Page 1

Programmer’s Manual

Covers the following models:

MP Nova

MP Compact Mark II

MP Compact Mobile Mark II

Page 2

Information in this manual is subject to change without notice and does not represent a commitment on

the part of Datamax-O’Neil Corporation. No part of this manual may be reproduced or transmitted in any

form or by any means, for any purpose other than the purchaser’s personal use, without the expressed

written permission of Datamax-O’Neil Corporation.

© 2009 by Datamax-O’Neil Corporation

Part Number: 540340.03

Page 3

PROGRAMMER’S REFERENCE MANUAL

Table of Contents

Table of Contents

Labelpoint features: ..........................................................................................2

Scalable text field.............................................................................................. 7

Bitmap text field (deprecated) ........................................................................10

The text to be printed ...................................................................................... 11

Fixed text ........................................................................................................11

Variable information.......................................................................................11

Counters.......................................................................................................... 11

Date and time .................................................................................................. 11

Best-before date ..............................................................................................12

Check digits ....................................................................................................13

Line breaks......................................................................................................13

Reverse video.................................................................................................. 13

Barcode symbologies...................................................................................... 16

Bar code interpretation.................................................................................... 19

Defining a 2D barcode field............................................................................ 19

2D barcode symbologies................................................................................. 20

Code 128 ......................................................................................................... 22

RSS .................................................................................................................23

RSS-14 ............................................................................................................ 23

RSS-14 Truncated...........................................................................................23

RSS Limited.................................................................................................... 23

RSS Expanded ................................................................................................23

MaxiCode........................................................................................................ 24

Structured Carrier Message.............................................................................24

Modes.............................................................................................................. 24

Escape Sequences ...........................................................................................25

Data encodation ..............................................................................................25

Structured Append ..........................................................................................25

Code PDF417.................................................................................................. 26

Security level ..................................................................................................26

QR Code..........................................................................................................28

Correction level............................................................................................... 28

Masking pattern ..............................................................................................28

Other escape sequences...................................................................................28

Changing a single variable..............................................................................31

Clearing variable information......................................................................... 32

Clearing the layout..........................................................................................32

Print command................................................................................................ 32

Dormant print (or trigged printkey) ................................................................ 32

Status request 1 ...............................................................................................33

Out of paper ....................................................................................................33

Label not removed (LTS)................................................................................33

Printer restarted...............................................................................................33

No paper in label sensor.................................................................................. 33

Out of ribbon................................................................................................... 34

Heap error ....................................................................................................... 34

Status request 2 ...............................................................................................34

Page 4

PROGRAMMER’S REFERENCE MANUAL

Table of Contents

Stopped on label gap.......................................................................................34

Print incomplete..............................................................................................34

Cool down state...............................................................................................34

Last paper movement type.............................................................................. 34

Layout outside label........................................................................................35

Status request 3 ...............................................................................................35

Operating parameters error .............................................................................35

Internal print button ........................................................................................ 35

Label stock...................................................................................................... 35

Status request 4 ...............................................................................................36

Out of paper ....................................................................................................36

Label not removed (LTS)................................................................................36

Out of ribbon................................................................................................... 36

Head lifted....................................................................................................... 36

Internal print button ........................................................................................ 36

Printer restarted...............................................................................................36

Status request 8 ...............................................................................................37

LTS installed...................................................................................................37

I2C board installed...........................................................................................37

Cutter installed................................................................................................ 37

Black mark photocell...................................................................................... 37

PHD board installed........................................................................................37

Barcode displacement..................................................................................... 52

HTML version ................................................................................................53

Text version ....................................................................................................53

Document start................................................................................................54

Document end................................................................................................. 54

Cutter mode..................................................................................................... 55

Cutting command............................................................................................ 55

Label-taken sensor (LTS) ...............................................................................55

Local printer....................................................................................................56

Network printer...............................................................................................56

Macros.............................................................................................................57

Loading a macro .............................................................................................57

Deleting a macro............................................................................................. 57

Executing a macro...........................................................................................57

Auto macro......................................................................................................57

Graphics.......................................................................................................... 58

Loading a graphics file....................................................................................58

Deleting a graphics file ................................................................................... 58

Counters.......................................................................................................... 59

Initialising counters......................................................................................... 59

Retrieving information about counters ........................................................... 60

Paper feed........................................................................................................60

Automatic reverse feed ...................................................................................60

Paper feed on command..................................................................................60

True two-way communication........................................................................ 61

ENQ - ACK/NAK...........................................................................................61

Page 5

PROGRAMMER’S REFERENCE MANUAL

Table of Contents

Data Format ....................................................................................................64

Segment record ............................................................................................... 64

Data record...................................................................................................... 64

End record.......................................................................................................65

Labelpoint load graphics command................................................................ 66

Graphics format ..............................................................................................66

Control Characters ..........................................................................................67

Limitations...................................................................................................... 67

Code page 850, MS-DOS Latin 1................................................................... 68

Swedish/Finnish character set (7-bit)..............................................................68

German character set (7-bit) ...........................................................................69

UK character set (7-bit) ..................................................................................69

French character set (7-bit) ............................................................................. 70

Norwegian/Danish character set (7-bit).......................................................... 70

Spanish character set (7-bit)............................................................................71

Italian character set (7-bit).............................................................................. 71

Code page 861, MS-DOS Icelandic................................................................72

Code page 1252, Windows Latin 1 (ANSI).................................................... 73

Code page HP Roman-8..................................................................................74

Code page 852, MS-DOS Latin 2 (Central Europe)....................................... 74

Code page 1250, Windows Latin 2 (Central Europe)..................................... 75

Code page 855, MS-DOS Cyrillic ..................................................................75

Code page 1251, Windows Cyrillic (Slavic) .................................................. 76

Code page 1253, Windows Greek ..................................................................76

Code page 1254, Windows Latin 5 (Turkish)................................................. 77

Code page 1257, Windows Latin 6 (Baltic Rim)............................................ 77

Code page ISO 8859-2....................................................................................78

Command summary........................................................................................ 79

Status requests................................................................................................. 79

!S1................................................................................................................... 79

!S2................................................................................................................... 80

!S3................................................................................................................... 80

!S4................................................................................................................... 81

!S8................................................................................................................... 81

Service Commands .........................................................................................82

Printer configuration ....................................................................................... 84

Bar code symbologies..................................................................................... 87

Example 1a - The shoe example................................................................................. 88

Example 1b - The shoe example with variables ......................................................... 89

Page 6

PROGRAMMER’S REFERENCE MANUAL

The Labelpoint command language

Introduction

The thermal printer family features a simple yet powerful command language, Labelpoint II

(LP II). This allows the printers to be controlled from most computers. Most common bar code

symbologies are available. Text and bar codes can be printed in all four directions

simultaneously. Counters for consecutive numbering are available and an integral real-time

clock allows labels to be time-stamped at print time.

Labelpoint II uses only printable ASCII characters to allow commands to be easily

manipulated in the host computer. This also avoids problems with control characters that some

computer systems reserve for internal use.

Labelpoint features:

• Easy-to-use command language

• Prints text, bar and matrix codes, lines, boxes and graphics

• Contains character sets for all major European languages

• Many barcode symbologies are standard

• Several 2-dimensional (matrix) codes

• Ten scalable fonts as standard (uses Unicode character set internally to be able to

use all latin and cyrillic characters)

• TCP/IP support (LPD, RTELNET)

• Terminal Server functionality (COM1 and/or COM2 connected to the network)

• Easy-to-use configuration menu accessible through COM ports, Telnet port or by

using a common web-browser.

• Date and Time symbols

• Ten onboard counters for consecutive numbering

Page 2

Page 7

PROGRAMMER’S REFERENCE MANUAL

The Labelpoint command language

The Labelpoint command language

Labelpoint consists of a number of commands for creating a label layout, configuring the

printer, checking the printer set-up etc.

The printer receives characters and interprets them as commands or as data. A command

instructs the printer to perform some action, e. g. create a field in the label layout. Data can, for

example, be variable data that is to be included in the print-out, or it can be a sequence of

commands that are to be stored in the printer file system.

The printer acts on incoming data on a line-by-line basis. Input data is buffered until the

end-of-line character is received. The default end-of-line character is CR (carriage return,

ASCII 13

interpreted. If the line begins with the command character it is treated as a command.

= 0D16). When an end-of-line character is received, the line of data received is

10

A command line starts with an ! character (ASCII 33

specifying the command type. Some commands take parameters.

Note! The ‘!’ character must be the first character on the command line. Otherwise the

line will look like a data line.

Example

To print one label, type:

!P1

To print 100 labels, type:

!P100

Some commands assume a default value if a parameter is omitted. The command

to print one label may be given as:

!P

The available commands and programming procedures are described in the following

sections.

Case is significant for command characters. If the wrong case is used the printer will ignore

the command.

Note! All commands must be terminated by the end-of-line character (normally CR.).

The end-of-line character will not be shown in the examples in this manual.

= 2116) , followed by a character

10

Page 3

Page 8

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Label layout definition commands

This chapter will explain label designing basics and commands used to create labels in

Labelpoint.

The print area

All items (fields) to be printed on a label must be defined with their position on the paper.

The coordinate system is shown below:

paper feed direction

Y

X

The X coordinate grows across the print head, from right to left, viewing the printer from the

front. The Y coordinate grows as the paper is fed out.

All fields have a print direction, which is specified by the up vector. This is the "natural" up

direction of the field. (The text on this paper has its up vector pointing to the top of the paper.)

The terminology of the compass is used to specify the up vector. "North" is defined as the

paper feed direction. Text printed with up vector =

the top of the characters appearing first. Up vector

left-most character of the text is the first to appear, etc.

The position of a field on the paper is given as its baseline and position.

The baseline is the coordinate of the bottom of the field. For fields with up vector

the baseline is the Y coordinate; for fields with up vector

fields the baseline is at the base of non-descending characters, so that descending characters

(e.g. 'j', 'g', and 'y') will extend below the baseline. ('Above' and 'below' always refer to the up

vector of the field, and may thus be different physical directions, depending on the up vector of

the field.)

The position parameter determines the position of the field in the direction perpendicular to

the up vector, i. e. sideways. It may be given as the position of either the left end, the right

end, or the center of the field.

N (north) is printed across the paper, with

E (east) is turned 90° clockwise, so that the

N or S,

E or W it is the X coordinate. For text

All coordinates are given in 1/10 of a millimeter. The same applies for the

length of the bars in a code, and the height and width of a black box.

Page 4

Page 9

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Building a label layout

Before printing, the label layout must be defined. The layout defines the position and other

attributes (size, font, barcode symbology etc.) of each item to be printed. When the print

command is issued, the resulting print picture is printed out. The print format can be changed

at any time.

The text to be printed can be fixed or variable. Fixed text is part of the layout and does not

change until the layout is changed. Variable text can be entered for each printout of a layout,

without changing the layout.

When the label layout with fixed data has been loaded in the printer the variable data (i. e.

text that changes for each printout) is sent, followed by the print command to print one or more

labels.

!F command defines a layout field, i. e. an item to be printed.

The

A layout field is one of the following:

• one or more lines of text

• a barcode or matrix code

• a line, box or frame

• graphics

When a ‘

layout is built by defining all the fields to be printed. A text, barcode, matrix code or graphics

field may include fixed or variable text, or both.

