Page 1

C-BOX 150

Installation Manual

Page 2

Datalogic Automation S.r.l.

Via S. Vitalino 13

40012 - Lippo di Calderara di Reno

Bologna - Italy

C-BOX 150

Ed.: 07/2007

ALL RIGHTS RESERVED

Datalogic reserves the right to make modifications and improvements without prior notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or

consequential damages resulting from the use of this material.

Product names mentioned herein are for identification purposes only and may be trademarks and or

registered trademarks of their respective companies.

© Datalogic Automation S.r.l. 2002-2007

821001271 (Rev. B)

Page 3

CONTENTS

1 INTRODUCTION .......................................................................................... 1

1.1 Product Description....................................................................................... 1

1.2 C-BOX 150 Compatible Devices................................................................... 2

2 INSTALLATION............................................................................................ 3

2.1 Package Contents......................................................................................... 3

2.2 Opening the Device ...................................................................................... 4

2.3 Mechanical Installation.................................................................................. 5

2.4 Electrical Connections and Hardware Setup................................................. 7

2.4.1 Power Supply................................................................................................ 8

2.4.2 System Wiring............................................................................................... 9

2.4.3 Scanner Chassis Grounding Jumper Settings ............................................ 12

2.4.4 Scanner Selection....................................................................................... 12

2.4.5 RS485 Bus Termination.............................................................................. 13

2.4.6 Powering C-BOX 150 From A Scanner....................................................... 13

2.4.7 OM4000 Jumper Settings ........................................................................... 14

2.4.8 Configuration Switch And 9-Pin Internal Connector .................................... 14

2.5 Operating Modes ........................................................................................ 16

2.5.1 GET/TEST/SEND Functions....................................................................... 16

2.5.2 LED Indicators ............................................................................................ 18

2.6 Typical Layouts ........................................................................................... 20

2.6.1 1000, 2000A/N, 4000 Family Scanners ...................................................... 20

2.6.2 2000N Family Scanners.............................................................................. 21

2.6.3 6000, 8000 Family Scanners ...................................................................... 22

2.7 Scanner Replacement ................................................................................ 23

3 TECHNICAL FEATURES........................................................................... 24

iii

Page 4

SAFETY PRECAUTIONS

POWER SUPPLY

ATTENTION: READ THIS INFORMATION BEFORE INSTALLING THE PRODUCT

- This product is intended to be installed by Qualified Personnel only.

The C-BOX 150 is intended to be supplied either by a UL Listed NEC Class 2 power

source, or a UL Listed ITE Limited Power Source (LPS), rated 10-30 V dc, minimum

0.5 A.

The overall value of power consumption of the system (C-BOX

150 + scanner) is given by adding the scanner power

consumption to that of the C-BOX 150. Refer to the manual of

CAUTION

See par. 2.4.1 for correct power supply connections.

CE COMPLIANCE

Warning: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

WEEE COMPLIANCE

the connected scanner for details about minimum/maximum

supply voltage and power consumption.

Information for the user in accordance with the European Commission Directive 2002/96/EC

At the end of its useful life, the product marked with the crossed out wheeled wastebin must be disposed of separately

from urban waste.

Disposing of the product according to this Directive:

• avoids potentially negative consequences to the environment and human health which otherwise could be

caused by incorrect disposal

• enables the recovery of materials to obtain a significant savings of energy and resources.

For more detailed information about disposal, contact the supplier that provided you with the product in question or

consult the dedicated section at the website www.automation.datalogic.com.

iv

ENGLISH

Page 5

ITALIANO

Informazione degli utenti ai sensi della Direttiva Europea 2002/96/EC

L’apparecchiatura che riporta il simbolo del bidone barrato deve essere smaltita, alla fine della sua vita utile,

separatamente dai rifiuti urbani.

Smaltire l’apparecchiatura in conformità alla presente Direttiva consente di:

• evitare possibili conseguenze negative per l’ambiente e per la salute umana che potrebbero invece

essere causati dall’errato smaltimento dello stesso;

• recuperare materiali di cui è composto al fine di ottenere un importante risparmio di energia e di risorse.

Per maggiori dettagli sulle modalità di smaltimento, contattare il Fornitore dal quale è stata acquistata

l’apparecchiatura o consultare la sezione dedicata sul sito www.automation.datalogic.com.

Benutzerinformation bezüglich Richtlinie 2002/96/EC der europäischen Kommission

Am Ende des Gerätelebenszyklus darf das Produkt nicht über den städtischen Hausmüll entsorgt werden. Eine

entsprechende Mülltrennung ist erforderlich.

Beseitigung des Produkts entsprechend der Richtlinie:

• verhindert negative Auswirkungen für die Umwelt und die Gesundheit der Menschen

• ermöglicht die Wiederverwendung der Materialien und spart somit Energie und Resourcen

Weitere Informationen zu dieser Richtlinie erhalten sie von ihrem Lieferanten über den sie das Produkt erworben

haben, oder besuchen sie unsere Hompage unter www.automation.datalogic.com.

Information aux utilisateurs concernant la Directive Européenne 2002/96/EC

Au terme de sa vie utile, le produit qui porte le symbole d'un caisson à ordures barré ne doit pas être éliminé avec les

déchets urbains.

