Page 1

PRELIMINARY

29F0408

32 Megabit (4M x 8-Bit)

Flash Memory

FEATURES:

• Single 5.0 V supply

• Excellent Single Event Effect

· - SEL

· - SEUTH: = 37 MeV/mg/cm

• Organization:

• Automatic program and erase

• 528-Byte page read operation

• Fast write cycle time

• Command/address/data multiplexed I/O port

• Hardware data protection

• Reliable CMOS floating-gate technology

• Command register operation

• 44 pin flat package

: > 60 MeV/mg/cm

TH

- SEU saturated cross section: 2E-6 cm2/bit

- Memory cell array: (4M + 128k) bit x 8bit

- Data register: (512 + 16) bit x 8bit

- Page program: (512 + 16) Byte

- Block erase: (8K + 256) Byte

- Status register

- Random access: 10 µs (max)

- Serial page access: 50 ns (min)

- Program time: 250 µs (typ)

- Block erase time: 2 ms (typ)

- Program/erase lockout during power transitions

- Endurance: 1,000,000 program/erase cycles

- Data retention: 10 years

2

2

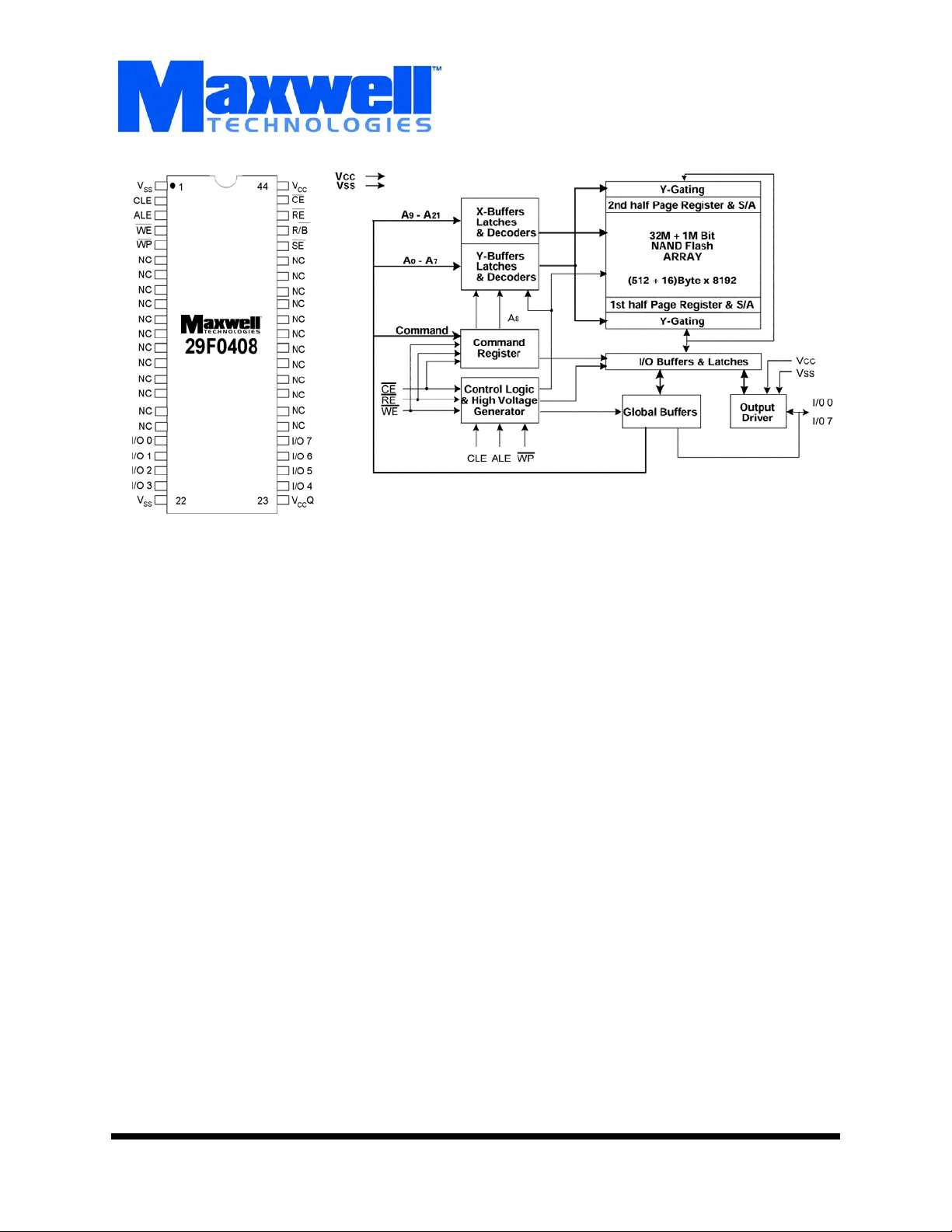

Logic Diagram

DESCRIPTION:

Maxwell Technologies’ 29F0408 high-performance flash memory. The 29F0408 is a 4M (4,194,304) x 8-bit NAND Flash

Memory with a spare 128K (131,072) x 8-bit. A program operation programs the 528-byte page in 250 µs and an erase

operation can be performed in 2 ms on an 8K-byte block. Data

within a page can be read out at 50 ns cycle time per byte.

The on-chip write controller automates all program and erase

functions, including pulse repetition, where required, and internal verify and margining of data. Even write-intensive systems

can take advantage of the 29F0408’s extended reliability of

1,000,000 program/erase cycles by providing either ECC

(Error Correction Code) or real time mapping-out algorithm.

These algorithms have been implemented in many mass storage applications. The spare 16 bytes of a page combined with

the other 512 bytes can be utilized by system-level ECC. The

29F0408 is an optimum solution for large non-volatile storage

applications such as solid state storage, digital voice recorder,

digital still camera and other portable applications requiring

nonvolatility.

Maxwell Technologies' patented R

ogy incorporates radiation shielding in the microcircuit package. Capable of surviving in space environments, the

29F0408 is ideal for satellite, spacecraft, and space probe

missions. It is available with packaging and screening up to

Class S.

