Page 1

Systems Guide

variant series

Page 2

variant

Page 3

SYSTEM INSTALLATION

The units can be installed in a

variant 25A/112A

number of ways. Typically several

units would be assembled to form a line array

cluster, but it can also be used alone, as a frontfill

or as an under- balcony unit. A wide range of

accessories and uses are available, and have been

described in the paragraphs below.

Planning/inspection

Before installing the system it

is advisable to run a simulation using the

FOCUS

This way we can determine the needs that should

be met by the rigging structures such as hoists,

cranes, beams, rigging points, etc. Besides

providing weight information, the program also

provides users with splay angle information, safety

pin positions and coverage predictions.

and every one of the aforementioned structures is

capable of supporting a superior load than that of

the complete system.

software utilizing the venue dimensions.

It is extremely important to assure that each

variant 25A/112A

variant 25A/112A

EASE

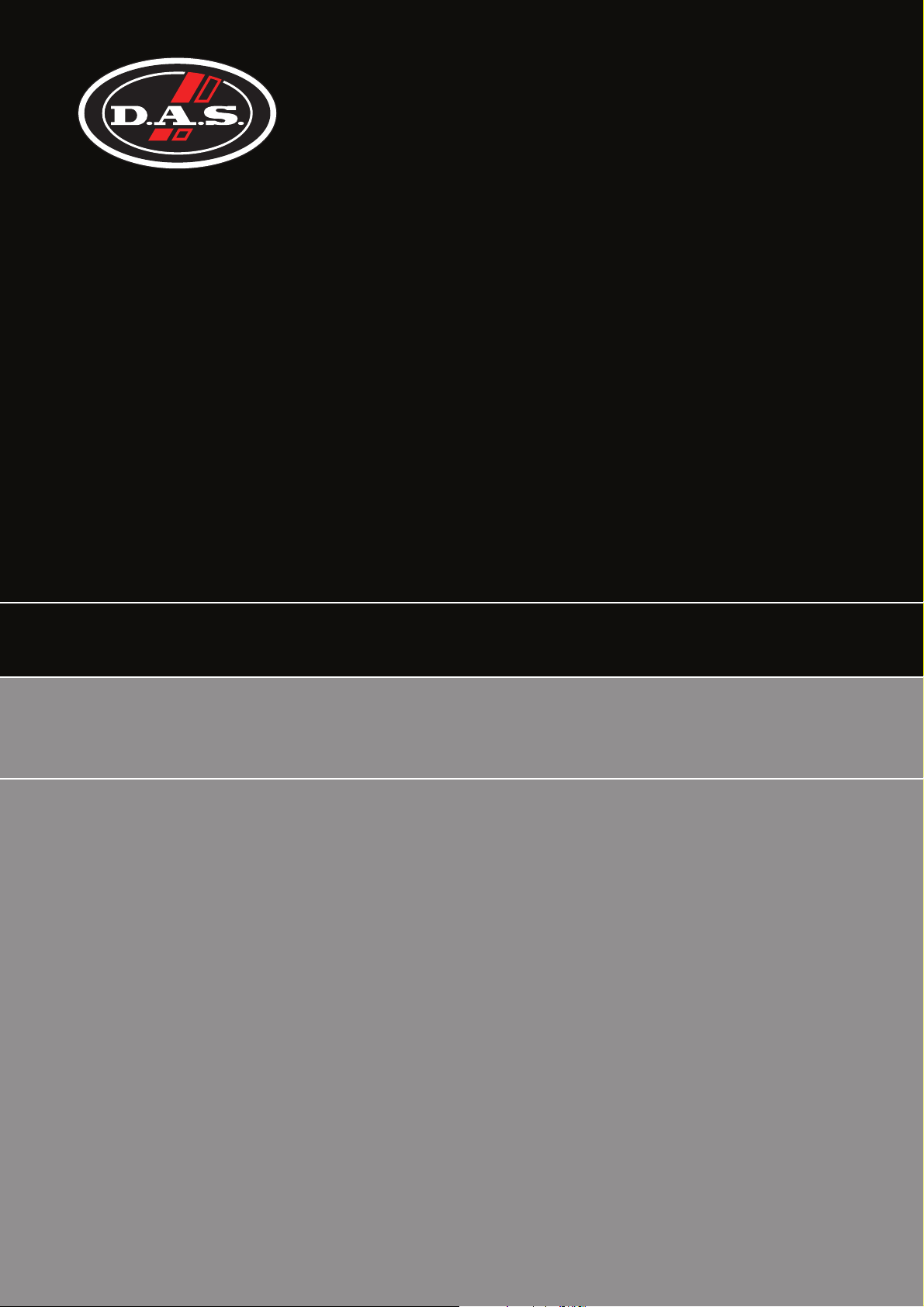

Installing a line array system

Whenever a cluster of only

units is to be assembled the procedure will be as

follows:

First step will be to attach the bumper

to the hoist. The chain sling needs to be attached

to the structure using the shackle provided with

the grid. The shackle will be inserted into the hole

recommended by the software.

The next step will be to mechanically connect

the first to the . In order to do so

rotate the connecting links (1) and then insert the

safety pins through the labeled holes to select the

splay angle between the and the grid

(2). Now both connecting links must be inserted

into the receptacles on the (3). Once this

has been done two more safety pins have to be

inserted to secure the boxes (4). It is highly

advisable to check that all of the safety pins have

been correctly inserted.

variant25A AX-V25

EASE FOCUS

variant 25A

variant 25A/112A

AX-V25

AX-V25

Inspection is the next step after planning and

acquiring all the necessary parts needed to elevate

the systems. All parts, including the hardware

attached to the enclosure, the safety pins, etc.

should be thoroughly inspected before each use.

Units exhibiting deformations, cracks or any other

defect should be replaced with new units.

It is important to establish an inspection routine

for the complete rigging system before each event

or installation as well as establishing the maximum

load specifications of the hoists to be used.

Rigging should be carried out by experts

familiar with the way the system functions and

their characteristics.

On occasions it may be convenient to have

additional tie down points to impede the array

from twisting or swinging.

