Page 1

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

Visualize · Mobilize · Realize MCL-Collection

123 Print v1.1x

User Manual

Visualize…printers with intelligence

Realize…123 Print

Page 2

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

i. Preface

Background

Copyright statement © 2007 MCL Technologies

123 Print is developed by MCL Technologies to bring intelligence to

Datamax printers.

123 Print v1.1x User Manual

DATAMAX is a registered trademark of Datamax Bar Code Products

Corporation. Seagull and BarTender are trademarks or registered

trademarks of Seagull Scientific, Inc. Microsoft, Windows, Windows XP,

Windows 2000, and Windows 98 are trademarks or registered

trademarks of Microsoft Corporation in the United States and/or other

countries. All other trademarks are the property of their respective

owners.

All specifications, terms and descr iptions of products and services are

subject to change without notice or recourse.

Page 3

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

Table of Contents

1. Primer........................................................................................................................ 5

1.1. What is 123 Print......................................................................................................... 6

1.2. Sample Labels............................................................................................................. 7

1.3. Project Flow................................................................................................................9

2. Getting Started ......................................................................................................... 12

2.1. Installation ............................................................................................................... 13

2.2. Activation................................................................................................................. 17

2.3. General Setup........................................................................................................... 25

3. Creating a Project...................................................................................................... 32

3.1. Project Description .................................................................................................... 33

3.2. User Interface........................................................................................................... 35

3.3. Labels...................................................................................................................... 51

3.4. Lookup Files.............................................................................................................. 89

3.5. System Setup ......................................................................................................... 110

4. Designing a Label .................................................................................................... 119

4.1. BarTender Integration.............................................................................................. 120

5. Using Processes ...................................................................................................... 128

5.1. Introduction to 123 Print Variables ............................................................................ 131

5.2. Branch................................................................................................................... 134

5.3. Date Operation........................................................................................................ 143

5.4. File Search ............................................................................................................. 147

5.5. Mathematic Operation.............................................................................................. 149

5.6. Other..................................................................................................................... 150

5.7. Serial Communications............................................................................................. 155

5.8. Processes on Variables............................................................................................. 159

6. Simulating Your Project............................................................................................ 171

6.1. Simulation Mode...................................................................................................... 172

6.2. Debugger Mode....................................................................................................... 176

7. Deploying a Printer Project ....................................................................................... 182

7.1. Connect / Disconnect Printer..................................................................................... 1 83

7.2. Printer Status.......................................................................................................... 187

7.3. Printer Control ........................................................................................................ 190

7.4. Load File / Control ................................................................................................... 193

7.5. Load Project ........................................................................................................... 208

7.6. Scripts ................................................................................................................... 209

October 2007 Page 3

Page 4

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

4

Appendix A – Sample License Certificate................................................................................. 218

Appendix B – Datamax Printer Setup...................................................................................... 220

Appendix C – Supported Datamax Printers .............................................................................. 221

Appendix D – System Requirements....................................................................................... 222

Appendix E – Mapping Label Graphic Elements ........................................................................ 223

Appendix F – Connectivity / Function Matrix ............................................................................ 224

October 2007 Page

Page 5

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

1. Primer

Overview

Document

introduction

Chapter 1

introduction

Topics This chapter covers the following topics:

Chapter 1 : Primer

This document is a User Guide for 123 Print V1.x. It is divided into

several chapters to give you a thorough understanding of the use of

123 Print.

Chapter 1 – Primer

Chapter 2 – Getting Started

Chapter 3 – Creating a Project

Chapter 4 – Designing a Label

Chapter 5 – Using Processes

Chapter 6 – Simulating Your Project

Chapter 7 – Deploying a Printer Project

Accompanying appendices provide supplementary information.

This chapter is a Primer that explains the basic concepts of 123 Print

and introduces you to its purpose and the philosophy behind it.

The goal of this Primer is to give you an understanding of the:

General capabilities of 123 Print

Kinds of labels you can print using 123 Print

General project flow behind the creation of static and dynamic

labels

Topic Page

1.1.

1.2

1.3

123 Print Purpose The purpose of 123 Print is to help you create and deploy simple

printing applications for your Datamax Printers. 123 Print manages one

printer at a time. Compatible with Seagull’s BarTender V7.72 and

above, it also allows you to easily create a nd integrate new printer

labels into your application.

What is 123 Print

Sample Labels

Project Flow

6

7

9

October 2007 Page 5

Page 6

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

6

Chapter 1 : Primer

1.1. What is 123 Print

General introduction This section gives an overview of 123 Print, its purpose and its benefits.

123 Print 123 Print is a design environment to create simple, stand-alone

Purpose The purpose of 123 Print is to:

Benefits 123 Print:

applications that run on Datamax printers.

123 Print is an all-in-one product for:

Label design through integration with Seagull Scientific’s BarTender

Data capture design

Application simulation and debugging

Application deployment to drive the printing process

123 Print lets you create printer applications that can initiate an

interactive screen dialogue with the user. This allows the user to input

variable data that is then merged with the labels you print.

123 Print is integrated with Seagull’s BarTender for easy addition of

multiple BarTender labels into your printer application.

Note: If you are interested in connectivity with host systems or

database access to BackOffice or ERP systems from your printer

application, consider using MCL-Designer for Datamax printers. As a

component of MCL-Collection, MCL-Designer allows you create printer

applications with easy host integration.

Make your Datamax printers intelligent

Quickly and easily create simple applications to run on your

Datamax printers

Provide a full application creation environment including label

design through integration with Seagull’s BarTender

Intelligence is in the printer thereby eliminating the need for an

intermediate PC application server to create and send labels to your

printers.

Inputs from barcode scanners, weight scales, etc. are handled

directly on the printer.

Variable input data from, for example, barcode scanners can be

inserted into labels and printed directly from the printer.

Integration with BarTender means you can quickly create new

labels or import existing BarTender labels into 123 Print for use

with your 123 Print projects.

Multi-purpose, multi-label projects for your Datamax pr inters with

up to 50 screens per selected label.

Ability to create friendly printer user interfaces easily.

October 2007 Page

Page 7

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

7

Chapter 1 : Primer

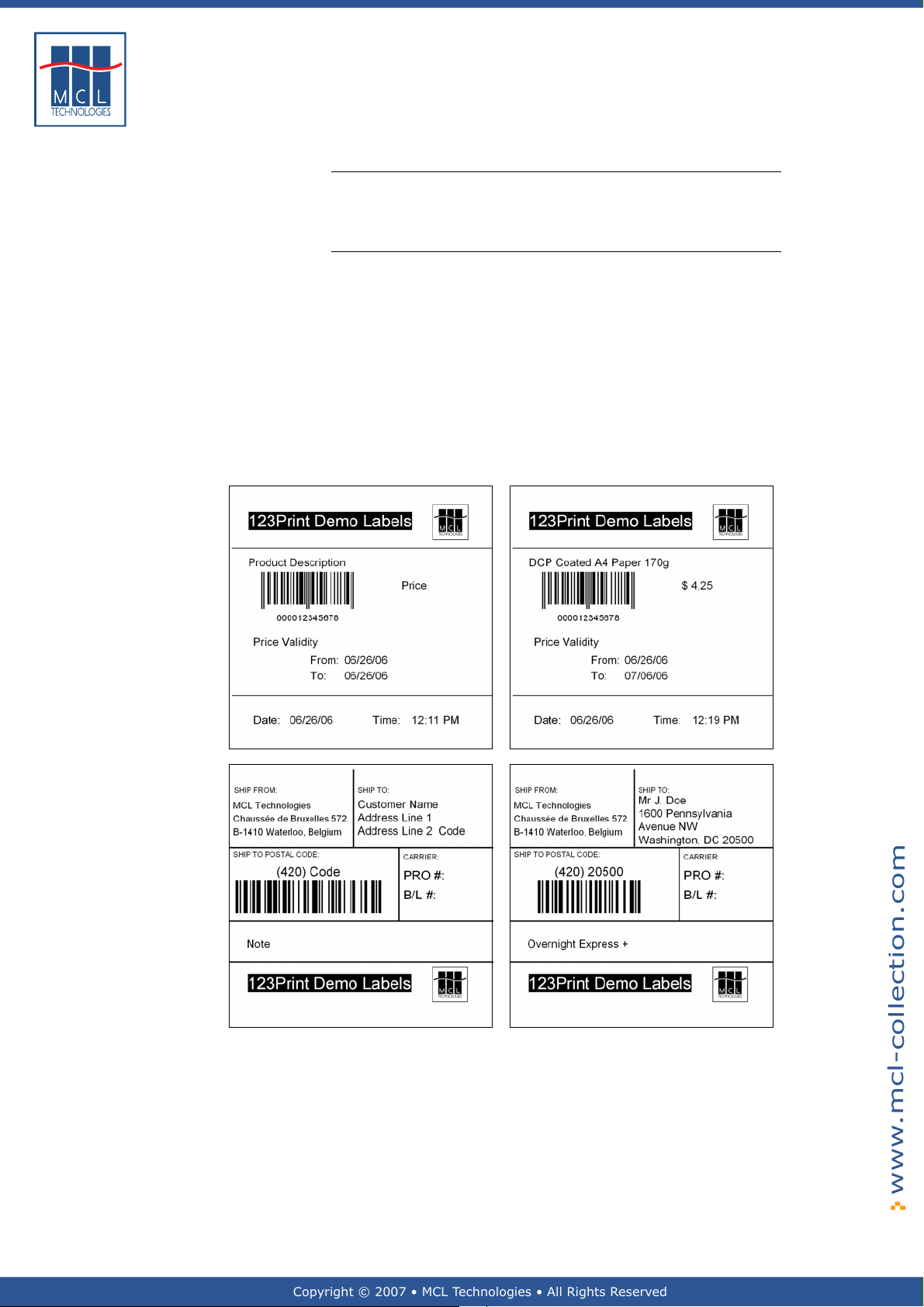

1.2. Sample Labels

General introduction This section shows some sample labels to give you an idea of the

Sample labels The sample labels shown here were designed using Seagull’ s

kinds of labels you can print using 123 Print projects on Datamax

printers.

BarTender label creation software.

123 Print provides the capability to associate and print variable data

on labels.

Consider the sample labels shown below. The labels on the left are

templates that would be saved on your printer with your 123 Print

project. The labels on the right show the actua l label that will come

off the printer after the 123 Print project inserts the variable data

into the template and initiate s a print of the completed label.

Your 123 Print project can receive variable data from many

sources—barcode scanner input, weight scale input, user keyboard

input, lookup files, etc.

