge Current (A)

Efficiency

0 1 2 3 4 5 6 7 8

88%

90%

92%

94%

96%

98%

100%

D001

V

BAT

= 14.8 V

V

BAT

= 11.1 V

V

BAT

= 7.4 V

Charge Current (A)

Efficiency

0 1 2 3 4 5 6 7 8

88%

90%

92%

94%

96%

98%

100%

D002

V

BAT

= 3.7 V

V

BAT

= 7.4 V

www.ti.com

6.7 Typical Characteristics

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

VIN = 20 V

Figure 2. Efficiency During Charging

VIN = 5 V

Figure 4. Efficiency During Charging

VIN = 12 V

Figure 3. Efficiency During Charging

VIN = 20 V

Figure 5. Efficiency During Boost

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

13

Page 14

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

7 Detailed Description

7.1 Overview

The bq24780S is a 1-4 cell battery charge controller with power selection for space-constrained, multi-chemistry

portable applications such as notebook and detachable ultrabook. It supports wide input range of input sources

from 4.5 V to 24 V, and 1-4 cell battery for a versatile solution.

The bq24780S supports automatic system power source selection with separate drivers for n-channel MOSFETS

on the adapter side and battery side.

The bq24780S features Dynamic Power Management (DPM) to limit the input power and avoid AC adapter overloading. During battery charging, as the system power increases, the charging current will reduce to maintain

total input current below adapter rating. If system power demand is temporarily exceeds adapter rating, the

bq24780S supports hybrid power boost mode (previously called "turbo boost mode") to allow battery discharge

energy to supplement system power. For details of hybrid power boost mode, refer to Device Functional Modes

section.

The bq24780S closely monitors system power (PMON), input current (IADP) and battery discharge current

(IDCHG) with highly accurate current sense amplifiers. If current is too high, adapter or battery is removed, a

PROCHOT signal is asserted to CPU so that the CPU optimizes its performance to the power available to the

system.

The SMBus controls input current, charge current and charge voltage registers with high resolution, high

accuracy regulation limits. It also sets the PROCHOT timing and threshold profile to meet system requirements.

