Page 1

82C84A

March 1997

Features

• Generates the System Clock For CMOS or NMOS

Microprocessors

• Up to 25MHz Operation

• Uses a Parallel Mode Crystal Circuit or External

Frequency Source

• Provides Ready Synchronization

• Generates System Reset Output From Schmitt Trigger

Input

• TTL Compatible Inputs/Outputs

• Very Low Power Consumption

• Single 5V Power Supply

• Operating Temperature Ranges

- C82C84A . . . . . . . . . . . . . . . . . . . . . . . . .0

- I82C84A. . . . . . . . . . . . . . . . . . . . . . . . -40

- M82C84A. . . . . . . . . . . . . . . . . . . . . . -55

o

C to +70oC

o

C to +85oC

o

C to +125oC

CMOS Clock Generator Driver

Description

The Intersil 82C84A is a high performance CMOS Clock Generatordriver which is designed to service the requirements of both CMOS

and NMOS microprocessors such as the 80C86, 80C88, 8086 and

the 8088. The chip contains a crystal controlled oscillator, a divide-bythree counter and complete “Ready” synchronization and reset logic.

Static CMOS circuit design permits operation with an external frequency source from DC to 25MHz. Crystal controlled operation to

25MHz is guaranteed with the use of a parallel, fundamental mode

crystal and two small load capacitors.

All inputs (except X1 and RES) are TTL compatible over temperature and voltage ranges.

Power consumption is a fraction of that of the equivalent bipolar circuits. This speed-power characteristic of CMOS permits the

designer to custom tailor his system design with respect to power

and/or speed requirements.