October 2007 Page

Page 8

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

8

Chapter 1 : Primer

October 2007 Page

Page 9

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

9

Chapter 1 : Primer

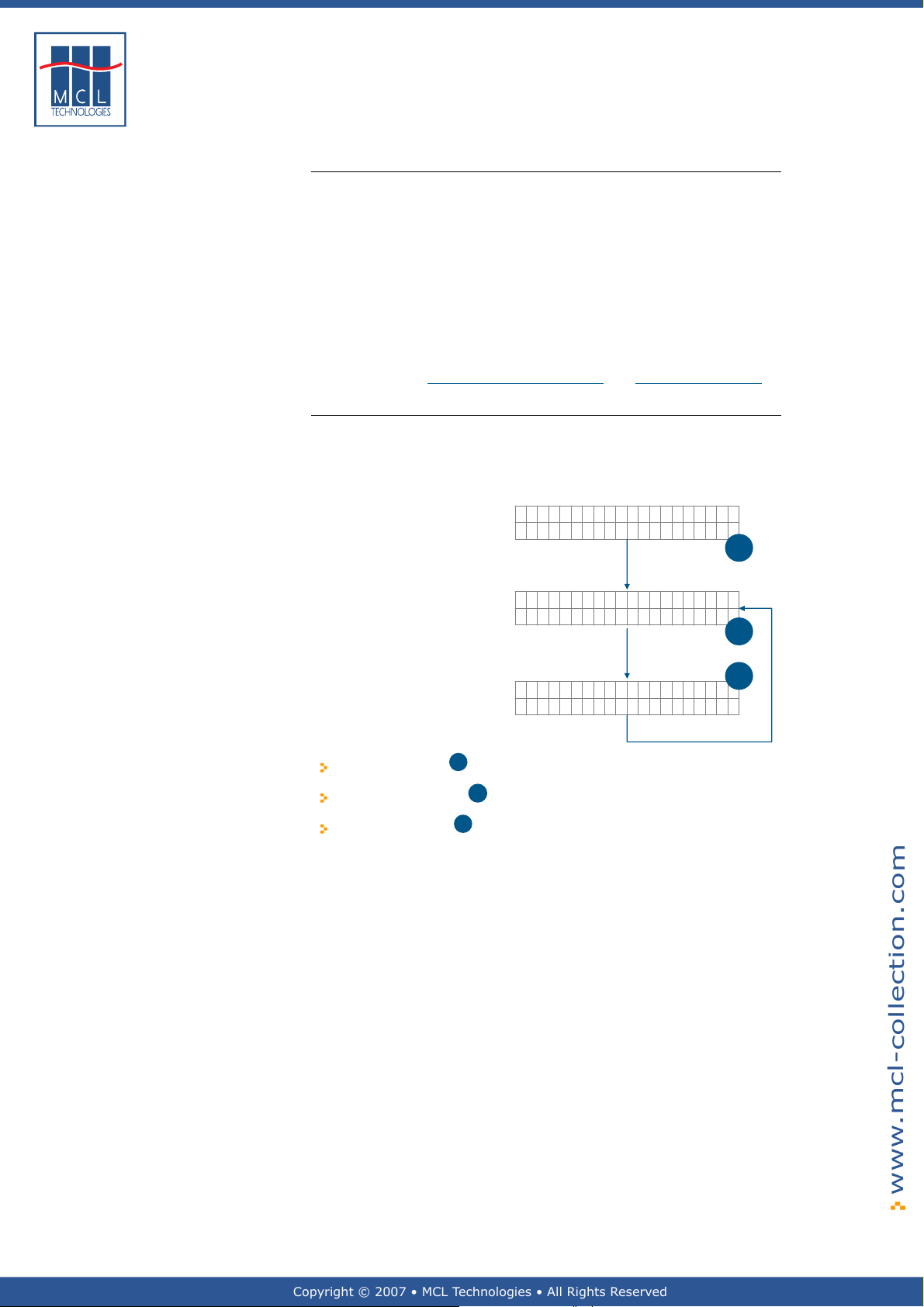

1.3. Project Flow

General introduction 123 Print structures your project flow using a combination of screens

User Interface Every 123 Print project follows a pre-defined screen flow. You configure

and processes that you create via 123 Print’s User Interface and

Labels.

This section gives a high level view of the flow and interrelation ship

between the screens that are created via the User I nterface and those

created via Labels.

With User Interface, you can print any static label you want.

With Labels, you can change a static label into a dynamic label by

merging in variable data from data collection, user screen prompts, and

processing logic.

Please reference Section

for detailed information about these functions.

these screens through the User Interface function. This is the only

screen flow function you need if you want to print static labels.

This core flow is depicted here.

3.2 – User Interface and Section 3.3 – Labels

Your Project Name

Ver 1.00

1

Select Label:

<Label Name>

2

3

<Label name>

Qty to Print:

The first screen 1 is a Welcome screen.

The second screen is the Select Label screen.

The third screen 3 is the Quantity to Print screen.

These screens are displayed in a black font on the Datamax printers.

When your 123 Print project is run on the printer, it first displays the

Welcome screen. It then goes into a lo o p alternating display between

the Select Label screen and the Quantity to Print screen.

Your application will loop infinitely between the second and third

screens until you press the Menu (ESC) button on the front panel of the

Datamax printer.

As you design your project in 123 Print, you have the option to

customize the Welcome screen. By default 123 Print proposes your

project name for the Welcome screen.

You then add the labels you want to be able to print from your project.

When your project is run, this list of labels is presented on screen (2).

The user presses the Fwd ↑ and Rev ↓ buttons on the printer’s front

panel to scroll through the list of available labels and, by pressing the

Ent ↵ button, selects the label that is required for a given operation.

Here is an example of what screen (2) might look like on a printer when

the fourth label in your project is a label f or pallets:

October 2007 Page

Page 10

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

10

Chapter 1 : Primer

Select Label:004

▼▲

Pallet Label

2

In this case, the third screen will look like the scr een below. Notice that

the label name, Pallet Label, from screen (2) has au tomatically been

displayed on the first line of screen (3).

Pallet Label

Qty to Print:1..

The user presses the Fwd ↑ and Rev ↓ buttons on the printer’s front

panel to increment or decrement the quantity of the label to be printed.

The user then presses the Ent ↵ button on the printer’s front panel to

initiate the printing. The label is printed in the quantity specified. The

project then loops back to display screen (2) again. The user can select

the same label for printing again, or may select a different label to

print.

This is useful in pallet building, for example. You may want to print

many item labels. Then, when all the items on the pallet have been

labeled, you can print a label for the e ntire pallet. In this case, the user

selects the item label many times and then finally selects the pallet

label once. The user then returns to printing item labels for the next

pallet build.

A fourth standard screen

of the 123 Print application logic but rather is displayed by the Datamax

printer whenever a print error occurs after

The default print error screen is as shown here

4

, a Print Error screen, exists. It is not part

3

above has been initiated.

3

▼▲

Print Error

4

Exit Retry

This message will be displayed, for example, if the label roll is out of

labels.

The User Interface function allows you to customize this error message.

Labels If you are only concerned with static labels, you only need to use the

Labels function to identify the static labels you want to include in your

project.

If, however, you want to create dynamic labels, you will want to take

advantage of the full capabilities provided in the Labels function.

The flow described above under User Interface is not sufficient to

include variable data on the label. Consider an item label, for example.

You want to print an item label with an item barcode, an item

description, and an item weight. However, you do not know in advance

which item, the item description, or the item weight (fruit, meat, etc.)

for the label to be printed. You want to collect this information and

merge it with your label format at the moment you print the label.

123 Print allows you to design this capability into your project. It allows

you to create a series of screens for user interaction, and implement a

series of processes for data manipulation or peripheral communications.

Since each label may involve a different set of variable data, these

screens and processes are associated with the given label in what is

called a label program.

Using the Labels function, you can design a series of screens and

processes to collect data that you then merge as variables into the label

to be printed.

The following diagram depicts the relationship between User Interfa ce

created screens and flow, and Labels created screens and flow.

October 2007 Page

Page 11

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

11

Chapter 1 : Primer

User Interface:

Core screen flow

Select Label:003

Item Label

Item Label

Qty to Print:1..

▼▲

▼▲

Labels:

Label program

2

Enter Item Code

_____________

Process:

Get Item Descripti on

from Lookup File

Item on Scale? Y/N

_

Process:

Weigh Item

Map variables into

label format

3

C

Item Code

A

D

Item

X

Description

B

E

Item’s Weight

Y

Z

Label printed

with item

code, item

description

and weight

merged in

User Interface:

The left-hand side of the diagram shows the core flow created

by User Interface. User input is required on screens

Labels:

The right-hand side of the diagram shows the flow of a label

program to capture the variable data needed to complete the

item label selected at

User input is required on screens at

The item code entered in

A process at

X

is used to browse through a lookup file to get

the item description for the item code entered in

The item description is saved in a variable at

When the user indicates at

weighed, a process at

save the item’s weight in a variable at

Label Mapping is used at

C

in

, D and E with the label format for the item label

The variable label information is then passed back to the User

Interface function at

User Interface and Labels relationship:

The selection of the item label at

program depicted on the right-hand side of the diagram

When the label program is finished, it passes control back to

the User Interface at

A

and B

A

is saved in a variable at C

A

D

B

that the item is ready to be

Y

is used to read the weight scale and

E

Z

to merge the variable data saved

3

for printing

starts the related label

3

to print the label

and 3

October 2007 Page

Page 12

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

2. Getting Started

Overview

Chapter 2

introduction

Topics This chapter covers the following topics:

This chapter describes the installation and setup of 123 Print.

Topic Page

Chapter 2 : Getting Started

2.1.

2.2

2.3

Installation

Activation

General Setup

2.3.1 DPL Connection

2.3.2 MCL Connection

2.3.3 Local Settings

2.3.4 Others

13

17

25

October 2007 Page 12

Page 13

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

13

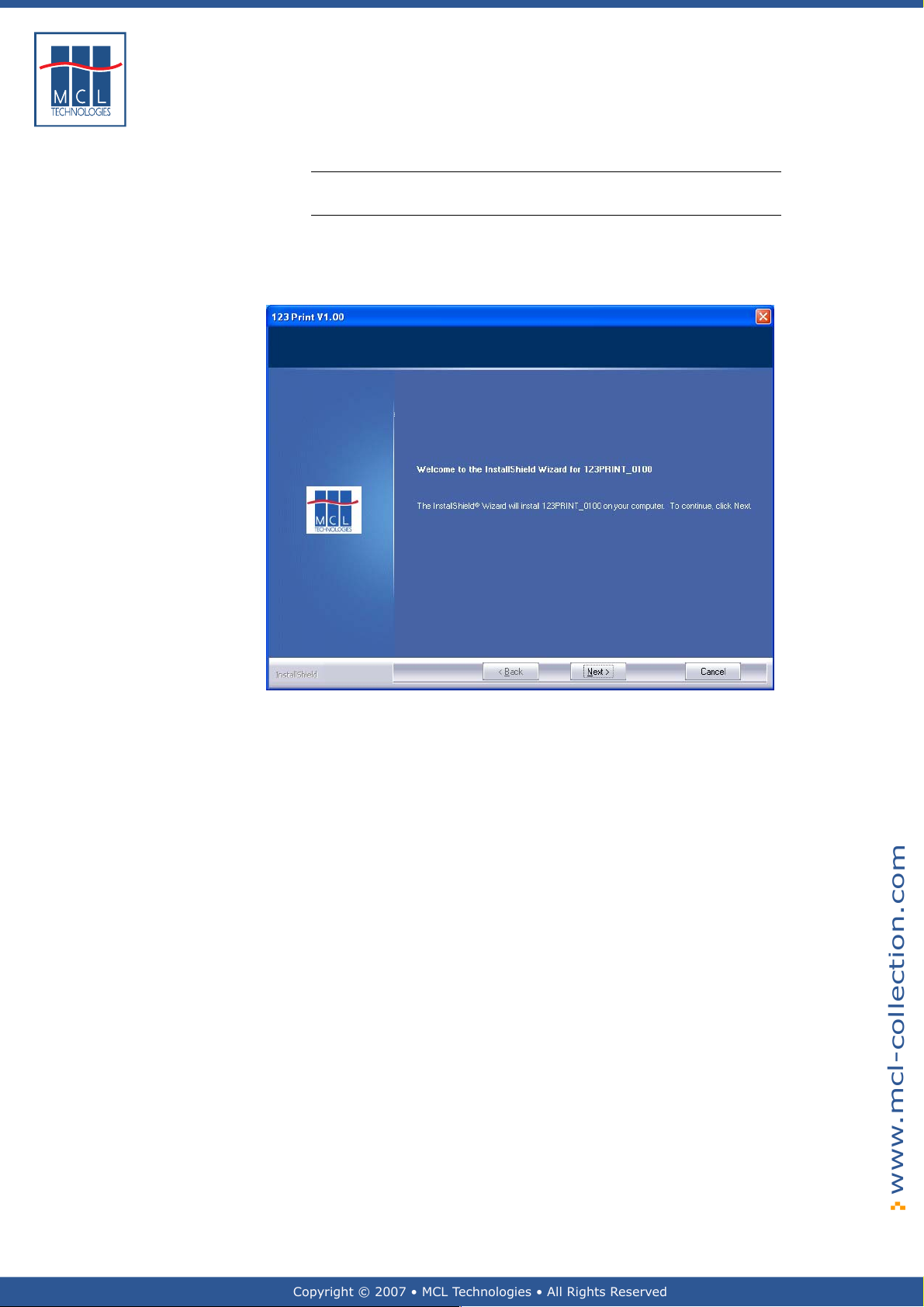

2.1. Installation

General introduction This section describes how to install 123 Print.