14

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

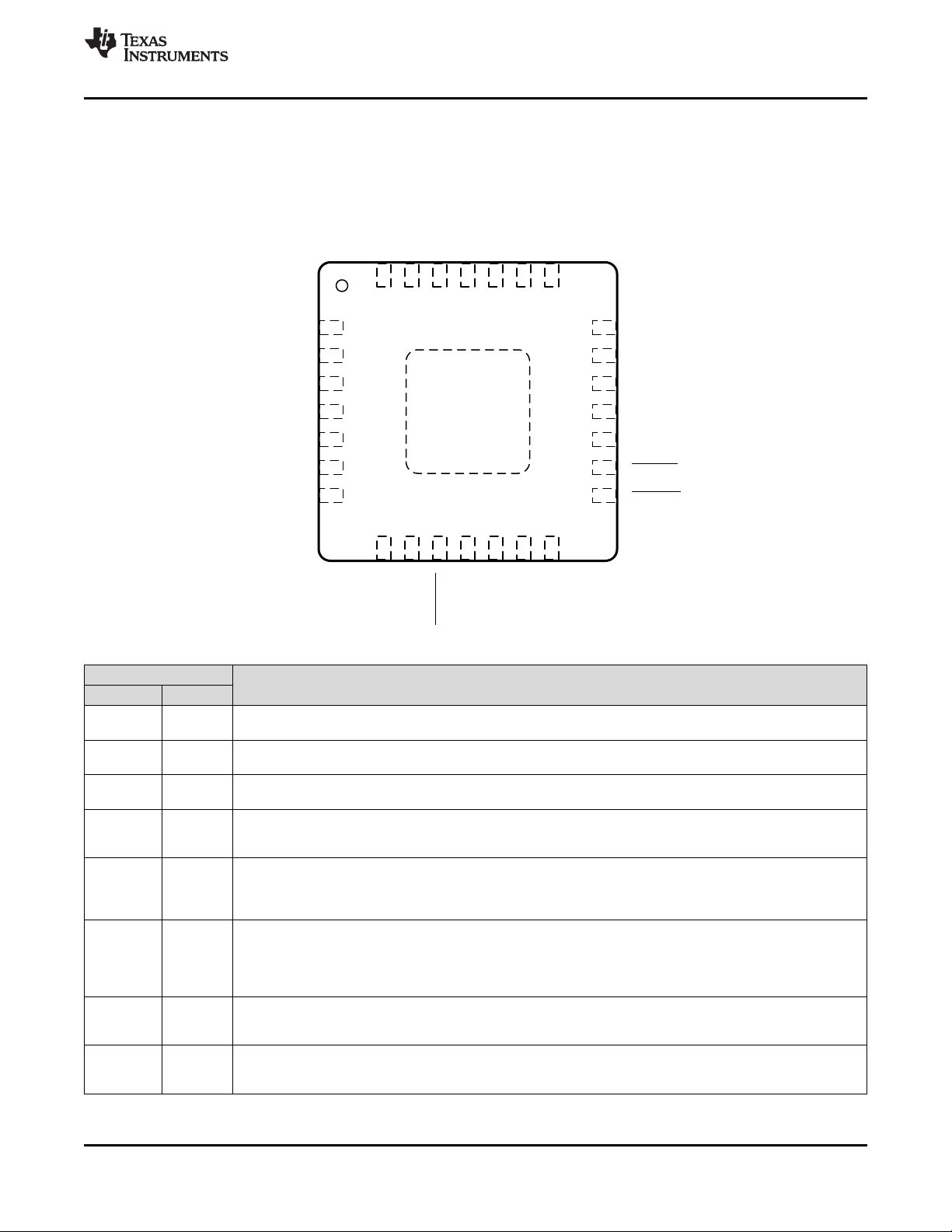

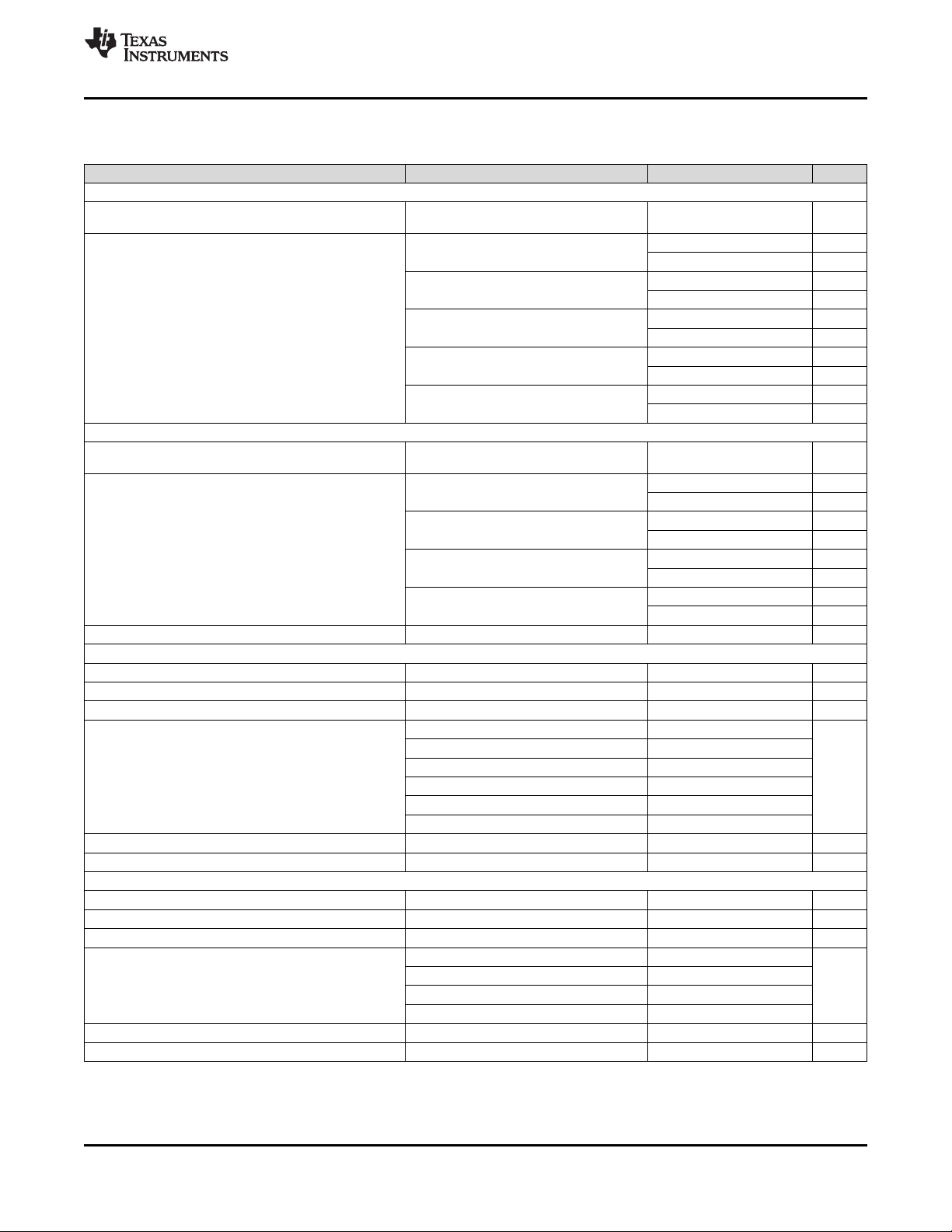

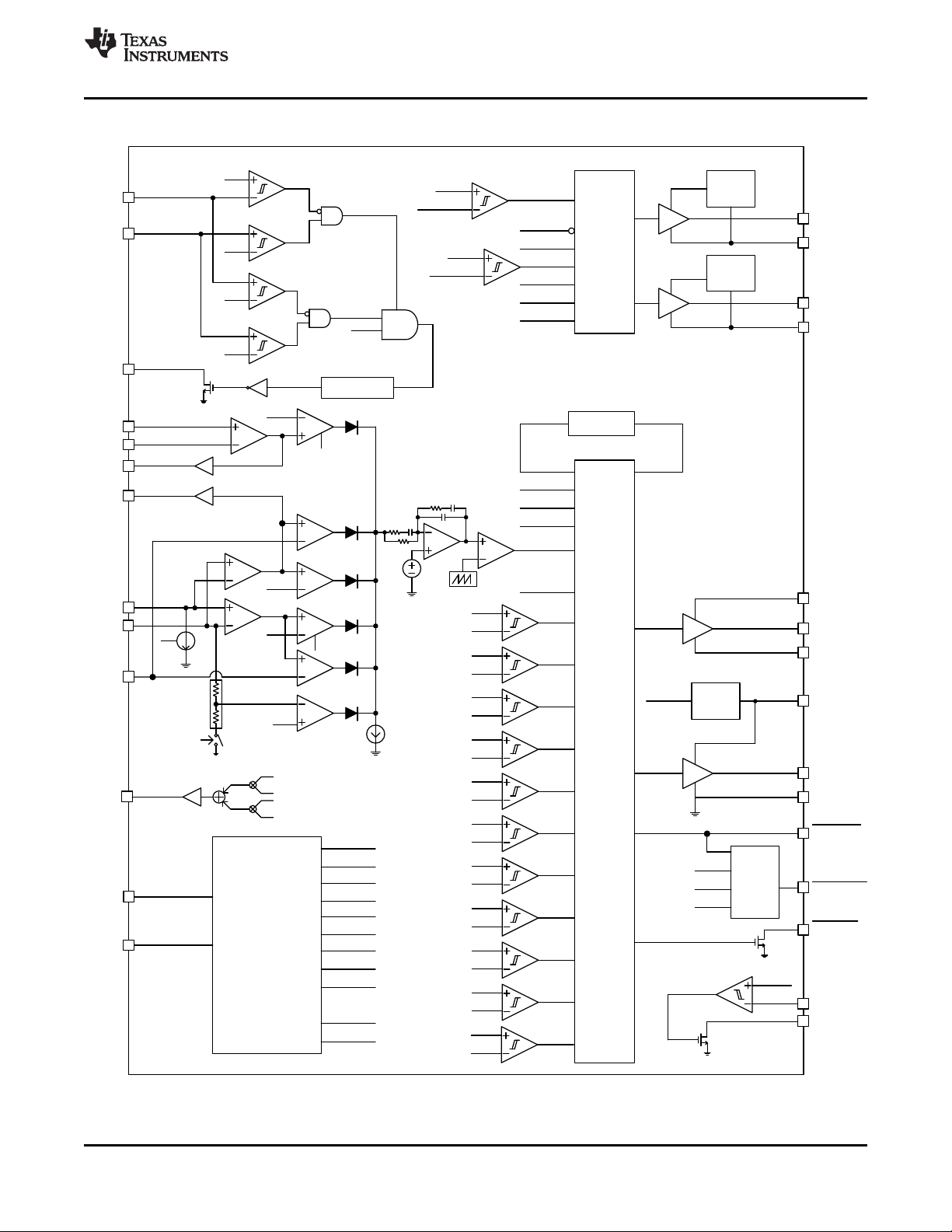

Page 15

150ms/1.3sec

Rising Deglitch**

20X**

16X

SELECTOR

LOGIC

ACDRV

CHARGE

PUMP

REGN

LDO

SMBUS Interface

ChargeOption()

