Page 1

Spyder3Print User Guide Index

Welcome to Spyder3Print Here’s an overview of how the application works.

Print Guide Rule. Using the optional Rule for reading targets.

Preferences. Allows access to user configurable settings.

Tools. Describes the advanced functions available from the Tools menu.

Printer Definition. Allows you to define features of your printer for later use.

Configure Printer Settings. Offers assistance in determining the best printer settings

for your uses.

Print Quality Check. Checks that your printer is performing properly.

Media Setting Check. Assists in determining the optimal media setting for

Spyder3Print.

Select Target. Allows the selection, preview, and printing of profiling targets.

Spectro Calibration. Calibrates your spectro to the white tile in the calibration base.

Read Patches. Selects or creates color target measurements in Spyder3Print.

Build Profile Setup. Offers a range of profile settings and adjustments, and builds

profiles accordly.

SpyderProofTM. Provides SoftProofs and printed samples using your profile.

Page 2

Remote Profiling. This tutorial describes the process of profiling a printer at a remote

location.

Printing with Custom Profiles. This tutorial describes the process of using your printer

profiles to print your documents.

Methods of Black and White Printing. This tutorial describes the available range of

methods for printing black and white digital images using inkjet printers.

Creating Tinted Black and White Profiles. This tutorial describes the process and

options when creating tinted black and white profiles.

Color Gamuts and Rendering Intents. This tutorial offers advanced information on the

details of printer profiles and their use.

SoftProofing. This tutorial covers advanced SoftProof tools in profile building and

image viewing.

Color Workflow for Digital Photography. This tutorial explains how to control color from

your camera, to your computer, to your printer.

Datacolor License Agreement. Describes the licensing restrictions that apply to use of

Spyder3Print and the profiles built with Spyder3Print.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 3

Welcome to Spyder3Print

Skip to:

Help Index

The Purpose of This Application

This assistant-based application will help you choose optimal settings for your printer,

and build high quality ICC compliant RGB printer profiles. Profiling allows your prints

to match, from screen to print, and between different printers, inks, or papers. These

printer profiles are then used by ICC-aware applications such as Adobe® Photoshop®

so that colors can be printed as they are intended. Typically users build a profile for

each different paper they use.

The Long Answer

This assistant will help you choose the best printer driver and media settings for

printing with your printer, make sure your printer is printing properly, and build RGB

format printer profiles for each of your printer, ink, and media combinations to assure

accurate, optimal prints. It will step you through the process of:

Defining Your Printer Type

•

Optimizing Your Printer Settings

•

Properly Printing a Test Chart

•

Connecting Your Spectro

•

Reading Your Test Chart

•

Building Your Profile

•

Making Adjustments to Your Profile

•

Page Setup: Landscape (horizontal) orientation in Page Setup is recommended for

use with Spyder3Print. Previews of all targets and test images are shown in an

embedded preview, with a larger, resizable, preview available by clicking on the

Page 4

embedded preview. All previews are formatted according to your selected page size

and orientation; changes to your page size or orientation will be immediately reflected

in the previews.

Under Windows 2000 it is necessary to have a printer driver installed in order to

access Page Setup. Page Setup in Mac OS X, and Windows XP/Vista can be configured

without having a printer driver installed.

Mac OS X Classic Mode: Classic Mode (which allows Mac OS 9 applications to run

under OS X) captures USB devices, and sometimes does not release them for use by

OS X applications. It is recommended that you quit Classic Mode before running

Spyder3 applications. If Spyder3Print cannot find a properly connected Spectro or

Printer, quit Classic Mode, and try again.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 5

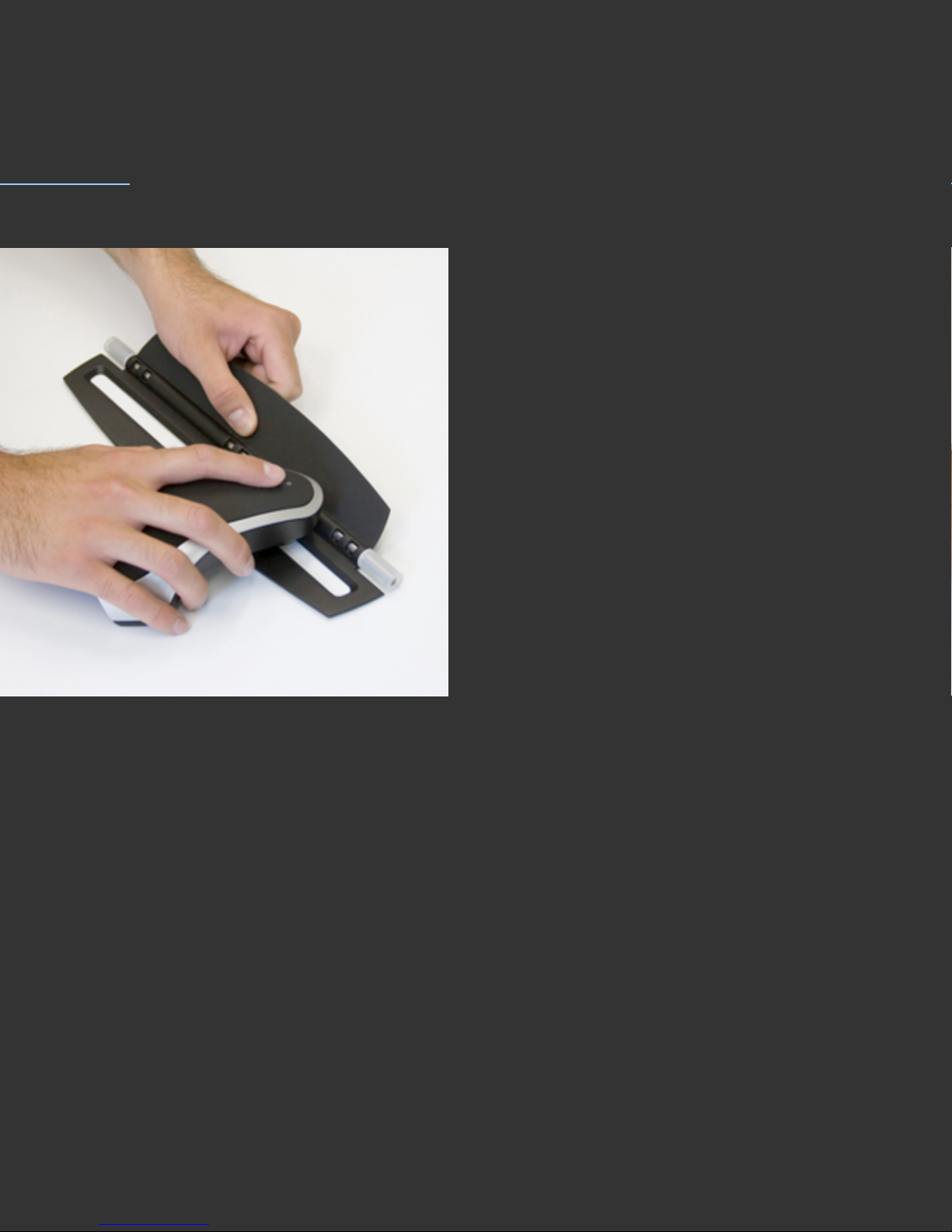

Print Guide Rule

Skip to:

Help Index

Usual Setting

Many users will find it faster to read patches freehand. But for those who prefer

assistance in keeping the patch reader in line vertically, the included Print Guide Rule

can be used.

The Purpose of This Step

To offer assistance for those who find freehand patchreading difficult or tiring.

The Long Answer

Many users will find it faster to read patches freehand. But for those who prefer

assistance in keeping the patch reader in line vertically, the included Print Guide Rule

will allow the users to focus on moving from patch to patch horizontally, while being

sure that the patch reader is correctly located vertically. The Rule can be rolled from

Page 6

row to row while retaining its orientation.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 7

Preferences

Skip to:

Help Index

Sensor

Communication Errors

Sensor Info

Sounds

Usual Setting

Preferences are located in the Spyder3Print menu. Default Preferences are ideal for

most users.

The Purpose of This Step

Preferences allows access to user configurable settings and special functions.

The Long Answer

Sensor: This popdown list allows you to toggle between two settings : Spectro, and

None. Choosing the None setting disconnects the Spectro from the application.

Choosing Spectro searches for and connects to the Spectro. Be sure the Spectro is

connected to a powered USB hub or directly to your computer to assure it will be

found, and will function properly. Do not connect the Spectro to your keyboard or

monitor, and theses are not fully powered locations. Some computers have front USB

ports that are not powered ports, so if your Specto fails to function from a front port,

connect to a powered hub or back port.

Communication Errors: If a communication error occurs and the Spectro is no

longer responding to commands, toggling to None, and back to Spectro should

Page 8

reestablish communication. After regaining communication with the Spectro, it may be

necessary to close the open measurement window, and reopen it from the saved

measurement files list to complete readings.

Sensor Info: The Sensor Information section displays Unit ID and Firmware version

information, which is useful if it is necessary to discuss hardware problems with

Datacolor Support. If the Spectro is not successfully connected to the software, these

lines display ???? instead of Hardware and Firmware informaton. It is not possible to

communicate with the Spectro while ???? values are displayed in this section.

Sounds: It is recommended that all three sounds options be checkmarked, to give

useful auditory prompts while using Spyder3Print. Individual users may have personal

preferences to turn one or more of these sound prompts off.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 9

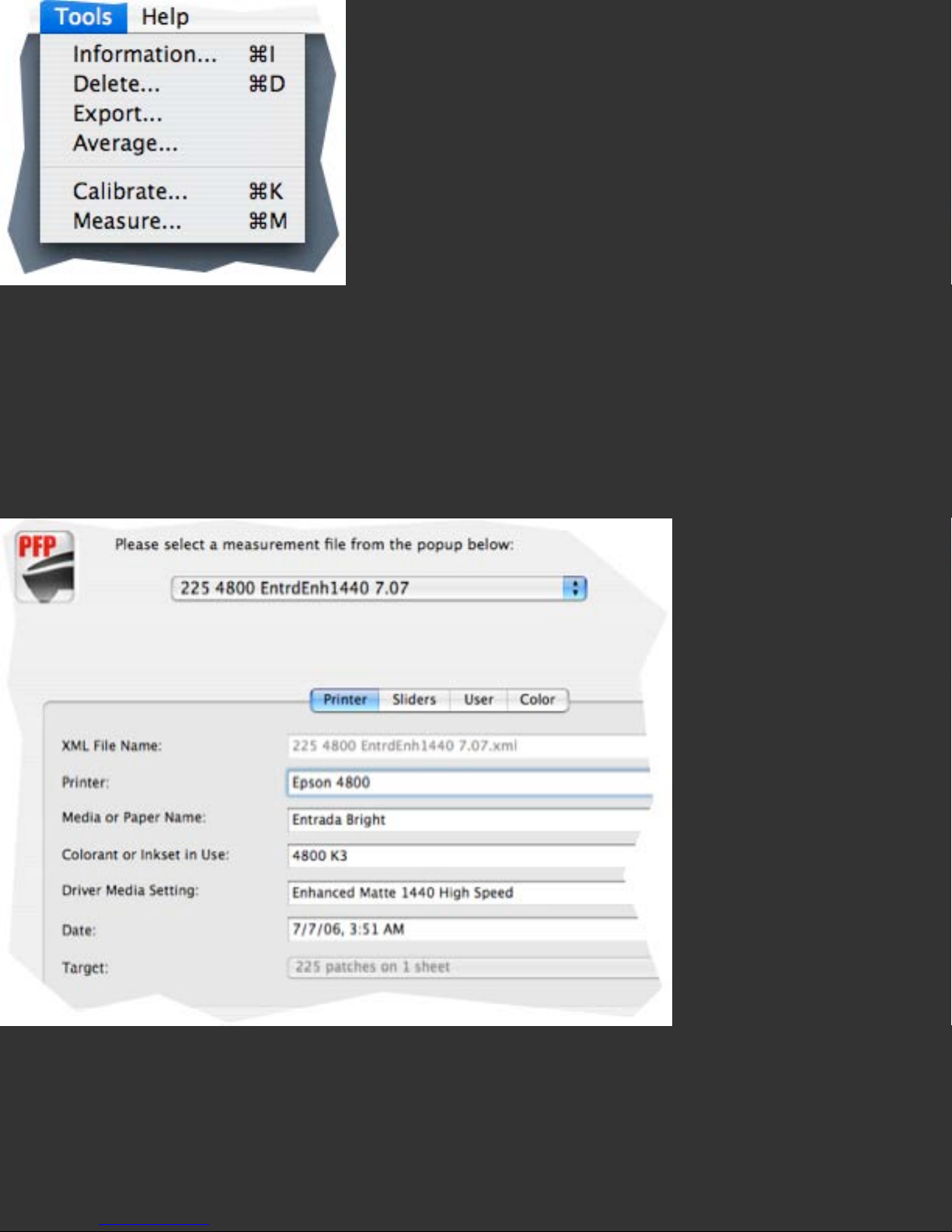

Tools

Skip to:

Help Index

Measurement File Information

Deleting Measurement Files

Exporting from Measurement Files

Averaging Existing Measurement Files

Calibrating the Spectro from the Tools menu

Taking Spot Measurements from the Tools menu

Exporting Measurement Logs

Usual Setting

Typical profile building occurs from the Wizard interface. The Tools menu is not

needed for standard profile building.

The Purpose of This Step

The Tools menu is used to access the specialty functions described below.

The Long Answer

Each Tools menu command and its uses are described below.

