Page 1

MVP SERIES

200MVP & 300MVP

THERMAL PRINTERS

Product Guide

May 2003

Page 2

www.bradyeurope.com

Summary

I. INTRODUCTION ............................................................................................. 3

II. PRINTER OVERVIEW

A. General Features/Unique Characteristics................................................ 4

B. Operating Requirements ......................................................................... 5

C. Printer Tour ........................................................................................... 14

D. Warranty Information............................................................................. 15

III. FEATURES / BENEFITS / SPECIFICATIONS.............................................. 16

IV. COMPETITIVE ANALYSIS........................................................................... 22

Brady 200MVP, Brady 300MVP versus Brady 200 M-e............................. 22

Brady 300MVP versus Zebra 90XiIII+........................................................ 23

Brady MVP Series versus CAB Apollo 3.................................................... 24

Brady MVP Series versus Argox 3000....................................................... 25

Brady MVP Series versus Datamax I-4208................................................ 26

Brady MVP Series versus Intermec E4...................................................... 27

Brady MVP Series versus Printronix T4204............................................... 28

Brady MVP Series versus Sato CL-408e ................................................... 29

Brady MVP Series versus TEC B-472 ....................................................... 30

Page 3

www.bradyeurope.com

I. INTRODUCTION

Brady Corporation, the market leader in labelling solutions, is proud to introduce the newest

members of the M Series family - the rugged, cost-effective, new 200MVP and 300MVP

thermal transfer printers. The MVP series printers provide the best value in an industrial

thermal transfer printer. Available in either 203 or 300 dpi, the MVP printers are easy to

operate and loaded with features, including colour-coded operator cues and an LCD display.

The durable, die cast aluminum frame provides a rugged platform for printing in operations

that require label production 12 hours per day, 5 days per week.

MVP Series Product Guide - 3 - Introduction

Page 4

www.bradyeurope.com

II. PRINTER OVERVIEW

The following sections are designed to quickly familliarise the user with the General

Features, Operating Requirements, and Warranty Coverage of the Brady MVP series

printers. For more detailed product information, consult the

A. GENERAL FEATURES / UNIQUE CHARACTERISTICS

The

200MVP/300MVP thermal printers are engineered and designed for light to medium

volume industrial text labelling and bar-code applications requiring an affordable,

performance printer (under 1800 € and 2200 € respectively).

Some of the unique characteristics specific to the

MVP series include:

MVP Series User’s Guide.

thermal

1. Quality Engineered Main Logic Board and Firmware

The internal make-up and components of the 200MVP/300MVP printers are

engineered for quality and optimised for thermal print capability The MVP

series printers are designed to meet the requirements of the value-conscious

consumer with an industrial, labelling application. Depending on the user’s

application preference and system requirements, the 200MVP/300MVP can

provide a rugged, reliable print solution to satisfy a variety of printing

requirements.

2. Durable, State-of-the-Art Performance

The 200MVP/300MVP is constructed of a highly durable, die-cast metal frame

that enables the printer to provide consistent print quality in many tough

industrial environments. Its 10 ips print speed ensures maximum productivity

and output. Add to that, the revolutionary connectivity and control solution of

BradyConnect

more value per € with this performance-packed winner!

3. Foolproof Design / Simple Operation

Regardless of a user’s level of experience or training, the 200MVP/300MVP

printers are highly intuitive to operate. Standard features like an LCD display,

colour-coded operator cues, auto-calibration and an auto-sensing power

supply make system configuration and printer set-up easy.

™

(WebView, Alert and ZBI) and you can see just how you get

MVP Series Product Guide - 4 - Printer Overview

Page 5

www.bradyeurope.com

4. Easy Access to Label and Ribbon Path / Ease of Loading & Maintenance

The MVP series’ embossed loading diagram, enlarged media window and

cantilever printhead simplify the printer loading process. The printer’s

cantilever printhead with head open-lock feature “locks” in place to enable full

uninhibited access to the printhead for cleaning and the media compartment

for media loading. In addition, user’s can utilise the media loading diagram

that is embossed in the printer’s steel frame or the enlarged media window to

monitor media supply status.

5. More Standard Features for the Money

The 200MVP/300MVP printer offers more standard features for the money

than ever before. Rugged metal construction, 10 ips print speed,

BradyConnect remote monitoring and configuration capability and a standard

LCD display are just a few of the ways this printer this printer offers more

value per euro than ever before.

B. OPERATING REQUIREMENTS

1. FONT SELECTION

Brady MVP series printers each offer an extensive range of font options for

the user to choose from, including:

Character Fonts

The 200MVP/300MVP contains 9 Standard Bitmapped Zebra Fonts including:

(A, B, C, D, E (OCR-B), F, G, H (OCR-A), GS); and 1 Smooth scalable Font

(CG Triumvirate Bold Condensed) scalable up to 10 x 10 point sizes.

Character Sets

The MVP series printers contain full ASCII character sets including IBM Code

Page 850 (International Characters and Graphics Symbols).

Custom Graphics/Logos

The 200MVP/300MVP printer supports user-defined fonts and graphics,

including custom logos.

A non-Roman font license option is also available which enables various

international fonts, including Serif, Sans Serif, Kanji, Hangul and Chinese, to

be downloaded to the printer for specialised global applications. NOTE

font license option REQUIRES either 1MB (minimum) Flash memory or

PCMCIA memory card)

For a detailed breakdown of font selections for the

Product Specifications section contained in this document.

2. LABEL DISPENSING

The 200MVP or 300MVP printer has the capability of dispensing printed labels

in tear-off or peel-off modes. In the tear-off mode, the label remains attached

to its stock backing and is presented outside the unit to be torn off against a

"tear-off" bar by the user. In the peel-off mode, the label is separated from its

stock backing by a peel bar and is presented to the user for easy removal and

application. The peel mode works in conjunction with an internal rewind

feature that neatly coils the label backing around a spindle for clean operation

and tidy removal of label backing material.

: Asian

MVP series, refer to the

MVP Series Product Guide - 5 - Printer Overview

Page 6

www.bradyeurope.com

3. PRINT SPECIFICATIONS / REGISTRATION REQUIREMENTS

Media Width:

Inter-Label Gap

(Distance between labels):

1.0" (25mm) min. to 4.5" (114mm)

max. on

200MVP or 300MVP

0.08" (2mm) to 0.16" (4mm)

(0.10" -.125” 2.5mm- 3.2mm

Recommended)

First Dot Location:

0.10" (2.5mm, not to exceed

–0.5/+1.0mm) from inside edge of the

media ±0.04mm

Vertical Registration Drift:

Horizontal Registration

Not to exceed ± 0.0393" (1.0mm)

Not to exceed ±0.0591" (1.5mm)

Drift:

Longitudinal Drift

± 0.0393" (1.0mm)

media type)

(between any two labels

(with respect to

printed from the same label roll)

Variation

(from leading label edge to marking):

0.0393" (1mm)

Media Thickness

0.0023" (0.058mm) to 0.010"

(0.25mm); die-cut labels, tickets and

Label Roll Size:

Tear-Off Bar:

Ribbon Orientation:

tags. 2.3 mils to 12 mils

8.0" (203mm) O.D. max. / 3.0"

(76mm) I.D. min.