Éliminer ce produit selon cette Directive permet de:

• éviter les retombées négatives pour l'environnement et la santé dérivant d'une élimination incorrecte

• récupérer les matériaux dans le but d'une économie importante en termes d'énergie et de ressources

Pour obtenir des informations complémentaires concernant l'élimination, veuillez contacter le fournisseur auprès

duquel vous avez acheté le produit ou consulter la section consacrée au site Web www.automation.datalogic.com.

Información para el usuario de accuerdo con la Directiva Europea 2002/96/CE

Al final de su vida útil, el producto marcado con un simbolo de contenedor de bassura móvil tachado no debe

eliminarse junto a los desechos urbanos.

Eliminar este producto de accuerdo con la Directiva permite de:

• evitar posibles consecuencias negativas para el medio ambiente y la salud derivadas de una eliminación

inadecuada

• recuperar los materiales obteniendo así un ahorro importante de energía y recursos

Para obtener una información más detallada sobre la eliminación, por favor, póngase en contacto con el proveedor

donde lo compró o consultar la sección dedicada en el Web site www.automation.datalogic.com.

DEUTSCH

FRANÇAIS

ESPAÑOL

v

Page 6

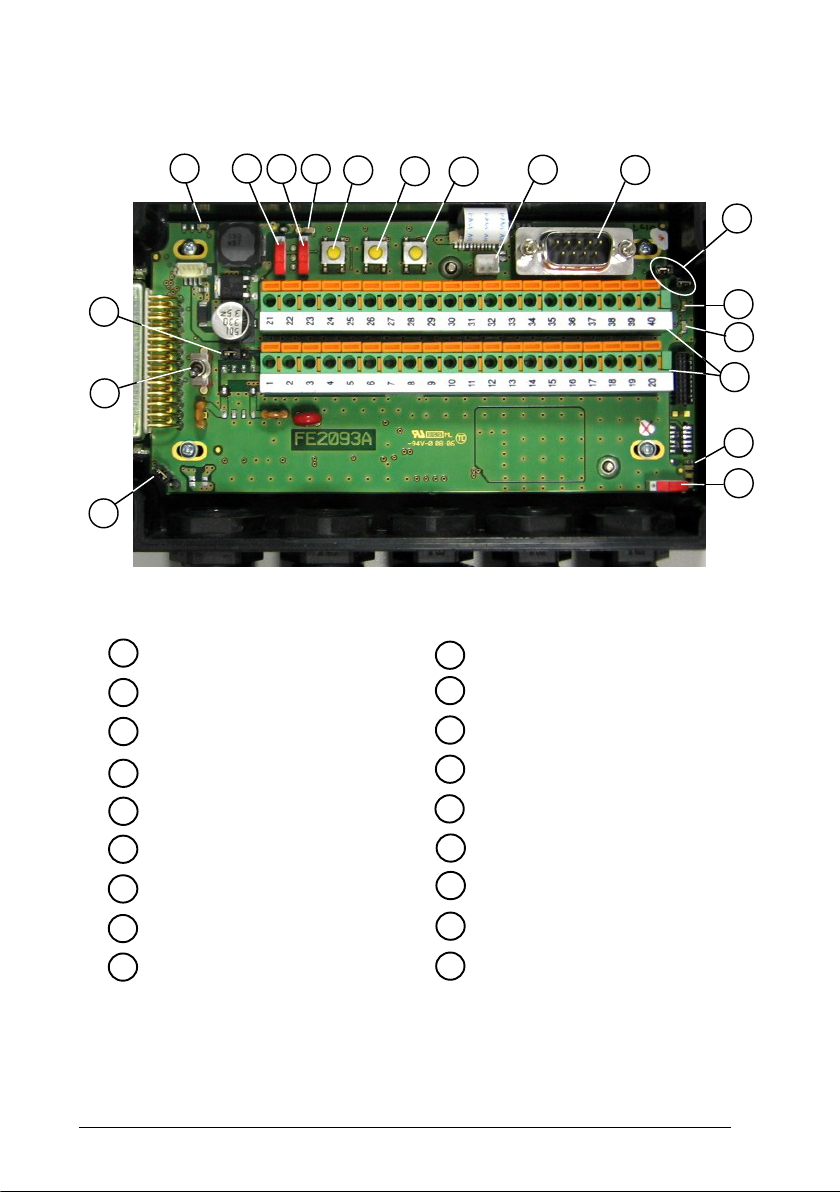

GENERAL VIEW

1

C-BOX 150

Figure A

25-pin scanner connector

1

3

2

vi

Compression connectors

2

Cover screws (4)

3

Page 7

A

C-BOX 150

3

4

5

6

7

8

9

10

11

12

2

1

18

Figure B - Bottom Inside

Power on switch

1

Chassis grounding jumper

2

Power polarity error LED (red)

3

RS485 Bus termin.switch

4

Scanner selection switch

5

Power on LED (green)

6

INT-30 power connector

10

uxiliary port connector

11

OM4000 jumpers

12

Warning LED (red)

13

Status LED

14

Spring clamp terminal blocks

15

13

14

15

16

17

Tx LED

GET button

7

TEST button

8

SEND button

9

vii

16

Configuration switch

17

Power source jumper

18

Page 8

GUIDE TO INSTALLATION

The following can be used as a checklist to verify all of the steps necessary for

complete installation of the C-BOX 150.

1) Read all information in the section "Safety Precautions" at the beginning of this

manual.

2) Correctly position and mount the C-BOX 150 within the reach of the barcode

scanner cable, according to the information in paragraph 2.3.

3) Make all electrical connections according to your application. See par. 2.4 and

2.6.