4

2

3

1

EN

6

5

variant S uideystems G

1

Page 4

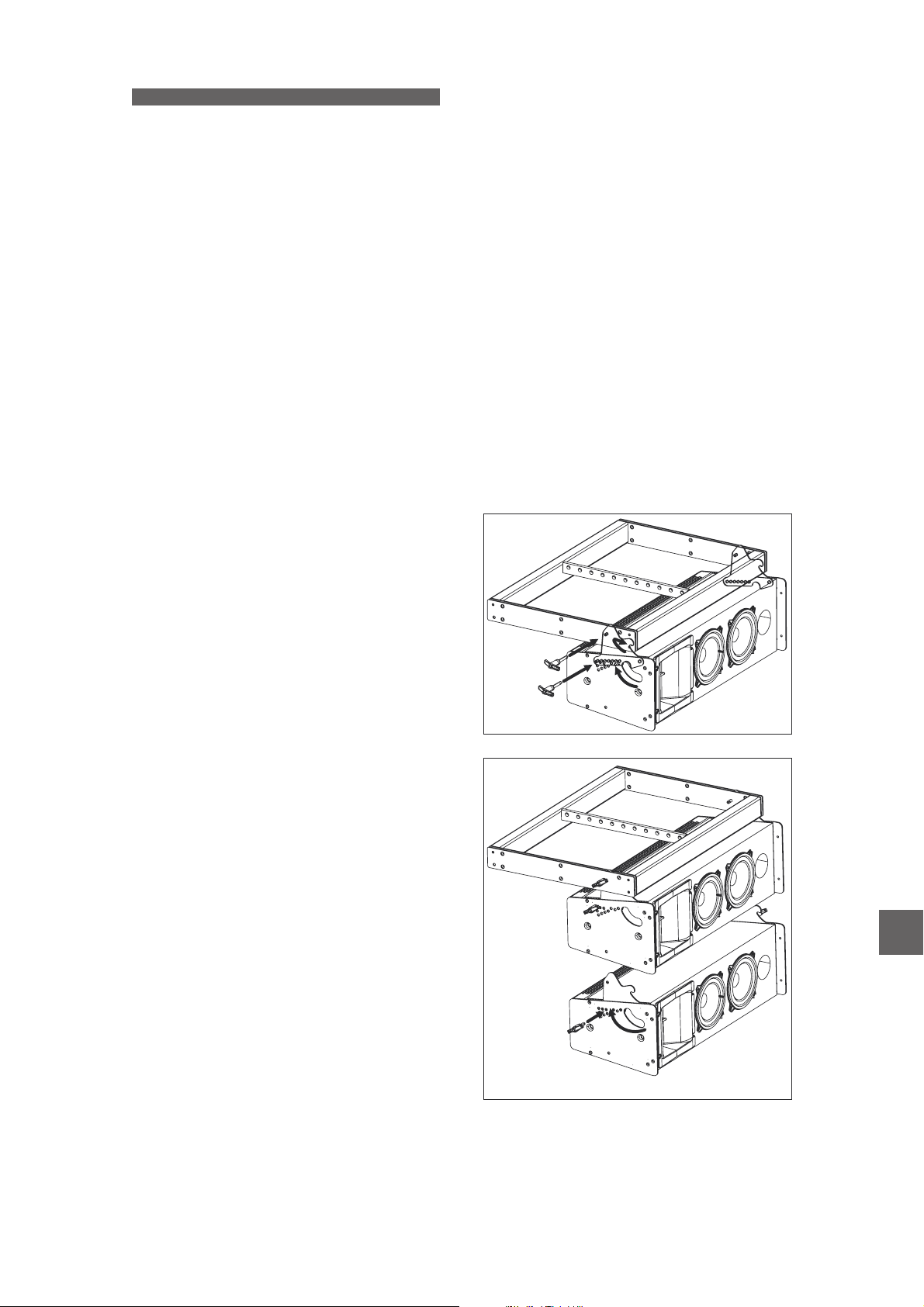

The procedure to mechanically connect the

second unit is similar. First rotate the connecting

links (5) in order to select the correct angle by

means of the safety pins (6). In this example the

selected angle is 2º. Once this has been done then

the enclosure must be hung from the first box (7)

and assured by means of one more safety pin (8).

3

4

2

1

7

variant 25A - max 20 units

4

3

8

2

1

EN

The above described procedure applies to the

rest of the units.

The basic procedure to hang the units is as

follows: rotate the connecting links (1) until the

desired angle is reached. Then introduce the

safety pins through the holes labeled with the

desired angle which should have been provided by

the prediction software (2). Now

introduce the connecting links into the receptacles

of the box above and hang the unit from the

rotating point (3). Finally introduce the safety pin

that secures the unit (4). This procedure will be

repeated as many times as enclosures are to be

assembled. This procedure is also identical in case

of flying systems.

2

variant112A

EASE FOCUS

variant 112A AX-V25

set up at 0º.