Standard

Ink Side Out

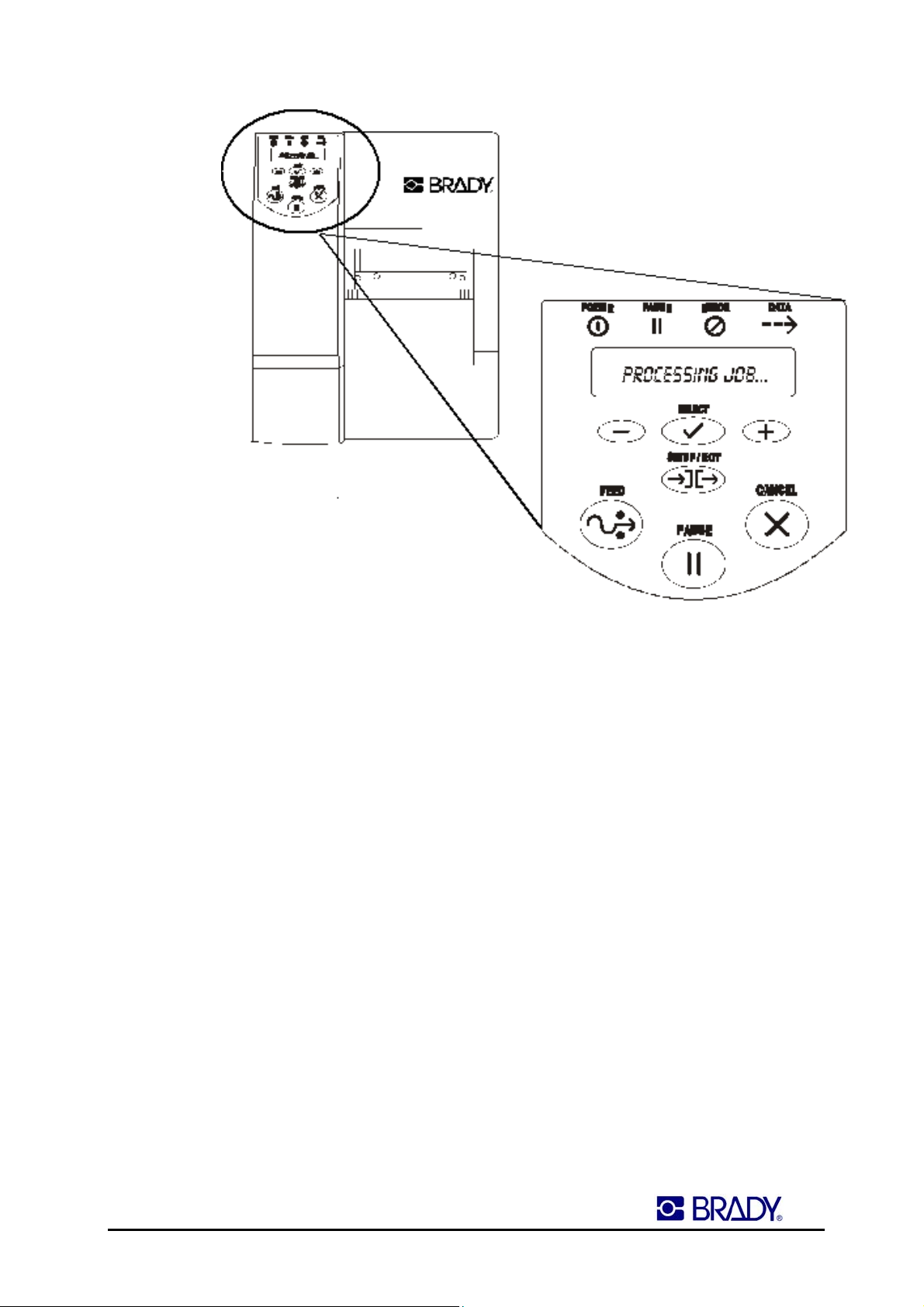

4. USER INTERFACE CONTROLS AND INDICATOR LIGHTS

A MVP series printer is equipped with a standard

LCD control panel for easy

user interface and operation. A 2-line, 16 character backlit display and tactile

feel buttons on the printer’s front panel enable users to fine-tune and control

their print settings, whenever needed, in dim or bright light from any angle.

The user can quickly make adjustments and configure the printer to meet the

specific needs of the application. Such adjustments can also be accomplished

without having to access a computer or software. The drawing of the MVP

series front panel (below) depicts the positioning of the indicator lights on the

200MVP/300MVP.

The LCD display is used in configuring the printer; selecting reports to be

printed by the Brady printer which identify available fonts, bar code

symbologies, images or formats stored in the printer; or a complete record of

the printer’s configuration settings; and diagnostic tests or security passwords.

The LCD display is also helpful in specifying error conditions and

communicating to the operator when the condition has been corrected.

MVP Series Product Guide - 6 - Printer Overview

Page 7

www.bradyeurope.com

Figure 1

MVP Series Product Guide - 7 - Printer Overview

Page 8

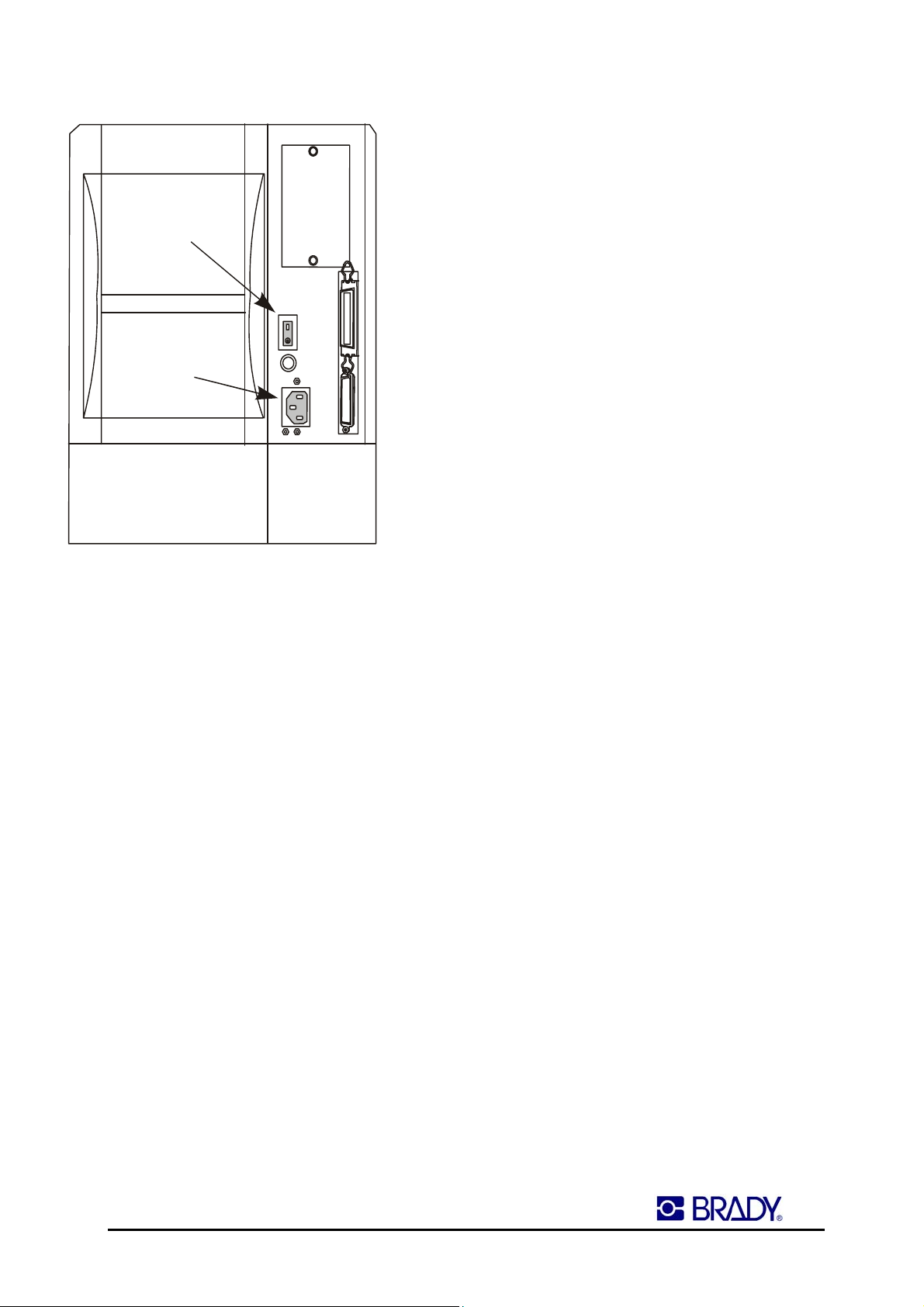

AC

power

switch

Connector

Figure 2

Location of Power Switch & Connector

ERROR INDICATOR

No error light indicates normal operation. A slow flashing error indicator light

signifies a “RIBBON IN” or “PRINTHEAD TEMP” issue. A fast flashing error

light indicates a “PRINTHEAD OPEN” error. A constant on error light

indicates a “PAPER OUT”, “RIBBON OUT” or “CUTTER JAM” condition. For

each error condition, the LCD display will identify the type of error and indicate

that the error is cleared once corrective action has occurred.

FEED BUTTON

The FEED key will cause the printer to immediately feed a single blank label.

Users can activate the FEED key to test label alignment and positioning and

proper printer operation before attempting to print a label.

CANCEL BUTTON

The CANCEL key will cancel a print job when the printer is in PAUSE mode.

If print jobs are currently printing in a queue from the host computer, pressing

the CANCEL key once will cancel the current print job. To delete all print jobs

in the printer’s memory, press and hold the CANCEL key for a minimum of 3

seconds until you see the DATA transmission light go off. This indicates that

all print jobs in the queue have been successfully canceled. Users can quickly

and easily cancel print jobs, by activating the CANCEL key on the printer’s

front panel, saving time and reducing label waste in the advent of a print error.

www.bradyeurope.com

A/C POWER SWITCH /INDICATOR LIGHT

The power switch is located at the back of the printer

directly above the power cord as indicated by the

diagram Figure 2. The power supply in the

200MVP/300MVP printer works over a broad voltage

range ( 90 to 265 VAC ). The power indicator light on

the display panel designates when the printer is

powered on.

PAUSE BUTTON

Activating the PAUSE key while the printer is printing

will cause the printer to stop or pause once the current

label is complete. No labels are lost during pause,

whereby the PAUSE indicator light will illuminate to

easily identify printer status to the user. Users can

utilise this key to pause a print job immediately, for any

reason, as required. Pressing the PAUSE button again

will cause print to resume exactly where it stopped.

DATA INDICATOR

No data light indicates normal operation. A slow

flashing data indicator signifies that the printer is unable

to accept more data from the host PC. A fast flashing

data light indicates that the printer is receiving data. A

constant on data light indicates that a partial format has

been received with no subsequent data activity.

MVP Series Product Guide - 8 - Printer Overview

Page 9

www.bradyeurope.com

SETUP/EXIT

The SETUP/EXIT key, as its name suggests, enters and exits the

configuration mode. This also allows a configuration change to be saved

temporarily, permanently or a default setting may be used.

SELECT

The SELECT key toggles the INCREMENT (+) and DECREMENT (-) keys

between the “scroll mode” and the “change mode”. Press once to use the (+)

or (-) keys to change the value of a selection. Press again to use the (+) and

(-) keys to scroll through the menu items.

For detailed instructions on how to adjust these settings or for related troubleshooting tips, refer to the 200MVP/300MVP User’s Guide.

5. SENSORS

The following sensor types are contained within the MVP series thermal

printers:

Checks the open/closed status of the printhead. If the

Printhead

Sensor:

printhead is open, the printhead light indicator will

immediately flash, warning users of a non-print

condition whereby the printhead must be closed

before attempting to print.

Transmissive sensors recognise the see-through

Transmissive /

Reflective

Media

Sensors:

"gaps", “notches” or joints between labels as light is

permitted to filter through these joints indicating the

label’s overall length. Similarly, the reflective sensor

option gauges label length via the black marks found

on the media backing which reflect light back to the

sensor from the label’s joint. Both sensor types

enable users to print on diverse label stocks including

continuous, notch, black mark, tag stock or perforated

and promote the printer’s auto-calibration feature.

During auto-calibration, the printer relies on such

sensor readings to automatically adjust to varying

label lengths promoting worry-free print capability on

varying media (label) types.

