Page 1

Alpha Industries, Inc. [781] 935-5150 • Fax [617] 824-4579 • Email sales@alphaind.com • www.alphaind.com 1

Specifications subject to change without notice. 2/00A

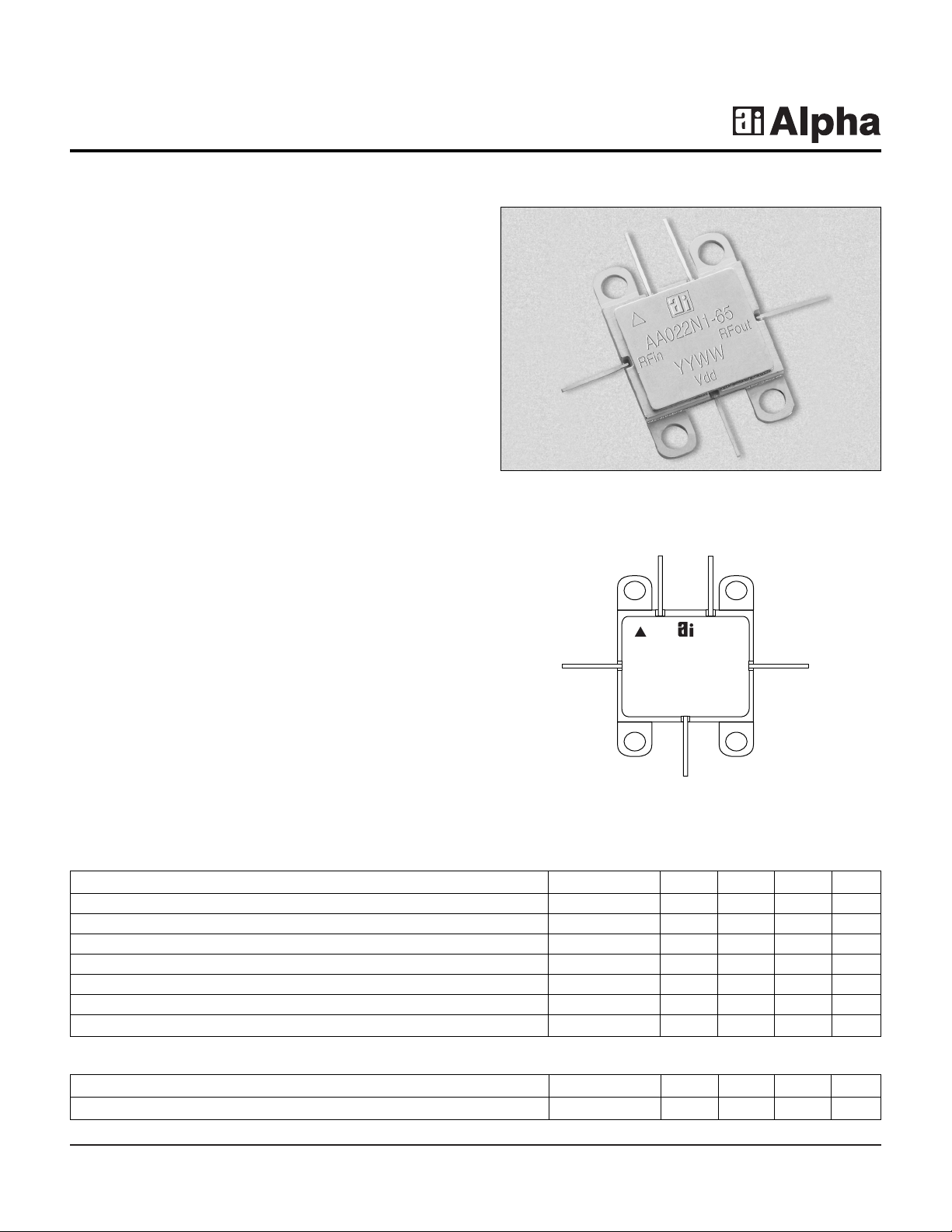

20–24 GHz Low Noise Amplifier

Features

■ 3.2 dB Noise Figure

■ 17 dB Gain

■ +9 dBm Output Power

■ Hermetic Package with Solderable Leads

■ Single Voltage Operation

■ 100% RF and DC Testing

AA022N1-65

Description

The AA022N1-65 is a broadband millimeterwave amplifier

in a hermetic package. The amplifier is designed for use

in millimeterwave communication and sensor systems as

the receiver front-end, transmitter gain stage, or local

oscillator gain stage when high gain, wide dynamic range,

and low noise figure are required. The solder-sealed

hermetic package provides excellent electrical

performance, excellent thermal performance, and

complete environmental protection for long-term reliability.

