Page 1

AP

AP----BLOT

APAP

BLOT

BLOTBLOT

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

This manual contains DAS reserved information. All rights reserved. Unauthorized copying of this manual or parts

is prohibited.

das

srl

Viale Tivoli Km 18,642 – 00018 Palombara Sabina (Roma) - Italy

Tel. (+39) 0774 66840 – 0774 637070 - Fax 0774 634039

E- ma il : in fo @d as it al y. co m - ht tp :/ /ww w. da si ta ly .c om

Page 2

Page 3

Ed.

Index

Indice

AP Blot– SERVICE MANUAL

Date

Data

SECTION 0

INTRODUCTION

Description

Descrizione

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Execution

Elaborazione

Verification

Verifica

Pag. 3

Approval

Approvazione

0 Rev. 00 29.04.08

0 Rev. 01 02.04.09

Important Notes:

To avoid errors during maintenance and repairs, carefully read the entire manual before

attempting any work on the instrument.

Issue

General revision

Pay particular attention to the “GENERAL SAFETY WARNINGS” in Section 1 and follow instructions for specific

operations precisely as indicated in this manual.

Page 4

Page 5

CONTENTS

AP Blot– SERVICE MANUAL

SECTION 0

INTRODUCTION

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 5

SECTION 1 GENERAL SAFETY ............................................................................................................................. 9

1.1.

GENERAL SAFETY WARNINGS AND SYMBOLS.............................................................................. 11

1.2.

INSTRUMENT USE AND CONDITIONS ............................................................................................... 11

1.3.

INTENDED USE/USERS OF THE INSTRUMENT................................................................................. 11

SECTION 2 INSTALLATION AND TECHNICAL SPECIFICATIONS ........................................................... 13

2.1.

INSTALLATION ...................................................................................................................................... 15

2.2.

WORK AREA............................................................................................................................................ 16

2.3.

TECHNICAL SPECIFICATIONS ............................................................................................................ 16

SECTION 3 MAINTENANCE PROCEDURES .................................................................................................... 17

3.1 SYSTEM ARCHITECTURE ........................................................................................................................ 19

3.2 REMOVING WORK AREA......................................................................................................................... 21

3.2.1. REMOVING WORK AREA .................................................................................................................... 21

3.2.2. Removing shaking plane......................................................................................................................... 23

3.3 DILUTOR UNIT ........................................................................................................................................... 24

3.3.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 24

3.3.1.1. Dilutor Unit ......................................................................................................................................................24

3.3.1.2. Dilutor mechanism ........................................................................................................................................... 25

3.3.1.3. Valve mechanism/Syringe................................................................................................................................ 25

3.3.1.4. Pump Unit ........................................................................................................................................................26

3.3.1.5. Probe ................................................................................................................................................................ 27

3.3.1.6. Probe Wash Basin ............................................................................................................................................27

3.3.1.7. Dilutor Unit PCB Electrical Diagram...............................................................................................................28

3.3.1.8. Dilutor unit hydraulic component diagram.......................................................................................................29

3.3.2. REGULAR DILUTOR UNIT MAINTENANCE ...................................................................................... 30

3.3.2.1. Visual checks ................................................................................................................................................... 30

3.3.3. SUBSTITUTING DILUTOR UNIT COMPONENTS .............................................................................. 31

3.3.3.1. Substituting valve – syringe – dispensation probe tubing.................................................................................31

3.3.3.2. Substituting valve mechanism..........................................................................................................................32

3.3.3.3. Substituting 3-way Electro valve......................................................................................................................32

3.3.3.4. Substituting 3-way valve mechanism ...............................................................................................................32

3.3.3.5. Substituting Peristaltic Pump Tubing ...............................................................................................................33

3.3.3.6. Substituting Dilutor Motor ...............................................................................................................................34

3.3.3.7. Substituting Opto SIDILOP PCB.....................................................................................................................35

3.3.3.8. Substituting INTERFA2 PCB ..........................................................................................................................35

3.3.3.9. Substituting probe wash basin ..........................................................................................................................35

3.4.

X–Y AXIS ................................................................................................................................................. 36

3.4.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 36

3.4.1.1. X – Y axis movement mechanism.................................................................................................................... 36

3.4.1.2. X- Y axis Electrical Functions Diagram........................................................................................................... 37

3.4.2. REGULAR MAINTENANCE FOR X–Y AXIS ........................................................................................ 38

3.4.2.1. Cleaning X-Y axis tracks..................................................................................................................................38

3.4.2.2. Check belt tension ............................................................................................................................................ 38

3.4.2.3. Check condition of flat cables ..........................................................................................................................38

3.4.3. CALIBRATING X–Y AXIS SETTINGS ................................................................................................... 38

3.4.3.1. X and Y axis belt tension..................................................................................................................................38

3.4.4. Substituting X–Y AXIS PARTS ............................................................................................................... 39

3.4.4.1. Substituting X-axis Movement Motor.............................................................................................................. 39

3.4.4.2. Substituting Y-axis Movement Probe Motor.................................................................................................... 40

3.4.4.3. Substituting Opto XGOLAV (X-axis movement) PCB.................................................................................... 40

3.4.4.4. Substituting X-axis movement belt ..................................................................................................................41

3.4.4.5. Substituting Flat Cables....................................................................................................................................41

3.4.4.6. Substituting X-Y axis movement flat cables ....................................................................................................41

3.4.4.7. Substituting INTEROP2 PCB (Y-axis movement)...........................................................................................42

3.5.

Z1 - Z2 AXIS ............................................................................................................................................. 43

3.5.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 43

3.5.1.1. Z1 - Z2 axis movement mechanism..................................................................................................................43

3.5.1.2. Z axis electrical circuit diagram .......................................................................................................................44

3.5.2. REGULAR Z AXIS MAINTENANCE...................................................................................................... 45

3.5.2.1. Z2 axis movement control.................................................................................................................................45

3.5.3. Z-AXIS CALIBRATION .......................................................................................................................... 45

3.5.4. SUBSTITUTING Z1 and Z2 AXIS PARTS ............................................................................................... 46

3.5.4.1. Substituting Z1 Axis probe................................................................................................................................46

3.5.4.2. Substituting Z1 Axis probe motor..................................................................................................................... 47

Page 6

AP Blot– SERVICE MANUAL

3.5.4.3. Substituting Z2 Axis probe ...............................................................................................................................47

3.5.4.4. Substituting Z2 Axis probe motor..................................................................................................................... 48

3.6.

SHAKING PLANE.................................................................................................................................... 49

3.6.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 49

3.6.1.1. Shaking plane movement mechanism ..............................................................................................................49

3.6.1.2. Shaking plane circuit diagram ..........................................................................................................................50

3.6.2. MAINTENANCE AND SHAKING PLANE CALIBRATION................................................................... 51

3.6.3. SUBSTITUTING SHAKING PLANE COMPONENTS ........................................................................... 51

3.6.3.1. Substituting Shaking Plane Motor.................................................................................................................... 51

3.6.3.2. Substituting opto PCBs ....................................................................................................................................52

3.7.

CAMERA .................................................................................................................................................. 53

3.7.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 53

3.7.2. CAMERA MAINTENANCE .................................................................................................................... 54

3.7.2.1. Checking USB cable connection ......................................................................................................................54

3.7.2.2. Cleaning lens....................................................................................................................................................54

3.7.3. CALIBRATE CAMERA........................................................................................................................... 54

3.7.4. SUBSTITUTING CAMERA AND/OR PARTS ........................................................................................ 54

3.7.4.1. Substituting camera ..........................................................................................................................................54

3.7.4.2. Substituting camera lens................................................................................................................................... 55

3.7.4.3. Substituting camera USB cable ........................................................................................................................55

3.7.4.4. Substituting LED light bar................................................................................................................................55

3.8.

OPTICAL SENSORS ................................................................................................................................ 56

3.8.1. DESCRIPTION OF HOW OPTICAL SENSORS FUNCTION ............................................................... 56

3.8.2. REGULAR MAINTENANCE .................................................................................................................. 56

3.8.2.1. Cleaning opto ...................................................................................................................................................56

3.8.2.2. Checking procedure.......................................................................................................................................... 56

3.8.3. CHECKING DISTANCE FOR OPTO COUPLERS (X AXIS) ................................................................ 57

3.8.4. CHECKING DISTANCE FOR OPTO COUPLERS (Y AXIS) ................................................................ 58

3.9.

USB COMMUNICATION ........................................................................................................................ 59

3.9.1. DESCRIPTION OF HOW IT WORKS ................................................................................................... 59

3.9.2. CHECK FUNCTIONALITY ................................................................................................................... 59

3.9.3. REPLACING DILAP21 and SIR4MOT PCBs ........................................................................................ 60

3.10. DILUTOR COMMAND LIST................................................................................................................... 61

3.11. HYDRAULIC CIRCUIT DIAGRAM ....................................................................................................... 66

3.11.1. REGULAR MAINTENANCE .............................................................................................................. 67

3.11.2. SUBSTITUTING HYDRAULIC CIRCUIT COMPONENTS ............................................................... 67

3.11.2.1. Electro-valve substitution.................................................................................................................................67

3.12. SUMMARY OF REGULAR MAINTENANCE ....................................................................................... 68

3.12.1. DILUTOR UNIT ................................................................................................................................. 68

3.12.2. X–Y AXIS ............................................................................................................................................ 68

3.12.3. Z2 AXIS............................................................................................................................................... 68

3.12.4. SHAKING PLANE .............................................................................................................................. 68

3.12.5. CAMERA ............................................................................................................................................ 68

3.12.6. OPTICAL SENSOR............................................................................................................................. 68

3.12.7. HYDRAULIC CIRCUIT ...................................................................................................................... 68

SECTION 0

INTRODUCTION

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 6

SECTION 4 CALIBRATION PROCEDURES (XCALIB) ................................................................................... 69

4.1.

INSTALLING SOFTWARE ..................................................................................................................... 71

4.2.

OPERATING MENU ................................................................................................................................ 72

4.3.

DESCRIPTION OF MENU FUNCTIONS ................................................................................................ 73

4.4.

INSTRUMENT BAR................................................................................................................................. 74

4.5.

SETTINGS ................................................................................................................................................ 75

4.5.1. HARDWARE CONFIGURATION .......................................................................................................... 75

4.5.2. Language................................................................................................................................................ 76

4.5.3. Communication port............................................................................................................................... 76

4.5.4. Serial number ......................................................................................................................................... 77

4.6.

WORK AREA............................................................................................................................................ 78

4.7.

MAIN FUNCTIONS.................................................................................................................................. 79

4.7.1. Tank level Sensors .................................................................................................................................. 79

4.7.2. Dispensation Test ................................................................................................................................... 79

4.7.3. Dilution Test........................................................................................................................................... 79

4.7.4. Movement Test........................................................................................................................................ 80

4.7.5. Print Preview.......................................................................................................................................... 82

4.7.6. Print........................................................................................................................................................ 82

4.7.7. Turn Light On......................................................................................................................................... 83

4.7.8. Close Function ....................................................................................................................................... 83

Page 7

AP Blot– SERVICE MANUAL

4.7.9. Exit ......................................................................................................................................................... 83

4.8.

DILUTOR.................................................................................................................................................. 84

4.8.1. Calibrate probe positions ....................................................................................................................... 84

4.8.2. Calibrate probe height ........................................................................................................................... 89

4.8.3. Calibrate LT ........................................................................................................................................... 91

4.8.4. Calibrate shaking plane ......................................................................................................................... 93

4.8.5. Calibrate syringe.................................................................................................................................... 95

4.8.6. Calibrate SUL ........................................................................................................................................ 98

4.8.7. Wash basin test....................................................................................................................................... 99

4.8.8. Prime .................................................................................................................................................... 101

4.8.9. Calibrate camera.................................................................................................................................. 102

4.8.10. Calibrate parameters........................................................................................................................ 104

4.8.11. Home................................................................................................................................................. 105

4.8.12. Turning motors off ............................................................................................................................ 105

4.8.13. Reset.................................................................................................................................................. 105

4.9.

? ............................................................................................................................................................... 106

4.9.1. Instrument information......................................................................................................................... 106

4.9.2. Software component information ......................................................................................................... 107

4.9.3. About .................................................................................................................................................... 107

SECTION 0

INTRODUCTION

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 7

SECTION 5 TROUBLE SHOOTING ................................................................................................................... 109

5.1 DILUTION / DISPENSATION................................................................................................................... 111

5.2 X - Y - Z MOVEMENTS ............................................................................................................................. 112

5.3 CAMERA.................................................................................................................................................... 112

SECTION 6 SCHEMATIC DIAGRAMS .............................................................................................................. 113

Page 8

Page 9

AP Blot– SERVICE MANUAL

GENERAL SAFETY

SECTION 1

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 9

SECTION 1

GENERAL SAFETY

Page 10

Page 11

AP Blot – SERVICE MANUAL

GENERAL SAFETY WARNINGS

SECTION 1

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

1.1. GENERAL SAFETY WARNINGS AND SYMBOLS

In this manual the following symbols stand for danger or warnings:

General DANGER symbol which indicates that a serious safety risk can occur if

instructions and warnings are not followed.

Indicates ELECTRICAL VOLTAGE which could cause death upon contact. Covers

with this symbol can only be removed and replaced by qualified personnel and only

after electrical power has been disconnected.