ChargeCurrent()

ChargeVoltage()

InputCurrent()

DischargeCurrent()

ManufactureID()

DeviceID()

UVLO*

3.2V

WAKEUP*

EN_REGN

ACOVP

0.6V

26V

2.4V

ACGOOD

VCC_SRN

ACOK_DRV

VREF_IAC

VREF_ICHG

ILIM

EN_CHRG

BATOVP

6mA

DAC_VALID

CHARGE_INHIBIT

EN_LEARN

VREF_VREG

VREF_ICHG

VREF_IAC

VREF_IDCHG

EN_BOOST

EN_DPM

10uA

200mV

RAMP

Frequency**

FBO

EAI EAO

PWM

ACOK_DRV

ACDRV

CMSRC+5.9V

ACDRV_CMSRC

ACOC

ACGOOD

CHARGE_INHIBIT

DAC_VALID

EN_LEARN

WATCHDOG

TIMER 175s**

WD_TIMEOUT

EN_CHRG

TYPE III

COMPENSATION

Tj

155C

TSHUT

CHG_OCP

SRP-SRN

120mV

CHG_UCP

5mV

SRP-SRN

LIGHT_LOAD

1.25mV

SRP-SRN

ACOC

ACP_ACN

2x ICRIT*

REFRESH

4.3V

BTST_PH

BATOVP

SRN

104%VREF_VREG

BATLOWV

2.5V

SRN

VCC_SRN

VCC

SRN+275mV

WAKEUP

FAST_DPM

ACP-ACN

107%xVREF_IAC

FET_LATCHOFF_EN

EN_LEARN

EN_REGN

EN_SHIP

FET_LATCHOFF_EN

VCC

ACDET

ACOK

ACP

ACN

IADP

SRP

SRN

SDA

SCL

GND

LODRV

REGN

PHASE

HIDRV

BTST

BATDRV

CMSRC

ACDRV

VREF_VREG

bq24780S

*Threshold is adjustable by registers

28

6

5

2

1

7

20

19

9

22

23

24

27

26

25

18

3

4

PWM

DRIVER

LOGIC

EN_DPM

IDCHG

PMON

BATPRES

15

PROC

HOT

detect

PROCHOT

10

IADPT

IDCHG

VSYS

8

11

12

CMPIN

13

CMPOUT

14

IREF_CMP**

VCC

(ACP-ACN)

BAT

(SRN-SRP)

EN_BOOST

17

BATSRC

BATDRV

CHARGE

PUMP

16

TB_STAT

5X

VREF_IDCHG

ACN

SRN+200mV

ILIM

21

CHG/

DCHG_EN

ILIM

120mV

1X

16X/5

www.ti.com

7.2 Functional Block Diagram

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

15

Page 16

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

7.3 Feature Description

7.3.1 Device Power Up

The bq24780S gets power from adapter or battery. After VCC is above its UVLO threshold, the device wakes up

and starts communication.

7.3.1.1 Battery Only

When VCC voltage is above UVLO, bq24780S powers up to turn on BATFET and starts SMBus communication.

By default, bq24780S stays in low power mode (REG0x12[15] = 1) with lowest quiescent current. When

REG0x12[15] is set to 0, the device enters performance mode. User can enable IDCHG buffer, PMON,

PROCHOT or comparator through SMBus. REGN LDO is enabled (except for IDCHG buffer) for accurate

reference.

7.3.1.2 Adapter Detect and ACOK Output

An external resistor divider attenuates the adapter voltage before it goes to ACDET. The adapter detect

threshold should typically be programmed to a value greater than the maximum battery voltage, but lower than

the maximum allowed adapter voltage. When ACDET is above 0.6V, all bias circuits are enabled.

The open drain ACOK output can be pulled to external rail under the following conditions:

• V

VCC_UVLOZ

• V

ACDET

• V

VCC

The REG0x37[11] tracks the status of ACOK pin. ACOK deglitch time is 150ms at the first time adapter plug-in,

and 1.3 sec at the following plug-ins after VCC or SRN is above its UVLOZ.

> 2.4 V

– V

SRN

< V

VCC

> V

VCC_SRN_FALL

< ACOVP

+ V

VCC_SRN_HYST

7.3.1.2.1 Adapter Overvoltage (ACOVP)

When the VCC pin voltage is higher than 26 V, it is considered adapter over voltage. ACOK is pulled low, and

charge is disabled. ACFET/RBFET are turned off to disconnect the high voltage adapter to system during

ACOVP. BATFET is turned on if turn-on conditions are valid.

When VCC voltage falls below 24 V, it is considered as adapter voltage returns back to normal voltage. ACOK is

pulled high by an external pullup resistor. BATFET is turned off and ACFET and RBFET is turned on to power

the system from the adapter.

7.3.2 System Power Selection

The bq24780S device automatically switches adapter or battery power to system. An automatic break-beforemake logic prevents shoot-through currents when the selectors switch.

The ACDRV drives a pair of common-source (CMSRC) N-channel power MOSFETs (ACFET and RBFET)

between adapter and ACP. The ACFET separates adapter from system and battery, and provides a limited di/dt

when plugging in adapter by controlling the ACFET turn-on time. Meanwhile, it protects the adapter when the

system or battery is shorted. The RBFET provides negative input voltage protection and battery discharge

protection when adapter is shorted to ground, and minimizes system power dissipation with its low R

DS(on)

compared to a Schottky diode.