Tear-Off /Peel-Off sensors enable the user to work at

Tear-Off / Peel-Off

Label Sensors:

their own pace and preferred mode of operation during

the labelling process. Peel-Off mode instructs the

printer to remove the label from its backing and wait

until the label is removed by the user before issuing a

new label. Tear-Off mode, similarly, allows individual

or groups of labels to be turn-off the printer’s tear bar

by pulling it down and away against the tear bar.

MVP Series Product Guide - 9 - Printer Overview

Page 10

www.bradyeurope.com

e

The paper/ribbon out sensor on the

Paper/Ribbon Out

Sensor :

200MVP/300MVP printer immediately detects when

ribbon or paper is exhausted before label data loss

occurs. Users are

warned exactly when to replace

ribbon or paper lessening the likelihood of print

interruptions.

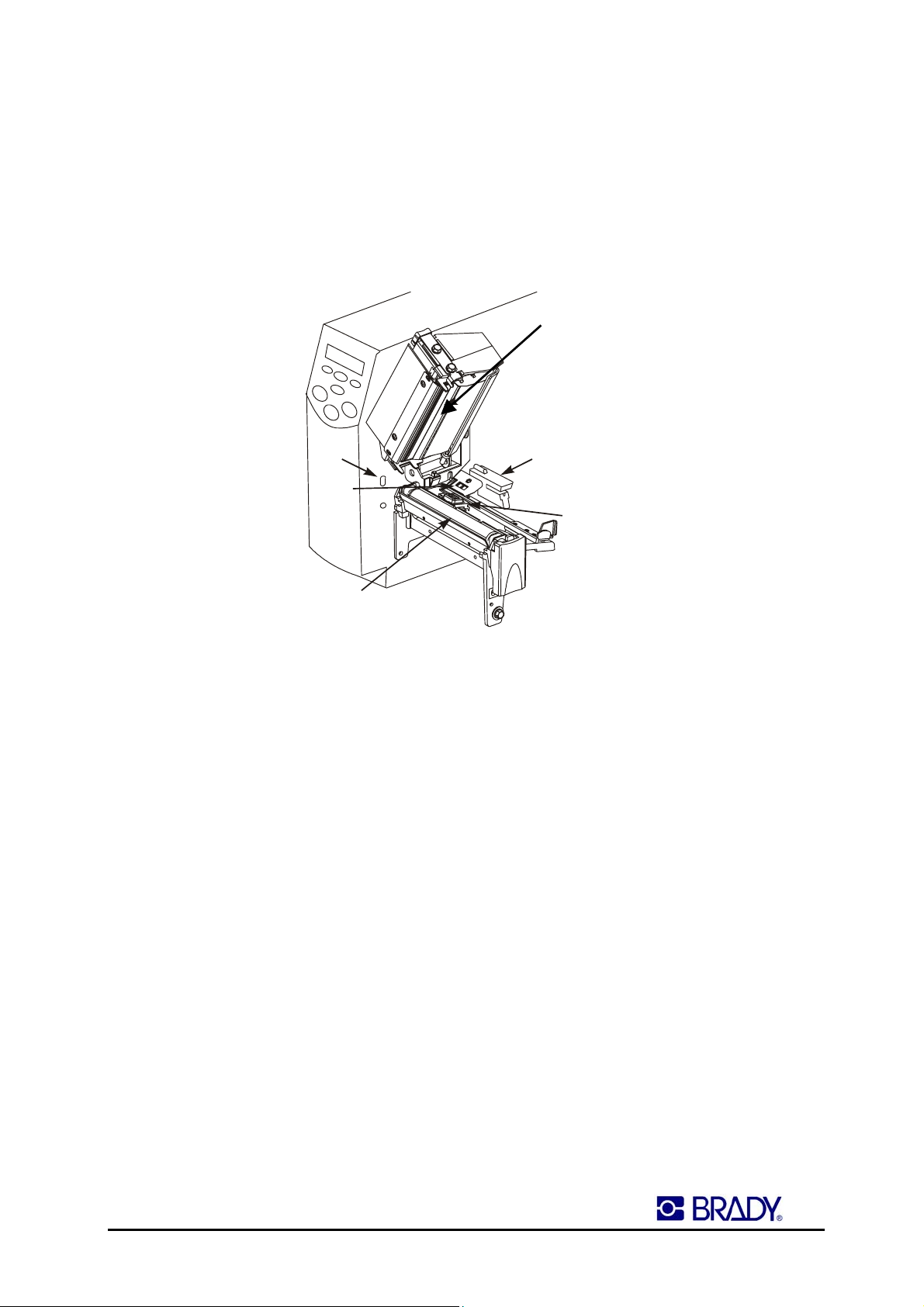

Printhead

Take label

sensor

Ribbon

sensor

Transmissive

sensor

Reflectiv

sensor

Platen roller

MVP Series Product Guide - 10 - Printer Overview

Page 11

www.bradyeurope.com

6. COMMUNICATION PARAMETERS

The MVP series printers offer two convenient ways to interface with a host: (1)

serial port connection or (2) parallel port connection. The following table

highlights the printer configuration set-up for serial and parallel interface.

Printer Port:

Pin # Description

1 Ground

* NOTE: Above 9-Pin Serial connector connects to PC host.

2 TXD 232 (transmit data)

output from printer

3 RXD 232 (receive data)

input to printer

4 RTS 232 (request to send)

output from printer

5 Not used

6 DSR 232 (data set ready)

input to printer

7 Ground

8 Not used

9 +5V @1A

10 Not used

11 Signal ground reference

12 Not Used

13 RXD 485- (receive data)

input to printer

14 TXD 485- (transmit data)

output from printer

15 Not used

16 RXD 485+ (receive data)

17-18 Not used

19 TXD 485+ (transmit data)

20 DTR 232 (data terminal

21-25 Not used

input to printer

output from printer

ready) output from printer

DB-25 Pin - Serial Printer Port Pinout:

MVP Series Product Guide - 11 - Printer Overview

Page 12

www.bradyeurope.com

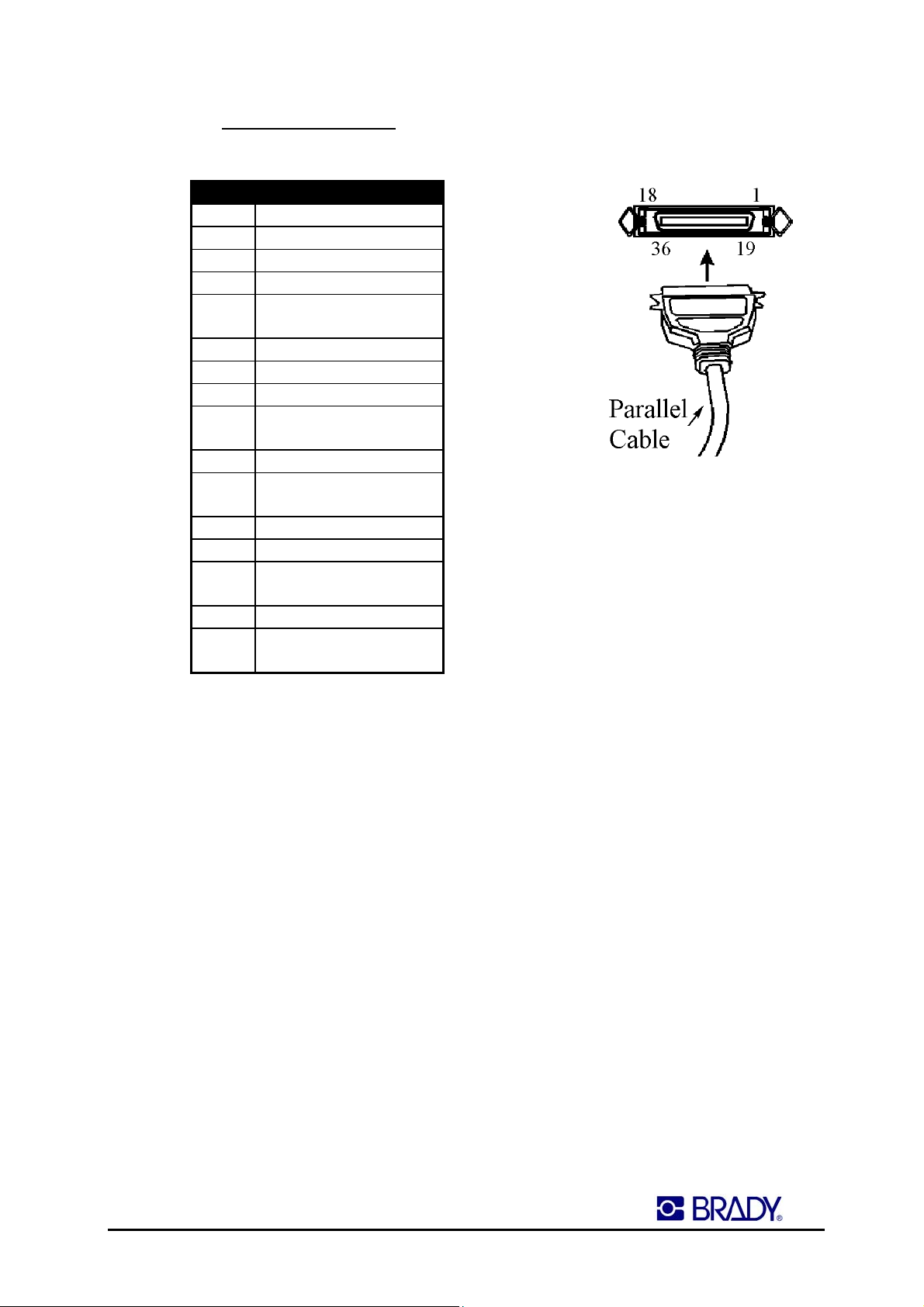

Bi-directional (36 Pin) – Centronics Parallel Printer Port Pinout:

Pin # Description

1 nStrobe/HostClk

2-9 Data Bits 1-8

10 nAck/PtrClk

11 Busy/Ptr Busy

12 PError/Ack Data

Req.