Indicates that the instrument uses reagents and corrosive, irritating or noxious

DANGEROUS CHEMICAL SUBSTANCES which could damage health.

Indicates that the instrument deals with potentially infectious samples (e.g. body

fluids such as urine) which could cause INFECTION/CONTAMINATION. Always

observe general safety precautions when any of these biological substances are

present.

Indicates that not following the correct instructions could damage instrument and/or

its proper functioning.

Indicates that important information concerning the instrument or a Section of the

document should be read carefully.

1.2. INSTRUMENT USE AND CONDITIONS

The instrument is intended for use in the following working conditions:

− as In Vitro Diagnostic (IVD) medical device as specified in the technical data

− with chemical reagents and accessories supplied and/or declared compatible with instrument

− at a specific temperature and humidity levels as specified in this manual

− not to be used and powered in a potentially explosive or fire hazardous environment

This instrument should only be used as described in this manual.

Any other use has to be regarded as improper.

1.3. INTENDED USE/USERS OF THE INSTRUMENT

The instrument should only be used for the intended purpose and in perfect technical conditions, only by

qualified personnel following strict safety procedures and regulations for accident prevention.

This manual contains instructions for qualified personnel:

− Only Qualified Technicians are entitled to service and repair the instrument with original spare

parts and after appropriate training.

Modifications of the instrument are not allowed. The user is liable for any improper

modifications and any subsequent consequences.

For extraordinary maintenance - request Specialized Technicians with authorised equipment and

original spare parts from authorised service centers.

Pag. 11

Page 12

Page 13

AP Blot – SERVICE MANUAL

INSTALLATION AND TECHNICAL SPECIFICATIONS

SECTION 2

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 13

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

Page 14

Page 15

AP Blot – SERVICE MANUAL

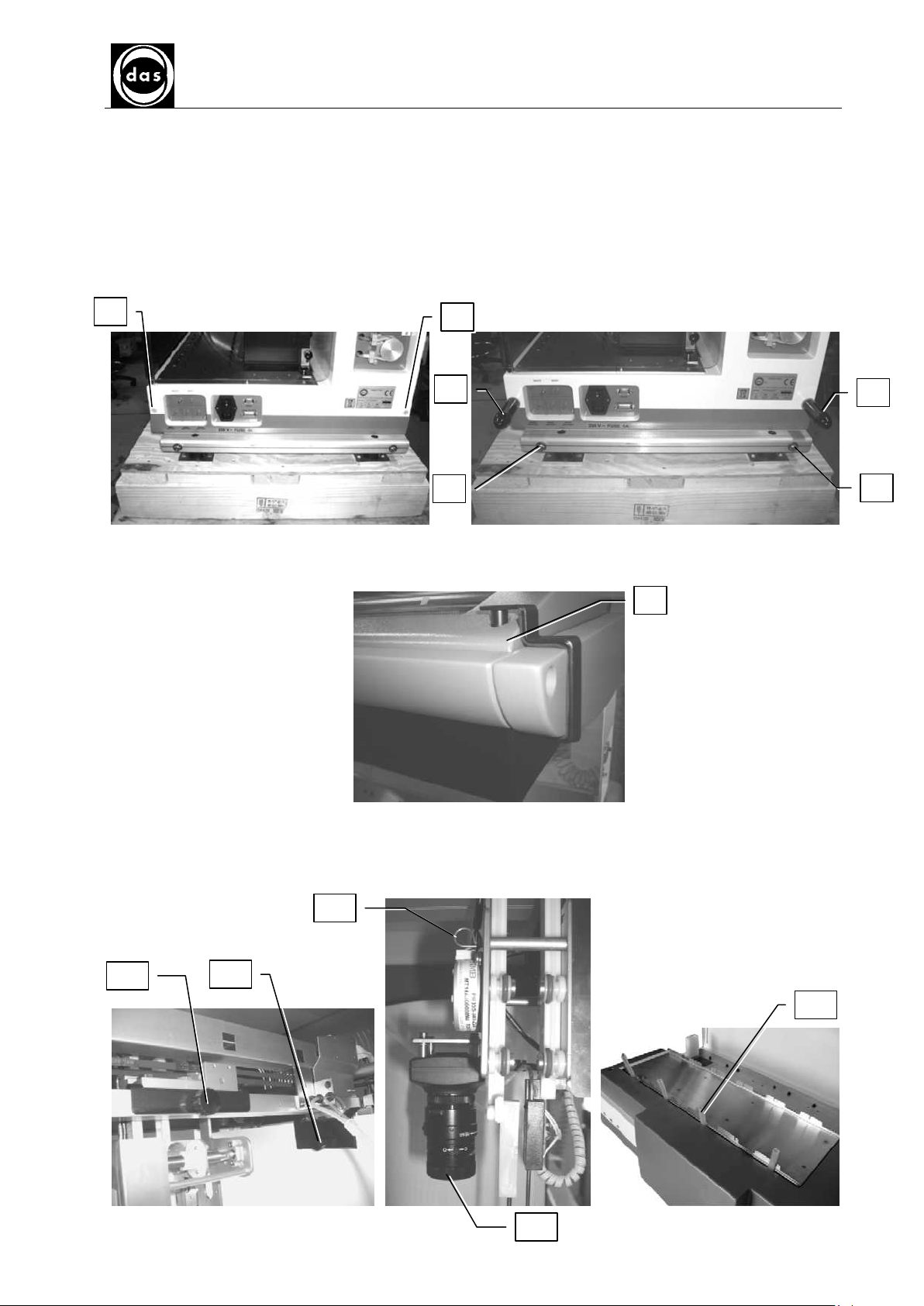

7

10

8

12

9

11

2

3

4

5

6

1

INSTALLATION AND TECHNICAL SPECIFICATIONS

SECTION 2

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 15

2.1. INSTALLATION

The instrument is packed with a wooden box. To unpack the instrument follow the instructions described below:

a) Remove the 2 plastic covers (1-2) from the instrument right side and the other ones from the left side. Screw

in the 4 handles on both sides (3-4) for manual instrument placement. Once in position remove the handles e

put back in place the plastic covers.

b) Remove the 4 screws that hold the instrument on to the wood base (5-6)

c) Remove screw and bracket (7), screw in the same place using the screw removed before

d) Remove,.- screw and bracket (7), screw in the same place the enclosed screw in the bag

e) Remove screws (8,9,10) and related brackets

f) Remove the Z block holder (11) as indicated

g) Remove the protection cap from the camera (12)

h) Remove the blocking tools (13) from the oscillating plane

Page 16

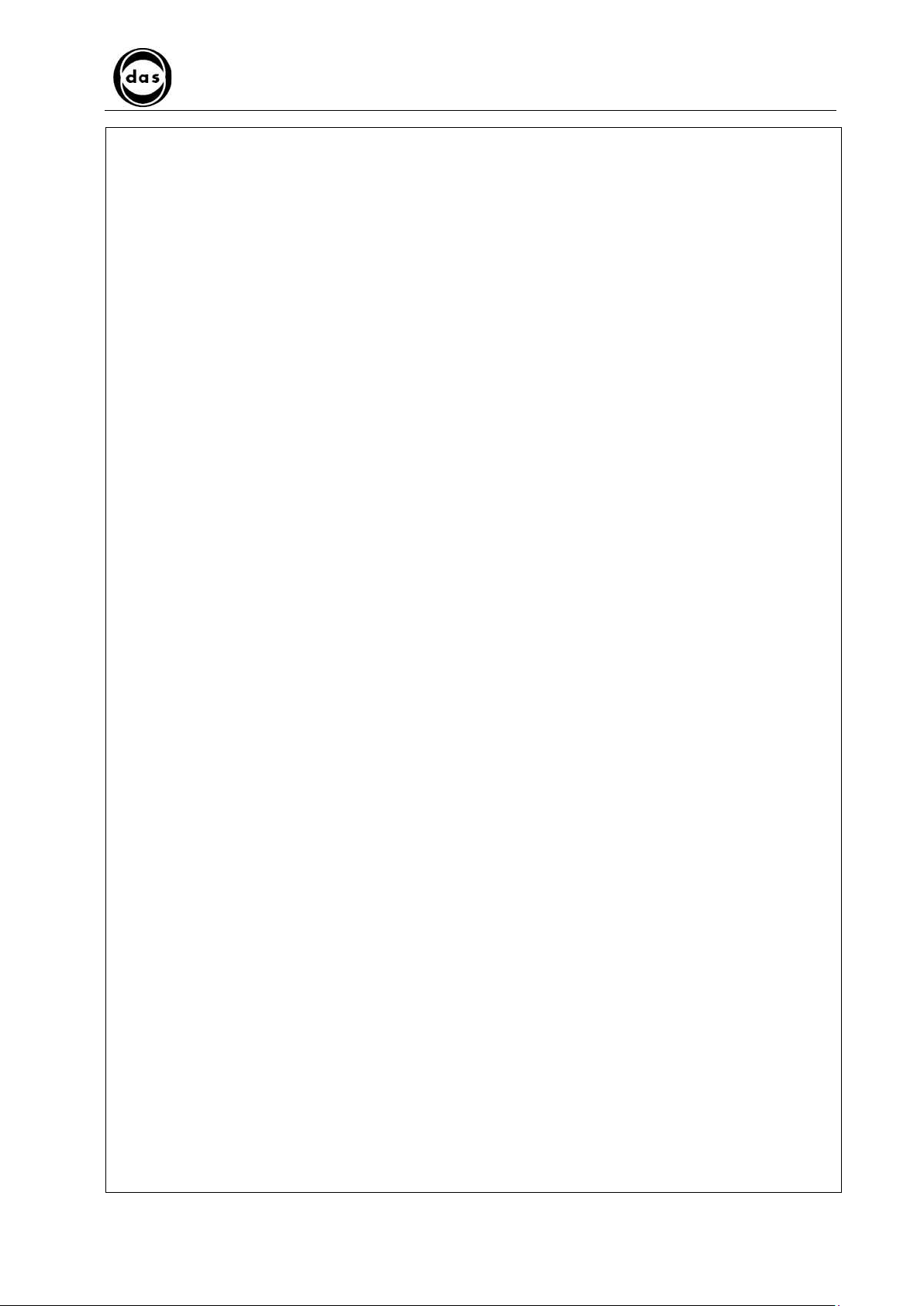

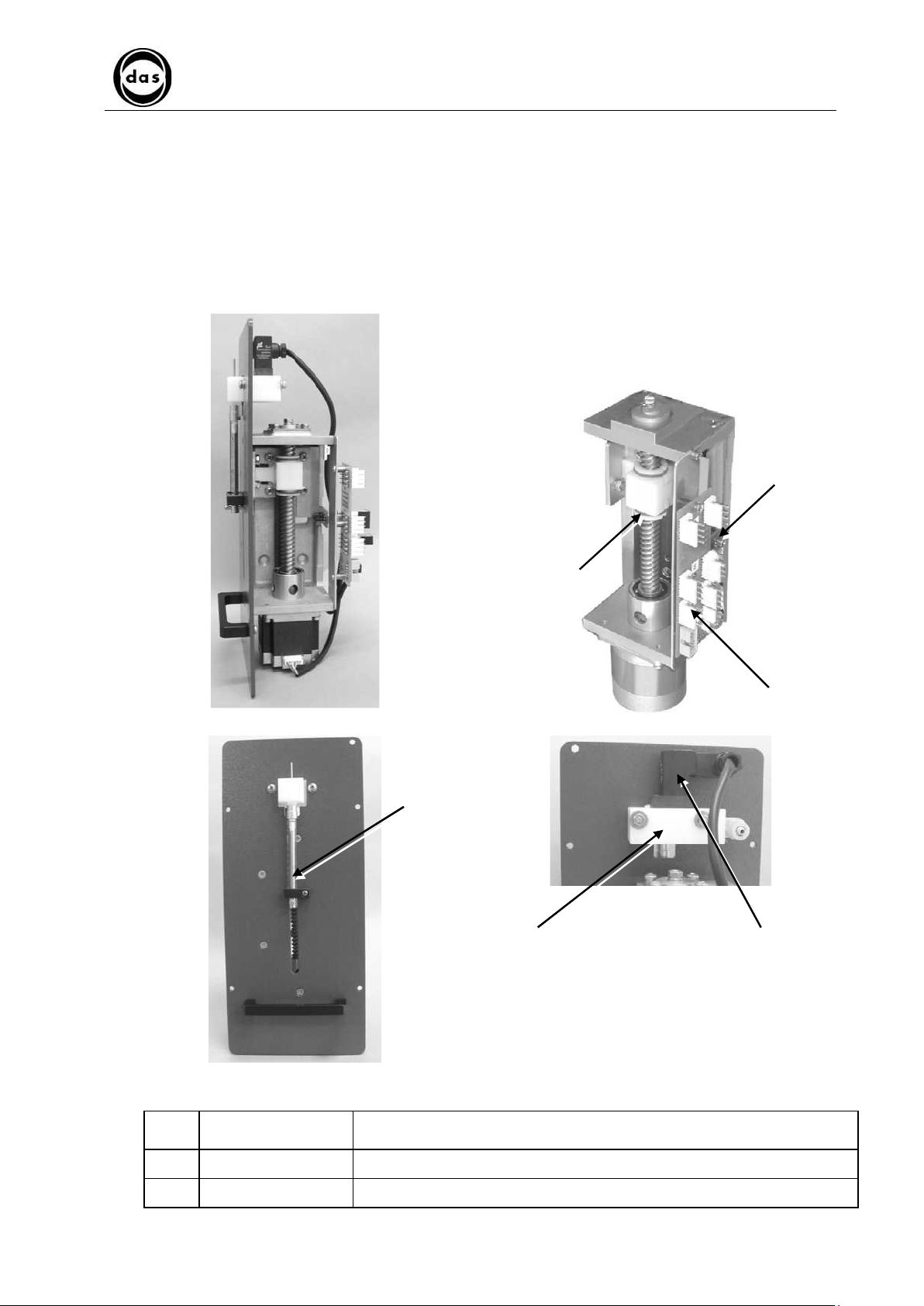

2.2. WORK AREA

AP-Blot work area showing the various components:

Probe washing

basin

48 position Sample rack Reagent and control rack Tanks

AP Blot – SERVICE MANUAL

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Pag. 16

Camera Calibration area Strip holder rack

Fig. 1 - AP-Blot Work Area

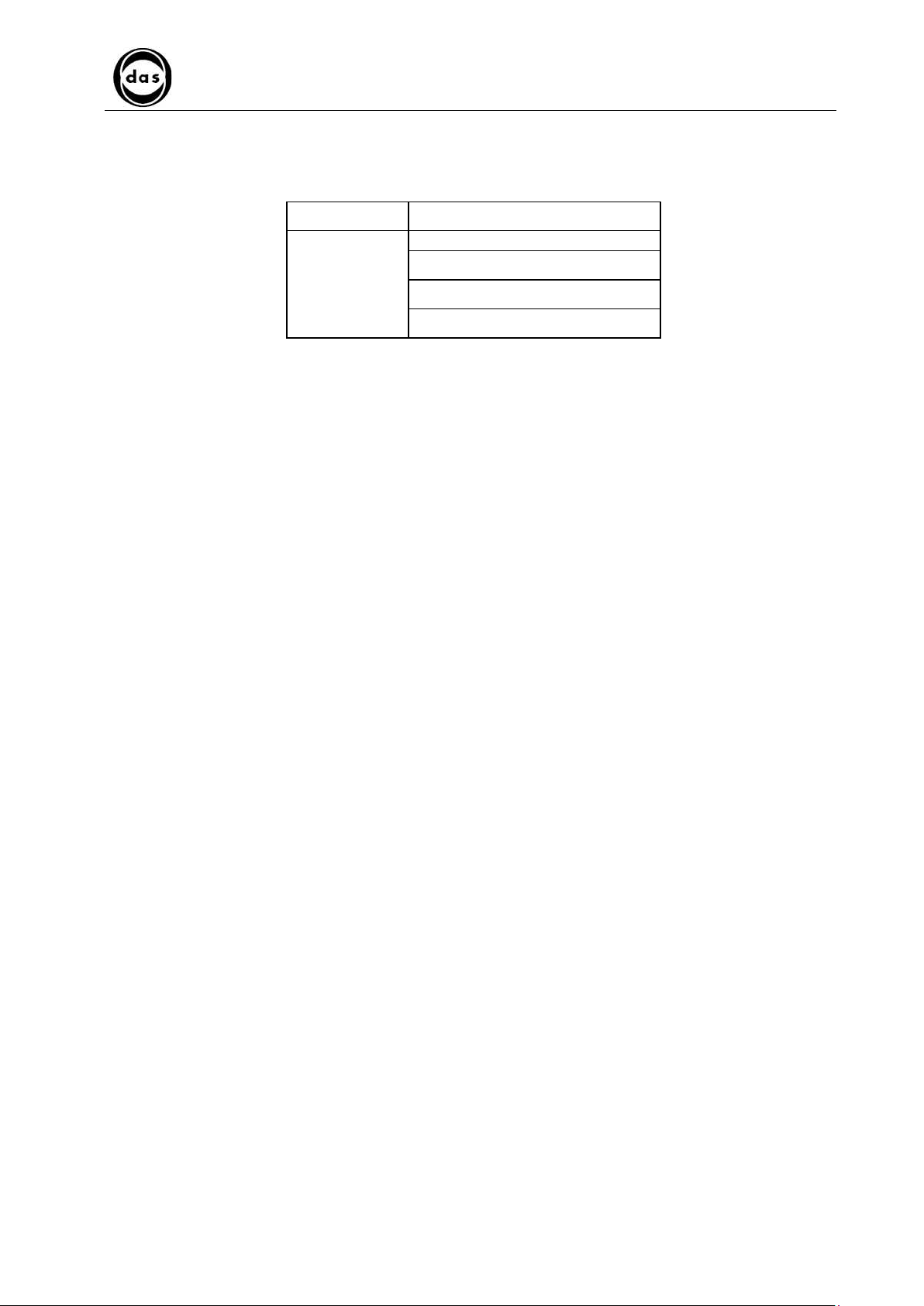

2.3. TECHNICAL SPECIFICATIONS

Sample rack

Reagent rack

Liquid Containers

Strip Holders

Dispensation System

Strip Washing

Image acquisition system

Dispensation

Software

Minimum PC Requirements

Power Requirements

Optional

Measurements

Weight

48 sample tubes (Ø 13mm)

6 x 100ml vials and 8 control positions

2 tanks for wash buffer and waste. Both with liquid level sensors

6 slides (8 strips per slide) to process up to strips on oscillating plane

1 dispensation and 1 aspiration probe

Liquid dispensation and aspiration via two instrument probes

High Resolution Colour Camera (3.3 Megapixels) mounted above Probes

Up to 2500 µl with a 1 µl resolution

Windows 2000 and XP compatible to set up work list, reports and result archive.

Loading work lists and transmit results via Host Computer interface (LIS)

− 200 MB free hard disk space

− CD-Rom reader

− RAM 512 MB

− Pentium 4

− Standard video card:VGA 1024x768 16 million colours

− Free USB 2.0 port

230/115 VAC, 50-60Hz, 150W

Bar Code Reader (BCR) for samples with position ID

79 x 61 x 65 h (in cm)

71 Kg

Page 17

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 17

SECTION 3

MAINTENANCE PROCEDURES

Page 18

Page 19

CAMERA

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

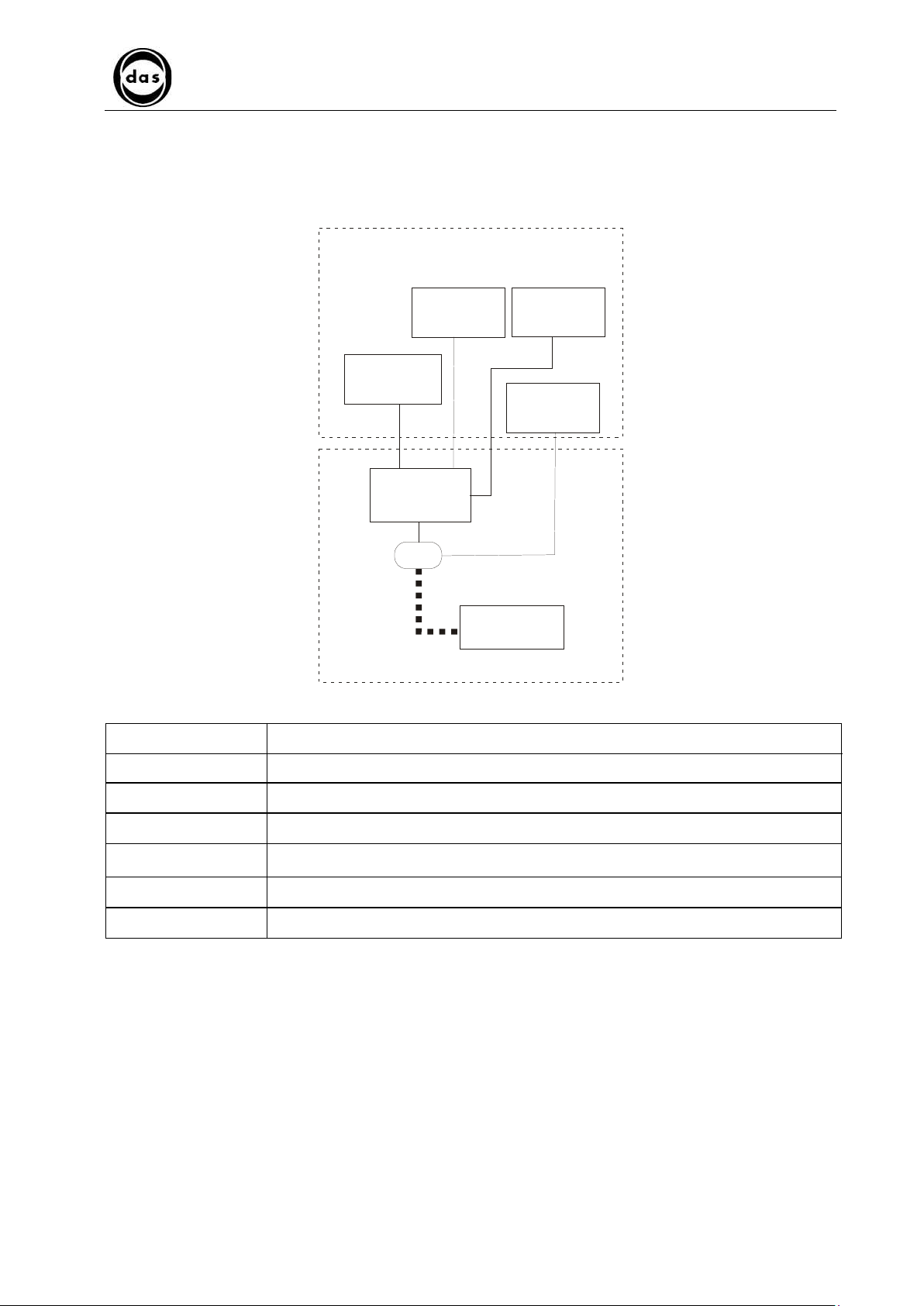

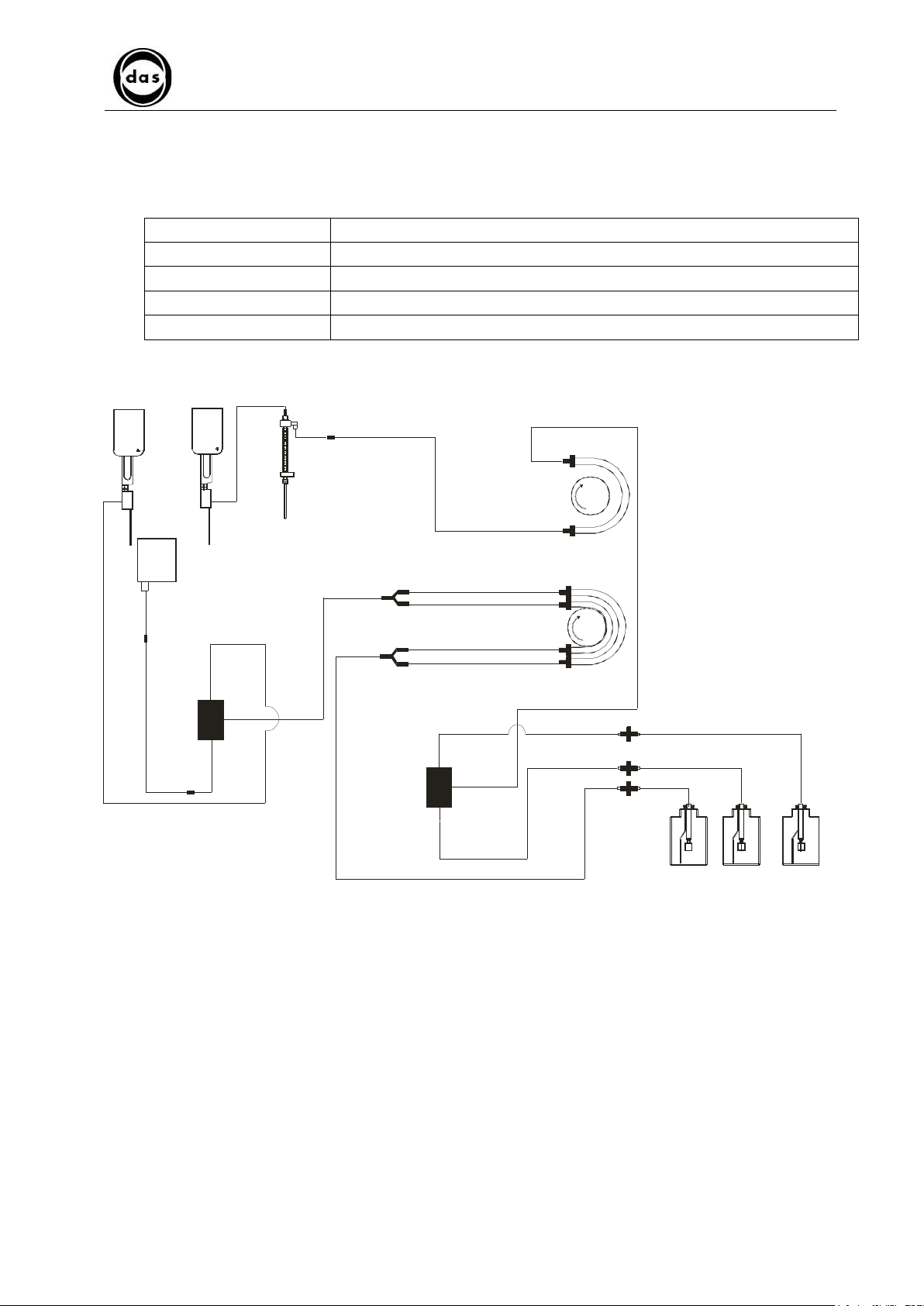

3.1 SYSTEM ARCHITECTURE

The system architecture is illustrated in the following diagram and described in table below:

Function group

Page 19

Control and check board

Functional unit Description

X-Y AXIS

Z1, Z2 AXIS

DILAP21

USB

DILUTOR

UNIT

SHAKING PLANE

Personal

Computer

X – Y Axis

Z1 Axis

Z2 Axis

Dilutor unit

Shaking Plane

Camera

The X-Y axis movement mechanism moves probe arms over work area with precision

The Z1 axis raises and lowers dispensing probe over work area.