!F’ command is received the printer adds the new field to the label layout. A label

Page 5

Page 10

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

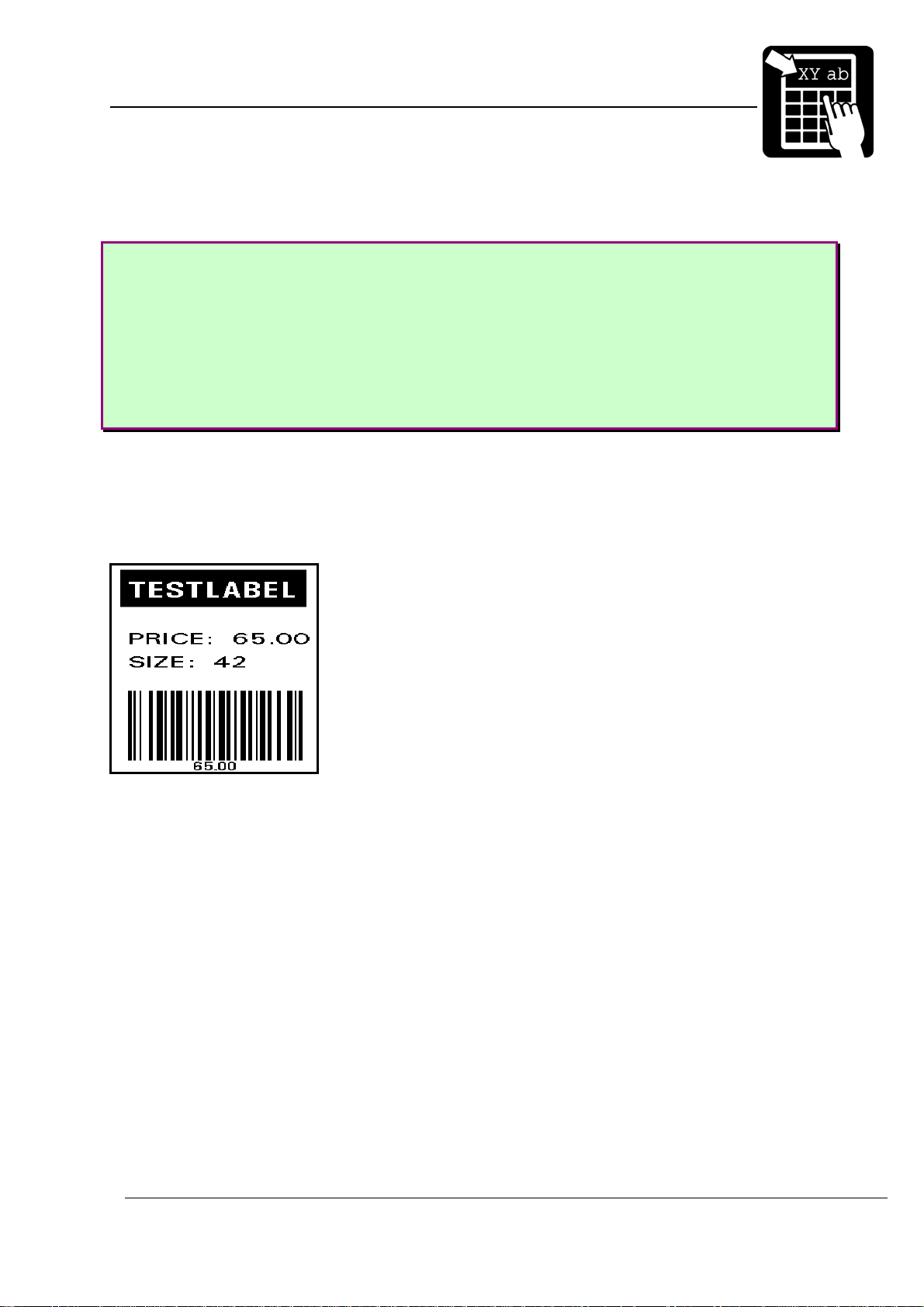

The shoe example:

!C

!Y24 60

!Y35 10

!Y42 1

!F T N 100 100 L 14 0 94030 "TESTLABEL"

!F T N 200 100 L 10 0 94021 "PRICE: 65.00"

!F T N 250 100 L 10 0 94021 "SIZE: 42"

!F C N 450 100 L 150 2 41 "65.00"

!F B N 120 90 L 80 240

!P

When sending this layout to the printer, you’ll get a 5 x 4 cm label with a black box at the

top, the size and price of the shoe, and a barcode at the bottom.

See further explanation for this example in section ‘Print Example’ at the end of this

document.

Page 6

Page 11

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Defining a text field

There are two different types of textfields, scalable and bitmap fields. Bitmap text fields are

deprecated, that is, not recommended for new designs but kept in this manual for backward

compatibility.

Scalable text field

The benefit of using scalable fonts is its possibility to use the highest possible resolution for

the letters, independent of the size defined. This is due to the font’s appearance being

calculated in run time.

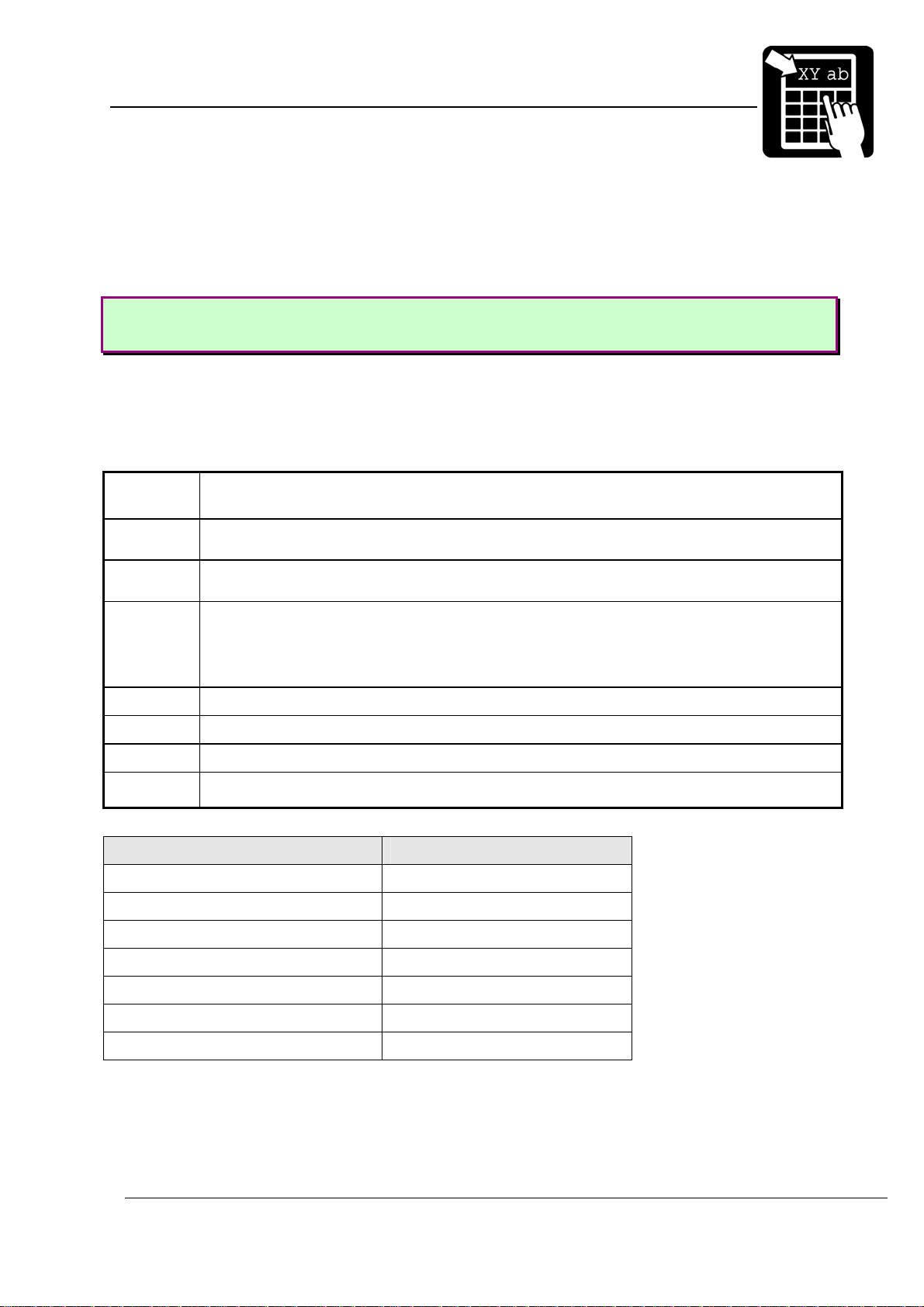

Syntax I

!F S <u> <b> <p> <a> <h> <s> <f> [wa] <“text“>

Syntax II

!F S <u> <b> <p> <a> <h> <w> <f> [s] <“text“>

Note! Parameters enclosed in <> are required and parameters enclosed in [] are

optional.

The parameters have the following meanings:

<u> Defines the direction of printing as the ‘up’ direction of the printed characters. One

upper-case character (N, E, S, or W).

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h> The font height, in points.

<w>

<f> The font number. See tables below.

<s>

<wa> Width adjustment, in percent. Valid values are 50 (%) to 200 (%).

The baseline of the field, in

1

The position, in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C = the field is centered around p.

The font width in points. To get normal character width, set parameter w to the same

value as parameter h.

Inter-character spacing in

To get normal character width, set parameter wa to 100.

This parameter is only used in syntax I. (Optional)

/10 mm.

1

/10 mm.

1

/10 points. (Optional in syntax II)

<”text”>

Specifies the text to be printed. The text must be enclosed in double quotes (

").

Page 7

Page 12

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Labelpoint uses Agfa Universal Font Scaling Technology® to generate scalable font

characters. Fonts are stored in either Agfa MicroType™ format or TrueType format.

There are ten fonts included in the printer. The printer also emulates a number of italic fonts

styles for sans serif fonts.

