Page 1

Aero-48 MANUAL DEL USUARIO / USER’S GUIDE

Page 2

Precauciones de Seguridad Safety Precautions

El signo de exclamación dentro de un triángulo indica la existencia

de importantes instrucciones de operación y mantenimiento en la

documentación que acompaña al producto.

El doble cuadrado indica equipo de Clase 2. The double square indicates Class 2 device.

No exponga este equipo a lluvia o humedad. Do not expose this device to rain or moisture.

No emplace altavoces en proximidad a equipos sensibles a campos

magnéticos, tales como monitores de televisión o material

magnético de almacenamiento de datos.

No existen partes ajustables por el usuario en el interior de este

equipo.

The exclamation point inside an equilateral triangle is intended to

alert the users to the presence of important operating and

maintenance (servicing) instructions in the literature accompanying

the product.

Do not place loudspeakers in proximity to devices sensitive to

magnetic fields such as television monitors or data storage

magnetic material.

No user serviceable parts inside.

Page 3

1. SYSTEM DESCRIPTION

The D.A.S. Audio AERO series offers two

units for applications requiring precise control of the

vertical coverage andhigh sound pressure levels.The

AERO-48 is an externally powered, three-way, high

efficiency line arraymodule which integrates two 15”

low frequency units with 4” voice coils, four 8” midrange devices which utilize 2.5” voice coils and two

compression drivers with 3” coils and 1.5” exit

geometry ina singleunit. Thecompression drivers are

coupled to two Serpis high frequency plane wave

adaptors insuring coherent high frequency summing

and the generation of a flat, isophasic wave front.

When increased sound pressure level in the low

frequency range is required, the system can be used

inconjunction withthe AERO-218 subwooferunit.

SUB

The system is ideal for applications such as

large-scale outdoor/indoorevents inarenas, stadiums

or theaters. Use of the DSP-3VS digital processor is

recommended for the AERO-48 and the DS

the subwoofer system. Not usingthe

P-1Sub

for

DSP-3VSdigital

processor with the AERO-48 will adversely affect the

soundquality andmay damagesystem components.

The model AERO-48 includestwo 15GN 15”

cone transducer with 4” EFW voice coils and

Neodymium magnet assemblies in a bass-reflex

configuration.Four 8MN, 8”speakersarranged ona V

shape, incorporating 2.5” EFW voice coils,

Neodymium magnet assemblies and TAF cooling

system are used for mid-range reproduction. High

frequencies are handled by two M-10N high

frequency compression drivers with 3” EFW coil,

Neodymium magnet and 1.5” exit coupled to twin

SERPIS plane wave guide. The SERPIS plane wave

adaptor alsoserves asa heatsink for thecompression

driver.

The AERO-218 includes two 18GN 18”

SUB

cone transducers with 4” EFW voice coils and

Neodymium magnets. This cabinet is intended for

applications when extending the frequency range of

thesystem isrequired.

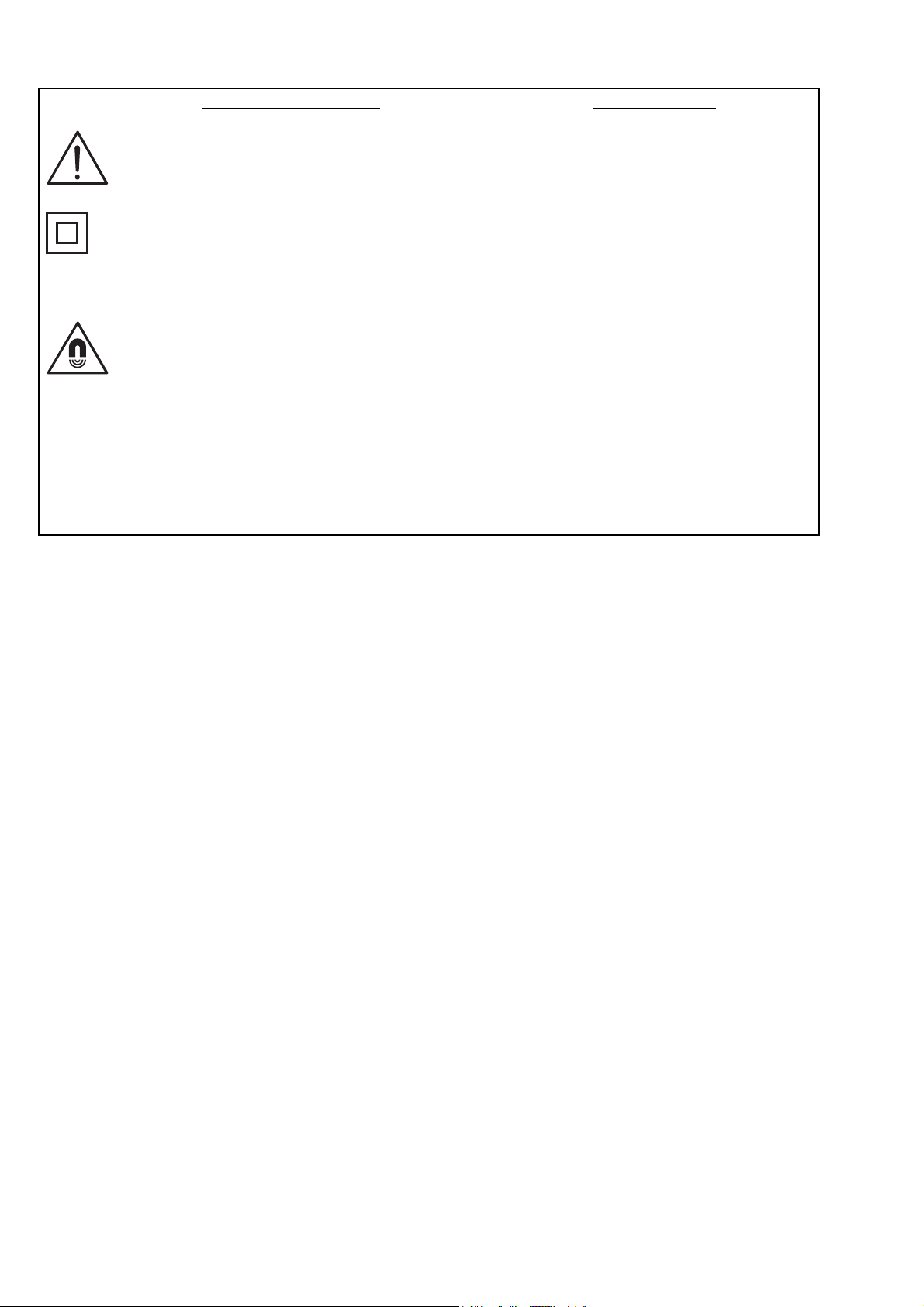

1400

WARNING!DONOTSUSPENDFROMTHISHANDLE

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

475

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

Both units are manufactured using 15/18

mm Finnish Birch plywood. The AERO-48 enclosure

shape istrapezoidal with5º angles.The AERO-218

SUB

enclosure is rectangular. The Aero-48 system

incorporates captive rigging hardware which is

compatible with one another and designed toprovide

a fast, simple and safe rigging by means of quick

release safetypins. Splayangles canbe changedfrom

0º to 3.2º in 0.8º increments and from 3.2º to 9.6º in

1.6ºincrements.

Tofacilitatetransport, theAERO-48 unitsare

equipped with a PL-48 front dolly panel attached by

means ofthe rigginghardware. The frontdolly panelis

useful when rigging systems. The PL-48S, a metal

dolly for vertically stacking 3 to 4 AERO-48 units is

available as an accessory. The AERO-218 units

SUB

canbe movedby wayof thefour rearlocated casters.

The loudspeakers used in the system

feature advanced technologies; new TAF (

cooling systems,Neodymium magnetic circuits

flow)

total air

which allowfor importantweight reductions, titanium

diaphragms for the high frequency sections,and lowmid frequency cones manufactured using crossed

fibers andelastic suspension thatprovide exceptional

stabilityin thevertical plane.