Further typical layouts are given in the Scanner Reference Manual.

4) Set all the proper configuration jumpers and switches according to your

application.

See all sub-paragraphs under 2.4.

5) Connect the scanner to the C-BOX 150.

6) Switch-on the system.

7) Wait until the Warning Led (WL, red) is switched off.

8) Through the internal 9-pin male connector, (it carries the Scanner Aux. Serial Port

signals), configure the scanner according to your specific application using either

the Genius™ or WinHost™ software configuration tool, see par. 1.2 for program

compatibility.

9) Force the 'Get Scanner Configuration' procedure using the internal keys (see

paragraph 2.5.1).

10) Wait until the Warning Led (WL, red) is switched Off.

Now the C-BOX 150 contains the scanner configuration.

The installation is complete.

viii

Page 9

INTRODUCTION

1

1 INTRODUCTION

1.1 PRODUCT DESCRIPTION

The C-BOX 150 is a connection box which can be used as an accessory to several

Datalogic family scanners.

Its main feature is to make the substitution of a Datalogic scanner in an installation

plain and easy.

To achieve this goal the C-BOX 150 provides the GET command to pass the

connected scanner’s configuration to the C-BOX 150 non volatile memory. The

SEND command allows a previously saved configuration to be transferred from the

C-BOX 150 to the scanner.

By default, at every power-on, the C-BOX 150 automatically sends the configuration

stored in its memory to the connected scanner. Therefore the substituted scanner will

be correctly configured.

The C-BOX 150 allows you to perform the following functions:

• Facilitate the connection of the scanner signals using a spring clamp connector.

• Get the scanner configuration and store it in memory.

• Force the scanner to the Test operating mode.

• Send the configuration stored in memory to the scanner.

The C-BOX 150 mechanical dimensions are 161 x 114.5 x 40 mm (6.34 x 4.51 x 1.57

in.). The C-BOX 150 weighs about 410 g (14.48 oz).

Electrical connection is provided through spring clamp terminal blocks inside the CBOX 150.

The scanner is connected to the C-BOX 150 through a 25-pin connector placed on

the left side of the housing.

A 9-pin connector placed inside the C-BOX 150 facilitates connection between an

external PC and the auxiliary serial interface of the scanner.

1

Page 10

1

C-BOX 150

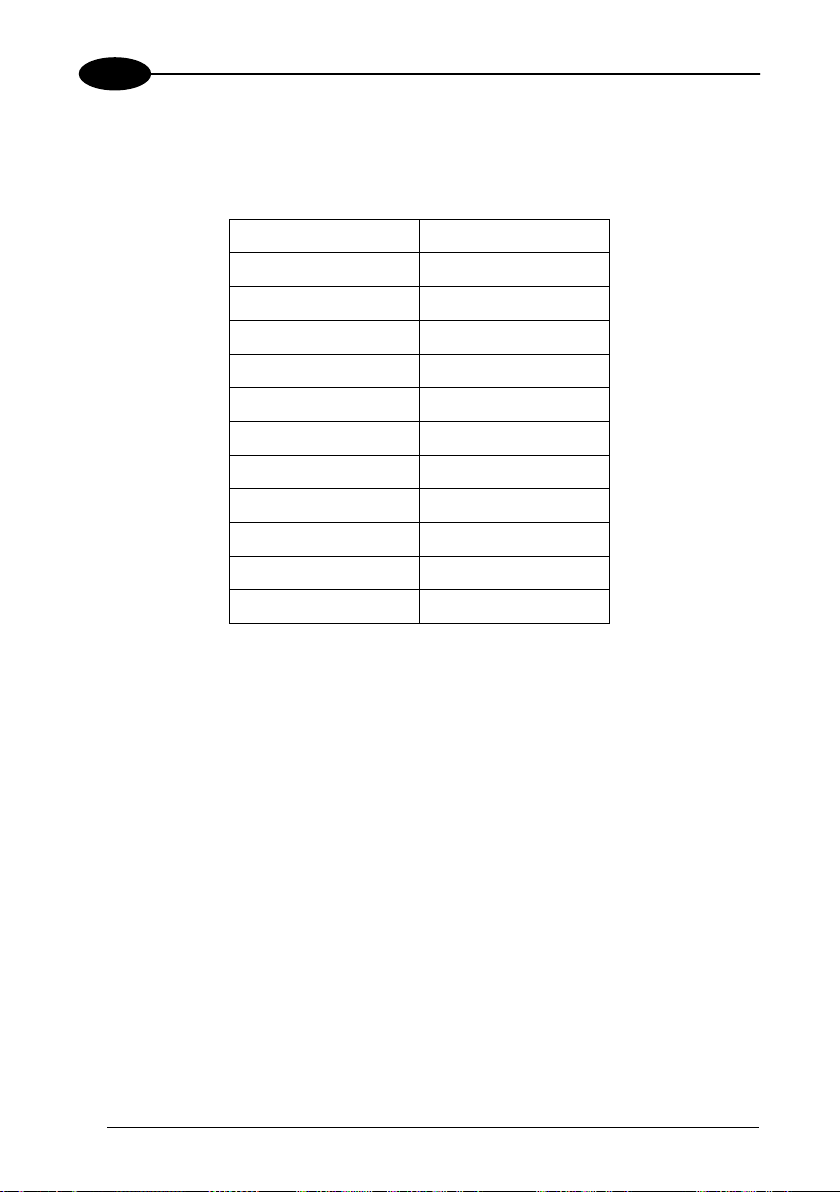

1.2 C-BOX 150 COMPATIBLE DEVICES

The C-BOX 150 can be connected to the following scanners through the 25-pin

connector illustrated in Figure A.