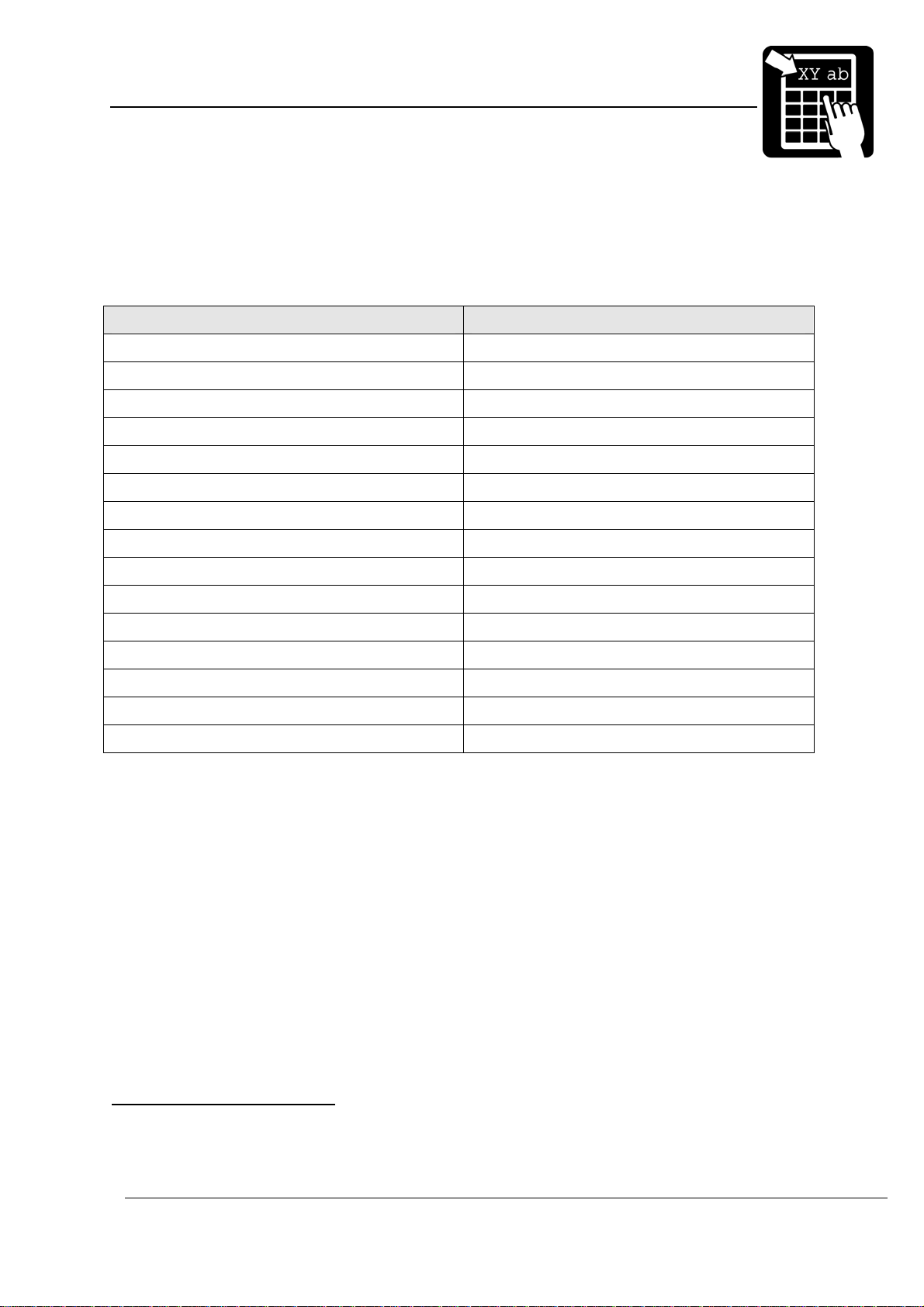

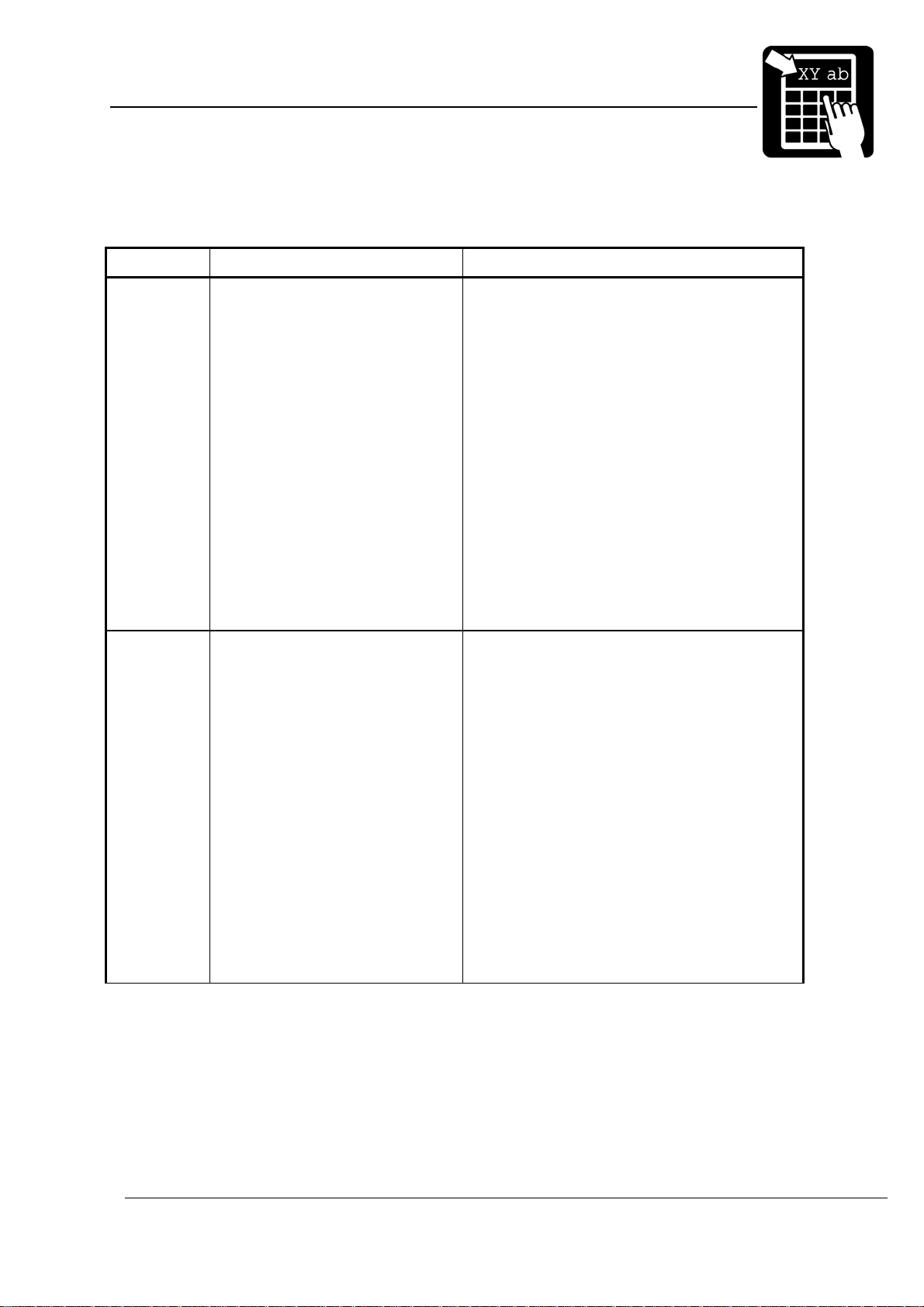

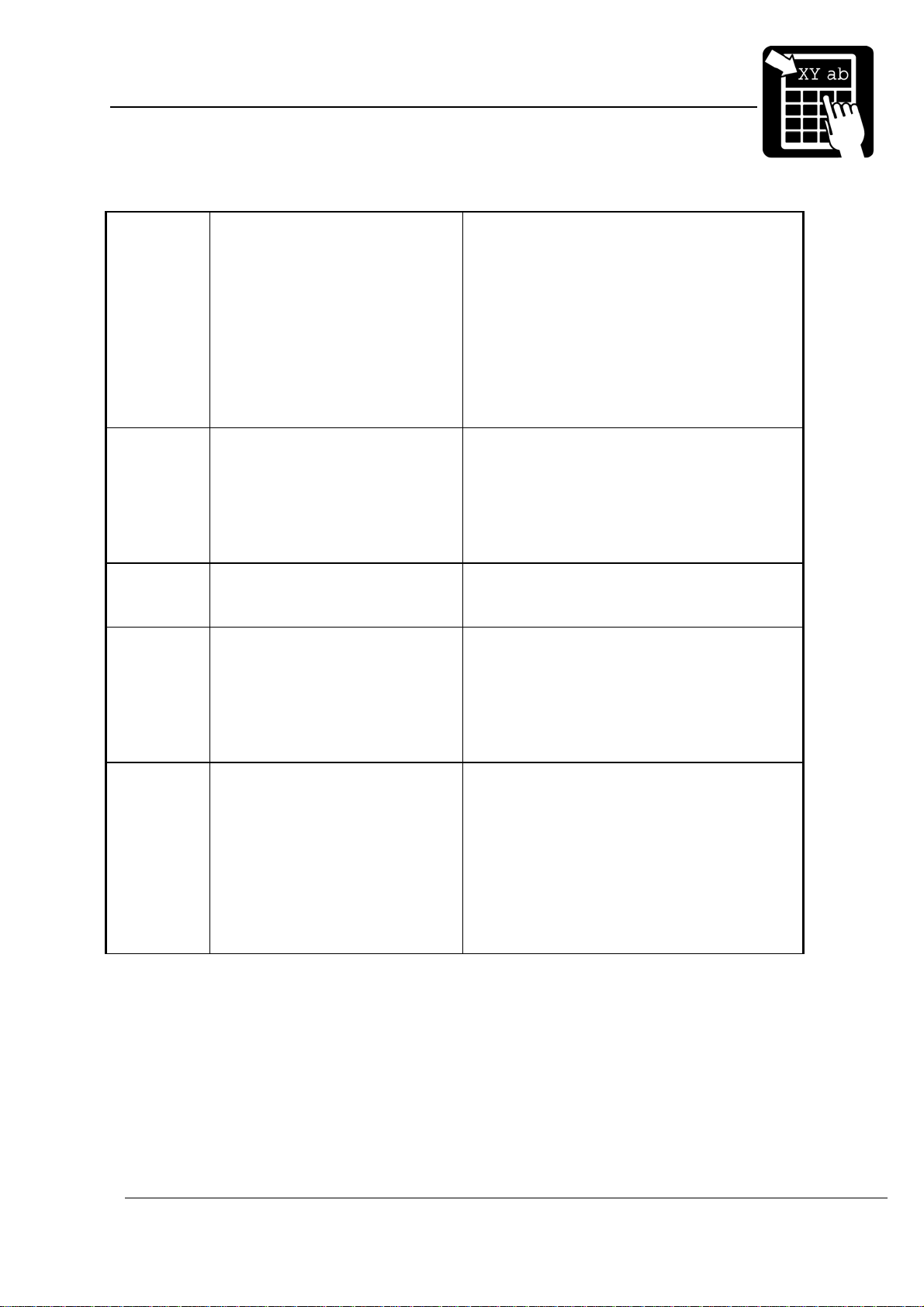

PCL typeface name PCL typeface number

Univers Medium

Univers Italic (emulated)

Univers Bold 1 94023

Univers Bold Italic (emulated) 1 94024

Univers Condensed Medium 2 94029

Univers Condensed Italic (emulated) 2 94039

Univers Condensed Bold 2 94030

1

1

94021

94022

Univers Condensed Bold Italic (emulated) 2 94040

CG Times 1 92500

CG Times Italic 1 92501

CG Times Bold 1 92504

CG Times Bold Italic 1 92505

Letter Gothic Bold 2 93779

Letter Gothic Bold Italic (emulated) 2 93780

Coronet (script) 2 90249

For faster printouts from MS-Windows systems, the Arial fonts and the Times New Roman

fonts are also emulated. On next page is a list with the fonts and their corresponding font

number:

1

Latin 1, 2, 5, 6, Greek and Cyrillic characters available

2

Latin 1, 2, 5 and 6 characters available

Page 8

Page 13

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

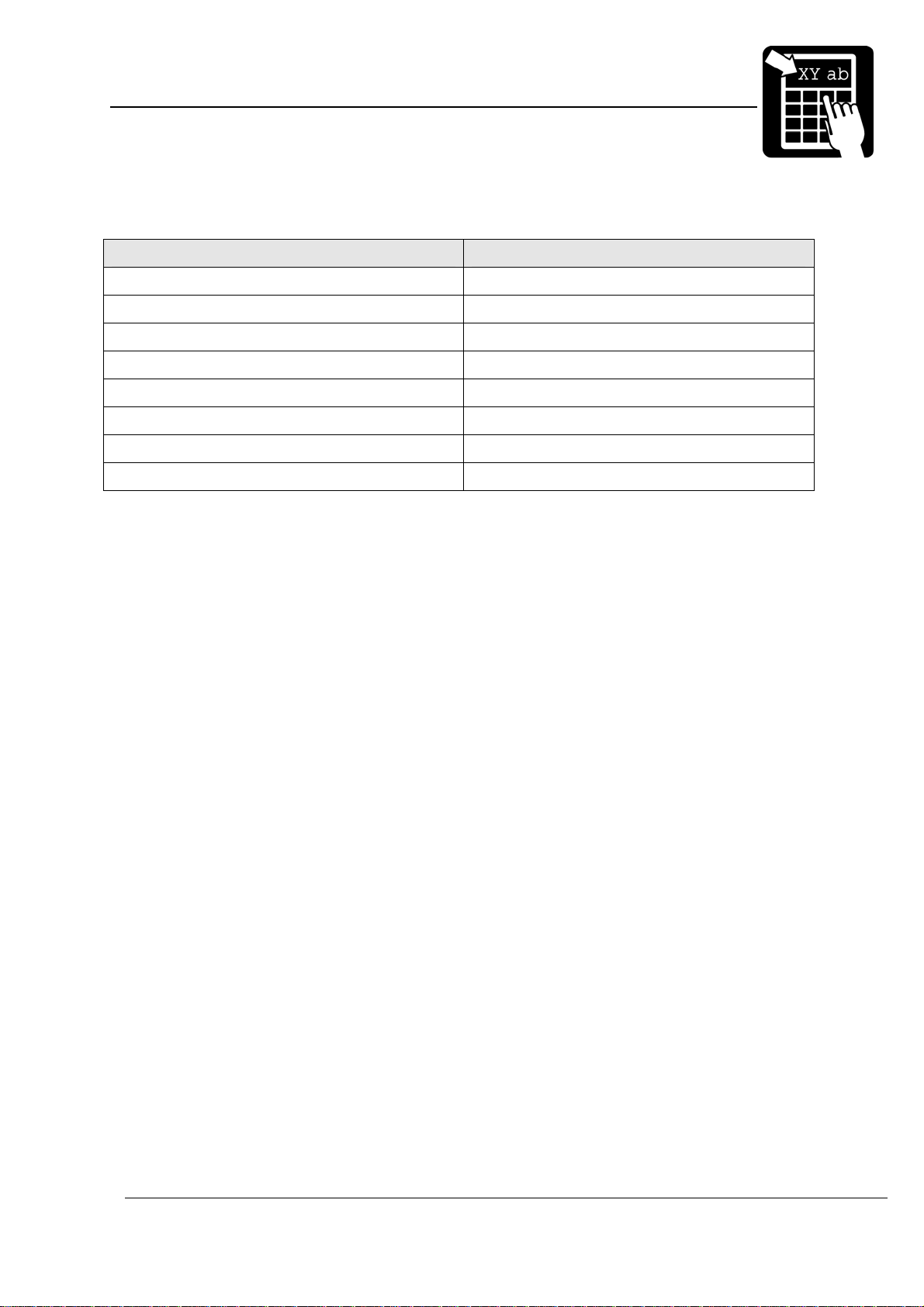

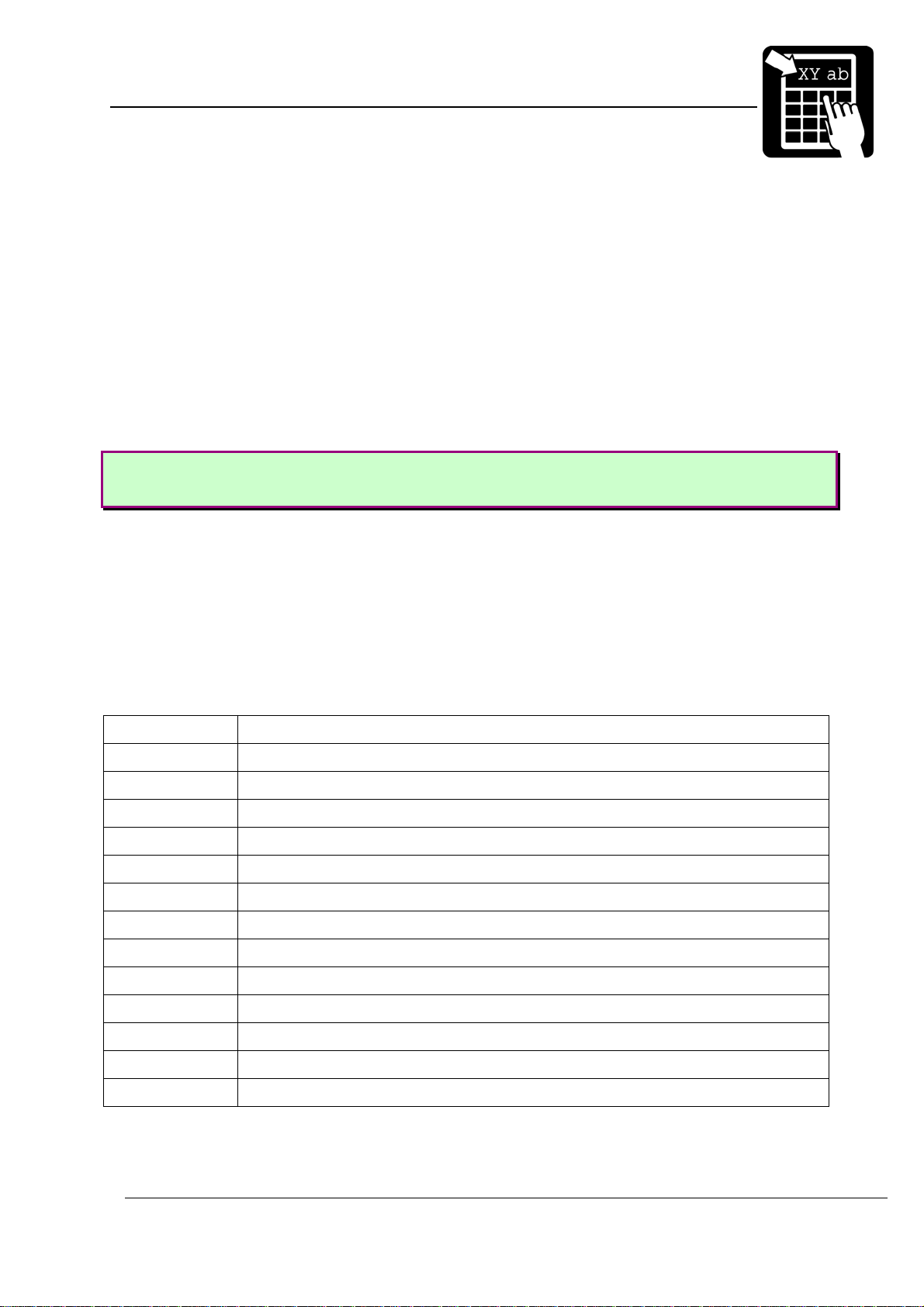

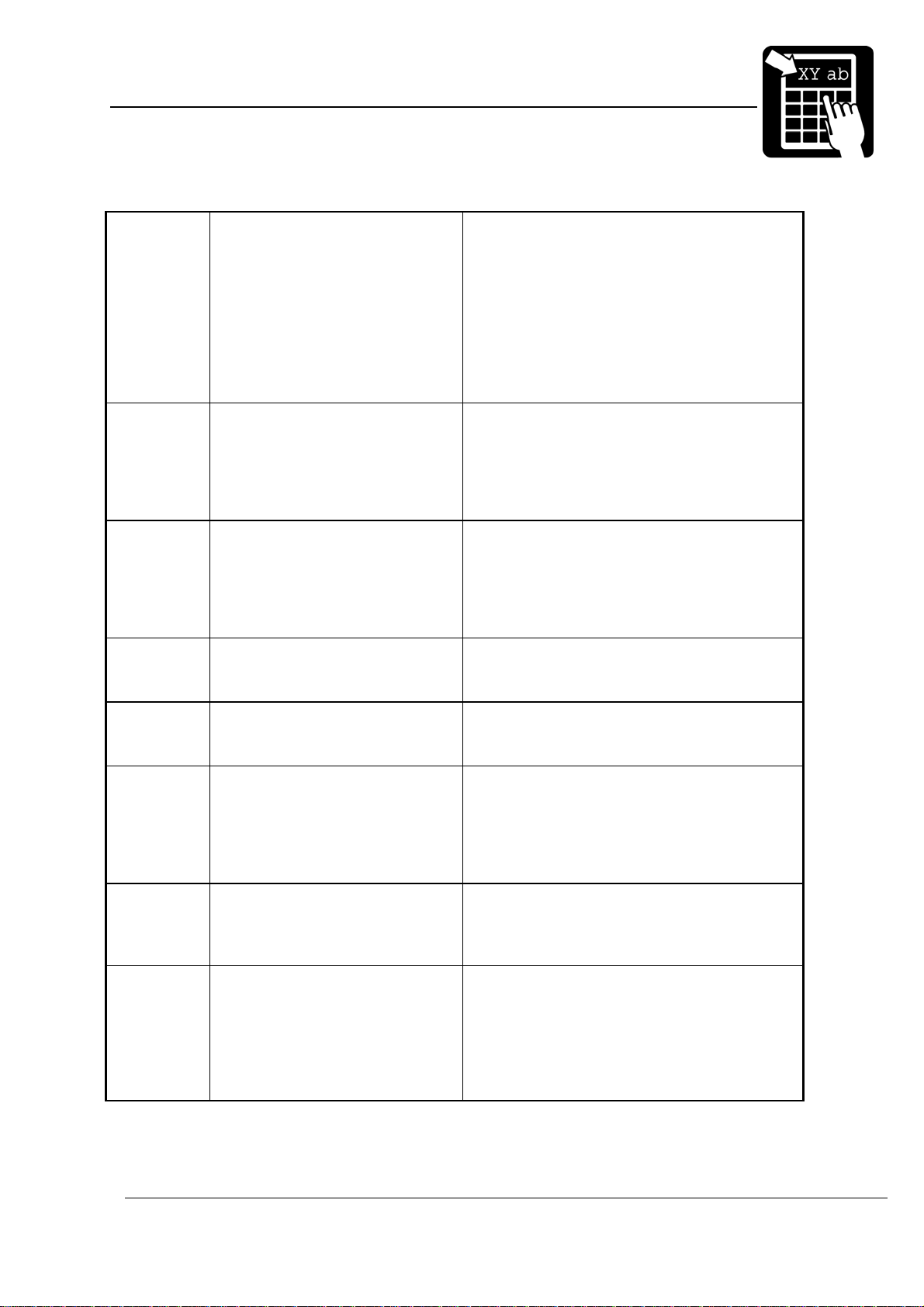

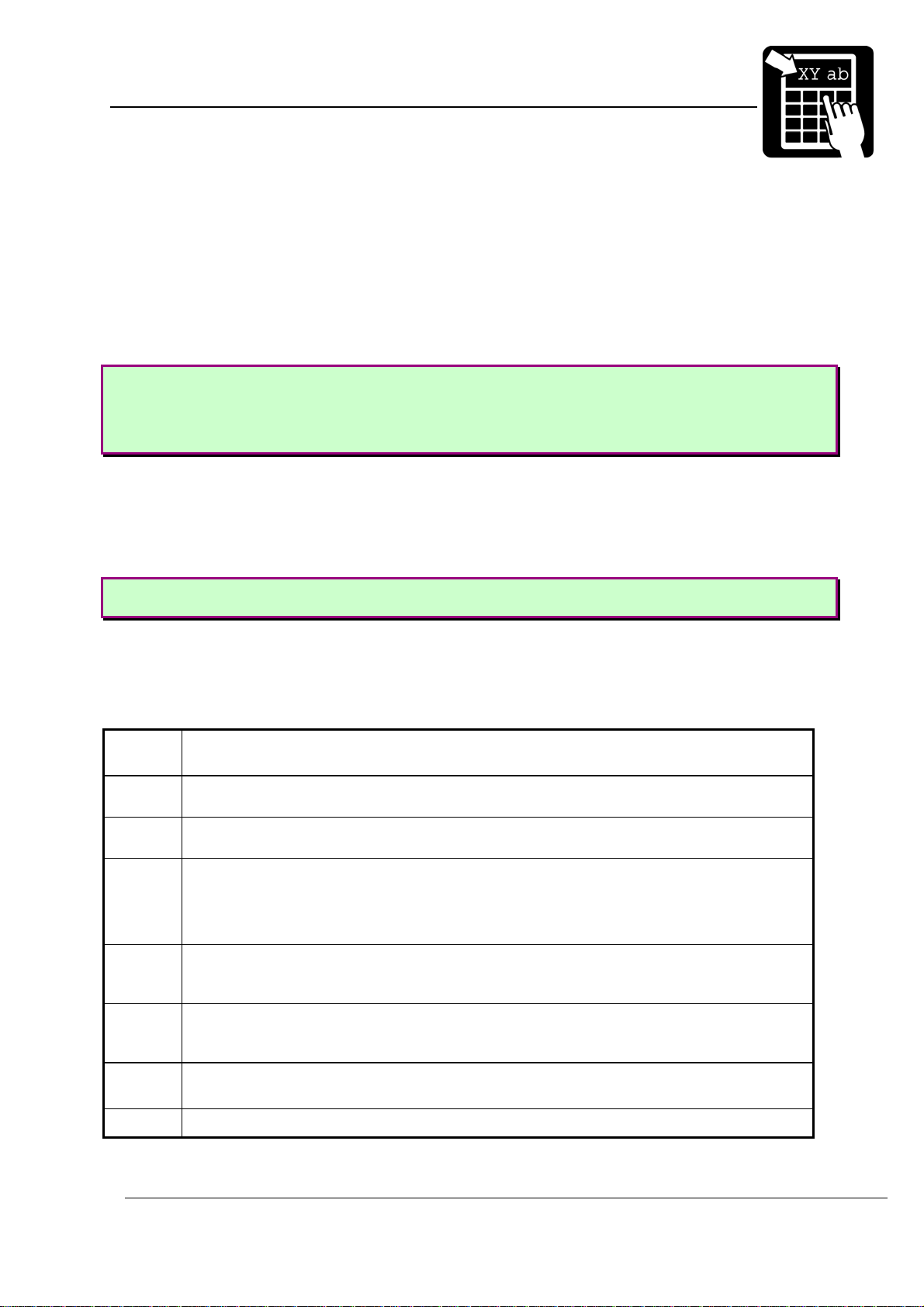

PCL typeface name PCL typeface number

Arial (emulated) 24459

Arial Italic (emulated) 24460

Arial Bold (emulated) 24461

Arial Bold Italic (emulated) 24462

Times New Roman (emulated) 24455

Times New Roman Italic (emulated) 24456

Times New Roman Bold (emulated) 24457

Times New Roman Bold Italic (emulated) 24458

Page 9

Page 14

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Bitmap text field (deprecated)

Bitmap text fields are deprecated. This section is kept for backward compatibility reasons.

Use scalable fonts instead.

Syntax

!F T <u> <b> <p> <a> <h> <w> <f> <”text”>

Note! Parameters enclosed in <> are required and parameters enclosed in [] are

optional.

The parameters have the following meanings:

<u> Defines the direction of printing as the ‘up’ direction of the printed characters. One

upper-case character (N, E, S, or W).

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h> The height expansion of the characters, 1 – 16.

<w> The width expansion of the characters, 1 – 16.

<f> The logical number of the font to be used for printing, 1 – 7.

<text>

The baseline of the field, in

1

The position, in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C = the field is centered around p.

Specifies the text to be printed. The text must be enclosed in double quotes (

/10 mm

1

/10 mm.

Bitmap font name Bitmap font number

7x9-dot bold 1

hv18r 2

15-dot bold 3

9-dot 4

").

19-dot bold x 18 5

hc42c 6

g19 x 12 7

Page 10

Page 15

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

The text to be printed

The text parameter can contain both fixed text and references to variable information that

changes after each print cycle.

Fixed text

Fixed text is entered with the keyboard with som exceptions.

%, “ and \ are used for different commands. They must therefore be entered twice to get

them printed.

To specify characters not available from the keyboard, either a national character escape

sequence ‘\x’ or a Unicode escape sequence ‘\u’ can be used.

Examples:

To print ‘Å’, type the sequence \xc5 (for code page 1252)

To print the Euro symbol ‘€’, type the sequence \u20ac.

Variable information

A variable text reference has the form %<n>V, where n is the number of the variable.

Counters

A counter reference has the form %<n>C where n is the number of the counter.

Date and time

Date and time can be retrieved from the internal real-time clock. The date and time format

is programmed by combining the codes below.

%H expands to the hour count (one or two digits) (24-hour clock).

%h expands to the hour count (one or two digits) (12-hour clock).

%M expands to the minute count (two digits).

%S expands to the seconds count (two digits).

%J expands to "AM" or "PM" depending on the hours.

%j expands to "a.m." or "p.m." depending on the hours.

%Y expands to the year (two digits).

%y expands to the year (four digits).

%N expands to the month (two digits).

%D expands to the day of the month (two digits).

%K Julian date (three digits).

%W Week of the year (two digits).

%XA Month (one character, ‘A’ to ‘L’).

%XW Weekday (one digit).

Page 11

Page 16

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

The date symbols can be defined with an offset for best-before dates. The offset value is

inserted between the ‘%’ character and the date symbol. The offset value can be either in days

or in months:

Best-before date

Today’s date in the examples below is assumed to be the 31 of January 1998 if nothing

else is specified.