variant S uideystems G

variant 112A - max 6 units

Note: The vertical angle between the first

and the flying grid can only be

Page 5

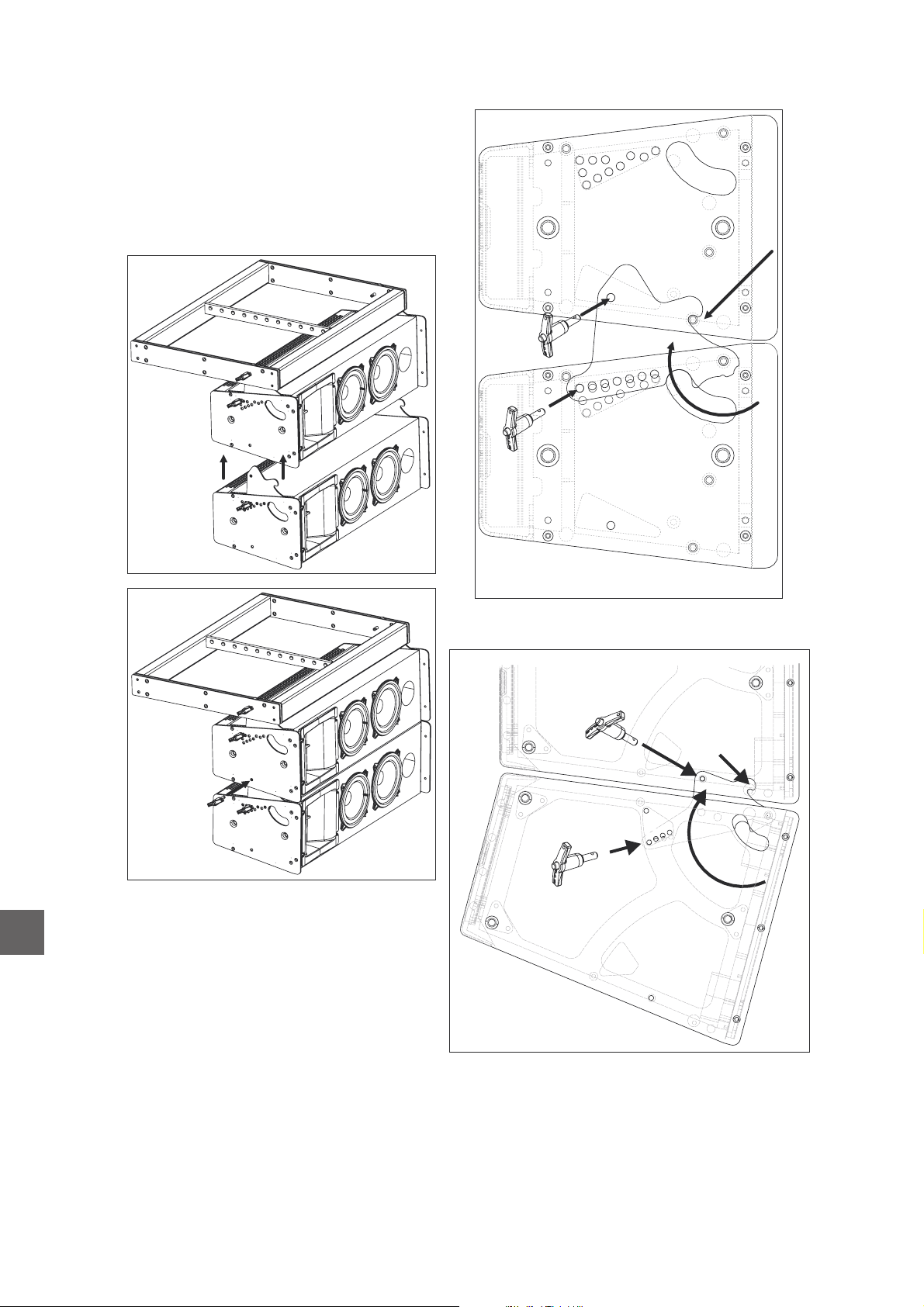

Assembling a system with flown subwoofers

variant 18A

The units feature integral rigging

hardware allowing them to be flown independently

or above enclosures.

variant25A

The first step will be to mechanically connect

variant 18A AX-V25

the first to the grid. 6 safety pins

are included in the rear side of the box in order to

do so. First rotate the rear side connecting links by

180º, and then the front side connecting links until

variant 18A AX-V25

the labeled position has been

reached. After that, insert the pin through the hole

labelled (2).

variant18AAX-V25

1

-5º

0º

5º

VARIANT25

0º

AX-V25

VARIA NT 18

1

2

The next step will be to hang one more

unit below the first one. To do so first both

18A

variant

connecting links will be rotated (4), then a safety

pin will be inserted into the hole labeled

variant 18A

(5) on the front side connecting link, and finally

both connecting links will be introduced into the

rigging hardware of the box above and secured by

means of two more safety pins (6).

6

-5º

0º

5º

VARIANT25

0º

AX-V25

VARIANT18

To secure the enclosure to the grid (3) two

more safety pins are needed on each side. Check

that the position of the connecting links are as

shown in the image below.

4

6

If units are to be hung from the

variant 25A

variant 18A

have to be rotated (7), then the safety pin must be

inserted into the hole that provides the desired

angle (8), and finally the connecting links have to

be introduced into the rigging hardware of the box

above and be secured by means of a safety pin on

each side (9).

subwoofers, first the connecting links

4

5

EN

3

3

9

7

8

variant S uideystems G

3

Page 6

The procedure in case of installing

variant 112A

systems is equivalent to the previous mentioned

before.