Scanner Configuration Tool

DS1100 * WinHost™

DS2100A WinHost™

DS2100N Genius™

DS2200 * WinHost™

DS2400A WinHost™

DS2400N Genius™

DS4600A WinHost™

DS6X00 Genius™

DX6400 Genius™

DS8100A Genius™

DX8200A Genius™

*10 and 30 Vdc versions only

2

Page 11

INSTALLATION

2

2 INSTALLATION

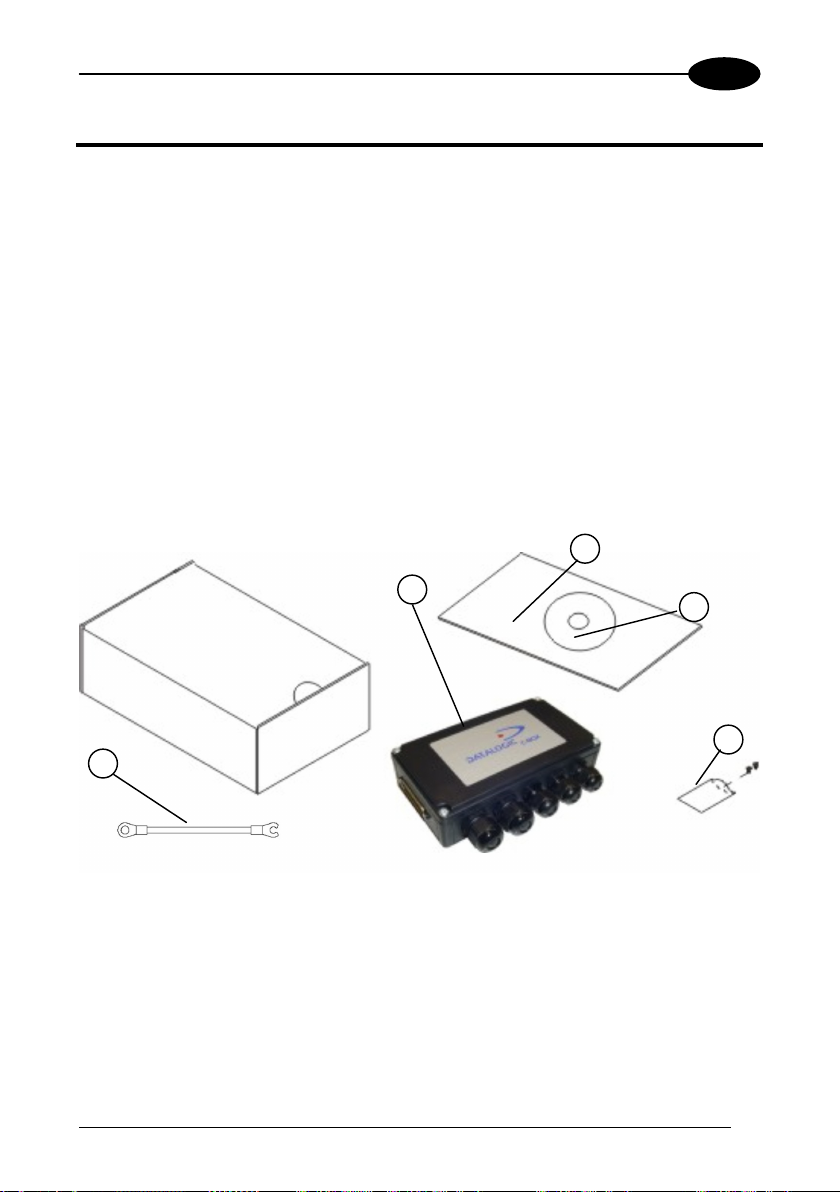

2.1 PACKAGE CONTENTS

Verify that the C-BOX 150 and all the parts supplied with the equipment are present

and intact when opening the packaging; the list of parts includes:

1) C-BOX 150

2) Installation manual

3) C-BOX 150 configuration CD-ROM

4) 2 mounting screws

5) Grounding cable

2

1

3

4

5

Figure 1 - C-BOX 150 Package Contents

3

Page 12

2

C-BOX 150

2.2 OPENING THE DEVICE

To install the C-BOX 150 or during normal maintenance, it is necessary to open it by

unscrewing the four cover screws:

The C-BOX 150 must be disconnected from the power supply

during this operation.

CAUTION

Figure 2 - Opening the C-BOX 150

It is possible to perform the following operations:

• Proceed with the cable connections (see paragraph 2.4.2).

• Mount the C-BOX 150 to a wall or panel.

4

Page 13

INSTALLATION

2

2.3 MECHANICAL INSTALLATION

The diagram below gives the overall dimensions of the C-BOX 150 and may be used

for its installation.

12

66

[0.47]

[2.60]

Ø3.5

[Ø0.14]

5

[0.20]

150

[5.91]

161

[6.34]

5

[0.20]

40

90

[1.57]

[3.54]

12

[0.47]

89.8

[3.54]

114.5

[4.51]

mm

inch

Figure 3 - Overall Dimensions

5

Page 14

2

C-BOX 150

C-BOX 150 can be installed to operate in different positions. The two screw holes

inside the housing of the C-BOX 150 are for mechanical fixture (Figure 4).