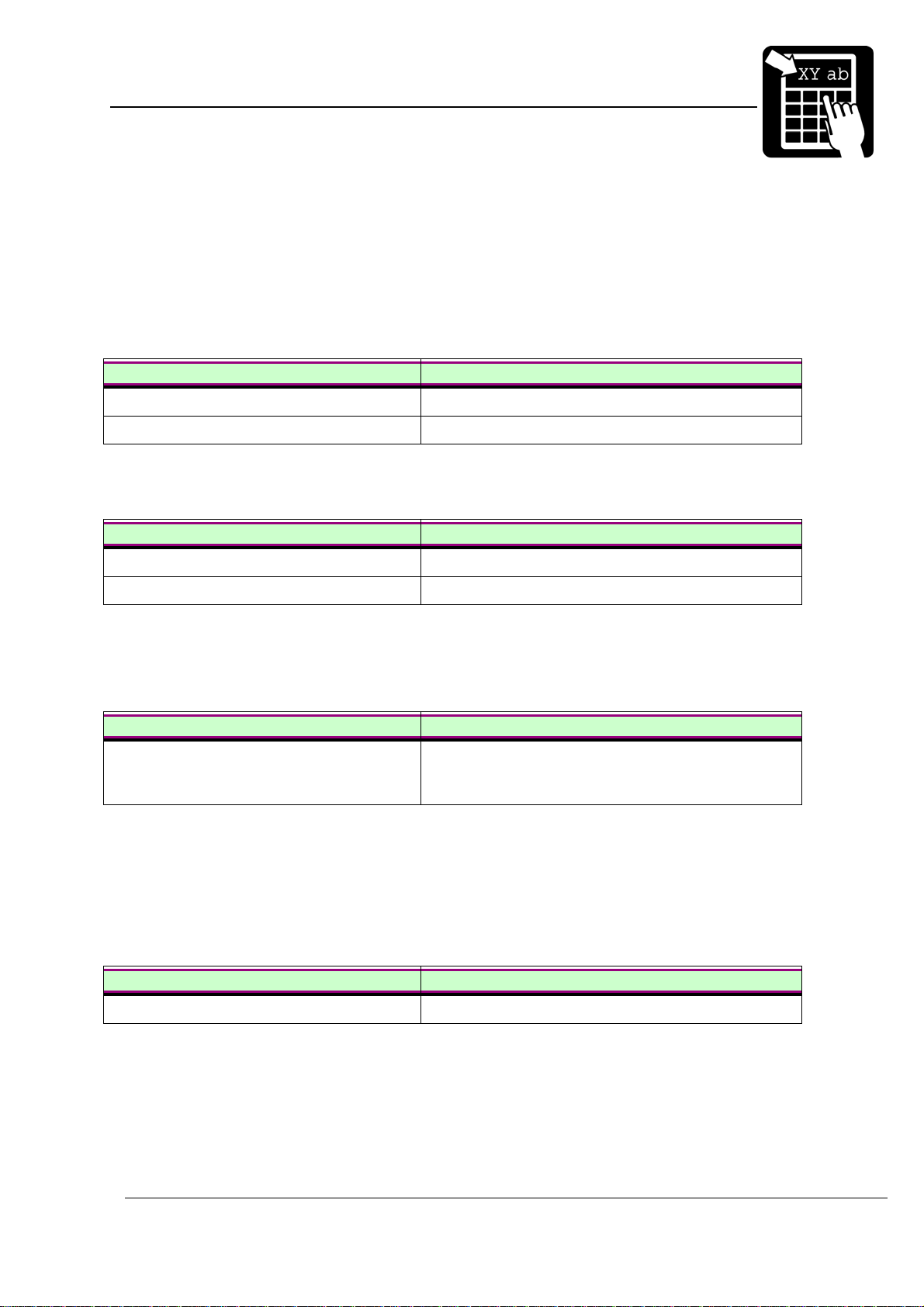

Input Output

%d10D/%d10N/%d10y 10/02/1998 (ten days best-before date)

%m1y-%m1N 1998-02 (one month best-before date)

The offset value may be a variable. If variable one is 30 and variable two is 12, then the

following examples will give the result:

Input Output

%d%1VD/%d%1VN/%d%1Vy 02/03/1998 (30 days best-before date)

%m%2Vy-%m%2VN 1999-01 (12 months best-before date)

It is possible to use the same best-before date even if the actual date changes and only

update it on a monthly basis. This is accomplished by the use of parameter 185, which

specifies what day in the month to update the best-before date. The syntax of the label data

does not need to be changed. See the following example where parameter 185 is set to ‘15’:

Input Output

%d10D/%d10N/%d10y 25/01/1998 (i.e. calculated from the 15th of

January even though today’s date is 31

January)

st

of

When today’s date reaches the 15

th

of February the output would be 25/02/1998, until 15th

of Mars where it would be 25/03/1998 and so on.

Another feature that can be automated is month truncation. If the calculated best-before

date exceeds a certain day in the calculated month, the resulting best-before date will be

rounded to the first of next month. The truncation day is specified by setting parameter 186.

See the following example where parameter 186 is set to ‘20’:

Input Output

%d10D/%d10N/%d10y 01/02/1998

Note! Earlier versions of Labelpoint did not support best-before dates, week numbers,

julian date, week day. Some programs, like Viewpoint, used a similar syntax internally,

which was converted to static text before sent to the printer.

Page 12

Page 17

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Check digits

Three different checksum types can be inserted in the textfield, EAN/UPC, Code39 and

UPU. For usage, se table below.

%Z EAN/UPC checksum. If the characters %Z are inserted in the text they will

be replaced by a 3:1 weighted modulo-10 check digit.

%zC Code39 checksum. If the characters %zC are inserted in the text, they will

be replaced by weighted modulo-43 check digit, which is calculated on the

preceding code39 characters.

%zP UPU checksum. If the characters %zP are inserted in the text, they will be

replaced by specially weighted modulo-11 check digit, which is calculated

on the preceding 8 digits.

Line breaks

The text to print may include line breaks (carriage return characters) which cause a new

field to be automatically generated at a standard distance below the previous field. This is a

convenient shorthand method when entering a number of text lines that are to be printed in the

same font.

Example:

!F T N 100 100 L 12 0 94021 “Printer

SÄTERIGATAN 20

S-417 64 GÖTEBORG, Sweden”

Note! If a % or " character is to be printed it must be entered twice (%% or ""), to

distinguish it from a % character marking a reference, or the " that terminates the text to

print.

Reverse video

Text can be printed in reverse video. This means that the text will be printed with a white

font on a black background. The black background square will extend one half character at the

sides of the text and extend up to the maximum ascender and down to the maximum

descender of the font. It is also possible to change the size of the background square in

percent, from 2-999(%) of its original size, which is the described scenario above.

The command to enable/disable reverse video mode is

enable and 0 to disable. To change the background square n can be set to a value between 2

and 999.

Example

!C

!F T N 100 100 L 24 0 92500 “Normal Video”

!Y162 1 // Turn on reverse video mode

!F T N 200 100 L 24 0 92500 “Reverse Video”

!Y162 200 // Turn on reverse video mode and set background // square to

!Y162 <n>, where n is set to 1 to

Page 13

Page 18

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

200%

!Y162 0 // Turn off reverse video mode

!P

Page 14

Page 19

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Defining a barcode field

This section describes how to create and select barcodes to be printed.

Syntax

!F C <u> <b> <p> <a> <h> <w> <s> [d] <”text”>

The parameters have the following meaning:

<u> Defines the direction of printing as the ‘up’ direction of the printed character.

One upper-case character (N, E, S, or W).

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h>

<w> The width expansion of the bars.

<s> The bar code symbology to be used. This parameter is a number according to

[d] Optional parameter. Specifies the maximum allowed displacement in east-west

<”text”> Specifies the text to be printed. See ‘Defining a text field’ above.

The baseline of the field in

1

The position in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C = the field is centred around p.

The height of the bars of the code in

table 1.

direction when defining a north- or south oriented barcode field. The

displacement is specified in

head diagnostics functionality, see ‘Print Head Diagnostics’ for more

information.

/10 mm.

1

/10 mm.

1

/10 mm.

1

/10 mm and only used in combination with print

Page 15

Page 20

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

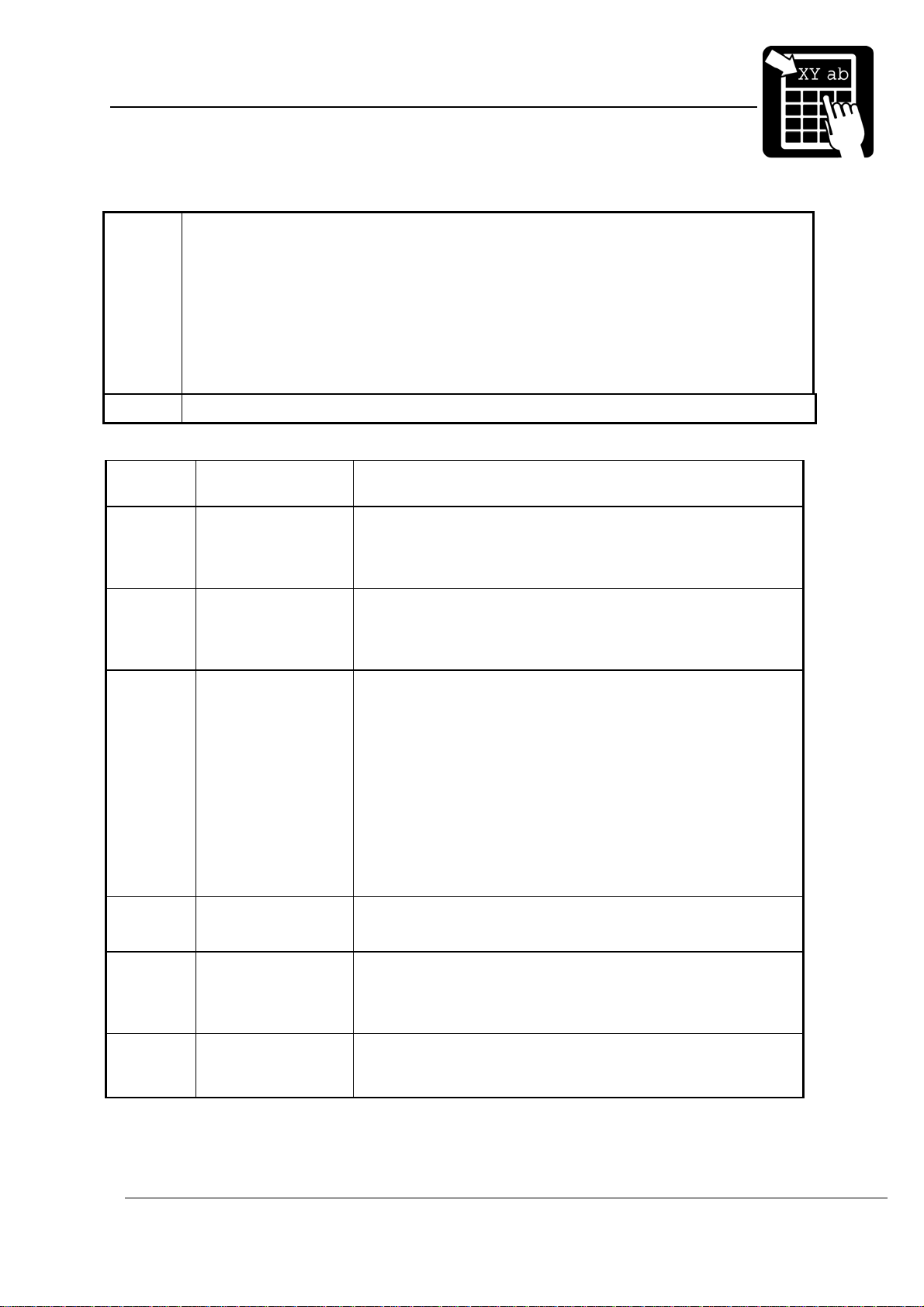

Barcode symbologies

Barcode symbology Barcode type, information

1

2

3

4

5

6

7

11

12

13

2 of 5 Interleaved – 2:1

2 of 5 Interleaved – 3:1

2 of 5 Interleaved – 5:2

2 of 5 Interleaved – 8:3

2 of 5 Interleaved – 13:5

2 of 5 Interleaved – 11:4

2 of 5 Interleaved – 7:3

Code 39 - 2:1

Code 39 - 3:1

Code 39 - 5:2

Numeric code, variable length. If a check

digit is required, it can be inserted with the

%Z command. The code must contain an

even number of digits. The printer will

therefore insert a leading 0 if necessary.

If the 2:1 ratio is used, a minimum width

expansion of 4 is required.

Alphanumeric code, variable length. If a

check digit is required, it can be inserted

with the %zC command (Code39 – modulo

43 checksum) or the %Z command

(EAN/UPC – modulo 10 checksum).