AD-PAK® packaging technol-

Memory

1000571

(858) 503-3300 - Fax: (858) 503-3301 - www.maxwell.com

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

1

Page 2

32 Megabit (4M x 8-Bit) Flash Memory

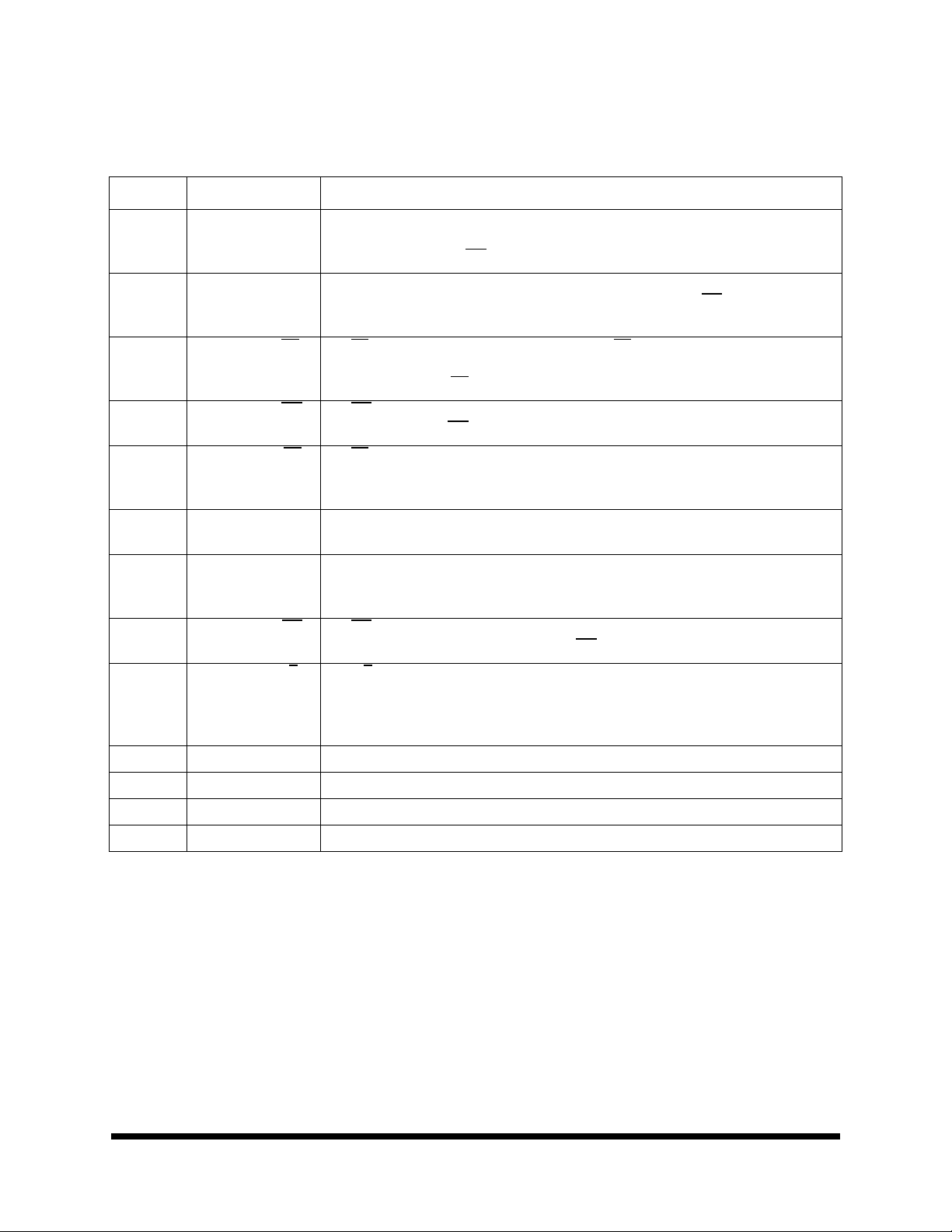

TABLE 1. PINOUT DESCRIPTION

PRELIMINARY

PIN SYMBOL DESCRIPTION

29F0408

2 Command Latch

Enable (CLE)

3 Address Latch Enable

(ALE)

43 Chip Enable (CE

4 Write Enable (WE

42 Read Enable (RE

40 Spare Area Enable

(SE)

18-21,

24-27

5 Write Protect (WP

41 Read/Busy (R/B

I/O Port: I/O0 ~ I/O7 The I/O pins are used to input command, address and data, and to output data during read

The CLE input controls the path activation for commands sent to the command register.

When active high, commands are latched into the command register through the I/O ports

on the rising edge of the WE

The ALE input controls the path activation for address and input data to the internal

address/data register. Addresses are latched on the rising edge or WE

input data is latched when ALE is low.

) The CE input is the device selection control. When CE goes high during a read operation,

the device is returned to standby mode. However, when the device is in the busy state during program or erase, CE

) The WE input controls writes to the I/O port. Commands, address and data are latched on

the rising edge of the WE

) The RE inputs is the serial data-out control, and when active drives the data onto the I/O

bus. Data is valid t

address counter by one.

The SE input controls the spare area selection when SE is high, the device is deselected

the spare area during Read1, Sequential data input and page Program.

operations. The I/O pins float to High-Z when the chip is deselected or when the outputs are

disabled.

) The WP pin provides inadvertent write/erase protection during power transitions. The inter-

nal high voltage generator is reset when the WP

) The R/B output indicates the status of the device operation. When low, it indicates that a

program, erase or random read operation is in process and returns to high state upon completion. It is an open drain output and does not float to High-Z condition when the chip is

deselected or when outputs are disabled.

REA

signal.

with ALE high, and

high is ignored, and does not return the device to standby mode.

pulse.

after the falling edge of RE which also increments the internal column

pin is active low.

6-17, 28-39 NC Not Connected

1, 22 V

44 V

23 V

1000571

SS

CC

Q Output Buffer Voltage

CC

Ground

Supply Voltage

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

2

Page 3

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

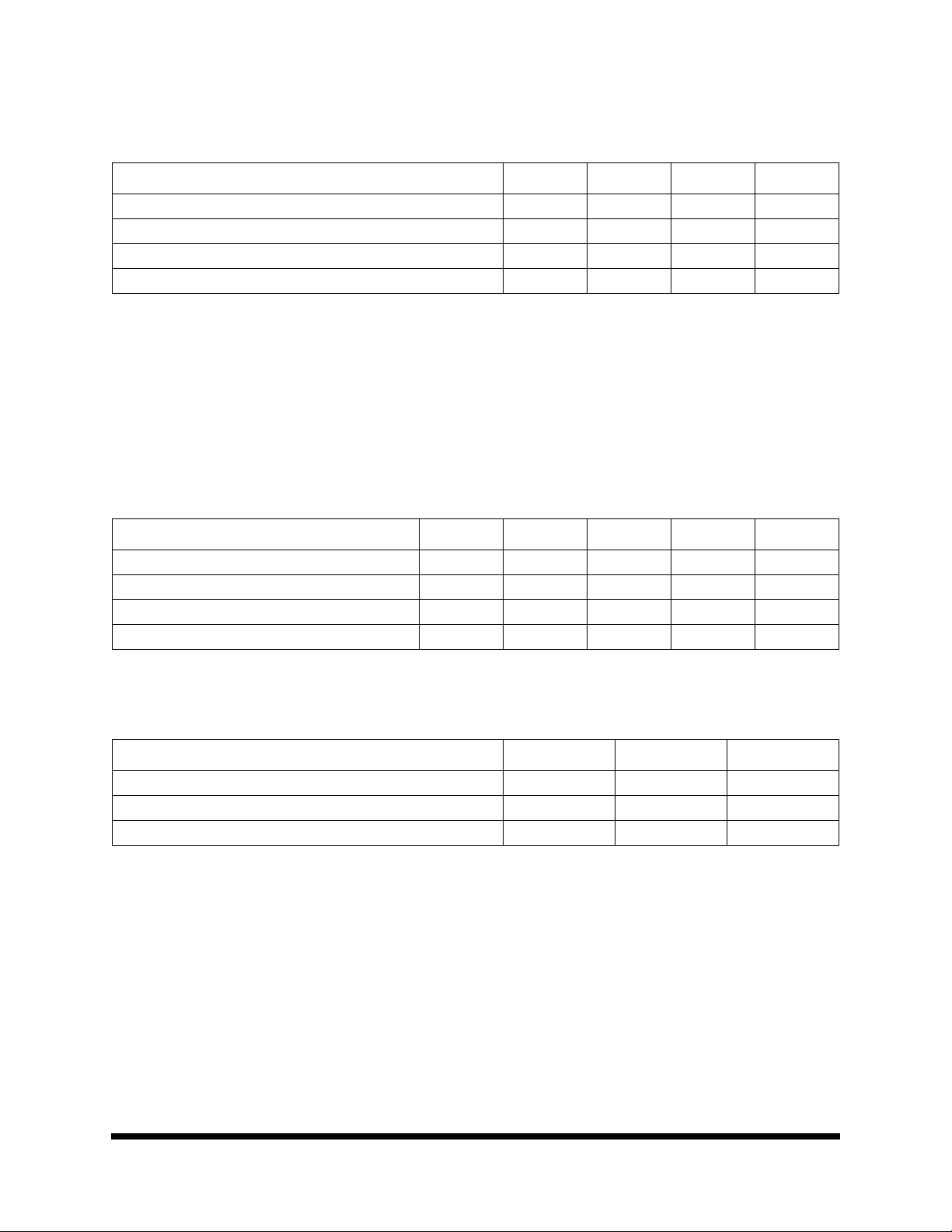

TABLE 2. 29F0408 ABSOLUTE MAXIMUM RATINGS

P

PRELIMINARY

Voltage on any pin relative to V

Temperature under bias T

Storage temperature T

Short circuit output current I

ARAMETER SYMBOL MIN MAX UNIT

SS

V

BIAS

STG

OS

IN

1,2

-0.6 7.0 V

-40 125

-65 150

-- 5 mA

1. Minimum DC voltage is -0.3 V on input/output pins. During transitions, this level may undershoot to -2.0 V for periods < 30 ns.

Maximum DC voltage on input/output pins is V

+ 0.3 V which, during transitions, may overshoot to VCC + 2.0 V for periods <

CC

20 ns.