13 Select/Xflag

14 nAuto Fd/Host Busy

15 Not Used

1617

18 +5V@1A

1930

31 nInit

32 nFault/nData Avail

3334

35 +5V thru 3.3K

36 nSelectIn/1284

The 8-bit parallel data interface supports bi-directional parallel communications in

“nibble mode”. The parallel interface provides a means of communication, which is

typically faster than serial interface methods.

Ground

Ground

Not used

active

MVP Series Product Guide - 12 - Printer Overview

Page 13

www.bradyeurope.com

7. PERIODIC MAINTENANCE

For optimum performance of the 200MVP or 300MVP thermal printer, Brady

recommends cleaning the printer on a regular basis using standard printer

parts and Brady cleaning supplies. Consult the User’s Guide for specific

details.

• Cleaning: The exterior is cleaned with a lint-free cloth and if necessary, a

mild detergent solution or desktop cleaner. Interior components –

including the printhead, platen roller, media sensor, peel bar and media

paths – are cleaned with an isopropyl alcohol soaked swab and a vacuum

cleaner or blown air to remove any dirt or dust particles that may have

accumulated during use.

As a general rule of thumb, Brady recommends cleaning the printhead

following ribbon replacement

• Lubrication: All mechanical parts of the MVP series printers are self-

lubricating and do not require additional lubrication. Hence, less time is

required to maintain the printer promoting increased user productivity.

8. PACKAGING SPECIFICATIONS

Brady is an ecologically conscious company that strives to manufacture

quality and "environmentally-friendly" products. Our shipping materials,

therefore, are devoid of chemicals (i.e. bleach) and are composed of

biodegradable paper / post consumable and biodegradable glues for easy

recycling. (The packaged shipping weight of a 200MVP or 300MVP is approx.

49 lbs. (22kg)).

MVP Series Product Guide - 13 - Printer Overview

Page 14

www.bradyeurope.com

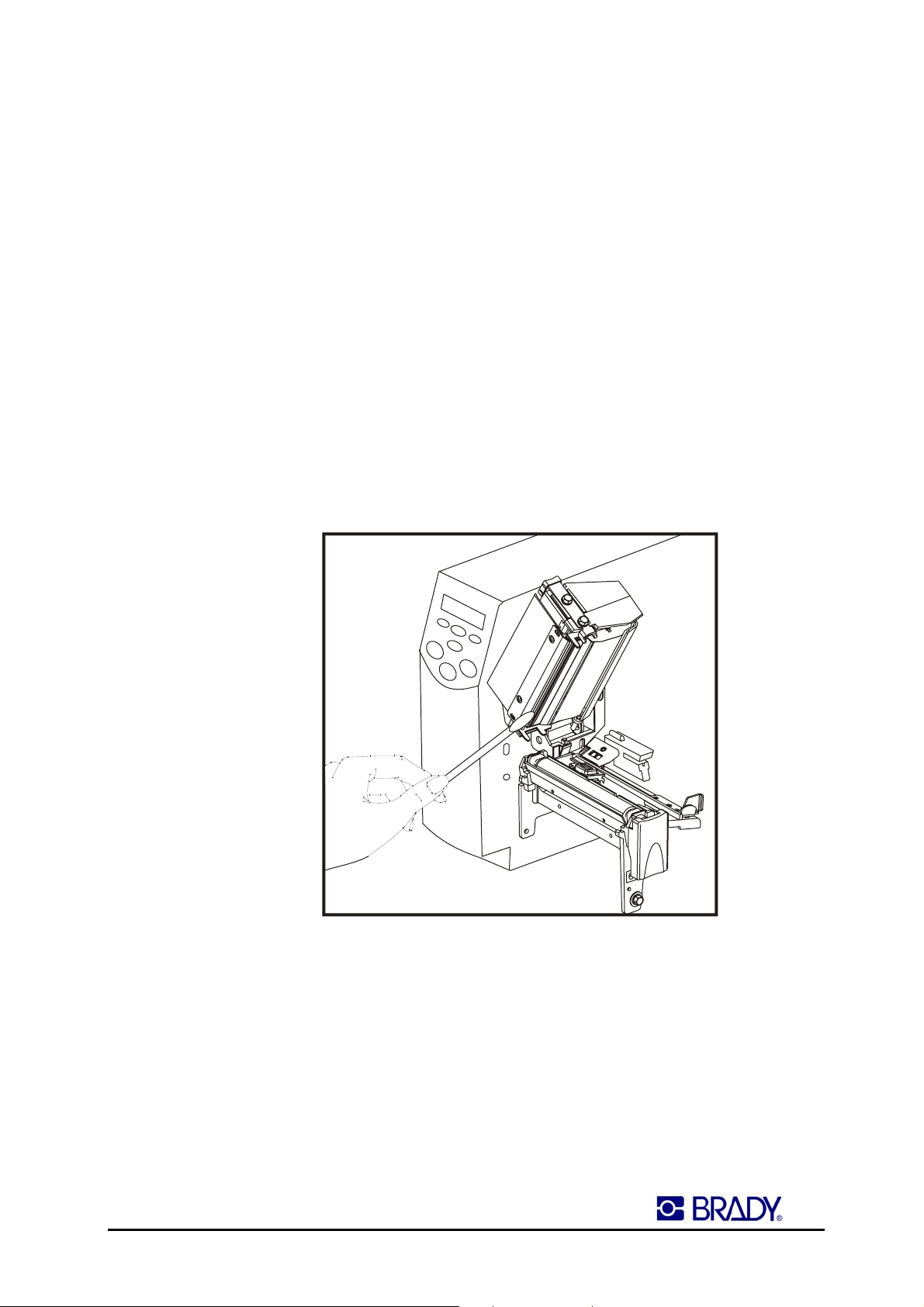

C. PRINTER TOUR

The Printer Overview Diagram below serves to orient the user as to the location of some of

the 200MVP/300MVP feature capabilities mentioned throughout this section.

1. Media Access Cover 7. Printhead / Printhead Open Latch

2. Ribbon Take-Up Spindle 8. LCD Control Panel

3. Media Supply Unwind 9. Platen Roller

4. Media Supply Guide 10 Ribbon Supply Spindle

5. Media Guide/ Moveable

11. Enlarged Media Window

Transmissive Sensor

6. Tear Plate 12. Printhead Pressure Adjustment Dials

MVP Series Product Guide - 14 - Printer Overview

Page 15

www.bradyeurope.com

D. WARRANTY INFORMATION

The MVP series printers are covered under the following Brady general warranties. For

complete Warranty Policy Information, refer to the 200MVP/300MVP User’s Guide.

1. GENERAL COVERAGE

The MVP series printers are warranted against defects in material or

workmanship for one year (12 months) from the date of purchase (with the

exception of the printhead – see below). This warranty does not cover

normal wear and tear and shall be null and void if the equipment is

modified, improperly installed or used, damaged by accident or neglect,

or in the event any parts are improperly installed or replaced by the user.

Proof of purchase or product registration is required. If proof of purchase or

product registration cannot be established, shipment date to the original buyer

(reseller or distributor) will be used to establish the warranty period.

2. PRINTHEAD COVERAGE

Brady MVP series warrants printhead for 6 months or 180 days from the date

of purchase, regardless of the number of labels printed.

3. RETURNED GOODS UNDER WARRANTY

The standard Brady policy is in effect for returning in-warranty product. A

Brady Return Material Authorization (RMA) must be obtained from our

Technical Support Group prior to returning any product.

Technical Support Information:

Telephone: France : 00 33 (0) 1 69 29 67 17

Benelux : 00 32 (0) 52 457 397

UK : 00 44 (0) 1295 228 205

Germany : 00 49 (0) 6103 7598 450

Italy : 00 39 02 967 005 07

Sweden : 00 46 (0) 8590 057 40

Eastern Europe : 00 36 23 42 85 26

E-mail: tech_support@bradycorp.com

MVP Series Product Guide - 15 - Printer Overview

Page 16

www.bradyeurope.com

e

III. FEATURES, BENEFITS & SPECIFICATIONS

RUGGED CONSTRUCTION

FEATURE FUNCTION

NEW Die-Cast

Aluminum

Base / Frame

Durable, metal construction

Die-casting enables precision

Mounting of the print mechanism and spindle, which

enhances print accuracy and

eliminates ribbon wrinkle.

END-USER

BENEFIT

Durable construction

surrounds critical components

providing printer longevity and

reliability.

Designed to withstands

harsh, industrial environments

Ensures consistent print

quality

SALES

CHANNEL

ADVANTAGE

Confidently sell Brady’s

reliability within a wide

range of operating

environments.

Satisfied customers are

repeat customers, leading

to future sales

.

NEW Die-Cast

Printhead

Mechanism

Print mechanism is embedded

into metal housing

Provides inherent rigidity for

printhead mechanism

Withstands general wear and t

facilitates media loading

STATE OF THE ART PERFORMANCE

FEATURE FUNCTION

FLASH Memory

(up to 8MB

available)

Optimised

Processing with

New Microprocessor

ZPL II firmware and optional

fonts can be upgraded and

enhanced without modifying

the electronics

ZPL printer has been

revamped to provide optimal

label format processing

performance.

Printer features a new

electronic design and a new

32-bit RISC microprocessor.

END-USER

BENEFIT

Convenient and cost

effective to keep printer firmware

current with the latest features

and enhancements. Updates can

be readily downloaded to the

printer from Brady’s website,

without a service call to replace

EPROMS.

Faster label processing and

throughput provides enhanced

productivity.

Can confidently sell

Brady’s reliable print

quality.

Customer perceives the

enhanced quality and

durability of the product.

SALES

CHANNEL

ADVANTAGE

Reduces technical

support and maintenance

requirements, more

efficient customer

support..