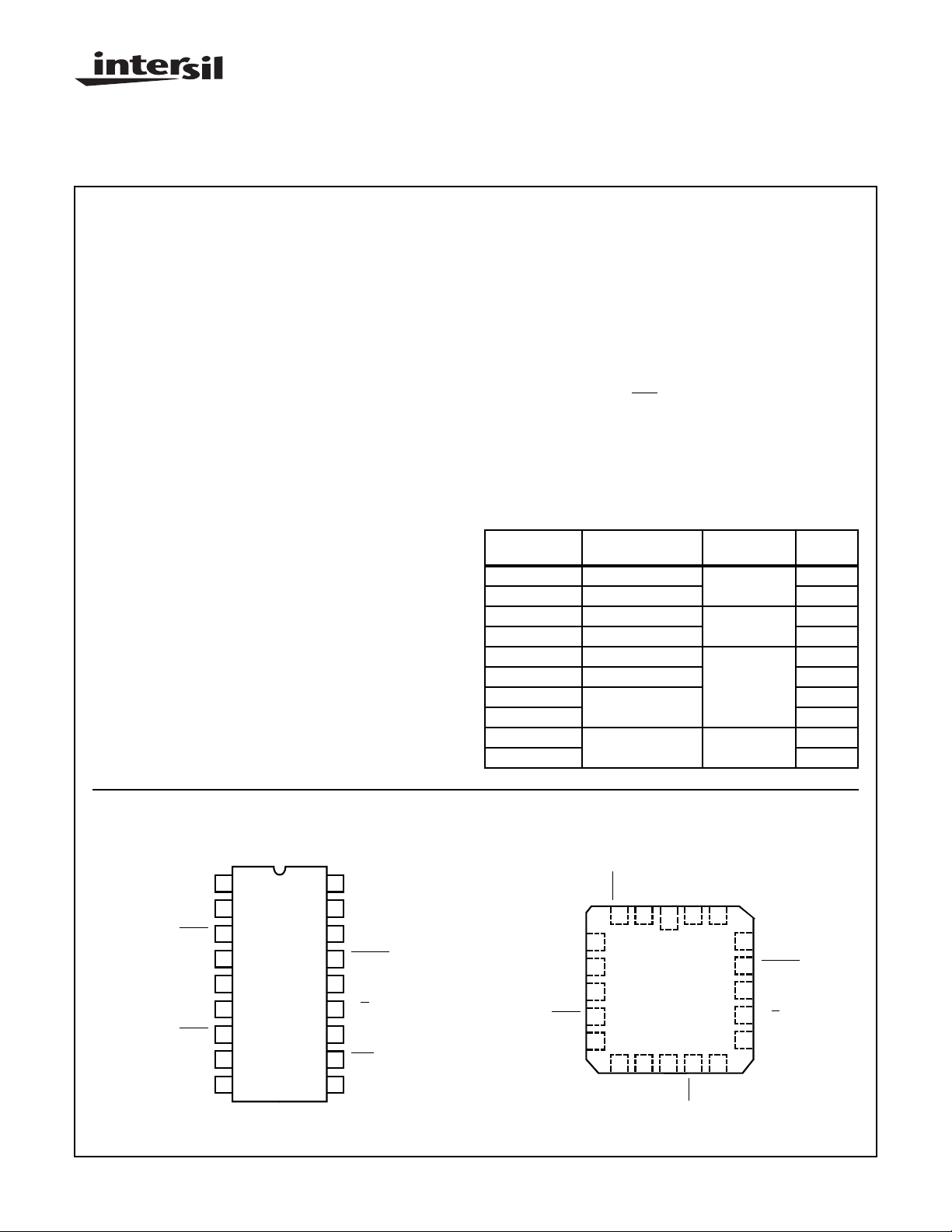

Ordering Information

PART

NUMBER TEMP. RANGE PACKAGE

CP82C84A 0oC to +70oC 18 Ld PDIP E18.3

IP82C84A -40oC to +85oC E18.3

CS82C84A 0oC to +70oC 20 Ld PLCC N20.35

IS82C84A -40oC to +85oC N20.35

CD82C84A 0oC to +70oC 18 Ld CERDIP F18.3

ID82C84A -40oC to +85oC F18.3

MD82C84A/B -55oC to +125oC F18.3

8406801VA SMD# F18.3

MR82C84A/B -55oC to +125oC 20 Pad CLCC J20.A

84068012A SMD# J20.A

PKG.

NO.

Pinouts

82C84A (PDIP, CERDIP)

TOP VIEW

PCLK

AEN1

RDY1

RDY2

AEN2

CLK

GND

1

2

3

4

5

6

7

8

9

| Copyright © Intersil Corporation 1999

CSYNC

READY

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

18

17

16

15

14

13

12

11

10

V

CC

X1

X2

ASYNC

EFI

C

F/

OSC

RES

RESET

RDY1

READY

RDY2

AEN2

4-287

82C84A (PLCC, CLCC)