Chapter 2 : Getting Started

Installation

1 Double-click on the 123 Print installation executable which you

have downloaded. The default folder in which 123 Print is installed

is C:\123Print

A welcome screen is displayed as shown below

2 Click Next to proceed with the installation

October 2007 Page

Page 14

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

14

Chapter 2 : Getting Started

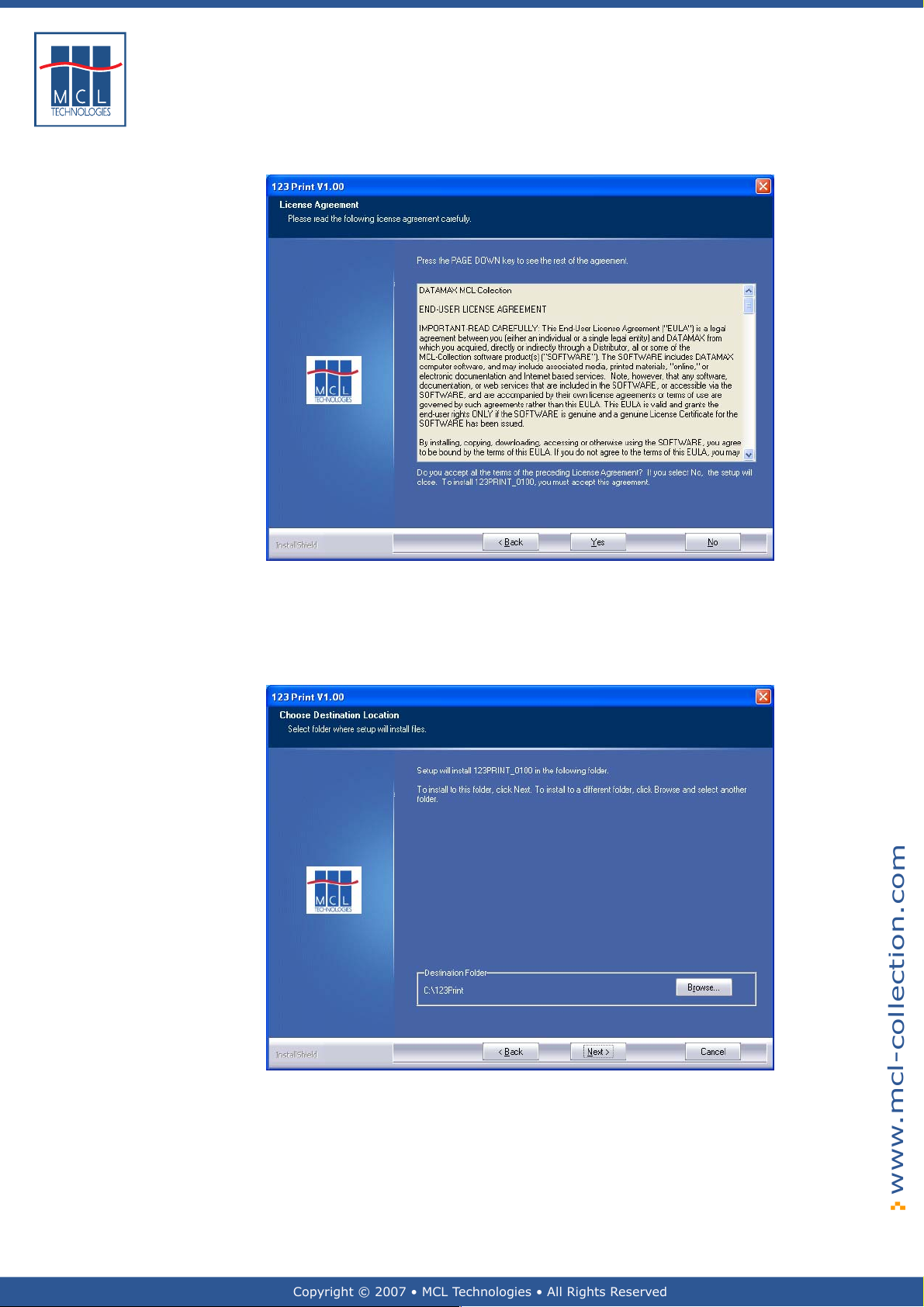

An end-user license agreement is displayed as shown below

To accept the license terms and proceed

3 Click Yes

As shown below, a screen is displayed prompting you to enter the

location where you want to install 123 Print.

4 Click Next to use the default folder for your installation, or

5 Edit the entry or browse for the folder where you want to install

123 Print

6 Click Next

October 2007 Page

Page 15

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

15

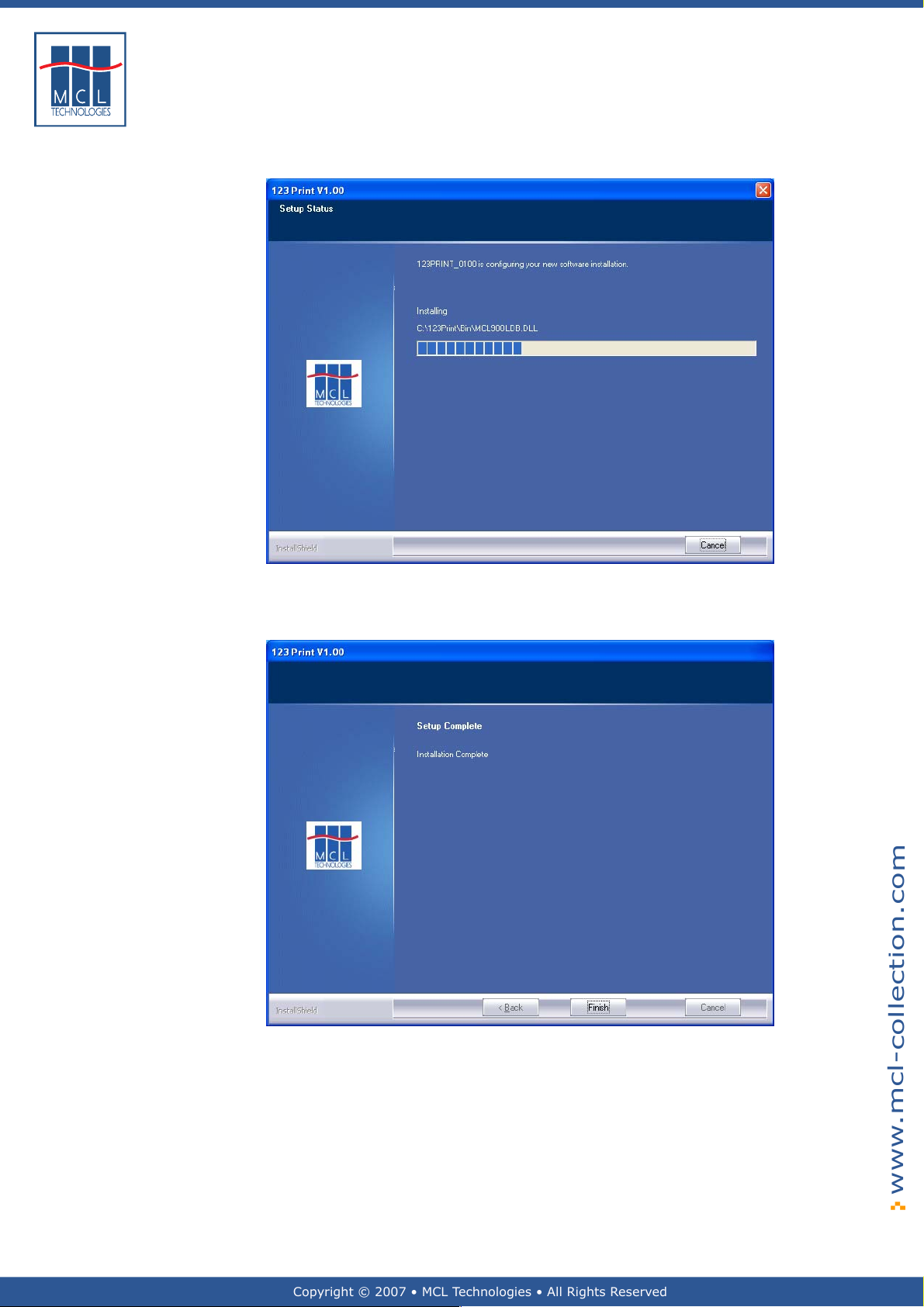

As shown below, a screen is displayed to show you the progress of the

installation

Chapter 2 : Getting Started

The following is displayed when installation is completed

7 Click Finish

October 2007 Page

Page 16

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

16

Starting 123 Print Once 123 Print is installed, start it by:

1 Double click on the 123 Print shortcut icon on the Windows

desktop

Chapter 2 : Getting Started

The 123 Print splash screen is superimposed on the 123 Print

environment

October 2007 Page

Page 17

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

17

Chapter 2 : Getting Started

2.2. Activation

General introduction This section describes the activation process for 123 Print.

During the activation process you will be prompted to choose between a

Software Activation and a Hardware Activation for your 123 Print

license. Be sure to understand the benefits of each method and the

consequences of choosing one method over the other.

Be sure to make your choice carefully. The activation method you

choose cannot be changed at a later stage.

Activation The first time you run 123 Print, you will be prompted to Activate the

software. To do this, you will need to have the License Certif icate ready

which you have received, by email, when you ordered 123 Print.

1 Get out your 123 Print License Certificate. Please see Appendix A

for a sample certificate.

2 Click Next to begin the Activation Process.

Note: No activation is requir ed to run the software in demo mode.

However, 123 Print has reduced capabilities when it is run in demo

mode. For example, you cannot download a project or execute a script.

October 2007 Page

Page 18

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

18

Chapter 2 : Getting Started

3 Enter the License Number found on your License Certificate

4 Click Next

October 2007 Page

Page 19

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

19

End-user license

agreement

Chapter 2 : Getting Started

MCL’s End-User License Agreement is displayed as shown below. Before

proceeding, you must read and accept these license terms.

5 Read and scroll down to the bottom of the terms

6 Check the checkbox to accept the license terms

7 Click Next

The 123 Print software registration form is displayed

8 Enter the details of the company to whom the License should be

registered

9 Click Next

Note: Only Organisation and Country are compulsory fields. However,

the more details you provide, the easier it will be for MCL Technologies

to provide technical assistance in the future, should assistance be

necessary.

October 2007 Page

Page 20

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

20

Software versus

hardware activation

Chapter 2 : Getting Started

The next step is to choose between Software Activation and Hardware

Activation.

This choice is very important as it cannot be changed at a later

stage.

Software Activation: Using this method of activation, 123 Print

computes a Serial Number from various components on your PC.

123 Print then ties your license number to this computed Serial

Number. Thus, your software becomes PC Dependent. You will

not be able to transfer your licensing details over to a different PC

if you want to install and run 123 Print on a different PC.