Better throughput is more

competitive.

High

performance

printhead and E

(Element,

Energy,

Enhanced performance

printhead combined with the

sophisticated energy control

3

system provides high quality

printing over a range of

speeds and materials..

Satisfies customer print

quality requirements for bar

codes, text and graphics.

Balances printhead energy

output for prolonged printhead

life.

Can confidently sell

Brady’s reliable print

quality over a range of

print applications.

Equalizer)

MVP Series Product Guide - 16 - Features and benefits

Page 17

www.bradyeurope.com

SIMPLE OPERATION

FEATURE FUNCTION

NEW Cantilever

Printhead (with

head open lock)

NEW STANDARD

BACK-LIT LCD

CONTROL PANEL

NEW Full-size

MEDIA WINDOW

Side-opening printhead,

unlatches easily providing

wide clearance and access

to the printhead.

Head open lock ensures that

the printhead stays in full open

position

Multi-functional display panel

enables operator to configure

the printer’s communication

parameters using 2 line, 16

character text, easy to read

error messages and

instructions; multi-lingual

support.

Oversized window permits

more light to enter the media

supply cavity.

END-USER

BENEFIT

Easier to load ribbon and

media. No threading required.

Easy access for cleaning;

keeping the printhead clean

improves print quality.

Fasters set up time.

Display is Backlit and easy to

read in dim or bright light from

any angle.

User can make adjustments

and configure the printer to meet

the specific needs of his

application.

Allows operator to monitor/

view supplies status from near or

far.

SALES

CHANNEL

ADVANTAGE

Widest media path in the

industry Compare our

wide access printhead

with the competitor’s

restricted access.

Simple to operate,

reducing support

requirements

Less support

requirements.

Improved customer

efficiency - Less

downtime

Colour-coded

operator “cues”

Auto-calibration

SUPPLIES

LOADING

DIAGRAM

EMBOSSED IN

THE MAINFRAME

Printhead

assembly

Media supply guide

Identifies which components

are adjustable in order to

operate or optimise the

printer.

Printer automatically

calibrates media at power up

or when printhead is opened.

Uses only a single label to

calibrate most applications.

Simplified loading of

supplies. Operator just

follows the diagram.

User can monitor when

supplies get low well before they

become depleted

Easy to use. Printer

operation is more intuitive, less

complicated with less training.

Automatically adjusts to any

size label. No operator

modification required.

Minimises label waste by

using one label for calibration

within typical applications.

Convenient and requires no

manual or training. The

instructions are never lost nor

wear off.

Easy to demonstrate

printer operations,

reduces training and

support requirements.

Easy to sell to customers

using various sized

labels. Reduces training

and support requirements

Reduces training

requirements for media

loading.

Less support

requirements-- user will

always load the printer

correctly.

Media

Media guide

Printhead open lever

hanger

supply

”

MVP Series Product Guide - 17 - Features and benefits

Page 18

www.bradyeurope.com

d

P

MODULAR DESIGN

FEATURE FUNCTION

Modular Design:

Field Installable

Options

Improved Serial

and Parallel

Communications

Printhead

replacement

without tools

ressure adjustment dials

Thumbscrew

All options are either configure

to order or field retrofit for

future applications.

Both ports are standard on

the base printer. An operator

can utilise either the serial or

parallel port to download

information from the host.

No tools or tedious

adjustments to replace worn

printheads. Just use your

fingers to remove ONE

thumbscrew. Printheads are

pre-aligned for ready

replacement.

END-USER

BENEFIT

Provides investment

protection. Allows user to pay for

the features needed today

without limiting future

opportunities to upgrade

applications change and grow.

Printer communicates in a

wide range of environments with

a variety of hosts, providing

flexible connectivity.

Reduces downtime with fast

and easy printhead replacement.

End-user can replace worn

printhead in minutes, eliminating

the need for a service call.

as their

SALES

CHANNEL

ADVANTAGE

Reduce speculative and

expensive inventory of

printers. Inventory the

options to provide

different configurations.

Ability to respond to

customers’ needs quickly

and easily. Provides

future upscale

opportunity.

No need to specify port at

time of order, since MVP

Series provides BOTH

serial and parallel.

Easy to integrate into a

variety of

communications

environments.

Easy to sell printhead

replacements.

MVP Series Product Guide - 18 - Features and benefits

Page 19

www.bradyeurope.com

Standard Features

• 203 dpi print resolution (8 dots/mm) or 300 dpi

resolution (12 dots/mm), dependent upon

model

• Firmware is FLASH resident/download

upgradeable

• Thin film print head with E

Control

• Thermal transfer and direct thermal printing of

bar codes, text, and graphics

• ZPL

• 32 bit RISC processor

• 4MB RAM memory (2MB User Available)

• Serial RS-232/422/485 and bi-directional

• Transmissive and Reflective sensing

• NEW Sleek personality / rugged metal design:

• NEW Die-cast print mechanism with head open

• NEW Standard LCD control panel: Back-lit, 2

• NEW Charcoal grey form design for improved

• Brady

• NEW BradyConnect™ - the revolutionary real-

®

or ZPL II® programming language,

selectable through software or front panel

parallel ports

technology

⇒ Die-cast aluminum frame: 0.20" (5mm)

thick – ensures parallelism of spindles for

consistent print quality

⇒ NEW metal die-cast base withstands

harsh industrial conditions

⇒ NEW Metal media cover with enlarged

clear window : easy to view supplies

lock withstands general wear & tear and

facilitates media loading

line, 16 characters w/ full menu to change setup options

smudge resistance

®

printer driver for Windows™ 3.X and

95/98/NT 2000/XP operating systems

time connectivity control solution:

⇒ WebView / Alert – (requires optional

ZebraNet™ PrintServer II)

⇒ ZBI™ - Programming Language

Interpreter for translation of foreign data

streams

3®

Element Energy

Optional Features

• Full-width guillotine knife cutter and catch tray, operates

under software control cutting labels individually or in strips

(not compatible with rewind and peel options)

Choice of 2 peel options:

⇒ Value-Peel – a front mount, passive peel option, w/

no take-up spindle

⇒ Liner-Take-Up option - full roll liner take-up spindle

accommodates standard printer base –works with

value peel option

Rewind – internally rewinds full roll of printed labels on 3”

core, or peels & rewinds liner

• PCMCIA Connector - Flash memory cards up to 8MB

• 1 or 2 MB of additional Flash memory

• Additional scalable and smooth bitmapped fonts available

• ZebraNet

and enables the use of the Webview and Alert features.

™

PrintServerII –provides Ethernet connectivity

Printing Specifications

• 203 dpi resolution (8 dots/mm)

- Dot size (W x L):

0.0049" x 0.0049" (0.125mm x 0.125mm)

• 300 dpi resolution (12 dots/mm)

- Dot size (W x L):

0.0033" x 0.0039" (0.084mm x 0.099mm)

• First dot location measured from inside media backing

edge:

0.10" ±.04" (2.5mm, not to exceed -.5mm +1.0mm)

• Maximum print width: 4.09" (104mm)

• Maximum non-continuous and continuous media print

length:

203 dpi 300 dpi

100" / 2540mm 49" / 1245mm

• Media registration tolerance:

• Vertical ≤ ±0.039" (±1.0mm) on non-continuous media

Horizontal

≤ ±0.039" (±1.0mm) within a roll of media

• Programmable print speeds:

- 203 dpi models = 2.0" (51mm) through 10" (254mm) per

second in 1" increments

- 300 dpi model = 2.0" (51mm) through 6" (152mm) per

second in 1" increments (25,4mm)

MVP Series Product Guide - 19 - Printer Specifications

Page 20

www.bradyeurope.com

Media Specifications

• Maximum label length: 39" (991mm)

• Media type: continuous, die-cut, tags, black-

mark

• Media web width (label and liner):

1.0" (25.4mm) to 4.50" (114mm)

* NOTE

• Minimum label length:

- Rewind mode: 0.25"(6,35 mm) (200MVP)/

.125” (3,17mm)(300MVP)

- Peel mode: 1.0" (25.4mm)

- Tear-off mode: 0.25" (200MVP)/ .125”

(300MVP)

- Cutter mode: 1.0" (25.4mm)

• Media thickness (label and liner):

0.0023" (0.058mm) to 0.010" (0.25mm)

• Maximum full-width media thickness for cutter:

0.25mm (0.010")

• Maximum media roll size:

8.0" (203mm) O.D. on a 3" (76mm) I.D. core

• Maximum fan-fold pack size:

8.0"L (203mm) x 4.5"W (114mm) x 6.2"H

(157mm)

• Gap and notch sensing standards:

- Interlabel gap: 2 - 4mm, preferably 2.54mm

- Sensing notch: 0.25"W (6mm) x 0.12"L (3mm)

- Sensing hole: 0.125" (3mm) diameter

: Value-Peel max width: 4.38" (111mm)

Ribbon Specifications

• Ribbon width: 2.00" (51mm) to 4.33" (110mm)

• Standard Lengths: 984' (300m) or 1476' (450m)

• Maximum ribbon roll size:

3.2" (81.3mm) O.D. on a 1.0" (25.4mm) I.D.

core

• Ribbon wound coated-side out

Font Specifications

203 dpi (8 dots/mm)

Fonts

A 9 x 5 U-L-D .044" x .029" 33.9

B 11 x 7 U .054" x .044" 22.6

C,D 18 x 10 U-L-D .088" x .059" 16.9

E 28 x 15 OCR-B .138" x .098" 10.1

F 26 x 13 U-L-D .128" x .079" 12.7

G 60 x 40 U-L-D .295" x .236" 4.2

H 21 x 13 OCR-A .103" x .093" 10.7

GS 24 x 24 SYMBOL .118" x .118" 8.4

Ø Variable U-L-D variable N/A

300 dpi (12 dots/mm)

Fonts

A 9 x 5 U-L-D .030" x .020" 50.0

B 11 x 7 U .037" x .030" 33.3

C,D 18 x 10 U-L-D .060" x .040" 25.0

E 41 x 20 OCR-B .137" x .087" 11.5

F 26 x 13 U-L-D .087" x .053" 18.8

G 60 x 40 U-L-D .200" x .160" 6.3

H 30 x 19 OCR-A .100" x .093" 10.7

GS 24 x 24 SYMBOL .080" x .080" 12.5

Ø Variable U-L-D variable N/A

† U - Uppercase L - Lowercase D – Descenders

• Bitmap fonts A through H and GS symbols are

• Smooth scalable font Ø (CG Triumvirate™ Bold

• IBM® Code Page 850 International Characters

Matrix

(in dots)

(H x W)

Matrix

(in dots)

(H x W)

expandable up to 10 times, height and width

independent

Condensed) is expandable dot-by-dot, height and

width independent

Type†

Type†

Minimum

Char. Size

(H x W)

Minimum

Char. Size

(H x W)

Maximum

Maximum

C.P.I.