TOP VIEW

AEN1

3212019

4

5

6

7

8

NC

9101112

CLK

PCLK

GND

CSYNC

V

RESET

CC

X1

18

X2

17

ASYNC

EFI

16

15

C

F/

14

NC

13

RES

OSC

File Number 2974.1

Page 2

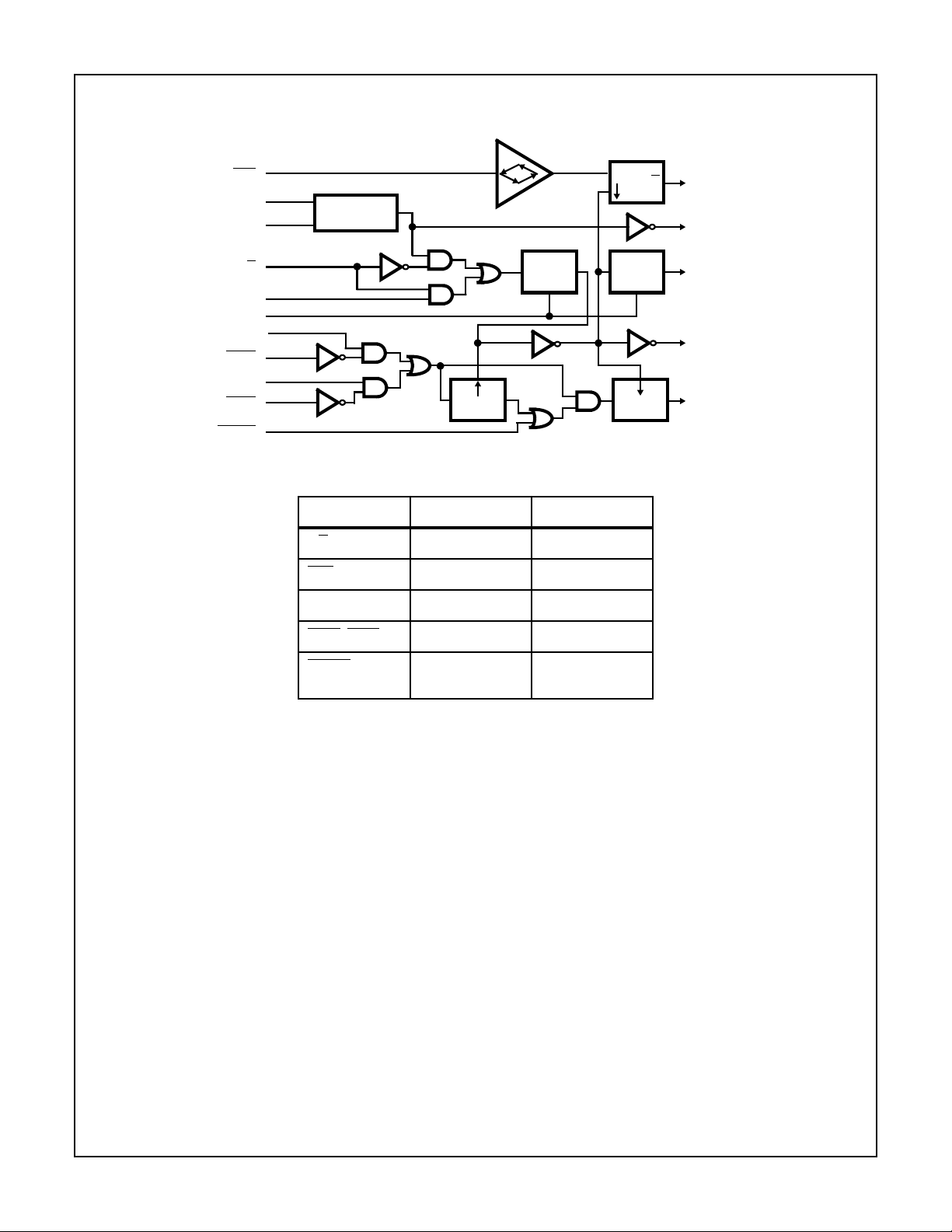

Functional Diagram

82C84A

RES

X1

X2

F/

EF1

CSYNC

RDY1

AEN1

RDY2

AEN2

ASYNC

11

17

16

13

C

14

1

4

3

6

7

15

XTAL

OSCILLATOR

CK

DQ

FF1

÷ 3

SYNC

D

CK

SYNC

CK

DQ

÷ 2

FF2

10

Q

RESET

12

OSC

2

PCLK

8

CLK

5

READY

CONTROL PIN LOGICAL 1 LOGICAL 0

F/C External Clock Crystal Drive

RES Normal Reset

RDY1, RDY2 Bus Ready Bus Not Ready

AEN1, AEN2 Address Disabled Address Enable

ASYNC 1 Stage Ready

Synchronization

2 Stage Ready

Synchronization

4-288

Page 3

82C84A

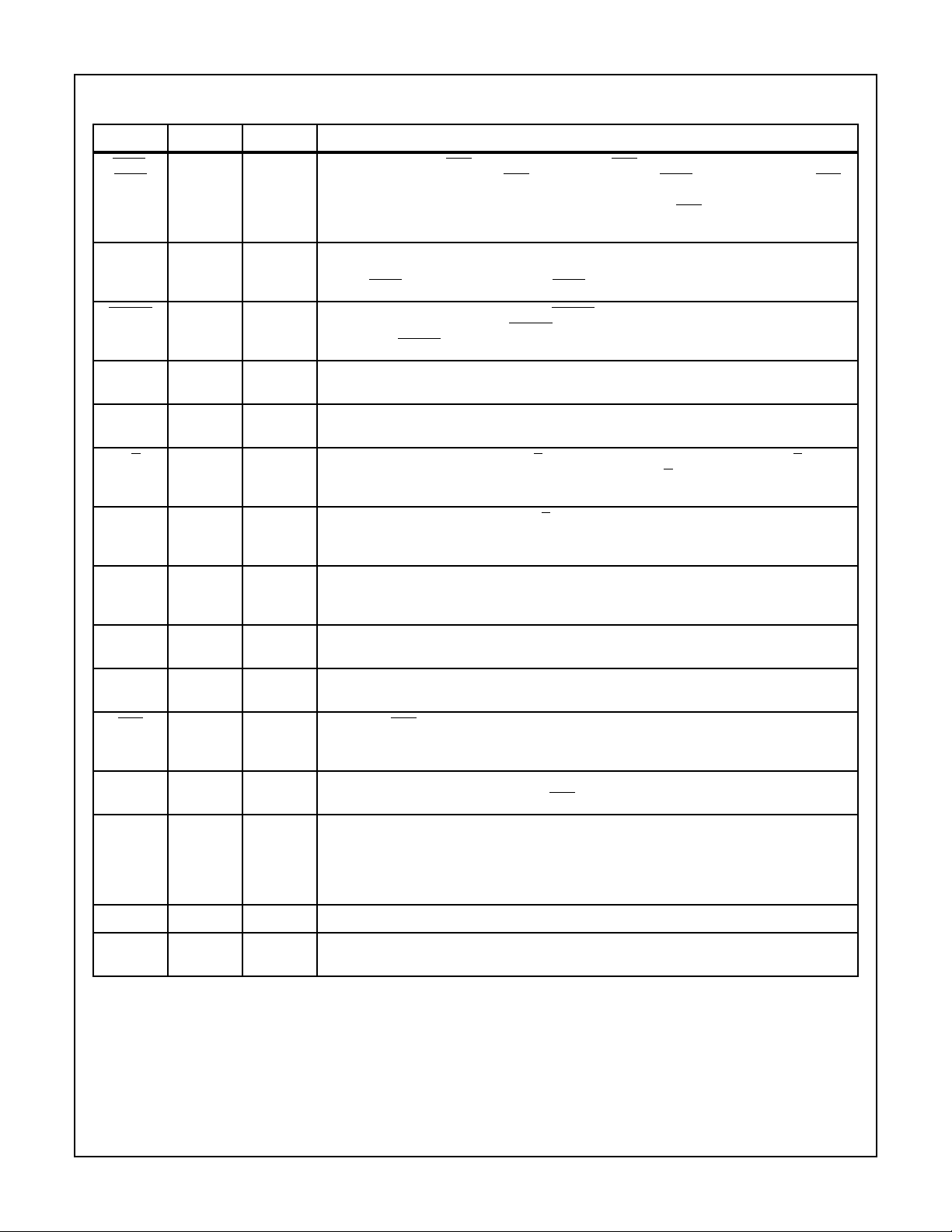

Pin Description

SYMBOL NUMBER TYPE DESCRIPTION

AEN1,

AEN2

RDY1,

RDY2

ASYNC 15 I READY SYNCHRONIZATION SELECT: ASYNC is an input which defines the synchronization

READY 5 O READY: READY is an active HIGH signal which is the synchronized RDY signal input. READY

X1, X2 17, 16 I O CRYSTAL IN: X1 and X2 are the pins to which a crystal is attached. The crystal frequency is 3

F/C 13 I FREQUENCY/CRYSTAL SELECT: F/C is a strapping option. When strapped LOW. F/C permits

EFI 14 I EXTERNAL FREQUENCY IN: When F/C is strapped HIGH, CLK is generated from the input fre-

CLK 8 O PROCESSOR CLOCK: CLK is the clock output used by the processor and all devices which di-

3, 7 I ADDRESS ENABLE: AEN is an active LOW signal. AEN serves to qualify its respective Bus

Ready Signal (RDY1 or RDY2). AEN1 validates RDY1 while AEN2 validates RDY2. Two AEN