Hardware Activation: This method of activation requires the

purchase of a Hardware Serial Number Key. Using this method of

activation, 123 Print ties your license number to the serial number

of your Hardware Key. Thus your software becomes PC

Independent. This means you can install and run 123 Print on a

different PC at anytime, providing you are able to plug your

Hardware Serial Number Key into the other PC. The Hardware Key

must be present for the software to run.

Once you have made your choice between Software and Hardware

activation:

10 Check the appropriate checkbox

11 Click Next

October 2007 Page

You are prompted to confirm your selection as shown below

Page 21

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

21

Chapter 2 : Getting Started

12 Click Next to confirm and proceed

The Activation mode screen is displayed as shown here

Indicate if you want to use on-line or off-line activation

13 Click the appropriate radio button

14 Click Next

Your system needs internet access for on-line activation to be possib le.

This example uses on-line activation. Consequen tly, the On-Line

Activation screen is displayed as shown below.

The off-line activation mode will step you through the activation process

in a similar fashion.

October 2007 Page

Page 22

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

22

Chapter 2 : Getting Started

15 Enter the Password found on your License Certificate

16 Click Next

You are prompted to confirm that your registration information is

accurate

17 Click Next to confirm the details you entered on the previous

October 2007 Page

screens.

123 Print now connects to MCL’s Licensing Server and records your

details on the server. The Licensing Server then returns an Activation

Key. When the Activation Key is received, your software is ready to be

used.

An Activation successful screen is displayed as shown below.

Page 23

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

23

18 Print this information and keep it in a safe place for later use in

case of disaster recovery.

Chapter 2 : Getting Started

19 Click Next to validate your activation.

You are now prompted to save a backup of your License Key. It includes

your license number, serial number and activation key.

20 Edit the entry or browse to the location where you want your

License Key backed up

21 Click Next

Note: It is very important for you to record and save a backup of your

license key. This is the only way MCL Technologies can help you recover

your 123 Print license in the event of a disaster.

October 2007 Page

Page 24

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

24

A successful backup screen is displayed as shown here.

Chapter 2 : Getting Started

Starting 123 Print When the activation is completed, 123 Print is started automatically. To

22 Click Finish

start 123 Print again in the future, double click on the 123 Print short

cut on the Windows desktop

The main 123 Print window is displayed as shown here

October 2007 Page

Page 25

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

25

Chapter 2 : Getting Started

2.3. General Setup

General introduction This section describes the setup of 123 Print to allow it to operate in

Setup To enter 123 Print’s setup, on the menu bar:

your environment. This setup involves the settings that are required by

123 Print to work with your printer, simulate your project, and integrate

with BarTender.

1 Click Tools

2 Click 123 Print Settings

The Setup dialogue box is displayed as shown here

Before you can do anything using 123 Print, you need to set up 123

Print for initial communicat ions with your printer for DPL Mode and MCL

Mode where:

DPL Mode refers to the mode in which 123 Print communicates with

the printer using DPL commands.

DPL is the Datamax language used to print a label and control the

printer. These are commands like <STX>F. Please refer to your

Datamax manual for more information.

DPL Mode is a one-way communication between 123 Print and the

printer.

MCL Mode refers to the mode in which 123 Print communicates

with the printer using MCL commands to direct the printer and run

MCL applications.

These are commands like NO|001|TF|INVENTORY.DAT|AA.DAT.

Please refer to your MCL-Link manual for more information.

MCL Mode is a two-way communication between 123 Print and the

printer. For example, 123 Print may ask for a parameter and

receive values in return, or 123 Print may send a file and receive

an acknowledgement upon the successful completion of the

transmission.

123 Print determines which mode to use—DPL Mode or MCL Mode.

123 Print always tries to use MCL Mode as the default mode.

However, if it cannot establish communications using MCL Mode,

then 123 Print reverts to using DPL Mode. This will occur if the

printer settings and 123 Print settings do not match for the values

given in Section

Connect/Disconnect Printer

2.3.2 – MCL Connection and Section 7.1 –

.

October 2007 Page

Page 26

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

26

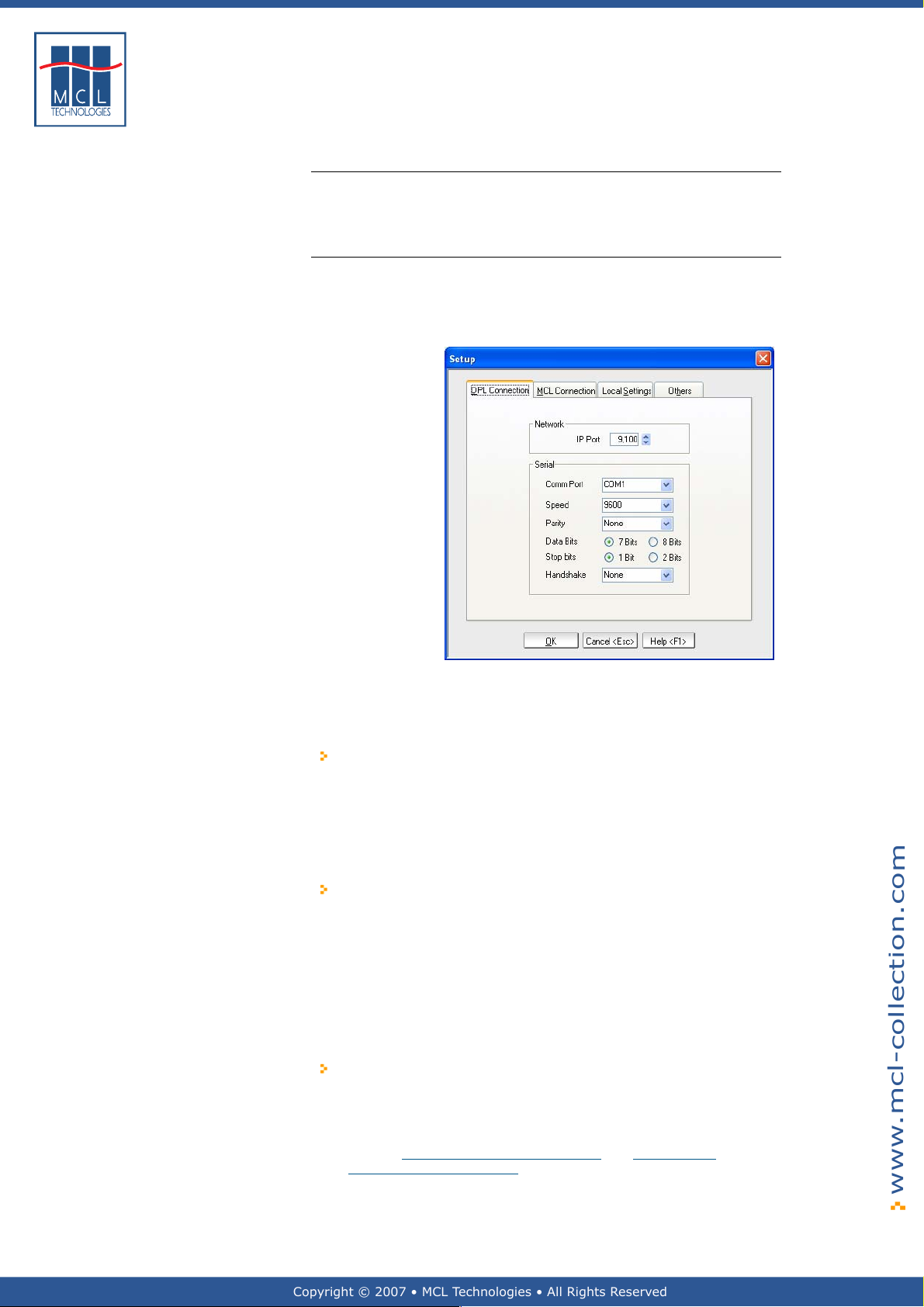

2.3.1. DPL Connection

DPL Connection Setup your printer interface fo r DPL Mode communications. In the

Setup dialogue box:

1 Click on the DPL Connection tab

If you want to use network communications for your DPL commands :

2 Edit the Printer TCP port with the appropriate port number

(typically 9100 or 3000).

If you want to use serial communications for your DPL commands:

3 Edit the Serial settings with values appropriate for your printer

These values may be found through the menu on your printer or in

your Datamax printer manual.

