Page 1

COMPLETE THE INLINE CARD ISSUANCE

PROCESS WITH MAIL-READY PACKAGES

Integrate the Datacard®MXi™envelope insertion system with the Datacard®MXD

™

card delivery system to create ready-to-mail packages completely inline, quickly

and efficiently.

• High productivity. The MXi system offers inline insertion, sealing and metering

with very minimal operator intervention. It places folded card carriers and up to

14 inserts into envelopes, creating up to 3,000 mail-ready pieces per hour. This

helps reduce cycle times and labor costs, and enhances security. Because the

entire issuance process occurs inline, it substantially reduces the risk of lost or

stolen cards.

• Truly modular design. The MXi system supports up to seven individual feeder

modules and bases, so you can mix and match according to your specific program

needs. Choose from the standard single-insert feeder, the dual-station tower feeder

that loads two inserts and helps save space, or the integrity verification feeder that

ensures the proper inserts are loaded.

• Selective inserting. The MXi system allows you to select unique inserts for

individual cardholders during the same print job and data stream. For example, a

bank can automatically add marketing inserts that align with a customer’s financial

needs. This capability enables you to process more mailings per hour, with fewer

interruptions for job setup, and maximize marketing impact.

DATACARD®MXi™ENVELOPE INSERTION SYSTEM

FOR THE DATACARD

®

MXD™CARD DELIVERY SYSTEM

Easy, intuitive operation

The MXi system is designed to

maximize ease of use for operators:

• Simple graphical user interface clearly

shows job progress, production

statistics, and operator assistance

messages

• Virtually all functionality, set-ups

and insertion maintenance are

programmed from an integrated

touchscreen PC

• MXi system requires minimal

manual adjustments

• Optional cascading increases the

capacity of a single insert type

without manual intervention

• Interface for postage metering that

supports many vendor models

Page 2

Datacard, MXD and MXi are registered trademarks,

trademarks and/or service marks of DataCard

Corporation in the United States and/or

other countries. Names and logos on sample cards

are fictitious. Any similarity to actual names,

trademarks or tradenames is coincidental.

©2006-2008 DataCard Corporation.

All rights reserved.

CD8-4102

11111 Bren Road West

Minnetonka, MN 55343-9015

+1 952 933 1223

www.datacard.com

DATACARD®MXi

™

ENVELOPE INSERTION

SYSTEM

The MXi system allows you to go from blank cards to personalized, ready-to-mail envelopes completely inline,

maximizing security and reliability.

MXi base system includes:

MXi base (holds envelope 20.0 in. W x 28 in. L 301 lbs. (137 kg)

feeder, monitor, keyboard) (50.8 cm x 71.12 cm)

Stand (holds base MXi) 20.0 in. W x 28.0 in. L 97 lbs. (44 kg)

(50.8 cm x 71.12 cm)

DTI 20.0 in. W x 19.7 in. L 55.0 lbs. (25.0 kg)

(50.8 cm x 50.038 cm)

Envelope stacker options include:

MXi envelope stacker 10.0 in. W x 72.0 in. L 106 lbs. (48 kg)

(25.4 cm x 182.88 cm)

Form/envelope high-capacity stacker 150 lbs. (68 kg)

Turn section 10.0 in. W x 46.0 in. L

(25.4 cm x 114.3 cm)

Elbow section 10.0 in. W x 57.0 in. L

(25.4 cm x 144.8 cm)

Feeder modules include:

Standard feeder 20.0 in. W x 16 in. L 55.0 lbs. (25.0 kg)

(50.8 cm x 40.64 cm)

Tower feeder 20.0 in W x 16 in. L 112.0 lbs. (51.0 kg)

(50.8 cm x 40.64 cm)

Integrity verification feeder 20.0 in W x 16 in. L 114.6 lbs. (52.0 kg)

(50.8 cm x 40.64 cm)