signal inputs are useful in system configurations which permit the processor to access two MultiMaster System Busses. In non-Multi-Master configurations, the AEN signal inputs are tied true

(LOW).

4, 6 I BUS READY (Transfer Complete). RDY is an active HIGH signal which is an indication from a

device located on the system data bus that data has been received, or is available RDY1 is qualified by AEN1 while RDY2 is qualified by AEN2.

mode of the READY logic. When ASYNC is low, two stages of READY synchronization are provided. When ASYNC is left open or HIGH, a single stage of READY synchronization is provided.

is cleared after the guaranteed hold time to the processor has been met.

times the desired processor clock frequency, (Note 1).

the processor’s clock to be generated by the crystal. When F/C is strapped HIGH, CLK is generated for the EFI input, (Note 1).

quency appearing on this pin. The input signal is a square wave 3 times the frequency of the desired CLK output.

rectly connect to the processor’s local bus. CLK has an output frequency which is 1/3 of the crystal or EFI input frequency and a 1/3 duty cycle.

PCLK 2 O PERIPHERAL CLOCK: PCLK is a peripheral clock signal whose output frequency is 1/2 that of

CLK and has a 50% duty cycle.

OSC 12 O OSCILLATOR OUTPUT: OSC is the output of the internal oscillator circuitry. Its frequency is

equal to that of the crystal.

RES 11 I RESET IN: RES is an active LOW signal which is used to generate RESET. The 82C84A pro-

vides a Schmitt trigger input so that an RC connection can be used to establish the power-up

reset of proper duration.

RESET 10 O RESET: RESET is an active HIGH signal which is used to reset the 80C86 family processors. Its

timing characteristics are determined by RES.