Chapter 2 : Getting Started

October 2007 Page

Page 27

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

27

Chapter 2 : Getting Started

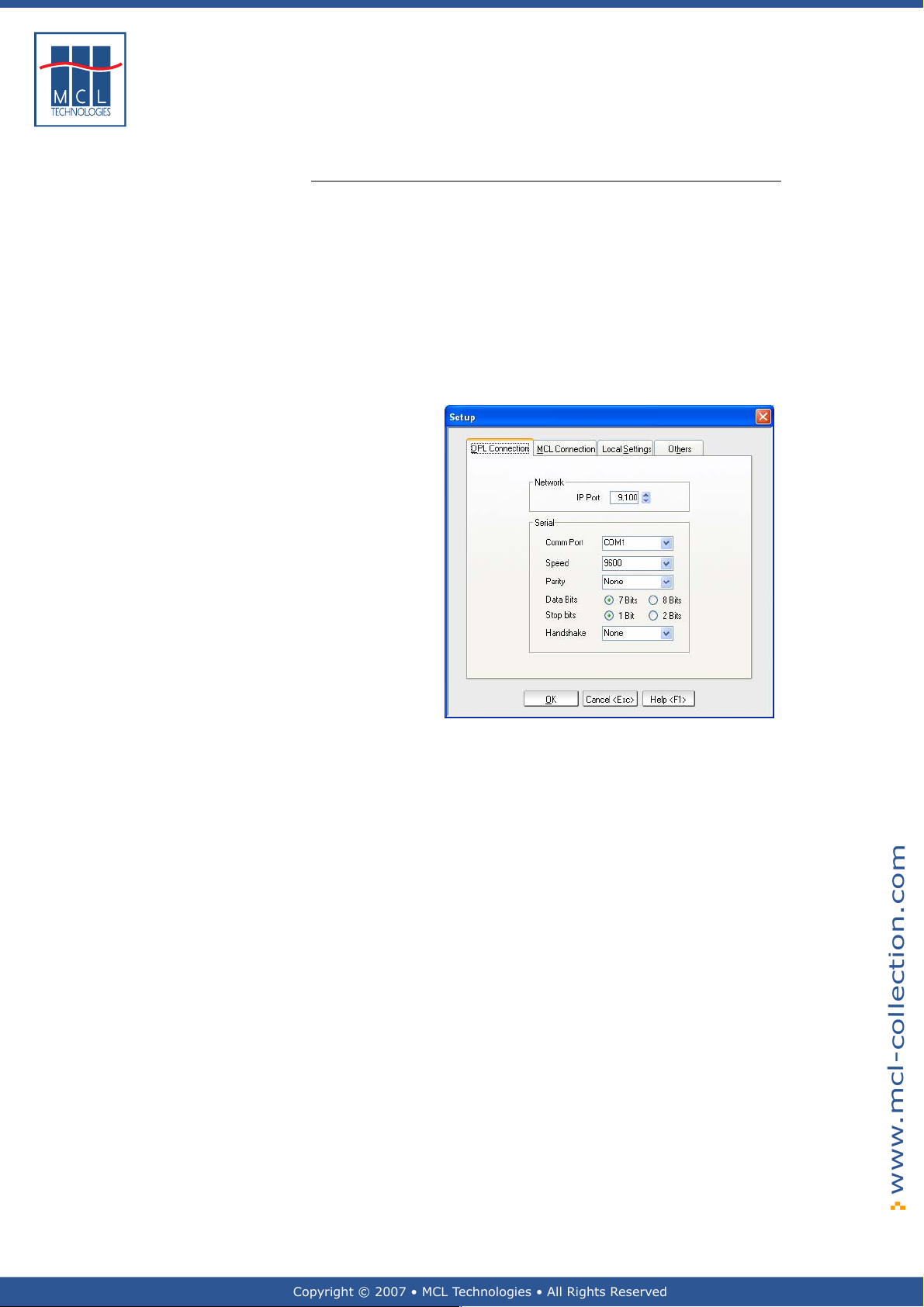

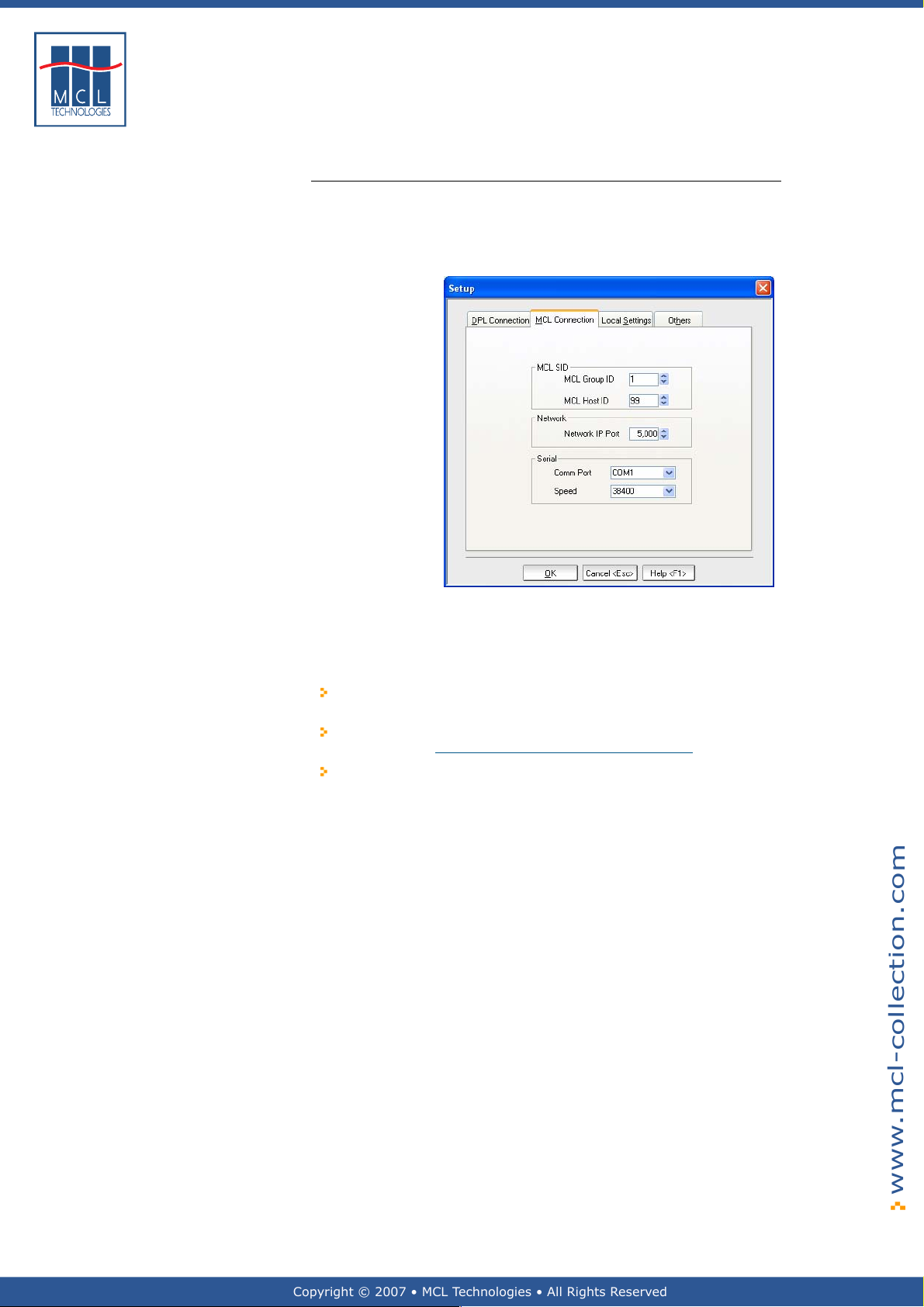

2.3.2. MCL Connection

MCL Connection Next setup yo ur printer interface for MCL Mode communications. In the

Setup dialogue box:

1 Click on the MCL Connection tab

The MCL Connection options screen is displayed as shown here

MCL Group ID can be any number from 001 to 255.

In the MCL Group ID setting, enter the value of the Group ID you

assigned to the printer to which you want to connect.

Think of the Group ID as a way of segmenting your printers similar

to a subnet segmentation of network devices.

Each printer is identified by 123 Print by combining Group ID +

MCL ID. (See Section

If you have, for example, 750 printers on your network, segment

your printers into 3 groups of 250 printers each. Assign each of the

250 printers to the same group and assign a Group ID of 001, 002

or 003, for example, to those printers. Then assign a unique MCL

ID such as a number from 001 – 250 to each of the printers within

the group.

These assignments will allow you to uniquely identify all 750

printers on your network.

MCL Host ID can be any number from 001 to 255. It is typically set to

099. This ID is used by the MCL protocol for communications between

the Datamax Printers and 123 Print. The MCL Host ID is used to identify

123 Print as the host for these printer communications.

UDP Port is typically 5000.

Comm Port is the port that 123 Print should use on its own platform to

communicate serially with a printer.

Speed is the baud rate of the serial port as determined by the printer.

Please reference your Datamax manual for information about serial

comm speed.

7.1 – Connect/Disconnect Printer).

October 2007 Page

Page 28

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

28

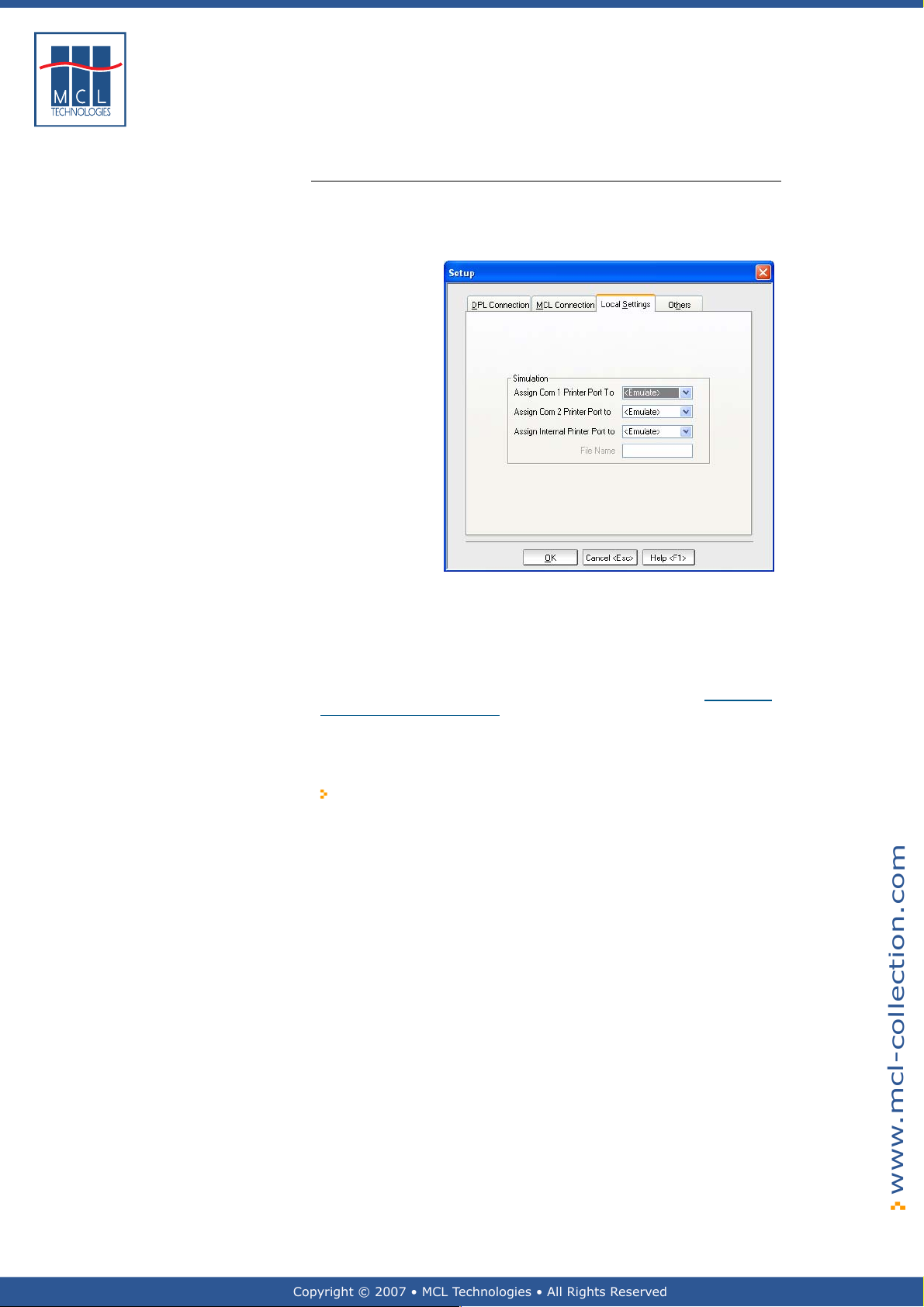

2.3.3. Local Settings

Local Settings Next, setup project simulation options. In the Setup dialogue box:

1 Click on the Local Settings tab

The Local Settings screen is displayed as shown here

Chapter 2 : Getting Started

The project you run on a printer may require inputs from peripherals

such as a barcode scanner on printer port 1 and weight scale on printer

port 2.

Therefore, when you simulate your project in 123 Print, you will want to

emulate the input these peripherals give or connect directly to the given

peripheral to receive its input on your development PC. (See Chapter 6

– Simulating Your Project).

This Simulation setup lets you define the source—emulation or

peripheral connection to a port on your PC—of these inputs for your

simulation.

Assign Com 1 Printer Port To

This option lets you indicate from where the simulator should

fetch the port 1 input in simulation. This is to simulate what

the final project will receive from printer port 1 when th e

project is running on a printer.

If this is a barcode scanner, you can choose to emulate the

scanner input, or you can connect the scanner to any port on

your PC. Indicate the port to which the barcode scanner will

actually be connected on your PC. The 123 Print simulator will

map this port as port 1 input.