To mount the C-BOX 150:

1) Open the C-BOX 150 by unscrewing the 4 cover screws. If necessary, using the

two mounting holes inside the device as a pattern, mark the panel with an

appropriate object and then drill two holes in the panel.

2) Align the C-BOX 150 and insert two screws and screw them into the panel until

tight (see Figure 4).

6

Figure 4 - Mounting C-BOX 150

Page 15

INSTALLATION

A

2.4 ELECTRICAL CONNECTIONS AND HARDWARE SETUP

The following figure shows the typical layout.

SCANNER

C-BOX 150

UXILIARY

INTERFACE

2

SCANNER

SYSTEM CABLES

SCANNER CONFIGURATION PC

Figure 5 – System Layout

A PC can be connected to the C-BOX 150 (and consequently to the scanner auxiliary

interface) through the internal 9-pin connector. This allows both scanner

configuration and monitoring of the data transmitted by the scanner (see the scanner

Reference Manual for more details).

The scanner auxiliary interface signals are also available on the internal spring clamp

connectors.

The scanner configuration and data monitoring are possible once the warning LED is

turned OFF.

The internal 9-pin connector can also be used to configure the C-BOX 150 with a PC,

through the WinHost utility.

After making system cabling and switch settings, connect the scanner to the 25-pin

connector on the left side of the C-BOX 150 housing.

Switch ON the C-BOX 150 power switch (see Figure 6).

By default, after power on, an automatic connection procedure takes place between

the C-BOX 150 and the scanner. During this phase, requiring a few seconds, the

warning LED is turned ON. Once the procedure had been completed successfully,

the warning LED is turned OFF.

To disable this automatic connection procedure, refer to WinHost Help Online.

7

Page 16

2

C-BOX 150

After system functioning has been verified, close the C-BOX 150 using the 4 cover

screws making sure the rubber seal is fitted correctly between the parts of the

housing.

It is recommended to use the dedicated grounding cable (included in

the package) to improve the C-BOX 150 noise immunity.

Simply connect its open end to the scanner cable’s fixing screw and

NOTE

the other end to the ground, as shown in the figure below.

2.4.1 Power Supply

Power is supplied to the C-BOX 150 through the pins provided on the spring clamp

connector.

The power switch (see Figure 6) switches the power supply ON or OFF for both the

C-BOX 150 and the connected scanner.

ON

OFF

Figure 6 - Power Switch ON/OFF Positions

8

Page 17

INSTALLATION

2

C-BOX

VS

1

GND

2

USER INTERFACE

V+ (10 - 30 Vdc)

GND

Figure 7 - Power Supply Connections

The power supply must be between 10 and 30 Vdc only.

Pin 1 is also electrically connected to pins 3 and 5, just as pin 2 is

electrically connected to pins 4 and 6. This is useful for external

NOTE

trigger/inputs connections.

The C-BOX 150 is protected against polarity reversal. A dedicated red

LED signals this condition until correct polarity is restored.

NOTE

2.4.2 System Wiring

The connection and wiring procedure for C-BOX 150 is described as follows:

1) Open the C-BOX 150 as described in paragraph 2.2.

2) Verify that the C-BOX 150 power switch is off (see Figure 6).

3) Unscrew the compression connectors and pass all the system cables

through them into the C-BOX 150 housing.

4) To connect the power and input/output signals:

• Prepare the individual wires of the system cables by stripping the

insulation back approximately 1 cm.

9

Page 18

2

C-BOX 150

• Using a device such as a screwdriver, push down on the lever directly

next to the clamp (see Figure 8).

• Insert the wire into the clamp and release the lever.

The wire will now be held in the spring clamp.

Figure 8 - System Cable Connections

The wiring used can be solid or stranded but must meet the following specifications.

All positions: 24 - 16 AWG 0.2 - 1.5 mm²

10

Page 19

INSTALLATION

2

The C-BOX 150 spring clamp connector pinouts are indicated in the following table.

Refer to the scanner Reference Manual for details.

Scanner Pinouts

Pin Name

1, 3, 5 VS

2, 4, 6 GND

7, 8 EARTH GROUND

*9, 13 RS485 CABLE SHIELD

20, 40 RESERVED

35 TX AUX

37 RX AUX

DS1100

DS2200

21 OUT1+ OUT1+ OUT1+ OUT1+ OUT1+

22 IO REF OUT REF OUT1- OUT1- OUT123 OUT2+ OUT2+ OUT2+ OUT2+ OUT2+

24 IO REF OUT REF OUT2- OUT2- OUT225 NC NC NC RESERVED OUT 3A

26 IN1- NC NC RESERVED OUT 3B

27 EXT TRIG+ EXT TRIG+ EXT TRIG A EXT TRIG+ EXT TRIG/PS A

28 EXT TRIG- EXT TRIG- EXT TRIG B EXT TRIG- EXT TRIG/PS B

29 NC NC NC IN1+ IN 2/ENC A

30 IO REF NC IN2- IN1- IN 2/ENC B

31 NC NC NC IN2+ IN 3A

32 NC NC NC IN2- IN 4A

33 RESERVED RESERVED RESERVED RESERVED IN 3A

34 RESERVED RESERVED RESERVED RESERVED IN 4A

36 NC RTSA ID-NET- GND IN 3B/IN 4B

38 NC CTSA ID-NET+ SGND AUX GND

39 SGND SGND GND SGND GND

DS2100A

DS2400A

DS2100N

DS2400N

DS4600A

DS6X00 DX6400

DS8100A

DX8200A

DS2100A/N DS2400A/N DS4600A DS6X00 DX6400 DS8100A DX8200A

*11, 15 TX232 TX485+ RTX485+

*12, 16 RTS232 TX485- RTX48517 RX232 RX485+

18 CTS232 RX485-

*10, 14, 19 SGND MAIN S G N D M A I N SGND MAIN

RS232 RS485FD RS485HD 20mA CL

(with INT-30 only)