1010

823

595

AERO-48

ALL DIMENSIONS IN MILIMETERS

WARNING!DONOTSUSPENDFROMTHISHANDLE

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

224

236

36

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

680

36

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

256

220

AERO-218SUB

ALL DIMENSIONS IN MILIMETERS

Aero-48 Manual del usuario/ User´s manual 30

Page 4

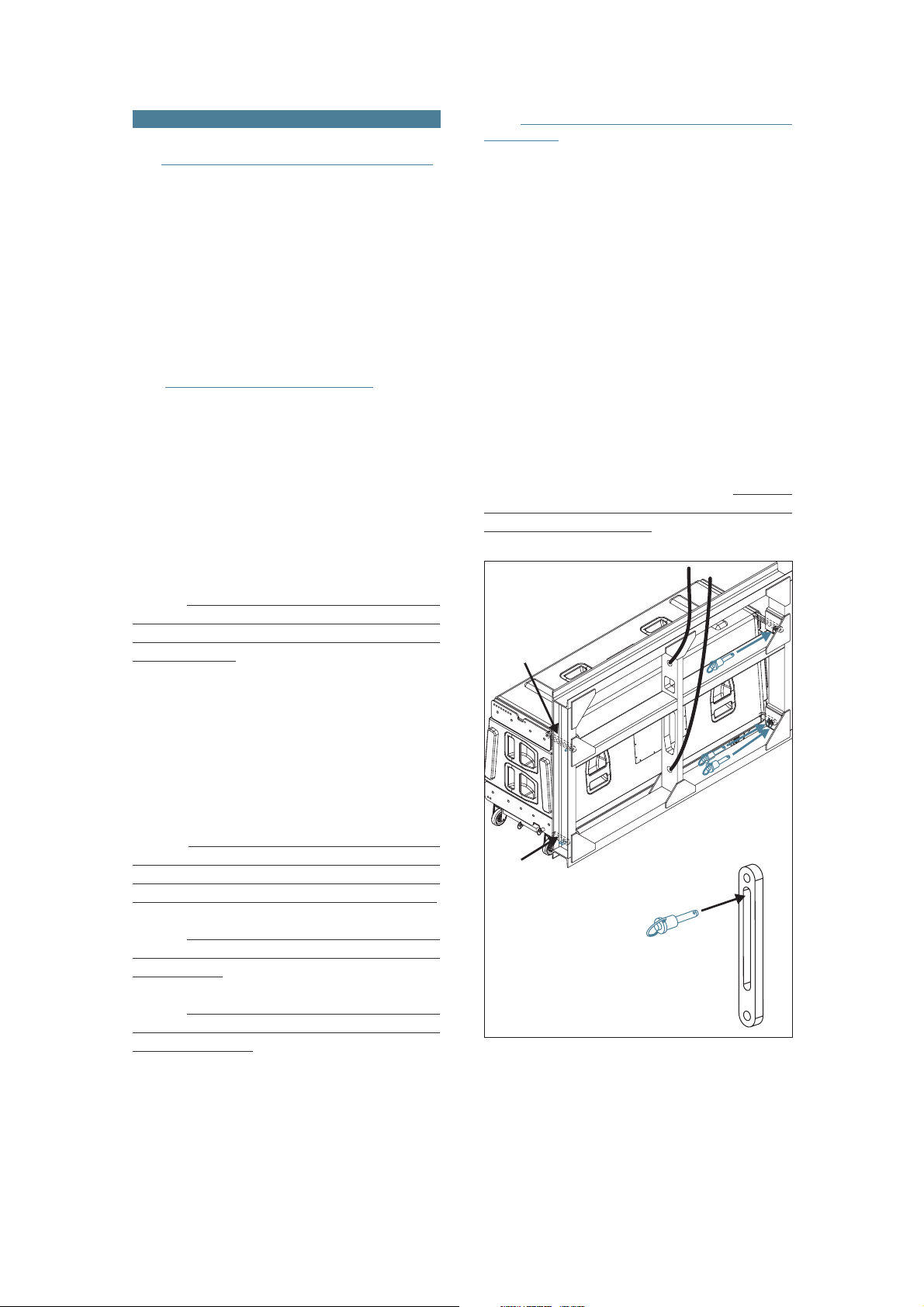

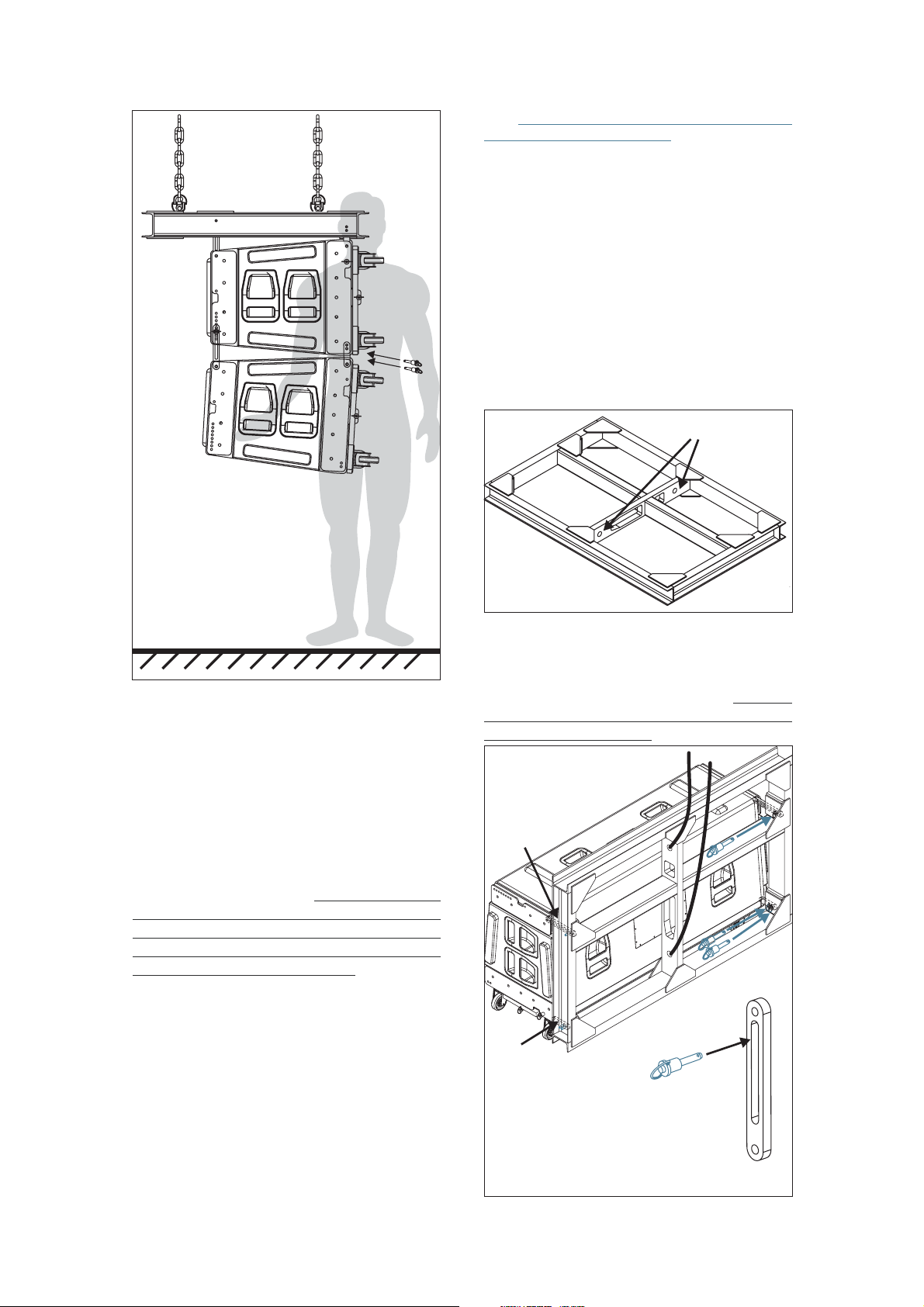

2. RIGGING SYSTEM

2.1WARNING

Thismanual containsneeded informationfor

flying DAS Audio line array systems, description of

the elements and safety precautions. To perform any

operations related to flying the system, read the

present document first, and act on the warnings and

advice given. The goal is to the allow the user to

become familiar with the mechanical elements

required to fly the acoustic system, as well as the

safety measures to be taken during set-up and

teardown.

Only experienced installers with adequate

knowledge of the equipment and local safety

regulations should fly speaker boxes. It is the user's

responsibility to ensure that the systems to be flown

(including flying accessories) comply with state and

localregulations.

The working load limits in this manual are

the results of tests by independent laboratories. It is

the user's responsibilityto stay within safe limits.It is

the user's responsibility to follow and comply with

safety factors, resistance values, periodical

supervisions and warnings given in this manual.

Product improvement by means of research and

development is ongoing at D.A.S. Specifications are

subjectto changewithout notice.

To this date, there is no international

standard regarding the flying of acoustic systems.

However, it is common practice to apply 5:1 safety

factors for enclosures and static elements. For slings

and elements exposed to material fatigue due to

friction andload variation the followingratios must be

met; 5:1 for steel cable slings, 4:1 for steel chain

slings and 7:1polyester slings. Thus, anelement with

a breaking load limit of 1000 kg may be statically

loaded with 200 kg (5:1 safety factor) and

dynamicallyloaded with142 Kg(7:1 safetyfactor).

When flying a system, the working load

must be lower than the resistance of each individual

flying point in the enclosure, as well as each box.

Hanging hardware should be regularly inspected and

suspect units replacedif in doubt. This isimportant to

avoid injury andabsolutely no risks shouldbe taken in

this respect. It is highly recommended that you

implement an inspection and maintenance program

on flyingelements, including reportsto be filledout by

the personnelthat willcarry out theinspections. Local

regulations may exist that, in case of accident, may

require you to present evidence of inspection reports

andcorrective actionsafter defectswere found.

Absolutely no risks should be taken with

regards to publicsafety. Whenflying enclosures from

ceiling support structures, extreme care should be

taken to assure the load bearing capabilities of the

structures so that the installation is absolutely safe.

Do not fly enclosures from unsafe structures. Consult

a certified professional if needed. All flying

accessories that are not supplied by DAS Audio are

theuser's responsibility.Use atyour ownrisk.