The Z2 axis raises and lowers aspiration probe over work area.

The dilutor unit aspirates and dispenses samples, calibrators, controls, and generally all

reagents. It also washes Z1 axis probe internally and externally.

The shaking plane shakes the 6 slides holding the strips to be processed

The camera acquires the images of the processed strips.

Page 20

The AP Blot communicates with the PC via a serial connection: between the Dilutor PCB and the PC.

The units controlled by the PCB are:

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

PCB Unit

X – Y Axis

Z1 – Z2 Axis

DILAP21

Dilutor unit

Shaking plane

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 20

Page 21

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.2 REMOVING WORK AREA

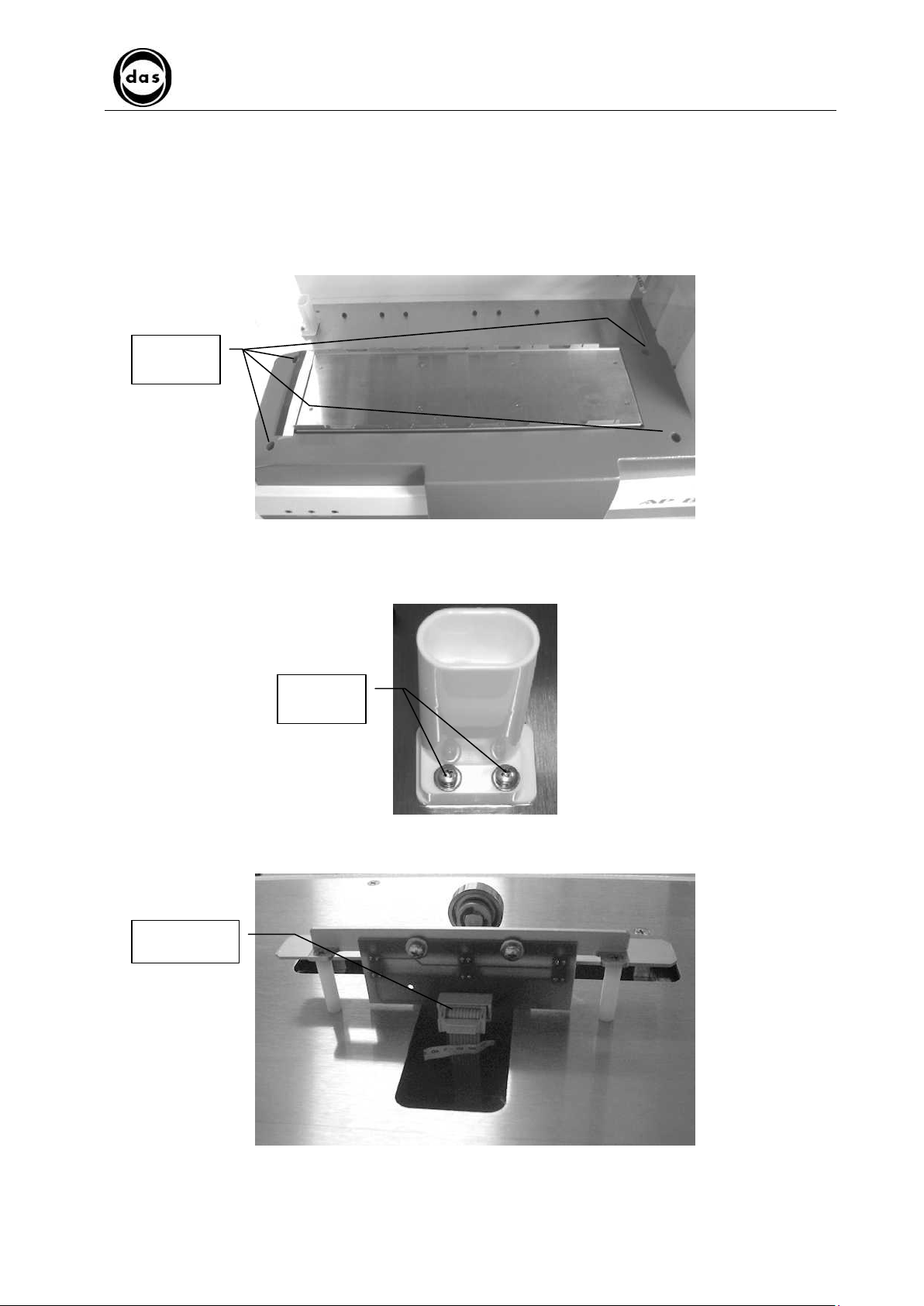

3.2.1. REMOVING WORK AREA

a) Turn off instrument

b) To remove strip holder tray plate first loosen four screws holding shaking plane

4 fixing

screws

Page 21

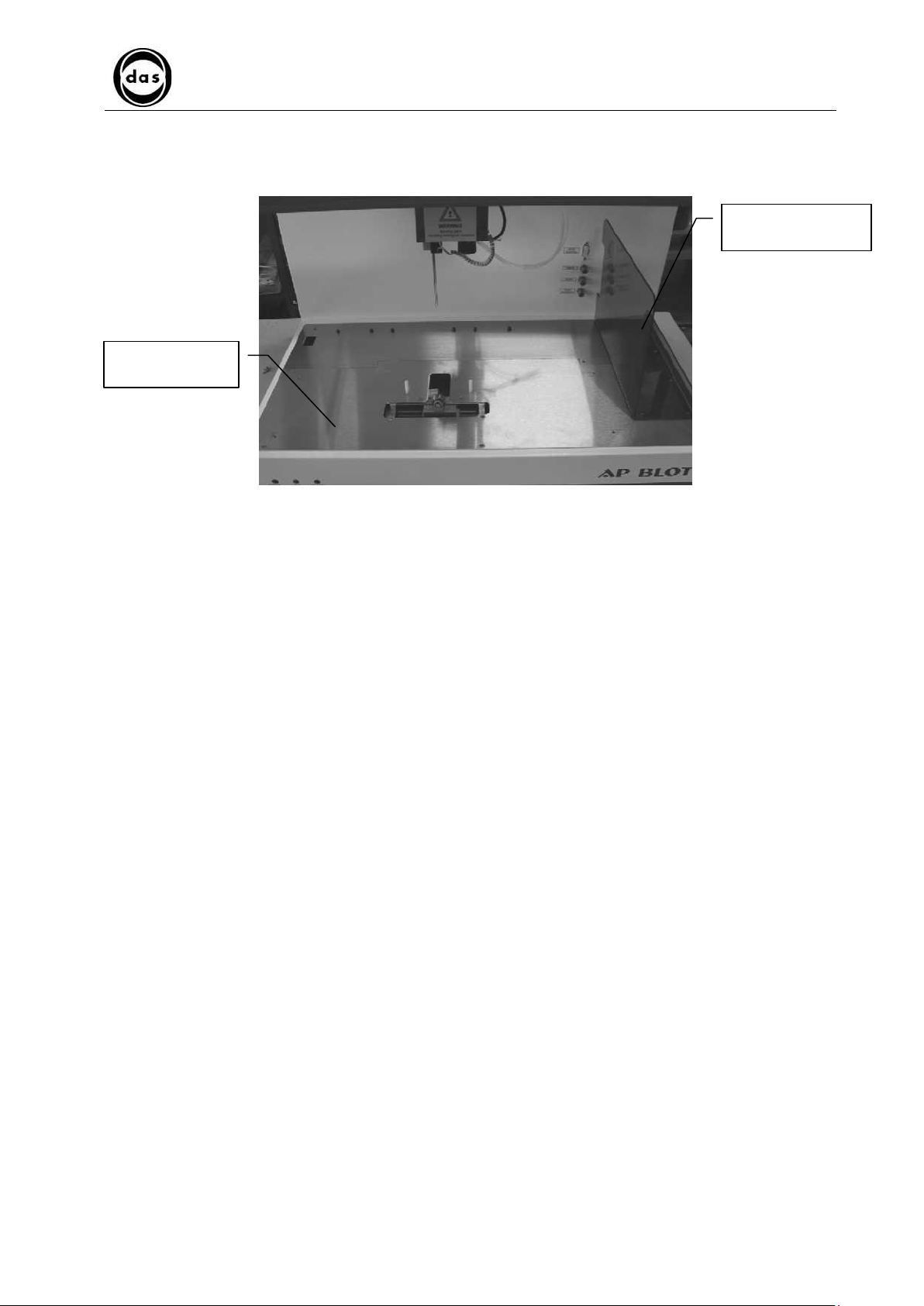

c) Remove 2 fixing screws from Probe wash basin and detach Waste (“OUT”) tube from under basin

2 fixing

screws

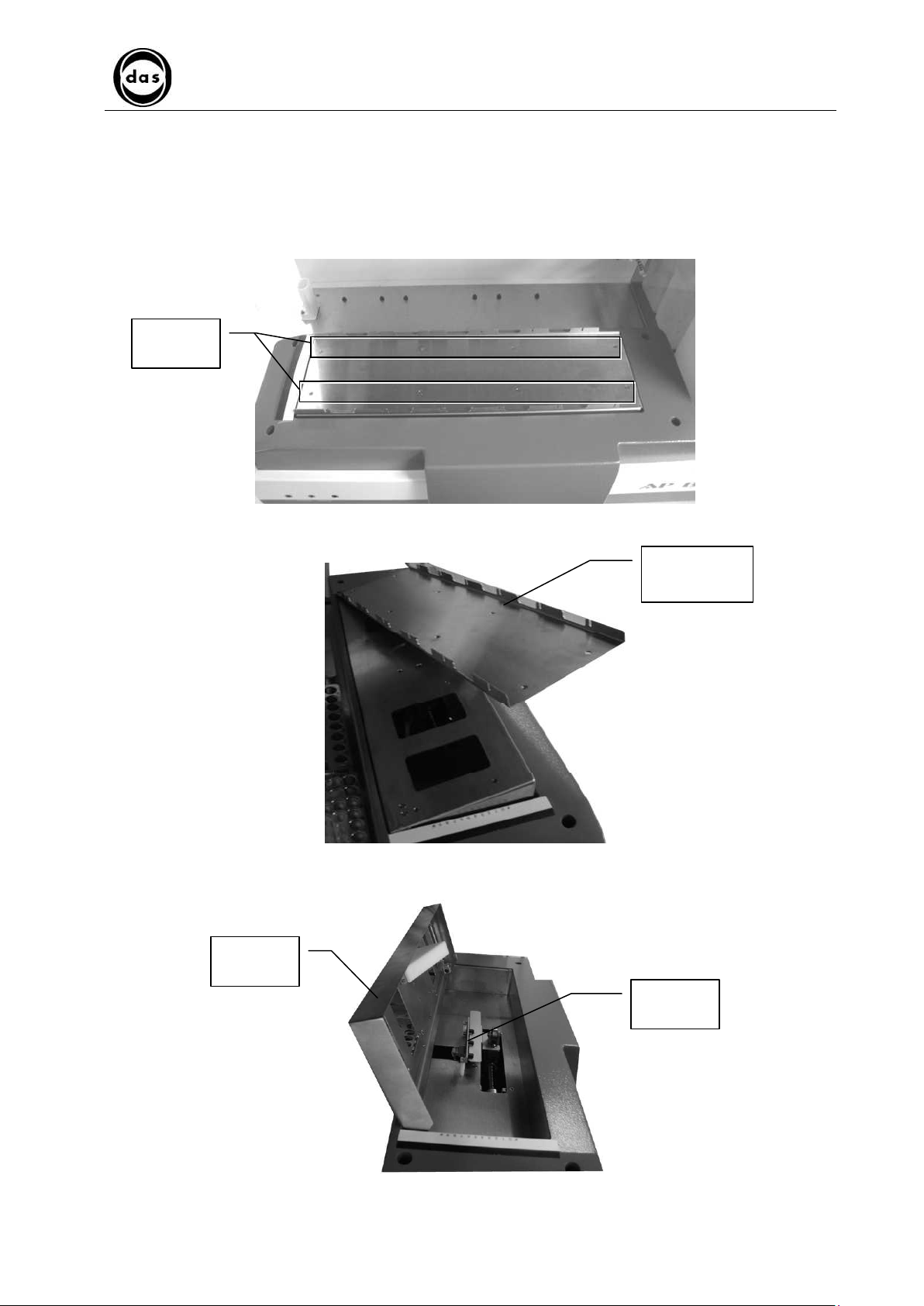

d) Remove connector from shaking plane positioning opto PCB (OP-Swing PCB)

1 connector

Page 22

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 22

e) Remove 8 screws from bottle separation carter

f) Remove 7 screws from aluminium shaking plane

Bottle separation

carter

Aluminium

shaking plane

g) Lift up and detach screws holding the shaking plane movement mechanism motor

h) NB: each time shaking plane support is moved, or removed calibrate shaking plane as described Para. 4.8.4.