-5º

0º

5º

VARIANT25

0º

AX-V25

VARIANT18

9

7

8

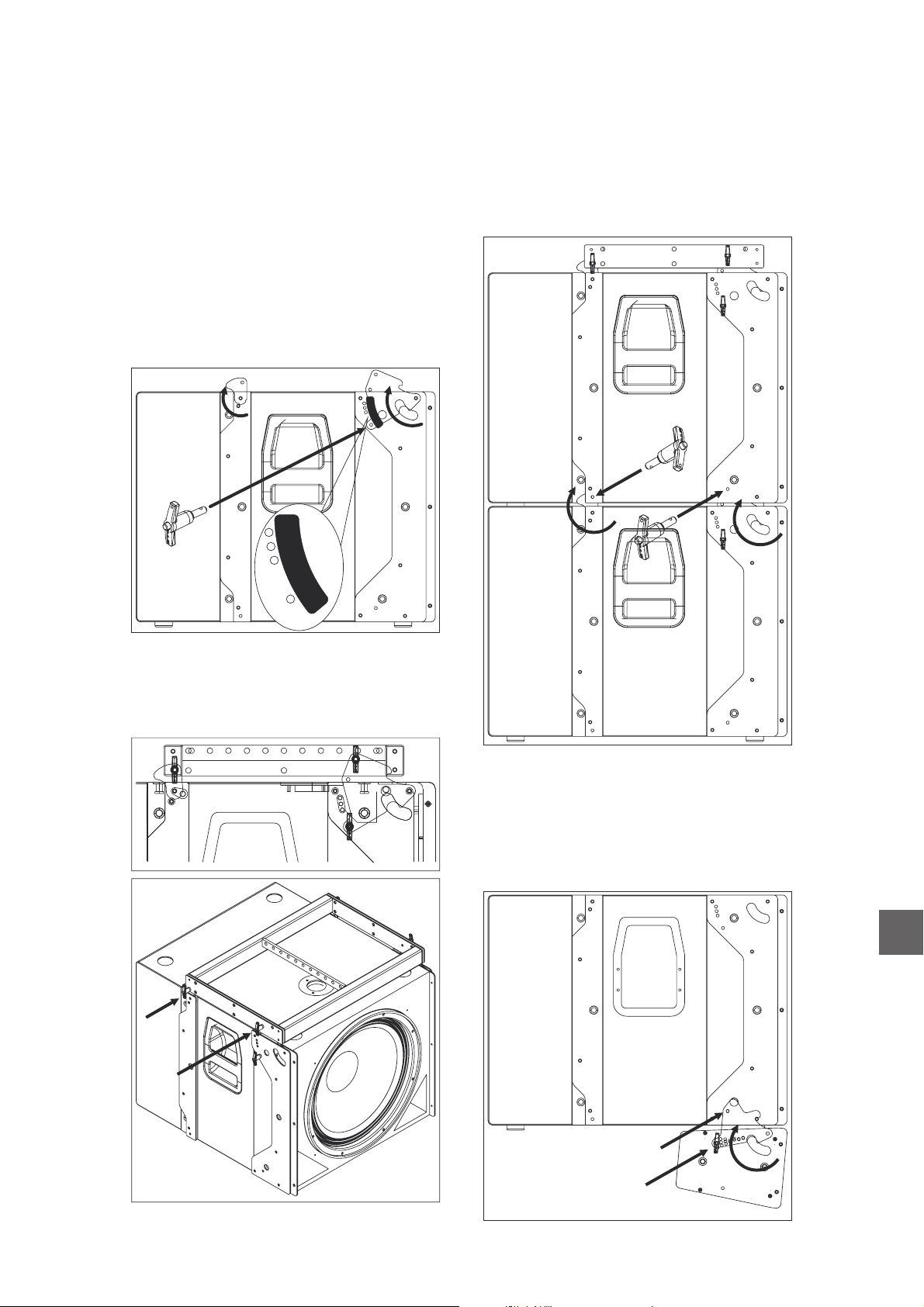

Stacking units on the subs

variant 18A

The units feature integral rigging

hardware which can also be used for stacking

variant 25A/112A

maximum recommended number of

units in this mode is 6. The maximum number of

variant 112A

The splay angles available between both

enclosures are 0º, 5º and -5º.