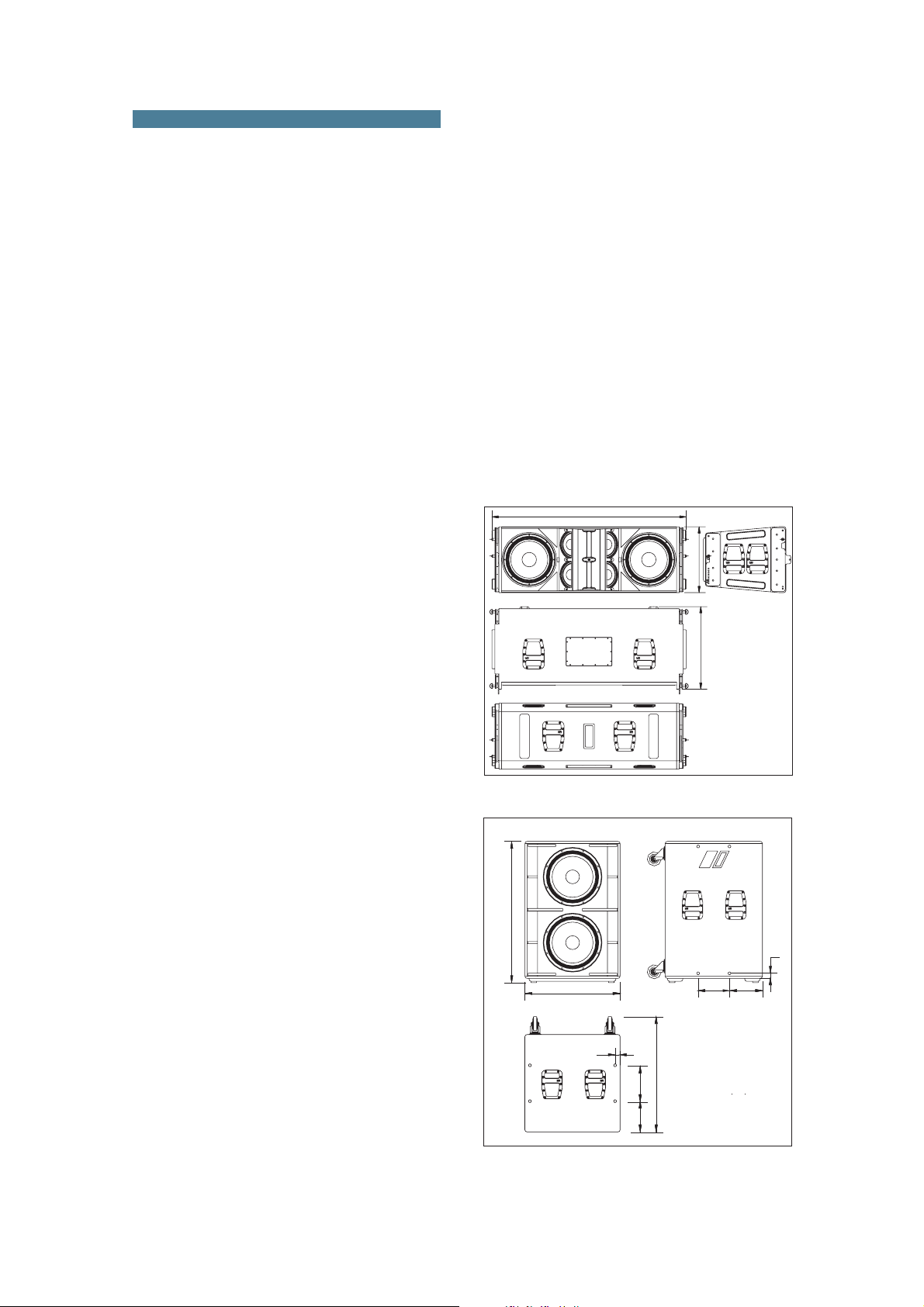

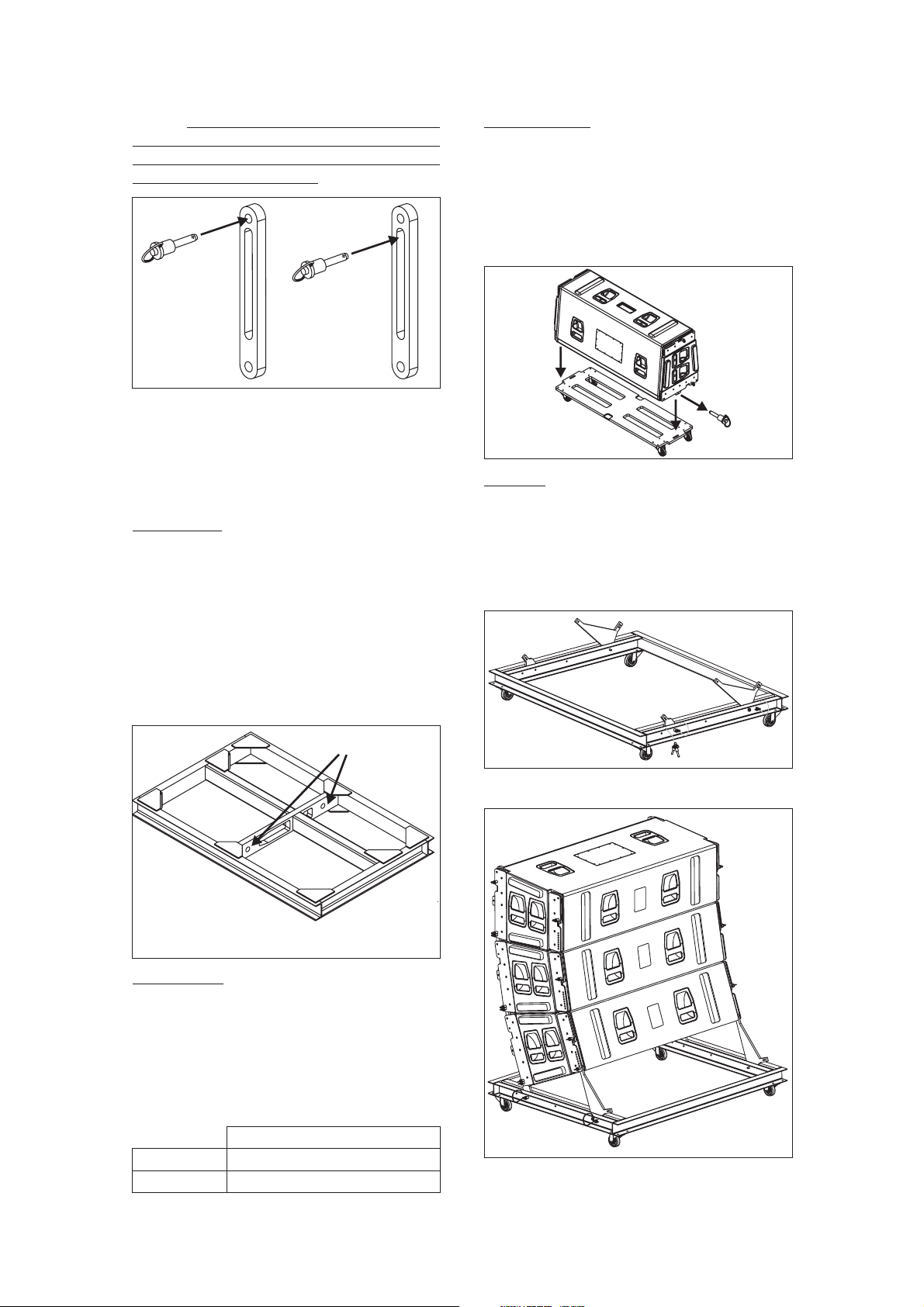

2.2 DESCRIPTION/ACCESSORIES

DAS Audio AERO-48 line array systems,

include 2 rigging structures on each side of the box.

Manufactured from zincplated steel they are painted

black and are affixed to aninternal plate with special

crop resistant screws. Two special stainless steel

guides are assembled to each of the structures:

G1A48(front guide)and G2A48(back guide),allow for

stacking or flying of boxes.

Splay angles can be

changed from 0º to 3.2º in 0.8º increments and from

3.2º to 9.6º in 1.6º increments.

To lock both guides,

six (6) quick release safety pins (supplied) must be

used.

The G1A48 front guide provides a solid

connection to the box and whatever is on top of it,

while the G2A48 rear guide determines the vertical

splay angle (whether stacked or flown), as a function

ofthe holewhere thepin getsinserted.

G2A48

QUICK RELEASE PIN 8X30

(6 UNITS PER CABINET)

G1A48

To aid the setting of the G2A48 guide in the

corresponding holein the topbox, eachhole is labeled

with an associated angle, both for stacked and flown

applications. To fit the guides into the holes, highly

resistant 8 mm quick release pins with a ball safety

lock areused.

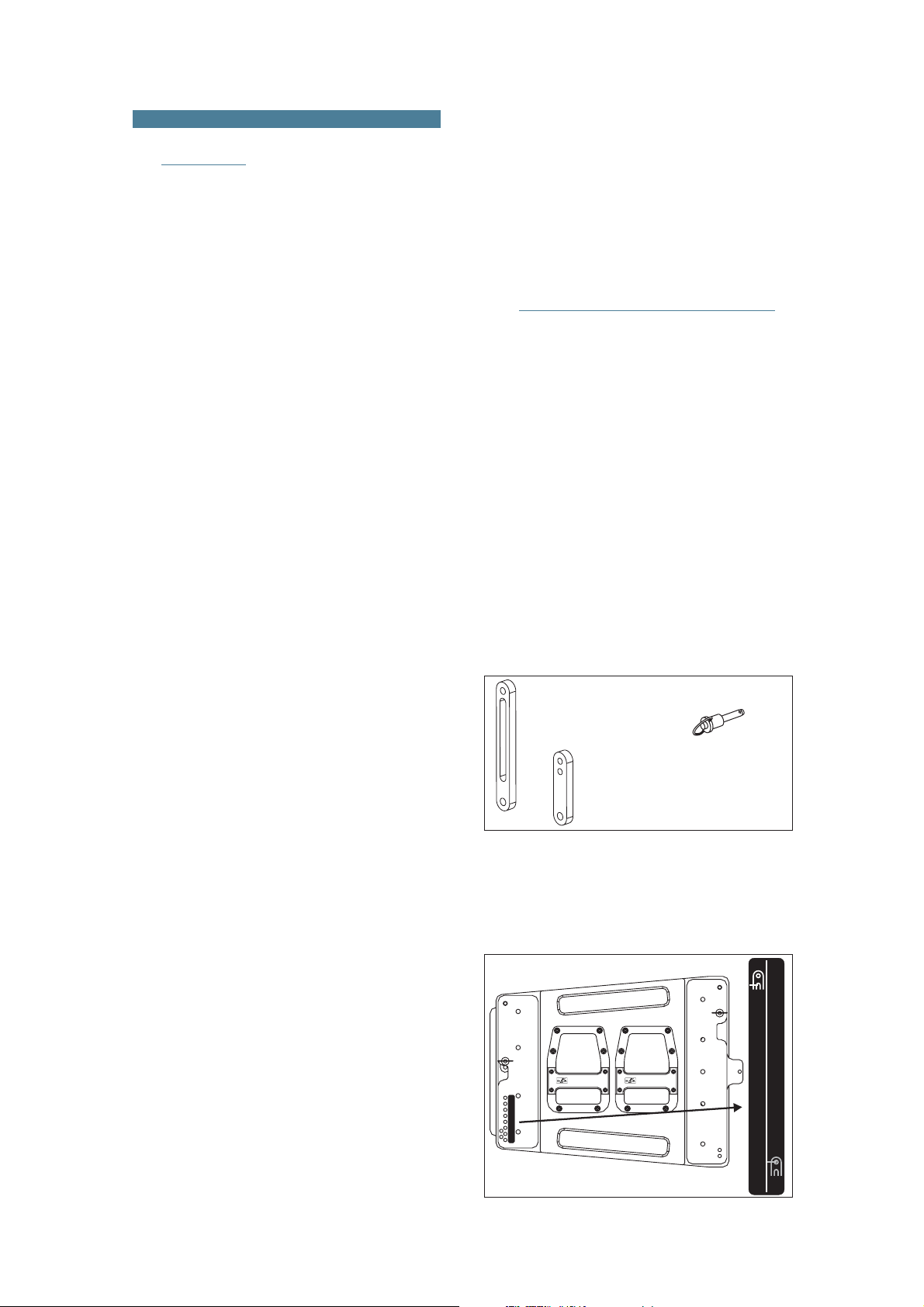

Fly

9.6º

8º9.6º

6.4º8º

4.8º6.4º

SOUNDPRODUCTS

WARNING!DONOT SUSPENDFROM THISHANDLE

®

¡ATENCIÓN!NOCUELGUE LACAJADE ESTEASA

SOUNDPRODUCTS

WARNING!DONOT SUSPENDFROM THISHANDLE

®

¡ATENCIÓN!NOCUELGUE LACAJADE ESTEASA

4.8º

3.2º

2.4º

1.6º

0.8º

3.2º

1.6º

0.8º

0º

0º

Stack

Aero-48 Manual del usuario/ User´s manual 31

Page 5

For flying boxes and defining the splay

angle, the pins must beinserted in the slot of guide 2,

G2A48, whereas for stacking ( ), the pin goes

throughthe tophole ofthe guide.

stacked

C) PlatformPL-48

The PL-48dolly panels facilitate transport of

the AERO-48 systems. They can also be used to

facilitate flyingthe systems.Each cover isattached to

the enclosure by using the flying hardware attached

to each box and is fixed with the quick release safety

pins.

STACK

All ofthe elements neededto rigor stack the

systems are integralto the enclosure (

and the quick release safety pins). The additional

items needed are the AX-AERO48 flying grid(bumper

bar), chains and hoists, the PL-48 or PL-48S dolly

platformsand theAX-COMBOflying grid.

A) AX-AERO48

The AX-AERO48 grid is made from 100 x50

x 6mm steel tubing and is designed to handle great

loads. It features a center reinforcement bar that is

also used for the lifting slings. The force of both the

rear and the front chain hoist will determine the tilt

angle of the whole array. The structure will be

attachedto thefirst enclosureof thearray bymeans of

the guides G1A48, G2A48, and six quick release

safetypins.

FLY

G1A48, G2A48

Pickup points

PL-48

D) PL-48S

The PL-48S platformis a valuableaccessory

which allows up to 3 or 4 AERO-48 units to be

transported in a stacked position, ready to be flown.

The PL-48S is made from steel and has 4 heavy duty

casterswith lockingbrakes.

PL-48S

Weight

: 75Kg (165 lbs)

Dimensions: 144x93x10 cm

(HxWxD)

B) Chainhoists

AX-AERO48 flyinggrid (bumper bar), whichshould be

used with two hoists, one located inthe front and the

other inthe rear.The hoists shouldhave a minimumof

1 Ton loadcapacity when flying up 8units and a 2 Ton

loadcapacity whenflying 9to 16units.