Page 23

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.2.2. Removing shaking plane

a) Turn off device

b) Remove 8 screws from strip holder tray plate.

8 fixing

screws

c) Remove strip holder tray plate

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

strip holder

tray plate

Page 23

d) Lift up shaking plane

Shaking

plane

OP-Swing

PCB

Page 24

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.3 DILUTOR UNIT

3.3.1. DESCRIPTION OF HOW IT WORKS

FUNCTION

The dilutor unit aspirates and dispenses samples, calibrators, controls and all reagents, and also cleans

inside of Z1 probe.

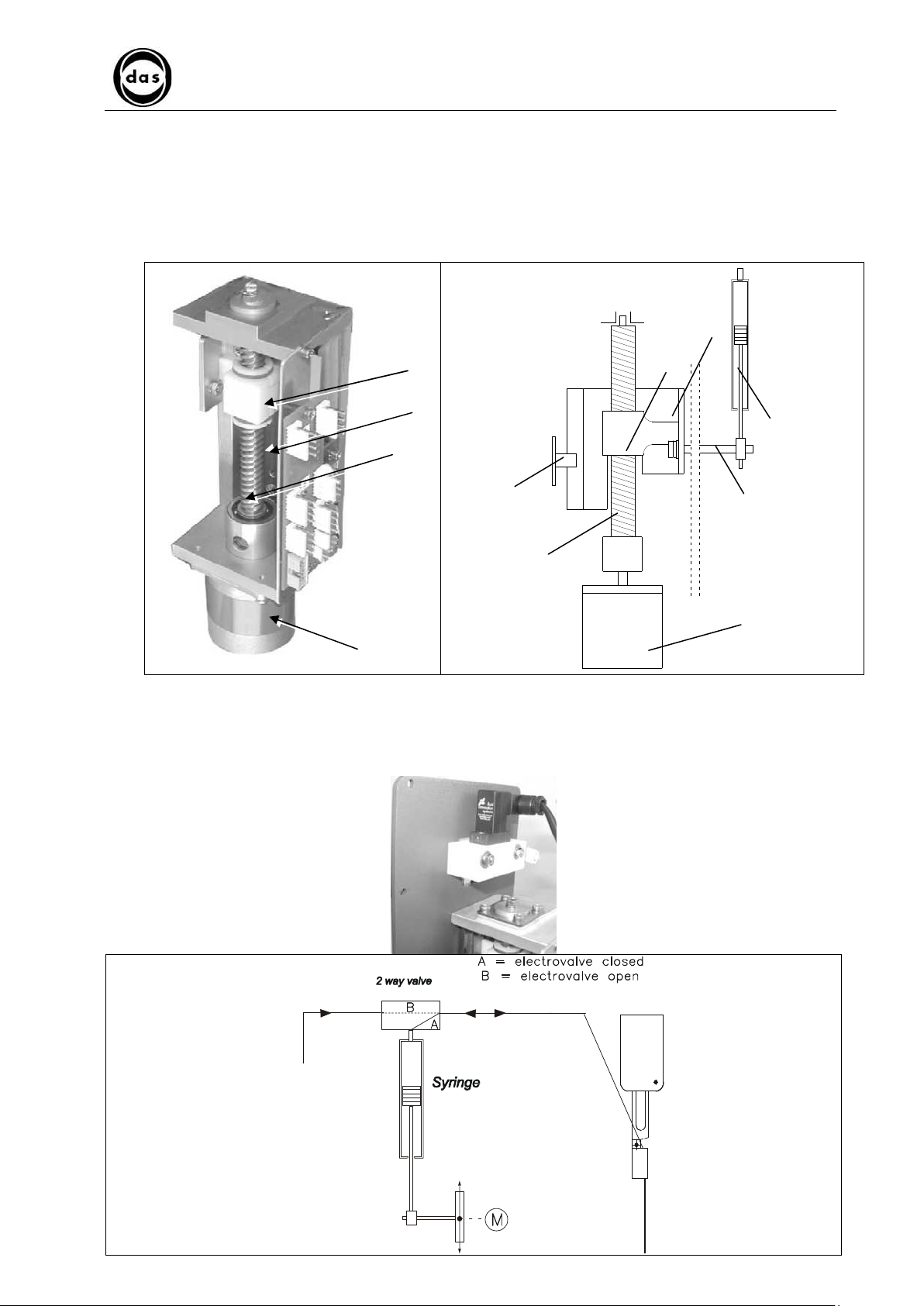

3.3.1.1. Dilutor Unit

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 24

SIDILOP

PCB

Syringe

Dilutor

movement

mechanism

Valve support

INTERFA2

PCB

Electro-valve

The DILUTOR UNIT is composed of following parts (clockwise direction):

1 Dilutor mechanism

2

3 Syringe

2-way Electro-valve For the aspiration of washing solution or for probe aspiration/dispensation

Moves probe with step motor

To aspirate and dispense

Page 25

Dilutor unit

4

5

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 25

3.3.1.2. Dilutor mechanism

This mechanism moves the syringe plunger (1) up and down in small steps. The movement is generated by a step

motor (2) which moves a special worm screw (3) inside a female plastic nut 4) fixed on a carriage (5) which runs along

a track (6) on 4 ball bearings. A shaft is mounted on the carriage (7) which then moves the syringe plunger (1). The

optic sensor (8) is mounted on the SIDILOP PCB and signals when the syringe plunger has reached the End line

(“home”) position.

4

6

1

3

8

7

3

2

2

3.3.1.3. Valve mechanism/Syringe

The valve mechanism connects the Wash bottle to the rest of the hydraulic syringe-probe circuit through the peristaltic

pump.

The syringe movement is generated by the dilutor unit and the syringe is connected to the dispensing probe

Page 26

MAINTENANCE PROCEDURES

3.3.1.4. Pump Unit

AP Blot - SERVICE MANUAL

SECTION 3

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

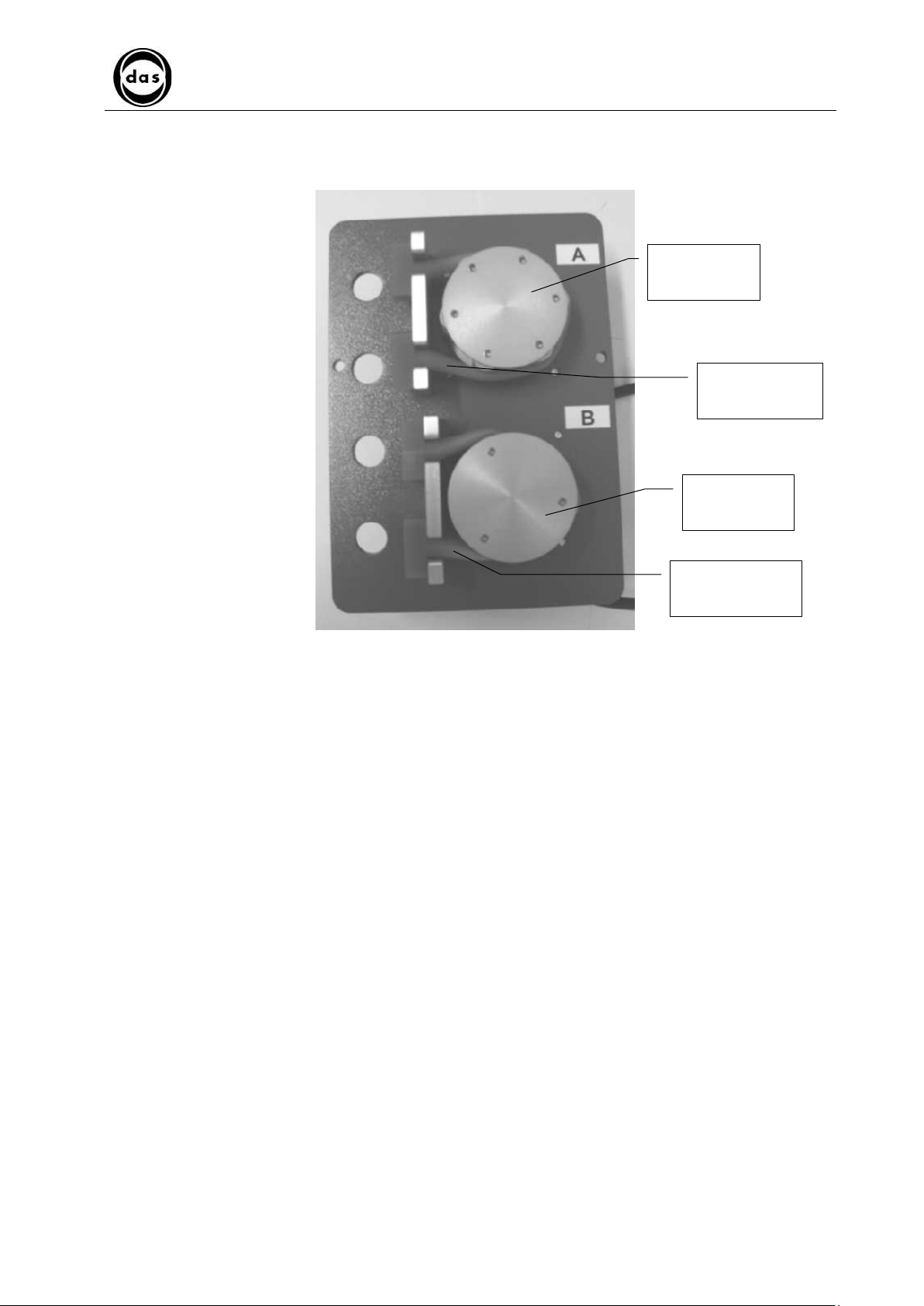

Peristaltic

pump A

Page 26

Peristaltic pump

tubing

Peristaltic

pump B

Peristaltic pump

tubing

The pump unit is made up of 2 peristaltic pumps composed of:

- rotating wheel

- stand

- peristaltic pump tubing

- step motor

Note:

• Pump A washes dispensation probe internally and externally and regulates WASH liquid flow during STRIP

WASH phase.

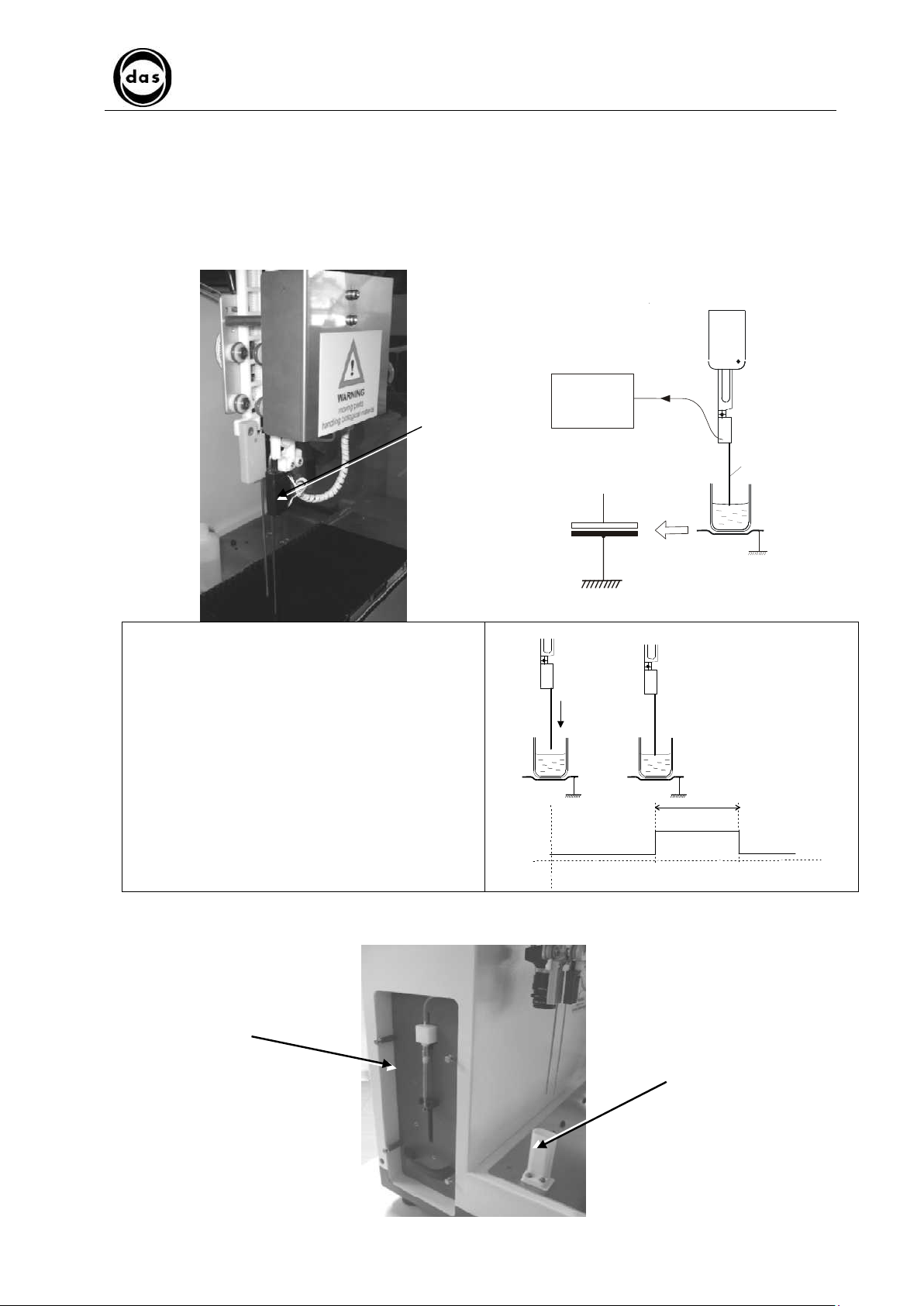

Page 27

Groud

Liquid level

Microprocessor

Impulse duration T

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.3.1.5. Probe

The probe has two functions:

• Liquid aspiration and dispensation

• Liquid sensor (for liquid level)

Aspiration and dispensation

The probe aspirates and dispenses controls, samples, etc.