CSYNC 1 I CLOCK SYNCHRONIZATION: CSYNC is an active HIGH signal which allows multiple 82C84As

to be synchronized to provide clocks that are in phase. When CSYNC is HIGH the internal

counters are reset. When CSYNC goes LOW the internal counters are allowed to resume counting. CSYNC needs to be externally synchronized to EFI. When using the internal oscillator

CSYNC should be hardwired to ground.

GND 9 Ground

V

CC

NOTE:

1. If the crystal inputs are not used X1 must be tied to VCC or GND and X2 should be left open.

18 VCC: The +5V power supply pin. A 0.1µF capacitor between VCC and GND is recommended for

decoupling.

4-289

Page 4

82C84A

Functional Description

Oscillator

The oscillator circuit of the 82C84A is designed primarily for

use with an external parallel resonant, fundamental mode

crystal from which the basic operating frequency is derived.

The crystal frequency should be selected at three times the

required CPU clock. X1 and X2 are the two crystal input

crystal connections. For the most stable operation of the

oscillator (OSC) output circuit, two capacitors (C1 = C2) as

shown in the waveform figures are recommended. The output of the oscillator is buffered and brought out on OSC so

that other system timing signals can be derived from this stable, crystal-controlled source.

TABLE 1. CRYSTAL SPECIFICATIONS

PARAMETER TYPICAL CRYSTAL SPEC

Frequency 2.4 - 25MHz, Fundamental, “AT” cut

Type of Operation Parallel

Unwanted Modes 6dB (Minimum)

Load Capacitance 18 - 32pF

Capacitors C1, C2 are chosen such that their combined

capacitance

C1 x C2

--------------------- -

CT =

C1 + C2

matches the load capacitance as specified by the crystal

manufacturer. This ensures operation within the frequency

tolerance specified by the crystal manufacturer.

Clock Generator

The clock generator consists of a synchronous divide-bythree counter with a special clear input that inhibits the

counting. This clear input (CSYNC) allows the output clock

to be synchronized with an external event (such as another

82C84A clock). It is necessary to synchronize the CSYNC

input to the EFI clock external to the 82C84A. This is accomplished with two flip-flops. (See Figure 1). The counter output is a 33% duty cycle clock at one-third the input

frequency.

NOTE: The F/C input is a strapping pin that selects either the crystal

oscillator or the EFI input as the clock for the ÷ 3 counter. If

the EFI input is selected as the clock source, the oscillator

section can be used independently for another clock source.

Output is taken from OSC.

(Including stray capacitance)

Clock Outputs

The CLK output is a 33% duty cycle clock driver designed to

drive the 80C86, 80C88 processors directly. PCLK is a peripheral clock signal whose output frequency is 1/2 that of CLK.

PCLK has a 50% duty cycle.

Reset Logic

The reset logic provides a Schmitt trigger input (RES) and a

synchronizing flip-flop to generate the reset timing. The reset

signal is synchronized to the falling edge of CLK. A simple RC

network can be used to provide power-on reset by utilizing this

function of the 82C84A.

READY Synchronization

Two READY input (RDY1, RDY2) are provided to accommodate two system busses. Each input has a qualifier (

AEN1 and

AEN2, respectively). The AEN signals validate their respective

RDY signals. If a Multi-Master system is not being used the

AEN pin should be tied LOW.

Synchronization is required for all asynchronous active-going

edges of either RDY input to guarantee that the RDY setup

and hold times are met. Inactive-going edges of RDY in normally ready systems do not require synchronization but must

satisfy RDY setup and hold as a matter of proper system

design.

ASYNC input defines two modes of READY synchroniza-

The

tion operation.

When ASYNC is LOW, two stages of synchronization are provided for active READY input signals. Positive-going asynchronous READY inputs will first be synchronized to flip-flop one of

the rising edge of CLK (requiring a setup time tR1VCH) and

the synchronized to flip-flop two at the next falling edge of

CLK, after which time the READY output will go active (HIGH).

Negative-going asynchronous READY inputs will be synchronized directly to flip-flop two at the falling edge of CLK, after

which the READY output will go inactive. This mode of operation is intended for use by asynchronous (normally not ready)

devices in the system which cannot be guaranteed by design

to meet the required RDY setup timing, TR1VCL, on each bus

cycle.

ASYNC is high or left open, the first READY flip-flop is

When

bypassed in the READY synchronization logic. READY inputs

are synchronized by flip-flop two on the falling edge of CLK

before they are presented to the processor. This mode is available for synchronous devices that can be guaranteed to meet

the required RDY setup time.