2. Permanent device damage may occur if ABSOLUTE MAXIMUM RATINGS are exceeded. Functional operation should be

restricted to the conditions as detailed in the operational sections of this data sheet. Exposure to absolute maximum ratings

conditions for extended periods may affect reliability.

TABLE 3. 29F0408 RECOMMENDED OPERATING CONDITIONS

(VOLTAGE REFERENCE TO GND, TA = -40 TO 85°C)

P

ARAMETER SYMBOL MIN TYP MAX UNIT

Supply voltage V

Supply voltage V

Input High Voltage V

Input Low Voltage V

CC

SS

IH

IL

4.5 5.0 5.5 V

000V

2.4 -- VCC ±0.5 V

-0.3 -- 0.8 V

°

C

°

C

TABLE 4. 29F0408 AC TEST CONDITION

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

P

ARAMETER MIN MAX UNIT

Input pulse levels 0.4 2.6 V

Input rise times -- 5.0 ns

Input and output timing levels 0.8 2.0 V

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

3

Page 4

32 Megabit (4M x 8-Bit) Flash Memory

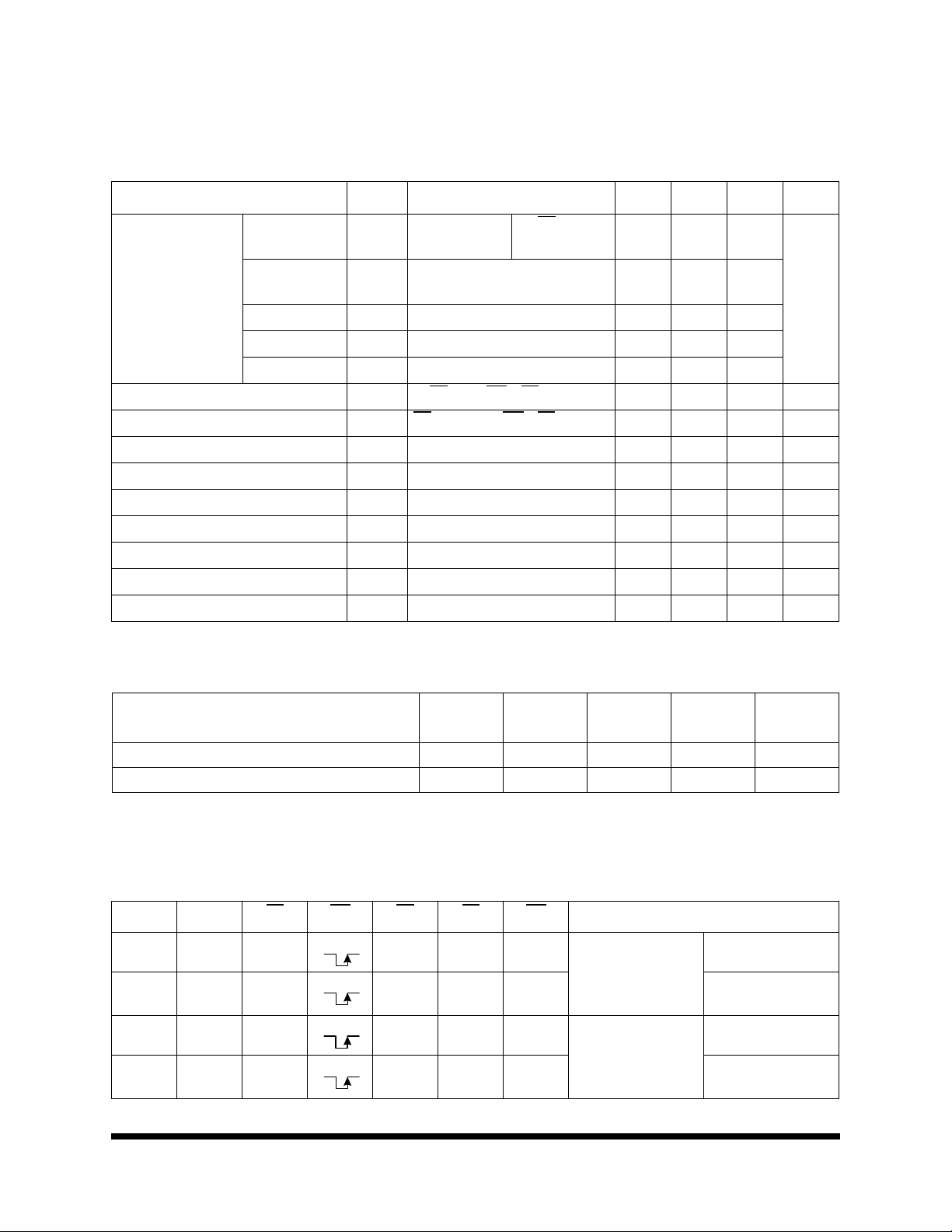

TABLE 5. 29F0408 DC AND OPERATING CHARACTERISTICS

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

PRELIMINARY

P

ARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

29F0408

Operating current Sequential read I

Command,

address input

Data input I

Program I

Erase I

Stand-by-current (TTL) I

Stand-by current (CMOS) I

Input leakage current I

Output leakage current I

Input high voltage, all inputs V

Input low voltage, all inputs V

Output high voltage level V

Output low voltage level V

Outuput low current (R/B) I

OL

TABLE 6. 29F0408 CAPACITANCE

t

= 50 ns CE = VIL,

CYCLE

t

CYCLE

CE = VIH, WP = SE = 0V/V

CE = VCC - 0.2, WP = SE = 0V/V

VIN = 0 to 5.5 V -10 -- 10 uA

V

= 0 to 5.5 V -10 -- 10 uA

OUT

IOH = -400 µA 2.4 -- -- V

IOL = 2.1 mA -- -- 0.4 V

I

CC1

CC3

CC4

CC6

CC7

SB1

SB2

LI

LO

IH

IL

OH

OL

I

= 0 mA

OUT

= 50 ns -- 15 30

CC

-- 15 30 mA

-- 15 30

-- 15 30

-- 25 40

-- -- 1 mA

-- 10 100 uA

CC

2.0----V

-- -- 0.8 V

(R/B) VOL = 0.4 V 8 10 -- mA

1

ARAMETER

P

SYMBOL TEST

Input/Output capacitance C

Input capacitance C

C

ONDITION

I/O

IN

VIL = 0V -- 10 pF

VIN = 0V -- 10 pF

MIN MAX UNIT

1. Capacitance is periodically sampled and not 100% tested.

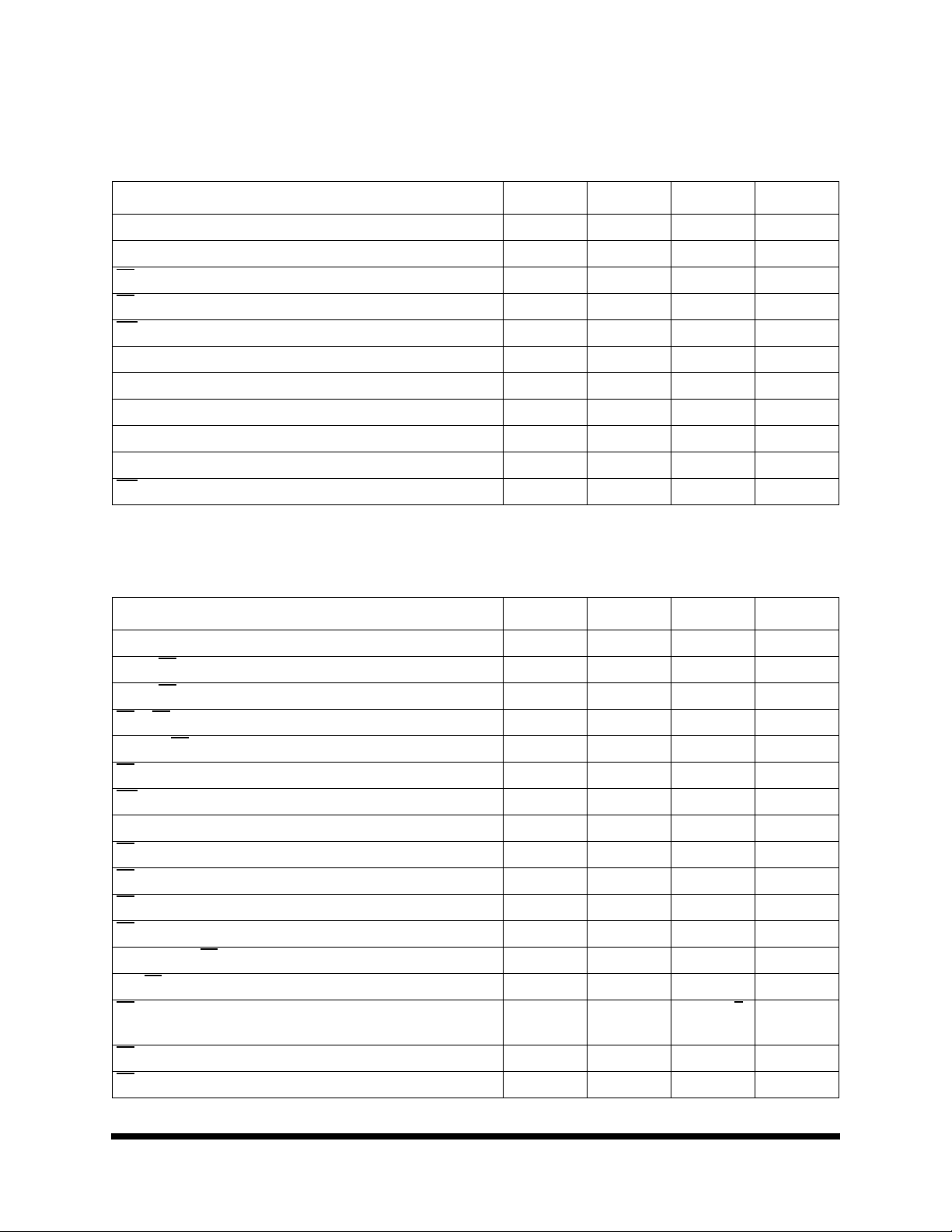

TABLE 7. 29F0408 MODE SELECTION

CLE ALE CE WE RE SE WP MODE

H L L H X X Read Mode Command Input

L H L H X X Address Input (3

Clock)

H L L H X H Write Mode Command Input

L H L H X H Address Input (3

Clock)

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

4

All rights reserved.

Page 5