A single supply voltage simplifies bias requirements. All

amplifiers are screened at the operating frequencies prior

to shipment for guaranteed performance. The amplifier is

targeted for millimeterwave point-to-point and point-tomultipoint wireless communications systems.

Parameter Symbol Min. Typ. Max. Unit

Bandwidth BW 20 19–25 24 GHz

Small Signal Gain G1517 dB

Noise Figure NF 3.2 3.9 dB

Input Return Loss RL

I

8dB

Output Return Loss RL

O

11 dB

Output Power at 1 dB Gain Compression P

1 dB

9 dBm

Temperature Coefficient of Gain dG/dT -0.028 dB/C

Electrical Specifications at 25°C (VD= 5.5 V)

Parameter Symbol Min. Typ. Max. Unit

Drain Current I

D

60 90 mA

DC

RF

Pin Out

RF In RF Out

V

DD

YYWW

AA022N1-65

RF In RF Out

V

D

N/CN/C

Page 2

20–24 GHz Low Noise Amplifier AA022N1-65

2 Alpha Industries, Inc. [781] 935-5150 • Fax [617] 824-4579 • Email sales@alphaind.com • www.alphaind.com

Specifications subject to change without notice. 2/00A

Characteristic Value

Operating Temperature (TC) -55°C to +90°C

Storage Temperature (TST) -65°C to +150°C

Bias Voltage (VD)6 V

DC

Power In (PIN) 13 dBm

Absolute Maximum Ratings