When the adapter is not present, ACDRV is pulled to CMSRC to keep ACFET and RBFET off, disconnecting the

adapter from the system. BATDRV stays at V

BATSRC

+ 6 V to connect battery to system if all of the following

conditions are valid:

• VCC> V

• V

ACN

< V

UVLO

SRN

+ 200 mV

• ACFET/RBFET off

After the adapter plugs in, the system power source switches from battery to adapter if all of the following

conditions are valid:

• ACOK high

• Not in LEARN mode

• In LEARN mode and V

< battery depletion threshold

SRN

16

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 17

www.ti.com

Feature Description (continued)

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

The gate drive voltage on ACFET and RBFET is V

+ 6 V. If the ACFET/RBFET have been turned on for 20

CMSRC

ms, and the voltage across gate and source is still less than 5.7 V, ACFET and RBFET are turned off. After 1.3s

delay, it resumes turning on ACFET and RBFET. If such a failure is detected seven times within 90 seconds,

ACFET/RBFET are latched off and an adapter removal and system shut down is required to force ACDET < 0.6

V to reset the IC. After IC reset from latch off, ACFET/RBFET can be turned on again. After 90 seconds, the

failure counter is reset to zero to prevent latch off.

To turn off ACFET/RBFET, one of the following conditions must be valid:

• In LEARN mode and V

is above battery depletion threshold;

SRN

• ACOK low

To limit the adapter inrush current during ACFET turn-on, the Cgs and Cgd external capacitor of ACFET must be

carefully selected following the guidelines below:

• Minimize total capacitance on system

• Cgs should be 40× or higher than Cgd to avoid ACFET false turn on during adapter hot plug-in

• Fully turn on ACFET within 20 ms, otherwise, charger IC will consider turn-on failure

• Check with MOSFET vendor on peak current rating

• Place 4-kΩ resistor in series with ACDRV, CMSRC, and BATDRV pin to limit inrush current.

7.3.3 Enable and Disable Charging

In charge mode, the following conditions have to be valid to start charge:

• Charge is enabled through SMBus (REG0x12[0], default is 0, charge enabled)

• ILIM pin voltage is higher than 120 mV

• All ChargeCurrent(), ChargeVoltage() and InputCurrent() registers have valid value programmed

• ACOK is valid (see Device Power Up for details)

• ACFET and RBFET turn on and gate voltage is high enough (see System Power Selection for details)

• V

does not exceed BATOVP threshold

SRN

• IC temperature does not exceed TSHUT threshold

• Not in ACOC condition (see Device Protections Features for details)

One of the following conditions stops on-going charging:

• Charge is inhibited through SMBus(REG0x12[0]=1)

• ILIM pin voltage is lower than 60 mV

• One of three registers is set to 0 or out of range

• ACOK is pulled low (see Device Power Up for details)

• ACFET turns off

• V

exceeds BATOVP threshold

SRN

• TSHUT IC temperature threshold is reached

• ACOC is detected (see Device Protections Features for details)

• Short circuit is detected (see Inductor Short, MOSFET Short Protection for details)

• Watchdog timer expires if watchdog timer is enabled (see Charger Timeout for details)

7.3.3.1 Automatic Internal Soft-Start Charger Current

Every time the charge is enabled, the charger automatically applies soft-start on charge current to avoid any

overshoot or stress on the output capacitors or the power converter. The charge current starts at 128 mA, and

the step size is 64 mA in CCM mode for a 10 mΩ current sensing resistor. Each step lasts around 400 μs in

CCM mode, till it reaches the programmed charge current limit. No external components are needed for this

function.

During DCM mode, the soft start up current step size is larger and each step lasts for longer time period due to

the intrinsic slow response of DCM mode.

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

17

Page 18

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

Feature Description (continued)

7.3.4 Current and Power Monitor

7.3.4.1 High Accuracy Current Sense Amplifier (IADP and IDCHG)

As an industry standard, a high-accuracy current sense amplifier (CSA) is used to monitor the input current

(IADP) and the discharge current (IDCHG). IADP voltage is 20X or 40X the differential voltage across ACP and

ACN. IDCHG voltage is 8X or 16X the differential voltage across SRN and SRP. After VCC is above UVLO and

ACDET is above 0.6 V, IADP output becomes valid. .

A maximum 100-pF capacitor is recommended to connect on the output for decoupling high-frequency noise. An

additional RC filter is optional, if additional filtering is desired. Note that adding filtering also adds additional

response delay. The CSA output voltage is clamped at 3.3 V. To lower the voltage on current monitoring, a

resistor divider from CSA output to GND can be used and accuracy over temperature can still be achieved

7.3.4.2 High Accuracy Power Sense Amplifier (PMON)

The bq24780S device monitors total available power from adapter and battery together. The ratio of PMON

voltage and total power K

allows input sense resistor 2x or 1/2x of charge sense resistor by setting REG0x3B[13:12] to 1.

I

PMON

= K

PMON(VIN

x IIN- V

A resistor is connected on the PMON pin to converter output current to output voltage. A maximum 100-pF

capacitor is recommended to connect on the output for decoupling high-frequency noise. An additional RC filter

is optional, if additional filtering is desired. Note that adding filtering also adds additional response delay. The

PMON output voltage is clamped to 3.3 V.

can be programmed in REG0x3B[9] with default 1 µA/W. The bq24780S device

PMON

x I

) (I

BAT

BAT

> 0 during charge; I

BAT

< 0 during discharge) (1)