C.P.I.

Bar Code Symbologies & Specifications

• Bar code modulus "X" dimension:

- Picket fence (non-rotated) orientation:

203 dpi = 4.9 mil to 49 mil

300 dpi = 3.3 mil to 33 mil

- Ladder (rotated) orientation:

203 dpi = 4.9 mil to 49 mil

300 dpi = 3.9 mil to 39 mil

• Bar code ratios: Dot selectable from 2:1 to 3:1

• Linear bar codes: Code 11, Code 39, Code 93 (USS-

93), Code 128 with subsets A/B/C and UCC Case

Codes, ISBT-128, UPC-A, UPC-E, EAN-8, EAN-13,

UPC and EAN 2 or 5 digit extensions, Plessey,

Postnet, Standard 2 of 5, Industrial 2 of 5, Interleaved

2 of 5, LOGMARS, MSI, Codabar

• 2-dimensional bar codes: Codablock, PDF-417, Code

49, DataMatrix, Maxicode, QR Code and Micro PDF-

417.

MVP Series Product Guide - 20 - Printer Specifications

Page 21

www.bradyeurope.com

Zebra Programming Language®

®

(ZPL

and ZPL II®)

• Communicates in printable ASCII characters

• Compatible with mainframe, mini, and PC hosts

• Downloadable objects include graphics,

scalable and bitmap fonts, label templates and

formats

• Adjustable print cache

• Data compression

• Automatic memory allocation for format while

printing

• Automatic serialisation of fields

• Format inversion (white on black)

• Mirror-image printing

• Four position field rotation (0º, 90º, 180º, 270º)

• Slew command

• Programmable label quantities with print,

pause, cut control

• Status messages to host upon request

• ZBI™ (Zebra BASIC Interpreter) – accessible

on MVP Series Printers:

⇒ Interpreting program module that sits

between the communication ports and the

ZPLII processing engine

⇒ Can be used to convert non-ZPL printer

programming language to ZPL commands

⇒ Direct interface to peripheral devices such

as bar-code scanners, weight scales, and

keyboards

⇒ Based on ANSI BASIC computer language

Communications Specifications

• Bi-directional parallel interface (supports IEEE

1284 in “nibble mode”)

• High-speed serial interfaces:

- RS-232C, RS422 and RS485 with DB25F

connector

- Configurable baud rate (600 - 38.4kB), parity,

and data bits. Stop bits at 1 or 2.

- Software (XON/XOFF) or hardware

(DTR/DSR) communication handshake

protocols

• ZebraNet

print server (10BASE-T)

Electrical Specifications

• Auto-detectable (PFC compliant) 90-265VAC,

48-62 Hz, 5A fused power supply

• Agency approvals: UL 1950, CISPR 22 (class

B), EN60950, EN500824, CSA 22.2 No. 95095, Canadian Doc. (class A), FCC (class B),

CE compliance

®

Print Server II - ethernet network

Physical Specifications

• Height: 13.32" (338mm)

• Width: 10.93" (278mm)

• Depth: 18.69" (475mm)

• Weight: 32.4lbs. (15kg)

• Shipping Weight: 49 lbs (22kg)

Environmental Specifications

• Operating environment:

Thermal transfer = 40º to 104ºF (5º to 40ºC)

Thermal direct = 32º to 104ºF (0º to 40ºC)

20% to 85% non-condensing R.H.

• Storage/Transportation environment:

-40º to 140ºF (-40º to 60ºC)

5% to 85% non-condensing R.H.

Preventative Maintenance

Brady recommends cleaning the printer on a regular

basis using standard Brady printer parts and

cleaning supplies. Consult your User’s Guide for

further details.

• Cleaning:

The exterior is cleaned with a lint-free cloth,

and if necessary, a mild detergent solution or

desktop cleaner. Interior components

(printhead, platen roller, media sensor, peel

bar, ribbon and media paths) are cleaned with

alcohol or blown air to remove any particles.

• Lubrication:

All mechanical parts are self-lubricating and do not require

additional lubrication.

• Print Registration:

Media registration and minimum label length are affected

by media type and width, ribbon type and print speed.

Performance improves as these factors are optimised.

Brady recommends always qualifying any application with

thorough testing

MVP Series Product Guide - 21 - Printer Specifications

Page 22

www.bradyeurope.com

IV. COMPETITIVE ANALYSIS

Brady 200MVP, Brady 300MVP versus Brady 200M-e

STANDARD FEATURES

List Price 2375 € / 3032 € 1795 € 2125 €

Max. Print Speed (ips) 2-6 ips (51-152mm) 2-10 ips (51-254mm) 2-6 ips (51-152mm)

Resolution (dots/mm)

Print Width (max. in.) 4.09" (104mm) 4.09" (104mm) 4.09" (104mm)

Max. Print Length (Std In.) 106” (2692mm) 105” (2667mm) 105” (2667mm)

Transmissive Sensor

Dot History Control YES YES YES

Bitmapped Fonts 9 Standard 9 Standard 9 Standard

Scalable Fonts

Frame Construction / Weight Metal / 55 lbs. (25kg) Metal / 32lbs (15kg) Metal / 32lbs (15kg)

LCD Display STD STD STD

ROM (Firmware) Flash Flash Flash

Standard DRAM 4MB (2MB User Available) 4MB (2MB User Available) 4MB (2MB User Available)

Std. Flash Memory 4MB(750K User Available) 2MB (Used by Firmware) 2MB (Used by Firmware)

2D Symbologies

Calibration Auto-calibration Auto-calibration Auto-calibration

Connectivity Serial & Bi-directional Parallel Serial & Bi-directional Parallel

Power Supply Broad range 90-265V Broad range 90-265V Broad range 90-265V

Std 203 (8mm) / 152 dpi option

STD Transmissive Sensor /

CG Triumvirate Bold Standard /

PDF417, Code49, Maxicode,

Codablock, Datamatrix, QR

OPTIONS

DRAM Upgradeable to: NO (4MB Standard) NO (4MB Standard) NO (4MB Standard)

Optional Asian Fonts:

Flash Memory Upgrade: NONE 1,2MB and 8MB Flash Option 1,2MB and 8MB Flash Option

Peel YES – Full label & liner

Rewind YES – Option YES – Option YES – Option

Cutter YES – Option YES – Option YES – Option

Ethernet YES – Option YES – Option YES – Option

Removable/Bi-Fold Door NO NO / NO NO / NO

Footprint (H x W x L):

purchase @ cost per font type

200M-e NEW

(6mm) / 300 dpi (12mm)

Reflective Option

12 additional available w/

EPROM option

YES – individual EPROM

15.5" x 11.2" x 19.5"

(394 x 283 x 459 mm)

Reflective & Transmissive Sensor

CG Triumvirate Bold Standard /

Maxicode, PDF417, MicroPDF,

Code49, Codablock, Datamatrix,

YES – w/ 1MB flash & Font Pack

YES – full roll w/ liner-take-up

200MVP

203 dpi (8dots/mm)

STD- moveable

Font Pack Option

QR

Option

spindle option

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

NEW

300MVP

300 dpi (12dots/mm)

STD- moveable

Reflective & Transmissive

Sensor

CG Triumvirate Bold

Standard / Font Pack Option

Maxicode, PDF417,

MicroPDF, Code49,

Codablock, Datamatrix, QR

Serial & Bi-directional

Parallel

YES – w/ 1MB flash & Font

Pack Option

YES – full roll w/ liner-take-up

spindle option

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

MVP Series Product Guide - 22 - Competitive Analysis

Page 23

www.bradyeurope.com

Brady 300MVP versus Zebra 90Xill+

STANDARD FEATURES

List Price 4495€ 2125€

Max. Print Speed (ips) 2-8ips (51-203mm) 2-6ips (51-152mm)

Resolution (dots/mm) 300 dpi (12 dots/mm) 300 dpi (12 dots/mm)

Print Width (max. in.) 3.4" (86mm) 4.09" (104mm)

Max. Print Length (Std In.) 80" (2032mm) 105" (2667mm)

Transmissive Sensor

Dot History Control YES YES

Bitmapped Fonts 9 Standard 9 Standard

Scalable Fonts CG Triumvirate Bold Standard

Frame Construction / Weight Metal / 50lbs (23kg) Metal / 32lbs (15kg)

LCD Display STD STD

ROM (Firmware) Flash Flash

Standard DRAM 16MB 4MB (2MB User Available)

Std. Flash Memory 2MB 2MB (Used by Firmware)

2D Symbologies

Calibration Auto-calibration Auto-calibration

Connectivity

Power Supply Broad range 90-265V Broad range 90-265V

Reflective/Transmissive Sensor

Maxicode, PDF417, MicroPDF,

Code49, Codablock, Datamatrix,

USB, serial and bi-directional

OPTIONS

DRAM Upgradeable to: NO (16MB Standard) NO (4MB Standard)

Optional Asian Fonts: YES

Flash Memory Upgrade: Up to 1 GB (compact flash) 1,2MB and 8MB Flash Option

Peel YES – Full label & liner option

Rewind YES – Option YES – Option

Cutter YES – Option YES – Option

Ethernet YES – Option YES – Option

Removable/Bi-Fold Door NO/YES -Option NO / NO

Footprint (H x W x L):

90XiIII+ NEW

STD

QR

Parallel, Twinax, Coax, DBF

Applicator interface

15.5" x 9.2" x 19.5"

(394 x 232 x 495 mm)

Reflective/Transmissive Sensor

CG Triumvirate Bold Standard /

Maxicode, PDF417, MicroPDF,

Code49, Codablock, Datamatrix,

Serial & Bi-directional Parallel

YES – w/ 1MB flash & Font Pack

YES – full roll w/ liner-take-up

300MVP

STD

Font Pack Option

QR

Option

spindle option

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

MVP Series Product Guide - 23 - Competitive Analysis

Page 24

www.bradyeurope.com

Brady MVP Series versus CAB A3

B RA D Y vs. CAB

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 40” (1000mm)

Print Length, optional w/add'l RAM 105" (2667mm) 40" (1000mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard Standard

Connectivity & Control Solution BradyConnect - Standard NO

Scalable Fonts Resident Standard Standard

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 4.7" (120mm)

min. 1.0" (25mm) 0.47" (12mm)

Label Length, max. 39" (991mm) 40” (1000mm)

min.