Page 10

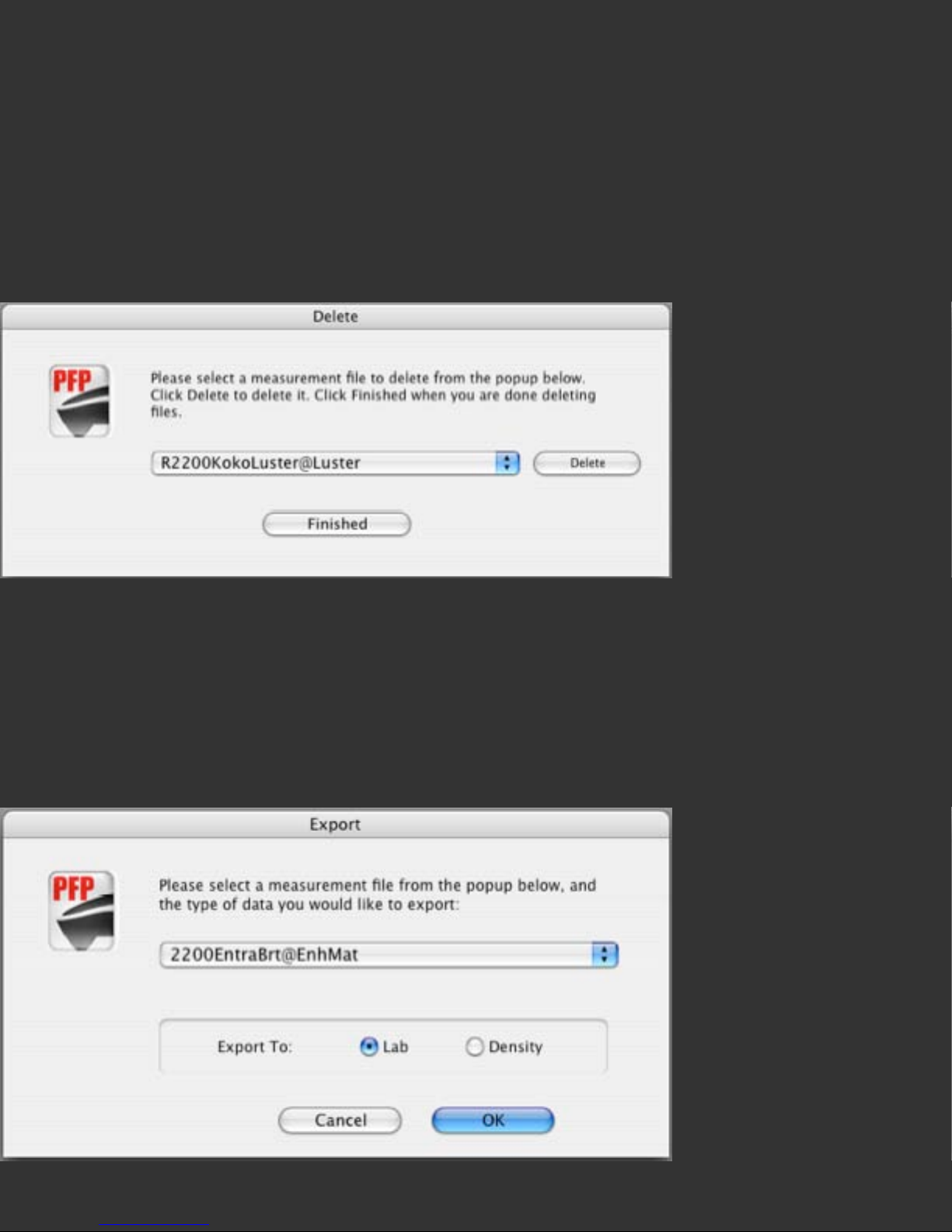

Measurement File Information: Users can determine printer, ink, paper, media

setting and other important information about a Measurement File by selecting it with

the Information tool. It is possible to copy, paste, and manually edit much of the

device information using one or more Information Windows, and to save the adjusted

versions under a new new using the Save As command.

Deleting Measurement Files: Existing Measurement files (as found in the Existing

Measurements Popdown list in the Read Patches screen) can be deleted from the Tools

menu Delete command. If you have incomplete, invalid, or unneeded measurement

sets, deleting them from the list will simplify finding sets as you need them.

Page 11

To delete a measurement set, choose the Delete command from the Tools menu. This

will open a floating window containing a popup menu listing all existing Spyder3Print

measurement sets currently in your Print Data folder. Choose the measurement set

you wish it delete, and click on the Delete button. A warning dialog asking if you are

sure you wish to delete this file will appear. A check box in this warning dialog allows

you to choose not to see this warning again, making deletion of multiple files faster.

Once you are finished deleting measurement sets, the Finish button allows you to exit

the Delete screen.

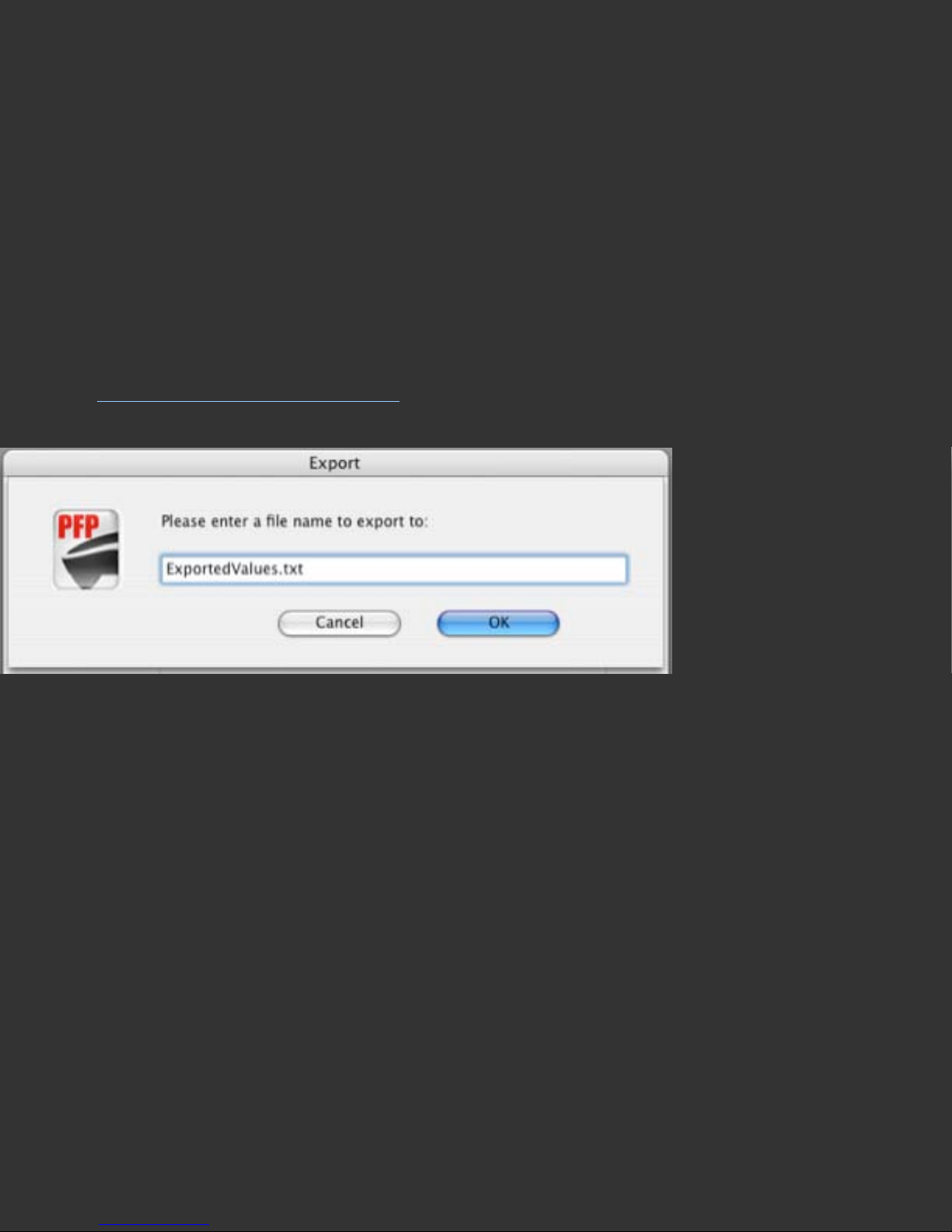

Exporting Measurements for Other Uses: If you have uses for measurement data

outside Spyder3Print, the Export command allows you to save out this information as

text files. Select Export from the Tools menu, and choose the existing Measurement

file from which you wish to export data, in the popup list the Export window provides.

Data can be exported in two forms: L*a*b* values, or Density values.

L*a*b* Export: L*a*b* values are the color measurements contained in the

Page 12

Measurement file, converted to a tab delineated text file, that will be written to the

Export subfolder in the application’s Data folder. After choosing the Lab radio button,

and then clicking the OK button, a second dialog will appear asking you to name your

new text file.

Density Export: Some uses require grayscale density values, instead of Lab values.

By selecting the Density radio button, visual density values suitable for certain

grayscale linearization and calibration purposes can be produced. Clicking the OK

button will bring up a second dialog asking you to name your new text file.

Other Export Formats: Other export formats are available by Creating Export Logs

with the

Spectro Measurements tool.

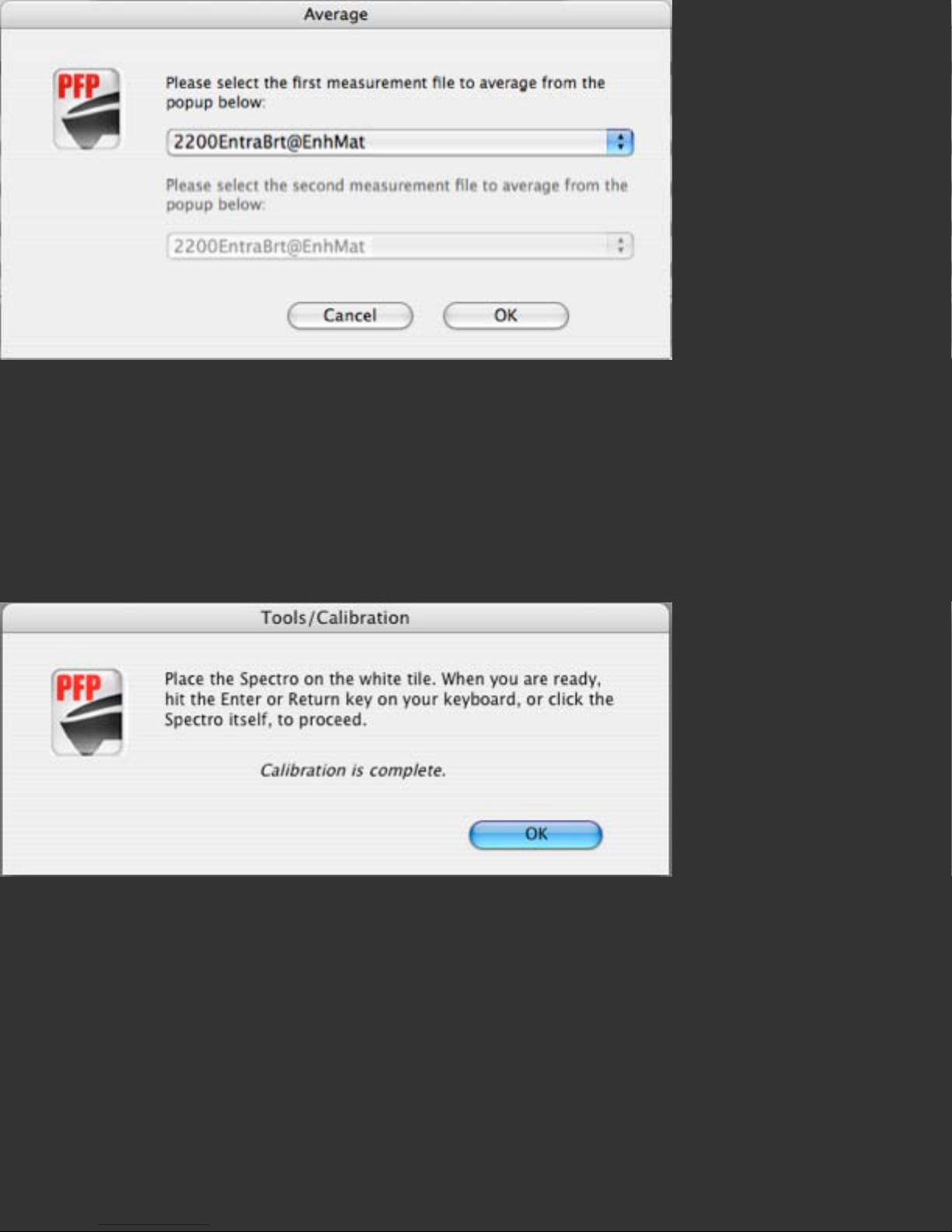

Averaging Existing Measurement Files: The Average command allows you to

produce a new measurement file containing averaged values for each measurement in

the two source files selected. This can be useful for smoothing out readings through

averaging two or more sets of files from the same target.

Select the first file you wish to average in the upper popup list. This will show all files

of the same format in the lower popup list. Only measurement sets with the same

number of measurements can be averaged. Once two compatible files have been

chosen, the OK button will become active, and you can name and save your averaged

measurement set. It will be saved to the PRO folder in the Data folder, and can be

used to build profiles like any other measurement file. To average four measurement

sets, first average two pair, then average the two resulting files.

Page 13

Tools Calibrate function: This button launches a calibration window that allows both

black and white tile calibrations. It is not necessary for standard use; the calibration

function occuring in the Wizard interface is all that is needed. Calibration from the

Tools menu is a for special testing and support purposes, or for calibration when using

the Tools Measure function.

Tools Measure function: This button launches a measure window that allows

measurements to be taken, and displays L*a*b* color values and Visual Density

values of for each patch after it is read. If a log of meaurements is desired, it can be

named, and exported as Lab, Visual Density, or special QTR linearization and QTR

CreateICC formats for use with QuadTone RIP®. Once the user completes the

measurement set, the Done button stops the export process, and closes the Measure

window.

Page 14

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 15

Printer Definition

Help Index

Entering Information about Your Printer

Save Template

Skip to Profiling Process

Usual Setting

Type in Printer, Paper, and Inkset names, then select the Next Button

The Purpose of This Step

This screen allows you to define the type of printer you will be profiling, and to enter

information about it that will be used throughout the process. This information is only

for labeling your target prints, it does not affect profile building.

The Long Answer

Entering Information about Your Printer

Printer Name: Enter the printer make and model number here.

Media or Paper Name: Enter the name of the paper or media you will be profiling

here.

Colorant or Inkset in Use: Enter the name of the inkset or colorants you will be

using here.

Driver Media Setting (Paper Type Selection): Enter the media setting you will be

selecting in the printer driver here, or leave blank, and determine this later, at the

Media Setting step.