See INT-30

instructions

DS1100 DS2200

*11, 15 RTX485+

*12, 16 RTX485-

17 RESERVED

18 RESERVED

*10, 14, 19 SG N D MA IN

* The signals on pins 9, 10, 11 and 12 are repeated on pins 13, 14, 15 and 16 to facilitate network

connections (i.e. Multiplexer connections using the RS485 half-duplex Interface). In this way the network bus

can enter and exit the C-Box 150 from different spring clamps but be physically connected together.

RS485HD

11

Page 20

2

C-BOX 150

2.4.3 Scanner Chassis Grounding Jumper Settings

The scanner chassis grounding method can be selected by positioning a jumper (see

Figure 9). In this way the scanner chassis can be connected to earth ground (only if

pins 7 or 8 are connected to a good earth ground) or to the power supply ground

signal. The scanner chassis can also be left floating but, in this case, the jumper

must be removed.

to EARTH

GROUND

(default)

Figure 9 – Chassis Grounding

to GND

floating

2.4.4 Scanner Selection

DS1100

DS2200

Other Devices

Figure 10 - Scanner Selection Switch

This switch must be set upward only when a DS1100 or a DS2200 scanner (10-30 V

version) is connected. For all the other devices the switch must be set downward.

12

Page 21

INSTALLATION

2

2.4.5 RS485 Bus Termination

ON

OFF

Figure 11 - Termination Resistance Switch

This switch enables or disables the insertion of the bus termination resistor for RS485

Half Duplex Multidrop applications.

In Multiplexer applications the termination resistor must be enabled

ONLY on the last device of the chain, the farthest away from the

Multiplexer (assuming the Multiplexer is the first device of the

chain). On all the other devices this resistor MUST NOT be enabled

CAUTION

(OFF position).

2.4.6 Powering C-BOX 150 From A Scanner

In order for C-BOX 150 to accept power from the scanner through the 25-pin

connector instead of the external power supply, a jumper can be positioned as

indicated in Figure 12.

This is useful, for example, in a typical Master Slaves layout with a Power Supply

Unit connected to the scanners (see paragraph 2.6) or to pass power to connected

accessories such as Encoder and Presence Sensor from DX8200A VAC models or

other scanner layouts. See the relative scanner Reference Manual for details.

EXTERNAL

Figure 12 – C-BOX 150 Power Source Jumper

13

PWR SUP.

(default)

SCANNER PWR

Page 22

2

C-BOX 150

2.4.7 OM4000 Jumper Settings

Figure 13 - OM4000 Jumpers

The jumpers allow connection to the EXT TRIG signals on separate spring clamp

terminals for applications which use the OM4000 Oscillating Mirror in Trigger Mode.

They are used together and they have the following significance:

when a jumper is in the J5 position (see Figure above) pin 40 is connected to pin 27

(EXT TRIG+); a jumper in J6 position connects pin 20 to pin 28 (EXT TRIG-).

If the jumpers are removed pin 20 and pin 40 are disconnected.

J5

J6

2.4.8 Configuration Switch And 9-Pin Internal Connector

The 9-pin internal connector may have two different functions according to the

position of the configuration switch.

Figure 14 - Configuration Switch and 9-pin Male Connector

POSITION MODE

Normal Operation (default): In this position, the C-BOX 150 is in the

normal operating mode. The configuration PC communicates with the

scanner through the 9-pin internal connector and the scanner

auxiliary serial interface. The internal connector pinout is illustrated in

the following table:

14

Page 23

INSTALLATION

9-pin C-Box 150 connector pinout in Normal mode

Pin Name Function

1 NC

2 RXA Auxiliary RS232

3 TXA Auxiliary RS232

4 NC

5 GND Ground

6 NC

7 RESERVED Device Dependent Signal

8 RESERVED Device Dependent Signal

9 NC

2

POSITION MODE

CFG: When the switch is in this position, the C-BOX 150 can be

configured. The communication with the scanner is interrupted and pins

2 and 3 are no longer dedicated to the scanner auxiliary interface but to

the C-BOX 150 configuration (see table below). The C-BOX 150 enters

configuration mode and waits to be configured through WinHost (see

WinHost Help On Line).

Once the C-BOX 150 configuration is completed, it is necessary to

return the switch in the Normal Operation position. At the end of the

reboot phase, the C-BOX 150 is ready to function with the new

configuration.

9-pin C-Box 150 connector pinout in Configuration mode

Pin Name Function

2 RX C-BOX 150 Configuration

3 TX C-BOX 150 Configuration

5 SGND Signal Ground

When the C-BOX 150 configuration is completed, remember to

return the Configuration switch in the Normal Operation position.

CAUTION

15

Page 24

2

C-BOX 150

2.5 OPERATING MODES

With the C-BOX 150, the following operating modes are possible:

Normal Operation: At power on, the C-BOX 150 tries to connect to the scanner.