32 Megabit (4M x 8-Bit) Flash Memory

TABLE 7. 29F0408 MODE SELECTION

CLE ALE CE WE RE SE WP MODE

29F0408

PRELIMINARY

LLL HL/H 1H Data Input

LLLH L/H

LLLHHL/H

XXXXXL/H

XXXXXXHDuring Erase (Busy)

XX

2

XXXXLWrite Protect

XXHXX0V/V

1. When SE is high, spare area is deselected.

2. X can be V

3. WP

should be biased to CMOS high or CMOS low for standby.

or VIH.

IL

TABLE 8. 29F0408 PROGRAM/ERASE CHARACTERISTICS

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

P

ARAMETER SYMBOL MIN TYP MAX UNIT

Program time t

Number of partial program cycles in the same page N

Block erase time t

PROG

OP

BERS

CC

1

1

1

X Sequential Read & Data Output

X During Read (Busy)

H During Program (Busy)

3

0V/V

CC

3

Stand-by

-- 0.25 1.5 ms

-- -- 10 cycles

-- 2 10 ms

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

5

Page 6

32 Megabit (4M x 8-Bit) Flash Memory

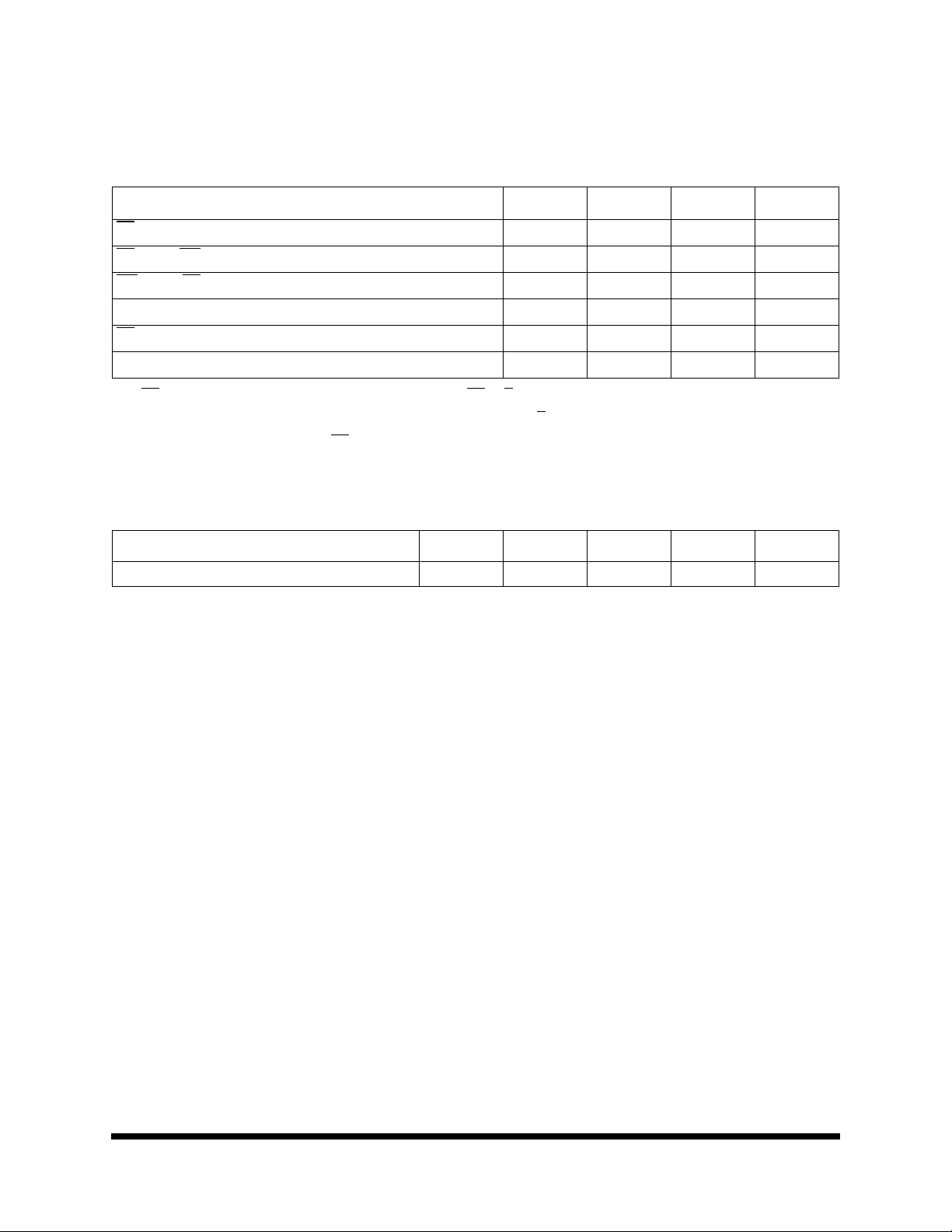

TABLE 9. 29F0408 AC TIMING CHARACTERISTICS FOR COMMAND/ADDRESS/DATA INPUT

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

PRELIMINARY

P

ARAMETER SYMBOL MIN MAX UNIT

29F0408

CLE set-up time t

CLE hold time t

CE

setup time t

CE

hold time t

WE

pulse width t

ALE setup time t

ALE hold time t

Data setup time t

Data hold time t

Write cycle time t

WE

high hold time t

TABLE 10. 29F0408 AC CHARACTERISTICS FOR OPERATION

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

P

ARAMETER SYMBOL MIN MAX UNIT

Data transfer from cell to register t

ALE to RE

ALE to RE

CE

Ready to RE

RE

WE

Read cycle time t

RE

RE

CE

RE

Output Hi-Z to RE

Last RE

CE

delay (read ID) t

delay (read cycle) t

to RE delay (ID read) t

low t

pulse width t

high to busy t

access time t

high to output Hi-Z t

high to output Hi-Z t

high hold time t

low t

high to busy (at sequential read) t

high to ready (in case of interception by CE at read)

1

t

CLS

CLH

CS

CH

WP

ALS

ALH

DS

DH

WC

WH

R

AR1

AR2

CR

RR

RP

WR

RC

Y

RHZ

CHZ

REH

IR

RB

CRY

0--ns

10 -- ns

0--ns

10 -- ns

25 -- ns

0--ns

10 -- ns

20 -- ns

10 -- ns

50 -- ns

15 -- ns

-- 10 µs

150 -- ns

50 -- ns

100 -- ns

20 -- ns

30 -- ns

-- 100 ns

50 -- ns

-- 35 ns

15 30 ns

-- 20 ns

15 -- ns

0--ns

-- 100 ns

-- 50 + tr (R/B)

2

ns

CE

high hold time (at the last serial read)

RE

low to status output t

1000571

3

12.19.01 Rev 2

t

CEH

RSTO

All data sheets are subject to change without notice

100 -- ns

-- 35 ns

©2001 Maxwell Technologies

All rights reserved.