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 27

Aspiration

Probe

Liquid Sensor

The probe is fitted with a liquid sensor which regulates

its movements near the liquid to be aspired.

This sensor reads the variations of the electrical capacity

of the circuit which consists of probe – liquid – ground.

The sensor circuit emits a low signal (level 0) until the

probe touches the liquid.

A high signal (level 1) is emitted to indicate when the

probe touches the liquid for duration ‘T’ in proportion to

the variation of the circuit capacity.

Adjusting probe sensitivity is based on the

duration/bandwidth of this impulse. (Below a certain

value this impulse is only considered noise and not valid

as a liquid surface signal).

sensor

Probe

3.3.1.6. Probe Wash Basin

The probe wash basin is used for external probe washing and to dispose of liquid excess.

Dilutor unit

Probe washing

basin

Page 28

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 28

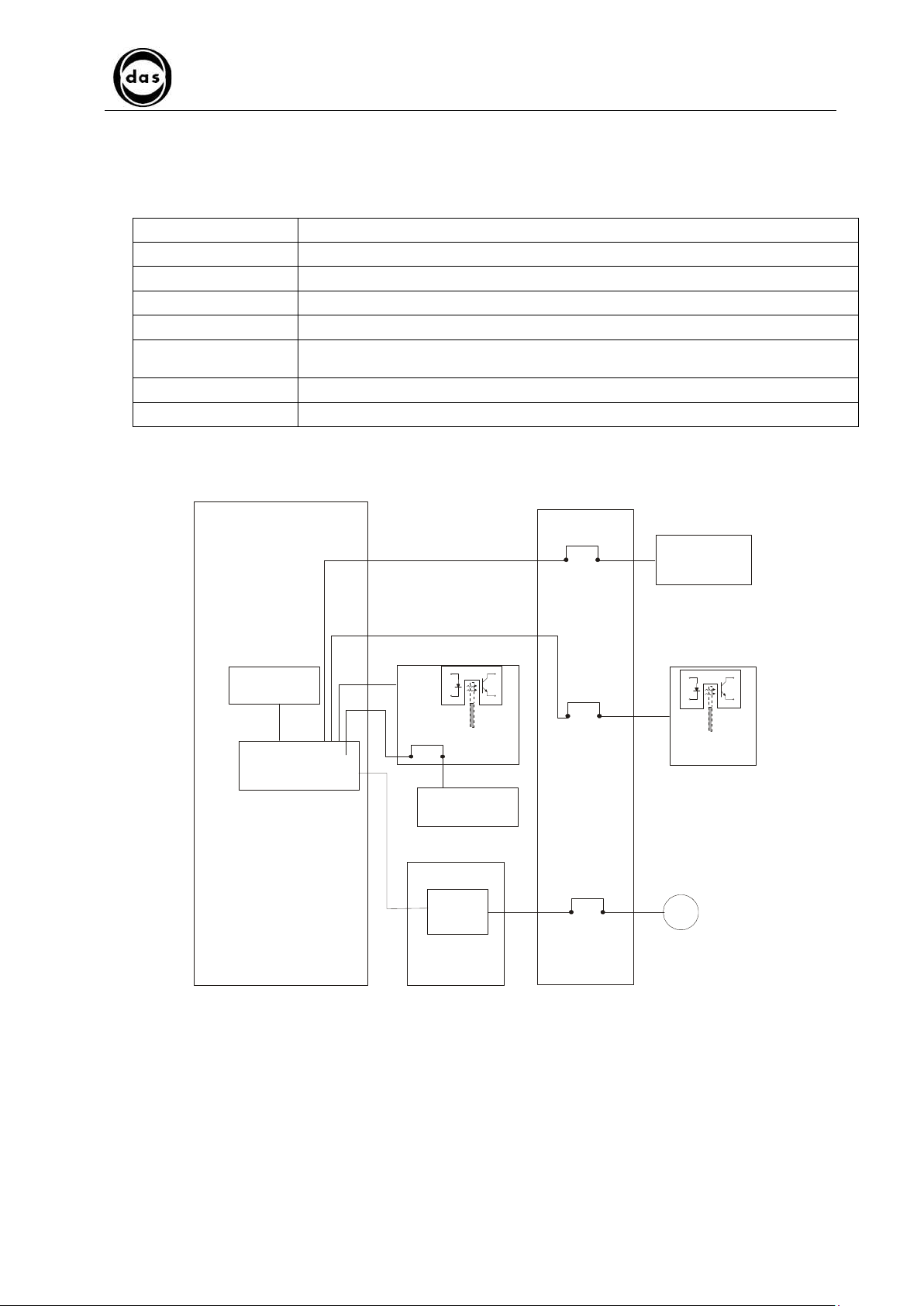

3.3.1.7. Dilutor Unit PCB Electrical Diagram

The table below describes each PCB and the various dilutor unit components they control and the diagram shows the

PCBs and the dilutor unit electrical circuit.

DILAP21 (Dilutor) PCB a micro-processor, a memory and electro-valve driver

SIR4MOT PCB syringe motor driver.

SIDILOP PCB optical sensor which senses when syringe has reached end line (“home”) position.

INTEROP2 PCB Support for liquid level sensor and cable distribution

INTERFA2 PCB Connects wire cables

Liquid Level Sensor Electronic circuit in a small container mounted on probe which signals contact with liquid surface

Syringe Motor A step motor which moves syringe plunger (with special “worm” screw inside the plastic nut).

Dilutor 2-way Electro-valve Manages washing solution aspiration or probe aspiration/dispensation.

(level)

Memory

Microprocessor

DILAP21 PCB

INTEROP2

PCB

Liquid Level

Sensor

Syringe

motor

driver

SIR4MOT

PCB

INTERFA2

PCB

2 way

electrovalve

SIDILOP

PCB

M

Syringe motor

Page 29

Dis pens ation probe

Aspir ation pr obe

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

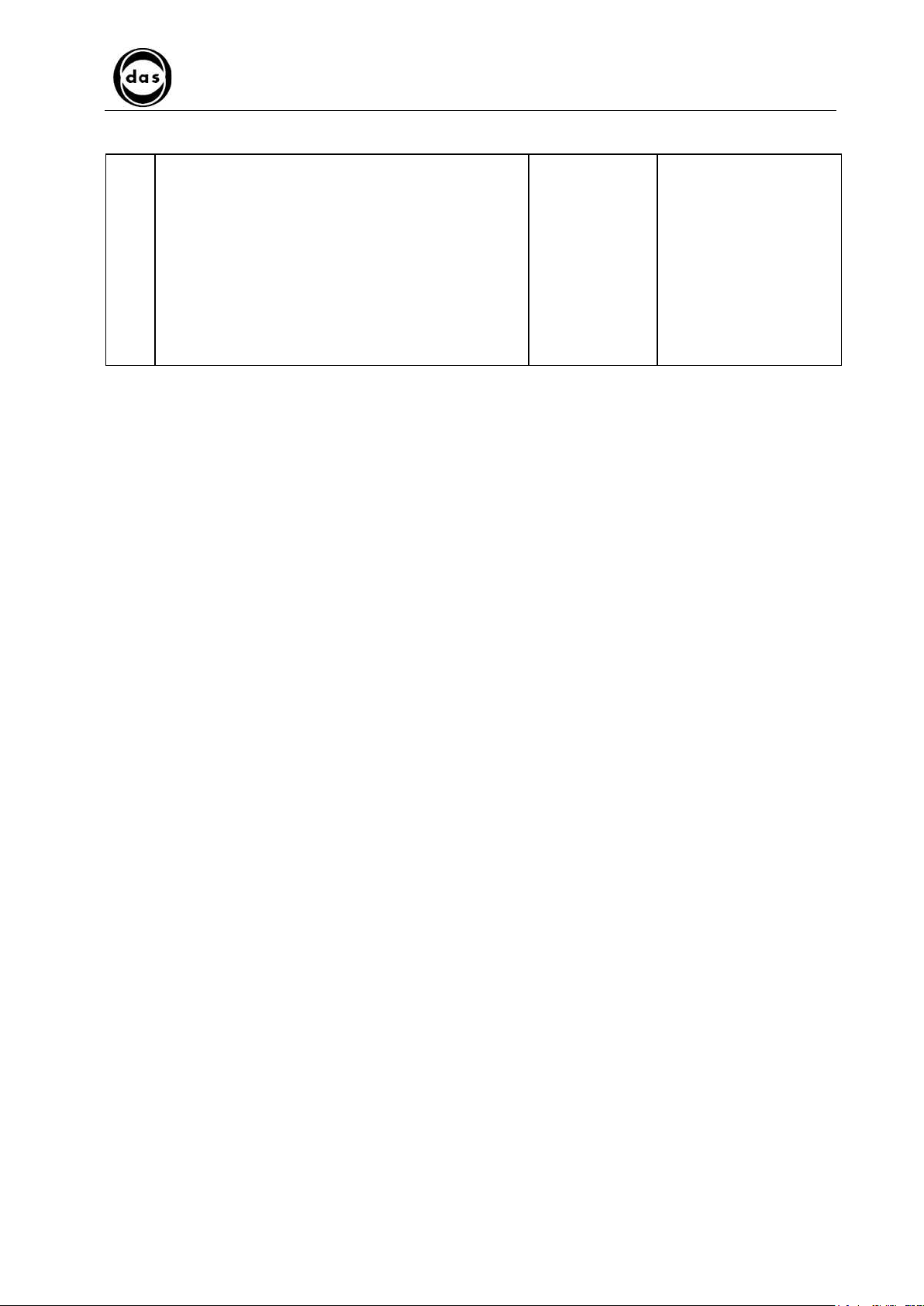

3.3.1.8. Dilutor unit hydraulic component diagram

The table below describes the different functions of the dilutor unit hydraulic components.

The diagram shows how the dilutor unit circuit is set up to work.

WASH bottle Contains probe-washing liquid, 5 litre capacity

Level Sensor Sensor for the three different bottles and connecting cables and connectors

Probe washing pump Peristaltic pump A for washing probe, internally and externally, driven by step motor

Probe wash basin For external probe wash and draining any excess liquid

Syringe For aspirating and dispensing liquid through probe

Page 29

3 way

Electro valve

Syringe

Needle washing basin

3 way E lectrovalve

Peristaltic P um p A

Peristaltic P ump B

WA SH

WA SH BU FFE R

WA STE

WA STE bottle

WA SH BU FFE R

bottle

WA SH bottle

Page 30

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.3.2. REGULAR DILUTOR UNIT MAINTENANCE

Visually check the following components:

− Tubing connecting Valve – Probe.

− Syringe plunger

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 30

1

3.3.2.1. Visual checks

• Tubing connecting Valve – Probe:

Check that there is no narrowing or kinks or obstructions on any of this tubing.

If these faults are found the tubing can be substituted as described in para. 3.3.3.1.

• Syringe plunger:

Check that the syringe plunger and tip are in good condition (they should be clean and without any liquid dripping

from syringe bottom).

If condition is unsatisfactory, substitute plunger following procedure described in para. 4.8.5.

• Syringe:

Check that syringe glass is in good condition. If any damage can be seen then substitute syringe following procedure

described in paragraph 4.8.5.

• Peristaltic pump tubing:

Check that tubing is in good condition and more specifically check that there are no traces of rubber around pump

area. If condition or area is unsatisfactory change this rubber tubing as described in para. 3.3.3.5.

• Shaking plane:

Check that shaking movement is smooth, with no obstructions or hesitations. If movement is unsatisfactory check

shaking mechanism as described in Para. 3.6.1.1.

• Camera Calibration strip:

Check that camera calibration strip is clean and intact. If condition is unsatisfactory, clean off strip with a clean cloth

and/or substitute strip.

• Camera:

Check that electrical cable is correctly plugged in

− Syringe

Every 4 months Ref. para. 3.3.2.1.

− Peristaltic Pump tubing

− Shaking plane

− Calibration Strip

− Camera

Page 31

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.3.3. SUBSTITUTING DILUTOR UNIT COMPONENTS

To substitute syringe and syringe plunger refer to para. 4.8.5.