Once the connection procedure is completed the C-BOX 150 verifies if an Automatic

SEND command must be executed. While executing the command, the serial

Auxiliary interface is not available for the user. After the command completion, the

warning LED will turn OFF and the Aux interface will become free for communication.

After the initialization procedure, in the Normal operating mode the scanner reads

barcodes and communicates with the host.

Also in this mode, through the C-BOX 150 internal buttons it is possible to

communicate with the scanner to perform one of the three GET/TEST/SEND

Functions (see paragraph 2.5.1).

Configuration (CFG): When the CFG switch is in CFG position (left) it is possible to

configure the C-BOX 150 parameters through WinHost.

2.5.1 GET/TEST/SEND Functions

The C-BOX 150 has three internal function buttons which are available in the Normal

operating mode.

C-BOX 150

GET TEST SEND

Figure 15 – Internal Function Buttons

The procedure to enable the GET/TEST/SEND function is the following:

1. Press both the left and right buttons at the same time for at least one second;

the warning LED will turn ON.

16

Page 25

INSTALLATION

2

2. Release the buttons.

3. Press the left button corresponding to the GET function, the center button

corresponding to the TEST function or the right button corresponding to the

SEND function.

Once the buttons are released in step 1, a ten-second timeout starts.

If no button is pressed within this time (no function is selected), the

procedure will be cancelled.

The C-Box 150 warning LED will turn OFF at the end of each

NOTE

procedure.

Function

Description

The C-BOX 150 reads the current scanner configuration

and permanently copies it in its own memory support.

GET (left button)

The C-BOX 150 preserves this configuration also when

switched off. The GET option can be disabled through

WinHost.

The C-BOX 150 forces the WinHost™ compatible scanners

only to run the Test Operating Mode (refer to the scanner

Reference Manual for details).

TEST (center button)

Press any button to quit the Test Operating Mode and

restore the scanner normal operating mode.

For Genius™ compatible scanners you should use the

scanner keypad.

The C-BOX 150 sends the configuration previously stored

in its own permanent memory support to the scanner’s

SEND (right button)

memory.

The SEND option can be disabled through WinHost; by

default it is Automatic.

To override the eventual default Automatic SEND service, it is possible

to preset a GET service by executing the enabling procedure

immediately at power-on.

NOTE

17

Page 26

2

C-BOX 150

2.5.2 LED Indicators

Power polarity error

(red)

The internal LEDs of the C-BOX 150 (see Figure above) indicate the following:

POWER ON (PWR) (green) indicates the C-BOX 150 is connected to the

Pow n)er on (gree

Figure 16 - LED Indicators

power supply and the power switch is ON.

Warning (red)

Status

(yellow)

TX

(green)

POWER POLARITY ERROR (red) indicates a wrong polarity. While activated, all other

LEDs will be off until the power feed is connected with

correct polarity.

WARNING (WL) (red) indicates a warning or error condition.

Off: the C-BOX 150 has terminated the Connection and/or

the Update phase; all the operations have been executed

successfully.

ON: during a connection procedure and/or the Update

phase (the system is busy) or during the C-BOX 150

Configuration Mode.

It flashes quickly when a GET command has been preset

at power on.

18

Page 27

INSTALLATION

2

1 blinking/sec: a requested operation has been terminated

abnormally.

2 blinking/sec: a wrong operation has been requested (for

example the configuration in memory is not compatible

with the connected scanner).

STATUS (SL) (yellow) indicates the status of the non-volatile memory

support.

Off: the memory is empty (no configuration on board).

1 blinking/sec: the memory is not empty (a Get scanner

configuration service has been executed)*.

2 blinking/sec: the memory is not empty (a Get Scanner

Configuration service has been executed); however the

saved configuration is not compatible with the current

scanner one.

TRANSMISSION (TX) (green) indicates there is communication between the C-

BOX 150 and the scanner. This LED blinks during the

connection procedure.

* This is the typical state after correct system installation.

19

Page 28

2

A

pply

C-BOX 150

2.6 TYPICAL LAYOUTS

2.6.1 1000, 2000A/N, 4000 Family Scanners

For 1000, 2000A/N and 4000 scanner families which operate in a point-to-point

single scanner configuration, a typical layout is shown below and the C-BOX 150 is

connected as follows.

C-BOX 150

2

Scanner

PWR su

3

Main serial interface

1

uxiliary serial interface (Local Echo)

2

External Trigger (for On-Line mode)

3

1

Laptop

Host

Figure 17 – Typical point-to-point scanner Layout

20

Page 29

INSTALLATION

2

2.6.2 2000N Family Scanners

For 2000N scanner families which operate in an ID-NET™ network configuration, a

typical layout is shown below and the C-BOX 150/100s are connected as follows.

Figure 18 – Typical ID-NET™ scanner Layout

C-BOX 150 can perform Backup/Restore of a whole cluster under the following

conditions:

the Master/Slave network is composed of one master and up to 9

•

Slaves maximum

the Master/Slave network must be either Synchronized or Multidata

•

In order to perform Backup/Restore of Master only, the C-BOX 150 Cluster

GET/SEND parameter must be configured to "Master only", see the WinHost Help

On-Line.

21

Page 30

2

C-BOX 150

2.6.3 6000, 8000 Family Scanners

For the 6000 and 8000 scanner families, the C-BOX 150 can operate in both point-topoint single scanner configuration layouts, and in a network cluster of scanners in

Master/Slave layouts.