2 Select the desired option for printer port 1 simulation.

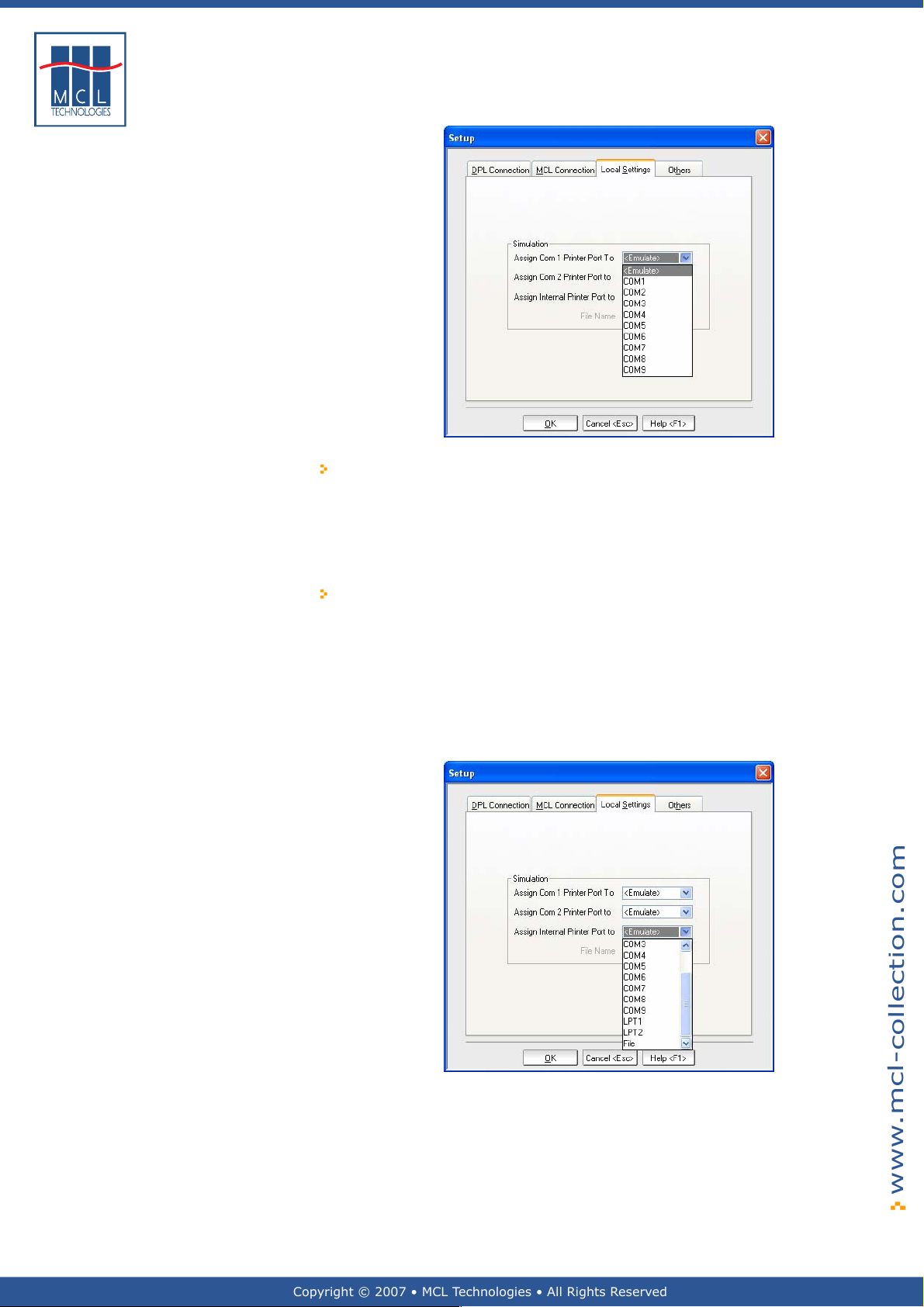

The com 1 simulation setting options are as shown below

October 2007 Page

Page 29

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

29

Assign Com 2 Printer Port To

This option is identical to the Assign Com 1 option. This option

simply lets you simulate a peripheral, such as a weight scale,

that would normally be connected to port 2 on the printer.

Chapter 2 : Getting Started

3 Select the desired option for printer port 2 simulation

Assign Internal Printer Port To

This option allows you to simulate label printing when you are

running your project in simulation.

You can emulate the label print or send the label as output to a

port on your development PC.

The output may be sent to a serial com port, an LPT (parallel)

port, or to a file. Sending the output to a file is useful if you

want to see the DPL code your project is using to print labels

The internal printer port simulation options are as shown below

on your printer.

4 Select the desired option for label printing simulation

5 Click OK

October 2007 Page

Page 30

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

30

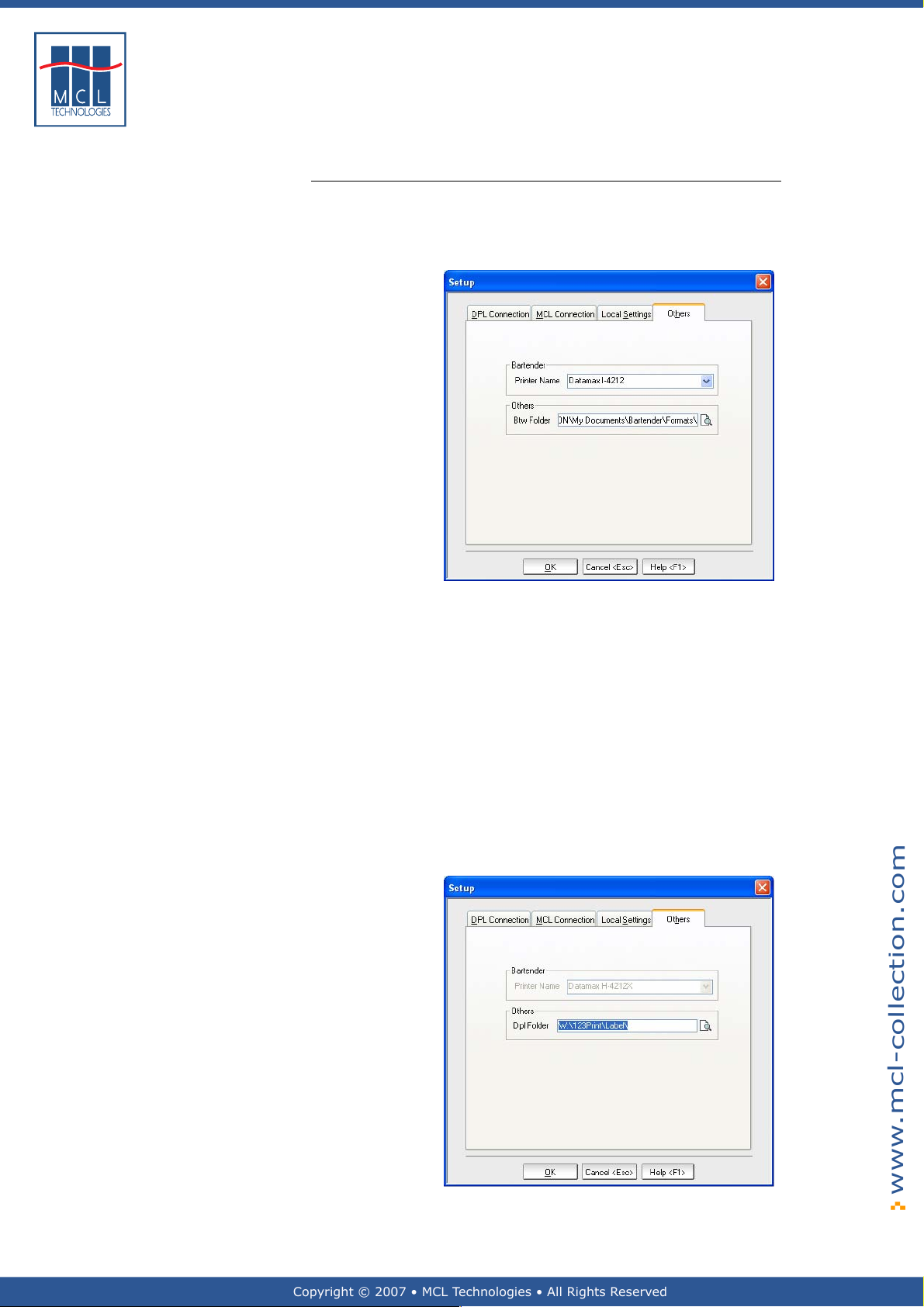

2.3.4. Others

Others Set up the values for 123 Print’s integration with BarTender or DPL

labels. In the Setup window:

1 Click the Others tab

The Others dialogue box is displayed as shown here

Chapter 2 : Getting Started

If BarTender is installed and activated on your system:

2 In the Printer Name field, identify the default printer to be used for

your project. 123 Print passes this printer model to BarTender to

use as the default printer for label design for your project when you

invoke BarTender from the 123 Print toolbar while creating your

project.

3 In the BTW Folder field, navigate to the folder you plan to use as

your common folder for your BarTender labels.

By default if BarTender is installed on your system, 123 Print assigns

MyDocuments/BarTender/Formats for your BarTender labels. This is the

default path BarTender uses when saving labels.

If BarTender is not installed on your system, 123 Print expects your

labels to be DPL labels. It assigns a default path of C:\123Print\Label as

the location of your DPL label folder.

4 Click OK to use this path or navigate to the folder you want to use

October 2007 Page

Page 31

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

Timer is used to set the duration, in seconds, of the display of the

Welcome screen. The Welcome screen is typically displayed

momentarily only

Chapter 2 : Getting Started

5 Edit the timer value, or

6 Use the up and down arrows beside the timer field to increment

or decrement the value of the field.

October 2007 Page

31

Page 32

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

3. Creating a Project

Overview

Chapter 3

introduction

Description 123 Print provides you with all the tools necessary to create

Topics This chapter covers the following topics:

This chapter describes how to use 123 Print to create projects and label

programs for your Datamax printers.

applications for your Datamax printer. A 123 Print project involves 4

basic screens:

Welcome Screen

Select Label screen

Quantity to Print screen

Print Error Message screen

You may associate several additional screens (up to 50) with each label

in your project. As you create these additional screens you are creating

what is called a label program.

Chapter 3 : Creating a Project

Topic Page

33

35

51

89

110

Display Only

3.1.

3.2

3.3

3.4

3.5

Project Description

User Interface

Labels

Lookup Files

System Setup

3.2.1 Welcome Screen

3.2.2 Select Label Screen

3.2.3 Quantity to Print Screen

3.2.4 Print Error Message Screen

3.3.1 Edit

3.3.2 Variables

3.3.3 Mapping

3.4.1 Add Lookup File

3.4.2 Add Lookup File from Import File

3.4.3 Add Lookup File from Scratch

3.4.4 Edit Lookup File Data

3.5.1 Soft Keys Setup – Graphical

3.5.2 Auxiliary Co mmunications

October 2007 Page 32

Page 33

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

33

Chapter 3 : Creating a Project

3.1. Project Description

General introduction This section describes how to begin creating your 123 Print project.

New Project Start first by creating a new project. On the menu bar:

1 Click File

2 Click New

Alternatively, on the tool bar, click on the New Project

The Project Description screen is displayed as shown here

icon.

Notice that there are 6 fields available to describe the p roject you are

creating:

Project Name *

Version *

Author

Printer Type *

Printer Name

Notes

The three fields flagged by * are compulsory fields.

The name you wish to assign to your

project/application

The build version of your application. This is a

number you assign for project version control

Typically your name or the name of the

company creating the application

The target Datamax printer model for the

project you are creating.

An alias for the targeted printer. This is useful

for the later management of a group of

printers

Notes you write about this project for future

reference

October 2007 Page

Page 34

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

34

On the Project Description screen:

Chapter 3 : Creating a Project

3 Edit the fields with the appropriate data

When you have completed editing these fields, notice that the following

buttons appear on the left-hand side of the main window:

The functions associated with these buttons are discussed in the

subsequent sections of this chapter. These are the functions used to

create your 123 Print project.

To return to the Project Description at any time, on the menu bar:

4 Click Project

5 Click Project Description.

Alternatively, simply cli ck the Project button

on the left-hand side of the main window

October 2007 Page

Page 35

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

35

Chapter 3 : Creating a Project

3.2. User Interface

General introduction This section describes the User Interface core screens of your 123 Print

User Interface

project.

The User Interface is where you configure the core screens with which

the user will interact on the Datamax printer.

Click the User Interface

hand side of the main window, or on the menu bar:

button on the left-

1 Click Project

2 Click User Interface

The User Interface window is displayed.

By default, the User Interface uses the project description values

entered in Section

information to present a User Interface, as shown below, that is

appropriate for the display type — text display or graphical display —

available on the printer model selected for the given project.

The User Interface window shows 4 default screens:

Welcome Screen

Select Label

Quantity to Print

Print Error Message

These 4 screens form the basis of all 123 Print projects you create.