6

Page 7

32 Megabit (4M x 8-Bit) Flash Memory

TABLE 10. 29F0408 AC CHARACTERISTICS FOR OPERATION

PRELIMINARY

(VCC = 5 V ± 10%, TA = -40 TO 85°C, UNLESS OTHERWISE NOTED)

P

ARAMETER SYMBOL MIN MAX UNIT

29F0408

CE low to status output t

RE

high to WE low t

WE

high to RE low t

Erase suspend input to ready t

RE

access time (read ID) t

Device resetting time (read/program/erase/after erase suspend) t

1. If CE

2. The time to Ready depends on the value of the pull-up resistor tied to R/B

3. To break the sequential read cycle, CE

goes high within 30 ns after the rising edge of the last RE, R/B will not return to VOL.

must be held high for longer than t

Y

Y

WHR

SR

READID

RST

pin.

CEH

.

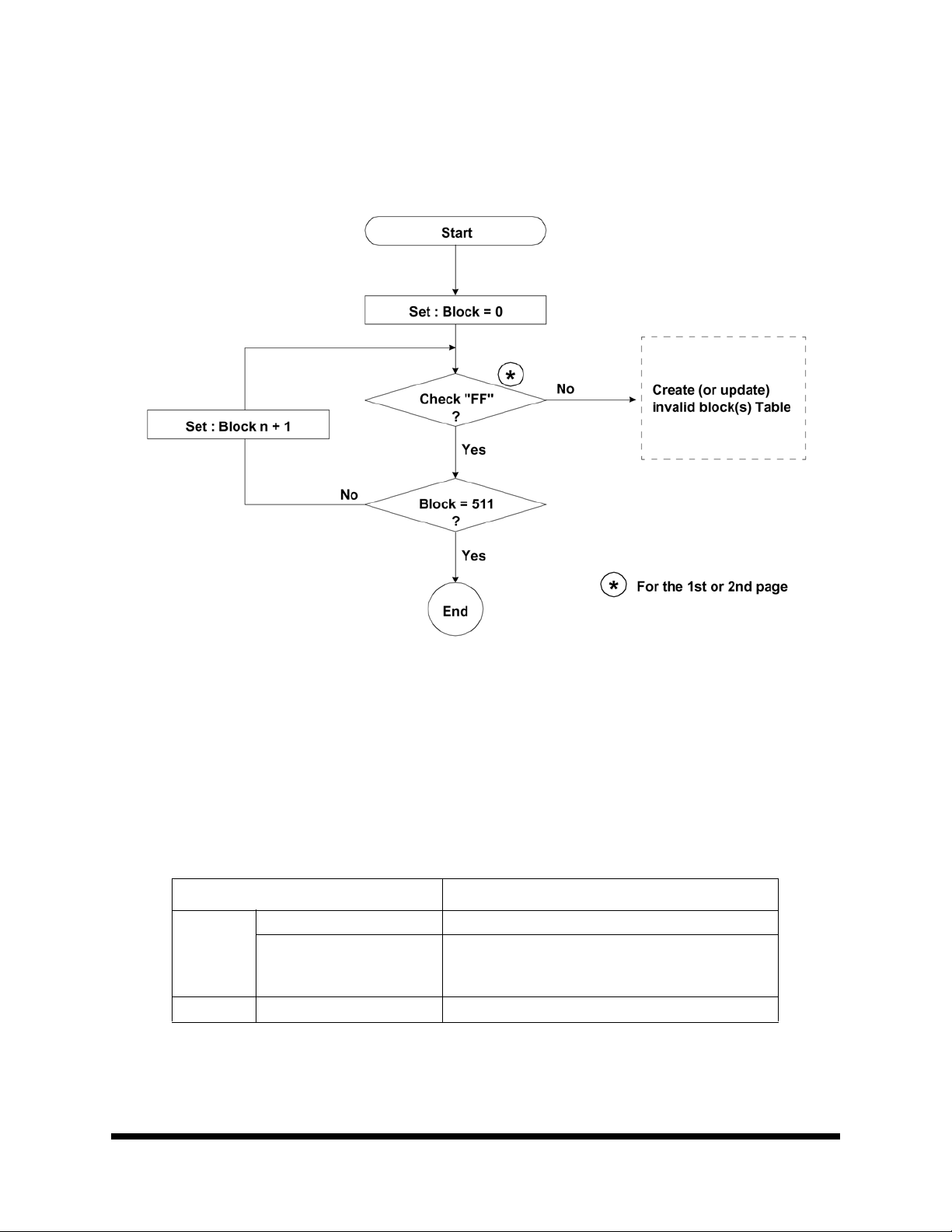

TABLE 11. 29F0408 VALID BLOCK

P

ARAMETER SYMBOL MIN TYP MAX UNIT

Valid Block Number N

1. The device may include valid blocks. Invalid blocks are defined as blocks that contain one or more bad bits. Do not try to

access these invalid blocks for program and erase. During its lifetime of 10 years and/or 1 million program/erase cycles, the

minimum number of valid blocks are guaranteed though its initial number could be reduced. (Refer to following technical note)