BAT

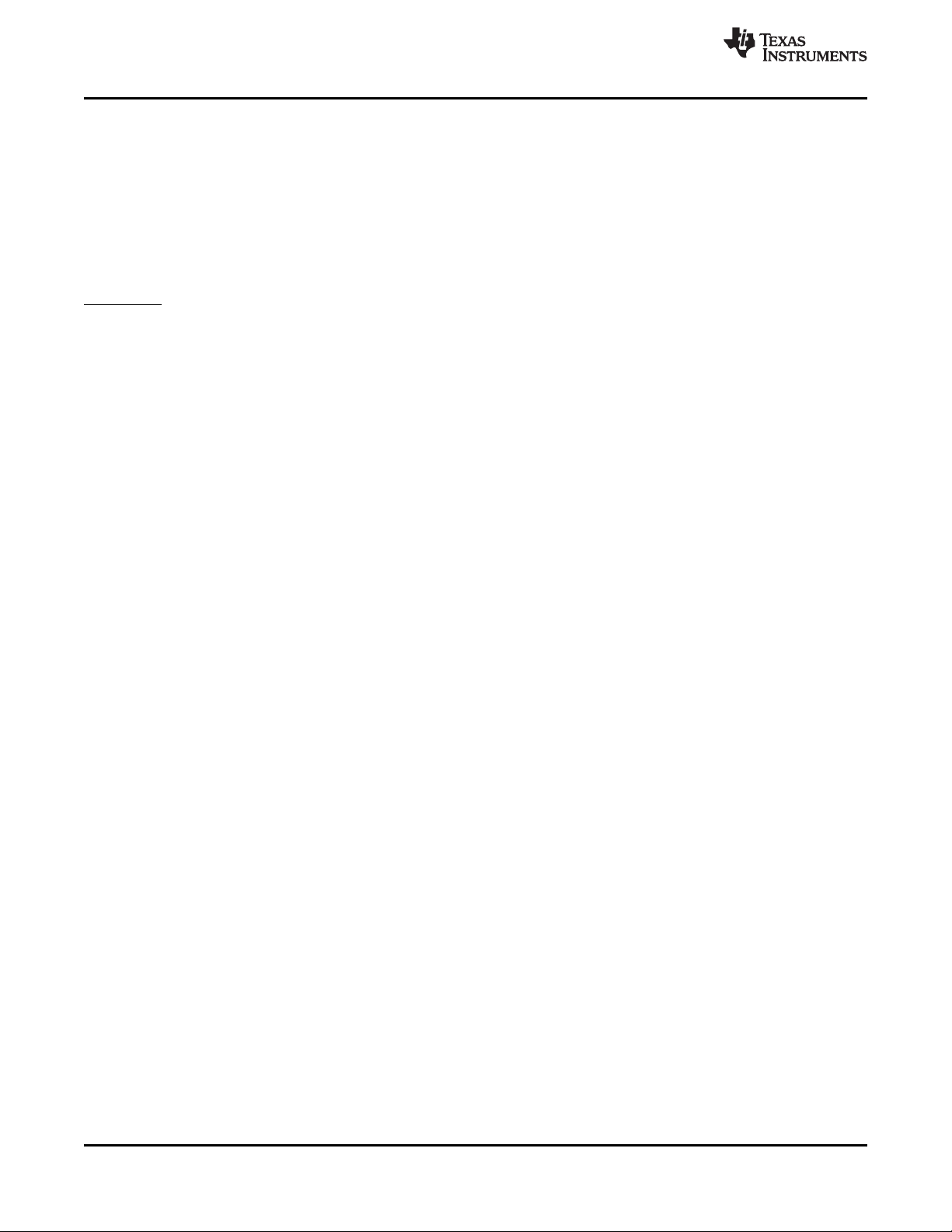

7.3.5 Processor Hot Indication for CPU Throttling

When CPU is running turbo mode, the peak power may exceed total available power from adapter and battery.

The adapter current and battery discharge overshoot, or system voltage drop indicates the system power may be

too high. When the adapter or battery is removed, the remaining power source may not support the peak power

in turbo mode. The processor hot function in bq24780S monitors these events, and PROCHOT pulse is asserted.

The PROCHOT triggering events include:

• ICRIT: adapter peak current

• INOM: adapter average current (110% of input current limit)

• IDCHG: battery discharge current

• VSYS: system voltage on SRN for 2s - 4s battery

• ACOK: upon adapter removal (ACOK pin HIGH to LOW)

• BATPRES: upon battery removal (BATPRES pin LOW to HIGH)

• CMPOUT: Independent comparator output (CMPOUT pin HIGH to LOW)

The threshold of ICRIT, IDCHG or VSYS, and the deglitch time of ICRIT, INOM, IDCHG or CMPOUT are

programmable through SMBus. Each triggering event can be individually enabled in REG0x3D[6:0].

18

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 19

o

o o

1

f

2 L C

S

IADP

INOM

IDCHG

Ref_DCHG

Ref

10-ms

Debounce

VSRP

1.05 V

50W

PROCHOT

≥10 ms

Adjustable

Deglitch

ICRIT

< 0.3 V

BATPRES

(One shot on rising edge)

20- sm

Deglitch

ACOK

(One shot on falling edge)

CMPOUT

www.ti.com

Feature Description (continued)

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

Figure 6. PROCHOT Profile

When any event in PROCHOT profile is triggered, PROCHOT is asserted low for minimum 10 ms (default

REG0x3C[4:3]=10). At the end of the 10 ms, if the PROCHOT event is still active, the pulse gets extended.

During one cycle of PROCHOT, all the triggering events are saved in status register REG0x3A[6:0] for easy test

debug and system optimization.

7.3.6 Converter Operation

The synchronous buck PWM converter uses a fixed frequency voltage control scheme and internal type III

compensation network. The LC output filter gives a characteristic resonant frequency:

The resonant frequency, fo, is used to determine the compensation to ensure there is sufficient phase margin for

the target bandwidth. The LC output filter should be selected to give a resonant frequency of 10- to 20-kHz

nominal for the best performance. Suggested component value for a charge current of 800-kHz default switching

frequency is shown in Table 1:

Table 1. Suggest Component Value for Charge Current of 800-kHz Default Switching Frequency

CHARGE CURRENT 2A 3A 4A 6A 8A

Output Inductor Lo (µH) 6.8 or 8.2 5.6 or 6.8 3.3 or 4.7 3.3 2.2

Output Capacitor Co (µF) 20 20 20 30 40

Sense Resistor (mΩ) 10 10 10 10 10

Ceramic capacitors show a DC-bias effect. This effect reduces the effective capacitance when a DC-bias voltage

is applied across a ceramic capacitor, as on the output capacitor of a charger. The effect may lead to a

significant capacitance drop, especially for high output voltages and small capacitor packages. See the

manufacturer's data sheet about the performance with a DC bias voltage applied. It may be necessary to choose

a higher voltage rating or nominal capacitance value to get the required value at the operating point.