1 8cabinets-->

9 16cabinets-->

Aero-48 Manual del usuario/ User´s manual 32

57x36.6x4 in

All units in a column will be flown from the

Chain hoist load capacity

>1000Kg

>2000Kg

Page 6

D) AX-COMBO

2.3 SAFETY FACTORS

The AX-COMBO is a rigging adapter to be

used when Aero-28 units are needed to be flown

under AERO-48 units asdowfill systems. Maximum 6

CA-28A unitsand 8 CA-28/CA-28B unitscan be flown

from this rigging grid. The AX-COMBO includes front

and rear steel guides which permit variation of the

angle between it and the last AERO-48 cabinet in the

cluster.Anglesvary from1.8º to9.6º.

G1A48

G2A48

G2A48

Weight

: 16.5Kg (36.3 lbs)

Dimensions: 143x60x5cm (56.3x23.6x2in)

AERO-48

The safety factor is defined as the

coefficient between the

breaking load limit and the

maximum safe working load limit (SWLL). In this

case, the breaking load limit of each of the flying

points is 4,000 kg (8,820 lbs) as determined by

destructive testing in independent laboratories. With

a 10:1 safetyfactor, atotal amount of 1,600kg (3,527

lbs) can be flown from the 4 flying points. Each flying

point has a capacity of 400 kg (882 lbs) with a 10:1

safetyfactor.

4 x 400Kg (10:1)

T

he maximum number of units that can be

suspended from the AX-AERO48 flyinggrid is 16. The

maximum limits established by the manufacturer

shouldnever beexceeded.

G2A48

AX-COMBO

CA-28

G1A48

The AX-COMBO is joined to the last AERO48 cabinet using G1A48 and G2A48 included steel

guides and6 quickrelease pins.The angle dependson

the hole of the rigging structures where the pins are

inserted, through the slots of G2A48. The first AERO28 unit is joined to the AX-COMBO using its G1A and

G2Aincluded camlinks.

Theuseoftwohoistswitha loadcapacity as

expressed on the previous page is mandatory. It

should be kept in mind that at certain moments, the

complete load may be supported by only one of the

hoists.

This is why the load capacity of the individual

hoist must be superior to the weight of the array

column.

Aero-48 Manual del usuario/ User´s manual 33

Page 7

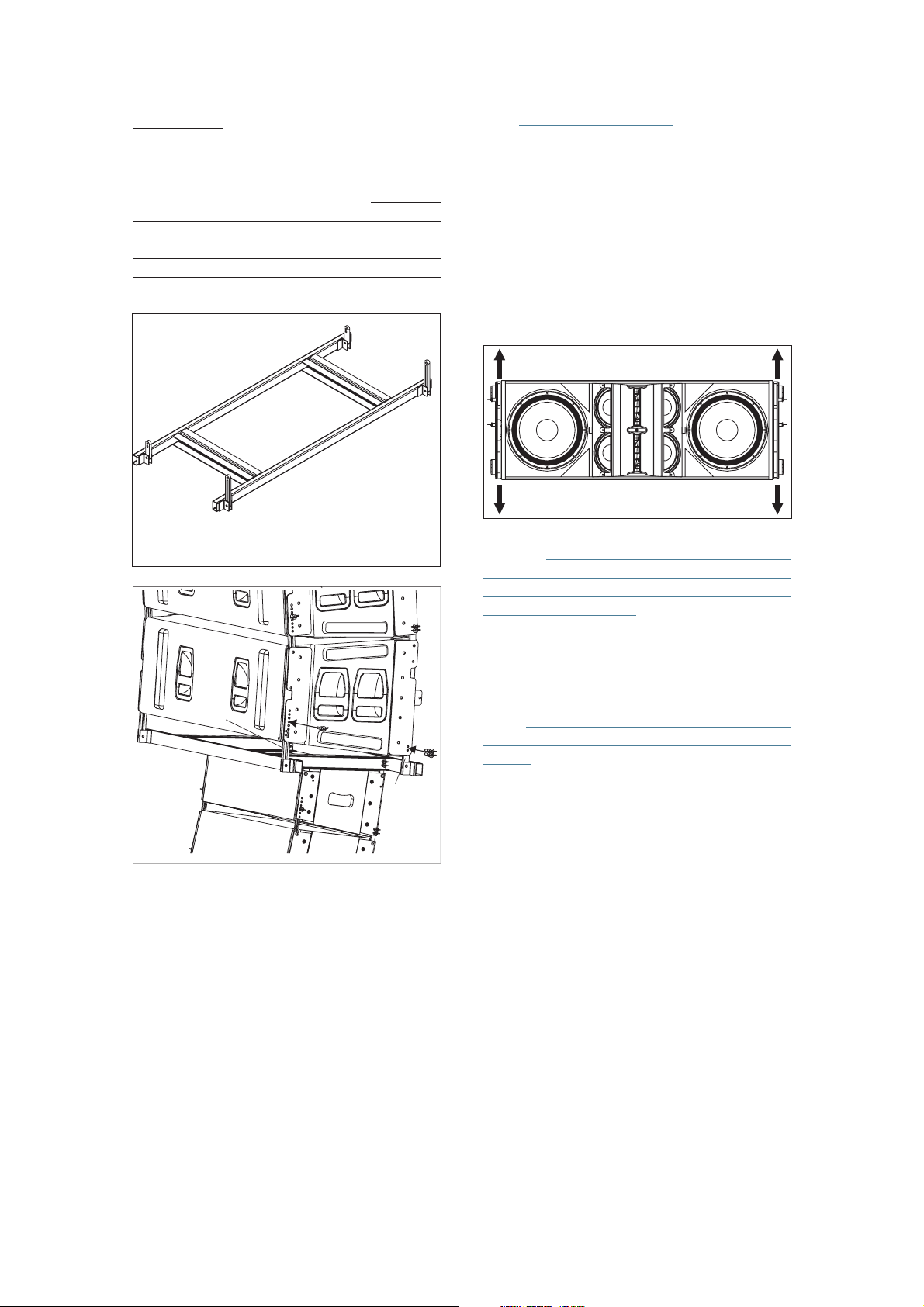

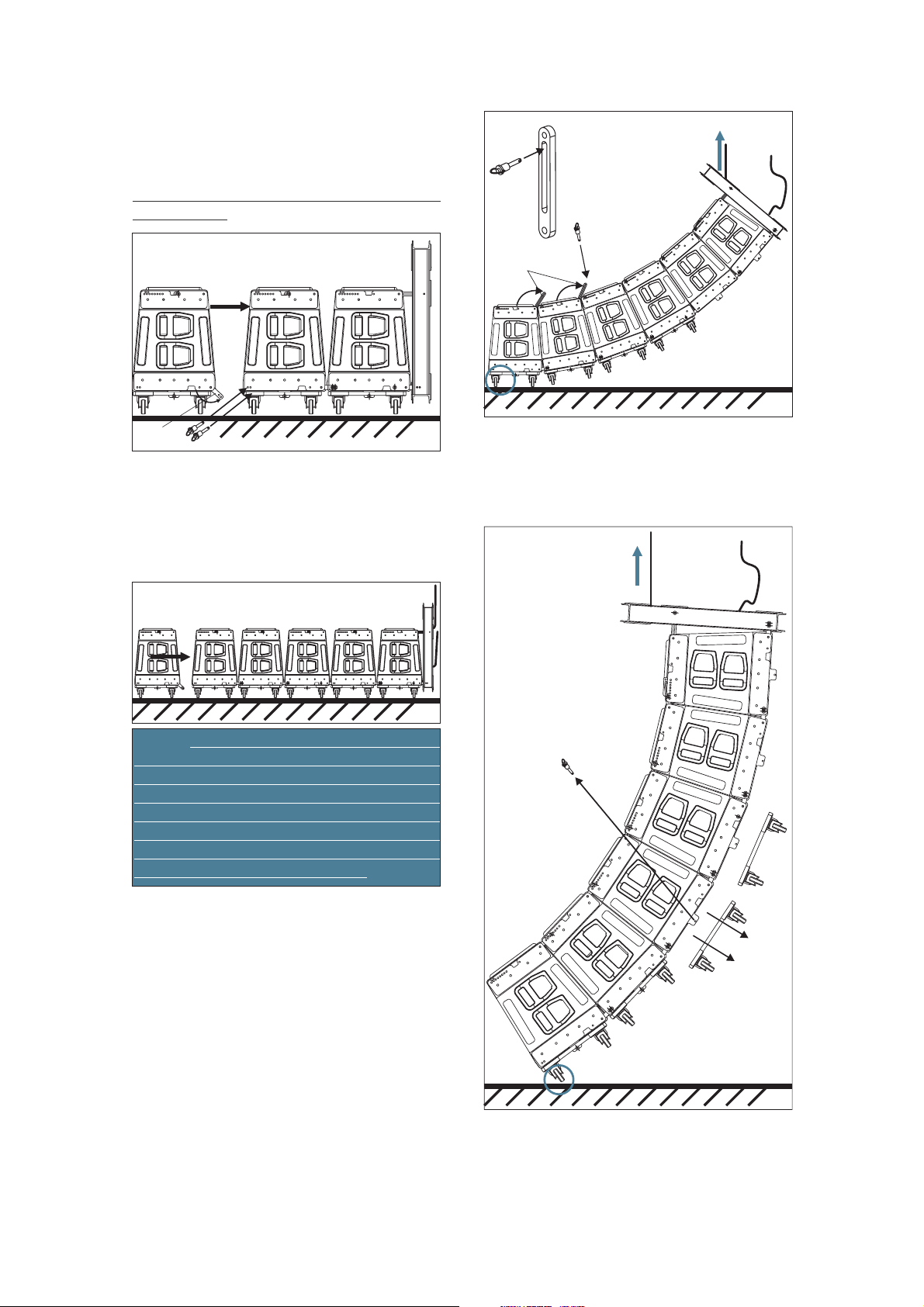

3. ASSEMBLING AN ARRAY

3.1TRANSPORTING THE CABINETS

AERO-48 units can be transported by using

the frontpanel dollyPL-48 orby usingthe PL-48Ssteel

dolly which can transport a maximum of 3 AERO-48

stackedin anarc or4 unitsstacked vertically.

The Aero-218SUBcan be transportedon the

rear located casters. Their rectangular shape

facilitates stacking without the use of the rigging

hardware.

3.2 PLANNING/INSPECTION

3.3 ASSEMBLING AN ARRAY “ONE

BY ONE”

When few units are to be used (minimum

systems recommended is 6 units) or when the dolly

platforms cannot be used due to a lack of space, the

enclosures willhave tobe hung “oneby one”.The first

step will to attach the AX-AERO48 grid structure to

the hoists.The chain slings needto be attached tothe

structure using the shackles provided with the grid.

Once this has been accomplished, the grid structure

can be placed in a vertical position by lifting the rear

hoist and lowering the front hoist so that the rear of

the grid is on top and the front of the grid at the

bottom,ready toreceive thefirst box.