ASYNC can be changed on every bus cycle to select the

appropriate mode of synchronization for each device in the

system.

EFI

CLOCK

SYNCHRONIZE

EFI

NOTE: If EFI input is used, then crystal input X1 must be tied to VCC or GND and X2 should be left open. If the crystal inputs are used,

then EFI should be tied to VCC or GND.

FIGURE 1. CSYNC SYNCHRONIZATION

DQ>D

Q

>

82C84A

CSYNC

(TO OTHER 82C84As)

4-290

Page 5

82C84A

Absolute Maximum Ratings Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+8.0V

Input, Output or I/O Voltage . . . . . . . . . . . GND -0.5V to VCC+0.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

Operating Conditions

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . +4.5V to +5.5V

Operating Temperature Range

C82C84A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0oC to +70oC

I82C84A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to +85oC

M82C84A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55oC to +125oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance . . . . . . . . . . . . . . . . θJA(oC/W) θJC (oC/W)

CERDIP Package . . . . . . . . . . . . . . . . 80 20

CLCC Package . . . . . . . . . . . . . . . . . . 95 28

PDIP Package. . . . . . . . . . . . . . . . . . . 85 N/A

PLCC Package . . . . . . . . . . . . . . . . . . 85 N/A

Storage Temperature Range. . . . . . . . . . . . . . . . . .-65oC to +150oC

Max Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . .+175oC

Lead Temperature (Soldering 10s) . . . . . . . . . . . . . . . . . . . . +300oC

(PLCC - Lead Tips Only)

Die Characteristics

Gate Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 Gates

DC Electrical Specifications V

SYMBOL PARAMETER MIN MAX UNITS TEST CONDITIONS

V

V

V

V

VT+ - VT- Reset Input Hysteresis 0.2 V

V

V

I

CCOP

NOTES:

1. F/C is a strap option and should be held either ≤ 0.8V or ≥ 2.2V. Does not apply to X1 or X2 pins.

2. Due to test equipment limitations related to noise, the actual tested value may differ from that specified, but the specified limit is

guaranteed.

3. CSYNC pin is tested with VIL≤ 0.8V.

4. ASYNC pin includes an internal 17.5kΩ nominal pull-up resistor. For ASYNC input at GND, ASYNC input leakage current = 300µA

nominal, X1 - crystal feedback input.

5. f = 25MHz may be tested using the extrapolated value based on measurements taken at f = 2MHz and f = 10MHz.

Logical One Input Voltage 2.0

IH

Logical Zero Input Voltage - 0.8 V Notes 1, 2, 3

IL

Reset Input High Voltage VCC -0.8 - V

IHR

Reset Input Low Voltage - 0.5 V

ILR

Logical One Output Current VCC -0.4 - V IOH = -4.0mA for CLK Output

OH

Logical Zero Output Voltage - 0.4 V IOL = +4.0mA for CLK Output

OL

II Input Leakage Current -1.0 1.0 µAVIN = VCC or GND except ASYNC,

Operating Power Supply Current - 40 mA Crystal Frequency = 25MHz

= +5.0V ±10%,

CC

TA = 0oC to +70oC (C82C84A),

TA = -40oC to +85oC (I82C84A),

TA = -55oC to +125oC (M82C84A)

2.2

CC

-V

V

--

C82C84A, I82C84

M82C84A, Notes 1, 2

IOH = -2.5mA for All Others

IOL = +2.5mA for All Others

X1: (Note 4)