14

15

16

17

Code 39 - 8:3

Code 39 - 13:5

Code 39 - 11:4

Code 39 - 7:3

Page 16

Page 21

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

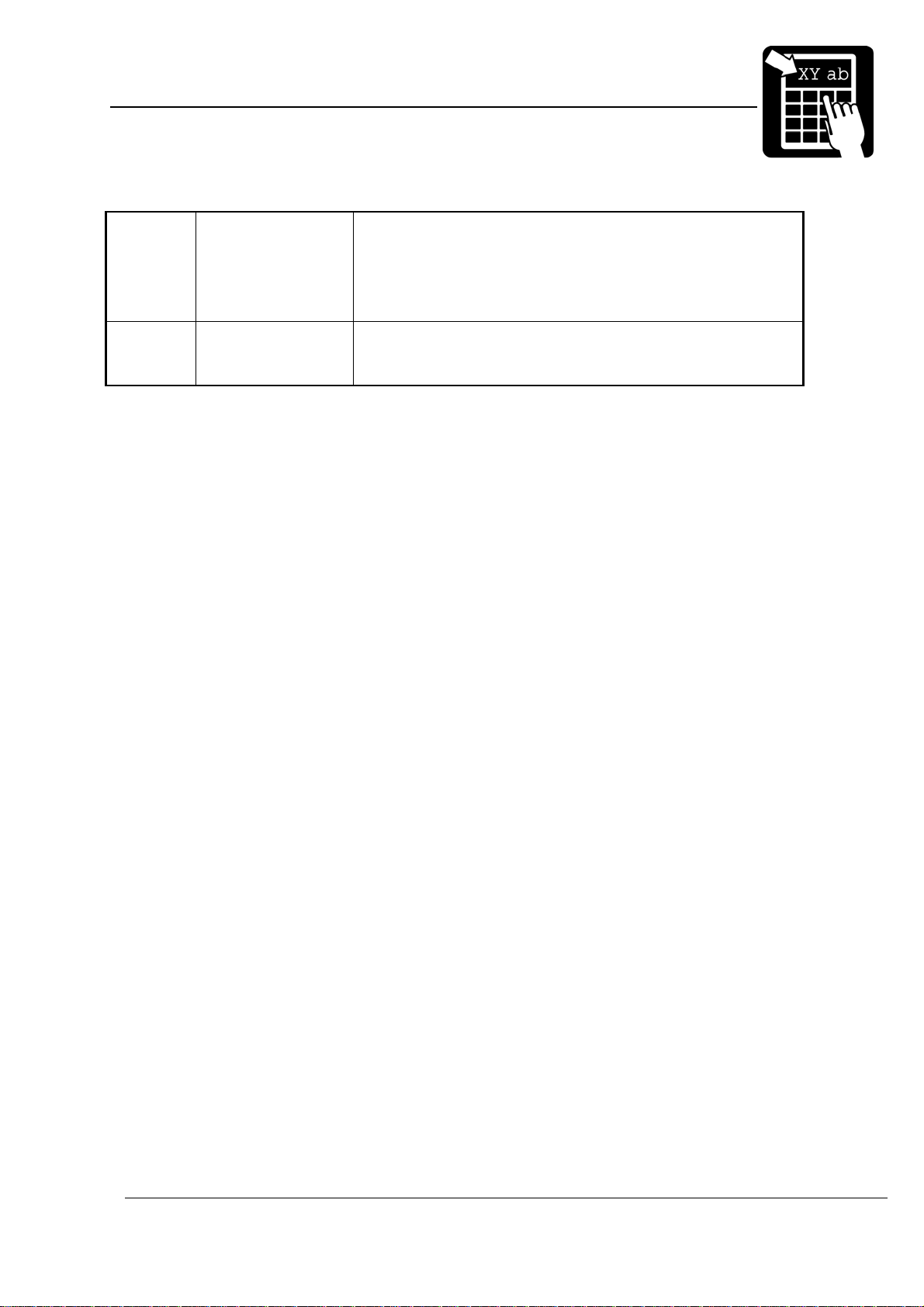

21

22

23

USS Codabar – 2:1

USS Codabar – 3:1

USS Codabar – 5:2

Numeric code, variable length. The start and

stop characters (‘A’, ‘B’, ‘C’ or ‘D’) must be

included in the input data.

24

25

26

27

31 UPC-A Numeric code. Requires 11 digits of input

32 EAN 13 Numeric code. Requires 12 digits of input

33 EAN 8 Numeric code. Requires 7 digits of input

34 UPC-E Numeric code. Requires 6 digits of input

USS Codabar – 8:3

USS Codabar – 13:5

USS Codabar – 11:4

USS Codabar – 7:3

data. The printer automatically appends the

check digit.

An EAN/UPC extension field could be

automatically appended by adding 2 or 5

digits to the input data.

data. The printer automatically appends the

check digit.

An EAN/UPC extension field could be

automatically appended by adding 2 or 5

digits to the input data.

data. The printer automatically appends the

check digit.

data. The printer automatically appends the

check digit.

35 EAN/UPC extension Numeric code. Requires 2 or 5 digits of

input data.

This code could maunally inserted with a

EAN/UPC extension barcode field, or

automatically inserted by adding 2 or 5

digits to a EAN 13 or UPC-A barcode field.

41 Code 128 All 128 ASCII characters plus control

characters can be encoded. The control

characters are explained further in - Code

128 function codes -. Variable length.

43 EAN 128 The same as Code 128, except that the

printer automatically inserts a FNC1 as the

first character. This is unique for the EAN

128 code.

(, ) and space characters are filtered in the

barcode, but printed in the human readable

text.

Page 17

Page 22

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

51

52

53

54

55

56

57

ITF 14 – 2:1

ITF 14 – 3:1

ITF 14 – 5:2

ITF 14 – 8:3

ITF 14 – 13:5

ITF 14 – 11:4

ITF 14 – 7:3

Numeric code, fixed length. Requires 13

digits of input data. The printer

automatically appends the check digit. A

frame is printed around the barcode.

The nominal wide-to-narrow ratio for ITF 14

is 5:2 and the nominal narrow bar width is

1,016 mm. At 8 dots/mm, the width

expansion for ITF 14 – 5:2 should then be

set to 4. At 12 dots/mm it should be set to 6.

The nominal height is 41,4 mm including the

frame.

64 RSS-14

RSS-14 Truncated

67 RSS Limited Numeric code. Encodes up to 14 digits of

68 RSS Expanded All 128 ASCII characters plus the FNC1

71

72

73

74

75

Code 2 of 5 – 2:1

Code 2 of 5 – 3:1

Code 2 of 5 – 5:2

Code 2 of 5 – 8:3

Code 2 of 5 – 13:5

Numeric code. Encodes up to 14 digits of

numerical data. By selecting height

expansion values to appropriate values,

RSS-14 and RSS-14 Truncated are used

respectively. See the RSS section for

appropriate values to distinguish between

the two codes.

numerical data. See the RSS section for

more information.

control character. Encodes up to 74 numeric

or 41 alphabetic characters. Variable length.

See the RSS section for more information. (,

) and space characters are filtered in the

barcode, but printed in the human readable

text.

Numeric code, variable length. Old version

of Interleaved 2 of 5. Only the bars carry

information. If a check digit is required, it

can be inserted with the %Z command.

If the 2:1 ratio is used, a minimum width

expansion of 4 is required.

76

77

Code 2 of 5 – 11:4

Code 2 of 5 – 7:3

The "2:1", "3:1", notation in the table defines the width ratio of the wide and narrow bar, in

dots. The width of all bars and spaces can be doubled, tripled, etc., by setting the

<width>

parameter in the field command to 2, 3, etc.

Note! Avoid using a width value of 1 when using 2:1 or 3:1 ratios. The resulting bars

will be too thin for most codes.

Page 18

Page 23

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Bar code interpretation

The printer will automatically print a human-readable text line below the bar code if it has

been configured to do so. (The command is described in section - Printer configuration -). This

can be done individually for each bar code in a label layout. The command to enable humanreadable text is:

!Y42 1 and to disable: !Y42 0

Example:

!Y42 0

!F C S 50 800 L 100 3 1 “%1V“

!Y42 1

!F C S 200 800 L 100 3 33 “%1V“

Defining a 2D barcode field

A two-dimensional (2D) code is normally a matrix code or a stacked barcode. Labelpoint

supports a number of 2D codes.

Syntax

!F C <u> <b> <p> <a> <h> <w> <s> [o] <“text“>

Note! Parameters enclosed in <> are required and parameters enclosed in [ ] are

optional.

The parameters have the following meaning:

<u> Defines the direction of printing as the "up" direction of the printed character. One

upper-case character (N, E, S, or W).

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h>

<w>

The baseline of the field, in

1

The position, in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C = the field is centred around p.

The height of the bars of the code in

16.

The width of the bars of the code in

16.

/10 mm

1

/10 mm.

1

/10 mm, or height expansion of the pixels, 1 –

1

/10 mm, orwidth expansion of the pixels, 1 –

<s> The bar code symbology to be used. This parameter is a number according to table

2.

[o] Optional parameter with different function depending on the code symbology:

Page 19

Page 24

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

For Royal Mail 4-State Customer Code and the KIX code:

Width adjustment. See 2D barcode Symbologies. A value of 50 % to 200 % is

allowed. 100 % is the default and means that the bar width and space widths are

the same.

For MaxiCode:

An optional two digit number used to define structured appends, where the first

digit specifies the symbol number, and the second digit specifies the total number

of symbols.

<”text”> Specifies the text to be printed. See ‘Defining a text field’ above.

2D barcode symbologies

61 PDF417 Stacked barcode. Arbitrary binary data, variable length.

More described in – PDF417 -.

81 USD-5 dot code Matrix code. Numeric data, variable length. 5 to 20 digits.

The printer automatically appends the check digit. The

USD-5 code always has the same size, so <h> and <w>

should be set to 1.

83 LEB code Stacked barcode. Alpha-numeric code, variable length. <w>

is the expansion factor. <w> = 1 means a dot width of 0.25

mm. <h> is not currently used and should be set to the

same value as <w>.

91 Royal Mail 4-State

Customer Code

(RM4SCC)

92 KIX barcode The same as Royal Mail 4-State code, except that no start,

101 QR Code, Model 1 Matrix code. Arbitrary binary data, variable length. More

102 QR Code, Model 2 Matrix code. Arbitrary binary data, variable length. More

‘Stacked’ barcode. The character set includes numeric

characters and upper-case (A-Z) characters. Start, stop and

checksum characters are automatically generated.

The height (<h>) may be from 4.22 mm to 5.84 mm. <w> is

the width including both bar and space. 20 - 24 bars per

25.4 mm is allowed. The bar width may be 0.38 - 0.63 mm.

Example:

!F C N 100 100 L 50 12 91 “1234567”

will give a 5 mm high code with 0.60 mm bar width and with

21 bars in 25.4 mm.

stop or checksum characters are generated.

described in – QR Code -. Model 1 is included for

backwards compatibility reasons. All new applications

should use Model 2.

described in – QR Code -. New version of the QR Code.

Should be used in new applications.

Page 20

Page 25

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

121

122

123

124

131 Data matrix Matrix code. Arbitrary binary data. A maximum of 3116

MaxiCode mode 2

MaxiCode mode 3

MaxiCode mode 4

MaxiCode mode 5

Table 2 – 2D code symbologies in Labelpoint

Matrix code developed by UPS (United Parcel Service)

which can encode about 100 characters of data in an area

of 28x27 mm. Modes 2 and 3 are optimized for encoding

postal address information. Mode 4 is used for encoding

arbitrary data. Mode 5 employs enhanced error correction.

numeric, 2335 alphanumeric characters or 1556 bytes

binary data can be coded.

Page 21

Page 26

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Code 128

Code 128 encodes the full ASCII character set, plus four special non-ASCII characters

(function codes) called FNC1, FNC2, FNC3, and FNC4. ASCII control characters and function

codes must be sent to the printer using escape sequences. An escape sequence consists of

the characters "??" followed by a third character.

To print a function code in the bar code send "??1" for FNC1, "??2" for FNC2, etc. To print

an ASCII control character (ASCII codes below 32

character corresponding to the desired control character. Any upper or lower case character in

the ASCII range 40

Example:

"??J" or "??j" is interpreted as the line feed character.

to 7E16 (6410 to 12710) will be recognised.

16

) send "??" followed by the alphabetic

10

"??[" or "??{" is interpreted as the ESC character (ASCII 27 = 1B

yields a single '?' in the code. It is thus possible to encode two consecutive ?'s by sending

"????" to the printer. Escape sequences that do not fit any of the above alternatives are

ignored.

The example below shows the commands to define two bar codes. The FNC2 (Message

Append) function character is included in the first code. The data for the second code is

terminated with a carriage return character. (FNC2 instructs the reader to concatenate the

present code with the next code scanned and transmit the data from both codes in one

message.)

Example:

!F C S 400 1000 L 100 2 41 "??2Printer"

!F C S 200 1000 L 100 2 41 "Printer??M"

). The sequence "???"

16

Page 22

Page 27

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

RSS

The RSS, Reduced Space Symbology, family of symbols is used for space-constrained

applications. Currently supported variations include RSS-14, RSS-14 Truncated, RSS Limited

and RSS Expanded. Accompanying 2D Composite Components are currently not supported.