Before installing the AERO systems it is a

good idea to run a simulation with the AEROWARE

program utilizing the venue dimensions. This way we

can determine the needs that should be met by the

rigging structures such as hoists, cranes, beams,

rigging points, etc. Besides providing weight

information, the program also provides users with

splay angle information, safety pin positions and

coveragepredictions.

It isextremely important toassure that each

and every one of the aforementioned structures is

capable of supporting a superior load than that of the

completesystem.

Inspection is the next step after planning

and acquiring all the necessary parts needed to

elevate thesystems. All parts,including the hardware

attached tothe enclosure,the safetypins, etc. should

be thoroughly inspected before each use. Units

exhibiting deformations, cracks or any other defect

shouldbe replacedwith newunits.

It is important to establish an inspection

routine for the complete rigging system before each

event or installation as well as establishing the

maximumload specificationsof thehoists tobe used.

The next stepis to attach thefirstunit to the

grid by introducing the G1A48 and G2A48 guides in

the receiving points ofthe grid structure and assuring

them with the six safety pins. The safety pins should

be inserted in the slot of the G2A48. It is very

important to make sure that the pins have been

insertedand lockedcorrectly.

AERO-48

G2A48

4

5

6

G1A48

3

2

1

AX-AERO48

Rigging should be carried out by experts

familiar with the way the systems function and their

characteristics.

On occasions, it may be convenient to have

additional tie down points to impede the array from

twistingor swinging.

Aero-48 Manual del usuario/ User´s manual 34

The quick release pins(3 and 4) must be

inserted through the slot of G2A48

Once the first unit of the array has been

attached to the AX-AERO48, the assembly should be

lifted by way of the rear hoist until the wheels of the

PL-48dolly platform lift off theground. From thispoint

on, the front hoist can be used to lift the box into a

horizontalposition.

3+4

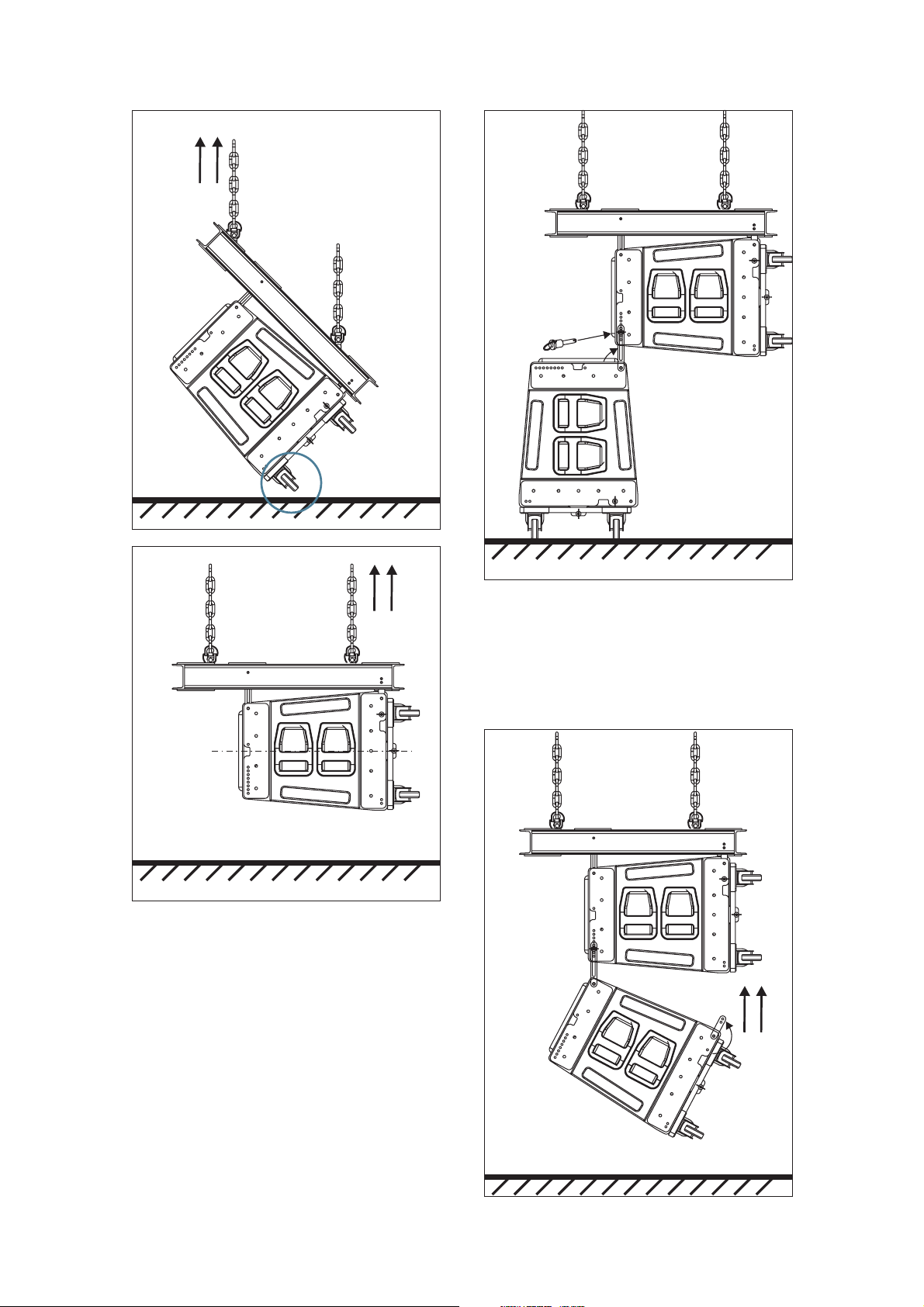

Page 8

Lifted by way of the rear hoist

until the wheels of the PL-48

dolly platform are off the ground.

Lift with the front hoist

until the box is in a

horizontal position.

Swing the G2A48 guide

into place and secure it

with the safety pin.

Once the splay angle between the first two

boxes has been determined, the front of the box can

be lifted into place. Three people will be needed to

undertake thisoperation, two tolift the boxand one to

fitthe G1A48guide andsafety pinsinto theupper box.

0º

Once the firstbox has been placed at0º and

raised approximately 75cm (30 in) the second box of

the array can be placed nearby. Once located in

position, the G2A48 guides of the second box should

be freed and inserted in the rear located receiving

points of the suspended box and secured with the

safetypins.

Lift the box and free

the G1A48 guides.

35Aero-48 Manual del usuario/ User´s manual

Page 9

Lift the box and introduce the

G1A48 guides securing them

with the safety pins.

Once the boxes have been joined, the front

dolly panels can be removed. The next boxes should

be attached “one by one” using the methods

described. Finally, the array should be hoisted to the

correct height and secured with slings to avoid

swinging.

3.4 ASSEMBLING AN ARRAY USING

THE PL-48 PLATFORM

The PL-48 platform can be used to easily

transport AERO-48 units to the assembling area. To

use this method ofassembling and hoisting the array,

there must be enough space to permit linking all the

boxesfrom thefront ofthe therigging hardware.

The first step will be to attach the AXAERO48 grid and the 2 hoists. Once this has been

accomplished, the grid structure can be placed in a

vertical position by lifting the rear hoist and lowering

the front hoistso that the rear of thegrid is on top and

the frontof the gridat the bottom,ready to receivethe

firstbox.

Rigging points

The nextstep is to attachthe first unit tothe

grid by introducing the G1A48 and G2A48 guides in

the receiving points ofthe grid structure and assuring

them with the (6) safety pins. The safety pins should

be inserted in the slot of the G2A48. It is very

important to make sure that the pins have been

insertedand lockedcorrectly.

AERO-48

This method is more time consuming than

assembling an array by the “all at once” procedure,

but is appropriate forsituations due to a lack of space

in which to array the system. During the process, the

safety pins should be checked making sure they are

secured correctly. Once the complete array has been

lifted into place, additional slings should be attached

tosecure thearray andavoid swinging.

G2A48

G1A48

3

2

4

1

5

AX-AERO48

6

3+4

36Aero-48 Manual del usuario/ User´s manual

Page 10

Once the first box is attached to the

structure, the remaining boxes should be brought to

the arrayand attachedrepeating theprevious steps (1

and 2) using G1A48 guides and safety pins per side

making sure that the pins have been inserted and

lockedcorrectly.

1

G2A48

Rear hoist FIRST!!

3

5

4

4

G1A48

same manner until all the array units are attached to

one another. For example, if we are assembling a six

unit array, the process will be repeated six times.

When all theunits are attached, the complete arrayis

readyto behoisted.

lifted from the rear hoist (3) so that the rear of the

enclosures come together due to their trapezoidal

shape. The front motor will be used only to take up

slack in thechain, all the weightshould be on therear

hoist. Proceed in this manner until the wheels of the

last enclosure are off the ground. From here on, the

arraycan nowbe liftedwith bothmotors.

2

Proceed to attach theremaining units in the

The complete assembly should begin being

The front motor will be used only to take up

slack in the chain,all the weight should be onthe rear

hoist. When the wheels of the last enclosure are off

theground thearray canbe liftedwith bothmotors.

Rear hoist FIRST!!

6

When the rear of the enclosures come

together,the G2A48 rear guides should be positioned

(4) into the hardware of the box above, inserting (5)

the safety pinsin the correct angleposition. Since the

boxesare flown,the safetypins shouldbe inthe slotof

theG2A48 guide.

As the array assembly is lifted (6 & 7), the

PL-48platforms shouldbe removed.

7

Once thecomplete array has beenlifted into

place, additional slings should be attached to secure

thearray andavoid swinging.

37Aero-48 Manual del usuario/ User´s manual

Page 11

Aero-48 Manual del usuario/ User´s manual 38

Page 12

To lower the system, both hoists should be

used until the lowest box is about 1 meter from the

ground. From there on, only the front hoist should be

used so that the array assembly begins to lean

forward, atthe same time, thePL-48 platformsshould

be reattached. When the wheels of the lowest

enclosure are firmly on the ground, the array

assemblycan nowbe loweredusing therear hoist.

While the array assembly descends, the

rear of the enclosures will come together, at that

moment, the safety pins which hold the G2A48

guides in place should be removed. Once removed,

the guides should be swung back into the box they

belong to. Finally, the boxes should be totally

detached from one another by releasing the G1A48

guide.

3.5 ASSEMBLING AN ARRAY

USING THE PLATFORM PL-48S

The PL-48S platform can be used to easily

transport 3/4 units of the AERO-48; in both arc shape

orstacked onthe platform.

The PL-48S platform can be used to

transport boxes forming a vertical arc, ready to be

flownor simplystacked.

Either way, dueto theweight of theboxes, it

isrecommendedthat forthe firsttime, the enclosures

be placed on the platform from a flown position. In

other words, the array should be suspended (either

onebyone orusing thePL-48S)and thenlowered onto

thePL-48S ingroups.

A) Cabinets splayed in arc (MAX. 3 units):

If we want to place six AERO-48 units on 2

PL-48S, the first step would be to suspend them all,

and then lowerthe array assembly onto the platforms

ingroups ofthree.