Outputs Open, Note 5

Capacitance T

SYMBOL PARAMETER TYPICAL UNITS TEST CONDITIONS

C

IN

C

OUT

= +25oC

A

Input Capacitance 10 pF FREQ = 1MHz, all measurements are

Output Capacitance 15 pF

referenced to device GND

4-291

Page 6

82C84A

AC Electrical Specifications V

SYMBOL PARAMETER

TIMING REQUIREMENTS

(1) TEHEL External Frequency HIGH Time 13 - ns 90%-90% V

(2) TELEH External Frequency LOW Time 13 - ns 10%-10% V

(3) TELEL EFI Period 36 - ns

XTAL Frequency 2.4 25 MHz Note 2

(4) TR2VCL RDY1, RDY2 Active Setup to CLK 35 - ns ASYNC = HIGH

(5) TR1VCH RDY1, RDY2 Active Setup to CLK 35 - ns ASYNC = LOW

(6) TR1VCL RDY1, RDY2 Inactive Setup to CLK 35 - ns

(7) TCLR1X RDY1, RDY2 Hold to CLK 0 - ns

(8) TAYVCL

(9) TCLAYX

(10) TA1VR1V

(11) TCLA1X

(12) TYHEH CSYNC Setup to EFI 20 - ns

(13) TEHYL CSYNC Hold to EFI 20 - ns

(14) TYHYL CSYNC Width 2TELEL - ns

(15) TI1HCL

(16) TCLI1H

TIMING RESPONSES

(17) TCLCL CLK Cycle Period 125 - ns Note 6

(18) TCHCL CLK HIGH Time (1/3 TCLCL) +2.0 - ns Note 6

(19) TCLCH CLK LOW Time (2/3 TCLCL) -15.0 - ns Note 6

(20)

TCH1CH2

(21)

TCL2CL1

(22) TPHPL PCLK HIGH Time TCLCL-20 - ns Note 6

(23) TPLPH PCLK LOW Time TCLCL-20 - ns Note 6

(24) TRYLCL Ready Inactive to CLK (See Note 4) -8 - ns Note 4

(25) TRYHCH Ready Active to CLK (See Note 3) (2/3 TCLCL) -15.0 - ns Note 5

(26) TCLIL CLK to Reset Delay - 40 ns

(27) TCLPH CLK to PCLK HIGH Delay - 22 ns

(28) TCLPL CLK to PCLK LOW Delay - 22 ns

(29) TOLCH OSC to CLK HIGH Delay -5 22 ns

(30) TOLCL OSC to CLK LOW Delay 2 35 ns

NOTES:

1. Tested as follows: f = 2.4MHz, V

switch between 0.4V and VCC -0.4V. Input rise and fall times driven at 1ns/V. VIL≤ VIL (max) - 0.4V for CSYNC pin. VCC = 4.5V and 5.5V.

2. Tested using EFI or X1 input pin.

3. Setup and hold necessary only to guarantee recognition at next clock.

4. Applies only to T2 states.

5. Applies only to T3 TW states.

6. Tested with EFI input frequency = 4.2MHz.

ASYNC Setup to CLK 50 - ns

ASYNC Hold to CLK 0 - ns

AEN1, AEN2 Setup to RDY1, RDY2 15 - ns

AEN1, AEN2 Hold to CLK 0 - ns

RES Setup to CLK 65 - ns Note 3

RES Hold to CLK 20 - ns Note 3

CLK Rise or Fall Time - 10 ns 1.0V to 3.0V

IH

= +5V± 10%,

CC

TA = 0oC to +70oC (C82C84A),

TA = -40oC to +85oC (I82C84A),

TA = -55oC to +125oC (M82C84A)

LIMITS

UNITS

= 2.6V, VIL = 0.4V, CL = 50pF, VOH≥ 1.5V, VOL≤ 1.5V, unless otherwise specified. RES and F/C must

(NOTE 1)

TEST

CONDITIONSMIN MAX

IN

IN

4-292

Page 7

Timing Waveforms

82C84A

(3)

NAME

EFI

OSC

CLK

PCLK

CSYNC

RES

RESET

I/O

I

O

O

O

I

I

O

(13)

tEHYL

tYHYL

(14)

tELEL

tOLCH

(29)

tCH1CH2

(20)

tYHEH

(12)

tCL2CL1

(21)

(30)

tOLCL

NOTE: All timing measurements are made at 1.5V, unless otherwise noted.

FIGURE 2. WAVEFORMS FOR CLOCKS AND RESETS SIGNALS

CLK

tR1VCH

(10)

(5)

(7)

tCLAYX

tAYVCL

(8)

(9)

(25)

tRYHCH

tCLR1X

RDY1, 2

tA1VR1V

AEN1, 2

ASYNC

READY

tCLA1X

tCLPH

(27)

tPLPH

(23)

tR1VCL

(7)tCLR1X

(11)

(24) tRYLCL

tELEH

tCLI1H

(6)

(19)

tCLCH

(17) tCLCL

tPHPL

(16)

(2)

(22)

tCLIL

(15)

tI1HCL

(26)

(1)

tEHEL

tCHCL

(18)

tCLPL

(28)

FIGURE 3. WAVEFORMS FOR READY SIGNALS (FOR ASYNCHRONOUS DEVICES)

CLK

tCLR1X

RDY 1, 2

tA1VRIV

AEN1, 2

(8)

ASYNC

READY

(10)

tA YVCL

tCLAYX

(7)