Note that the settings for width/height ratio of the RSS barcodes will differ between 200dpi and

300dpi layouts. The width/height ratio for respective RSS symblology is specified in the

following sections.

RSS-14

RSS-14 is a linear symbology that supports omni-directional scanning. It encodes full 14digit EAN/UCC Item Identification. RSS-14 is dimensioned as 96X wide by 33X high. X equals

"X" dimension or narrow bar width. The check-digit is added by the printer.

Example:

!F C S 200 1000 L 200 4 64 "1541215000015"

RSS-14 Truncated

This variant of RSS is identical to RSS-14 but allows truncation of the height to 13X. The

normal RSS-14 symbol has a height of 33X. X equals "X" dimension or narrow bar width. The

check-digit is added by the printer.

Example:

!F C S 200 1000 L 80 4 64 "1541215000015"

RSS Limited

RSS Limited is a linear symbology that encodes the same data as defined for RSS-14. The

encoding process is though different and limits the values assigned for Indicator digits to 1 or

0. The result is an RSS code that can be printed very small. RSS Limited is dimensioned as

71X wide by 10X high. X equals "X" dimension or narrow bar width. X equals "X" dimension or

narrow bar width. The check-digit is added by the printer.

Example:

!F C S 200 1000 L 50 4 67 "1541215000015"

RSS Expanded

RSS Expanded is a variable length, linear symbology that is encoded differently than RSS-

14. This symbology allows up to 74 numeric or 41 alphabetic characters. The FNC1 EAN/UCC

Function Character is also supported by entering “#”. Apart from encoding EAN/UCC Item

Identification, RSS Expanded also encodes all EAN/UCC Application Identifier Element

Strings. Width dimension is variable.

Example:

!F C S 200 1000 L 100 4 68 "1045566#17040301"

Page 23

Page 28

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

MaxiCode

MaxiCode is a two-dimensional symbology built up by an array of hexagons surrounding a

central recognition pattern (bullseye). Reed-Solomon error correction is used to ensure

integrity of the encoded data.

Structured Carrier Message

The primary message in modes 2 and 3 contains the following formatted data: Ship to

Postal Code, Ship to Country Code ISO 3166 3-digit code, Class of Service.

Example:

!F C S 100 1000 L 1 1 122 "[)>\x1e Message Header

01\x1d96 Transportation Data Format Header

SE41764\x1d Postal Code

752\x1d Country Code

001\x1d Class of Service

1Z12345677\x1d Tracking Number

UPSN\x1d Standard Carrier Alpha Code

1234556\x1d UPS Account Number

089\x1d Julian Day of Collection

1234\x1d Shipment ID Number

1/1\x1d Package n/x

10\x1d Package Weight

Y\x1d Address Validation

SÄTERIGATAN 20\x1d Ship To Street Address

GÖTEBORG\x1d Ship To City

N/A\x1e Ship To State

\x04" End of Transmission

Further detailed information can be retrieved from

http://www.maxicode.com/maxicode/MaxicodeGuide.html

Modes

Mode 2 and 3: Structured Carrier Message – The first 20 codewords encodes the

Structured Carrier Message. Use mode 2 when the postal code is numeric and mode 3 when

the postal code is alphanumeric.

Example, a mode 2 and mode 3 MaxiCode:

!F C S 100 1000 L 1 1 121 "[)>\x1e01\x1d9641764\x1d752\x1d001\x1e\x04"

!F C S 400 1000 L 1 1 122 "[)>\x1e01\x1d96SE41764\x1d752\x1d001\x1e\x04"

Mode 4: Standard Symbol – The symbol provides 93 6-bit codeword for data encodation.

Example:

!F C S 100 1000 L 1 1 123 "MaxiCode Mode 4"

Mode 5: Enhanced Error Correction – The symbol provides 77 6-bit codewords for data

encodation.

Example:

!F C S 100 1000 L 1 1 124 "MaxiCode Mode 5"

Page 24

Page 29

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Escape Sequences

Nonwritable characters can be sent with the standard Labelpoint escape sequence \x<hh>.

Note that if either ASCII 0A hex or ASCII 0D hex shall be part of the data stream, the \0a or

\0d style escape sequence must be used. Otherwise they are treated as line breaks and

removed from the data stream.

Data encodation

The MaxiCode encodes data in six-bit codewords. Hence, in order to encode the full ASCII

set, shift symbols must be used to switch between different character sets. This means that

fewer symbols can be used to encode the real data. This must be considered so that data is

not truncated.

If the data consist of more than nine consecutive numbers, they are compacted into six

codewords. This means that for a mode 4 symbol, a maximum of 138 digits can be encoded.

Structured Append

It is possible to connect several MaxiCode symbols in order to encode larger quantities of

data through the use of structured append. To specify that a symbol is part of a structured

append, use the [o] parameter. The first digit specifies the symbol number, and the second

digit specifies the total number of symbols. There can be a maximum of eight connected

symbols.

Example:

!F C S 100 1000 L 1 1 123 12 "MaxiCode Mode 4 Symbol 1 of 2"

Page 25

Page 30

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Code PDF417

PDF417 is a two-dimensional bar code with built-in security. A PDF417 symbol can contain

arbitrary binary data. The following rules must be followed when entering the data for a

PDF417 code.

1. Control characters (ASCII 00 - 1F hex and 7F hex) must be sent as escape

sequences.

2. The double quote " (ASCII 22 hex) serves as terminator for the input data and must

be sent as an escape sequence if it is to be encoded in the symbol.

3. The back slash \ (ASCII 5C hex) is used as escape character and must be sent as

an escape sequence if it is to be encoded in the symbol.

All other characters, not mentioned in 1, 2, and 3, can be sent as ordinary data.

Any character can be sent as an escape sequence. An escape sequence consists of the

escape character followed by a two-digit hexadecimal value. The escape character is \ (ASCII

5C hex). For example, to encode a CR. (carriage return, ASCII 0D hex) in the code, send the

escape sequence \0D.

The escape character (\) and the double quote (") must be sent as escape sequences if they

are to be encoded (ie. \5C and \22, resp).

The data to be printed must be enclosed within double quotes ("). The lines of data may be

256 characters long maximum. A CR. or a CR. LF must be sent to break the lines. (This does

not affect the data in the code, the line breaks serve merely to limit the line length.)

To encode the string

Printer prints

PDF417

the following command could be sent to the printer.

Example:

!F C N 400 200 L 6 2 61 "Printer prints\0DPDF417\0D"

To improve readability when looking at program listings, etc. it could also be sent as

follows:

!F C N 400 200 L 6 2 61 "

Printer prints\0D

PDF417\0D"

Security level

PDF417 allows the user to tune the amount of error correction added to the code to suit a

specific application. This is called security level and can be set to a value between 0 and 8. 0

is the lowest level which provides error detection only, 8 is the highest level. The default in the

printer is security level 4.

The command to set the security level is

Page 26

Page 31

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

!V61 <n>

where <n> is the desired security level.

For example, to set the security level to 6, enter the command

!V61 6

Page 27

Page 32

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

QR Code

The QR Code has two main options: Correction level and masking pattern. They are set

with an escape sequence in the data string.

Correction level

The correction level is set with the sequence

\L<x>

where <x> is the desired level:

L High density Level

M Standard Level

Q High Reliability Level

H Ultra High Reliability Level

Masking pattern

The masking pattern is usually automatically selected, but can be set manually. The escape

sequence is

\M<n>

where <n> is the desired masking pattern 0 – 7 or 8 which means no masking. If omitted,

the most optimal masking pattern is automatically selected.

Other escape sequences

See the section about PDF417 for information on how to encode non-printable characters.

Example:

!F C S 100 1000 L 1 1 102 "\LQ\M3 QR Code – High Reliability, Pattern 3"

Page 28

Page 33

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Defining a line/box field

A line/box field appears as a black area on the label or as a frame window. Diagonal lines

can be made using Syntax II.

Syntax I !F B <u> <b> <p> <a> <h> <w> <b>

Syntax II !F B D <y0> <x0> <lw> <y1> <x1>

Note! For diagonal lines must x0 > x1 and y0 > y1

<u> Defines the direction of printing as the "up" direction of the printed character.

One upper-case character (N, E, S, or W). Since there is no inherent ‘up’ or ‘down’

in a black box this parameter is just a convenience which allows lines and boxes

to be specified the same way text and bar code fields are specified.

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h>

<w>

<b>

<y0> Source y-coordinate.

<x0> Source x-coordinate.

<lw>

<y1> Destination y-coordinate.

<x1> Destination x-coordinate.

The baseline of the field, in

1

The position, in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C =

the field is centered around p.

The height of the box or width of the line, in

The width of the box or length of the line, in

The width of the border of a window frame, in

or set to 0 a filled (solid) box will be created.

Line width, in

/10 mm

1

/10 mm.

1

/10 mm.

1

/10 mm

1

/10 mm

1

/10 mm. If this parameter is omitted

Page 29

Page 34

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Defining a graphics field

A graphics field is linked to a graphics file. The graphics file may be downloaded after the

graphics field has been defined.

Syntax !F G <u> <b> <p> <a> <h> <w> <"name">

The parameters have the following meaning:

<u> Defines the direction of printing as the "up" direction of the printed character.

One upper-case character (N, E, S, or W).

<b>

<p>

<a> The alignment relative to the position. One upper-case character.

<h> The height expansion of the original graphics file, 1 – 16.

<w> The width expansion of the original graphics file, 1 – 16.

<name> The name of the graphics file to be printed. The name must be enclosed in double

The baseline of the field in

1

The position, in

L = left end of the field aligned at p.

R = right end of the field aligned at p.

C = the field is centered around p.

quotes (

") and can also contain variables. See examples below.

/10 mm

1

/10 mm.

For information on how to download graphics files, see section ‘File System’.

Examples:

!F G N 300 500 C 1 1 "Printer"

This command creates a field linked to the graphics file named PRINTER.G.

File name containing variable information.

!F G N 300 500 C 1 1 "FILE%1V"

If variable 1 is ‘10’, then this command creates a field linked to the

graphics file named FILE10.G.

Page 30

Page 35

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

Variable information in text and bar code fields

Lines that are not commands (i. e. lines that do not begin with the command character) are

assumed to be variable information (text). The printer counts the number of variable text lines

received, and each line is assigned to the next variable text. The first line of text is copied to

variable text no. 1, the next line to text no. 2, etc. The variables are cleared and the count is

reset to zero when either the !C or the !R command is received.

Copies of the last label printed, will be printed if the print button is pressed before the next

print command is received. (Clearing the label format or the variable data prevents printing

copies.)

Example 1:

!C

!F T N 100 100 L 10 0 94021 "Type: %1V

Serial no. %1C

Date: %D/%N/%y"

!F C N 370 100 L 120 3 1 "%2V"

!F T N 410 100 L 10 0 94023 "PART NO: %2V"

THERMAL PRINTER (BASIC)

123456

!P

THERMAL PRINTER (EXTENDED)

987654

!P

The resulting printout of this example would contain the current date and current value of

counter 1 and might look as shown below. Note how the date print is created and the empty

line between the "Type" and "Serial no" lines. Variable 2 is referenced twice, in the bar code

and the text below the code.

First printout: Second printout:

Note! Only the variable information has to be sent for each label to be printed, once the

print format has been defined.

Changing a single variable

Page 31

Page 36

PROGRAMMER’S REFERENCE MANUAL

Label layout definition commands

The command !W<n> "<data>" allows text to be entered into one specific variable. The

string <data> is assigned to the variable specified by <n>. All other variables remain

unchanged. If the variable does not exist, it will be created.

Clearing variable information

The command !R deletes all the variable texts from memory. The next non-command line

will be copied to variable text no. 1, etc. This command is useful to remove any stray

information which may have been assigned to the variable texts. It also clears the print buffer

and so prevents making copies of the last label printed.

Clearing the layout

The command !C clears the print format, i. e. removes all the fields defined. It also clears

all variables. This command is used to delete the current print format before defining a new

layout and whenever it is desirable to reset the printer to a known idle state.

Send the

preceding the command character may make the command look like a variable text line.

!C command twice when clearing the printer, since any stray characters

Print command

The command !P<n> prints out <n> copies of the current label layout. If <n> is

omitted or is not a positive number it defaults to 1.

The counters are updated after each label printed. If the time or date is printed, it is updated

for each label. Copies of the last label can be printed by pressing the print button, until the !R

or !C command is received. Such copies are identical to the last label printed, i. e. the

date/time and up-down counters are not updated.

Dormant print (or trigged printkey)

This printmode requires parameter 67, printkey mode, to be set to dormant print. When set,

the printkey can be used to trig a new printout, updating counters, time and date. There are

two dormant print modes; limited and unlimited. Which mode to use depends on the print

command. If the !P command is used, a label or a batch of labels will be printed as normal, but

an unlimited number of new printouts can be made after this by repeatedly pressing the

printkey. By using

printouts are possible. After this a new layout must be loaded, or !P can be used to enter the

unlimited dormant print mode. Use service commands 93 and 39 to find out how many

dormant printouts that have been made or are remaining, respectively.