(Tear / Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8.0" (203mm)

Max Ribbon Length 1476' (450m) 1182' (360m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option YES – Option

Non-Roman (Asian) Font License YES - Option N/A

Cutter YES - Option YES - Option

LCD Display Standard YES

Rewind YES - Option YES - Option

Additional RAM (up to) 1,2MB & 8MB Flash Up to 64MB (compact flash)

OTHER

Standard RAM 4MB DRAM 8MB DRAM

Processor / Buffer 32 bit 32-bit

Interface

Serial YES – STD YES – STD

Parallel YES – STD YES – STD

Ethernet YES – Option YES-Option

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 22 lbs.(10kg)

Size (H" x W" x L")

BASE UNIT LIST PRICE 1795 € / 2125 € 1830 € / 2080 €

Brady

MVP Series

203 (8 dots/mm) /

300 dpi (12 dots/mm)

2" - 10" / sec

(51mm - 254mm)

0.25” (6.35mm 200dpi), 0.125”

(3.18mm300dpi) / 1.0 (25mm)

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

CAB

A3

4.09" (104mm)/4.26"

(108.4mm)

203 dpi (8 dots/mm) /

300 dpi (12 dots/mm)

6 IPS (150mm/sec.) / 8 IPS

(200mm/sec.)

0.19” (5mm) / 1.0 (25mm)

10.7" x 9.5" x 17.5"

(274 x 242 x 446mm)

CAB is a German

manufacturer of bar code label

printers, applicators and

specialised cutting machines.

They have a strong reputation

in Europe for manufacturing hiquality/performance products.

However, the performance

capabilities of the MVP series

still provide more value-add, as

evidenced below.

Disadvantages of CAB A3

vs. Brady MVP Series

• Max 10 ips print speed on

MVP series versus 8 ips

on A3.

• The 300MVP prints on

smaller label heights.

According to the Brady

standard formats

• The MVP series offers

BradyConnect remote

connectivity and control

solution (standard). A

feature currently not

available on the A3

printers.

• Higher list price on A3-

200 dpi compared to

Brady’s 200MVP priceperformance value.

MVP Series Product Guide - 24 - Competitive Analysis

Page 25

www.bradyeurope.com

Brady MVP Series versus Argox 3000

ARGOX, founded in 1996 in Taiwan, is

BRADY vs. Argox

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.1" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 30" (736mm)

Print Length, optional w/add'l RAM 105" (2667mm) 30" (736mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard Unknown

Connectivity & Control Solution BradyConnect - Standard NO

Scalable Fonts Resident Standard YES

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 4.3" (110mm)

min. 1.0" (25mm) 1.0" (25mm)

Label Length, max. 39" (991mm) 30" (736mm)

min. (Tear /

Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8.0" (203mm)

Max Ribbon Length 1476' (450m) 1180’ (360m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES – Option YES – Option

Non-Roman (Asian) Font License YES – Option Unknown

Cutter YES – Option YES – Option

LCD Display Standard Standard

Rewind YES – Option YES – Option

Additional RAM (up to) 1, 2MB & 8MB Flash 2MB DRAM

OTHER

Standard RAM 4MB DRAM 512K DRAM

Processor / Buffer 32 bit 32-bit

Interface

Serial YES – STD YES – Option

Parallel YES – STD YES – STD

Ethernet YES – Option NO

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 25 lbs.(11kg)

Size (H” x W” x L”)

BASE UNIT LIST PRICE 1795 € / 2125 € 1900 €

Brady

MVP Series

203 (8 dots/mm)/ 300

DPI (12 dots/mm)

2" - 10" / sec

(51mm - 254mm)

0.25” (200dpi), .125”

(300dpi) / 1.0 (25mm)

13.3” x 10.9” x 18.7”

(338 x 277 x 475 mm)

Argox

3000

300 DPI (12 dots/mm)

2” – 6” / sec

(51mm - 152mm)

1.0 (25mm)

9.4” x 9.8” x 16”

(240 x 250 x 408mm)

an engineering oriented provider of

systems & solutions for computer based

barcode labelling systems. Their

mission is to bring her leading

innovation and first-rate productivity into

the Auto ID industry with a commitment

- to be the most competitive and reliable

supplier of desktop label printers.

Disadvantages of Argox 3000 vs.

Brady MVP Series

• MVP series offers BradyConnect

remote connectivity and control

solution (standard).

• Max 10ips print speed on MVP

series versus 6ips on Argox 3000.

• More 2D fonts on MVP series

compared to Maxicode and

PDF417 variety on Argox 3000.

• More standard DRAM and

upgradeable memory on MVP

versus Argox 3000. Hence ability

to print longer label formats.

• Brady offers European, technical

support versus the offshore

capabilities of Argox.

MVP Series Product Guide - 25 - Competitive Analysis

Page 26

www.bradyeurope.com

Brady MVP Series versus Datamax I-4208

BRADY vs. Datamax

Brady

MVP Series

Datamax

I-4208

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.09" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 99" (2,515mm)

Print Length, optional w/add'l RAM 105" (2667mm) 99" (2,515mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard Standard

Connectivity & Control Solution BradyConnect - Standard NO

Scalable Fonts Resident Standard Standard

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 4.65" (118mm)

min. 1.0" (25mm) 1.0" (25.4mm)

Label Length, max. 39" (991mm) 99" (2,515mm)

min. (Tear /

Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8" (203mm)

Max Ribbon Length 1476' (450m) 1,968' (600m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option YES – Option

Non-Roman (Asian) Font License YES - Option Unknown

Cutter YES - Option YES – Option

LCD Display Standard Standard

Rewind YES - Option YES – Option

Additional RAM (up to) 1, 2MB & 8MB Flash 1MB Flash

OTHER

Standard RAM 4MB DRAM 8MB STD (No Charge)

Processor / Buffer 32 bit 32-bit 66Mhz

Interface

Serial YES – STD YES – STD

Parallel YES – STD YES – STD

Ethernet YES – Option YES – Option

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 45 lbs. (20.5 kg.)

Size (H" x W" x L")

BASE UNIT LIST PRICE 1795 € / 2125 € 1785 €

203 (8 dots/mm) /

300 (12 dots/in)

2" - 10" / sec

(51mm - 254mm)

0.25” (200dpi), 0.125” (300dpi)

/ 1.0 (25mm)

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

203 (8 dots/mm)

2-6 IPS

(51-152mm/sec.)

0.25" (6mm)

18.6" x 12.62" x 12.7"

(472 x 320 x 322mm)

Datamax recently introduced their

E, I and W class printers to

streamline their product line.

Disadvantages of Datamax I4208 vs. Brady MVP Series

• The MVP series offers

BradyConnect remote

connectivity and control

solution (standard). A feature

currently not available on

Datamax printers.

• Ribbon sensor on Datamax

senses ribbon spindle

movement, whereby MVP

sensor looks for presence of

ribbon at the printhead.

Hence, Datamax unit could

continue printing on ribbon

trailer causing blank labels

and data loss to occur as

well as possible printhead

damage.

• 8ips max. print speed on I4208 versus 10 ips on MVP

series.

• LED indicator lights difficult

to read versus MVP series

high contrast LCD –

readable in either dim or

bright light.

MVP Series Product Guide - 26 - Competitive Analysis

Page 27

www.bradyeurope.com

Brady MVP Series versus Intermec E4

Bra dy vs. Intermec

Brady

MVP Series

Intermec

E4

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.09" (104mm)

Print Length, max. w/std RAM 105" (2667mm) Unknown

Print Length, optional w/add'l RAM 105" (2667mm) Unknown

Dots/Inch, std 203 (8 dots/mm) / 300 dpi opt 203 (8 dots/mm)

Max Print Speed 2" - 10" / sec (51mm – 254mm) 6 ips (152mm/sec)

Auto-Calibration Standard NO

Connectivity & Control Solution BradyConnect - Standard

Scalable Fonts Resident Standard Standard

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 4.5" (114mm)

min. 1.0" (25mm) 0.4" (10mm)

Label Length, max. 39" (991mm) Unknown

min. (Tear

/ Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 6.0” (152mm)

Max Ribbon Length 1476' (450m) 656' (200m)

0.25” (200dpi), 0.125” (300dpi) /

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option Standard

Non-Roman (Asian) Font License YES - Option NO

Cutter YES - Option YES - Option

LCD Display Standard NO

Rewind YES - Option Standard

Additional RAM (up to) 1, 2 & 8MB Flash 1MB Flash

1.0 (25mm)

EasyLan10I – Option

(Ethernet dependent)

OTHER

Standard RAM 4 MB DRAM 512K DRAM

Processor / Buffer 32 bit 32-bit

Interface

Serial YES – STD YES – STD

Parallel YES – STD YES – STD

Ethernet YES – Option NO

Shell & Case Construction Metal Plastic

Weight 32lbs (15kg) 10 lbs. (4.7kg.)