These screens can be edited. They contain a combination of data entry

fields and editable text.

A variety of colors are used on these screens to help config ure them:

Gray

Blue

Red

Green

= User read-only text on printer

= Variable content in project development

= User variable input field on printer from barcode scanner

= User variable input field on printer from front panel or

3.1 – Project Description. It also uses this

connected keyboard

October 2007 Page

Page 36

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

36

Chapter 3 : Creating a Project

Text Display

The User Interface for a text display printer is as shown here:

Graphical Display -

Large

The User Interface for a large graphical display printer is as shown here.

October 2007 Page

Page 37

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

37

Chapter 3 : Creating a Project

Graphical Display -

Small

The User Interface for a small graphical display printer is as shown here:

Graphical Display -

Status Toolbar

The status toolbar across the top of the graphical display screens gives

the following printer status:

Printer is Ready

Printer is Paused

Printing Error

Printer is Printing

The Printer is Printing status is accompanied by the Printer Ready status

and a Printing Progress indicator as shown here:

October 2007 Page

Page 38

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

38

Chapter 3 : Creating a Project

3.2.1. Welcome Screen

Welcome Screen The Welcome screen is the first screen the user will see when they start

Text Display The Welcome Screen editing window for a text display printer is as

your 123 Print project on the printer. You can edit the welcome you

want to give the user. Notice that, by default, 123 Print uses the details

you entered in the Project Description in Section 3.1.

To edit the Welcome screen, on the User Interface window:

1 Click on the Welcome screen, or

2 Click the Welcome button at the bottom of the window

As with the Interface Screen, the Welcome Screen varies according to

the display type available on the printer model s elected for the given

project.

shown here:

Edit the Welcome screen to give the desired information

3 On Line 1 enter up to 20 characters of text

4 On Line 2 choose one of the system variables as shown below:

If you select Project Version, the Version you enter in th e Project

Description in Section 3.1 is displayed on Line 2 of the Welcome screen.

Similarly, if you select Printer Model, the Printer Type you enter in the

Project Description in Section 3.1 is displayed on Line 2 of the Welcome

screen.

October 2007 Page

Page 39

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

39

As you make your changes, the result will appear in the display in the

top-half of the editing window.

Chapter 3 : Creating a Project

Graphical Display -

Large

The clock

window sets the delay period for this screen. By default, this delay is

set to 2 seconds. This means that when the project is run on the

printer, the printer will pause for 2 seconds on the Welcome screen

before moving on to the Select Label screen. You can edit the Welco me

screen delay:

next to the Welcome screen in the top-half of the editing

5 Edit the value of the delay from 0 - 99 seconds, or

6 Increment or decrement the value of the delay using the up and

down arrows

If the delay is set to zero (0) seconds, a user will have to press a

button on the printer to advance the application to the next screen.

To accept the changes made to the Welcome screen:

7 Click OK

To edit the Welcome screen for a graphical display project, on the User

Interface window:

beside the delay entry field.

1 Click on the Welcome screen, or

2 Click the Welcome button at the bottom of the window

Alternatively, on the User Interface window:

3 Simply double click on the thumbnail view of the Welcome screen

The Welcome Screen editing window for a large graphical display

printer is as shown here:

Graphical Display

October 2007 Page

Elements

Notice that this screen displays a Status Toolbar in a header across th e

top, printer key labels in a footer across the bottom, and two lines of

text on the main display. Each of the screens for graphical display

printers uses this same format.

From left to right, the Status Toolbar shows respectively Printer Status,

printer system date, and printer system time. For more information

about Printer Status see Section

Display - Status Toolbar.

3.2 – User Interface - Graphical

Page 40

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

40

The Footer Soft Keys show the function of the Datamax printer keys in

an MCL application. These may be defined on a project-by-project basis

as described is Section

Only

.

The two lines of the main graphical d isplay show the same information

as that shown on the two lines of a text display screen for the

equivalent screen. For example, as shown above, by default, the

<Project name> and <Project Version> are displayed on the Welcome

screen for both the text display and graphical display printers.

Although default content is provided, each of the screens provides a

number of options for screen content. To edit the Welcome screen:

3.5.1 - Soft Keys Setup – Graphical Display

Chapter 3 : Creating a Project

4 Select a Header option

5 Select a Line 1 option

6 Select a Line 2 option

7 Select a Footer option.

8 Click OK

Below shows the options available for a Header.

Alternatively, instead of choosing one of the pre-defined options,

9 Type fixed text in any of the edit boxes

Some screens, such as the Welcome Screen and Printer Error Message

screen also support the addition of an optional image. The image must

be a monochrome wallpaper image in *.bmp format with a size of

240x320 pixels.

To add an image:

10 Click on the Image checkbox or Image button.

A standard Windows browse window is displayed.

11 Navigate to and select the image to be displayed on the given

screen.

October 2007 Page

Page 41

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

41

Chapter 3 : Creating a Project

Below shows an example of a Welcome screen edited to ha ve an image

and fixed text on Line 2:

Graphical Display -

Small

As with the text display screen, the clock

the Welcome screen delay:

control allows you to edit

12 Edit the value of the delay from 0 - 99 seconds, or

13 Increment or decrement the value of the delay using the up and

down arrows

beside the delay entry field.

14 Click OK

If the delay is set to zero (0) seconds, a user will have to press a

button on the printer to advance the application to the next screen.

The Welcome Screen editing window for a small screen graphical

display printer is as shown below. The properties and options available

for this screen are identical to those described above for the large

screen graphical display.

October 2007 Page

Page 42

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

42

Chapter 3 : Creating a Project

3.2.2. Select Label Screen

Select Label screen The Select Label screen is displayed after the Welcome screen has been

Text Display The Select Label Screen editing window for a text display printer is as

displayed. You may edit this screen to give the user different prompts

than those supplied by default by 123 Print.

To edit the Select Label screen, on the User Interface window:

1 Click on the Select Label screen, or

2 Click the Select button at the bottom of the window

As with the Welcome Screen (Section

Select Label Screen varies according to the display type available on

the printer model selected for the given project.

shown here:

3.2.1 – Welcome Screen), the

This screen is the default screen that is displayed when a user is

required to select a label on a printer running a 123 Print application.

Edit this screen to create the user screen prompt you want displayed

3 On Line 1 enter up to 15 characters of text. The arrows on this

line are not removable. By default the user can always scroll

through the list of available labels.

October 2007 Page

Page 43

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

43

Graphical Display -

Large

Chapter 3 : Creating a Project

4 On Line 2 choose the method you want to use to select t he label

The Datamax printer cannot accept input from both a co nnected

keyboard and a barcode scanner for a given input field. However, it can

accept input from the front panel and a connected keyboard, or from

the front panel and a barcode scanner, or from just the front panel.

To edit the Select Label screen, on the User Interface window:

1 Click on the Select Label screen, or

2 Click the Select button at the bottom of the window

Alternatively, on the User Interface window:

3 Simply double click on the thumbnail view of the Select Label

screen

The Select Label Screen editing window for a large graphical display

printer is as shown here:

October 2007 Page

Notice that this screen has the same display screen editing options — a

Header, Footer and two lines on the main display — as tho se described

in Section

The two lines of main display text show, by default, the same content

on the Select Label screen for both the text display and graphical

display printers:

Fixed user prompt “Select Label to Print” and

The option “List of Label Names (Up/Dwn Scrolling)”

3.2.1 – Graphical Display Elements.

Page 44

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

44

Chapter 3 : Creating a Project

Graphical Display -

Small

4 Select a Header option

5 Edit the User Prompt box to display the desired prompt

6 On Select Label choose the method you want to use to select the

label. These options are the same as those described above for

Select Label - Text Displays.

7 Select a Footer option

8 Click OK

Alternatively, instead of choosing one of the pre-defined options,

9 Type fixed text in any of the edit boxes

10 Click OK

The Select Label Screen editing window for a small screen graphical

display printer is as shown below. The properties and options available

for this screen are identical to those described above for the large

screen graphical display.

October 2007 Page

Page 45

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

45

3.2.3. Quantity to Print Screen

Quantity to Print

screen

Text Display The Quantity to Print Screen editing window for a text display printer is

To edit the Quantity to Print screen, on the User Interface window:

1 Click on the Quantity to Print screen, or

2 Click the Quantity button at the bottom of the window

As with the Welcome Screen (Section

Quantity to Print Screen varies according to the display type available

on the printer model selected for the giv en project.

as shown here:

Chapter 3 : Creating a Project

3.2.1 – Welcome Screen), the

This screen is the default screen displayed for a user to select the

quantity of a label to be printed.

Line 1 automatically displays the name of the Label chosen on the

Select Label screen. Line 1 is therefore not editable.

By default the user can always increment or decrement the quantity of

the labels to be printed. Therefore, the arrows on line 2 are not

removable.

Three quantity input methods are available as shown here:

3 On Line 2 choose the quantity input method you want to use

The Datamax printer cannot accept input from both a co nnected

keyboard and a barcode scanner for a given input field. However, it can

accept input from the front panel and a connected keyboard, or from

October 2007 Page

Page 46

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

46

Graphical Display -

Large

Chapter 3 : Creating a Project

the front panel and a barcode scanner, or from just the front panel.

If you choose Qty Using Front Panel, the user must use the

Fwd ↑ and Rev ↓ buttons on the front panel to increment or

decrement the quantity.

If you choose Qty Using Keyboard, keyboard and front panel

input is enabled; the user may input a quantity from t he

keyboard or use the Fwd ↑ and Rev ↓ buttons on the front

panel to increment or decrement the quanti ty.

If you choose Qty Using Barcode Reader, the user can scan

the quantity or use the Fwd ↑ and Rev ↓ buttons on the front

panel to increment or decrement the quanti ty.

4 Click OK

The graphical display Select Quantity Screen is equivalent to the text

display Quantity to Print Screen.

To edit the Select Quantity screen, on the User Interface window:

1 Click on the Select Quantity screen, or

2 Click the Quantity button at the bottom of the window

Alternatively, on the User Interface window:

3 Simply double click on the thumbnail view of the Select Quantity

screen

The Select Quantity Screen editing window for a large graphical display

printer is as shown here:

October 2007 Page

Notice that this screen has the same display screen editing options — a

Header, Footer and two lines on the main display — as tho se described

in Section

The two lines of main display text show, by default, the same content

on the Quantity to Print screen for both the text display and graphical

display printers:

Fixed user prompt “Select quantity to print” and

The option “Qty Using Front Panel”

3.2.1 – Graphical Display Elements.

Page 47

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

47

Graphical Display -

Small

Chapter 3 : Creating a Project

4 Select a Header option

5 Edit the User Prompt box to display the desired prompt

6 On Select Quantity choose the method you want to use to input

the quantity. These options are the same as those des cribed above

for Quantity to Print - Text Displays.

7 Select a Footer option

8 Click OK

Alternatively, instead of choosing one of the pre-defined options,

9 Type fixed text in any of the edit boxes

10 Click OK

The Select Quantity Screen editing window for a small screen graphical

display printer is as shown below. The properties and options available

for this screen are identical to those described above for the large

screen graphical display.

October 2007 Page

Page 48

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

48

3.2.4. Print Error Message Screen

Print Error Message

screen

Text Display The Print Error Message editing window for a text display printer is as

The Print Error Message Screen is displayed by the Datamax printer

whenever it detects a print error. You can display whatever message is

appropriate here for your environment.

To edit the Print Error Message screen, on the User Interface

window:

1 Click on the Print Error Message screen, or

2 Click the Error button at the bottom of the window

As with the Welcome Screen (Section

Print Error Message Screen varies according to the display type

available on the printer model selected for the given project.

shown here:

3.2.1 – Welcome Screen), the

Chapter 3 : Creating a Project

Graphical Display -

Large

Line 1 and Line 2 are both editable. Both allow up to 20 characters of

text.