Date: Leave the automatic date information here, unless you have a special need to

adjust it.

Page 16

Save Template

This option allows users to batch process profiles. Set printer data as desired, choose

Save Template, name your Measurement Set, and select the desired Target. Repeat to

define other Measurement Sets. Printed targets with accurate information from these

batch-created templates can be printed by choosing the template in the lower half of

the Measure Patches screen, backing up one screen to the Select Target screen, and

printing. Repeating this process will print all the desired targets with the correct

printer info on each.

Skip to Profiling Process

If you do not need assistance checking that your printer is properly configured, and

that all inks or colorants are printing as desired, or assistance in determining the

optimal media setting for your chosen paper, then use this button to skip ahead to the

profiling process. We do recommend that you run through the process in its entirety at

least the first time you profile so that you have a complete understanding of the

program.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 17

Configure Printer Settings

Help Index

Print Settings in Spyder3Print

Printer Driver Settings

Epson Driver Settings

Canon Driver Settings

HP Driver Settings

Windows Specific Settings

Print Settings in Adobe PhotoShop

Print Settings in Adobe PhotoShop Elements

Settings in Other Applications

Usual Setting

Please use the same printer driver settings when printing profiling charts as when

printing final work, to assure maximum consistency and accuracy in profile usage. It is

also important to turn off color management at the printer driver to assure that profile

targets, as well as final prints, are not effected by driver color adjustments being

unintentionally added to the print process.

The Purpose of This Step

Using optimal and consistent printer settings is important to obtaining high quality,

consistent prints. Avoiding unintended driver color adjustments is necessary for

accurate color management.

The Long Answer

It is important to become familiar with the printer settings available for your printer,

and choose settings that work well with the types of media you use, for the types of

work that you print.

Some printers, such as color lasers, have few if any user configurable settings, so no

Page 18

choices are necessary. For printers with a wide range of choices, you will need to

experiment to determine which settings will be most effective for you. Use these

settings when printing profile charts, and continue to use them when printing with the

profiles you create. If you are not thoroughly familiar with your driver settings, it is a

good idea to note the settings, or make screenshots of them, for future reference, so

that you can be consistent in what settings you use.

It is a good idea to experiment with the driver options, and see what results they offer

with the type of papers you intend to print on and the type of files you print, in order

to assure that you obtain the best possible results.

Print Settings in Spyder3Print

Spyder3Print will automatically print your color charts without applying any

unintended color adjustments to them. The only configurations necessary, when

printing directly from Spyder3Print, are the printer driver settings. These driver

settings are very important. Review the driver settings section below to be sure you

are properly configuring them. Please note that driver settings must be set from the

Print command menus, unless they are saved in advance into a driver configuration

set. Always check your driver settings at time of printing, to be sure they have not

defaulted to unintended settings.

To print Spyder3Print color targets from remote printers, it is recommended that you

install Spyder3Print on the computer attached to the printer, and run the application in

Demo mode to check printer settings and print color targets.

Printer Driver Settings

Following the main print window, in Spyder3Print as well as other applications, there

are Printer Driver Settings windows. These vary with different brands and models of

printers. Typically there are resolution and quality related settings that the user must

test to determine appropriate choices. There are also color adjustments settings. For

working with custom ICC printer profiles, it is usually best to set these choices to Off

or None to allow the profile to do the color correction for you, without competition

from any driver color adjustments.

Page 19

Some typical drivers and settings will be shown here to give you an idea of where to

find the necessary items, and how to set them. Please note that these driver settings

vary between brands and models of printers, as well as between operating system

versions, so it is not possible to cover all possible examples.

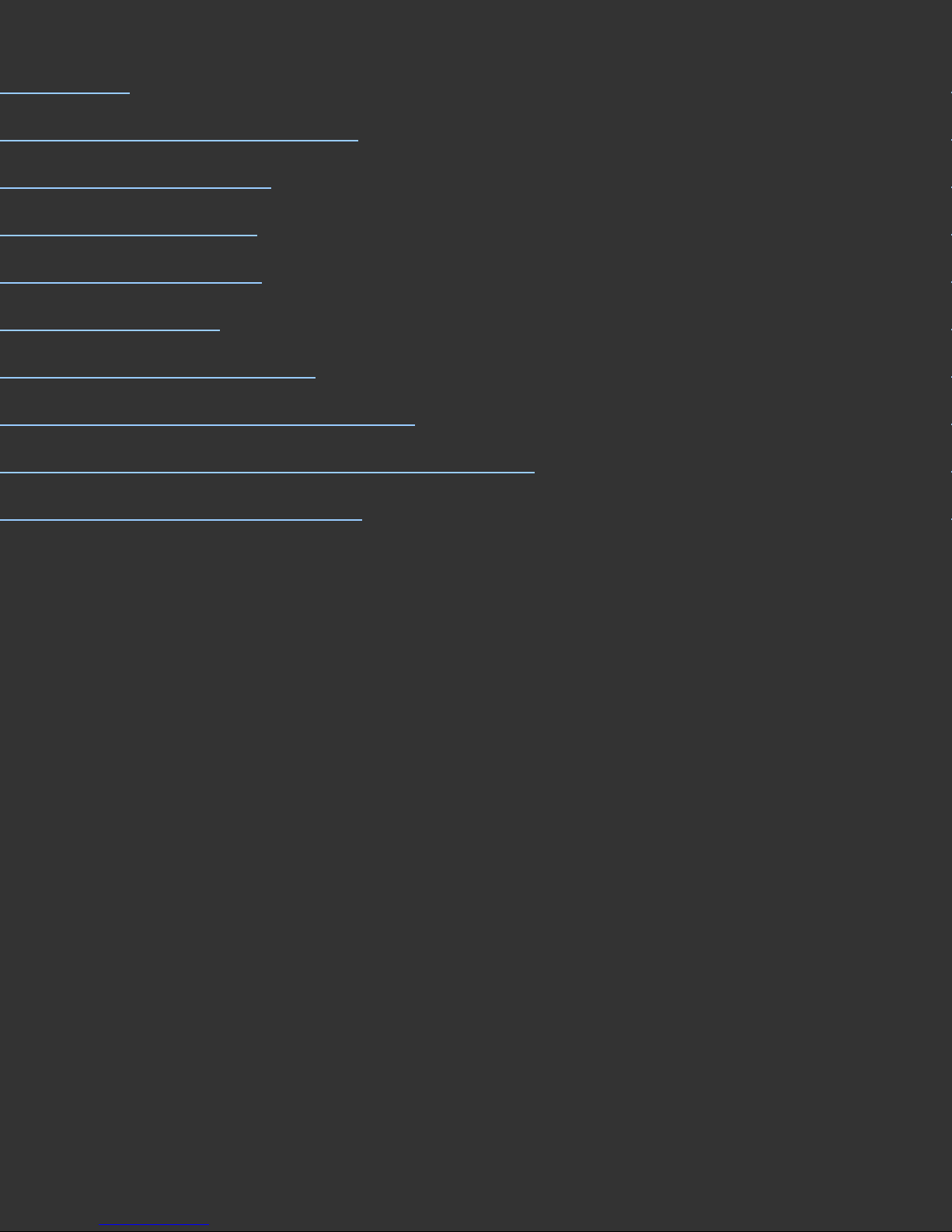

This illustration is from a typical Epson inkjet driver under one version of Mac OS X.

Other drivers and OS versions will vary. There are two sections in the pop-down menu

that are important for color managed printing: Printer Settings, and Printer Color

Management. ColorSync might seem as though it would contain color management

settings, but it does not.

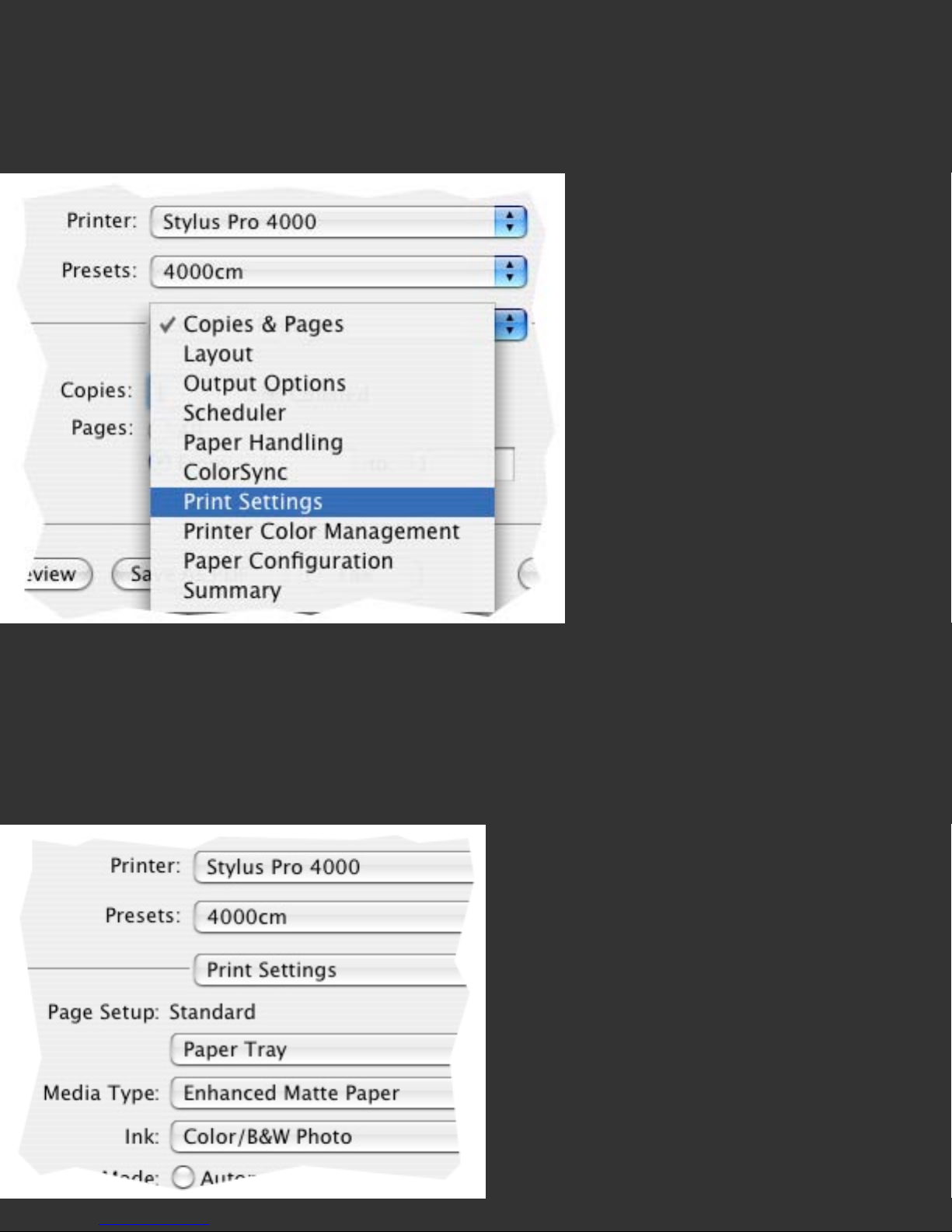

Page 20

This close-up from the above Epson driver window shows that the Print Settings

section included the Media Type list. This list is where choices of media type settings

occur, and is important for use with the Media Setting Check window.

This close-up from the above Epson driver window shows that the Printer Color

Management section included the option for disabling color corrections by the printer,

by choosing ‘Off (No Color Adjustment)’. This, or some similarly named setting, is

available in many inkjet drivers to perform this function.

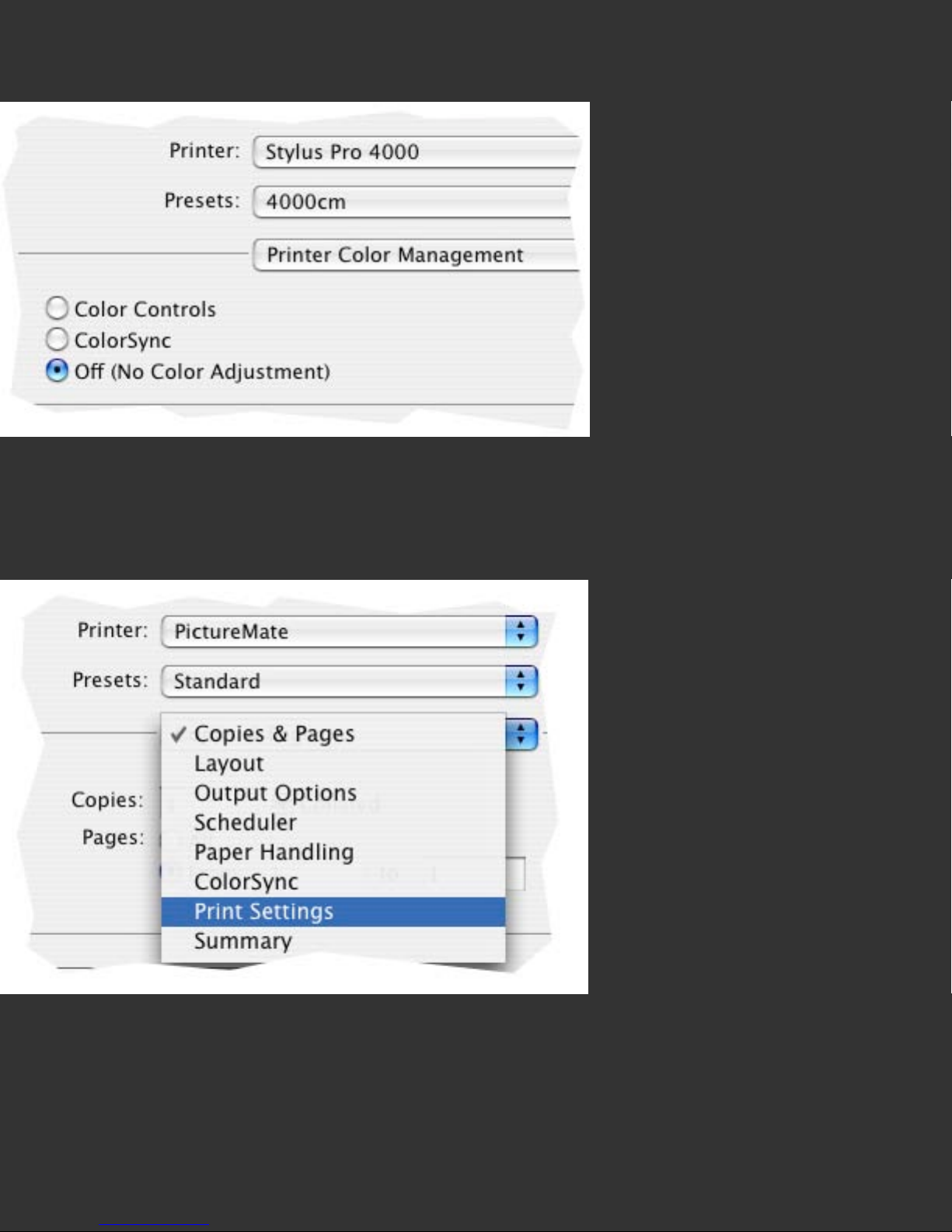

This driver from a less complex Epson inkjet printer contains no Printer Color

Management section at all. In this case, users would use the standard color setting the

driver provided, and build their profiles on top of that color setting.