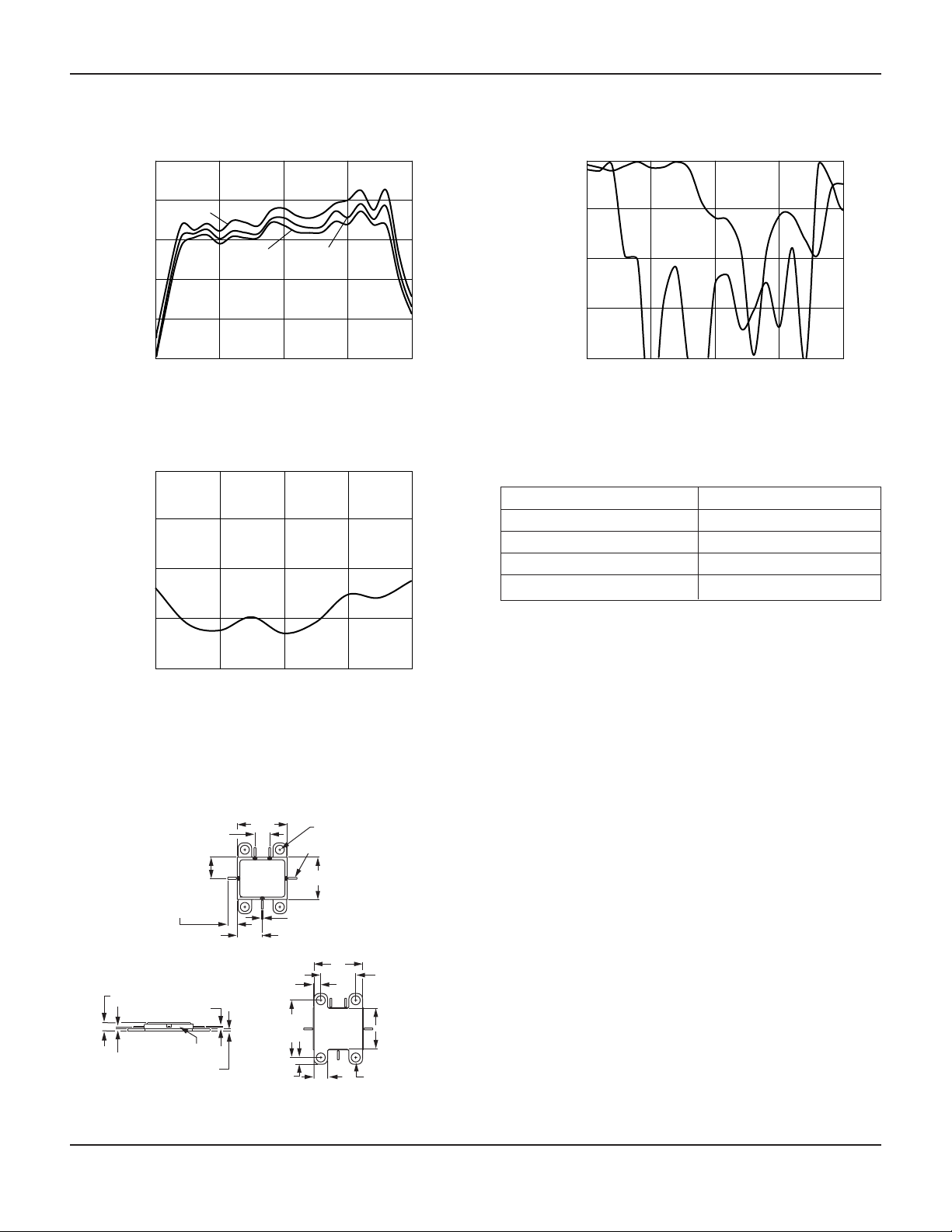

0

5

10

15

20

25

10 15 20 25 30

Gain (dB)

Frequency (GHz)

Gain vs. Frequency

-55˚C

+85˚C

+25˚C

2

3

4

5

6

Noise Figure (dB)

Frequency (GHz)

Noise Figure vs. Frequency

20 21 22 23 24

-20

-15

-10

-5

0

10 15 20 25 30

Return Loss (dB)

Frequency (GHz)

Return Loss vs. Frequency

S

22

S

11

Typical Performance Data

Outline

0.106 (2.69 mm)

0.053

(1.35 mm)

0.272

(6.91 mm)

± 0.002

0.194 (4.92 mm)

0.053

(1.35 mm)

0.445

(11.30 mm)

± 0.002

0.318

(8.08 mm)

± 0.002

CW-10

MATERIAL

0.164 (4.16 mm)

0.115 (2.92 mm)

± 0.002

0.388 (9.86 mm)

0.328 (8.33 mm)

0.075 (1.91 mm)

± 0.010

0.010 (0.25 mm)

± 0.001

0.378 (9.60 mm) ± 0.003

∅ 0.070 (1.78 mm)

KOVAR

0.065

(1.65 mm)

MAX.

0.005

(0.13 mm)

± 0.001

0.015

(0.38 mm)

0.010

(0.25 mm)

± 0.002

CERAMIC

Page 3

20–24 GHz Low Noise Amplifier AA022N1-65

Alpha Industries, Inc. [781] 935-5150 • Fax [617] 824-4579 • Email sales@alphaind.com • www.alphaind.com 3

Specifications subject to change without notice. 2/00A

Typical S-Parameters at 25°C (VD= 5.5 V)

Frequency

S

11

S

21

S

12

S

22

(GHz) Mag. Ang. Mag. Ang. Mag. Ang. Mag. Ang.