The following table lists procedures and paragraphs relevant to these substitutions.

Substituting valve – syringe – dispensation probe tubing Ref. para. 3.3.3.1

Substituting valve mechanism Ref. para. 3.3.3.2

Substituting 3-way Electro valve Ref. para. 3.3.3.3

Substituting 3-way valve mechanism Ref. para. 3.3.3.4

Substituting Peristaltic Pump Tubing Ref. para. 3.3.3.5

Substituting Dilutor Motor Ref. para. 3.3.3.6

Substituting Opto SIDILOP PCB Ref. para. 3.3.3.7

Substituting INTERFA2 PCB Ref. para. 3.3.3.8

Substituting probe wash basin Ref. para. 3.3.3.9

Page 31

3.3.3.1. Substituting valve – syringe – dispensation probe tubing

a) Disconnect AWG15 tubing from probe

AWG15

tubing

b) The old tubing (to be replaced) should be used as a guide or ‘driver’/track

c) Join the ends of the old and new tubing together with adhesive tape.

d) Slowly pull old tubing.

e) Separate new tubing from the original “driver” tubing and join the new tubing to the valve unit joint and probe.

Page 32

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 32

3.3.3.2. Substituting valve mechanism

a) Turn on instrument. Run XCalib Program (See Section 4). From “Dilutor” pulldown menu select “Calibrate

syringe” and follow instructions.

b) Click on “Remove syringe” to fully open syringe plunger.

c) Turn off machine

d) Remove AWG 15 tubing from valve joint

e) Unscrew syringe from valve mechanism in an anti-clockwise direction and extract it

f) Remove tubing joined to valve mechanism

g) Remove valve connector by undoing fixing screw

Hexagonal head

Connector/

Electro-valve

fixing screw

Valve mechanism

tubing join

h) Remove valve mechanism by undoing 2 fixing nuts

i) Insert new valve mechanism and re-block it with 2 fixing nuts.

j) Replace valve and connector

k) Replace hydraulic connections

l) Replace syringe in movement shaft and screw it back into valve mechanism in a clockwise direction.

m) Turn on instrument again and run a prime to rinse hydraulic circuit

3.3.3.3. Substituting 3-way Electro valve

Note: to replace electro valve follow procedure described in para. 3.11.2.1.

3.3.3.4. Substituting 3-way valve mechanism

Note: to replace valve mechanism follow procedure described in para.3.11.2.1.

Page 33

B

A

3.3.3.5. Substituting Peristaltic Pump Tubing

a) Turn on instrument. Run XCalib program. From “Dilutor” menu select “Prime”

b) Detach wash loading and buffer tubing from their bottles

c) Set prime for at least 60 seconds to empty hydraulic circuit. Select ‘Prime’

d) After this prime rinse, detach tubing and then slip tubing off pumps.

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Peristaltic pump tubing

White / Black

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 33

Blue / White

e) Place new peristaltic tubing into position and re-connect it up following the diagram sticker on device.

f) Reconnect both Wash loading and Buffer tubing to their respective bottles.

g) Run another prime by selecting “Prime” option to rinse hydraulic circuits again

Page 34

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.3.3.6. Substituting Dilutor Motor

a) Remove AWG15 tubing.

b) Remove 4 screws from dilutor unit stand.

c) Remove connector that joins dilutor motor to INTERFA2 PCB

d) Loosen two grub screws that block motor axis mechanism .

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 34

two grub screws

e) Remove the motor by loosening the 4 fixing screws

4 syringe motor

fixing screws

f) Re-position new motor and block it in position with 4 motor fixing screws and tighten grub screws that were

previously loosened (in step ‘d’)

g) Restore motor and INTERFA2 – PCB connections.

Page 35

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.3.3.7. Substituting Opto SIDILOP PCB

a) Remove AWG15 tubing.

b) Remove 4 screws from dilutor panel.

c) Remove connector between SIDILOP PCB and INTERFA2 PCB.

d) Unscrew fixing screws.

e) Re-position new PCB and attach it with fixing screws

f) Re-connect new SIDILOP and INTERFA2 PCB.

3.3.3.8. Substituting INTERFA2 PCB

a) Remove AWG15 tubing.

b) Remove 4 screws from dilutor panel.

c) Remove connectors from INTERFA2 PCB and two screws attaching it to the plate.

d) Substitute PCB and re-attach it with the 2 screws; follow numbering to re-position connectors correctly.

e) Replace dilutor unit in position.

3.3.3.9. Substituting probe wash basin

a) Unscrew probe wash basin from work area.

Page 35

b) Lift up basin and disconnect Waste (“OUT”) tubing

c) Substitute probe wash basin

d) Reconnect “OUT” tubing to probe wash basin .

e) Replace basin on work area with screws removed previously and proceed to centering procedure for probe 1 as

described in para. 4.8.1

Page 36

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.4. X–Y AXIS

3.4.1. DESCRIPTION OF HOW IT WORKS

3.4.1.1. X – Y axis movement mechanism

FUNCTION:

The X – Y axis movement mechanism moves probe arm precisely over work area.

Page 36

The X axis movement mechanism moves the X axis carriage (1). The Y axis is fastened on the carriage (2). The

movement is generated by a motor (3) and a pulley (4), a serrated belt (5) and an idle wheel (6). The XGOLAV

opto PCB is mounted on the X axis carriage (1). The encoder (7) controls the position along X-axis through

encoder slits.

3

5

4

7

The Y axis mechanism moves carriage along Y Axis (1) on which the Z1 and Z2 axis are fixed. The movement is

generated by step motor (2) with a serrated belt (3) and an idle wheel (4). The INTEROP2 PCB (5) is mounted on

the Y Axis carriage (1). The encoder (6) controls the position along Y-axis through the encoder slits.

4

1

6

1-2

2

6

5

Page 37

X axis motor

Y axis motor

3.4.1.2. X- Y axis Electrical Functions Diagram

The table below describes the electrical components of each PCB which effects the movement of the X-Y axis.

The arrangement is shown in the diagram.

DILAP21 PCB Microprocessor and memory.

SIR4MOT PCB Controls X - Y axis.

XGOLAV “X” PCB Controls opto with which the encoder controls axis position.

INTEROP2 ”Y” PCB

Opto couplers

INTERFA1 PCB Connectors for wiring.

INTERFA2 PCB Connectors for wiring.

AP22MOT PCB Connectors for wiring.

X axis motor Step motor

Y axis motor Step motor

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

The Opto couplers, together with the selectors, control:

1) Y probe position

2) Z1 and Z2 probes position

3) ZZ probe position

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 37

INTEROP2 “Y”

PCB

Memory

M

INTERFA2

PCB

XGOLAV “X”

Microprocessor

PCB

X axis

motor

driver

M

Y axis

motor

driver

DILAP21 PCB

SIR4MOT

PCB

PCB

INTERFA1

AP22MOT

PCB

Page 38

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 38

3.4.2. REGULAR MAINTENANCE FOR X–Y AXIS

Cleaning X-Y axis tracks Every 6 months Ref. para. 3.4.2.1

Check belt tension Every 6 months Ref. para. 3.4.2.2

Check condition of flat cables Every 6 months Ref. para. 3.4.2.3

3.4.2.1. Cleaning X-Y axis tracks

a) Use a sponge/clean cloth to wipe dust off and clean up any other dirty residue.

b) Uniformly spread the grease along the tracks with the same slightly damp sponge/cloth.

3.4.2.2. Check belt tension

a) If there is an excessive vibration when X and Y axis moves, then adjust the tension of the belts (Ref. Para.

3.4.3.1.).

b) If X and Y axis block during their movement check that belts are not too tight (Ref. Para. 3.4.3.1.).

3.4.2.3. Check condition of flat cables

a) Check that flat cables are not touching any metal parts.

b) Check that cables maintain their original folds.

3.4.3. CALIBRATING X–Y AXIS SETTINGS

To center X-Y-axis refer to para. 4.8.1.

The following table lists the relevant paragraphs describing the different possible calibrations

Errore. L'origine riferimento non è stata trovata.

Every 6 months Ref. para. 4.8.1.2

X and Y axis belt tension Every 6 months Ref. para. 3.4.3.1

3.4.3.1. X and Y axis belt tension

a) Regulate X axis belt tension by turning idle wheel.

b) Regulate Y axis belt tension by loosening the fixing screws from the Y axis motor, move the motor along in the Y

direction until the belt has reached the correct tension

c) Once the correct tension has been achieved, tighten the fixing screws.

X-Axis idle wheel

Y-Axis motor

Page 39

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.4.4. Substituting X–Y AXIS PARTS

Substituting X-axis Movement Motor Ref. para. 3.4.4.1

Substituting Y-axis Movement Probe motor Ref. para. 3.4.4.2

Substituting Opto XGOLAV (X-axis movement) Ref. para. 3.4.4.3

Substituting X-axis movement belt Ref. para. 3.4.4.4

Substituting Flat Cables Ref. para. 3.4.4.5

Substituting X-Y axis movement flat cables Ref. para. 3.4.4.6

Substituting INTEROP2 PCB (Y-axis movement) Ref. para. 3.4.4.7

3.4.4.1. Substituting X-axis Movement Motor

a) Remove protective cover from device by loosening the screws on top.

b) Remove motor connector from INTERFA2 PCB.

c) Loosen 2 dowels on wheel which sustains the belt.

Page 39

2 dowels

d) Remove motor by loosening 4 fixing screws.

4 fixing

screws.

e) Position new motor, and secure it by tightening the 2 dowels.

f) Reconnect connector to INTERFA2 PCB.

g) Replace cover.

Page 40

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.4.4.2. Substituting Y-axis Movement Probe Motor

a) Remove top cover by undoing screws on top of device.

b) Remove connector which joins motor to AP22MOT PCB

c) Remove motor after loosening 4 fixing screws.

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

4 fixing

screws

Page 40

d) Place new motor in position and fix in place with 4 screws.

e) Check belt tension.

f) Reconnect motor to AP22MOT PCB with connector

3.4.4.3. Substituting Opto XGOLAV (X-axis movement) PCB

a) Remove top cover after undoing screws on top.

b) Remove connector attached to XGOLAV PCB.

c) To substitute it unscrew PCB from plate.

XGOLAV

PCB

2 fixing

screws

d) Place new PCB in position and screw it to the plate with two fixing screws

e) Re-insert connector onto PCB.

f) Check centering of X axis (see para. 4.8)

g) Replace top cover.

Page 41

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.4.4.4. Substituting X-axis movement belt

a) Remove screws fixing instrument cover to remove cover.

b) Loosen 3 grub screws fixing both ends of belt.

c) Replace belt and then tighten 3 grub screws which fixed the 2 ends of belt.

d) Check that belt is correctly tightened.

e) Remount cover

3.4.4.5. Substituting Flat Cables

a) The flat cables are held in position by plastic cable holder bands.

cable holder

bands

Page 41

b) Remove PCB connectors 6

c) Remove cable holder bands and gently pull out flat cable.

d) Insert new flat cable and replace all previous cable holder bands.

e) Carefully re-insert connectors in correct positions.

3.4.4.6. Substituting X-Y axis movement flat cables

a) Remove device top cover after undoing top screws

b) Remove connectors between Y axis motor and AP22MOT PCB

c) Remove all plastic cable holder bands.

d) Remove cable blocking plates PIASTRINE CHE BLOCCANO I CAVI DI MOVIMENTO

e) Dismount INTERFA1 PCB from base of frame

f) Remove black blocking plate and then undo 2 fixing screws from AP22MOT PCB

g) After removing all remaining protection - replace chain with AP22MOT and INTERFA1 PCBs on each end

h) Remount new cable with PCBs and reposition all cable holder bands

i) Remount cover

AP22MOT PCB

X-Y-axis

movement flat

Cable blocking

Plate

INTERFA1 PCB

Cable blocking

Plate

Page 42

3.4.4.7. Substituting INTEROP2 PCB (Y-axis movement)

a) Undo fixing screws to remove device top cover

b) Detach connectors from INTEROP2 PCB and remove 4 fixing screws.

2 fixing screws

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 42

2 fixing screws

c) Reposition new PCB and secure it with 4 fixing screws.

d) Reinsert connectors.

e) Check Y-axis centering

f) Check Z maximum value.

g) Reposition cover and screw back screws

Page 43

Asse Z

2

1

2

3

4

4

1

2

3

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 43

3.5. Z1 - Z2 AXIS

3.5.1. DESCRIPTION OF HOW IT WORKS

3.5.1.1. Z1 - Z2 axis movement mechanism

FUNCTION OF Z1 AXIS (dispensation)

Z1 Axis moves the dispensation probe up and down over the instrument work area. This movement is driven by a step

motor (1) with a pinion mounted on its shaft (2) that transmits the movement to the carriage (3).

The optical sensor, by means of the carriage encoder (4), detects the probe End line (“home”) position.

FUNCTION OF Z2 AXIS (aspiration)

Z2 Axis moves the aspiration probe up and down over work area.

The movement is driven by a step motor (1) with a pinion mounted on its shaft (2) that transmits the movement to the

carriage (3).

The optical sensor, by means of the carriage encoder (4) detects probe home position.

The camera is mounted on back plate and is used to acquire images.