Page 21

This illustration of the Print Settings from the simple driver shows that the only choice

that would effect print color is the selection of ‘Color’ or ‘Black & White’ settings.

Please note that with many printers, using the ‘Color’ setting and a custom color

profile may produce more desirable Black & White prints than the Black & White

setting.

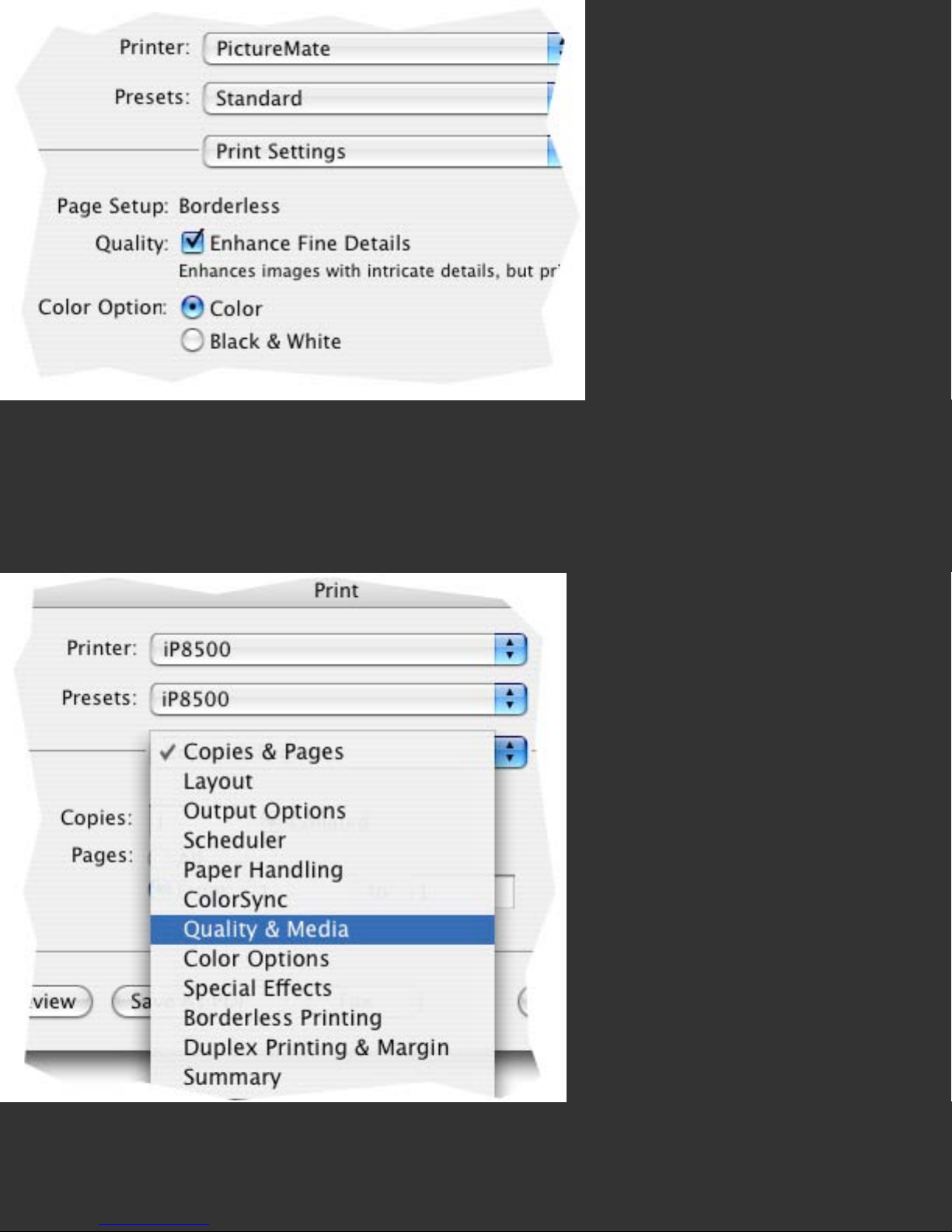

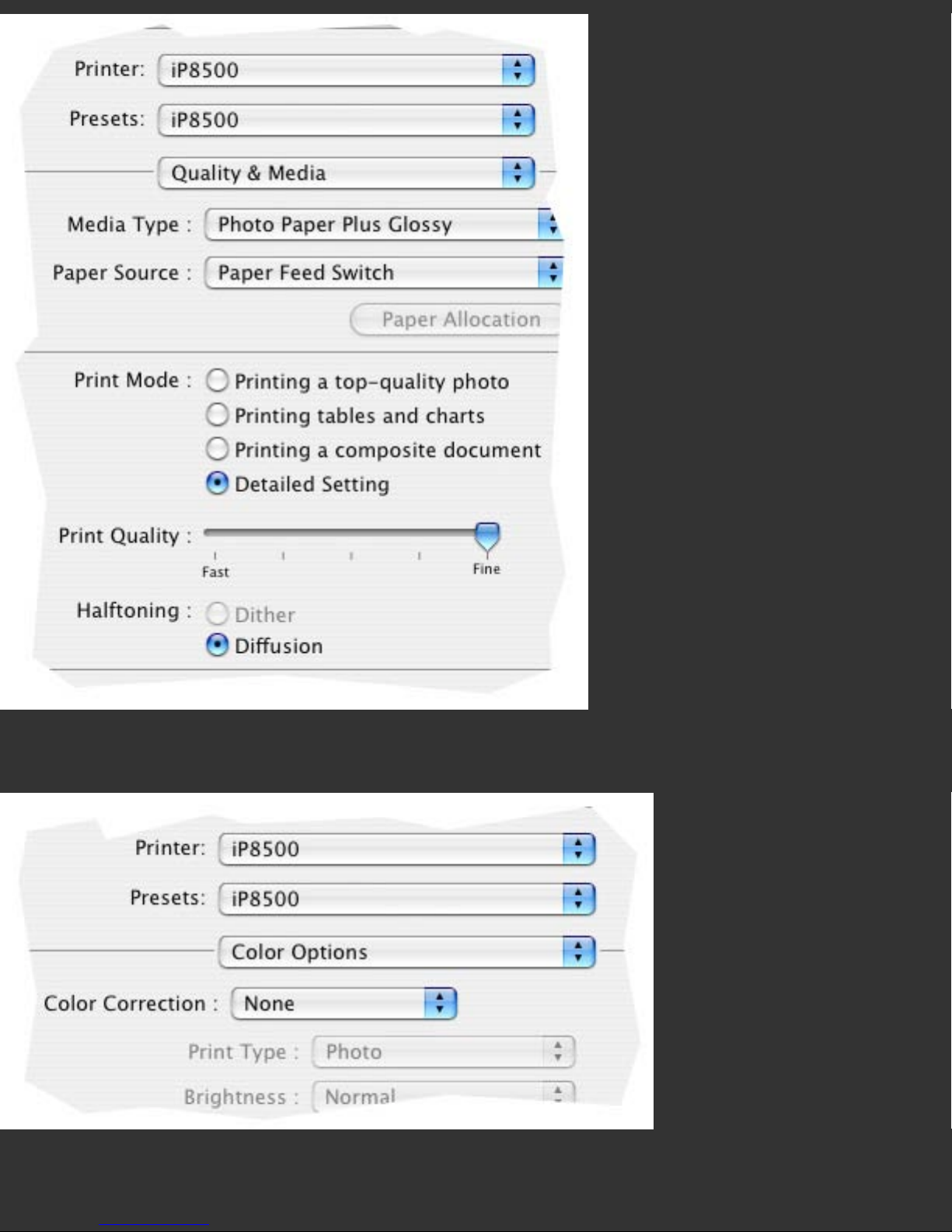

This is an illustration of a Canon inkjet driver under OS X. Similar to the more

advanced Epson driver above, there are two menu items that effect color

management: ‘Quality and Media’, and ‘Color Options’. While the names vary a bit

from the Epson versions, the functions are similar.

Page 22

The ‘Quality and Media’ section of the driver contains the Media Settings, where paper

type would be chosen, and where Media Setting Checks would be performed.

Printer Color Management is turned off in the ‘Color Options’ section of the driver, by

choosing ‘None’. This is important both for printing color targets, and when printing

images through the resulting color profiles; interference from color adjustments at the

Page 23

printer driver level must be avoided.

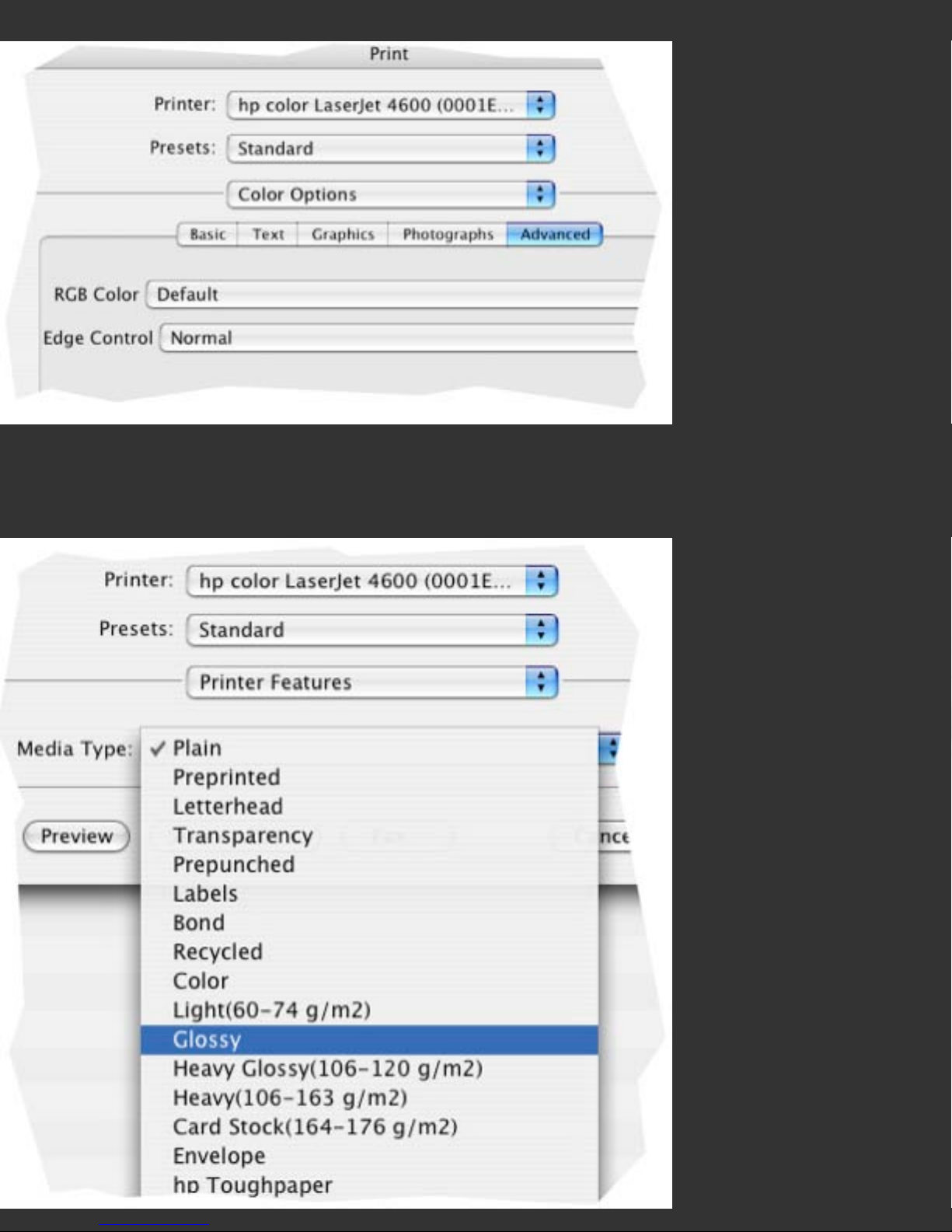

The HP Laserprinter driver shown above is typical of many laser drivers. It shows a

number of color options under different headings, but none of them are actually

configurable, so none need to be reviewed or set before printing.

Page 24

The only user selectable item in the above HP driver is media type, with a selection of

media that HP considers appropriate for laser printer uses. Users would want to

experiment with a range of these media types, to determine which one might be

optimal for the media in use. For laser printers, different media settings may effect

feeding of paper thicknesses more than they effect color densities.

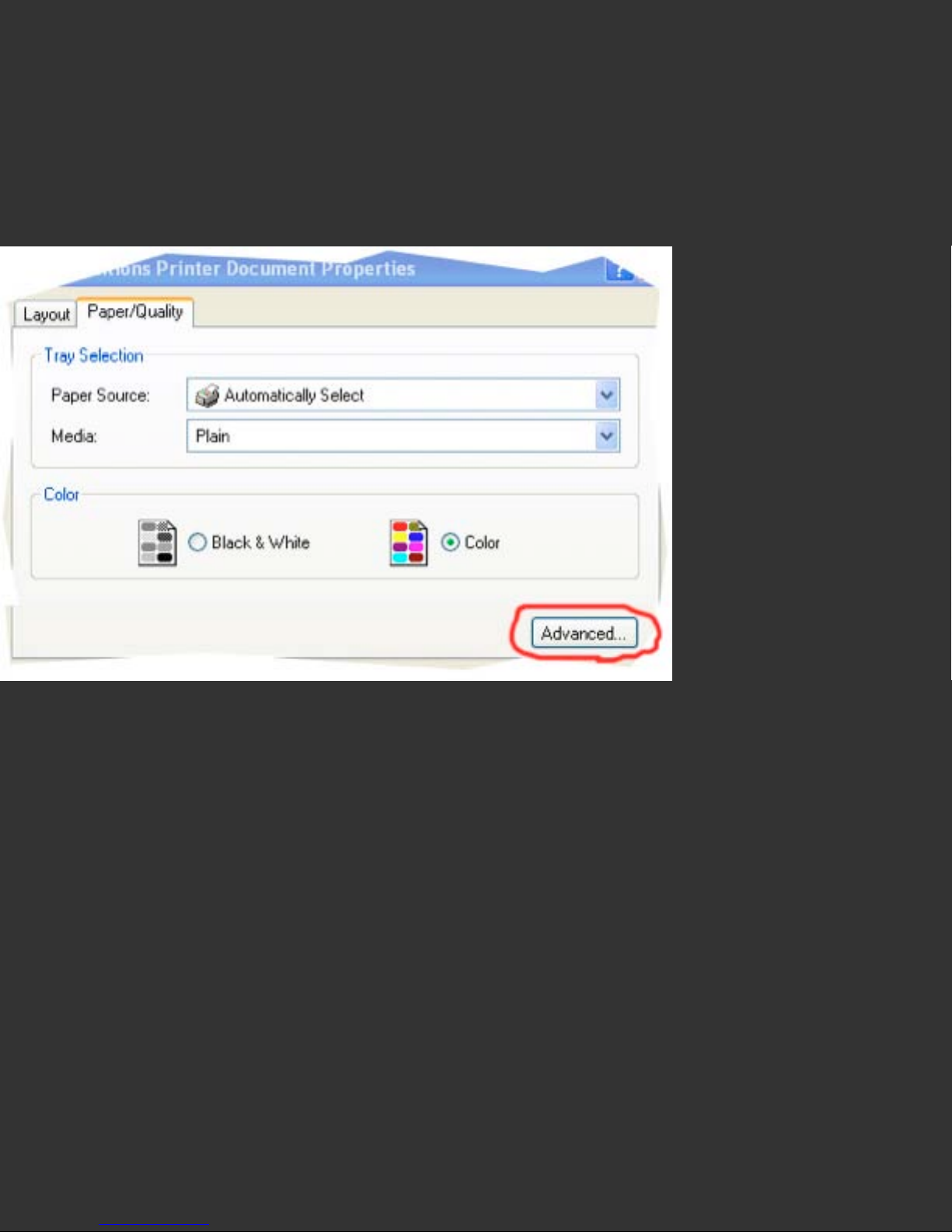

Windows driver settings can be in a somewhat different driver location.

They occur in the ‘Advanced Printer Options’, accessed from the ‘Advanced’ button in

the main printer driver window. Under Windows Vista printers options are no longer

configured from Page Setup, but from Print, similar to how it works on the Mac.

Page 25

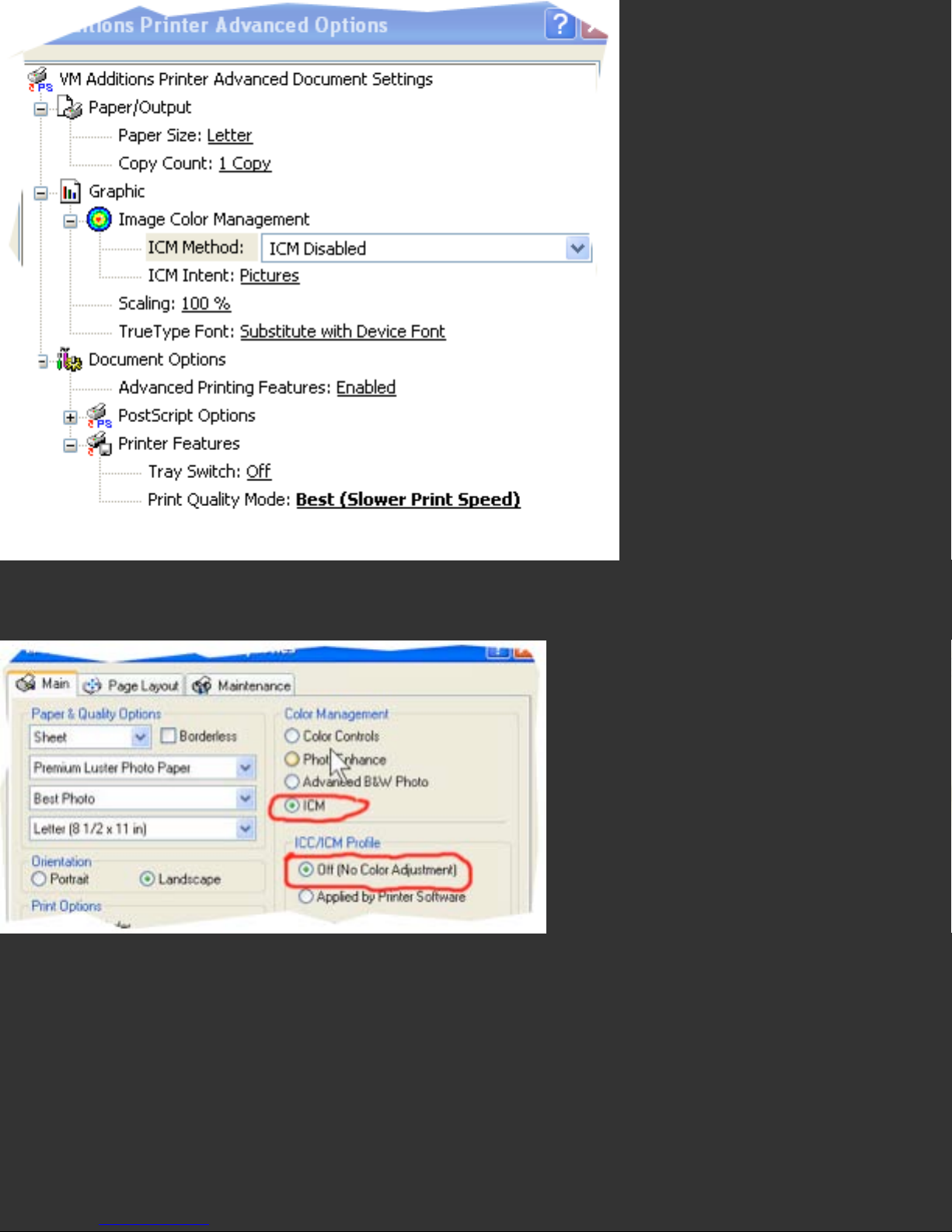

In this XP Advanced Printer Options Window ICM has been disabled.

Here is another XP driver with ICM selected, so that Driver Color Adjustment can be

turned Off. In most cases choosing ‘No Color Management’ or ‘ICM Disabled’; or in

some cases choosing ‘ICM’, then a subsetting of ‘None’ or ‘Off’ will assure that no

unintended color conversions occur.

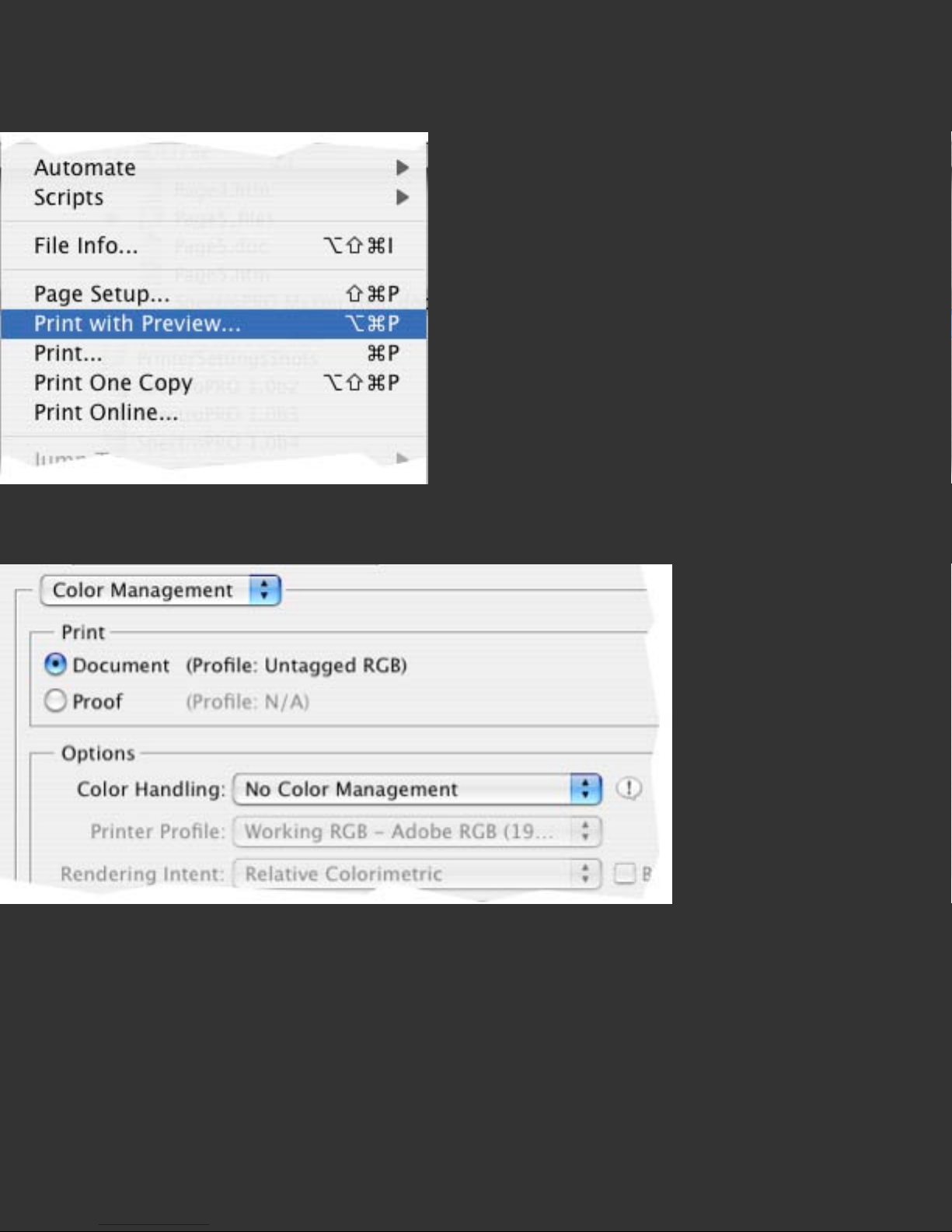

Advanced Topic: Print Settings in Adobe PhotoShop®

When printing from Photoshop, always use the Print with Preview command, and

choose Show More Options’ at the bottom of the main print page, then Color

Page 26

Management’ in the pop-down list that appears. Color Profiling Charts should be

printed with the Source Space set to Document, and Color Handling set to No Color

Management; or prior to CS2 set the Print Space to Same as Source which is at the

top of the popdown list.

Photoshop’s Print with Preview Command (Simplified to Print Command in CS3)

Photoshop Color Management settings as they would be set to print a color profiling

target.

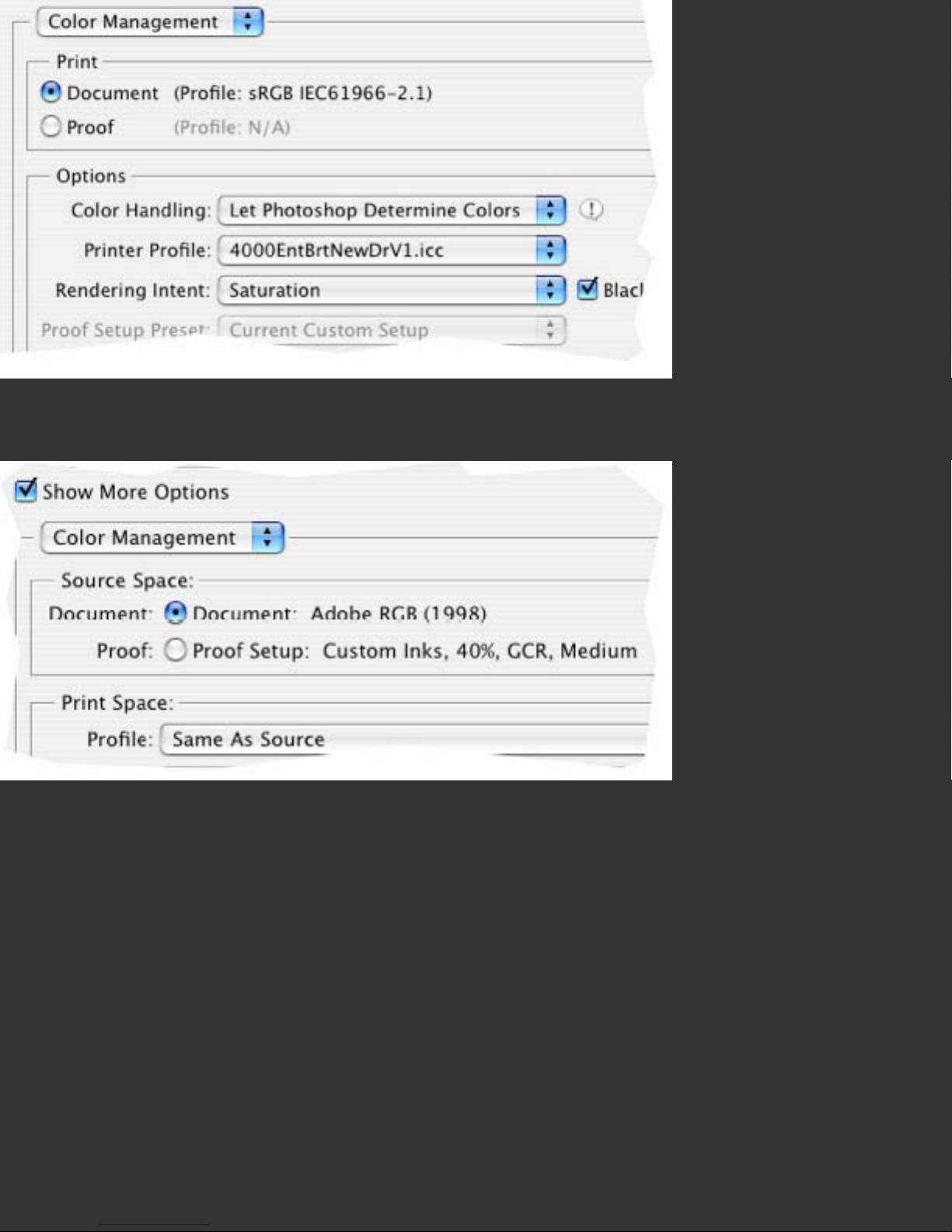

Page 27

PhotoshopCS2’s Color Management Settings, as they would be set to print images (not

profiling targets) through a custom profile.

These are typical of settings used in previous versions of Photoshop to print profiling

targets without unintended color conversions.

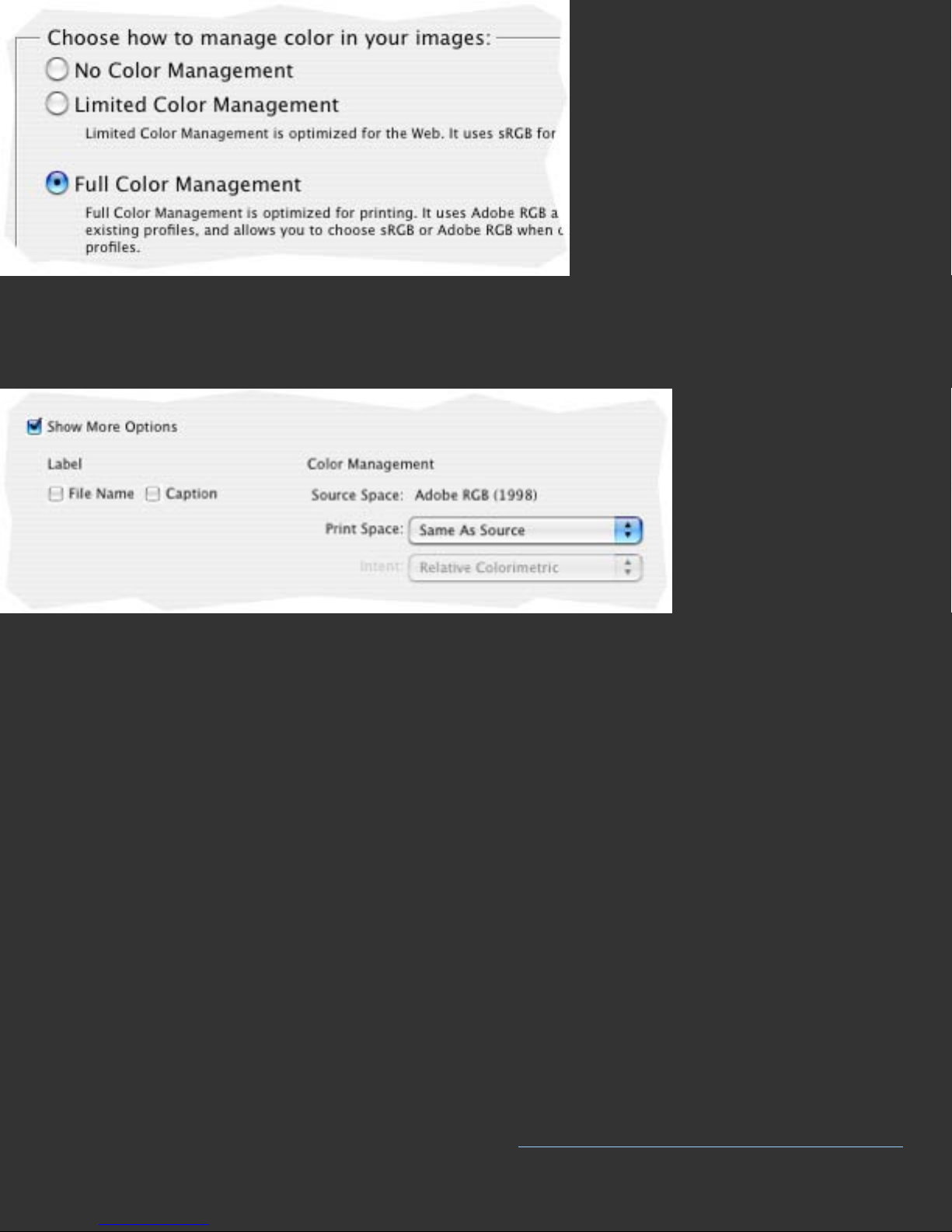

Advanced Topic: Print Settings in Adobe PhotoShop Elements®

When printing from Photoshop Elements, set the Color Settings (found under the

Photoshop Elements Menu item) to Full Color Management.

Page 28

To print from Elements use the Print command, and choose Show More Options at the

bottom of the main print page, then under Color Management set the Print Space to

Same as Source when printing a profiling target.

Advanced Topic: Settings in Other Applications

Color managed applications offer some type of setting for choosing an output or

printer profile. This is where you will choose your custom profile, once it is built. But if

you need to print a Color Profiling Chart from such an application, it is important to set

the printer profile choice to Same as Source or None in order to avoid printing the

chart through a preexisting profile, which will invalidate the profiling process. Please

note that non-color managed applications, ones that do not offer a printer profile

choice when printing, cannot be used directly with ICC printer profiles. If you use such

an application, consider alternative applications that offer color management, at least

for your printing needs. Adobe Photoshop Elements® (Mac and Windows) or ACD

PhotoCanvas® are examples of low cost applications that offer simple color

management.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website: http://www.datacolor.com/Spyder3

Page 29

Print Quality Check

Skip to:

Help Index

Print Quadrant Function

Spotting Missing Ink Channels

Usual Setting

Print the Quality Check Print, examine for problems, then select the Next Button to

continue.

The Purpose of This Step

This screen allows you to print a Quality Check Print to assure that your printer is

printing correctly before printing a Color Profiling Chart. If your printer is not printing

properly, then the resulting profile will not correctly describe your printer.

The Long Answer

Print Quadrant Function: You can print up to four different Quality Checks on a

single Letter or A4 sheet by selecting different quadrant settings for each, and

reinserting the same sheet of paper, the same side up, and in the same orientation,

for each Quality Check print. The preview image on the right side of the window

indicates which quadrant the Quality Check image will be printed in.

Page Setup: Spyder3Print is designed to be used in Landscape (Horizontal) mode, so

it is recommended that you use it in that orientation. It is optimized for Letter or A4

paper, so it is most effective to print your media setting check prints on these sheet

sizes.

Examine the Quality Check Print for areas with skipped lines or poor print quality. If

such areas are evident, then use your printer’s cleaning command to clear up the

problem before continuing. If repeated clean commands (and rest periods after each

set of three cleaning commands) do not correct the problem, let the printer rest

Page 30

overnight (which may improve output) and try again the next day. If issues persist,try

replacing the ink or colorant supply, which may correct the problem. If, after repeated

cleaning and replacement attempts, the printer still is not producing clean, smooth,

output on a reasonable paper, then it may be necessary to contact the printer

manufacturer for further assistance. Please keep in mind that profiling a substandard

printer is not a solution to any color issues the problems may cause.

Quality Check Print with Misfiring Jets.

In this case the problem is in the Magenta ink channel, either with both Light and Dark

Magenta inks, or in the Magenta channel of a printer that does not use Light Magenta

ink. Most printers do not use Red ink, and it would be the Magenta channel that would

be causing the problems in the Red ramp. In those few printers that do use Red ink,

many colors in the Red range continue to be blended from Magenta and Yellow ink,

with few shades of Red being printed from the Red ink cartridge.

Page 31

Spotting Missing Ink Channels

Not all problems show as skips or uneven print areas. In some cases an entire ink or

toner color is missing, resulting in smooth, even Quality Check Prints, but not proper

image colors. Compare your Check Print to the image below to assure all colors are

printing. Keep in mind that not all printers’ inks are the same color. If your red is a bit

orange, or your blue a bit purple, that does not mean there is a problem, unless there

are missing colors somewhere else in the check image. Below is an example of a

correct Quality Check Print, followed by examples of problem prints.

Color Order: From left to right the diagram contains: Red, Green, Blue, Cyan,

Magenta, Yellow, and Black. Please note that the color called Red is usually a blend of

full Magenta and Full Yellow, and may not be precisely Red in tone, while the color

called Blue is usually comprised of full Cyan and full Magenta, and often appears more

purple than blue. The Black ramp will show whatever black generation method your

printer driver uses, so many of the patches in the gray areas of the black ramp will be

printed using combinations of colors other than the black colorant.

Page 32

Correct Quality Check Print, No Skips, No Missing Ink Colors

The image above illustrates the type of result you would see with the Light Magenta

ink empty or not printing. Note that only part of the Magenta ramp is blank, and that

the color of other (secondary) ramps is also effected.

Page 33

The image above illustrates the type of result you would see with the Dark Cyan ink

empty or not printing. Note that it effects far less of the print than a Light Ink failure.

It is important to look at the color initials at the top of the Check Print and be sure

that they match the colors printed below them; here they do not.

Page 34

The image above illustrates the type of result you would see with the Black ink empty

or not printing. Note that it effects far less of the print than either a Light or Dark Ink

failure. Printer problems with Light Black inks can be difficult to detect. Pay particular

attention to the ‘K’ ramp, to see that it gradates properly.

Page 35

The image above illustrates the type of result you would see if the jets were misfiring,

and printing color in areas that should be white. While it is worth attempting to clean a

printer that is showing such symptoms, it is likely that you will need to replace the

printheads. For many HP printers, the heads are part of the cartridge, and replacing

the cart will replace the problem jets, eliminating the issue. For many Canon inkjets

(and some HPs), the heads are separate, user replaceable components, and

purchasing replacement heads will eliminate the problem. For Epson inkjets, the heads

are not a user replaceable part, and it will be necessary to contact Epson customer

support.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 36

Media Setting Check

Skip to:

Help Index

What Media Settings Do

Print Quadrant Function

Media Setting Finalization

Color Density Sliders

Analyzing Media Setting Check Prints

Analyzing Photo-Content

Usual Setting

Print a series of Check Prints, four to a page, at varying media settings, including ones

with unrelated names, and review to see which offers the optimal output. Then use

this optimal setting when building and using your profile.

The Purpose of This Step

This screen allows users to print Media Setting Check Prints at different driver media

settings (paper type selections) to assure that the media setting choice is optimal

before profiling the printer. If the choice is not optimal, then the resulting profile will

not have the color range or detail it would have from an optimal setting.

The Long Answer

The optimal media setting for profiling and printing on a particular paper may not be

the media setting with the most likely name. It is worth testing a range of media

settings to determine which one will actually perform best with your combination of

settings, colorants, and media.

The Media Setting Check Print shows the entire color universe of your printer, colorant

and media combination, in nine slices of nine steps by nine steps. You can print this

image at different driver media (paper type) settings to assist you in determining

which is most suitable for your combination of printer, colorant, paper, and settings.

Page 37

Photographic content is included at the bottom of the Check Print to assist in

determining the photographic qualities of differing media settings

What Media Settings Do: Different media settings will lay down different densities of

ink in the various sections of the check print, and offer varying degrees of linearity

(consistancy) in the steps between adjacent patches. Printers which offer smoother,

more linear, gradients in the check print require fewer patches in the final profiling

target. Printers with significant local variations require more patches to profile

effectively.

Page Setup: This application is designed to be used in Landscape (Horizontal) mode,

so it is recommended that you use it in that orientation. It is optimized for Letter or A4

paper, so it is most effective to print your media setting check prints on these sheet

sizes.

Print: This button allows you to print the Media Setting Check Print in the currently

selected location, with the current Media Setting Notes listed below it. Please be sure

that the Media Setting name you have typed into the Media Setting box is the same as

the setting you select in the print driver. If it is not, cancel the print, return to the

Media Settings Check window, retype the correct Media Setting name, and choose

Print again.

Print Quadrant Function: You can print up to four different media settings on a

single Letter or A4 sheet by selecting different quadrant settings for each, and

reinserting the same sheet of paper, the same side up, and in the same orientation,

for each Media Setting Check print. The preview image on the right side of the window

indicates which quadrant the Media Setting Check image will be printed in. Be sure to

label each quadrant print with the correct media setting in the Media Setting box

before printing, so that you will know what media setting each quadrant represents.

Page 38

Letter size page with four Media Setting Check Prints on one sheet.

Media Setting Finalization: After determining the optimal media setting from those

tested, be sure to type that optimal setting name into the Media Setting box before

continuing, so that this information will be included on your Profiling Target. Then use

this media setting both when printing your profiling target, and when using your

custom profile.

Color Density Sliders: Some recent inkjet printers offer a color density slider that

can be used to adjust the overall density of ink; however these printers also have

excellent default ink densities for most media types, so it is not usually necessary to

adjust the slider to achieve good media setting results. Not adjusting the slider has

the added advantage of not requiring the user to remember what slider settings were

used for each paper profile. Most driver adjustments, excepting color density sliders,

are disabled when setting printers to the No Color Adjustment setting used with

custom profiles.

Advanced Topic: Analyzing Media Setting Check Prints

Overall, the goal is even, smooth gradients in all directions without undue breaks or

indistinguishable steps. The areas that deserve the most attention when reviewing a

Check Print are the gradations to black, the primary and secondary colors, and inking

Page 39

issues. Its important to keep in mind that lower quality papers often exhibit problems

in the areas described, and that for some paper, printer and ink combinations these

issues cannot be eliminated, only minimized. On better papers, there may be multiple

media settings that offer acceptable results. So consider your media setting tests a

check of whether you wish to use a particular paper with your printer, as well as what

setting to use when profiling it and printing through your custom profile.

Black Generation: check how your printer, colorant and media combination work with

the particular media setting to create near black tones. Patches near the black patch

in the upper left hand corner, and in the nearby planes may vary with different media

settings.

Near Black Patch Locations

Compare a range of likely media settings. Look for the following elements:

• A smooth gradation to black, this is ideal.

• Avoid settings that print too many near black patches, blocking up entire groups of

patches.

Page 40

Clogged Near Blacks

• Avoid settings that have a lack of near black patches, jumping directlyto medium

grays from black.

Weak Near Blacks

• Avoid settings that have excessively off-color near black patches, often occurring in

the third section. This is not as significant as other Black issues, but should be

considered.

Off - Color Near Blacks

• Look for a good color range in the patches leading into the Black Generation areas,

without any unexpected color shifts.

Primaries: check how your printer, colorant and media combination work with the

particular media setting to create near primary colors. The primary and secondary

colors, circled in these images, may vary with different media settings.

Page 41

Green, Cyan, and Blue Primaries occur in the same section as Black

Yellow, Red, and Magenta Primaries occur in the same section as White

Page 42

Comparing Settings: Compare a range of media settings. Look for the following

elements:

• Bright primary colors, without overinking

• Good color range and brightness in other colors in the image

• Good gradation from Primary colors into the rest of the color space.

This image shows a good gradation from Blue to Black, with distinct patches

throughout.

This image shows a problematic gradient from Blue to Black, with excess inking, which

causes several of the patches to print full Blue, with no visible steps. A media setting

that causes results such as this is best avoided, even though it offers bright primaries.

Page 43

This image shows a problematic gradient between blue and green, which results in a

visible stairstep pattern. This type of break is not as undesirable as overinked

primaries, but should be avoided if possible.

Inking issues: There are a range of possible inking issues that a particular

combination of printer, colorant and media may cause. Inking issues assume that you

are using an ink-based printer, though excess colorant and other related issues are

also possible with other printer types. Look for the following signs:

• Overinking most commonly shows as lack of patch distinction, as shown above, but

also results in many of the other problems noted below.

• Bleeding of inks outside their patch boundaries, blurring one patch to another, or

bleeding into the white surround.

Page 44

Here the blue areas have bled both between patches, and beyond the edge of the

chart.

• Mottling of inks within patches, showing grainy, uneven areas where the ink is

heaviest, often where two or more colors are mixed at high ink levels.

The above illustration shows what mottling might look like if it occurred where Dark

Page 45

Cyan, Yellow, and Black inks were all being used to create deep greens.

• Worming may look similar to mottling, but it occurs within the dither pattern of the

printer. Larger, often worm-like, shapes may occur in the printer’s dithering pattern in

certain flat color patches. This is a function of the printer’s dithering algorithm, and

while it may appear that profiles improve or worsen worming, they really only move it

from one place to another. If the place they move it to is not part of the test image, it

may appear to have been eliminated, but a different set of flat color patches could

make it reappear. Worming effects only flat color areas, so typically does not cause

problems in photographic images, unless flat areas such as clear skies display the

problem. Again: dithering based issues cannot be caused or cured by profiling, or even

printer settings, unless you are using a driver that offers multiple dithering choices, in

which case testing the dithering options may produce a choice that minimizes this

problem.

Worming artifacts in a printer’s dithering patterns.

• Bronzing is an effect that can be caused by excess ink in the near blacks. Bronzing

shows as a difference in color tone between black and near black areas of a print when

viewed at an angle to the light source, often showing a bronze sheen. In some cases

the only solution to bronzing is choosing a different paper or inkset, in other cases, a

lighter inking media setting can improve results.

Page 46

• Gloss Differential is similar in nature to bronzing, but occurs in the lighter areas of

prints. It is a difference in the glossiness of uninked paper and adjacent inked areas. It

is only an issue with Gloss and Luster surfaces. A few printer models offer a gloss

optimizer option, which applies an unpigmented ink to blank areas to reduce gloss

differential. Other recent printers utilize high gloss inks which also minimize the

difference in gloss between printed and unprinted areas. Gloss differential cannot be

controlled through choice of media settings, nor through using ICC profiles. If your

gloss and luster prints exhibit gloss differential, and you find it undesirable, then

consider changing papers, inks, or printers to find a more acceptable result, or spray

your prints with a quality archival fixative overspray after printing. This reduces gloss

differential, while at the same time providing increased water resistance, and in most

cases longer print life.

Analyzing Photo-Content

The photo content in the Media Setting Check Print allows for checking how well a

media setting’s gradiations and densities represent photographic content. A color cast

is not important here, as that can be corrected with the profiling process, but

problems with blown out hightlights, overinked dark areas, or posterization (visible

steps where none should be present) are more difficult for a profile to compensate for.

The above image shows good photo content.

Page 47

This version of the photo content shows blown out highlights.

This version of the photo content shows clogged shadows.

This version of the photo content shows posterization.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 48

Select Target

Skip to:

Help Index

Selecting a Profiling Target

Extended Grays Target

Changing Target Text

Target Drying

Usual Setting

The 150 patch Fast Target is recommended for first time users. Users looking for more

exacting results will prefer the 225 patch High Quality Target, which prints on the

same size sheet, and takes only an extra minute to read. Users planning to print Black

and White as well as Color images will want to augment their Color target with the

Extended Grays target. Please be sure you printed target is dry before measuring. For

more information see

Target Drying below.

The Purpose of This Step

This screen allows you to choose, preview, and print a Profiling Target for use in

building a custom printer profile.

The Long Answer

This step allows you to choose one of several printer profiling targets, preview what

that target will look like printed at your current Page Setup settings, adjust if

necessary, and print the target on the paper you wish to custom profile.

Page Setup: Spyder3Print is designed for landscape mode, so it is recommended that

you use it in that orientation. It is optimized for Letter or A4 paper, so it is most

effective to print your Profiling Targets on these sheet sizes, unless you are using the

Large Expert Target, which is designed for larger sheets and rolls.

Page 49

Selecting a Profiling Target

Initial Testing: When first becoming familiar with using Spyder3Print, it will save

considerable time, effort, paper, and colorant, if practice profiles are built at the 150

patch or 225 patch settings.

Which target for which uses? Most newer inkjet printers are quite linear, and offer

similar results at all three target resolutions. Minor improvements can sometimes be

seen in the more difficult near black areas with the 225 patch target over 150 patch

results.

Older, less linear inkjets, as well as many color lasers and dye subs, may profit by

additional patches. For these printers, comparing results from a 225 patch target to

those of a 729 patch target built for the same colorants and paper will show you

whether any improvements are possible from additional patches. Once you are aware

of which target is optimal for a particular printer, you can continue to use that target

for building future profiles for that device.

The Extended Grays target can be added to any color target to build a composite color/

grayscale profile. This can improve neutrality and detail in grayscale prints, but will

only be apparent in color images with large areas of subtle grayscale content.

Changing Target Text: To change the Printer Name and Media Setting text that will

print on your target, click the back button, and insert the new information in the text

entry boxes. Then use the Next arrow to return to the Select Profile Target screen. To

change other target info, depress the Control key while clicking the back arrow, to

return in one step to the Printer Definition page, where all text lines are accessible.

The Skip to Profiling Process button will allow you to return directly to the Select

Profile Target window from this screen.

150 Patch Target: This is the standard target, and produces excellent results for

many printers and uses. It samples the entire printer gamut at a 5 x 5 x 5 matrix, plus

additional patches in the most demanding areas. This target offers larger patches on

standard size sheets, allowing the user to move more quickly between patches, further

increasing speed and accuracy. Typically this target takes less than three minutes to

measure. This target is designed for printing on Letter or A4 paper in Landscape

Page 50

orientation for best results.

Sample 150 Patch Profiling Target, formatted on Letter size Landscape oriented paper.

225 Patch Target: This is the High Quality target, and produces improved results for

difficult printers and advanced uses. It samples the entire printer gamut at a 5 x 5 x 5

matrix, plus a larger range of additional patches in the most demanding areas. This

target offers more patches on standard size sheets, allowing the user to achieve

advanced profile accuracy without extra paper and ink usage, and only about a minute

in additional reading time. This target is designed for printing on Letter or A4 paper in

Landscape orientation for best results.

Page 51

Sample 225 Patch Profiling Target, formatted on Letter size Landscape oriented paper.

729 Patch 3 Page Target: This is the Expert target formatted to print on three

sheets of standard Letter or A4 paper, and produces improved results for difficult

printers and advanced uses in areas where the 225 patch target does not include extra

patches. It samples the entire printer gamut at a 9 x 9 x 9 matrix. This target offers

more patches on standard size sheets, allowing the user to achieve advanced profile

accuracy without oversize media, but requires significantly more measuring time than

lower patch targets. This target is designed for printing on Letter or A4 paper in

Landscape orientation for best results.

Page 52

Sample 729 Patch 3 Page Profiling Target, formatted on three sheets of Letter size

Landscape oriented paper.

729 Patch 1 Page Target: This is the Expert target formatted to print on a single

sheet of larger paper, and produces identical profile results to the 729 patch 3 Page

target described above. This target is designed for printing on a single sheet of 13x19

inch, 17x22 inch, SuperA3/B, or B, or C paper in Landscape orientation for best

results. For owners of large format printers, this target offers added convenience in

printing and measuring high patch targets on a single sheet. For printing on roll

media, select one of the page sizes noted above in landscape format to configure the

target onto the roll.

Page 53

Sample 729 Patch 1 Page Profiling Target, formatted on one sheet of 17x22 inch size,

Landscape oriented paper.

Extended Grays Target: This target augments any color target with extra data in the

gray and near gray areas, for improved printing of grayscale images and gray

elements in color images. Print both a color target and the gray target, and measure

both to build a gray augmented color profile. Print on letter or A4, in landscape

orientation. Be sure to print both color and extended gray targets for use together on

the same media, at the same settings for accurate results.

Page 54

Sample Extended Grays Target, formatted for Letter size Landscape Oriented Paper.

Target Preview: Choosing any of the available targets will generate a live preview of

that target at your current page setup. This avoids accidentally formatting in a difficult

to read manner. If an inappropriate format is generated, adjust your page setup to

reflect more effective page size and orientation.

Page 55

150 Patch Target formatted for A4 Portrait Orientation. Note that the patches are tall

and narrow, which is undesirable for reading along the rows. Changing to landscape

orientation in Page Setup would correct this problem.

Full Size: This button allows the user to view an enlarged version of the formatted

target. Using the arrow keys, the RGB values of each patch can be previewed in this

larger window as well. Clicking on the small, embedded, preview will also pop-up this

enlarged view.

Page Setup: This button allows the user to change the size or orientation of the

target print, by accessing the OS level Page Setup utility for your printer. For most

targets Letter or A4 pages oriented in a Landscape mode are recommended. For the

729 Patch one page target, 13 x 19, SuperA3/B or larger sheets are necessary. For

Page 56

these larger sheets, landscape mode is still recommended.

Print Target: This button allows the user to print the selected target, at the selected

page setup and orientation, complete with target information entered in previous

steps. Please review information in the

Configure Printer Settings section to assure

that optimal printer settings are selected, and that color correction is turned off in the

driver.

Advanced Topic: Target Drying

Some devices, such as color lasers, require no target drying time before

measurement. Some inkjet printer, ink and paper combinations are immediately dry,

or offer wet colors nearly identical to their dry colors. Epson UltraChrome inks, for

example, do not color shift during drying and require no more than ten minutes wait

before profiling on most papers. Dye inksets used in a wide range of printer makes

and models do require extended drying time on some papers. The reasons for this

include color shifting, which may render a profile build shortly after printing

inaccurate, and durability, which may mean that the process of running the Spectro

over sections that are not yet dry may damage the target print. In cases where the

target print is sensitive to Spectro contact, placing a sheet of non-sticking paper over

the lower section of the target, and moving it down as the rows are measured, can

improve results.

Drying Times: Typically matte media require less drying time than luster or gloss.

Pigment inks may require less drying time than dyes. A minimum wait of ten minutes

is recommended in all cases, but particularly sensitive ink and paper combinations

may require as long as two days in humid conditions.

To determine whether drydown is a problem with a specific printer, colorant, and

media combination, measure a medium gray, a bright red, and a dark blue patch

shortly after printing, and note the L*a*b* values. Patches M3, F6, and E1 on the 150

or 225 patch targets would be effective for this purpose. Remeasure 48 hours later,

and compare the results. Variations in L*, a*, or b* of much more than one unit

denote significant drydown changes, and indicate that this media and colorant

combination should be allowed to dry before being measured.

As long as a target print has not been damaged by measuring it wet, remeasurement

Page 57

of the same printed target at a later time will produce a corrected version of the

profile. To learn how to take spot measurements, see the Tools Measure Function

section in

Preferences Help.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website: http://www.datacolor.com/Spyder3

Page 58

Spectro Calibration

Skip to:

Help Index

Calibrating to the White Tile

Spectro Connection

Connection failure

Usual Setting

Place Spectro on the calibration base, checking that the white tile is situated below the

Spectro-head, press the Spectro button on the top of the device. Wait for calibration

to be completed, and the application will auto-forward to next step.

Spectro Positioning Note: Using a proper height table and chair eases the patch

reading process. If you find your hand slipping forward on the Spectro your chair may

be too high (or your table too low). If the back of the Spectro seems too high or too

large, your chair may be too low (or your table too high).

The Purpose of This Step

This screen allows you to calibrate your Spectro, prior to taking measurements with it,

to ensure accuracy.

The Long Answer

Attach your Spectro to a USB port prior to launching this application, in order to have

it auto-connect. If the Spectro Calibration screen tells you it does not find a Spectro

attached to your computer, then please follow the directions in the

section below. If Calibration is successful, you will automatically be forwarded to the

Read Patches screen.

Calibrating to the White Tile

Place the Spectro on the white tile in the calibration base. Check that the Spectro is

Spectro Connection

Page 59

correctly located, and press the top of the Spectro, or hit the enter or return key on

the computer to trigger calibration. When the calibration process is complete, the

application will automatically move forward to the Read Patches screen. If calibration

fails, an error message will appear. Should this occur, please check your connections,

and attempt calibration again.

Spectro Connection

First check that the device is properly connected. Next go to the application’s

preferences in the menu bar…

and choose the device from the Sensor popdown list. If a Spectro is connected, but

does not register in the Sensor Information section (showing ???? instead) then toggle

from Spectro, to None, then back again to trigger another search for the Spectro.