Size (H" x W" x L")

BASE UNIT LIST PRICE 1795 € / 2125 € 1420 €

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

6.7" x 9.3" x 13.8"

(170 x 236 x 350mm)

Unknown

The Intermec Technologies name

has global recognition coupled

with a reputation for being a one

source supplier of complete AIDC

solutions (e.g. systems provider

printers, labels, data collection

terminals, etc). Compared to

Brady, their company focus

remains heavily geared toward

RF systems and terminals – and

less on labels and printers.

Disadvantages of Intermec E4

vs. Brady MVP Series

• Faster print speed capability

• Plastic housing on Intermec

• Standard LCD and Ethernet

• No auto-calibration feature

• The MVP series offers

• Full 8” roll capacity on MVP

• More DRAM memory on

on MVP (up to 10ips) versus

6ips on the E4.

E4 versus full metal

enclosure on MVP Series.

option on MVP versus no

Ethernet or LCD on E4.

on E4 versus standard on

Brady MVP.

BradyConnect remote

connectivity and control

solution (standard).

series versus 6” on Intermec

E4.

MVP series (2MB versus

512K) enabling users to print

longer label formats up to

105”.

MVP Series Product Guide - 27 - Competitive Analysis

Page 28

www.bradyeurope.com

Brady MVP Series versus Printronix T-4204

Founded in 1974, Printronix

BRADY vs. Printronix

Brady

MVP Series

Printronix

Thermaline

T-4204

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.09" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 45" (1143mm)

Print Length, optional w/add'l RAM 105" (2667mm) 45" (1143mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard NO

Connectivity & Control Solution BradyConnect - Standard Optional– PrintNet Plus

Scalable Fonts Resident Standard NO

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 4.5" (114mm)

min. 1.0" (25mm) 1.0" (25.4mm)

Label Length, max. 39" (991mm) 45" (1143mm)

min. (Tear /

Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8" (203mm)

Max Ribbon Length 1476’ (450m) 1181' (360m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option Standard

Non-Roman (Asian) Font License YES - Option NO

Cutter YES - Option YES – Option

LCD Display Standard Standard

Rewind YES - Option Standard

Additional RAM (up to) 1, 2 & 8MB Flash N/A

203 (8 dots/mm)/

300 (12 dots/mm)

2" - 10" / sec

(51mm - 254mm)

0.25” (200dpi), 0.125” (300dpi)

/ 1.0 (25mm)

6" / sec (152mm)

OTHER

Standard RAM 4 MB DRAM 4MB DRAM / 4MB Flash

Processor / Buffer 32 bit 32-bit

Interface

Serial YES – STD YES – STD

Parallel YES – STD YES – STD

Ethernet YES – Option YES – Option

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 35 lbs. (16kg.)

Size (H" x W" x L")

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

BASE UNIT LIST PRICE 1795 € / 2125 € 2428 €

12.2" x 9.3" x 15.75"

(310mm x236mm x 400mm)

203 (8 dots/mm)

N/A

is an acknowledged supplier

and innovator of line matrix

printers and continuous form

laser printers. Their T5000

thermal printer line expands

their product focus into the

realm thermal bar coding.

Disadvantages of

Printronix T-4204 vs. Brady

MVP Series

• Higher list price on

T4204 versus affordable

MVP series.

• 10ips print speed on

MVP versus max 6 ips

on T4204.

• The MVP series comes

standard with

BradyConnect remote

connectivity and control

solution. PrintNet Plus is

optional on T4204 and

limited to Java

platforms. Also, does

not include ZBI function.

• NO auto-calibration on

T4204 versus standard

on MVP

• Collapsible ribbon

release on MVP series

versus cumbersome

core to core system on

T4204

• More expandable

memory on MVP series

versus T-4204.

MVP Series Product Guide - 28 - Competitive Analysis

Page 29

www.bradyeurope.com

Brady MVP Series versus Sato CL408e

BRADY vs. Sato

Brady

MVP Series

Sato

CL408e

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.10" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 14" (356mm)

Print Length, optional w/add'l RAM 105" (2667mm) 49" (1249mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard NO

Connectivity & Control Solution BradyConnect - Standard NO

Scalable Fonts Resident Standard Standard

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 5.15" (131mm)

min. 1.0" (25mm) 0.87" (22mm)

Label Length, max. 39" (991mm) 49" (1249mm)

min. (Tear /

Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8.0" (203mm)

Max Ribbon Length 1476' (450m) 1476' (450m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option YES – Option

Non-Roman (Asian) Font License YES - Option Unknown

Cutter YES - Option YES – Option

LCD Display Standard Standard

Rewind YES - Option NO

Additional RAM (up to) 1, 2MB & 8MB Flash

203 (8 dots/mm)

300 (12 dots/in)

2" - 10" / sec

(51mm - 254mm)

0.25” (200dpi), 0.125” (300dpi)

/ 1.0 (25mm)

(51mm - 152mm)

4MB Flash / 16 MB

OTHER

Standard RAM 4MB DRAM 18MB STD

Processor / Buffer 32 bit 32-bit RISC/133 MHz

Interface

Serial YES – STD YES – STD

Parallel YES – STD IEEE/USB

Ethernet YES – Option YES – Option

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 29 lbs. (13 kg.)

Size (H" x W" x L")

BASE UNIT LIST PRICE 1795 € / 2125 € 1582 €

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

12.6" x 16.9" x 10.6"

(320 x429 x 269mm)

203 (8 dots/mm)

2" - 6" / sec

Unknown

PCMCIA-OPT

Sato’s business philosophy is

based on the notion of

manufacturing rugged,

dependable bar code printers

for warehousing and industrial

environments.

Disadvantages of Sato

CL408e vs. Brady MVP

Series

• The MVP offers

BradyConnect remote

connectivity and control

solution (standard).. A

feature currently not

available on Sato printers.

• No auto-calibration on

CL408e -instead dip

switches are factory set at

1/8” between labels.

• LCD standard on CL408e

but only enables you to

receive error messages,

on-line/off-line ready

signal and darkness

settings – all other

configurations are dip

switch controlled.

• Made in Japan (i.e.

sourcing of parts and

technical expertise may

take longer and be more

difficult to obtain).

MVP Series Product Guide - 29 - Competitive Analysis

Page 30

www.bradyeurope.com

Brady MVP Series versus TEC B-472

TEC Corporation is a

Japanese based

manufacturer of retail and

package delivery systems

and other electronic systems

and components. TEC’s

AIDC product offerings

include thermal bar code

printers and POS terminals.

Disadvantages of TEC B472 vs. Brady MVP Series

• The MVP offers

BradyConnect remote

connectivity and control

solution (standard).

• Scaleable fonts standard

in MVP versus bitmap

variety on TEC B-472.

• NO auto-calibration on

TEC B-472 versus

standard on MVP series

• Slower 16-bit processor

on TEC B-472 versus

32-bit on MVP.

• Less standard DRAM

and Flash memory on

TEC 472 versus MVP.

• Made in Japan (i.e.

sourcing of parts and

technical expertise may

take longer and be more

difficult to obtain).

BRADY vs. TEC

Brady

MVP Series

TEC

B-472

PRINT FEATURES

Direct thermal, Direct Thermal DT / TT DT / TT

Print Width, max. 4.09" (104mm) 4.09" (104mm)

Print Length, max. w/std RAM 105" (2667mm) 15" (384mm)

Print Length, optional w/add'l RAM 105" (2667mm) 35" (896mm)

Dots/Inch, std

Max Print Speed

Auto-Calibration Standard NO

Connectivity & Control Solution BradyConnect - Standard NO

Scalable Fonts Resident Standard NO

MEDIA FEATURES

Liner Width, max. 4.5" (114mm) 5.5" (140mm)

min. 1.0" (25mm) 2.0" (51mm)

Label Length, max. 39" (991mm) 35" (896mm)

min. (Tear /

Peel-Off)

Roll Size, O.D. & Mounting 8.0" (203mm) 8" (203mm)

Max Ribbon Length 1476' (450m) 1968' (600m)

OPTIONS

Tear-Off Standard Standard

Peel-Off YES - Option Standard

Non-Roman (Asian) Font License YES - Option Standard

Cutter YES - Option YES – Option

LCD Display Standard Standard

Rewind YES - Option Standard

Additional RAM (up to) 1, 2MB & 8MB Flash 1MB RAM / 4MB PCMCIA

203 (8 dots/mm)

300 (12 dots/mm)

2" - 10" / sec

(51mm - 254mm)

0.25” (200dpi), 0.125” (300dpi)

/ 1.0 (25mm)

(51mm - 254mm)

OTHER

Standard RAM 4MB DRAM 512 DRAM/ 256K Flash

Processor / Buffer 32 bit 16-bit

Interface

Serial YES – STD YES

Parallel YES – STD YES – Option

Ethernet YES – Option NO

Shell & Case Construction Metal Metal

Weight 32lbs (15kg) 37 lbs. (17 kg.)

Size (H" x W" x L")

BASE UNIT LIST PRICE 1795 € / 2125 €

13.3" x 10.9" x 18.7"

(338 x 277 x 475 mm)

12.1" x 11.4" x 18.1"

(308mm x291 x 460mm)

NOTE: ALL product data based on manufacturers’ published spec sheets, which are subject to

change without notice. N/A or Unknown denotes data not found or available.

203 (8 dots/mm)

2" - 10" / sec

N/A

MVP Series Product Guide - 30 - Competitive Analysis

Loading...

Loading...