2. The 1st block, which is placed on the 00h block address, is guaranteed to be a valid block.

VB

502 508 512 Blocks

-- 45 ns

0--ns

60 -- ns

-- 500 µs

-- 35 ns

-- 5/10/500/5 µs

1,2

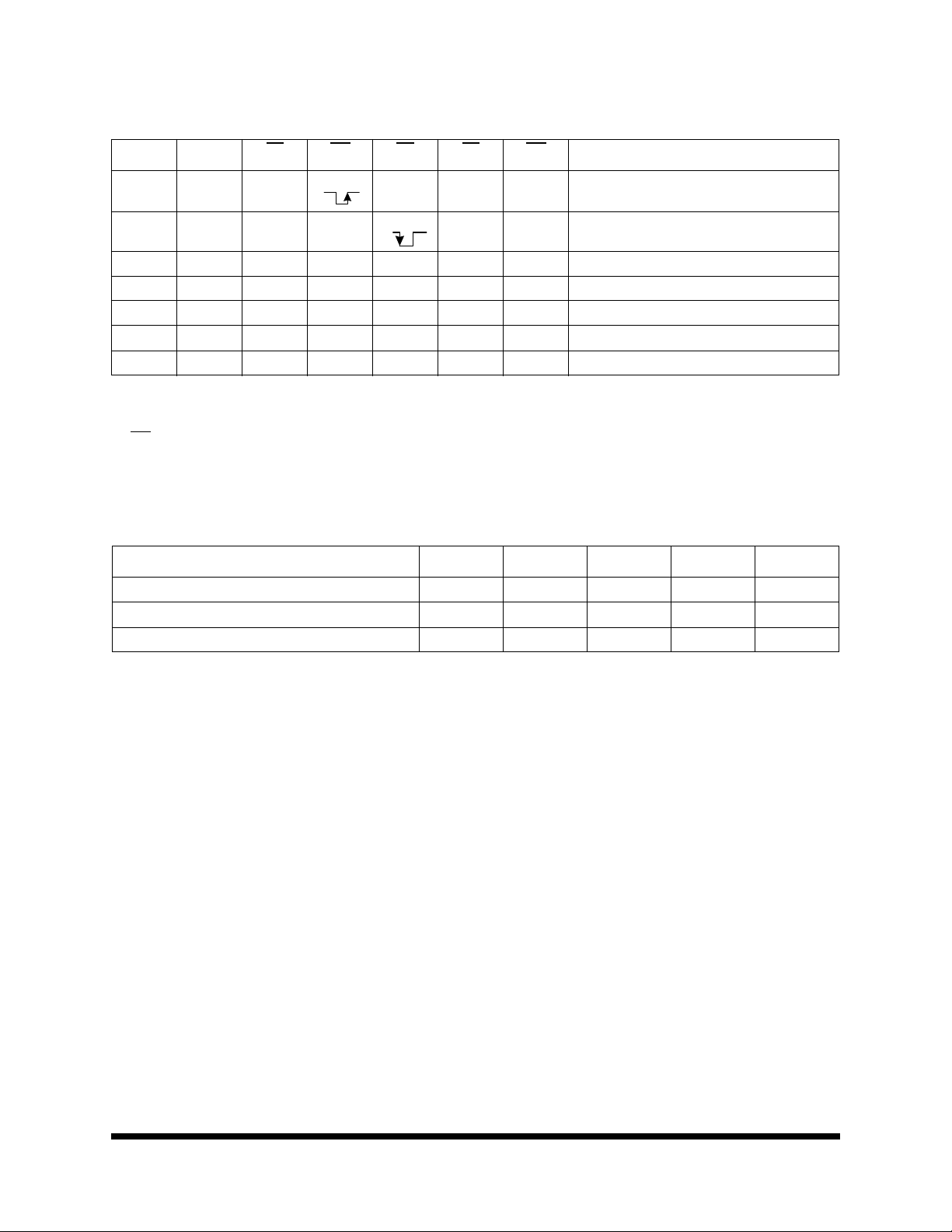

NAND FLASH TECHNICAL NOTES

Invalid Block(s)

Invalid blocks are defined as blocks that contain one or more invalid bits whose reliability is not guaranteed by the

manufacturer. Typically, an invalid block will contain a single bad bit. The information regarding the invalid block(s) is

called as the invalid block information. The invalid block information is written to the 1st or the 2nd page of the invalid

block(s) with 00h data. Devices with invalid block(s) have the same quality level as devices with all valid blocks and

have the same AC and DC characteristics. An invalid block(s) does not affect the performance of valid block(s)

because it is isolated from the bit line and the common source line by a select transistor. The system design must be

able to mask out the invalid block(s) via address mapping. The 1st block of the NAND Flash, however, is fully guaranteed to be a valid block.

Identifying Invalid Block(s)

All device locations are erased (FFh) except locations where the invalid block information is written prior to shipping.

Since the invalid block information is also erasable in most cases, it is impossible to recover the information once it

has been erased. Therefore, the system must be able to recognize the invalid block(s) based on the original invalid

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

7

Page 8

32 Megabit (4M x 8-Bit) Flash Memory

block information and create the invalid block table via the following suggested flow chart (Figure 1). Any intentional

erasure of the original block information is prohibited.

29F0408

PRELIMINARY

FIGURE 1. FLOW CHART TO CREATE INVALID BLOCK TABLE

Error in write or read operation

Over its lifetime, the additional invalid blocks may occur. Through the tight process control and intensive testing, additional block failure rate is minimized which is projected below 0.1% until 1 million program/erase cycles. Refer to the

qualification report for the actual data. The following possible failure modes should be considered to implement a

highly reliable system. In the case of status read failure after erase or program, block replacement should be done. To

improve the efficiency of memory space, it is recommended that the read or verification failure due to single bit error

be reclaimed by ECC without any block replacement. The said additional block failure rate does not include those

reclaimed blocks.

FAILURE MODE DETECTION AND COUNTERMEASURE

Write Erase failure Status read after erase Æ Block replacement

Program failure Status read after program

Read Single bit failure Verify ECC

ECC: Error Correcting Code

Example. 1-bit correction and 2-bit detection

1000571

Æ Hamming Code, etc.

Read back (verify after program)

ECC correction

Æ ECC correction

12.19.01 Rev 2

All data sheets are subject to change without notice

Æ Block replacement

Æ Block replacement or

8

©2001 Maxwell Technologies

All rights reserved.