Asse Z

1

Page 44

DILAP21 PCB

INTEROP2 PCB

Microprocessor

M

Z2 Axis motor

M

Z1 Axis motor

3.5.1.2. Z axis electrical circuit diagram

The diagram shows the different electronic functions with the relevant PCBs for the Z axis, followed by a brief

description and the following table lists the various PCBs and their components.

DILAP21 PCB Contains the microprocessor, memory and Z-axis motor drivers

INTEROP2 PCB Contains optical sensor to detect probe end line run (“home”) position.

Z1 – Z2 axis motor Step motor which moves Z1 – Z2 axis probes

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 44

Liquid

Memory

sensors

Z

Axis

1

motor

driver

Z Axis

2

motor

driver

Page 45

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 45

3.5.2. REGULAR Z AXIS MAINTENANCE

3.5.2.1. Z2 axis movement control

a) Turn on device and run XCalib programme. From “Dilutor” pulldown menu select “Calibrate height” then select a

strip holder plate and select probe 1, Select “Go down” option

b) Check that movements are smooth and linear

c) Repeat movement control also on probe 2.

d) If movements are not smooth or/and linear check pinion or carriage and replace parts if necessary

e) If any parts are substituted verify movements as in point (b)

3.5.3. Z-AXIS CALIBRATION

To calibrate Z-axis refer to para. 4.8.

The following table lists the relevant paragraphs describing different possible calibrations

Calibrate probe height Para. 4.8.2

Calibrate LT Para. 4.8.3

Calibrate SUL Para. 4.8.6

Page 46

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.5.4. SUBSTITUTING Z1 and Z2 AXIS PARTS

Substituting Z1 Axis probe Para. 3.5.4.1

Substituting Z1 Axis probe motor Para. 3.5.4.2

Substituting Z2 Axis probe Para. 3.5.4.3

Substituting Z2 Axis probe motor Para. 3.5.4.4

3.5.4.1. Substituting Z1 Axis probe

a) Remove instrument cover

b) Remove protective carter by unscrewing two fixing screws

Page 46

2 fixing

screws

c) Detach AWG15 tubing from Probe

d) Remove liquid sensor cable connector from INTEROP2 PCB

e) Remove screw that fixes probe to stand

fixing screw

f) Replace probe with new probe and tighten fixing screw

g) Reconnect probe and liquid sensor connector (NON CE SU VERSIONE ITaliana) to INTEROP2 PCB and

reposition AWG15 tubing to Probe

h) Check Z axis settings: Z steps and LT parameter

i) Check X-Y centering

Page 47

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.5.4.2. Substituting Z1 Axis probe motor

a) Remove instrument cover

b) Remove Z1 axis protective carter by unscrewing two fixing screws

c) Remove motor connector from INTEROP2 PCB and remove cable holder bands

Motor fixing

screws

Page 47

d) Remove motor fixing screws

e) Replace motor and all connections between PCB and motor, re-position cable holder bands

f) Check that Z axis movements are smooth

g) Check Z1 axis steps

h) Check X-Y axis centering.

3.5.4.3. Substituting Z2 Axis probe

a) Remove silicon tubing connected to probe

b) Unscrew probe fixing screw

c) Replace probe and tighten fixing screw

d) Check centering of dispensation probe

e) Check distance between probes in home position (HH command with DIL PCB) is about 1 mm. If distance is

incorrect, remove instrument cover and adjust encoder on INTEROP2 PCB until probes are 1 mm distance

apart.

f) Check Z axis step setting .

Page 48

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.5.4.4. Substituting Z2 Axis probe motor

a) Remove Z1 protective carter after undoing two fixing screws

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 48

2 fixing

screws

b) Remove motor connector from INTEROP2 PCB and remove cable holder bands

c) Remove fixing screws and change motor

Motor fixing

screws

d) Reconnect motor to PCB and replace cable holder bands

e) Check that Z2 axis movement is smooth.

f) Check Z1 movements and steps.

g) Check X-Y centering as described in para. 3.4.3.1.

Page 49

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 49

3.6. SHAKING PLANE

3.6.1. DESCRIPTION OF HOW IT WORKS

3.6.1.1. Shaking plane movement mechanism

The shaking plane moves (shakes) the slides with the strips to be processed. The slides are placed on the ‘hinged’

shaking plane (1) and the movement is driven by a worm screw (2) on a ball-bearing (3) which moves along a wedge

(4) mounted under the shaking plane. The ball-bearing moves back and forth on the wedge generating the up and

down movement of the plane.

The minimum and maximum shaking excursion is controlled by 3 opto positioning sensors (5).

1

4

2

2 3

Page 50

M

Oscillating

(Flat position)

3.6.1.2. Shaking plane circuit diagram

The table lists the PCBs and the electrical components that move the Shaking plane.

This is followed by a diagram of the mechanism.

APE-IF-DIL-AP21 PCB Z1 and Z2 axis motor drivers

OP-SWING PCB Shaking plane optical sensors that control movement

Shaking plane Motor Step Motor that moves worm screw and ball bearing for shaking plane movement

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 50

Down

Home

Up

OP-SWING PCB

Shaking

plane

motor

driver

plane

motor

INTERFA7 PCB

DILAP21 PCB

Page 51

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.6.2. MAINTENANCE AND SHAKING PLANE CALIBRATION

For calibration and maintenance of shaking plane refer to para. 4.8.4.

The following table lists the calibration procedures described in the relevant paragraphs.

3.6.3. SUBSTITUTING SHAKING PLANE COMPONENTS

Substituting Shaking Plane Motor Para. 3.6.3.1

Substituting opto PCBs Para. 3.6.3.2

3.6.3.1. Substituting Shaking Plane Motor

a) Remove aluminium work area as described in Para. 3.1.

b) Estrarre il piano di lavoro in alluminio

c) Loosen two nuts blocking motor axis.

Page 51

two nuts blocking

motor axis

d) Undo 4 fixing screws to remove motor

e) Position new motor, replace and tighten 4 fixing screws and nuts

f) Replace aluminium work area.

g) Proceed with calibrating shaking plane para 4.8.4.

4 fixing screws

Page 52

Connector

Fixing screws

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.6.3.2. Substituting opto PCBs

a) Remove work area as described in Para. 3.2.1.

b) Detach connector from Opto PCB to be substituted

c) Remove fixing screws to undo PCB

d) Reposition new PCB check that the Opto is not touching the encoder and replace the connector

e) Reposition work area

f) Calibrate shaking plane

Page 52

Page 53

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 53

3.7. CAMERA

3.7.1. DESCRIPTION OF HOW IT WORKS

The camera is used to acquire digital images of each single strip. These images are then automatically elaborated

by the software and each single blot is analysed.

The camera is mounted on a stand (1) next to the probe unit.

The Optical Unit is made up of the camera (2) and lens (3).

The lens is screwed on the camera with a 5mm mount (4).

There are two rings with screw threads: one can be turned to focus (5) and the other (6) regulates the aperture.

For camera calibration see Para. 4.8.9

1

2

4

5

6

3

Page 54

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 54

3.7.2. CAMERA MAINTENANCE

Check USB cable connection Para. 3.7.2.1

Lens cleaning Para. 3.7.2.2

3.7.2.1. Checking USB cable connection

a) Check that USB cable is correctly connected to the camera. When cable is correctly connected then check

that the camera is communicating with PC

b) Turn on device. Run XCalib program . From “Dilutor” menu select “Calibrate Camera” and check that images of

the work area are correctly being visualised by the camera and displayed.

3.7.2.2. Cleaning lens

a) Clean lens with a soft cloth lightly dampened with alcohol.

3.7.3. CALIBRATE CAMERA

To calibrate camera refer to para. 4.8.9.

The table below lists the calibration procedures described in the relevant paragraphs.

3.7.4. SUBSTITUTING CAMERA AND/OR PARTS

Substituting camera Para. 3.7.4.1

Substituting camera lens Para. 3.7.4.2

Substituting camera USB cable Para. 3.7.4.3

Substituting LED light bar Para. 3.7.4.4

3.7.4.1. Substituting camera

a) Turn off instrument

b) Manually move the Z axis unit out of the way to ensure free access to camera

c) Detach USB cable from camera

d) Remove 3 hexagonal screws that hold camera to stand

e) Unscrew lens in clock-wise direction and remove it

f) Screw lens to new camera and reposition it on the stand and fix it with the 3 hexagonal screws.

g) Insert USB cable

h) Calibrate new camera as described in Para. 4.8.9

Page 55

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

3.7.4.2. Substituting camera lens

a) Turn off device

b) Manually move Z-axis unit out of the way to ensure free access to lens

c) Detach USB cable from camera

d) Remove 3 hexagonal head screws fixing camera to stand

e) Unscrew lens in clockwise direction then remove it

f) Screw in a new lens onto camera and block it to the stand with the 3 hexagonal head screws

g) Insert USB cable

h) Calibrate camera as described in Para. 4.8.9.

3.7.4.3. Substituting camera USB cable

a) Turn off device.

b) Undo fixing screws above cover and then remove cover.

c) Open left flap

d) Detach camera USB cable

e) Carefully pull out cable from X and Y axis plastic box chain

f) Detach USB connector from the USB hub on the left flap

g) Pull out USB cable

h) Insert new cable by repeating above procedures in reverse (from point g to point a)

i) Calibrate camera as described in Para. 4.8.9.

j)

Page 55

3.7.4.4. Substituting LED light bar

a) Turn off device

b) Undo fixing screws to then remove cover.

c) Remove two plastic screws fixing LED light bar

d) Undo Panduit connection behind Y axis motor

e) Position new LED light bar

f) Reconnect all electrical connections

g) Replace cover

Page 56

1

2

2

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 56

3.8. OPTICAL SENSORS

3.8.1. DESCRIPTION OF HOW OPTICAL SENSORS FUNCTION

The optical sensors detect the position or movement of a mechanism and translates this information into an electrical

signal. The sensor consists of an infrared diode emitter and a photosensitive receiver, in a single container.

Sensor 1 is utilized for the zero position; Sensor 2 is utilized for detecting the position of the first well or first filter.

Opto couplers in plastic box

1

encoder slits

Encoder zero

position

1° well position

1 = Zero LED

2 = Signal LED

3.8.2. REGULAR MAINTENANCE

3.8.2.1. Cleaning opto

Clean opto sensors around every 6 months using a soft brush to remove any traces of dirt or dust.

3.8.2.2. Checking procedure

The various opto PCBs function in different units. The following table lists these different units, the PCBs and the

relevant paragraph to refer to for replacement procedures.

UNIT PCB Ref. procedure

Dilutor

X axis

Y axis

Z axis

SIDILOP Para. 3.3.3.7

XGOLAV (X movement) Para. 3.4.4.3

INTEROP2 Para. 3.4.4.7

INTEROP2 Para. 3.4.4.7

Page 57

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 57

3.8.3. CHECKING DISTANCE FOR OPTO COUPLERS (X AXIS)

a) Click on Tcom exe icon to open Tcom program

b) Select DIL PCB.

c) Type in HH to position probe in Home position.

d) TypeMX5

e) Type XKX.

f) First display should show Signal led=0 (uncovered opto) and zero led=1 (covered opto) - select X key until

these values change into signal led=1 and zero led=0.

g) Note how many steps are required until signal led=1 and zero led=1 (sequence A).

h) Continue selecting X key until both signals indicate a value of “1”.

i) Note how many steps are required until signal led=1 and zero led=1 (sequence B).

j) The difference in steps between sequence A and sequence B should not be more than 3 steps.

X AXIS TEST

hh

D=> gd1

D=> xkx Select X to repeat, other keys to exit

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 0

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 1 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

X: signal LED = 0 zero LED = 1

Sequenza “A ”

Sequenza “B ”

Page 58

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 58

3.8.4. CHECKING DISTANCE FOR OPTO COUPLERS (Y AXIS)

a) Click on Tcom exe icon to open Tcom program

b) Select DIL PCB.

c) Type in HH to position probe in Home position.

d) TypeMY5

e) Type XKY.

f) First display should show Signal led=0 (uncovered opto) and zero led=1 (covered opto) - select Y key until

these values change into signal led=1 and zero led=0.

g) Note how many steps are required until signal led=1 and zero led=1 (sequence A).

h) Continue selecting Y key until both signals indicate a value of “1”.

i) Note how many steps are required until signal led=1 and zero led=1 (sequence B).

j) The difference in steps between sequence A and sequence B should not be more than 3 steps.

Y AXIS TEST

hh

D=> gd1

D=> xky Select X to repeat, other keys to exit

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 0

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 1 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

Y: signal LED = 0 zero LED = 1

---------------------------------------------------

Sequenza “A”

Sequenza “B”

Page 59

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

3.9. USB COMMUNICATION

3.9.1. DESCRIPTION OF HOW IT WORKS

FUNCTION

The instrument and PC can communicate through a USB connection.

COMPOSITION

Doc. N° MDS-AP-26-00-02

Rev.01

Date: 02.04.2009

Page 59

DILAP21

PCB

USB

Personal

Computer

3.9.2. CHECK FUNCTIONALITY

a) Start TCom program and set up communication port - type “VE” to display Dilutor PCB firmware version

b) If access to Control Panel is not possible then follow the connection diagram as follows:

PCBs APE-IF-DIL-AP21 connector J15

c) If connection sequence is correct, then substitute the PCB which is not communicating properly

Page 60

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES