Datacolor AHIBA IR, AHIBA IR Pro Installation Manual

AHIBA IR & IR Pro

Quick Installation Guide

IMPORTANT: ALWAYS REFER TO USER MANUAL FOR MORE COMPLETE & DETAILED INSTRUCTIONS

1. Ensure Installation site has the following:

Power: 230V ( 10%), 15A, 50/60 Hz, single phase with earth ground.

It is recommended to use surge protected and dedicated line.

Water (AHIBA IR Pro only): Use only filtered and softened water.

Pressure: 2-3 bar (30-45 psi)

Hardness: <10 dH

Temperature: Ideally <15C

Hose: Min. diameter 3/8” (10mm), Hi Temp.

Unit Foot Print: 864 x 597 x 648mm (H x W x D) minimum

(For detailed external dimensions and footprint – Refer to Technical Data section in User Manual)

2. Open top of shipping box.

▪ Remove system accessories box carefully.

▪ Caution: Accessories box contains sensitive and fragile parts; handle with care to

prevent damage.

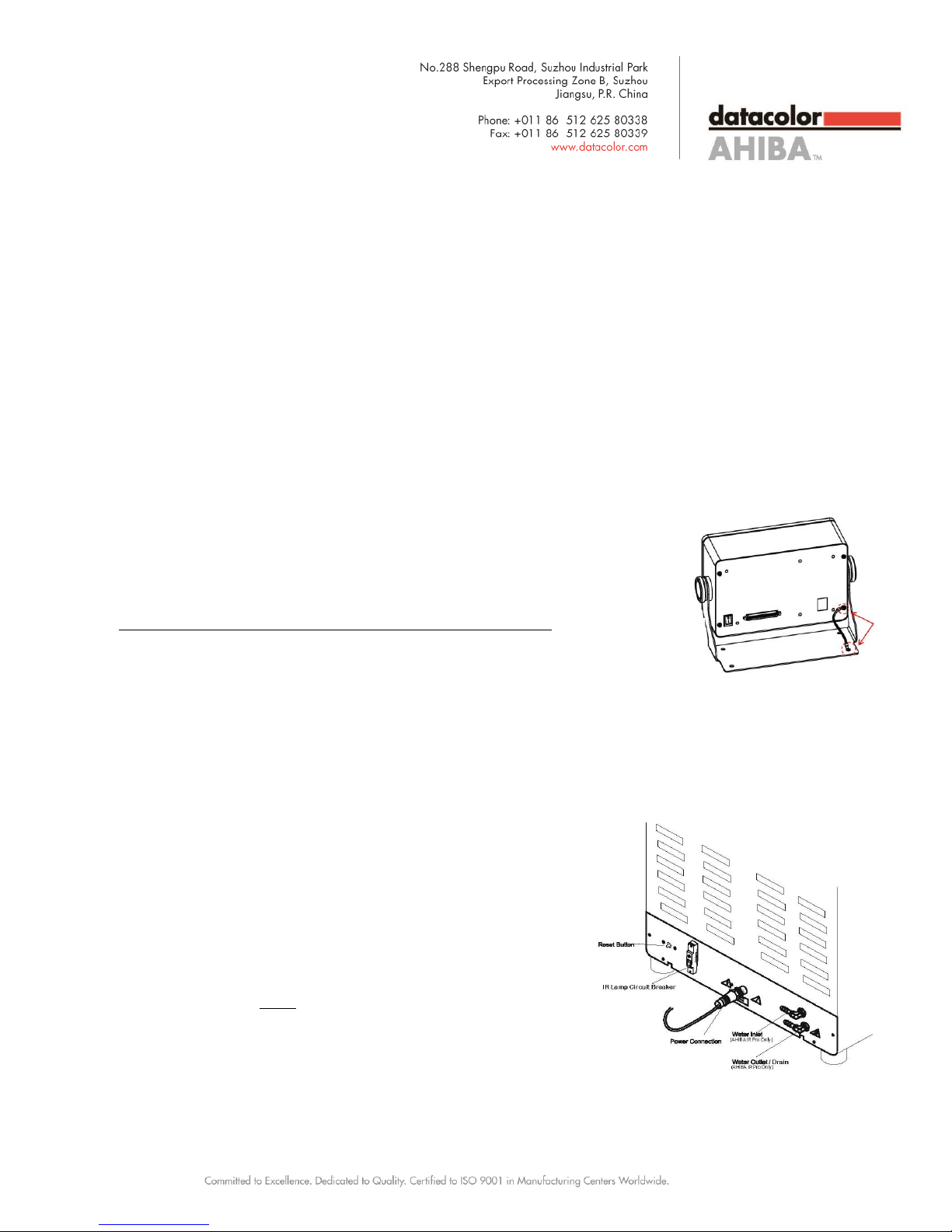

▪ Check that the shipment is complete (Refer to included Packing Slip). The unit’s controller and

mounting bracket are contained within a separate box. Remove the controller and mounting

bracket from this box and mount the controller on the unit using the screws mounted in the top

of the unit.

▪ Be sure to connect controller grounding wire as shown in the diagram (Fig. 01).

▪ Connect the I/O cable from the unit to the controller’s rear panel. Ensure screws are tight.

▪ Remove the unit from its pallet (caution: unit weighs approx. 74Kg (163 lb), a minimum of 2

people are required to lift).

▪ Place unit of level and stable table/bench top with a minimum of 140 Kg load capacity.

3. Provide sufficient space between the back of unit and the wall. The rear of the unit must be a minimum of 6 inches from any

surface. This is required for adequate airflow for the instrument fans and will prevent kinking of hoses if the unit is an AHIBA IR

Pro.

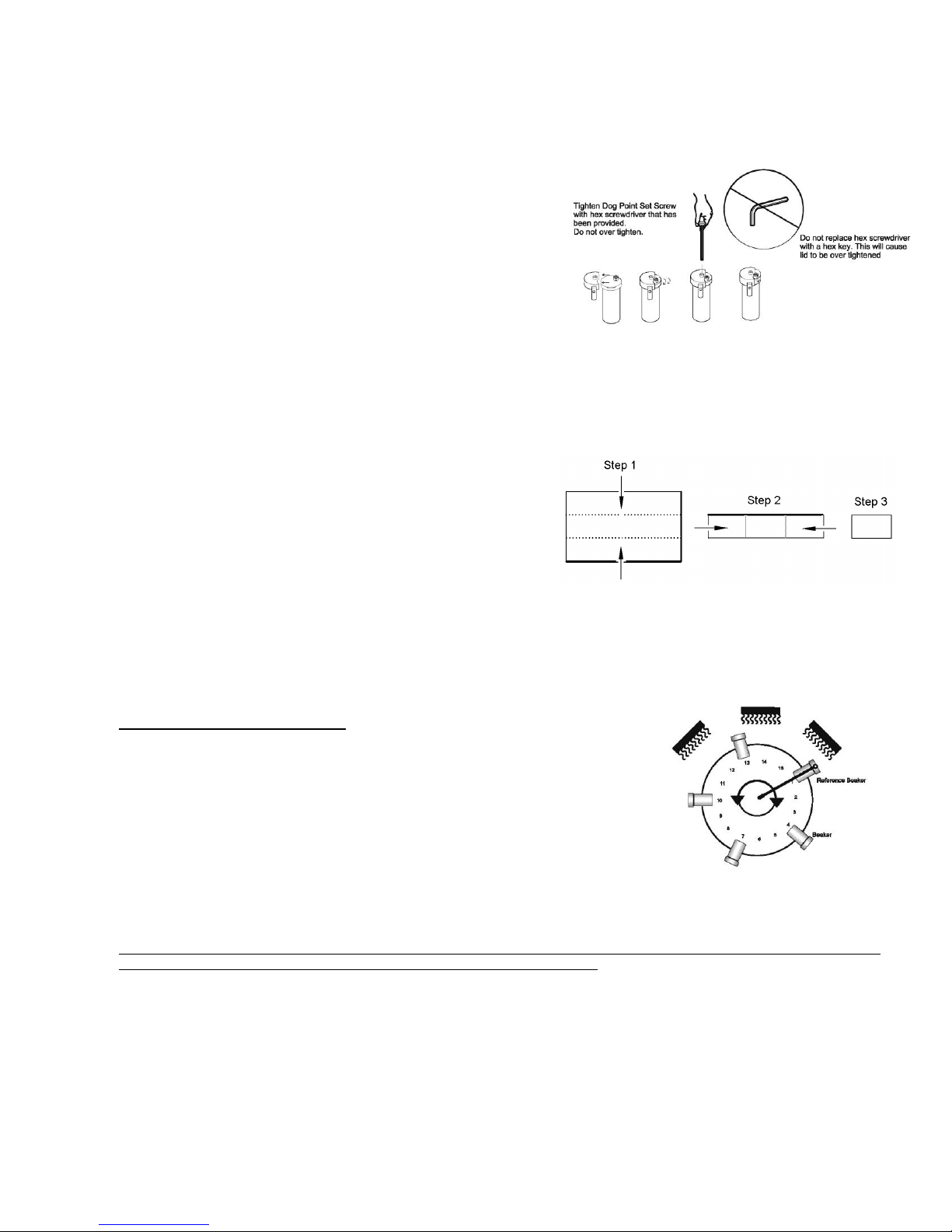

4. During shipment the unit might be stored where ambient temperature is low. This could cause the thermostats to trip. Press

the Red Reset button located on the rear panel of the unit. (See fig. 02)

5. Ensure IR lamp circuit breaker is “on”. (See fig. 02)

6. Refer to labels on the back of unit for proper connection.

(AHIBA IR Pro Only)

Caution: Improper installation of hoses can cause damage to the machine.

▪ Important: The water outlet hose must always be channeled to a lower

elevation than machine water outlet.

Important!!! (AHIBA IR Pro only)

Before powering up the unit Slowly turn

inlet water on and check for any leaks.

Doc. No. 72-990120-English

Fig. 01

Fig. 02

November 23, 2017

No.288 Shengpu Road, Suzhou Industrial Park, Export Processing Zone B, Suzhou, Jiangsu, P.R. China P +011 86.512.625.80338 F +011 86.512.625.80339

www.datacolor.com

7. Loading the beakers

For best results adhere to the following:

▪ Do not mix beakers sizes: Be consistent.

o Only install beakers of the same size. (Ex. Do not mix 150cc with 300cc)

o Do not mix black coated beakers with stainless steel beakers.

o Do not over tighten the beaker lids

▪ Over tightening can lead to o-ring wear and damage to the

beaker lid.

▪ Beaker Tightening Instructions

o Hand tighten the beaker lid closing screw firstly