Up to 3,000 packages per hour

Letter; A4

See MXD/MXi Paper Guidelines document for further details

Standard (single) feeder: Up to 350 inserts; max. thickness of 4 mm

Tower feeder (top): Up to 250 inserts; max. thickness of 2 mm

Tower feeder (bottom): Up to 250 inserts; max. thickness of 4 mm

Integrity verification feeder Up to 250 inserts; max. thickness of 2 mm

Module Specifications

Physical dimensions

and weight

Speed

Form sizes accepted

Insert and envelope sizes

Feeder capacity

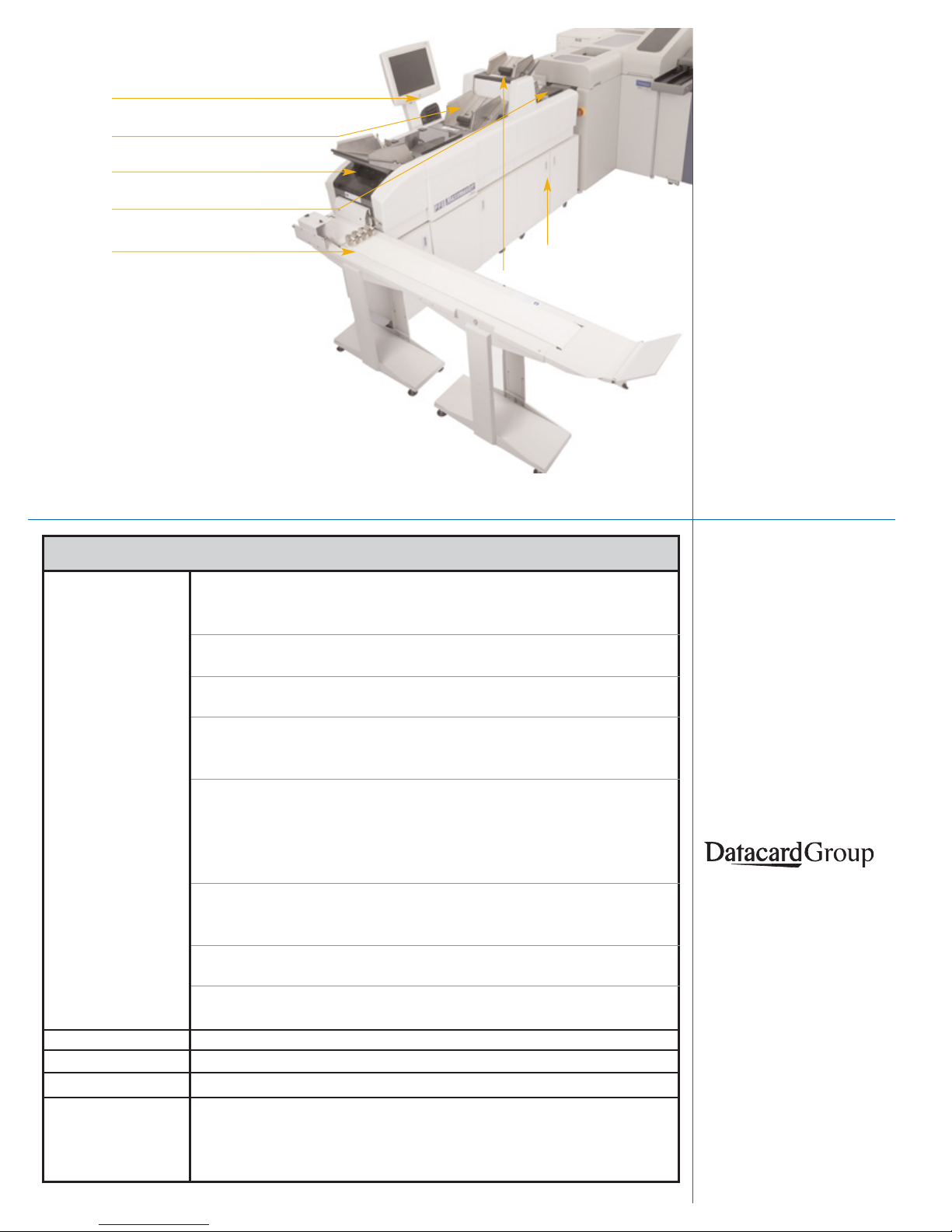

MXi PC screen

DTI (transfer interface)

Standard feeder

Envelope feeder

MXi envelope stacker*

Base for feeders

(storage cabinet)

Tower feeder

* Also compatible with the form/envelope high-capacity stacker

Loading...

Loading...