Slave 2 Slave1

Master

CAB-610X CAB-610X

CAB-610X

CAB-610X

BTK-6000

Slave 5 Slave 4

Figure 19 – Typical Lonworks scanner Layout

CAB-610X

CAB-63XX

BTK-6000

CAB-60XX

CAB-63XX

Slave 3

C-BOX 150

PS

Encoder

Host

PWR-240

In a Master/Slave layout with a great number of Slaves, a Power

Supply Unit can be connected to the scanners and the C-BOX 150

can accept the scanner power by setting the Power Source Jumper

NOTE

in the right position. See paragraph 2.4.6

C-BOX 150 can perform Backup/Restore of a whole cluster under the following

conditions:

the Master/Slave network is composed of one master and up to 9

•

Slaves maximum

the Master/Slave network must be either Synchronized or Multidata

•

the A.S.R. mode must be disabled

•

22

Page 31

INSTALLATION

2

In order to perform Backup/Restore of Master only, the C-BOX 150 Cluster

GET/SEND parameter must be configured to "Master only", see the WinHost Help

On-Line.

2.7 SCANNER REPLACEMENT

If you have to replace the scanner with another one:

1. Switch-off the system.

2. Connect the new scanner.

3. Switch-on the system.

4. Wait until the Warning Led (WL, red) is switched Off.

Now the new scanner has been automatically (default) updated with the correct

configuration!

23

Page 32

3

C-BOX 150

3 TECHNICAL FEATURES

ELECTRICAL FEATURES

Power

Supply voltage 10 to 30 Vdc

Power consumption max. 2.5 W + scanner

USER INTERFACE

LED indicators Power ON, Warning, Status

Tx, Polarity inversion

PHYSICAL FEATURES

Mechanical dimensions 161 x 114.5 x 40 mm (6.34 x 4.51 x 1.57 in)

Weigh t about 410 g. (14.48 oz.)

SOFTWARE FEATURES

Parameter storage Non-volatile internal memory

ENVIRONMENTAL FEATURES

Operating temperature

Storage temperature

Humidity max. 90% non condensing

Vibration resistance

IEC 68-2-6 test FC

Shock resistance

IEC 68-2-27 test EA

Protection class

-10 to 50 °C (14 to 122 °F)

-20 to 70 °C (-4 to 158 °F)

14 mm @ 2 to 10 Hz;

1.5 mm @ 13 to 55 Hz;

2 hours on each axis

3 shocks on each axis

(when correctly connected to the scanner)

2g @ 70-200 Hz

30g; 11 ms;

IP64

24

NOTE

The features given are typical at a 25 °C ambient temperature (if not

otherwise indicated).

Page 33

DECLARATION OF CONFORMITY

07

Datalogic Automation S.r.l.,

Via S. Vitalino 13

40012 - Lippo di Calderara

dichiara che

declares that the

déclare que le

bescheinigt, daß das Gerät

declare que el

C-BOX-XXX Connection Box; e tutti i suoi modelli

and all its models

et tous ses modèles

und seine Modelle

y todos sus modelos

sono conformi alle Direttive del Consiglio Europeo sottoelencate:

are in conformity with the requirements of the European Council Directives listed below:

sont conformes aux spécifications des Directives de l'Union Européenne ci-dessous:

der nachstehend angeführten Direktiven des Europäischen Rats:

cumple con los requisitos de las Directivas del Consejo Europeo, según la lista siguiente:

89/336/EEC EMC Directive e 92/31/EEC, 93/68/EEC emendamenti successivi

and further amendments

et ses successifs amendements

und späteren Abänderungen

y succesivas enmiendas

Basate sulle legislazioni degli Stati membri in relazione alla compatibilità elettromagnetica ed alla sicurezza dei

prodotti.

On the approximation of the laws of Member States relating to electromagnetic compatibility and product safety.

Basée sur la législation des Etats membres relative à la compatibilité électromagnétique et à la sécurité des produits.

Über die Annäherung der Gesetze der Mitgliedsstaaten in bezug auf elektromagnetische Verträglichkeit und

Produktsicherheit entsprechen.

Basado en la aproximación de las leyes de los Países Miembros respecto a la compatibilidad electromagnética y las

Medidas de seguridad relativas al producto.

Questa dichiarazione è basata sulla conformità dei prodotti alle norme seguenti:

This declaration is based upon compliance of the products to the following standards:

Cette déclaration repose sur la conformité des produits aux normes suivantes:

Diese Erklärung basiert darauf, daß das Produkt den folgenden Normen entspricht:

Esta declaración se basa en el cumplimiento de los productos con las siguientes normas:

EN 55022 (C

A

MENDMENT A1 (CLASS A ITE), October 2000

EN 61000-6-2, October 2001:

Lippo di Calderara, April 2nd, 2007 Lorenzo Girotti

LASS A ITE), August 1994:

Bologna - Italy

L

IMITS AND METHODS OF MEASUREMENTS OF RADIO DISTURBANCE

CHARACTERISTICS OF INFORMATION TECHNOLOGY EQUIPMENT

LECTROMAGNETIC COMPATIBILITY (EMC).

E

P

ART 6-2: GENERIC STANDARDS – IMMUNITY FOR INDUSTRIAL

ENVIRONMENTS

Product & Process Quality Manager

Page 34

www.automation.datalogic.com

Loading...

Loading...