Page 9

32 Megabit (4M x 8-Bit) Flash Memory

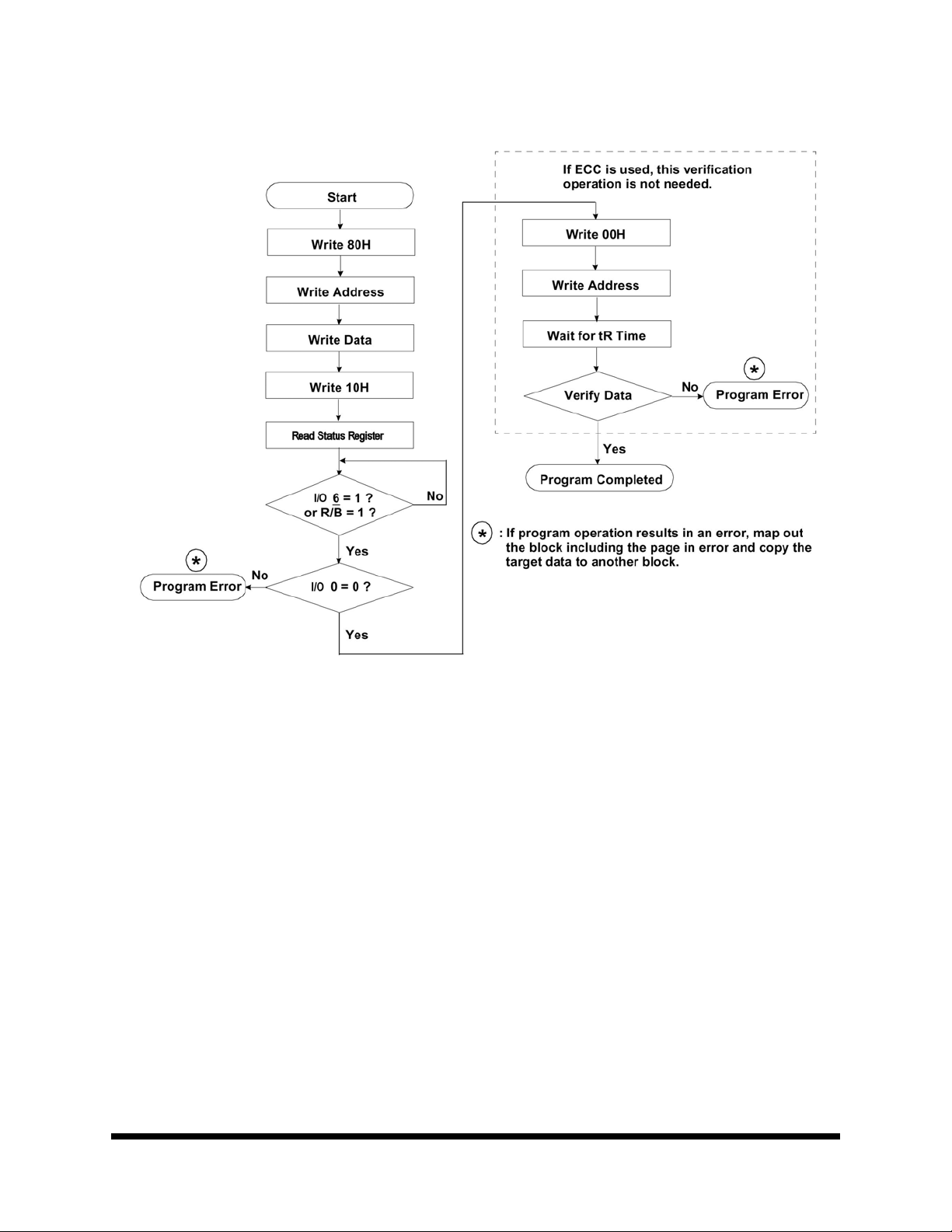

FIGURE 2. PROGRAM FLOW CHART

PRELIMINARY

29F0408

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

9

Page 10

32 Megabit (4M x 8-Bit) Flash Memory

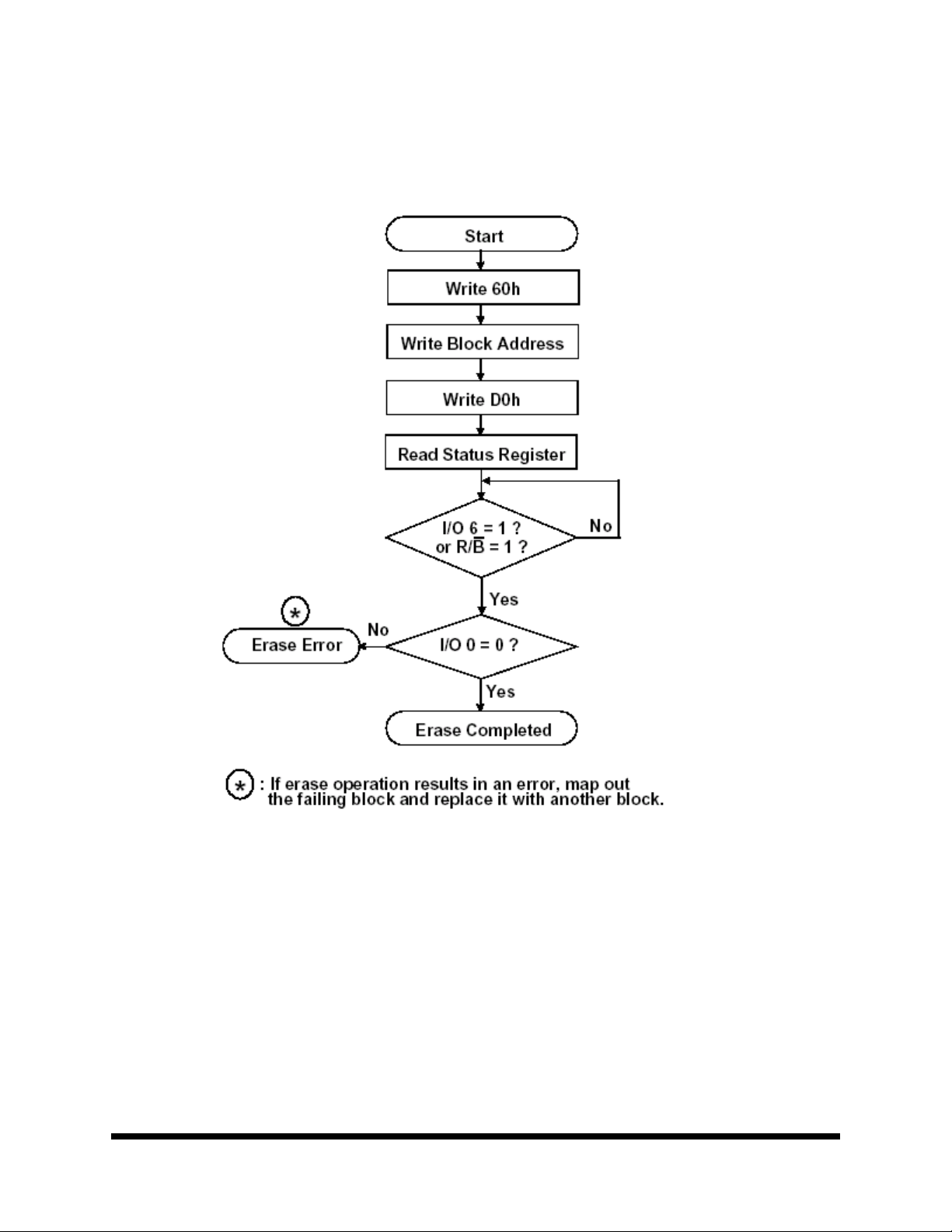

FIGURE 3. ERASE FLOW CHART

PRELIMINARY

29F0408

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

10

Page 11

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 4. READ FLOW CHART

PRELIMINARY

29F0408

1000571

FIGURE 5. BLOCK REPLACEMENT

12.19.01 Rev 2

All data sheets are subject to change without notice

11

©2001 Maxwell Technologies

All rights reserved.

Page 12

32 Megabit (4M x 8-Bit) Flash Memory

Pointer Operation:

The 29F0408 has three modes to set the destination of the pointer. The pointer is set to “A” area by the “00h” com-

PRELIMINARY

mand, to “B” area by the “01h” command, and to “C” area by the “50h” command. The Destination Pointer Table shows

the destination of the pointer, and the block diagram shows the diagram of its operation.

29F0408

TABLE 12. DESTINATION OF POINTER TABLE

FIGURE 6. BLOCK DIAGRAM OF POINTER OPERATION

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

12

Page 13

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 7. EXAMPLES OF PROGRAMMING WITH SUCCESSIVE POINTER OPERATION

PRELIMINARY

TABLE 13. POINT STATUS AFTER EACH OPERATION

29F0408

System Interface Using CE don’t-care.

For a easier system interface, CE may be inactive during the data-loading or sequential data-reading as shown below.

The internal 528byte page registers are utilized as seperate buffers for this operation and the system design gets

more flexible. In addition, for voice or audio applications which use slow cycle time on the order of u-seconds, de-activating CE during the data-loading and reading would provide significant savings in power consumption.

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

13

Page 14

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 8. PROGRAM OPERATION WITH CE DON’T CARE

PRELIMINARY

29F0408

Timing requirements: If CE is is exerted high

during data-loading, tCS must be minimum

10ns and tWC must be increased accordingly.

FIGURE 9. READ OPERATION WITH CE DON’T CARE

Timing requirements: If CE

during sequentialdata-reading, the falling edge

of CE to valid data(tCEA) must be kept greater

than 45ns.

is is exerted high

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

14

Page 15

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 10. COMMAND LATCH CYCLE

PRELIMINARY

29F0408

FIGURE 11. ADDRESS LATCH CYCLE

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

15

Page 16

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 12. INPUT DATA LATCH CYCLE

PRELIMINARY

29F0408

FIGURE 13. SEQUENTIAL OUT CYCLE AFTER READ (CLE = L, WE = H, ALE = L)

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

16

Page 17

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 14. STATUS READ CYCLE

FIGURE 15. READ1 OPERATION (READ ONE PAGE)

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

17

Page 18

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 16. READ1 OPERATION (INTERCEPTED BY CE)

PRELIMINARY

29F0408

IGURE 17. READ2 OPERATION (READ ONE PAGE)

F

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

18

Page 19

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 18. SEQUENTIAL ROW READ OPERATION

FIGURE 19. PAGE PROGRAM OPERATION

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

19

Page 20

32 Megabit (4M x 8-Bit) Flash Memory

FIGURE 20. BLOCK ERASE OPERATION (ERASE ONE BLOCK)

PRELIMINARY

IGURE 21. MANUFACTURE & DEVICE ID READ OPERATION

F

29F0408

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

20

Page 21

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

DEVICE OPERATION

PAGE READ

PRELIMINARY

Upon initial device power up, the device defaults to Read1 mode. This operation is also initiated by writing

00h to the command register along with three address cycles. Once the command is latched, it does not

need to be written for the following page read operation. Three types of operations are available : random

read, serial page read and sequential read.

The random read mode is enabled when the page address is changed. The 528 bytes of data within the

selected page are transferred to the data registers in less than 10 ms(tR). The CPU can detect the completion of this data transfer(t

registers, they may be read out in 50 ns cycle time by sequentially pulsing RE

low transitions of the RE

umn address(column 511 or 527 depending on state of SE

After the data of last column address is clocked out, the next page is automatically selected for sequential

read.

) by analyzing the output of R/B pin. Once the data in a page is loaded into the

R

with CE staying low. High to

clock output the data starting from the selected column address up to the last col-

pin).