(2)

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

19

Page 20

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

7.3.6.1 Continuous Conduction Mode (CCM)

With sufficient charge current, the inductor current does not cross 0, which is defined as CCM. The controller

starts a new cycle with ramp coming up from 200 mV. As long as EAO voltage is above the ramp voltage, the

high-side MOSFET (HSFET) stays on. When the ramp voltage exceeds EAO voltage, HSFET turns off and lowside MOSFET (LSFET) turns on. At the end of the cycle, ramp gets reset and LSFET turns off, ready for the next

cycle. There is always break-before-make logic during transition to prevent cross-conduction and shoot-through.

During the dead time when both MOSFETs are off, the body-diode of the low-side power MOSFET conducts the

inductor current.

During CCM, the inductor current always flows and creates a fixed two-pole system. Having the LSFET turn-on

keeps the power dissipation low and allows safe charging at high currents.

7.3.6.2 Discontinuous Conduction Mode (DCM)

During the HSFET off time when LSFET is on, the inductor current decreases. If the current goes to 0, the

converter enters DCM. Every cycle, when the voltage across SRP and SRN falls below 5 mV (0.5 A on 10 mΩ),

the undercurrent-protection comparator (UCP) turns off LSFET to avoid negative inductor current, which may

boost the system through the body diode of HSFET.

During DCM the loop response automatically changes. It changes to a single-pole system and the pole is

proportional to the load current.

7.3.6.3 Non-Sync Mode and Light Load Comparator

As the charge current is below 125 mA (on 10-mΩ sense resistor), the light load comparator keeps LSFET off.

The converter enters non-sync mode. With LSFET, body diode blocks negative current in the inductor so that no

current flows back to the input. As charge current rises above 250 mA, LSFET turns on again.

7.3.6.4 EMI Switching Frequency Adjust

The charger switching frequency can be adjusted 600 kHz or 1 MHz to solve EMI issues through SMBus

command REG0x12[9:8].

7.3.7 Battery LEARN Cycle

A battery LEARN cycle can be activated through the REG0x12[5]. When LEARN is enabled, the system receives

power from the battery instead of the adapter turning off ACFET/RBFET and turning on BATFET. The LEARN

function allows the battery to discharge in order to calibrate the battery gas gauge over a complete discharge

and charge cycle. The controller automatically exits the LEARN cycle when the battery voltage is below the

battery depletion threshold. The system switches back to adapter input by turning off BATFET and turning on

ACFET/RBFET. After the LEARN cycle, REG0x12[5] is automatically reset to 0.

When the battery is removed during LEARN mode, BATPRES rises from low to high and the device exits LEARN

mode. ACFET/RBFET quickly turns on in 100µs to prevent the system from crashing. The turn-on triggered by

BATPRES is faster than that triggered by battery depletion comparator.

7.3.8 Charger Timeout

The bq24780S device includes a watchdog timer to terminate charging or hybrid power boost mode if the charger

does not receive a write ChargeVoltage() or write ChargeCurrent() command within 175 s (adjustable through

0x12[14:13] command).

If a watchdog timeout occurs, all register values keep unchanged, but converter is suspended. A write to

ChargeVoltage(), or ChargeCurrent(), or change REG0x12[14:13] resets watchdog timer and resumes converter

for charging or hybrid power boost mode. The watchdog timer can be disabled, or set to 5, 88, or 175 s through

SMBus command REG0x12[14:13]).

20

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 21

bq24780S

www.ti.com

SLUSC27C –APRIL 2015–REVISED MARCH 2017

7.3.9 Device Protections Features

7.3.9.1 Input Overcurrent Protection (ACOC)

The bq24780S device cannot maintain the input current level if the charge current has been already reduced to

0. When the input current exceeds 1.25x or 2x of ICRIT set point (with 12-ms blank-out time), ACFET/RBFET is

latches off and an adapter removal is required to force ACDET < 0.6 V to reset IC. After IC reset from latch off,

ACFET/RBFET can be turned on again.

The ACOC function threshold can be set to 1.25x or 2x of ICRIT (REG37[9]) current or disabled through SMBus

command (REG0x37[10]).

7.3.9.2 Charge Overcurrent Protection (CHGOCP)

The bq24780S device has cycle-by-cycle peak overcurrent protection. It monitors the voltage across SRP and

SRN, and prevents the current from exceeding the threshold based on the charge current set point. The highside gate drive turns off for the rest of the cycle when over current is detected, and resumes when the next cycle

starts.

The charge OCP threshold is automatically set to 6, 9, and 12 A on a 10-mΩ current sensing resistor based on

charge current register value. This prevents the threshold from being too high, which is not safe, or too low,

which can be triggered in typical operation. Select proper inductance to prevent OCP triggering in typical

operation due to high inductor current ripple.

7.3.9.3 Battery Overvoltage Protection (BATOVP)

The bq24780S device does not allow the high-side and low-side MOSFET to turn-on when the battery voltage at

SRN exceeds 104% of the regulation voltage set point. If BATOVP lasts over 30 ms, charger is completely

disabled. This allows a quick response to an overvoltage condition – such as when the load is removed or the

battery is disconnected. A 6-mA current sink from SRP to GND is only on during BATOVP and allows

discharging the stored output inductor energy that is transferred to the output capacitors.

7.3.9.4 Battery Short

When battery voltage on SRN falls below 2.5 V, the converter resets for 1 ms and resumes charge if all the

enable conditions in the Enable and Disable Charging section are satisfied. This prevents overshoot current in

the inductor, which can saturate the inductor and may damage the MOSFET. The charge current is limited to 0.5

A on 10-mΩ current sensing resistor when BATLOWV condition persists and LSFET keeps off. The LSFET turns

on only for a refreshing pulse to charge BTST capacitor.

7.3.9.5 Thermal Shutdown Protection (TSHUT)

The WQFN package has low thermal impedance, which provides good thermal conduction from the silicon to the

ambient, to keep junction temperatures low. As an added level of protection, the charger converter turns off for

self-protection whenever the junction temperature exceeds the 155°C. The charger stays off until the junction

temperature falls below 135°C. During thermal shutdown, the REGN LDO current limit is reduced to 14 mA.

Once the temperature falls below 135°C, charge can be resumed with soft start.