If the device is successfully found on the USB tree, then its information will now

register in the Sensor Information section of the window. You are now connected, and

ready to calibrate the device.

Page 60

Connection failure: If the Spectro fails to connect to the application, the Sensor

Information will not register. In such cases, please check that both ends of the

Sensor’s USB cable are firmly connected. The Spectro should be attached directly to a

USB port on the computer, or to a powered hub, which is currently plugged into a

power source. Do not use an unpowerd USB port, or connect the Spectro to your

keyboard or monitor, as these ports may not provide suffient power to run the Spectro.

Mac OS X Classic Mode: Classic Mode (which allows Mac OS 9 applications to run

under OS X) captures USB devices, and sometimes does not release them for use by

OS X applications. It is recommended that you quit Classic Mode before running

Spyder3 applications. If Spyder3Print cannot find a properly connected Spectro, quit

Classic Mode, and try again.

Cable Testing: If direct connection to a computer USB port does not allow the

Spectro to communicate to the application, test with a different USB cable, to

determine if the cable is the source of the problem. The Spectro connects with a

standard USB camera cable, so most digital camera owners will have at least one such

cable available for testing.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website:

http://www.datacolor.com/Spyder3

Page 61

Read Patches

Skip to:

Help Index

New Measurement File Naming

The Patch Reading Process

Checking for Patch Reading Errors

Saving the Measurements

Existing Measurement Files

Deleting Existing Measurement Files

Extended Grays Measurement Files

Selecting Blank Templates for Printing and Measuring

Usual Setting

Users will typically name their measurement file, then choose the Read Patches

button, to read the patches of their printed target into the floating template window,

then close the floating window to continue.

Backing Note: For thin papers it is recommended to read the patches on a white

surface, or ideally to have one or more further sheets of the same paper below the

sheet being read, to assure accurate readings. Reading thin media on backings of

other colors can effect reading results. For printing on canvas that will be stretched

and framed, a black backing for patch reading may be more representative of the final

image conditions.

Spectro Positioning Note: Using a proper height table and chair eases the patch

reading process. If you find your hand slipping forward on the Spectro your chair may

be too high (or your table too low). If the back of the Spectro seems too high or too

large, your chair may be too low (or your table too high).

Target Positioning Note: It is easiest to position the target sideways on the table,

Page 62

and move the Spectro towards you when measuring patches. This uses the body’s

most controlled motion when moving from patch to patch, and allows easier viewing of

the Spectro’s location on the target.

The Purpose of This Step

This screen allows you to measure the color patches of a printed profiling target into a

Measurement File, or to select a previously built Measurement File instead.

The Long Answer

Measurements for building a printer profile can be obtained either by reading all the

color patches in a printed target to a new Measurement File, or by selecting an

existing Measurement File, with or without remeasuring any of its patches. If you have

measured your patches previously, and wish to remeasure a few of them, or rebuild

your profile with different slider settings, then please go to the

Files section below.

Existing Measurement

New Measurement File Naming

To create a new Measurement File, first click on the Save Measurements to… button.

This will generate a new Measurement File. Name as appropriate to best describe your

combination of device, colorant, media, and settings.

The Patch Reading Process

Read Patches Button

Next click on the Read Patches button to start the reading process. This will open a

floating window containing the target previously chosen in Select Profiling Target

window. If the printed target you intend to read is not the same configuration as the

Patch Reading Template in the floating window, close the floating window, and use the

Back button to return to Select Profiling Target, and choose the appropriate target,

before returning to the Read Target window. This will generate the correct patch

Page 63

reading template.

Patch Reading Template: The patch reading template displays a rectangle for each

correlating color patch in the printed target. Each rectangle is divided diagonally into

an upper left section and a lower right section. The upper left section displays the pure

color value for this patch. The lower right section displays white, until a measurement

for the patch occurs, then displays that measured value. The pure and measured

values will not be identical, but the relative relationship between them is useful for

checking measurements. Multipage templates will have page buttons at the bottom

center to allow navigating from one page to another.

Patch Reading Navigation: At any time, the user can move to a different patch by

using the arrow keys on the keyboard. This allows for moving backwards to reread a

misread patch, or navigating throughout a target to view the values of measured

patches.

Portion of a target in Split Display mode, with patches measured through patch 7G;

patch 7H will be measured on the next click of the Spectro button.

Patch Display Modes: The popdown list in the lower right hand corner of the

Template allows the user to fill the entire square with either the pure or the measured

values. The pure RGB values will show the target as it displayed when sent to the

printer for printing. The measured values will show the L* a* b* values measured by

the Spectro for each patch. Selecting the Measured Display mode is useful to obtain a

clearer view of measurements to detect any errors in patch reading. It is

recommended that measurements be made in the Split mode, and reviewed in the

Measured mode prior to finalization. Toggling between Pure to Measured mode, using

Page 64

the 1 and 3 number keys, is an excellent way to check that the pattern of measured

patches matches the pattern of pure patches.

Patch Value Display: In the lower left hand corner of the screen values for the

currently selected patch are shown. The arrow keys can be used to navigate to any

patch. In Pure mode, the display shows the RGB values sent to the printer. In Split or

Measured modes, the display shows the measured L* a* b* value for the selected

patch, if that patch has been measured.

Using the Spectro: Now begin reading the patches on your printed target, beginning

in the upper left hand corner, and moving across each row, as the colored highlight

indicates. Place the nose of the Spectro flush on each patch, and push the top plate of

the Spectro (or the Enter or Return key) to initiate reading. There will be a click sound

when the measurement starts, and a different click sound when the measurement is

complete. The reading process takes less than a second per patch. Move the Spectro

to the next patch and repeat. With practice, reading rates of a patch per second are

possible on faster computers.

Backing Note: For thin papers it is recommended to read the patches on a white

surface, or ideally to have one or more further sheets of the same paper below the

sheet being read, to assure accurate readings. Reading thin media on backings of

other colors can effect reading results. For printing on canvas that will be stretched

and framed, a black backing for patch reading may be more representative of the final

image conditions.

Spectro Positioning Note: Using a proper height table and chair eases the patch

reading process. If you find your hand slipping forward on the Spectro your chair may

Page 65

be too high (or your table too low). If the back of the Spectro seems too high or too

large, your chair may be too low (or your table too high).

Target Positioning Note: It is easiest to position the target sideways on the table,

and move the Spectro towards you when measuring patches. This uses the body’s

most controlled motion when moving from patch to patch, and allows easier viewing of

the Spectro’s location on the target.

Sound System Requirements: Note that it is necessary to have a sound card in

your computer and internal or external speakers, with the volume turned up in order

to use the auditory cues for patch reading. Reading from visual cues only is a slower

process.

Sound Preferences: In the application preferences…

Page 66

the user can configure the measurements sound cues. The default setting is to have

all three sound cues on, and this is the recommended mode. With experience, users

may find they prefer to turn one or more of these sounds off. This can be done by

unchecking the associated preference item for that sound.

At the end of each row, a bell tone indicates that the row has been completed, like the

return bell of a typewriter. If the Spectro has not reached the final patch of the row

when this bell tone sounds, then a patch reading error has occurred. At completion of

the final row, if all patches of all rows have been read, a double bell tone will sound.

This double bell will not occur on rereadings; only on initial completion of the target.

Advanced Topic: Checking for Patch Reading Errors

Live updating as each patch is read allows the user to review the current location in

the template at any time. Column letters and row numbers allow for location of any

patch. The return bell tone indications completion of each row. Breaks in the color

pattern within rows highlight situations where a patch has been skipped or measured

twice. In any case where an error has occurred, the arrow keys can be used to back

up one or more patches, to a location before the error occurred, and reading can

Page 67

continue from that location.

In this example the circled patch does not fit the pattern of this page, indicating a

double reading in a previous patch. This type of error will cause the end of row tone to

sound at the wrong time, cuing the user that an error has occurred. Use the arrow

keys to return to the beginning of this row, and reread patches until the incorrect area

is overwritten.

When all patches (and for multipage templates, all pages) have been measured a

dialog box appears noting completion of measurements. It is recommended at this

point that the Patch Display mode be changed to Measured mode, and all measured

values be reviewed visually for possible errors. If a single patch does not align

properly with the gradients surrounding it, arrow to that location, and remeasure that

patch to see if remeasurment improves the result. It is possible that the Spectro was

not flush with the surface of the paper, or not entirely on the color patch, causing an

incorrect reading. If remeasurement does not change the value, then the variation is

probably correct, and may be visible in the printed target as well.

In this example, the circled patch is too dark, and does not fit the pattern of the

adjacent patches. It should be remeasured to check that this is not a patch reading

error.

Saving the Measurements

Page 68

Patch measurements are saved to the measurement file as they occur. Once

measuring and reviewing of the patch values is complete, close the floating template

window, and click the Next button to advance to the Build Profile Setup screen. It is

possible to use the Back button to return to the Read Patches screen for further review

or correction of patch values, or review and adjustment can occur at a later time by

selecting as an existing measurement file.

Existing Measurement Files

The Existing Measurement File option allows users to choose a previously measured

combination of device, colorants and media, for purposes such as remeasurement of

questionable areas, or for building variations of the original profile using the sliders

available in the following profile building section of the application. All previously

saved Measurement Files are available by name from the popdown list in this section.

Unless a file is intentionally deleted, it will remain available for later reuse.

Extended Grays Measurement Files

Building profiles using an Extended Grays measurement file in addition to a color

measurement file requires checking the Use Extended Grays Data checkbox. AFter

checking this box, select the correct color measurement file in the main popup list,

and the matching Extended Grays measurement file in the special Extended Grays

popup list. The Extended Grays popup will only appear if you have at least one

Extended Grays measurement file in your PRO Data folder. Only Extended Grays

measurement files will be visible in the Extended Grays popup list, as they are the

only type of file appropriate for this use.

Page 69

Selecting Blank Templates for Printing and Measuring

Blank templates with printer definition information and preselected targets can be

accessed from the Existing Measurement Files section on the lower half of the Read

Patches screen as well. Choose the template by name. This will display the blank patch

set, confirming that this is a batch template file. Move back one screen using the Back

arrow to then print the selected template file. Repeat for all template files to be

printed, and each will contain the correct printer, ink, paper, media setting

information, on the previously selected profiling target. Once printed and dried, these

batched targets can be read by selecting each again in the Select Existing

Measurements File section of the screen, and clicking on the View/Measure button.

Extended Grays targets would be selected in the main popup list for batch target

printing and measuring, not the cascade popup list, where they are selected before

building a composite color/grayscale profile.

Advanced Topic: Deleting Existing Measurement Files

Existing Measurement Files can be removed from the pop-down list by choosing the

desired measurement file in the popdown list, then pressing the Control key while

clicking on the Measurement File name. A dialog box will ask if you are sure you wish

to delete this file. Choosing Yes will remove the file.

Further Information

For information such as a list of Frequently Asked Questions and details on all

Datacolor products be sure to visit our website: http://www.datacolor.com/Spyder3

Page 70

Page 71

Build Profile Setup

Skip to:

Help Index

Naming your Profile

Choose Profile Resolution

Select a Location for Saving Your Profile

Reference White and Black Functions

Basic Slider Adjustments

Advanced Slider Adjustments

Adjustment Presets

Absolute Grays Checkbox

Curve Importing

Editing Profiles Using Curves

Building a Profile

Usual Setting

Users will typically choose the Profile Name button, adjust the profile name, and click

on the Next Button, to generate a custom ICC profile. Sliders are usually left at the

default (zero) position initially.

The Purpose of This Step

This screen allows you to name your profile, choose the profile resolution, select a

location for saving your profile (if your operating system offers more than one), and

build your profile, with or without slider adjustments and black and white preview

adjustments.

The Long Answer

Page 72

Naming Your Profile

Selecting the Name Profile button will bring up a floating window containing a default

profile name. Adjust this profile name as desired. Since it is possible to build a range

of profiles from this same set of measurements, users may choose to append further

information to clarify what version this particular profile represents.

If a series of profiles are to be build in Spyder3Print using different settings such as

Viewing Light Brightness and Color Temperature adjustments, then each could have VB

+6 or CT-5 appended to the profile name to indicate a Viewing Light Brightness setting

of +6, or a Color Temperature setting of –5. Similar abbreviations can be used for the

Brightness slider (BR), Contrast slider (CO), and Saturation slider (SA). The Cyan >

Red slider (CY), Magenta > Green slider (MA), and the Yellow > Blue slider (YE), each

have positive and negative values, so it is not necessary to note the second color in

the profile name.

Advanced Topic: Profile Name Length and Extensions

Profile names are limited to 27 characters for maximum compatibility, so abbreviations

will be necessary to store the maximum amount of information in the profile name.

Varying OS versions and applications allow different profile name lengths, and

popdown boxes and lists differ in the length available to display profile names.

Spyder3Print’s profile name length restrictions attempt to maximize compatibility with

all of these situations.

Names are automatically appended with a profile file name extension .icc on Mac and .

icm on Windows. File name extensions of .icm and .icc are interchangeable; the Mac

OS recognizes .icm profiles and Windows recognizes .icc profiles.

Advanced Topic: Profile Location

Page 73

Mac: Under Mac OS X, there are two recommended locations at which a user can

store ICC profiles: in the ColorSync profiles folder in the root level Library on your

main (OS containing) drive, or the ColorSync Profiles folder in the Library folder within

your personal user folder. This popdown allows you to toggle between these two

options.

Location of Mac OS X ColorSync Profiles folder.

Profiles stored in the Root Level Library are available to all users. Those stored in your

User Library are accessible only when you are logged in to your own account. Since

other users may wish to print with the profiles you create, it is generally

recommended that you store them in the Root Library, and this is the default setting.

If you have reasons to prefer to keep your profiles private, then you can change this

setting for any profile you create.

It is also possible to move profiles from one ColorSync folder to the other after they

have been created. Copying a profile so that it occurs in both locations can cause

confusion, when the profile appears in menus and lists twice.

Please note that it is the root library ColorSync Profiles folder that is opened by

Spyder3Print when the File Menu “Open Profiles...” command is selected. This

command simply gives users easy access to the main profiles folder in each supported

Operating System.