Waiting 10 µs again allows for reading of the selected page. The sequential read operation is terminated by

bringing CE high. The way the Read1 and Read2 commands work is like a pointer set to either the main

area or the spare area. The spare area of bytes 512 to 527 may be selectively accessed by writing the

Read2 command with SE pin low. Toggling SE

starting address of the spare area while addresses A4 to A7 are ignored. Unless the operation is aborted,

the page address is automatically incremented for sequential read as in Read1 operation and spare sixteen

bytes of each page may be sequentially read. The Read1 command (00h/01h) is needed to move the

pointer back to the main area. Figures 22 thru 25 show typical sequence and timings for each read operation.

during operation is prohibited. Addresses A0 to A3 set the

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

21

Page 22

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 22. READ1 OPERATION

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

22

Page 23

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 23. READ2 OPERATION

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

23

Page 24

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 24. SEQUENTIAL ROW READ1 OPERATION

FIGURE 25. SEQUENTIAL READ2 OPERATION (SE = FIXED LOW)

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

24

Page 25

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PAGE PROGRAM

The device is programmed basically on a page basis, but it does allow multiple partial page programming of

PRELIMINARY

a byte or consecutive bytes up to 528, in a single page program cycle. The number of consecutive partial

page programming operation within the same page without an intervening erase operation must not exceed

ten. The addressing may be done in any random order in a block. A page program cycle consists of a serial

data loading period in which up to 528 bytes of data may be loaded into the page register, followed by a nonvolatile programming period where the loaded data is programmed into the appropriate cell. Serial data

loading can be started from 2nd half array. About the pointer operation, please refer to the attached technical

notes.The serial data loading period begins by inputting the Serial Data Input command (80H), followed by

the three cycle address input and then serial data loading. The bytes other than those to be programmed do

not need to be loaded.

The Page Program confirm command (10h) initiates the programming process. Writing 10h alone without

perviously entering the serial data will not initiate the programming process. The internal write controller

automatically executes the algorithms and timings necessary for program and verify, thereby freeing the

CPU for other tasks. Once the program process starts, the Read Status Register command may be entered,

with RE

monitoring the R/B

and Reset command are valid while programming is in progress. When the Page Program is complete, the

Write Status Bit (I/O0) may be checked (Figure 26). The internal write verify detects only errors for "1"s that

are not successfully programmed to "0"s. The command register remains in Read Status command mode

until another valid command is written to the command register.

and CE low, to read the status register. The CPU can detect the completion of a program cycle by

output, or the Status bit (I/O6) of the Status Register. Only the Read Status command

1000571

FIGURE 26. PROGRAM & READ STATUS OPERATION

12.19.01 Rev 2

All data sheets are subject to change without notice

25

©2001 Maxwell Technologies

All rights reserved.

Page 26

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

BLOCK ERASE

The Erase operation can erase on a block (8K Byte) basis. Block address loading is accomplished in two

PRELIMINARY

cycles initiated by an Erase Setup command (60h). Only address A13 to A21 is valid while A9 to A12 is

ignored. The addresses of the block to be erased to FFh. The Erase Confirm command (D0h) following the

block address loading initiates the internal erasing process. This two-step sequence of setup followed by

execution ensures that memory contents are not accidentally erased due to external noise conditions. At the

rising edge of WE

erase-verify. When the erase operation is completed, the Write Status Bit (I/O0) may be checked. Figure 27

details the sequence.

after the erase confirm command input, the internal write controller handles erase and

FIGURE 27. BLOCK ERASE OPERATION

READ STATUS

The device contains a Status Register which may be read to find out whether program or erase operation is

complete, and whether the program or erase operation completed successfully. After writing 70h command

to the command register, a read cycle outputs the contents of the Status Register to the I/O pins on the falling edge of CE or RE, whichever occurs last. This two line control allows the system to poll the progress of

each device in multiple memory connections even when R/B

need to be toggled for updated status. Refer to table 14 for specific Status Register definitions. The command register remains in Status Read mode until further commands are issued to it. Therefore, if the status

register is read during a random read cycle, a read command (00h or 50h) should be given before sequential

page read cycle.

1000571

12.19.01 Rev 2

pins are common-wired. RE or CE does not

All data sheets are subject to change without notice

26

©2001 Maxwell Technologies

All rights reserved.

Page 27

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

TABLE 14. READ STATUS REGISTER DEFINITION

READ ID

The device contains a product identification mode, initiated by writing 90h to the command register, followed

by an address input of 00h. Two read cycles sequentially output the manufacture code(ECh), and the device

code (E3h) respectively. The command register remains in Read ID mode until further commands are issued

to it. Figure 28 shows the operation sequence.

1000571

FIGURE 28. READ ID OPERATION

12.19.01 Rev 2

All data sheets are subject to change without notice

27

©2001 Maxwell Technologies

All rights reserved.

Page 28

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

RESET

The device offers a reset feature, executed by writing FFh to the command register. When the device is in

PRELIMINARY

Busy state during random read, program or erase modes, the reset operation will abort these operation. The

contents of memory cells being altered are no longer valid, as the data will be partially programmed or

erased. Internal address registers are cleared to "0"s and data registers to "1"s. The command register is

cleared to wait for the next command, and the Status Register is cleared to value C0h when WP

Refer to table 15 for device status after reset operation. If the device is already in reset state a new reset

command will not be accepted to by the command register. The R/B

Reset command is written. Reset command is not necessary for normal operation. Refer to Figure 29 below.

pin transitions to low for t

RST

FIGURE 29. RESET OPERATION

is high.

after the

TABLE 15. DEVICE STATUS

DATA PROTECTION

The device is designed to offer protection from any involuntary program/erase during power-transitions. An

internal voltage detector disables all functions whenever V

protection and is recommended to be kept at V

The two step command sequence for program/erase provides additional software protection.

during power-up and power-down as shown in Figure 30.

IL

is below about 2V. WP pin provides hardware

CC

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

28

Page 29

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 30. AC WAVEFORMS FOR POWER TRANSITION

READY/BUSY

The device has a R/B output that provides a hardware method of indicating the completion of a page program, erase and random read completion. The R/B

or erase command is written to the command register or random read is begin after address loading. It

returns to high when the internal controller has finished the operation. The pin is an open-drain driver

thereby allowing two or more R/B outputs to be Or-tied. An appropriate pull-up resister is required for proper

operation and the value may be calculated by following equation.

pin is normally high but transitions to low after program

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

29

Page 30

32 Megabit (4M x 8-Bit) Flash Memory

29F0408

PRELIMINARY

FIGURE 31. READY/BUSY

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

30

Page 31

32 Megabit (4M x 8-Bit) Flash Memory

PRELIMINARY

29F0408

44 PIN RAD-PAK® FLAT PACKAGE

SYMBOL

MIN NOM MAX

A 0.132 0.147 0.160

b 0.015 0.017 0.019

c 0.006 0.008 0.10

D 1.188 1.200 1.212

E 0.668 0.675 0.682

E1 -- -- 0.705

E2 0.450 0.455 0.460

E3 0.098 0.110 0.122

e 0.050 BSC

L 0.350 0.370 0.390

Q 0.022 0.027 0.032

S1 0.005 -- --

N44

F44-01

Note: All dimensions in inches

DIMENSION

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

31

Page 32

32 Megabit (4M x 8-Bit) Flash Memory

Important Notice:

These data sheets are created using the chip manufacturer’s published specifications. Maxwell Technologies verifies

PRELIMINARY

functionality by testing key parameters either by 100% testing, sample testing or characterization.

The specifications presented within these data sheets represent the latest and most accurate information available to

date. However, these specifications are subject to change without notice and Maxwell Technologies assumes no

responsibility for the use of this information.

Maxwell Technologies’ products are not authorized for use as critical components in life support devices or systems

without express written approval from Maxwell Technologies.

Any claim against Space Electronics Inc. must be made within 90 days from the date of shipment from Maxwell Technologies. Maxwell Technologies’ liability shall be limited to replacement of defective parts.

29F0408

1000571

12.19.01 Rev 2

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

32

Page 33

32 Megabit (4M x 8-Bit) Flash Memory

)

Product Ordering Options

29F0408

PRELIMINARY

29F0408

Model Number

RP

F X

Feature

Screening Flow

Package

Option Details

Monolithic

S = Maxwell Class S

B = Maxwell Class B

E = Engineering (testing @ +25°C

I = Industrial (testing @ -55°C,

+25°C, +125°C)

F = Flat Pack

1000571

Radiation Feature

Base Product

Nomenclature

12.19.01 Rev 2

RP = R

AD-PAK® package

32 Megabit (4M x 8-Bit) Flash

Memory

All data sheets are subject to change without notice

33

©2001 Maxwell Technologies

All rights reserved.

Loading...

Loading...