Last cabinet of the array

MAX. 3

units

Splayed units on PL48S ready to be rigged.

The PL-48S platform has two types of

moving pieces. One of them is fixed (PL-48S_2) and

can only be swung around, the other is free (PL48S_1) andis joinedto theplatform bywayof asafety

pin. The smaller piece PL-48S_1 attaches to the front

enclosure hardwareand the largerPL-48S_1 attaches

tothe back:

MAX. 4

units

Units stacked on a PL48S.

PL-48S_1

Lower thearray untilthe lowest boxis about

15cm (aprox.6 in.)above thePL-48S platform.

2

1

Release the PL-48S_2 piece by removing

the safety pins (1). Next, swing the pieces and

introduce them (2) into the rear rigging hardware of

thelowest box,securing themwith thesafety pin(3).

PL-48S_2

Aero-48 Manual del usuario/ User´s manual

39

Page 13

Once thetwo PL-48S_2 havebeen attached

to theboxes (3) usingone safety pinper piece, thePL48S_1 pieces can be attached. Remove the safety

pins (4)and insert them into the rigging hardware (5)

securing them(6) byusing twopins perpiece.

3

1

5

4

6

Once the PL-48S_1 and PL-48S_2 have

been securedto the lowerbox, this shouldbe lowered

so that the PL-48S_1 piece can be secured to the PL48Splatform (7)using thesafety pins.

7

The lowest box is now attached to the

platform. Now the array should be lowered until the

boxes are resting on one another. When the lower

three boxes are in this position, the safety pins

attached to the G2A48 guides joining boxes 3 and 4

should be removed to separate the array into two

groupsof boxes.

2

3

8

9

4

9

8

9

5

8

6

On flown systems, boxes are numbered

from top to bottom, the top box being number 1 and

thelower boxbeing numbersix.

With the number 4, 5 & 6 boxes resting on

each other, the safety pins that definethesplay angle

can be removed (8) and the PL-48S_2 guides can

return to their stored position (9). It is mandatory to

remove the safety pins between boxes 3-4, but

between 4-5, and 5-6, they can be left in place with

theangle preparedfor thenext event.

40Aero-48 Manual del usuario/ User´s manual

Page 14

Boxes 3-4 should be separated at the front

by removing the safety pins (10) that secure the

G1A48guides.

The first groupof boxes has now been freed

and isstacked safely onthe PL-48S platform.Tomove

the stack, slightly raise the upper group of boxes and

rollaway thelower group.

10

12

11

When the G1A48 pieces have been freed,

they should be turned (11) and stored (12) within the

corresponding box, in this case number 4, using the

mechanismincluded inthe rigginghardware.

41Aero-48 Manual del usuario/ User´s manual

Page 15

The next step is to roll under the remaining

boxes, an empty PL-48S and lower the boxes until

they are within close proximity of the platform. The

procedure should now be repeated, freeing the PL48S_2 pieces (13) from the platform, turning them

(14) and securing them (15) to the rear rigging

hardwareof thenumber 3box.

The last step consists of lowering the

remaining arrayso thatthe safetypins canbe inserted

(18) into the holes of the PL-48S_1 pieces and the

platform.

15

PL-48S_2

14

Continue lowering the systems and secure

(16) the PL-48S_1 pieces tothe front rigging points of

box3, inserting2 safetypins ineach (17).

Whenever a safety pin is inserted, it is

recommended thatthey be checked tomake sure that

they are correctly attached. Pull the safety pin

outward to make sure that it is in the locked position.

17

13

16

PL-48S_1

18

As inthe caseof thefirst groupof boxes,itis

not necessary to remove the safety pins securing the

G2A48 guideswhich determine splayangle. They can

remain in as they are, ready for the next event. The

samegoes forthe AX-AERO48grid.

B) Stacked units (MAX. 4 units):

Besides using the PL-48S platform for

transporting and flying the systems, it can also be

used for ground stacking.

boxes, it is recommended thattheybe flown first and

then lowered to the platform and stacked. For

stability reasons, it is recommended that no more

than 4boxes be stacked.

used, theyshould bearranged sothat thesplay angles

do not make the platform unstable. Once the boxes

are flown, they can be lowered onto the PL-48S

platform by using the hoists to position the array so

that the

guides.

safety pins can be inserted into the G2A48

Due to the weight of the

In theevent that 4 boxesare

The PL-48S_2 piece on the platform has 2

holes, the lower one offers a 0º angle between box

and platform and the upper hole offers a 1.6º angle,

meaningthat thebox isleaning forward.

42Aero-48 Manual del usuario/ User´s manual

Page 16

The arrangement in the following picture is

an unstable one.The smaller the splay anglebetween

cabinets, the more the stability. Obviously, the most

reliable stack in terms of stability istheone when the

splayangle betweenall ofthe cabinetsis 0º.

6.4º

4.8º

-1.6º

The anglebetween the box andthe platform

will be -1.6º whenthe safetypin isinserted inthe hole

on thebottom of theback guide, andthe holeon top of

the PL-48S_2 piece. Let us go now through the

complete process of stacking the boxes after they

havebeen previouslyflown.

3.2º

As mentioned above, the hole in which the

safety pin is inserted in the PL-48S piece will

determinethe splayangle ofthe bottombox, beit 0ºor

-1.6º. The following pictures will make things more

clear.

0º

The anglebetween the box andthe platform

will be 0º when the safety pin is inserted in the hole

on the bottom of the back guide, and the hole on the

bottomof thePL-48S_2 piece.

1

2

43Aero-48 Manual del usuario/ User´s manual

Page 17

After having rolled a PL-48S platform under

the array, the PL-48S_1 pieces (1,2 and 3) must be

detached from the platform and introduced (4) in the

frontrigging structureof thelower box.

Now the entire cluster can be lowered so

thePL-48S_1 piecesget intoreach ofthe platform.

Thenext stepis tofix thePL-48S_2 piecesto

the rear rigginghardware of the box.In order to doso,

the platform shouldbe raised up till thebottom hole in

the rigging hardware and the hole in the PL-48S_2

match together. Then the safety pins can be inserted

in the holes. As has been said before, the splay angle

between the platformand the box is given bythe hole

usedin thePL-48S_2 piece.

4

3

Both PL-48S_1 pieces must now be

attached (5)to thebox onthe bottom bymeans oftwo

safetypins oneach side.

5 PL-48S_1

7

6

PL-48S_2

The hole chosen in this example, is the one

onthe bottomof thePL-48S piece,being 0ºthe angle.

44Aero-48 Manual del usuario/ User´s manual

Page 18

At thispoint thePL-48S_1and thePL-48S_2

piecesarebothconnectedto thebox. Thereis onlythe

PL-48S_1 piece left to be attached to the platform.

Move the platform upwards till the holes in the PL48S_1 piece and the holes in the platform match

together.Theninsert thesafety pins(8).

Lower the cluster till the platform is resting

onthe floor.

9

8

When the boxes are flown the safety pins

must be insertedin the G2A48 slots.Now we want to

stack theboxes, so thenext step isto release thepins

from theslots and introducethem in the G2A48holes.

It must be done by first lowering the boxes till the

safety pins can be removed, then raise the boxes till

the holes fit together and finally insert the safety pins

again.

Fly

G2A48

Stack

G2A48

10

11

G2A48

1

2

3

12

4

45Aero-48 Manual del usuario/ User´s manual

Page 19

The cluster must now be lowered (10) until

the safety pins (11) on the rear side of box number 4

can beremoved. Once safetypins have been released

the cluster must be raised or lowered (13) until the

hole in the G2A48 piece matches with the hole that

determinesthe anglechosen bythe user.

13

4.8º

14

15

16

17

Safety pinscan now be inserted(14). In this

example, the set up angle between boxes 3 and 4 is

4.8º.

It is important to check that pins cannot be

removed by pulling outward and that they have been

inserted in the G2A48 hole instead of the guide slot.

Otherwise the box would not remain in the expected

angle.

The procedure is the same for the next

boxes. The cluster must be lowered again (15) until

the safety pins of box 3 are loose. Remove the pins

(16) so the G2A48 rear guides return to their stored

position (17). Insertthe safety pins into theholes (18)

that determine the angle previously selected for

stacking. Repeat the same procedure with box

number 1: lower the cluster (19), free the rear guides

G2A48(20 &21) andselect theangle.

19

20

21

18

3.2º

4.8º

46Aero-48 Manual del usuario/ User´s manual

Page 20

In orderto set upthe angle betweenboxes 1

and 2you must pull up(23) from the griduntil the hole

in the G2A48 piece fits with the hole that determines

thestacking angle.Then insertthe safetypins (24).

23

24

1.6º

3.2º

4.8º

At this point the boxes are safely stacked.

Finally, theAX-AERO48grid should be detached from

boxnumber 1.

47Aero-48 Manual del usuario/ User´s manual

Page 21

3.6 ASSEMBLING A CLUSTER

USING THE PL-48S PLATFORM

AERO-48 boxes canbe easily transported in

groups ofthree when stackedon the PL-48Splatform.

This arrangement is also useful and saves time when

setting up a cluster. Let us see what would the

procedurebe whenflying asix boxcluster.

In order to attach the box on top to the grid,

front guides G1A48 and rear guides G2A48 must be

swung (2) and inserted into the AX-AERO48 grid

receiving points. Oncethis has been done, detach the

6 safety pins from their receptacles and secure the

boxto thegrid.

After the AX-AERO48 grid has been

attached to the motors, it should be lifted at about

1.8m (5.5 ft) from the ground. Now the platform

containing the first threestacked AERO-48 boxes can

berolled underthe grid.

1

2

1

2

Once G1A48,G2A48 of thetop cabinet have

been secured (3) to the grid, rotate

( ), fit them into the upper box rigging hardware and

4

securethem withthe safetypins ( )

Whenever a safety pin is inserted, it is

always advisable to make sure it has been correctly

lockedby pullingoutward.

the G2A48 pieces

5 .See nextpage.

48Aero-48 Manual del usuario/ User´s manual

Page 22

The angles that can be seen in the example

3

3

4

4

are 0.8ºbetweenthe first and secondboxes, and 1.6º

between the second and the third boxes. The cluster

can now be lifted by the two motors, and the PL-48S

platformdetached.

The first step to detach the PL-48Splatform

from the bottom box is to release (6) the safety pins

which secure the PL-48S_1 piece to the platform and

the PL-48S_2 piece to the box. After raising the

cluster a bit, the safety pins which connect the PL48S_1 piece to the box can be released (8) also. PL48S_1 piece should now be reattached again to the

platform.

Select the angle between cabinets

introducing (5) the pins in the holes of the rigging

systemthrough theslot ofG2A48.

0.8º

5

1.6º

5

6

PL-48S_2

8

PL-48S_1

7

6

49Aero-48 Manual del usuario/ User´s manual

Page 23

Place the remaining group of boxes under

thecluster,then lowerthe clusteruntil bothfront sides

get in close proximity. G1A48 front guides (9) of the

first box onthe platform can nowbe swung and left in

the uprightposition, ready to beinserted into thefront

rigginghardware ofthe nextbox.