7.3.9.6 Inductor Short, MOSFET Short Protection

The bq24780S device has a unique short circuit protection feature. Its cycle-by-cycle current monitoring feature

is achieved through monitoring the voltage drop across RDS(on) of the MOSFETs after a certain amount of

blanking time. In case of a MOSFET short or inductor short circuit, the overcurrent condition is sensed by two

comparators and two counters are triggered. After seven short circuit events, the charger is latched off and

ACFET and RBFET are turned off to disconnect the adapter from the system. BATFET is turned on to connect

the battery pack to the system. To reset the charger from latch-off status, the IC VCC pin must be pulled below

UVLO or the ACDET pin must be pulled below 0.6 V. This can be achieved by removing the adapter and shutting

down the operation system. The low-side MOSFET Vds monitor circuit is enabled by REG0x37[7], and the

threshold is 750 mV. The high-side MOSFET Vds monitor circuit is enabled by REG0x37[6], and the threshold is

250 mV. During boost function, the low-side MOSFET short circuit protection threshold is used for cycle-by-cycle

current limiting, charger does not latch up.

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

21

Page 22

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

www.ti.com

Due to the amount of blanking time to prevent noise when MOSFET just turns on, the cycle-by-cycle charge

overcurrent protection may detect high current and turn off MOSFET first before the short circuit protection circuit

can detect short condition because the blanking time has not finished. In such a case, the charger may not be

able to detect a short circuit and the counter may not be able to count to seven then latch off. Instead the

charger may continuously keep switching with very narrow duty cycle to limit the cycle-by-cycle current peak

value. However, the charger should still be safe and does not cause failure because the duty cycle is limited to a

very short time and the MOSFET should still be inside the safety operation area. During a soft start period, it may

take a long time instead of just seven switching cycles to detect short circuit based on the same blanking time

reason.

7.4 Device Functional Modes

7.4.1 Battery Charging

The bq24780S charges 1-4 cell battery in constant current (CC), and constant voltage (CV) mode. The host

programs battery voltage in REG0x15(). According to battery voltage, the host programs appropriate charge

current in REG0x14(). When battery is full or battery is not in good condition to charge, host terminates charge

by setting REG0x12[0] to 1, or setting either ChargeVoltage() or ChargeCurrent() to zero.

See the Feature Description section for details on charge enable conditions and register programming.

7.4.2 Hybrid Power Boost Mode

The bq24780S device supports the hybrid power boost mode by allowing battery discharge energy to system

when system power demand is temporarily higher than adapter maximum power level so the adapter does not

crash. After device powers up, the REG0x37[2] is 0 to disable hybrid power boost mode. To enable hybrid power

boost mode, host writes 1 to REG0x37[2]. The TB_STAT pin and REG0x37[1] indicate if the device is in hybrid

power boost mode.

To support hybrid power boost mode, input current must be set higher than 1536 mA for 10 mΩ input current

sensing resistor. When input current is higher than 107% of input current limit in REG0x3F(), charger IC allows

battery discharge and charger converter changes from buck converter to boost converter. During hybrid power

boost mode the adapter current is regulated at input current limit level so that adapter will not crash. The battery

discharge current depends on system current requirement and adapter current limit. The watchdog timer can be

enabled to prevent converter running at hybrid power boost mode for too long.

7.4.2.1 Battery Discharge Current Regulation in Hybrid Power Boost Mode

To keep the discharge current below battery OCP rating during boost mode, the bq24780S device supports

discharge current regulation. After device powers up, the REG0x37[15] is 0 to disable discharge current

regulation. To enable discharge current regulation, host writes 1 to REG0x37[15].

Once the battery discharge current is limited, the input current goes up to meet the system current requirement.

The user can assert PROCHOT to detect input current increase (ICRIT or INOM), and request CPU throttling to

lower the system power.

22

Submit Documentation Feedback Copyright © 2015–2017, Texas Instruments Incorporated