(4)

tR1VCL

(9)

(25)

tRYHCH

tCLR1X

tCLA1X

(7)

(11)

(24)

tRYLCL

FIGURE 4. WAVEFORMS FOR READY SIGNALS (FOR SYNCHRONOUS DEVICES)

4-293

tR1VCL

(6)

Page 8

Test Load Circuits

DEVICE UNDER TEST

NOTES:

1. CL =100pF for CLK output.

2. CL = 50pF for all outputs except CLK.

3. CL = Includes probe and jig capacitance.

82C84A

2.25V

R = 740Ω FOR ALL OUTPUTS

EXCEPT CLK

OUTPUT FROM

FIGURE 5. TEST LOAD MEASUREMENT CONDITIONS

463Ω FOR CLK OUTPUT

C

L

(SEE NOTE 3)

C1

24MHz

PULSE

GENERATOR

TRIGGER

C2

C1

C2

X1

X2

C

F/

CSYNC

CLK

LOAD

(SEE NOTE 1)

PULSE

GENERATOR

EF1

V

CC

F/

CSYNC

CLK

C

LOAD

(SEE NOTE 1)

FIGURE 6. TCHCL, TCLCH LOAD CIRCUITS

V

CC

AEN1

X1

X2

RDY2

F/

C

AEN2

CSYNC

CLK

READY

OSC

LOAD

(SEE NOTE 1)

LOAD

(SEE NOTE 2)

PULSE

GENERATOR

TRIGGER

PULSE

GENERATOR

EF1

V

CC

F/

AEN1

RDY2

AEN2

CSYNC

CLK

C

READY

LOAD

(SEE NOTE 1)

LOAD

(SEE NOTE 2)

FIGURE 7. TRYLCL, TRYHCH LOAD CIRCUITS

AC Testing Input, Output Waveform

INPUT

+ 0.4V

V

IH

1.5V 1.5V

VIL - 0.4V

NOTE: Input test signals must s witch between VIL (maximum) -0.4V and VIH (minimum) +0.4V. RES and F/C must switch between 0.4V and

VCC -0.4V. Input rise and fall times driven at 1ns/V. VIL≤ VIL (max) -0.4V for CSYNC pin. VCC -4.5V and 5.5V.

4-294

OUTPUT

V

OH

V

OL

Page 9

Burn-In Circuits

V

CC

GND

V

CC

GND

V

CC

GND

F9

F6

F5

F7

F8

R2

R2

R2

R2

R2

R2

R1

R1

R1

R1

R1

82C84A

MD82C84A CERDIP

1

2

3

4

5

6

7

8

9

MR82C84A CLCC

V

CC

C1

18

17

16

R3

15

R1

14

R1

13

12

R1

11

10

R1

R2

R2

R2

R2

R2

F0

OPEN

F10

F1

F11

V

CC

GND

F12

V

CC

GND

V

NOTES:

= 5.5V ±0.5V, GND = 0V.

V

CC

VIH = 4.5V ±10%.

VIL = -0.2 to 0.4V.

R1 = 47kΩ,±5%.

R2 = 10kΩ,±5%.

R3 = 2.2kΩ,±5%.

R4 = 1.2kΩ,±5%.

C1 = 0.01µF (minimum).

F0 = 100kHz ±10%.

F1 = F0/2, F2 = F1/2, . . . F12 = F11/2.

F5

/ 2

CC

F7

F8

OPEN

R4

R4

R4

R4

/ 2

CC

F6

F9

V

R4

R4R4R4

3212019

4

5

6

7

8

9101112

R4

R4R4R4

/ 2

/ 2

CC

CC

V

V

V

CC

C1

F0

F12

18

17

16

15

14

13

/ 2

CC

V

R4

R4

R4

OPEN

F10

F1

F11

OPEN

4-295

Page 10

Die Characteristics

82C84A

DIE DIMENSIONS:

66.1 x 70.5 x 19 ± 1mils

METALLIZATION:

Type: Si - AI

Thickness: 11k

Å ± 1kÅ

Metallization Mask Layout

AEN1 PCLK CSYNC V

RDY1

READY

RDY2

GLASSIVATION:

Type: SiO

2

Thickness: 8kű 1kÅ

WORST CASE CURRENT DENSITY:

1.42 x 10

82C84A

CC

5

A/cm

2

X1

X2

ASYNC

EFI

AEN2

CLK

GND RESET

RES OSC

F/

C

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

4-296

Loading...

Loading...