The first step will be to mechanically connect

the first unit to the

variant 25A variant 18A

enclosure. Four safety pins, which are included in

the box, will be necessary to do so. First rotate the

connecting links (1) on the until the

desired angle is achieved and introduce the safety

pin through the hole labeled with the desired splay

angle (2). The three available angles are 0º, 5º and

-5º. Look at the label on the box.

units on top of them. The

variant 25A

units to be stacked on the subs is 2.

variant 18A

variant18A

2

Before attaching the first to the

1

variant 25A

subwoofer unit, the connecting links must be

rotated (3) until the desired splay angle with the

next unit on top is reached. Once the desired

angle has been reached the safety pins will be

introduced (4) into the corresponding hole.

3

4

In order to attach the unit to the

subwoofer unit, introduce the connecting (5) links

on the into the receptacles on the

variant 25A

variant 18A

. Then two safety pins (6) must be

introduced (one per side) to secure one enclosure

to the other.

variant 25A

EN

5

6

4

variant S uideystems G

Page 7

introduced into the 0º labeled hole, while in the

picture below the safety pin has been introduced

into the +5º labeled hole.

Before attaching the first to the

variant 112AIn the picture above the safety pin has been

subwoofer unit, the connecting links must be

rotated (3) until the desired splay angle with the

next unit on top is reached. Once the desired

angle has been reached the safety pins will be

introduced (4) into the corresponding hole.

The rest of the boxes will be set up using the

above explained procedure for connecting rods

and safety pins ( See page 2).

The first step will be to mechanically connect

the first unit to the

variant 112A variant 18A

enclosure. Four safety pins, which are included in

the box, will be necessary to do so. First rotate the

connecting links (1) on the until the

variant 18A

desired angle is achieved and introduce the safety

pin through the hole labeled with the desired splay

angle (2). The three available angles are 0º, 5º and

-5º. Look at the label on the box.

-5º

0º

5º

VARIANT25

variant18A

4

In order to attach the unit to the

3

variant 112A

subwoofer unit, introduce the connecting (5) links

on the into the receptacles on the

variant 112A

variant 18A

. Then two safety pins (6) must be

introduced (one per side) to secure one enclosure

to the other.

5

6

0º

AX-V25

VARIANT18

EN

2

1

In the graph above the quick release pins have

been inserted in the center hole of the

rigging hardware, so the angle between both

systems is 0º.

If more cabinets are going to be stacked

repeat the process described on page 2.

variant S uideystems G

variant 18A

5

Page 8

System installation using the ceiling support AXC-V25

variant 25A

The units can be set up as a long

array of more than four enclosures (as explained

above) or as a small array of 2, 3 or 4 units. In the

latter case the highly resistant grid

accessory is not necessary. Instead the

AX-V25

AXC-V25

ceiling mount accessory can be used to hang a

cluster of up to four units.

First attach the ceiling mount accessory to the

ceiling or a beam. Before doing so be sure that the

load bearing capability of these elements is

enough. The will be attached to the ceiling

AX-V25

by means of six nº 10 rawlplugs and six 7 x 40

mm screws.

Grower (lock) washer

Metal washer

AXC-V25

Before connecting the first box to the ceiling

mount accessory the two M8x30 DIN965 screws

must be removed from the and

replaced by two M8x35 DIN912.

M8X30 DIN965

variant 25A

M8x35 DIN 912

Rubber washer

Three different washers must be used along

the M8x35 DIN912 screws and placed in the

following order- grower (lock) washer, metal

washer and rubber washer.

In order to hang the rest of the boxes the

captive rigging hardware and safety pins will be

used, and the procedures described on the 4.3

paragraph of this manual will be followed. The

picture below shows three units

variant 25A

hanging from the ceiling.

EN

6

variant S uideystems G

Page 9

When a pair of hook clamps are attached to

the ceiling mount accessory, it can be fixed to a

truss structure such as the one shown in the

picture below:

The accessory can also be used as a

AXC-V25

support for up to two units on a pole

mount accessory, on top of one unit.

To do so the accessory is to be used

upside-down and a special pole mount adaptor

must be fixed to it by means of two M8x35

DIN912 screws, nuts and washers. A 10º splay

angle is recommended in order to achieve a 20º

vertical coverage.