By default, Line 1 displays the message Print Error.

By default, Line 2 displays the actions available to the user when a

print error occurs.

When a print error occurs, two user actions are possible—exit the

project or retry to print the label. These actions are initiated by

pressing buttons on the front panel of the printer.

The project will exit when either the REV or ESC button on

the left-hand side of the printer front panel is pressed.

The printer will retry to print the label when the ENT button

on the right-hand side of the printer front panel is pressed.

You are not obligated to maintain this convention and may edit both

lines of the screen to suit your environment.

3 Edit Line 1 with the desired error text message

4 Edit Line 2 with the desired error text message

5 Click OK

To edit the Print Error Message screen, on the User Interface

window:

1 Click on the Print Error Message screen, or

2 Click the Error button at the bottom of the window

Alternatively, on the User Interface window:

3 Simply double click on the thumbnail view of the Print Error

October 2007 Page

Page 49

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

49

Message screen

The Print Error Message Screen editing window for a large graphical

display printer is as shown here:

Chapter 3 : Creating a Project

Graphical Display -

Small

Notice that this screen has the same display screen editing options — a

Header, Footer and two lines on the main display — as tho se described

in Section

3.2.1 – Graphical Display Elements.

4 Select a Header option

5 Edit Line 1 to display the desired print error message

6 Select a Line 2 option

7 Select a Footer option

8 Click OK

The option <Label Name> is the name of the label that is being printed

when this print error occurs.

Alternatively, instead of choosing one of the pre-defined options,

9 Type fixed text in any of the edit boxes

10 Click OK

The Printer Error Message screen also supports the addition of an

optional image. The image must be a monochrome wallpaper image in

*.bmp format with a size of 240x320 pixels.

To add an image:

11 Click on the Image checkbox or Image button.

A standard Windows browse window is displayed.

12 Navigate to and select the image to be displayed on the given

screen.

The Print Error Message Screen editing window for a small scr een

graphical display printer is as shown below. The properties and options

available for this screen are identical to those described above for the

large screen graphical display.

October 2007 Page

Page 50

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

50

Chapter 3 : Creating a Project

October 2007 Page

Page 51

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

51

Chapter 3 : Creating a Project

3.3. Labels

General introduction The Labels function allows you to add the following capabilities to your

Associate a label To associate an existing label to your 123 Print project, enter the Labels

123 Print projects

Associate pre-designed labels

Associate screen prompts with a label to collect user input, suc h as

an item product code, to be printed dynamically on the label

Collect input from printer peripherals, such as a barcode scanner or

weight scale, to be printed dynamically on a label

Add logic to manipulate the input data, such as extract the weight

from a weight scale input data stream , and merge it into the label

to be printed

This section describes how to associate an existing label to your project.

This can be a static label you simply want to print. It can also be a

static label you want to use as a template for creating dynamic labels.

This section also describes the functions available for cr eating a

dynamic label using screen prompts, peripheral inputs, and processing

logic. This combination of screens, variable data, and logic is referred to

as a label program.

The pre-designed labels that you associate with your 123 Print project

may be any DPL label or a label created using Seagu ll Scientific’s

BarTender. Please reference

information about creating BarTender labels for 123 Print.

function

Chapter 4 – Designing a Label

for

1 Click the Labels button on the left-hand side

of the main window.

Alternatively, on the 123 Print menu bar,

2 Select Project

3 Select Labels

The Labels List window is displayed as shown here

October 2007 Page

Page 52

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

52

Chapter 3 : Creating a Project

To associate a label with your 123 Print project,

4 Click the button at the bottom of the Labels List window

Each time you add a label, 123 Print assigns a sequence number to the

label. This system assigned number is displayed in the Labels List

window in the left most column called #. This number determines the

sequence order in which the labels are displayed on the Select Label

Screen (see Section

When you Add a label, the Label Properties screen is displayed as

shown here

3.2.2 – Select Label Screen).

Label Properties

The Label Properties screen allows you to associate a given label to

your project. The Label Properties screen is also the entry point to

create a label program.

5 Set the label properties as appropriate for the given label:

Nbr

File Name

Label Name

Quantity to

Print

After Print

Enter the number you wish to assign to the label

in your 123 Print project. This number is displayed

on the Select Label Screen when the user is

choosing which label to print for a given operation

Enter the path and name or browse to search for

the label you want to add to your project. Valid

file types are *.btw, *.dpl and *.txt (if the *.txt

file contains DPL code)

Assign a name to this label. This is displayed on

the Select Label screen when the user is choosing

which label to print for a given operation.

If you want the user to enter a quantity, check the

Prompt for quantity checkbox. Assign a default

value and maximum value to help the user. If you

want to set a fixed quantity to print with no user

prompting, uncheck the Prompt for quantity

checkbox and enter the fixed value in the default

value box. These entries are used on the Quantity

to Print screen as described in

Setup what you want to do after the label has

been printed. You can

Loop on the same label. This returns you

to the first screen of the label program

Return to the Select Label screen

Run a different label. Identify a label to

print next, automatically, without user

input. Reference it by its Nbr number.

Section

3.2.3.

October 2007 Page

Page 53

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

53

Label template for

dynamic label

Chapter 3 : Creating a Project

Static label If you are simply associating a static label, you are done using the

Labels function for this label

6 Click OK to close the Labels Properties and return to the Labels List

window to add other labels as necessary

Once you have added a label, in this case the labe l LocationMCL2.btw,

and setup the Label Properties, three buttons become functional on the

Label Properties window as shown here

Note: Any static label may be used as a template for a dynamic label

The functions associated with these buttons are discussed in the

subsequent sections of this chapter. These are the main functions used

to create your label programs.

When you have completed your Edit, Variables, and Mapping functions

for a given label,

Edit allows you to modify your label design from within 123

Print.

See Section

Variables allows you to add screen prompts and logic to your

label design.

See Section

Mapping allows you to associate variable data with a label

template.

See Section

3.3.1 - Edit

3.3.2 - Variables

3.3.3 – Mapping

7 Click OK to close the Labels Properties and return to the Labels List

window to add other labels as necessary

October 2007 Page

Page 54

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

54

Chapter 3 : Creating a Project

3.3.1. Edit

General Introduction If you have Seagull Scientific’s BarTender installed and activated on

Edit

your system, and are working with a BarTender *.btw file, when you

press Edit, 123 Print starts Bartender wi th your active label open for

editing.

If you do not have a BarTender label and are working directly with a

*.txt or *.dpl file, Edit will display the DPL code of the label for editing.

1 Click the Edit button to view and edit your selected label.

If you are working with a *.dpl label, the DPL co de is opened in the Edit

DPL File window as shown here

If you are working with a *.btw label, the label is opened in BarTender

as shown here

For more information on label design with BarTender, please refer to

Chapter 4 – Designing a Label

.

October 2007 Page

Page 55

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

55

3.3.2. Variables

General introduction

Variables

Variables

Text Display

Variables is one of the main functions in 123 Print to enable you to

create labels that are printed with dynamic content.

Consider the labels shown in

include variable data such as the date and time at the moment the label

was printed. This function allows you to include this kind of variable

information on your labels.

This section describes how to use the Variables function to collect

dynamic content for your labels.

After adding a label to your 123 Print project as described in Section 3.3

– Labels, to add variable content to your labels, on the Label Properties

dialogue box:

1 Click the Variables button

The Variables function allows you to build a dialogue between your label

program (see Section

screen prompts. These are displayed on the left-hand side of the

123Print Designer window as shown below. You can assign up to 50

screens to each label. Each screen is editable. The first line is text to

prompt the user about what data to enter. The second line is where the

user will enter the required data. You define these screen prompts in

the editing window on the right.

Text displays are used in this section to show how to use Variables. The

procedure is identical for graphical display printers.

The 123Print Designer window for a text display printer is as shown

here. Up to four prompt screens are displayed at a time for text display

printers.

Use the scroll bar provided to navigate through your prompt screens.

Chapter 3 : Creating a Project

Section 1.2 – Sample Labels. These labels

1.3 – Project Flow) and the user via a series of

October 2007 Page

Page 56

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

56

Chapter 3 : Creating a Project

Graphical Display -

Large

The 123Print Designer window for a large graphical display printer is as

shown here. Only one prompt screen is displayed at a time for large

graphical displays.

Use the scroll bar provided to navigate through your prompt screens.

Graphical Display -

Small

The 123Print Designer window for a small graphical display printer is as

shown here. Up to 2 prompt screens are displayed at a time for small

graphical displays.

Use the scroll bar provided to navigate through your prompt screens.

October 2007 Page

Page 57

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

57

Creating a label

program

To show you how to design a label program, an example is used

extensively herein. This example creates Warehouse Shelving labels,

like the one shown below, for a self-service warehouse. The user would

print labels like this to indicate t he location for all the products in the

warehouse. The labels would then be applied to the shelving racks in

the warehouse to assist customers in finding the prod uct they want to

purchase.

Text displays are used in the following example. However, the

procedure is identical for graphical displays.

Chapter 3 : Creating a Project

To get started designing your label program,

1 Select the first (from top to bottom) available prompt screen on the

left-hand side of the 123Print Designer window

In the Warehouse Shelving example, the program first prompts the

User to enter the location in the warehouse for a given product. To do

this, on line 1,

2 Type Product Location:

October 2007 Page

Page 58

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

58

Input Methods When you enter a prompt, you must select an Input Method for the

prompt. This determines how the user will be able to enter data on the

given screen. The Input Methods are entered on Line 2 of a screen

prompt. The following Input Methods are available:

Front Panel UP/Down Numeric

External Keyboard

External Barcode Reader

Weight Scale

Select Value From List

Select Value From File

Display Data

The various Input Methods available for line 2 are discussed in Section

3.3.2.1 to 3.3.2.7. Please see these sections for more detailed

explanations about the Input Methods you can use to create a us er

friendly interface for your label program.

For the Warehouse Shelving example, on line 2 of the screen prompt

you are creating,

Chapter 3 : Creating a Project

s

3 Select External Keyboard, as shown here

Once an Input Method has been selected, 123 Print displays a window

in which you set the properties of the chosen input type. Each Input

Method has its own specific set of properties.

The properties window for the External Keyboard input is as shown

below

October 2007 Page

Page 59

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

59

Chapter 3 : Creating a Project

The Warehouse Shelving example only requires two of the input

properties to be setup:

Result Variable

Force Uppercase

The Result Variable is the variable where the user’s input will be saved

when they enter a location on the screen prompt.

The Force Uppercase will prevent the user from entering lowercase

letters when they enter a location on the screen prompt.

To assign a Result Variable for the location for the Warehouse Shelving

example,

4 Click on the next to the Result Variable field

The Variables window is displayed as shown here

October 2007 Page

Page 60

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

60

Various kinds of Variables may be used in a 123 Print label program. To

work with the variables, select one of tabs:

User Local

All Local

Global

System

You cannot write to a System Variable. Therefore, these are

not applicable for use as a resultant variable and are grayed

Please see Section

detailed information about variables.

Returning to the Warehouse Shelving example, create the Variable in

which you wish to store the input Location information:

out whenever you are creating a resultant variable.

5.1 – Introduction to 123 Print Variables for more

Chapter 3 : Creating a Project

5 Click on the first available user local variable – in this case, A0

6 Type in the name you want to assign to this Variable – in this case,

Location

7 Click OK

October 2007 Page

Page 61

Copyright © 2007 • MCL Technologies • All Rights Reserved

www.mcl-collection.com

61

Chapter 3 : Creating a Project

Notice that the Result Variable field has now been filled with the name

of the Variable you just created: [A0] Location.

You have now completed the first prompt screen of your label program.