5.0 -0.23 154.65 -43.85 86.28 -45.99 85.59 -0.02 64.98

7.0 -0.23 -111.06 -37.45 56.97 -51.79 -104.35 -0.05 159.26

9.0 -0.08 13.10 -8.78 102.07 -44.05 66.64 -0.61 -116.95

11.0 -0.65 104.53 8.89 152.07 -37.56 -114.12 -1.01 -40.73

12.0 -0.99 -48.85 15.42 -26.69 -47.14 130.43 -0.42 168.72

13.0 -0.51 166.36 15.79 157.28 -49.08 37.53 -9.57 22.43

14.0 -0.10 55.47 16.34 -5.38 -47.31 112.82 -10.10 24.64

15.0 -0.67 -55.35 15.16 -139.82 -37.37 -47.11 -27.18 -136.61

16.0 -0.63 156.89 16.13 84.35 -40.46 -161.21 -14.25 51.89

17.0 -0.10 18.10 15.92 -48.83 -44.76 90.70 -10.82 -54.46

18.0 -0.83 -83.22 15.81 -169.31 -43.32 6.41 -21.13 -167.32

19.0 -4.28 152.57 17.65 60.67 -36.37 -126.11 -25.24 -155.34

20.0 -5.74 -61.50 17.80 -95.05 -35.20 98.48 -12.39 -88.92

21.0 -6.01 -179.42 16.90 133.41 -35.38 -12.60 -11.58 144.87

22.0 -9.01 88.52 16.55 14.42 -34.87 -115.99 -16.93 44.72

23.0 -19.60 48.18 16.75 -110.63 -31.84 151.62 -15.07 -156.77

24.0 -9.00 -41.19 18.64 127.32 -30.18 33.65 -12.31 56.67

25.0 -5.49 147.20 17.87 -32.70 -32.94 -79.66 -16.74 109.43

26.0 -5.53 -9.75 19.57 -165.11 -36.65 -80.66 -8.81 -38.71

27.0 -8.00 -45.79 17.63 87.22 -35.32 98.43 -20.32 -13.38

28.0 -9.41 -22.84 19.14 -81.69 -28.71 77.45 -0.46 -21.58

29.0 -2.80 -165.39 11.16 135.62 -25.82 -63.56 -2.14 -149.84

30.0 -2.33 100.83 6.39 21.60 -28.49 -164.40 -5.02 115.71

32.0 -2.61 -97.59 -0.47 151.84 -29.33 -9.95 -2.70 -119.75

34.0 -1.05 62.48 -4.75 -49.44 -42.31 -155.10 -2.59 74.44

36.0 -5.37 -174.78 -2.17 42.82 -37.64 -35.81 -8.87 -99.71

38.0 -2.11 -176.06 -16.06 -112.92 -48.35 -143.83 -2.90 44.51

40.0 -2.85 -79.93 -11.61 5.61 -31.46 -46.85 -1.07 -108.06

Page 4

20–24 GHz Low Noise Amplifier AA022N1-65

4 Alpha Industries, Inc. [781] 935-5150 • Fax [617] 824-4579 • Email sales@alphaind.com • www.alphaind.com

Specifications subject to change without notice. 2/00A

Leaded Millimeterwave Package

Handling and Mounting

The leaded millimeterwave package requires careful

mounting design to maintain optimal performance.

Handling

The leaded millimeterwave package is extremely rugged.

Care should be exercised when handling with metal tools.

Only personnel trained in both ESD precautions and

handling precautions should be allowed to handle these

packages.

Package Construction

The construction of the leaded millimeterwave package

consists of a metal base and ceramic walls. The

package is topped by a solder-sealed metal lid. All metal

parts are gold-plated.

Mounting Design

The leaded millimeterwave package is mounted by placing

it in a hole cut in a printed circuit board. The bottom of the

package leads should be in the same plane as the top

surface of the printed circuit board traces.The hole should

be cut as close as possible to the outer dimensions of the

package to minimize the gap between package and

printed circuit board. The gap should be no more than

0.005" (0.127 mm). The base of the package should be

mounted directly to a surface that provides a good ground

plane for the printed circuit board and provides a good

thermal ground.

Mounting the Package

The leaded millimeterwave package should be attached

to its mounting surface using a silver-filled conductive

paste epoxy or solder. Care should be taken to ensure that

there are no voids or gaps in the epoxy or solder underfill

so that a good ground contact is maintained.

Screw hardware attachment should be used in addition

to epoxy or solder in situations where additional

mechanical integrity is desired. Care should be exercised

when tightening screws because over-tightening could

deform the package base.

Connecting the Package

Connection of the package leads to the printed circuit

board traces is accomplished with solder.Attached leads

should lie flat upon the printed circuits board traces.

Package leads can be trimmed if desired.

Leaded Millimeterwave Package Mounting

Printed Circuit Board

Rogers 4003

0.008" (0.20 mm) Thick

Electrically & Thermally

Conductive Ground Plane

Minimize RF

Gap Widths

Soldered Leads

RF In

RF Out

DC Connection

0–80 Screw

Loading...

Loading...