Page 23

bq24780S

www.ti.com

SLUSC27C –APRIL 2015–REVISED MARCH 2017

7.5 Programming

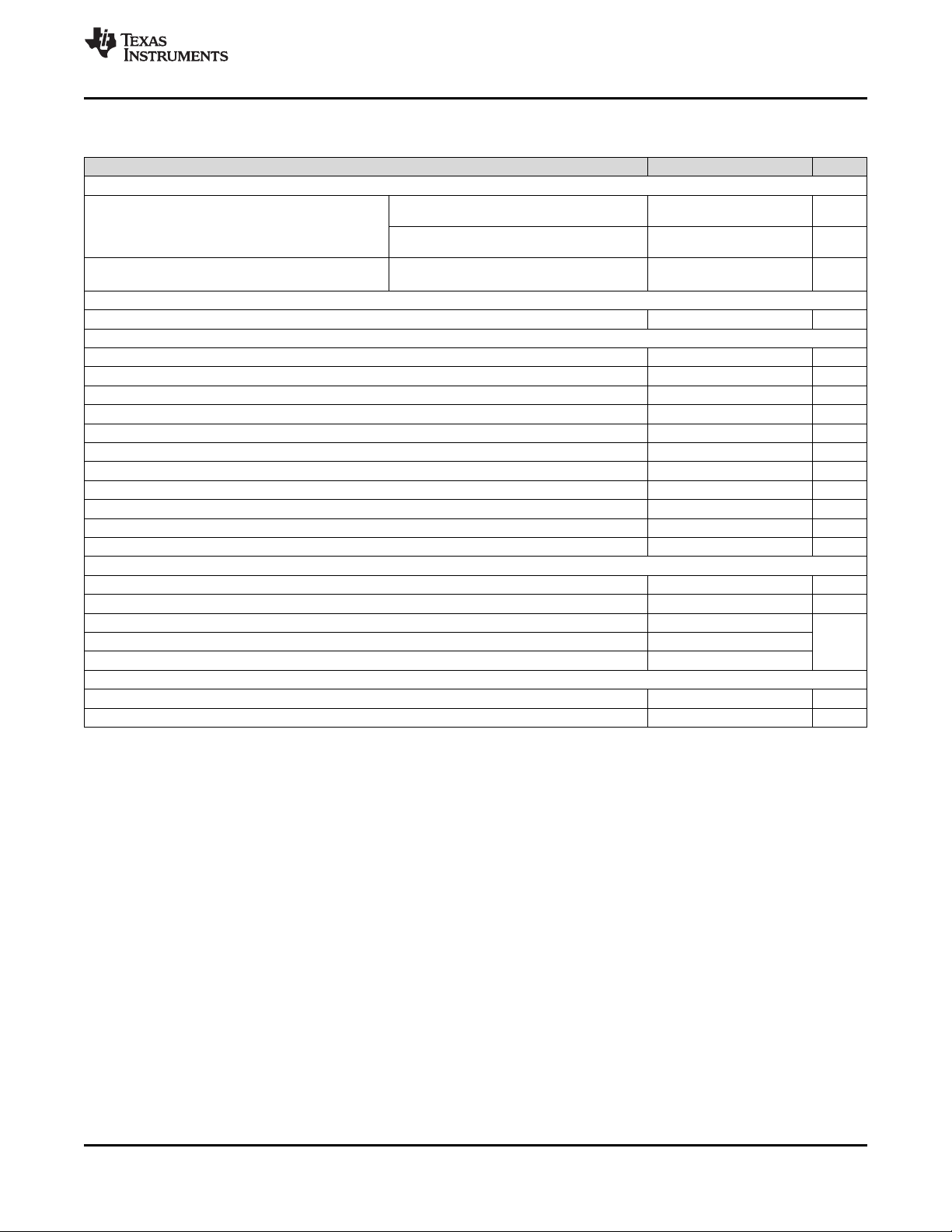

7.5.1 SMBus Interface

The bq24780S device operates as a slave, receiving control inputs from the embedded controller host through

the SMBus interface. The bq24780S device uses a simplified subset of the commands documented in System

Management Bus Specification V1.1, which can be downloaded from www.smbus.org. The bq24780S device

uses the SMBus read-word and write-word protocols (shown in Table 2 and Table 3) to communicate with the

smart battery. The bq24780S device performs only as a SMBus slave device with address 0b00010010 (0x12H)

and does not initiate communication on the bus. In addition, the device has two identification registers, a 16-bit

device ID register (0xFFH) and a 16-bit manufacturer ID register (0xFEH).

SMBus communication starts when VCC is above UVLO.

The data (SDA) and clock (SCL) pins have Schmitt-trigger inputs that can accommodate slow edges. Choose

pullup resistors (10 kΩ) for SDA and SCL to achieve rise times according to the SMBus specifications.

Communication starts when the master signals a start condition, which is a high-to-low transition on SDA, while

SCL is high. When the master has finished communicating, the master issues a stop condition, which is a low-tohigh transition on SDA, while SCL is high. The bus is then free for another transmission. Figure 7 and Figure 8

show the timing diagram for signals on the SMBus interface. The address byte, command byte, and data bytes

are transmitted between the start and stop conditions. The SDA state changes only while SCL is low, except for

the start and stop conditions. Data is transmitted in 8-bit bytes and is sampled on the rising edge of SCL. Nine

clock cycles are required to transfer each byte in or out of the bq24780S device because either the master or the

slave acknowledges the receipt of the correct byte during the ninth clock cycle. The bq24780S supports the

charger commands listed in Table 2.

7.5.1.1 SMBus Write-Word and Read-Word Protocols

Table 2. Write-Word Format

S

(1)(2)

(1) Master to slave

(2) S = Start condition or repeated start condition

(3) W = Write bit (logic-low)

(4) Slave to master (shaded gray)

(5) ACK = Acknowledge (logic-low)

(6) P = Stop condition

SLAVE

ADDRESS

(1)W(1)(3)

ACK

(4)(5)

COMMAND

(1)

BYTE

ACK

(4)(5)

LOW DATA

(1)

BYTE

ACK

(4)(5)

HIGH DATA

BYTE

7 bits 1b 1b 8 bits 1b 8 bits 1b 8 bits 1b

MSB LSB 0 0 MSB LSB 0 MSB LSB 0 MSB LSB 0

Table 3. Read-Word Format

(1)

S

(2)

SLAVE

ADDRESS

(1)W(1)(3)

ACK

(4)(5)

COMMAND

(1)

BYTE

7 bits 1b 1b 8 bits 1b 7 bits 1b 1b 8 bits 1b 8 bits 1b

MSB LSB 0 0 MSB LSB 0 MSB LSB 1 0 MSB LSB 0 MSB LSB 1

(1) Master to slave

(2) S = Start condition or repeated start condition

(3) W = Write bit (logic-low)

(4) Slave to master (shaded gray)

(5) ACK = Acknowledge (logic-low)

(6) R = Read bit (logic-high)

(7) NACK = Not acknowledge (logic-high)

(8) P = Stop condition

ACK

(4)(5)

(1)

S

(2)

SLAVE

ADDRESS

(1)

R

ACK

(1)

(6)

(4)(5)

LOW DATA

BYTE

ACK

(1)(5)

HIGH DATA

(4)

(1)

BYTE

(4)

ACK

(4)(5)

NACK

P

(1)(6)

(1)(7)P(1)(8)

Submit Documentation FeedbackCopyright © 2015–2017, Texas Instruments Incorporated

23

Page 24

A B C D E F G H I J K

t

LOW

t

HIGH

SMBCLK

SMBDATA

t

SU:STA

t t

HD:STA SU:DAT

HD:DAT SU:DAT

t t

t

SU:STOtBUF

A = START CONDITION E = SLAVE PULLS SMBDATA LINE LOW I = ACKNOWLEDGE CLOCK PULSE

A B C D E F G H I J K L M

t

LOW

t

HIGH

SMBCLK

SMBDATA

t

SU:STAtHD:STA

SU:DAT

t

t

HD:DAT

HD:DAT

t

t

SU:STOtBUF

bq24780S

SLUSC27C –APRIL 2015–REVISED MARCH 2017

7.5.1.2 Timing Diagrams

A = Start condition H = LSB of data clocked into slave

B = MSB of address clocked into slave I = Slave pulls SMBDATA line low

C = LSB of address clocked into slave J = Acknowledge clocked into master

D = R/W bit clocked into slave K = Acknowledge clock pulse

E = Slave pulls SMBDATA line low L = Stop condition, data executed by slave

F = ACKNOWLEDGE bit clocked into master M = New start condition

G = MSB of data clocked into slave

www.ti.com

Figure 7. SMBus Write Timing

A = Start condition G = MSB of data clocked into master

B = MSB of address clocked into slave H = LSB of data clocked into master

C = LSB of address clocked into slave I = Acknowledge clock pulse

D = R/W bit clocked into slave J = Stop condition