Lower the cluster until the G1A48 front

guides fit into the rigging hardware ofthe bottom box

andinsert thetwo safetypins (10)perside.

9

10

50Aero-48 Manual del usuario/ User´s manual

Page 24

With the front guides correctly secured,

swing the G2A48 (11) rear guides belonging to the

box on top of the second group and lower the grid till

the guides fit into the rigging hardware of the next

box. Set the angle between both boxes by inserting

thesafety pinsin thecorrect hole.

From here on, the process is similar to the

previously described. Detach the safety pins from

their receptacleson thesides of theboxes, swing(12)

the G2A48 rear guides, place them into the rigging

hardware of the next box and insert (13) the safety

pins in the holes which define the angle previously

selected.

0.8º

11

1.6º

1.6º

13

12

3.2º

13

12

4.8º

13

12

51Aero-48 Manual del usuario/ User´s manual

Page 25

4. SIGNAL PROCESSING

4.2 LIMITER SETTINGS

The use of the DSP-3VS digital processor is

highly recommended when running the AERO-48

sound system, and the use of the DSP-1Sub when

running the AERO-218Sub. Whenever another

loudspeakermanagementsystem isgoing to beused,

it should be configured with the parameters provided

by the manufacturer. Not doing so may damage the

system´s speaker components and affect the sound

quality.

The DSP-3VS digital processor is a threeway crossover with gain controls that offer +/- 6dB

variation per way. The processor has two inputs and

six outputs with level indication and muting for each

of the outputs. The digital processor includes fourth

order filters and parametric equalizers. The user

adjustablelimiters areaccessible fromthe frontpanel.

The DSP-3VS includes 10 presets that can

be selected fromthe front panel. Eachpreset memory

recalls specific operating parameters for a specific

DASspeaker systems.The selectedprogram isvisible

onthe LCDscreen locatedon thefront panel.

4.1 DSP-3VS INSTRUCTIONS

The following formulas can be used to establish the

limiter voltage:

AmplifierData:

rms rms

V=P *Z

G=

rms

V/S

G =20log(V /S)

dB rms

Where P is the amplifier RMS power in

rms

watts

Zis theload impedancein ohms

Gis theamplifier gain

Sis theamplifier sensitivityin volts

dB

G isthe amplifiergain indB

Limitersettings:

dd

V= P *Z

Limitlevel (v)=V /G

d

Limitlevel (dBu)=20log[limitlevel (v)/0.775]

Where P is the maximum power to be

d

deliveredin watts

To selecta program, turn therotary mini-DIP

switch onthe frontpanel labelled“Presets”. Thename

of the recalled preset will appear on the LCD screen.

The firsttime theDSP-3VSis connected, thenumber 1

program for the AERO-48 system will appear on the

frontpanel screen.

To select the limit levels for each of the

ways, turn the rotary mini-DIP switches on the front

panel labelled “Limiters”. The limit level expressed in

Vrmsand dBuappears onthe frontpanel screen.

The “Settings” button allows the user to

check thesaved limitlevels. The limitlevels appear on

the screen and after 5 seconds, the preset program

returnsto thescreen.

Thelimitlevelstobe enteredshould beequal

to or lower than the sensitivity of the amplifiersused.

Amplifier manuals provide the sensitivity at 8 Ohms

and 4Ohms. Takeinto account the load impedanceat

which the amplifiers will be working when adjusting

thelimit levels.

When usingamplifiers with a greateroutput

power than that recommended by the speaker

manufacturer, the limit levels should be adjusted so

notto exceedthe powercapabilities ofthe speakers.

Ejemplo:

Amplifier

Prms

GdB

G

S

1400W@4ohm

1.84 volts@4ohm

850W@8ohm

32dB

40 X

2 volts@8ohm

In this example we are going to feed the

highs of anAERO-48 with one amplifier channel. Total

impedance of 4 M-10N high frequency drivers, as

wired in the AERO48, is 8 Ohms. The maximum rms

power to be delivered to the highs, or Pd, should be

700W(700/4=175W perdriver).

d

P =700W@8ohm

d

V = 700*8=74.8v

Limit level (v)=V /G=74.8/40=1.84

d

Limit level (dBu)=20log(1.84/0.775)=7.6

Important Notice: The programs stored in

the memories of the DSP-3VS have been designed to

provide optimum performance and balance between

the different ways. In order to maintain this balance,

equalgain amplifiersshould beused.

52Aero-48 Manual del usuario/ User´s manual

Page 26

aero-48

5. SYSTEM CONNECTION

CONFIGURATION 1 (3 WAY STEREO SYSTEM FOR MID-LARGE SIZED VENUES)

aero-48

CONNECTIONS

LINK

RECOMMENDED AMPLIFIERS

CH-A CH-B

±4HF

±3MF

±2LF2

±1LF1

2 x 600W@8ohm

2 x 1200W@4ohm

2 x 1200W@4ohm

2 x 1200W@4ohm

±4HF

±3MF

±2LF2

±1LF1

LINK

DSP-3VS

LINE IN

DSP-3VS OPERATING PARAMETERS

LOW MID HIGH

GAIN

DELAY

POLARITY

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

158 Hz LR-24

0.8 oct (Q=1.8)

0dB

0.4 ms

Normal

30 Hz LR-24

50 Hz

+6 dB

0dB

0.4 ms

Normal

158 Hz LR-24

1 kHz LR-24

353 Hz

-2 dB

0.3 oct (Q=4.8)

450 Hz

-3dB

0.8 oct (Q=1.8)

650 Hz

-2dB

0.3 oct (Q=4.8)

-7 dB

0ms

Invert

1 kHz LR-24

2.5 kHz

-3 dB

0.35 oct (Q=4.1)

10.1 kHz

+12 dB

1 oct (Q=1.4)

12.5 kHz

+7 dB

0.3 oct (Q=4.8)

53Aero-48 Manual del usuario/ User´s manual

Page 27

aero-218SUB

aero-48

CONFIGURATION 2 (4 WAY STEREO SYSTEM FOR MID-LARGE SIZED VENUES)

aero-48

a SUBero-218

®

ELECTRONICS

CONNECTIONS

RECOMMENDED AMPLIFIERS

CH-A CH-B

±1LF ±1LF

2 x 1400W@4ohm

DSP-3VS

DSP-1Sub

LINE IN

DSP-3VS + DSP-1SUB OPERATING PARAMETERS

LOWSUB MID HIGH

GAIN

DELAY

POLARITY

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

+3 dB

Variable

Normal

23 Hz LR-24

85 Hz LR-24

36 Hz

+10 dB

0.4 oct (Q=3.6)

158 Hz LR-24

0.8 oct (Q=1.8)

0dB

0.4 ms

Normal

50 Hz LR-24

60 Hz

+3 dB

0dB

0.4 ms

Normal

158 Hz LR-24

1 kHz LR-24

353 Hz

-2 dB

0.3 oct (Q=4.8)

450 Hz

-3dB

0.8 oct (Q=1.8)

1 kHz LR-24

0.35 oct (Q=4.1)

1 oct (Q=1.4)

®

ELECTRONICS

2.5 kHz

10.1 kHz

-7 dB

0ms

Invert

-3 dB

+12 dB

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

650 Hz

-2dB

0.3 oct (Q=4.8)

12.5 kHz

+7 dB

0.3 oct (Q=4.8)

54Aero-48 Manual del usuario/ User´s manual

Page 28

6.OPERATING PARAMETERS

AERO-48 BSS OPERATING PARAMETERS

LOW MID HIGH

GAIN

DELAY

POLARITY

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

AERO-48 XTA OPERATING PARAMETERS

GAIN

DELAY

POLARITY

158 Hz LR-24

0.8 oct (Q=1.8)

0dB

0.4 ms

Normal

30 Hz LR-24

50 Hz

+6 dB

LOW MID HIGH

0dB

0.4 ms

Normal

158 Hz LR-24

0.3 oct (Q=4.8)

0.8 oct (Q=1.8)

0.3 oct (Q=4.8)

0dB

0.4 ms

Normal

1 kHz LR-24

353 Hz

-2 dB

0.35 oct (Q=4.1)

450 Hz

-3 dB

650 Hz

-2 dB

0dB

0.4 ms

Normal

1 kHz LR-24

10.1 kHz

1 oct (Q=1.4)

12.5 kHz

0.3 oct (Q=4.8)

-7 dB

0ms

Invert

2.5 kHz

-3 dB

+12 dB

+7 dB

-8.8 dB

0ms

Invert

AERO-48+AERO218SUB BSS OPERATING PARAMETERS

LOWSUB MID HIGH

GAIN

DELAY

POLARITY

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

AERO-48+AERO218SUB XTA OPERATING PARAMETERS

GAIN

DELAY

POLARITY

0.4 oct (Q=3.6)

+3 dB

Variable

Normal

23 Hz LR-24

85 Hz LR-24

36 Hz

+10 dB

+3 dB

Variable

Normal

158 Hz LR-24

0.8 oct (Q=1.8)

0dB

0.4 ms

Normal

50 Hz LR-24

60 Hz

+3 dB

LOWSUB MID HIGH

0dB

0.4 ms

Normal

158 Hz LR-24

0.3 oct (Q=4.8)

0.8 oct (Q=1.8)

0.3 oct (Q=4.8)

0dB

0.4 ms

Normal

1 kHz LR-24

353 Hz

-2 dB

0.35 oct (Q=4.1)

450 Hz

-3 dB

650 Hz

-2 dB

0dB

0.4 ms

Normal

-7 dB

0ms

Invert

1 kHz LR-24

2.5 kHz

-3 dB

10.1 kHz

+12 dB

1 oct (Q=1.4)

12.5 kHz

+7 dB

0.3 oct (Q=4.8)

-8.8 dB

0ms

Invert

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

29.5 Hz LR-24

157 Hz LR-24

50.6 Hz

+5.5 dB

0.67 oct (Q=2.1)

157 Hz LR-24

1000 Hz LR-24

354Hz

-2 dB

0.28 oct (Q=5.1)

454 Hz

-3 dB

0.75 oct (Q=1.9)

655 Hz

-2 dB

0.27 oct (Q=5.3)

1 kHz LR-24

22 kHz LR-24

2.52 kHz

-3 dB

0.32 oct. (Q=4.5)

10.3 kHz

+13.8 dB

0.6 oct (Q=2.4)

12.7 kHz

+5.5 dB

0.17 oct (Q=8.5)

LOW-CUT

HIGH-CUT

EQ.1 FREQ.

EQ.1 LEVEL

EQ.1 BW.

EQ.2 FREQ.

EQ.2 LEVEL

EQ.2 BW.

EQ.3 FREQ.

EQ.3 LEVEL

EQ.3 BW.