AXC-V25

variant 25A

variant 18A

20º

AXC-V25

Pole Mount

M8x35 DIN912

AXC-ZT

EN

variant S uideystems G

7

Page 10

variant 112A

The units can be set up as a

cluster of more than three enclosures (as explained

above) or as a small array of 2 units. In the latter

case the highly resistant grid accessory is

not necessary. Instead the ceiling mount

AX-V25

AXC-V112

accessory can be used to hang a cluster of up to

four units.

First attach the ceiling mount accessory to the

ceiling or a beam. Before doing so be sure that the

load bearing capability of these elements is

enough. The will be attached to the

AX-V112

ceiling by means of six nº 10 rawlplugs and six 7

x 40 mm screws.

AXC-V112

Grower (lock) washer

Metal washer

M8x35 DIN 912

Rubber washer

Three different washers must be used along

the M8x35 DIN912 screws and placed in the

following order- grower (lock) washer, metal

washer and rubber washer.

EN

Before connecting the first box to the ceiling

mount accessory the two M8x30 DIN965 screws

(per side) must be removed from the

variant 112A

and replaced by two M8x35 DIN912.

M8x30 DIN 965

In order to hang the rest of the boxes the

captive rigging hardware and safety pins will be

used, and the procedures described on the 4.3

paragraph of this manual will be followed. The

picture below shows two units

variant 112A

hanging from the ceiling.

8

variant S uideystems G

Page 11

When a pair of hook clamps ( ) are

attached to the ceiling mount accessory, it can be

fixed to a truss structure such as the one shown in

the picture below:

The accessory can also be used as

AXC-V112

a support for up two unit on a pole

mount accessory, on top of one unit. To

do so the accessory is to be used

upside-down and a special pole mount adaptor

must be fixed to it by means of two M8x35

DIN912 screws, nuts and washers. A 15º splay

angle is recommended in order to achieve a 30º

vertical coverage.

AXC-V112

variant 112A

AXC-AT

variant 18A

AXC-ZT

AXC-V112

M 8x35 DIN912

EN

variant S uideystems G

9

Page 12

System installation using the wall support AXW-V25

Up to three units can be wall

mounted by means of the accessory.

variant 25A

AXW-V25

First the accessory must be fixed to the wall,

making sure in advance that the work load of the

wall allows for it. The wall mount accessory will be

attached to the wall using six nº 10 rawlplugs and

six 7 x 40 mm screws.

Then hang the first unit from the

variant 25A

wall mount accessory. The two M8x30 DIN965

screws have to be removed from each side of the

box and replaced by two M8x35 DIN912 screws.

Grower washer

Metal washer

M8x35 DIN 912

Rubber washer

EN

M8X30 DIN965

Three different washers must be used along

the M8x35 DIN912 screws and placed in the

following order- grower (lock) washer, metal

washer and rubber washer.

Warning!! If three units have to be

variant 25A

hung it is advisable to fix the box in the middle to

the wall mount accessory.

In order to hang the rest of the boxes the

captive rigging hardware and safety pins will be

used, and the procedures described on the 4.3

paragraph of this manual will be followed. The

picture below shows three units fixed to

variant 25A

the wall.

10

variant S uideystems G

Page 13

Page 14

www.dasaudio.com

SI_VA_01_EN

D.A.S. AUDIO, S.A.

C/. Islas Baleares, 24

46988 Fuente del Jarro

Valencia, SPAIN

Tel. 96 134 0525

Tel. Intl. +34 96 134 0860

Fax 96 134 0607

Fax Intl. +34 96 134 0607

D.A.S. AUDIO OF AMERICA, INC.

Sunset Palmetto Park

6816 NW 77th Court.

Miami, FL. 33166 - U.S.A.

TOLL FREE: 1-888DAS4USA

Tel. +1 305 436 0521

Fax +1 305 436 0528

D.A.S. AUDIO ASIA PTE. LTD.

25 Kaki Bukit Crescent #01-00/02-00

Kaki Bukit Techpark 1

Singapore 416256

Tel. +65 6742 0151

Fax +65 6742 0157

Loading...

Loading...