!p<n> no printout will be made until the printkey is pressed and only <n>

The dormant print mode is useful if the printer is to be used standalone to generate unique

printouts without having to be connected to a host after the layout is loaded and/or it is

important that only a specific amount of unique labels are to be printed, but not all at once.

Page 32

Page 37

PROGRAMMER’S REFERENCE MANUAL

Service commands

Status request commands

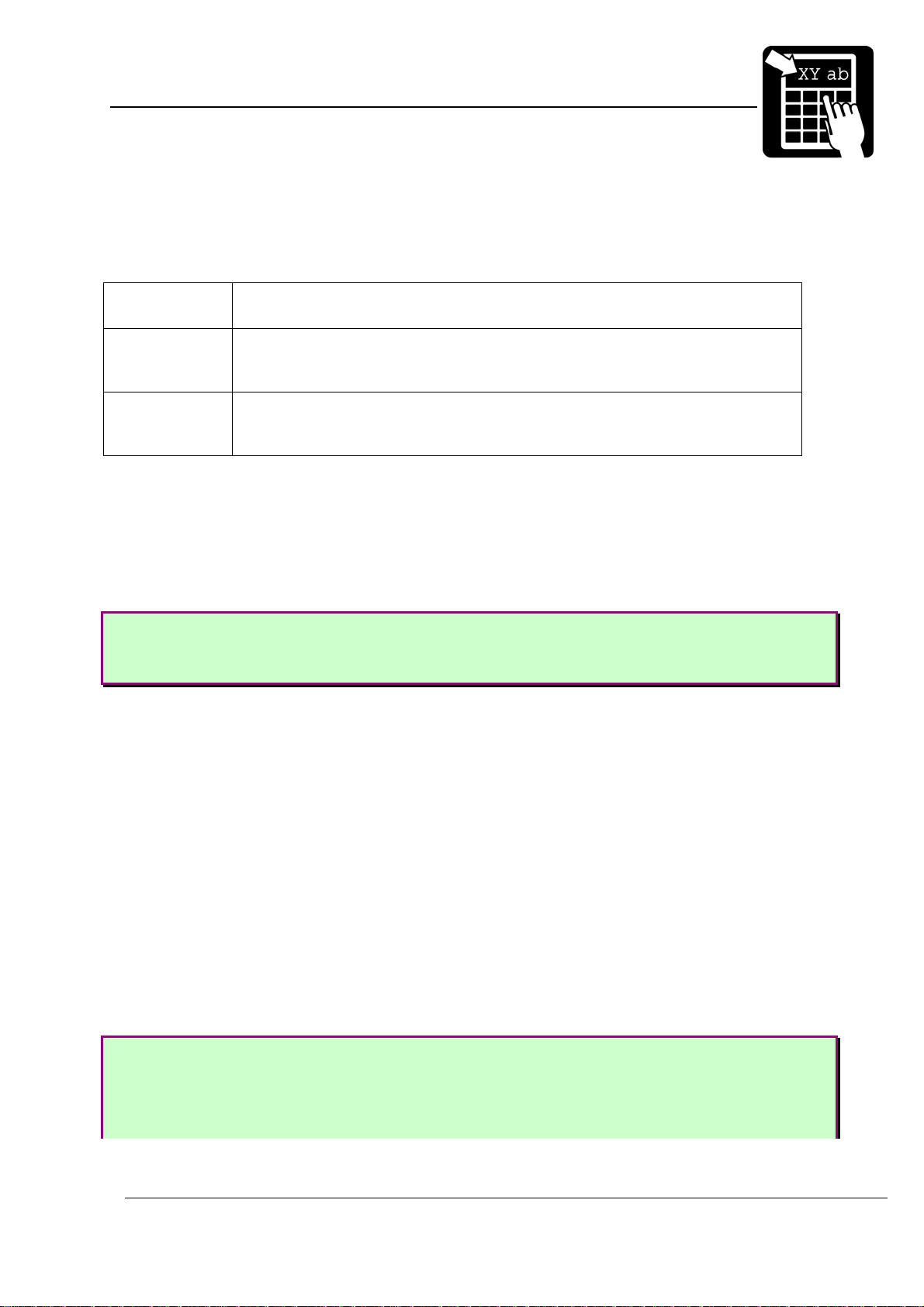

The status request command is !S<n> where n represents the number of the status

request. The printer responds with a string of 8 digits, followed by a carriage return character.

Each digit in the string is either

0 Ù Normal value (for error flags) or not available/not executed (for peripherals)

1 Ù Error value or abnormal condition (for error flags) or connected/executed (for per.)

Status request 1

0 or 1. The meaning of each digit in the status response is:

heap error

not used

not used

out of ribbon (TT models only)

no paper in paper sensor

printer restarted

label not removed (LTS)

out of paper

Out of paper

The printer has run out of paper. Operator intervention is necessary, as described below.

Label not removed (LTS)

‘1’ Ù Label has not been removed. The printer cannot continue to print until the label has

been taken.

Printer restarted

If this flag is set it means that the printer has been restarted since the last status 1 or status

4 requests. This bit is cleared by the status 1 or status 4 requests.

No paper in label sensor

This flag is set if there is currently no paper in the paper sensor. This can occur if there is

no paper in the printer or if a label gap happens to be in the paper sensor. If there is no

possibility of a label gap being positioned in the label sensor when the printer stops after a

print cycle this flag can provide additional security.

This flag is different from the paper out flag, since paper out is only detected during a paper

feed or print cycle. If the printer is switched off and then on, paper out is no longer flagged,

even if no paper has been loaded.

Page 33

Page 38

PROGRAMMER’S REFERENCE MANUAL

Service commands

Out of ribbon

The printer has run out of ribbon. Operator intervention is necessary, as described below.

Heap error

The heap (dynamic memory pool) is corrupt. This is a serious error which can not be

corrected. The only remedy is to power the printer off and on to restart the program.

Status request 2

layout outside label

not used

not used

last paper movement type

not used

cool down state

print incomplete

stopped on a label gap

Stopped on label gap

The last print or paper feed cycle stopped on a label gap, i. e. the paper is now

synchronised, if label stock is installed in the printer. If continuous stock is installed this flag will

never be set.

Print incomplete

The last print cycle was interrupted before printing was complete, either because a label

gap occurred or because the printer has run out of paper. This means that some information

may be missing from the printout.

Cool down state

When printing large batches using layouts with a large amount of blackness and/or the

printer is located in an environment with temperatures above room temperature, the system

temperature of the printer might after a while be too high to continue normal operation. If so,

the printer will enter a cool down state, which is indicated by this status flag. The LED will be

flashing with a red light and the internal fan will run at maximum speed until temperature has

decreased to operational level. Printing will then continue as normal, no sent information will

be lost.

Last paper movement type

This flag is set when the forward paper feed command is executed, i. e. a

with positive feed length. All other paper movements will reset the flag (by the print button or

on command from the host).

!K command

Page 34

Page 39

PROGRAMMER’S REFERENCE MANUAL

Service commands

This flag allows the host to detect when the operator has moved the paper by pressing the

print button. It is not safe to issue a reverse paper feed command when the paper is not in a

known position.

Layout outside label

This flag can be used to check if any part of the layout is outside the label. See parameter

178 and 179 for more information.

Status request 3

not used

label stock

not used

internal print button active

not used

operating parameters error

not used

not used

Operating parameters error

The printer configuration memory is corrupt. Use Service command !V3200 to reset all

parameters to their default state and then download the apropriate configuration file or use the

configuration menu to setup the printer.

Internal print button

This flag is

issued.

Label stock

The printer automatically detects the type of paper installed (labels or continuous). If label

stock is loaded, this flag will be

1 if the print button on the printer is pressed at the moment the status request is

1.

Page 35

Page 40

PROGRAMMER’S REFERENCE MANUAL

Service commands

Status request 4

not used

printer restarted

not used

internal print button active

head lifted

out of ribbon (TT models only)

label not removed (LTS)

out of paper

Status 4 assembles some of the most commonly needed status flags in one command.

Out of paper

Described above.

Label not removed (LTS)

Described above.

Out of ribbon

Described above.

Head lifted

‘1’ Ù Print head is lifted. Printing cannot continue until print head has been restored to print

position.

Note! This feature requires optional hardware for Compact models.

Internal print button

Described above.

Printer restarted

Described above.

Page 36

Page 41

PROGRAMMER’S REFERENCE MANUAL

Service commands

Status request 8

PHD board installed

Black mark photocell

Cutter installed

2

C-board installed

I

LTS installed

not used

not used

not used

LTS installed

‘1’ Ù LTS is installed. Note! Only Nova models have this feature.

2

I

C board installed

For Compact models, this flag has two different meanings depending on the version of the

power supply board currently installed.

Power supply board version 1

‘1’ Ù The control board for cutter and LTS (label-taken sensor) is installed and has been

initialized.

Power supply board version 2

2

‘1’ Ù The I

initialized.

For Nova models this flag is normally always set, meaning the I

functioning properly. If not, there might be some problem with the I

electrical interference of some kind.

Cutter installed

‘1’ Ù The cutter is installed and working. This is verified for each cutting cycle.

‘0’ Ù The cutter is either not connected or is jammed (cannot get back to home position).

Note! If no I

Black mark photocell

‘1’ Ù Black mark photocell installed. Note! Nova models have a media-positioning sensor

(MPS) instead, which contain both gap- and blackmark sensors. This status flag will be set

only if black mark is selected.

C circuit for cutter, LTS, LED and head lifted is functioning and has been

2

C connected board is

2

C bus connection, i.e.

2

C board is installed, this flag will never be set.

PHD board installed

‘1’ Ù Print-Head diagnostics board installed and activated. Note! Nova models always

have this feature as default.

Page 37

Page 42

PROGRAMMER’S REFERENCE MANUAL

Service commands

Service commands

The service commands provide a number of different utilities. The printer responds with a

line of data to a service command.

The command syntax is !V<i>

Note! Some commands take an additional argument after <i>.

Service command (i) Description

9 [m] Software revision level. If parameter m is zero or omitted, the

printer responds with a string of the form 4.12. If m is equal to 1,

the internal revision is appended. Example: 4.12.07.

11 Software date. The printer responds with a string of the form

Feb 19 1999 10:28:20

12 Label count. The printer responds with the total number of labels

printed.

13 Available dynamic RAM, in bytes.

15 Total paper movement, in mm.

16 PROM number. The printer responds with a string of the form

L412-0. ///Deprecated! Use !V9 instead

17 [m] Total paper movement. The printer responds with the amount of

paper it has printed. If parameter m is omitted, the printer responds

with the total paper movement, in metres. The following information

can also be received depending on the parameter m value:

1 – Total paper feed in mm.

2 – Total paper feed in inch.

3 – Total paper feed in feet.

19 Available file system memory, in bytes.

20 <hh:mm:ss> Set the time in the clock in the printer (24-hour clock). The clock is

kept running by a battery when the printer is switched off.

Example: !V20 14:30:00

21 <yy-mm-dd>

or

21 <yyyy-mm-dd>

Set the date in the clock in the printer.

Example: !V21 1999-02-22

22 [m] Get date and time. The response is a string in the form

99-02-22 14:30:00

if parameter m is 0 or omitted, and

1999-02-22 14:30:00

otherwise.

23 <m> Get name of bitmap font by logical number. The response is the

name of font number <m>. (///Deprecated! Use !V80 instead)

Page 38

Page 43

PROGRAMMER’S REFERENCE MANUAL

Service commands

24 <“name”> Get logo information. Quotes must be entered. The string ‘name’ is

the name of a logo stored in printer file system. The response is a

string of four numbers describing the logo (height, width,

orientation and number of bytes per row).

25 <m> Get information about logo number m. The response is a string of

the form: “logoname” 75 58 0 8, where logoname is the name of the

logo and the numbers are the same as for !V24. For information

about other types (macros, rasterized fonts), see !V48.

26 <”name”’> Displays the contents of a macro. Quotes must be entered. The

string ‘name’ is the name of a macro stored in printer file system.

31

32 <m> Get the current state of counter number m. The response is a string

Get length of the last paper movement. The response is in

of five numbers, representing:

y the current value of the counter

y the increment value

y the width of the counter

y the update interval

y the number of labels printed with the current values

1

/10 mm.

33 Get number of failing dots received from print head diagnostics

(PHD). The PHD functionality is an extra harware option for

Compact models but default for Nova models.

34 <m> Used in combination with service command 33 to get the position

of the failing dot(s). For instance, if service command 33 returns the

value 2 then ‘!V34 1’ returns the position of the first failing dot and

‘!V34 2’ the position of the second failing dot.

39 Gets the remaining number of dormant printouts since last !p<n>

was received. If unlimited printouts is active a ‘*’ is returned. See

Dormant print for more information.

40 <m> Get the name of bitmap font number, where parameter m is the

physical number of the font, not the logical (mapped) number.

44 Automatically sets the sensitivity of the paper sensor. The printer

feeds out some paper to assess the opaqueness of the paper and

then sets the sensitivity of the paper sensor. This command should