o Then using the supplied Hex driver turn the beaker lid screw

approximately ¼ - ½ turn should be sufficient closing and sealing pressure for the beaker lid to avoid leaking of the solution.

▪ If additional tightening is needed to seal it could mean and issue with the O-ring or other beaker components and may need

replacement.

8. Preparing samples

▪ When performing a job, always fill the beakers with equal amounts of sample and dye liquor.

▪ Do not under- fill or over fill a beaker. Refer to applications section of User Manual

for detailed information. (Note: The o-ring in the beaker lid can push out to release

pressure caused by an improperly filled beaker. If this happens re-install the o-ring

and check sample-to-liquor ratio).

▪ Samples should be wet out, rung and folded

▪ Always ensure that the reference beaker contains a sample. Never perform a

job without the

o reference beaker as part of the dyeing process.

9. Sample Folding

▪ Fabric should be folded as shown in this example.

Do not crumple fabric and stuff into beaker.

10. Beaker Placement

▪ Always install the reference beaker in a position where the sensor can be easily connected to the

connection port on the beaker lid.

Avoid heavy bending of the sensor cable.

▪ Fill the rest of the wheel evenly, always maintaining wheel balance no matter how many beakers

are installed.

▪ Sensor is mounted to the beaker wheel hub with a locking collar; it should not be removed from

this point.

o Always connect sensor after the reference beaker is installed on the beaker wheel and

always remove the sensor cable from the reference beaker before removing the

beaker from the wheel.

▪ Unnecessary stress and bending of the sensor can lead to premature failure.

11. Cleaning

▪ Refer to user manual for more detailed information on cleaning.

▪ The unit should be cleaned as needed with a mild soap and clean cloth to ensure inner and outer casing remains clean.

▪ ALL accessories must be thoroughly cleaned and dried after each dye process to remove any residual dyestuffs and chemical auxiliaries to

avoid dye cross contamination and chemical sedimentation on the accessories surface.

Loading...

Loading...