20.9 Hz LR-24

83.4 Hz LR-24

34.4 Hz

+10 dB

0.36 oct (Q=4)

49.6 Hz LR-24

157 Hz LR-24

59 Hz

+2.5 dB

0.79 oct (Q=1.8)

157 Hz LR-24

1000 Hz LR-24

0.28 oct (Q=5.1)

0.75 oct (Q=1.9)

0.27 oct (Q=5.3)

One ofthe mostimportant parts of a multi-way soundreinforcement systemis the digitalcontroller.There

are alotof fine products available;D.A.S. Audio hasselected the following onesapart from the DSP-3VS, DSP-1Sub

D.A.S.controllers:

Company

Model

BSS Audio XTA Electronics

FDS 336 Omnidrive DP 226

354Hz

-2 dB

0.32 oct. (Q=4.5)

454 Hz

-3 dB

655 Hz

-2 dB

1 kHz LR-24

22 kHz LR-24

2.52 kHz

-3 dB

10.3 kHz

+13.8 dB

0.6 oct (Q=2.4)

12.7 kHz

+5.5 dB

0.17 oct (Q=8.5)

55Aero-48 Manual del usuario/ User´s manual

Page 29

7. POWERING THE SYSTEM

The following tablespresent power data delivered to each componentand limiter settings depending on

theamplifier model:

D.A.S H-4000 AMPLIFIER GAIN 40x / 32 dB

AMPLIFIER CONFIGURATION: 4 x AERO-48/4xH-4000

AMPLIFIER

CHANNEL

CH-1

Amplif. 4(HF)

CH-1

Amplif. 3(MF)

CH-2

CH-1

Amplif. 2(LF)

CH-2

CH-1

Amplif.1(LF)

CH-2

AMPLIFIER

CHANNEL

SPEAKON NL8

PINS

NUMBER OF

SPEAKERS

PINS 4± 4 x M-10N

PINS 4±CH-2

PINS ±3

PINS ±3

PINS ±2

PINS ±2

PINS ±1

PINS ±1

4 x M-10N

8 x 8MN

8 x 8MN

2 x 15GN

2 x 15GN

2 x 15GN

2 x 15GN

D.A.S E-20 AMPLIFIER GAIN 40.6x / 31.5 dB

AMPLIFIER CONFIGURATION: 4 x AERO-48/4xE-20

SPEAKON NL8

PINS

NUMBER OF

SPEAKERS

LOAD

IMPEDANCE

8 W

8 W

4 W

4 W

4 W

4 W

4 W

4 W

LOAD

IMPEDANCE

POWER AT

NOMINAL

IMPEDANCE

850 W

850 W

1400 W

1400 W

1400 W

1400 W

1400 W

1400 W

POWER AT

NOMINAL

IMPEDANCE

RECOMMENDED

LIMITATION

700 W / 8 W

700 W / 8 W

1400 W / 4 W

1400 W / 4 W

1400 W / 4 W

1400 W / 4 W

1400 W / 4 W

1400 W / 4 W

RECOMMENDED

LIMITATION

POWER

PER

SPEAKER

175 W

175 W

175 W

175 W

700 W

700 W

700 W

700 W

POWER

PER

SPEAKER

LIMITER

V /dBu

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

1.84 / 7.6

LIMITER

V /dBu

CH-1

Amplifier 4(HF)

CH-1

Amplifier 3(MF)

CH-2

CH-1

Amplifier 2(LF)

CH-2

CH-1

Amplifier 1(LF)

CH-2

PINS 4± 4 x M-10N

PINS 4±CH-2

PINS ±3

PINS ±3

PINS ±2

PINS ±2

PINS ±1

PINS ±1

4 x M-10N

8 x 8MN

8 x 8MN

2 x 15GN

2 x 15GN

2 x 15GN

2 x 15GN

8 W

8 W

4 W

4 W

4 W

4 W

4 W

4 W

600 W

600 W

1000 W

1000 W

1000 W

1000 W

1000 W

1000 W

600 W / 8 W

600 W / 8 W

1000 W / 4 W

1000 W / 4 W

1000 W / 4 W

1000 W / 4 W

1000 W / 4 W

1000 W / 4 W

150 W

150 W

125 W

125 W

500 W

500 W

500 W

500 W

1.84 / 7.6

1.84 / 7.6

1.65 / 6.6

1.65 / 6.6

1.65 / 6.6

1.65 / 6.6

1.65 / 6.6

1.65 / 6.6

56Aero-48 Manual del usuario/ User´s manual

Page 30

AERO-48

FEATURES

THREE-WAY, HIGH DIRECTIVITY LINE ARRAY MODULE

2 x 15” LOW FREQUENCY NEODYMIUM CONE TRANSDUCERS

4 x 8” MID FREQUENCY NEODYMIUM CONE TRANSDUCERS

2 x 1.5” EXIT, 3 ” DIAPHRAGM NEODYMIUM COMPRESSION DRIVER

TWIN “SERPIS” PLANE-WAVE GENERATORS

AERO-WARE PREDICTION SOFTWARE

series

INTRODUCTION

The AERO-48 is an externally powered,

high efficiency line array module which integrates

low, mid and high frequency transducers in a

single unit. The ruggedly built enclosure is easy to

transport by means of the frontpaneldollyand the

captive rigging hardware makes flying safe and

simple. The unit is ideal for applications requiring

high sound pressure levels and precise control of

theverticalcoverage.

APPLICATIONS

The AERO-48 system is well suited for

large-scale outdoor events or indoor venues such

as theaters, arenas or stadiums. The system can

be used in conjunction with the AERO-218SUB

subwoofer unit for increased sound pressure level

inthelow frequencyrange from28Hz to83 Hz.

SPECIFICATIONS

Frequency response ( 3dB) 45Hz-18kHz

Horizontal coverage angle (-6dB)

Vertical coverage angle (-6dB)

On axis sensitivity 1W/1m

Maximum peak SPL

Recommended processor

Transducers

Low frequency

Nominal impedance/ power

Mid frequency

Nominal impedance/ power

High frequency

Nominal impedance/ power

Neodymium magnets in all the transducers

Recommended amp power 2xAERO-48 in parallel

Enclosure detail

Shape

Dimensions (HxWxD)

Material

Finish

Rigging hardware

Connector

Weight

90º nominal

Splay dependent

LF: 99dB MF: 104dB HF: 112dB

LF: 137dB MF: 139dB HF: 141dB

DAS digital controller DSP-3VS. Using AERO-48

system without the DSP-3VS controller will result

in poor sound quality and can damage transducers

2 x 15”-MODEL 15GN, 4” voice coil

2x8 ohms/ 2x 600W RMS

4 x 8”-MODEL 8MN, 2.5” voice coil

8 ohms/ 700W RMS

2 x M-10N, 3” voice coil

16 ohms/ 300W RMS

LF 1000/1400W 4

1 W

MF 1000/1400W 4

Trapezoidal 5º

47.5x140x60cm (18.7x55x23.6in)

Wisa Birch Plywood

Black polyurethane paint

Integrated in cabinet

MAX. 16 units@10:1 Safety factor

2x NL8 Speakon wired as

100kg (220lbs)

LF 1100/1400W 4

2 W

W

HF 600/800W 8

W

LF LF1212MF3HF4

DESCRIPTION

The AERO-48 three-way system

incorporates two15” low frequency units with 4”

voice coils, four 8”mid-range deviceswhichutilize

2.5” voice coils and two compression drivers with

3” coils and 1.5” exit geometry. The compression

drivers are coupled to two Serpis high frequency

plane wave adaptors which insure coherent high

frequency summing and the generation of a flat,

isophasic wavefront. The components make use

of lightweight neodymium magnet assemblies for

overall weight reduction and the sophisticated

T.A.F. cooling scheme provides higher power

handlingandlow powercompression.

The trapezoidal enclosure is

manufactured from Wisa® birch plywood and is

finished in a durable catalyzed polyurethane paint.

A fabric covered steel grill protects the

loudspeaker components. The captive rigging

hardware and 5º enclosure angles permit splay

angles ranging from 0º to 9.6º in 0.8º and 1.6º

increments. Ten handles and a front panel dolly

with four heavy-duty casters facilitate

maneuvering.

®

SOUND PRODUCTS

Page 31

AERO-218SUB

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTEASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

FEATURES

DIRECT RADIATING SUBWOOFER UNIT

EXTENDED LOW FREQUENCY RESPONSE

2 X 18” LOW FREQUENCY NEODYMIUM CONE TRANSDUCERS

FOUR HEAVY-DUTY CASTERS

SPECIFICATIONS

Frequency response ( 3dB)

On axis sensitivity 1W/1m

Maximum peak SPL

Recommended processor

Recommended amp power

Transducers

Low frequency

Nominal impedance

Neodymium magnets

28Hz-83Hz

103dB

140dB

DAS controller DSP-1Sub

1400W @4 ohm

2 x 18”-MODELO 18GN, 4” bobina

4 ohms wired in parallel

series

INTRODUCTION

The AERO-218SUB is a high efficiency,

arrayable subwoofer unit designed to provide low

frequency reinforcement for the AERO-48. The

front-loaded bass-reflex configuration and large

enclosure volume offer a compelling bass

response.

APPLICATIONS

The AERO-218SUB is designed for

applications where high sound pressure levels of

extended low frequency response are needed.

Events such as live concerts or large scale

presentationswillbenefit from the AERO-21SUB.

DESCRIPTION

The AERO-218SUB incorporates two 18”

low frequency units with 4” voice coils and

lightweight neodymium magnet assemblies. The

sophisticated T.A.F. cooling scheme offers

effective heatremoval for highpowerhandling and

low power compression. The rectangular

enclosure is manufactured from Wisa® birch

plywood and is finished in a durable catalyzed

polyurethane paint. A fabric covered steel grille

protects the loudspeaker components. The

rectangular shape and physical dimensions of the

AERO-218SUB allow theunit to be groundstacked

with ease. Eight handles and four heavy-duty

castersfacilitatemaneuvering.

The AERO-218Sub unit has a frequency

range covering 28 Hz to 83 Hz (±3 dB) with a

sound pressure level reaching 140 dB SPL at 1

meter. The DSP-1Sub processor permits sub level

andphaseadjustments.

Enclosure

Shape

Dimensions (HxWxD)

Material

Finish

Connector

Weight

®

SOUND PRODUCTS

Rectangular

101 x 68 x 82.5cm (40 x 27 x 32.5in)

Wisa Birch Plywood

Black polyurethane paint

2x NL8 wired as ±1

82kg (181lbs)

1010

WARNING!DONOTSUSPENDFROMTHISHANDLE

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

680

36

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

WARNING!DONOTSUSPENDFROMTHISHANDLE

823

256

220

ALL DIMENSIONS IN MILIMETERS

¡ATENCIÓN!NOCUELGUELACAJADEESTE ASA

224 236

36

Page 32

D.A.S AUDIO, S.A. C/. Islas Baleares, 24 - 46988 Fuente del Jarro - Valencia, SPAIN Tel. 96 134 0525 - Tel. Intl. +34 96 134 0860 Fax. 96 134 0607 - Fax. Intl. +34 96 134 0607

D.A.S AUDIO of AMERICA, Inc. Sunset Palmetto Park- 6816 NW 77th Court - Miami, FL 33166 U.S.A. TOLL FREE : 1-888DAS4USA Tel. 305 436 0521 - Fax. 305 436 0528

http://www.dasaudio.com

US/AERO-01

Loading...

Loading...