Page 1

Rigging Manual

AERO-20A / AERO-20.120A

El colgado del equipo sólo debe realizarse

ut il iz an do l os he rr aj es de c ol ga do

recomendados y por personal cualificado.

No cuelgue la caja de las asas.

The appliance should be flown only from

th e r iggin g p oin ts an d b y qual ified

personnel. Do not suspend the box from

the handles.

Page 2

CONTENTS

RIGGING SYSTEM: WARNINGS

4 UNITS MOUNTING ON A PL-20S

ARRAY MOUNTING WITH GROUPS OF 4 UNITS ON A PL-20S

ARRAY DISASSEMBLY IN GROUPS OF 4 UNITS ON A PL-20S

COMBINATION WITH AERO-40A ARRAY

STACKING SYSTEMS

TRANSPORTING

ANNEX I : Tools for rigging systems

ANNEX II : Maximum load capacity for AX-AE20

ANNEX III : Advice for EASE Focus 2 use

3

4 - 10

11 - 19

20 - 23

24 - 26

27 - 28

29 - 32

33

34 - 35

36 - 38

Manual de Colgado / aero series / Rigging Manual

Page 3

RIGGING SYSTEM

Warning

This manual offers all the necessary

information for flying DAS Audio systems.

To any operations related to flying a

system, read the present document first

and act on the warnings and advice

given. The goal is to allow the user to

become familiar with the mechanical

elements required to fly the acoustic

system, as well as the safety measures to

be taken during set-up and teardown.

Only experienced installers with

adequate knowledge of the equipment

and local safety regulations should fly

speaker boxes. It is the user´s

responsibility to ensure that the systems

to be flown (including flying accessories)

comply with state and local regulations.

The working load limits in this manual

are the results of tests by independent

laboratories. It is the user´s responsibility

to follow and comply with safety factors,

resistance values, periodical supervisions

and warnings given in this manual.

Product improvement by means of

research and development is on going at

DAS Audio Specifications are subject to

change without notice.

It is common practice to apply 5:1

safety factors for enclosures and static

elements. For slings and elements

exposed to material fatigue due to friction

and load variation the following ratios

must be met; 5:1 for steel clable slings;

4:1 for steel chain slings and 7:1 for

polyester slings. Thus, an element with a

breaking load limit of 1000 kg may be

statically loaded with 200 kg (5:1 safety

factor) and dynamically loaded with 142

kg (7:1 safety factor).

When a system is flying, the working

load must be lower than the resistance of

each individual flying point in the

enclosure, as well as each box. Hanging

hardware should be regularly inspected

and suspect units replaced if in doubt.

This is important to avoid injury and

absolutely no risks should be taken in this

respect. It is highly recommended that

you implement an inspection and

maintenance program on flying elements,

including reports to be filled out by the

personnel that will carry out the

inspections. Local regulations may exist

that, in case of accident, may require you

to prevent evidence of inspection reports

and corrective actions after defects were

found.

Absolutely no risks should be

taken with regards to public safety.

When flying enclosures from ceiling

support structures, extreme care should

be taken to assure the load bearing

capabilities of the structures so that the

installation is absolutely safe. Do not fly

enclosures from unsafe structures.

Consult a certified professional if needed.

All flying accessories that are not

supplied by DAS Audio are the user´s

responsibility. Use at your own risk.

Manual de Colgado / aero series / Rigging Manual

3

Page 4

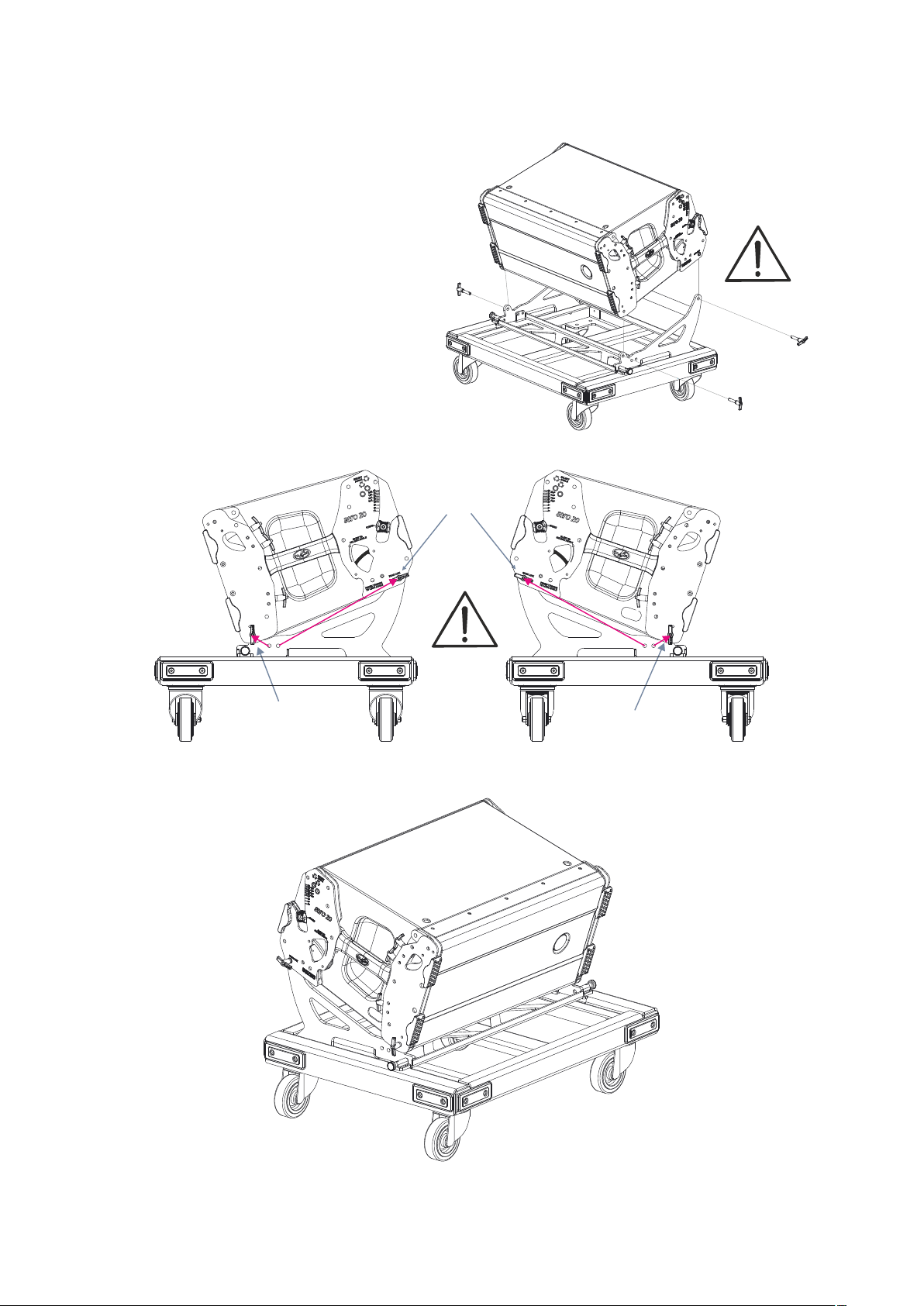

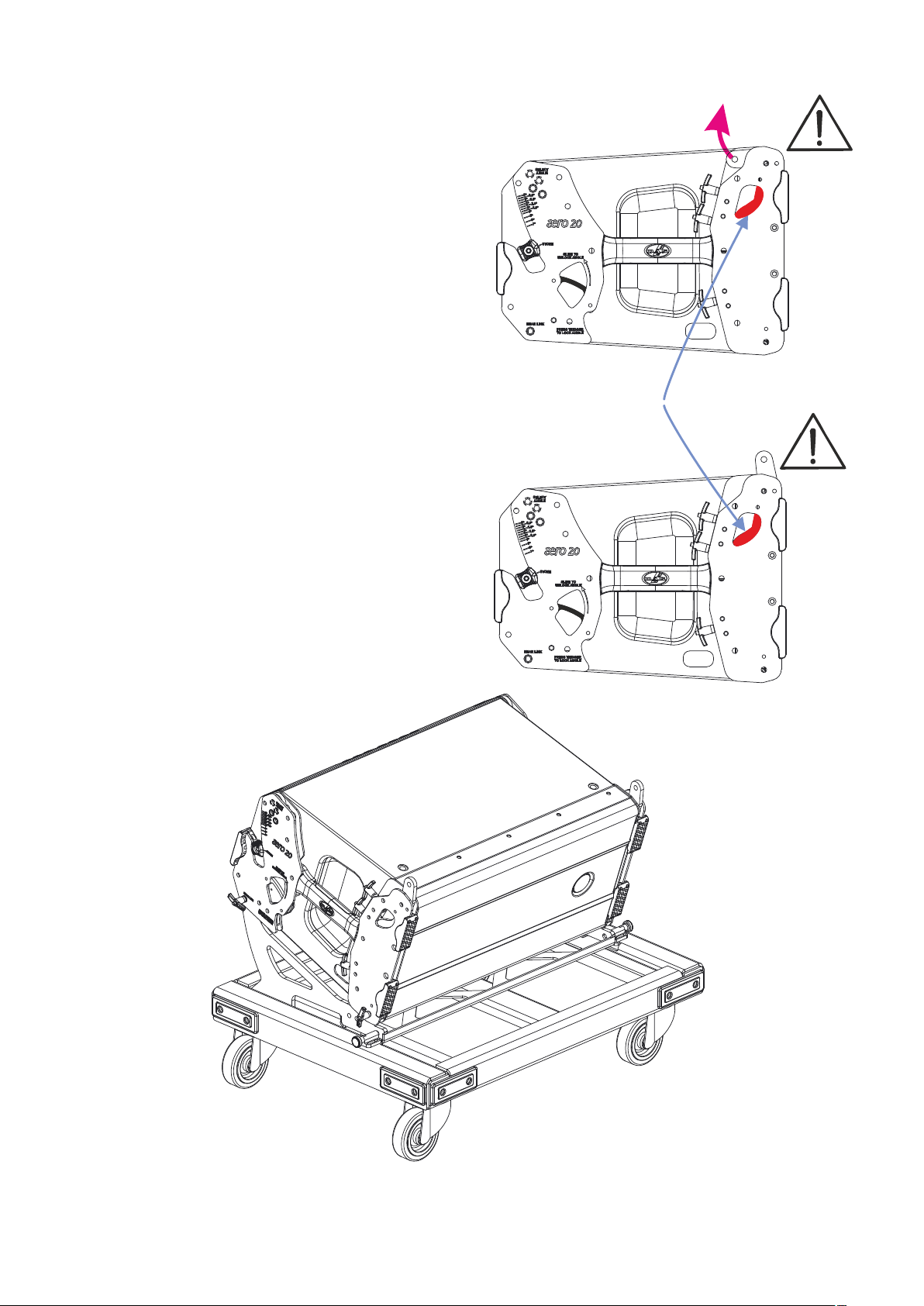

4 UNITS MOUNTING ON A PL-20S

The groups of 3 or 4 units are easy to transport by truck as we will see in this section. We will also see

the preparation.

If we look at the PL-20S, we will see the two security pins on the sides (see figure). These pins allow to

hold the first enclosure to the platform.

Rear part of the

PL-20S platform.

Front part of the

PL-20S platform.

PL-20S

W.L.L.: 160kg

Security pins on

the PL-20S platform side.

Rear part of the

PL-20S platform.

Front part of the

PL-20S platform.

Side view of the PL-20S platform.

Security pins on

the PL-20S platform side.

Front view of the PL-20S platform.

Side view of AERO-20A unit

Looking at the side of AERO-20A unit, we

observe the blocking angle trigger.

Warning: Make sure the trigger is hidden,

blocking the angle, so that the box is fixed to

the platform safely.

4

Manual de Colgado / aero series / Rigging Manual

When you push the trigger, you will block AERO-20A angles.

Page 5

Lift the enclosure by the handles and sit it

gently over the platform.

Remove the security pins and hold the

enclosure with them.

Check that the four security pins are well

positioned.

Rear security pins:

REAR LINK

Front security pin

Front security pin

Final mounting of one enclosure on a PL-20S platform.

Manual de Colgado / aero series / Rigging Manual

5

Page 6

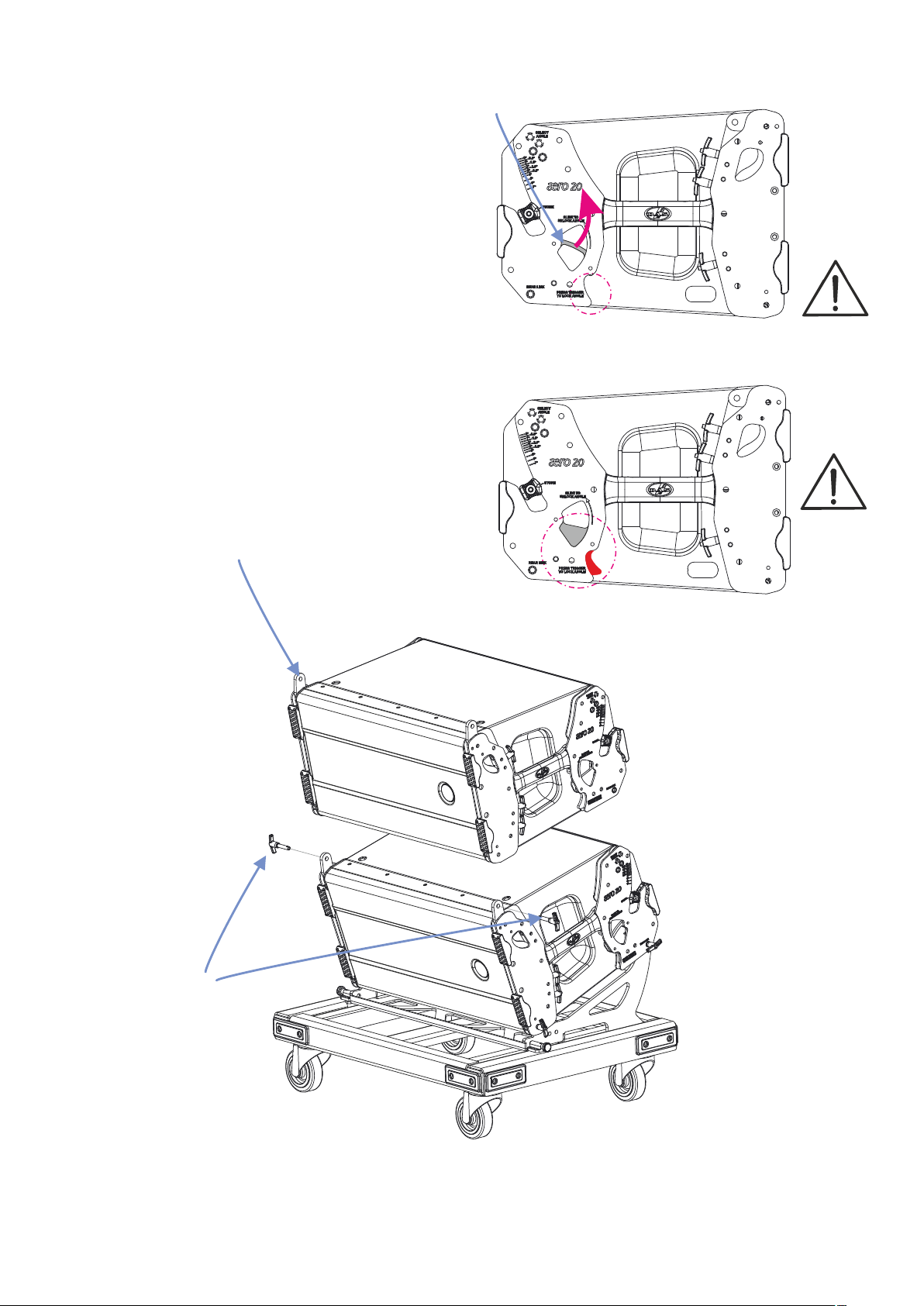

Lets add another enclosure over the previous.

We need to look at the side controls of the

enclosure and act on them like in the figure.

We push up the front rods (as seen in the

figure), we will deploy them and we will lock them

into position. Make sure they are properly locked

for safety.

The front rod remains locked, unless you press

the front triggers so that we can bring it to its initial

position, folded on the side.

The result, platform included, can be seen in

the figure below.

Move the front

folded rod

Front trigger

Click !

Front rod

unfolded

Figure of the enclosure on the platform PL-20S

with the rods ready to add another enclosure over it.

6

Manual de Colgado / aero series / Rigging Manual

Page 7

Now we unlock the angle in the second box,

before leaning it on the first (in this configuration

the rear trigger is hidden).

To do this we will move the handles on the

sides of the box up to the end where you will hear

a click.

At that time the rear trigger will come out, the

handle will lock, and it will unlock the angle.

Taking the second enclosure by the handles,

we will lower it gently upon the first enclosure, until

it rests upon it.

Remove the safety pins on each side of the

enclosure, and to anchor the enclosure we will use

these pins, as shown in the figures.

Note: We can leave the front rods

prepared for stacking the third box.

Side handle

Hidden rear trigger

Click !

Front

security

pins

Visible rear trigger

This figure shows mounting of two enclosures on a PL-20S platform.

Manual de Colgado / aero series / Rigging Manual

7

Page 8

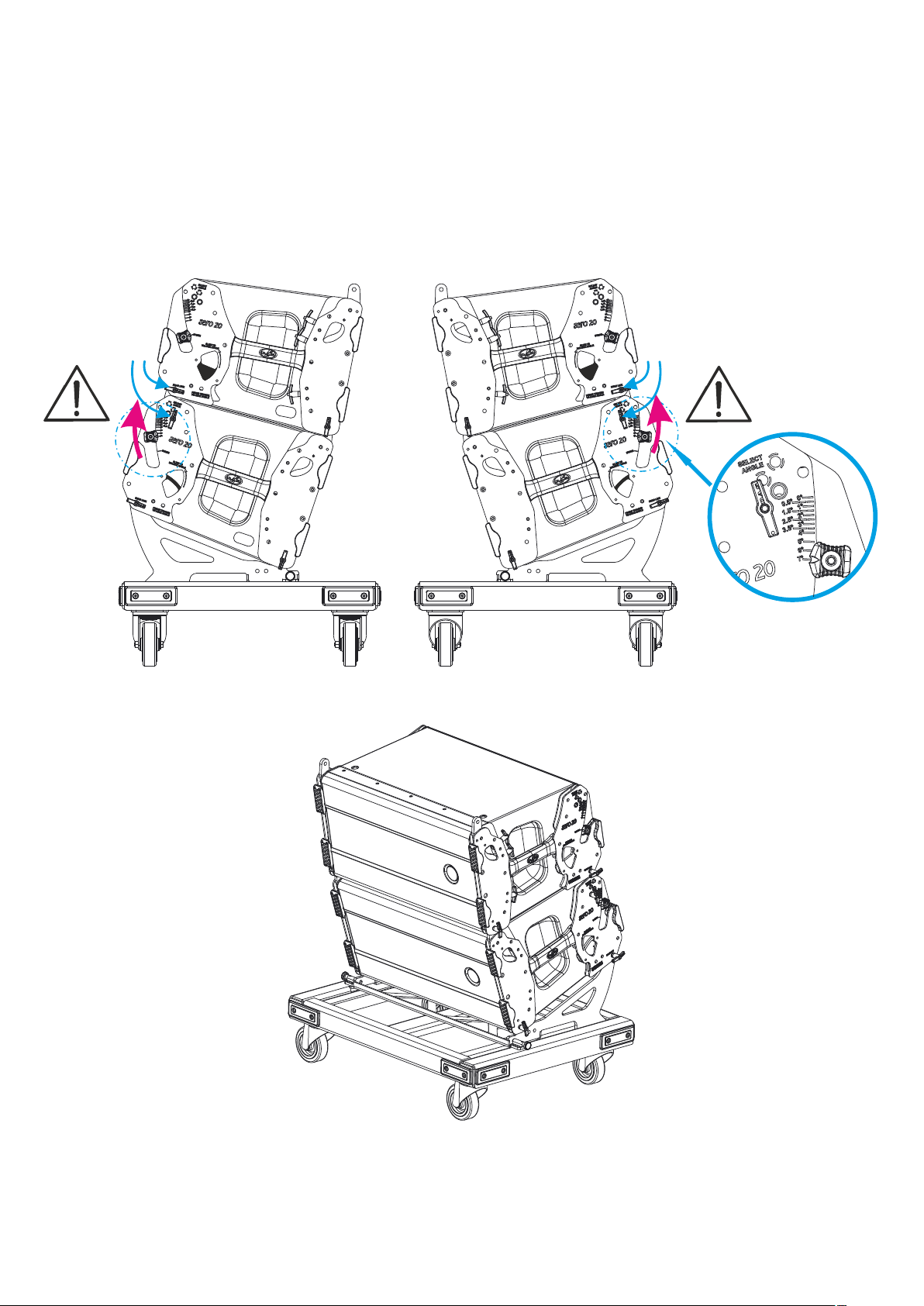

Once the second enclosure is supported by the first and the front safety pins are positioned, we will

choose 7º (which is the maximum possible for this model), with the angle selector and we will put the rear

safety pins on the first enclosure (two on each side of the enclosures): put pins in REAR LINK holes of

second enclosure and others, in the holes corresponding to 7º angle, on the first enclosure (as shown in the

figures below).

Check that all safety pins are located correctly because they will have to withstand the weight of all the

enclosures.

Security

pins

Security

pins

DETAIL

This figure shows final mounting of two enclosures on a PL-20S platform.

8

Manual de Colgado / aero series / Rigging Manual

Page 9

Now we should unlock the angle in the third enclosure to place it on the second (in this configuration the

rear trigger is hidden, as seen on page 7).

To do this we will move the handles on the sides of the enclosure up to the end where you will hear a

click.

At that time the rear trigger will come out, the moved handle will be locked and it will unlock the angle.

Taking the third enclosure by the handles, we will lower it gently upon the second enclosure, until it rests

upon it.

Remove the safety pins on each side of the box and to anchor the enclosure we will use these pins as

shown in the figures, on page 7.

Once the third enclosure is supported by the second and the front safety pins are positioned, we will

choose also 7º with the angle selector and we will put the rear safety pins on the second enclosure (two on

each side of the enclosures): put pins in REAR LINK holes of third enclosure and others, in the holes

corresponding to 7º angle, on the second enclosure (as shown in the figures below and as seen on page 8).

Check that all safety pins are located correctly because they will have to withstand the weight of all the

enclosures.

These figures show final mounting of three

enclosures on a PL-20S platform. We can leave

the front rods prepared for stacking the fourth

enclosure, only if the group isn't finished.

Manual de Colgado / aero series / Rigging Manual

9

Page 10

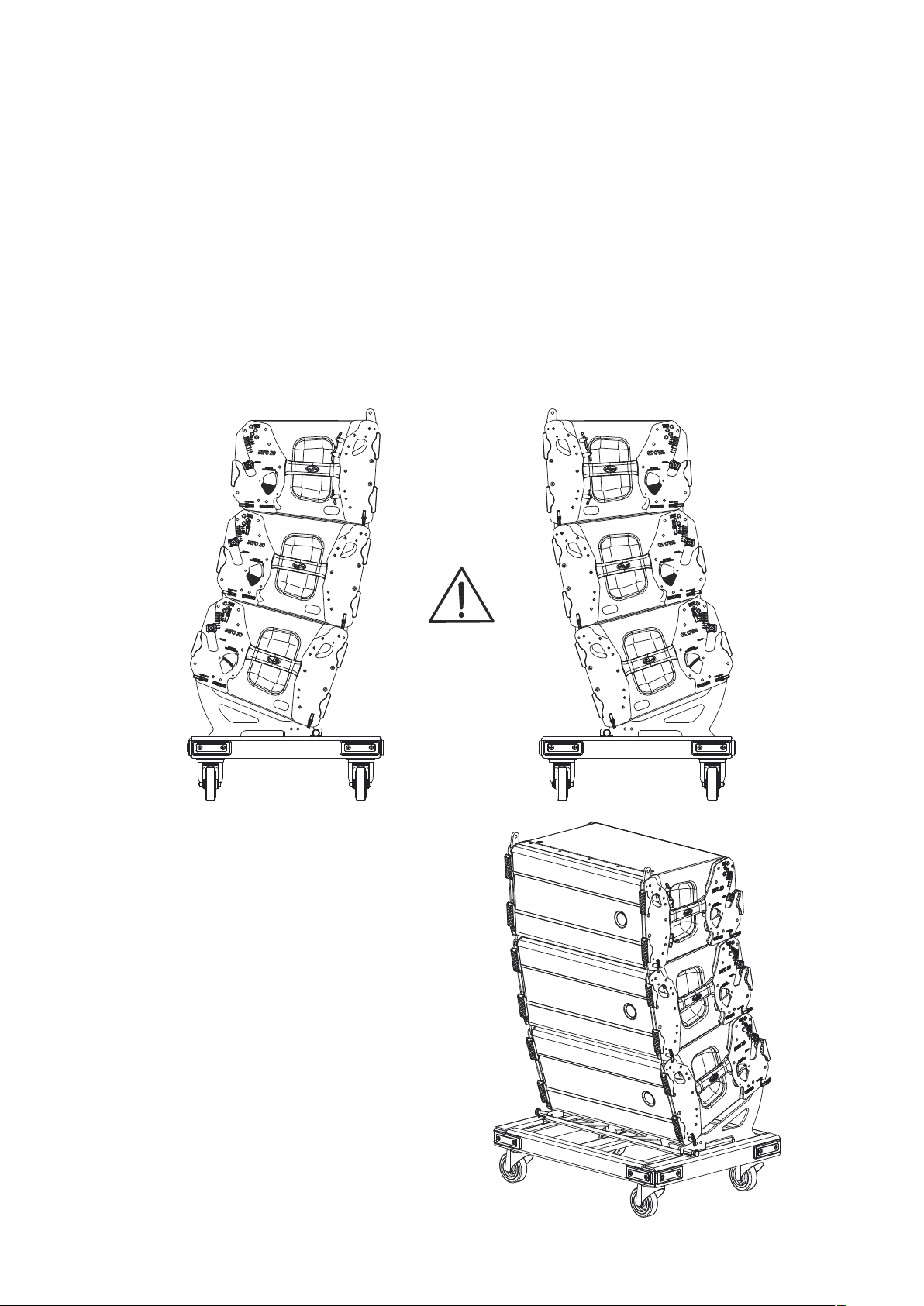

Now we should unlock the angle in the fourth enclosure to place it on the third (in this configuration the

rear trigger is hidden, as seen on page 7).

To do this we will move the handles on the sides of the enclosure up to the end where you will hear a

click.

At that time the rear trigger will come out, the moved handle will be locked and it will unlock the angle.

Taking the fourth enclosure by the handles, we will lower it gently upon the third enclosure, until it rests

upon it.

Remove the safety pins on each side of the box and to anchor the enclosure we will use these pins as

shown in the figures, on page 7.

Once the fourth enclosure is supported by the third and the front safety pins are positioned, we will

choose also 7º with the angle selector and we will put the rear safety pins on the second enclosure (two on

each side of the enclosures): put pins in REAR LINK holes of fourth enclosure and others, in the holes

corresponding to 7º angle, on the third enclosure (as shown in the figures below and as seen on page 8).

Check that all safety pins are located correctly because they will have to withstand the weight of all the

enclosures.

These figures show final mounting of four

enclosures on a PL-20S platform.

Do not stack more than four boxes so as

not to endanger stability.

10

Manual de Colgado / aero series / Rigging Manual

Page 11

ARRAY MOUNTING WITH GROUPS OF 4 UNITS ON A PL-20S

The groups of 3 or 4 units are easy to

transport by truck.

Lets see in this section how to mount an array

with groups of four units.

Firstly, we will mount the AX-AE20 onto the top

enclosure of the first group of four units.

Therefore, to mount the AX, the rods of the

upper unit of the group should be extracted, as

explained in the previous section.

The result is shown in the figure at the right.

Then, place the side parts of the AX inserting

safety pins, as shown in the figure below.

Check that the security pins are well positioned

because they will support the weight of the rest of

the enclosures.

Rods

DETAIL

Note:

Select 0º angle and the

safety pin should put it

to lock the rear rod

RESULT

Manual de Colgado / aero series / Rigging Manual

11

Page 12

With the help of the Ease Focus software we can

determinate which point is the correct one to join

the side pieces with the crossbar of the AX-AE20,

called PICKUP-AX-AE20, and with the help of the

security pins, as shown in figures.

If we use two lift motors, we will use a second

PICKUP-AX-AE20 which joins through the same way

to the pinpoint marked by Ease Focus software.

Check that the security pins are well

positioned.

DETAIL

AX-AE20

W.L.L.: 715 kg

PICKUP-AX-AE20

W.L.L.: 715 kg

RESULT

Lastly, hook the lift motor. In case two lift motors are needed, hook each one to each PICKUP-AX-AE20.

Like in every security operation, use adecuate security elements.

12

Manual de Colgado / aero series / Rigging Manual

Page 13

Proceed to assign the angles to each enclosure.

Note that the angle for the first enclosure is 0º (the security pin is positioned in the SELECT ANGLE hole

for this angle). This is the right position for it.

With the help of the Ease Focus software we will know the correct angle to each enclosure. This process is

similar for all the enclosures.

But first, pay attention to the silkscreen on the enclosure's side.

SELECT ANGLE

holes for

security pins

Example of blue

discontinuous line

Example of white

continuous line

Angle selector handle

We can see that there are two types of lines (continuous and discontinuous), with two colors (white and

blue).

Thus, each selectable angle is matched with a hole to fix a security pin, ie, a hole presents the same type

of line and color that the angle chosen with the angle selector handle.

Therefore, if we choose an angle, we will place a security pin in the hole with the same type of line and

color (see example below).

Example: SELECT ANGLE = 7º

Manual de Colgado / aero series / Rigging Manual

13

Page 14

Now, we shall proceed to assign the angles between each

pair of enclosures.

Remember that the angle for the first enclosure is 0º (the

security pin is positioned in the SELECT ANGLE hole for this

angle). This is the right position for it.

Also remember that you have to do the same in the reciprocal

sides of the same boxes (in the figures only one side is

illustrated).

1.- Take out the

security pin from

the SELECT

ANGLE hole of the

lower enclosure.

2.- Select the desired

angle, for example 1º.

DETAIL

DETAIL

14

DETAIL

4.- Push the rear

trigger to lock the

angle in each side of

the enclosure.

3 .- R epl ace t he

security pin in the

appropriate "SELECT

ANGLE" hole. In the

example, into 1º (this

hole is the same as

for 7º, 5º, 3º and 1º).

Manual de Colgado / aero series / Rigging Manual

DETAIL

Page 15

Once that we have assigned the angle between the first pair of enclosures, acting on both sides of

enclosures, we shall repeat the same process to select the angle between the second and third. And so on

until the last.

We shall reallocate the angles of the example so that they may be more usual angles, we are going to

think of an array consisting of 8 enclosures.

Note: The selected angles will be visible when we lift the enclosures, so before lifting the group you can

easily assign, and change, angles.

In this new case, we shall assign:

Between first and second: 0.5 °

Between second and third: 1

Between third and fourth: 1.5 °

Note that the angle is obtained by acting on the lower enclosure, so that we may have determined angle

between the fourth and fifth enclosures, you should act on the fifth when you have added it.

At this point, so that we may add more enclosures we should disengage the platform.

1º

DETAIL

2º

LIFT

1º

1º

As shown in the figures: First we will remove

the security pins of the platform (4 units) and then

we shall lift the group of enclosures.

When lifting, we see that the group separates

from the platform, and we shall hear a few clicks

when selected angles will be blocked between the

enclosures.

Manual de Colgado / aero series / Rigging Manual

15

Page 16

This figure shows the result when we lift the

group.

0º

0,5º

1º

1,5º

16

Manual de Colgado / aero series / Rigging Manual

Page 17

Box No.1

Box No.2

Now, we shall proceed to assign the angles in the next

group of 4 units, as before, with the same procedure we shall

assign:

Between fourth and fifth: 2º

Between the fifth and sixth: 4º

Between the sixth and seventh: 6º

Between the seventh and eighth: 7º

As we have done before and according to the following

figures.

1.- First, we will draw the

rods from the upper unit (box

No.5) of the new group of boxes

1.

(as on page 11). Then we shall

assign the angle between the

upper enclosure of the next

group and the lower enclosure

of the previous group. For this,

we will insert the security pins in

the SELECT ANGLE holes

corresponding to 2º.

Box No.3

Box No.4

Box No.5

Box No.6

Box No.7

DETAILS

2.

3.

2.- We shall let down

the previous group until

the front rods of the

upper box of the new

group (box No.5) are

aligned with the holes of

the lower enclosure of

the previous group (box

No.4). Then we shall put

the security pins to link

the front.

3.- We shall continue

lowering the upper group

until fully supported by the

lower group. Finally, we

will put the security pins in

REAR LINK holes of box

No.4, joining all boxes.

Box No.8

Manual de Colgado / aero series / Rigging Manual

17

Page 18

Once the upper enclosure of the new group is

joined, we will assign the angles of the other

enclosures, following the instructions of the Ease

Focus software.

In this example:

Between fourth and fifth: 2º

Between fifth and sixth: 4º

Between sixth and seventh: 6º

Between seventh and eighth: 7º

The procedure for assigning angles to the

boxes is the same as described with the first

group of 4 units.

As already mentioned, after assigning the

angle you need, you will have to press the

rear trigger to lock it.

The same applies to the process for removing

the platform.

1º

DETAIL

2º

LIFT

1º

1º

18

Manual de Colgado / aero series / Rigging Manual

Page 19

Here, the figures show final mounting for this example of a typical array with 8 units.

0º

0.5º

1º

1.5º

2º

4º

6º

7º

Manual de Colgado / aero series / Rigging Manual

19

Page 20

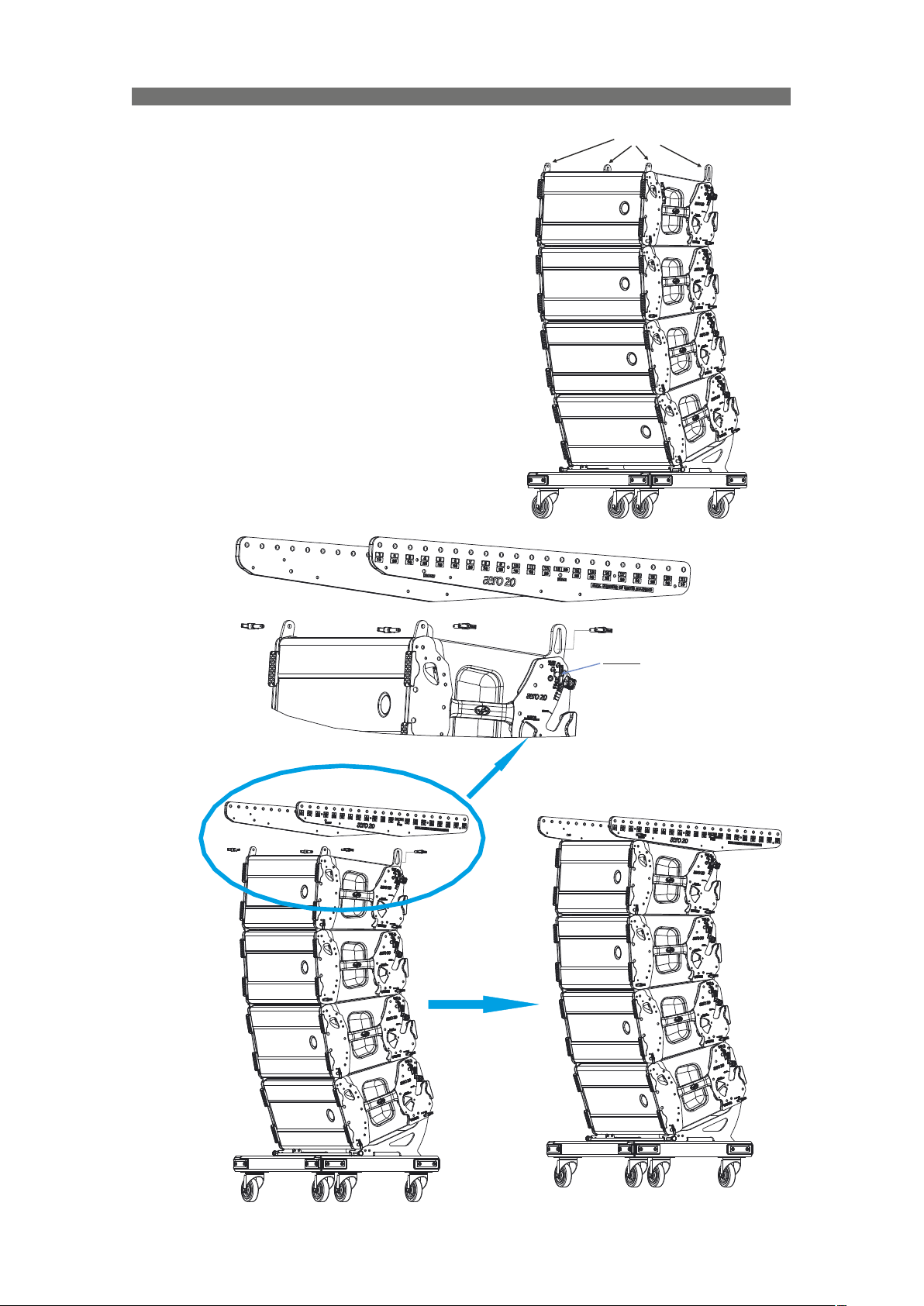

ARRAY DISASSEMBLY IN GROUPS OF 4 UNITS ON A PL-20S

The groups of 4 units are easy to transport by truck as we shall see below. This section describes how to

disassemble an array in groups of 4 units.

First, we go down aligning the array with the platform PL-20S, as shown in the figures below.

20

Manual de Colgado / aero series / Rigging Manual

Page 21

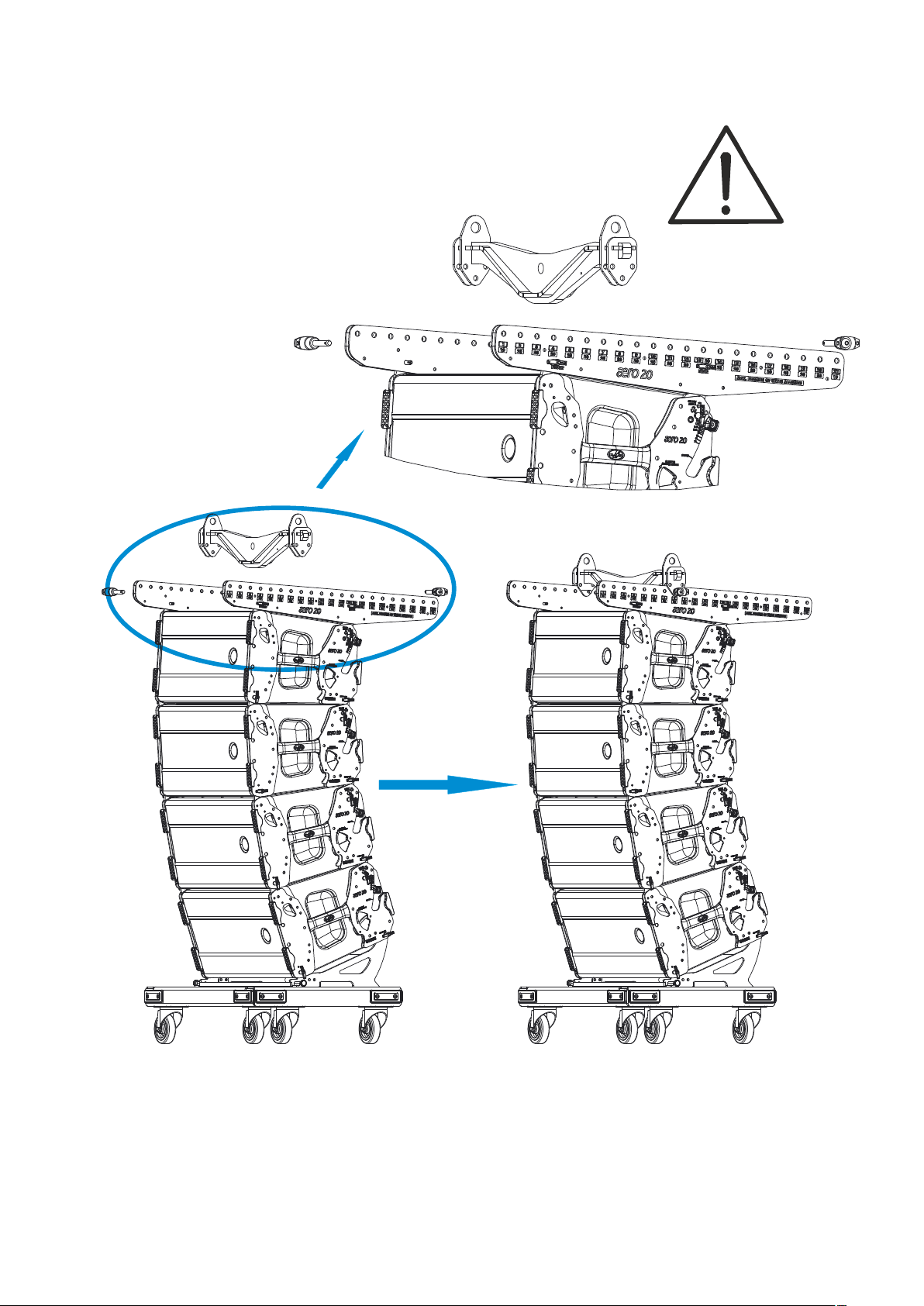

Before supporting the array on the platform, it is important to unlock the angles of the

corresponding boxes (see figure boxes No.2, No.3 and No.4, leaving the No.1 blocked), just as seen on

page 7, so that the angles can fold, when we go down with the enclosures, onto the platform.

Box No.4

Box No.3

Box No.2

Box No.1

Manual de Colgado / aero series / Rigging Manual

Box No.4

Box No.3

Box No.2

Box No.1

21

Page 22

Now, we shall give the two lateral pins of the platform a half turn

as shown in the below figure (1).

This will allow us to release the tray of the platform (2) and raise it.

Align the front holes of the tray and the enclosure, and link them

with two security pins (3).

DETAIL

3

3

2

1

These lateral pins

release the tray

from the platform

Then we will go down the array until it rests on

the platform (4). Be very careful with this

operation to avoid accidents. Use personal

safety elements required as safety shoes,

gloves, etc.

We will turn the lateral pins of the platform so

that the tray is blocked and, finally, place the

security pins in the REAR LINK holes (5).

1

4

22

5

Manual de Colgado / aero series / Rigging Manual

Page 23

Now, we will continue going down the array,

resting it on the platform. When the four lower

boxes are resting, we shall proceed to remove the

security pins, as shown in the following figures.

1.- We shall remove the

security pins of the REAR

LINK holes of the upper box.

1.

2.- Then we shall remove

the front security pins.

2.

DETAILS

3.

3.- We shall lift the rest of

the array a little and we shall

draw this group of boxes

from under the top group,

then we shall fold the front

rods acting on the front

trigger, we will remove the

security pins of SELECT

ANGLE holes and we will

move the handles to STORE

position (folding the rear

rods).

To d i s a s s e m b l e t h e

remaining enclosures, we shall

proceed as with the first group.

Manual de Colgado / aero series / Rigging Manual

23

Page 24

COMBINATION WITH AERO-40A ARRAY

The AERO-20A and AERO-40A units can be combined to form an array. This type of mixed array requires

an accessory, the AX-COMBO2040. In this section we will learn how to use it.

AX-COMBO2040

WLL: 300 kg

Place two pins

on each side

The AX-COMBO2040 should be mounted on the

aero20A group as shown in the figures.

Check that all security pins are located correctly

because they will withstand the weight of all the AERO-20A

enclosures.

In our website you will find an explanatory guide to the

different types of DAS Audio Group, S.L. security pins,

and where they are used, with explanatory drawings.

The result can be seen in the figure below.

The pins to link with AERO-40A

are included in AX-COMBO2040.

Place the pin in

SELECT ANGLE hole

that we have obtained

in the Ease Focus

software, for our

application.

24

Manual de Colgado / aero series / Rigging Manual

Page 25

As shown in the following figures, AERO-20A and AERO-40A enclosures joined by the AX-COMBO2040

PIN

Ø (mm)

L (mm)

Ref.

PIN-6-C

6

15

30003600

PIN-6623

30002878

PIN-8-C

8

22

30006080

PIN-8830

30002877

accessory.

Check that all security pins are located correctly because they will have to withstand the weight of all the

enclosures. They are of different sizes and are placed in both sides of the accessory.

PIN-8

PIN-8-C

PIN-8-C

In our website you will find an explanatory guide to the different types of security pins provided by DAS

Audio Group, S.L., and where they are used, with explanatory drawings. Here, is a chart with the different

sizes.

Ø

L

PIN-8

Manual de Colgado / aero series / Rigging Manual

25

Page 26

The result, when we lower the array of AERO40A onto an AERO-20A group and join them, we

will have:

The result is shown in the figure at the right.

It will suffice with that we lift the array, remove

the platform and secure the array to the correct

height, to complete the assembly of this

combination of boxes.

To disassemble, we must continue with the

same sequence of steps, but in reverse order.

Note: Save the PIN 8 type in the interior holes

of AX-COMBO2040, to prevent loss.

26

Manual de Colgado / aero series / Rigging Manual

Page 27

STACKING SYSTEMS

The PL-20S platform can help transport the units, but if used to stack systems, the array could be

unstable, because the array’s angles can move the center of gravity. This is the reason why we don't

recommend its use to stack systems.

However, the PL-218CS doesn’t have this problem, so it is possible to use it for stacking systems and to

transport them (maximum of 3 units of any version of LX-218CA).

Therefore, we will have the following accessories for stacking systems of aero series:

The PL-218CS is a platform that allows the

transportation and stacking use, up to 3 stacked

units of LX-218CA (all versions).

These holes allow to

screw the AXS platforms to

the subwoofer cabinets

PL-218CS

WLL: 400 kg

AXS-AE20

WLL: 150 kg

The AXS-AE20 is a platform that allow the stacking of AERO-20A units (up to a maximum of 4 units), over

subwoofer enclosures.

Warning: The platform and the subwoofer enclosures should be joined, with screws or with

endless ratchet straps (not included), for a safe stacking (see the examples below).

With endless

ratchet straps

Manual de Colgado / aero series / Rigging Manual

With screws

27

Page 28

The AXS-AE20 accessory allows assigning angles to the enclosures easily, following the instructions (see

the figures below).

0º

The AXS-AE20 accessory in combination with the AXC-ZT accessory allows for system applications

as shown in the lower figures.

Warning: Don’t stack more units than recommended:

MAX STACKED UNITS:

Ÿ 4 UNITS on AXS-AE20

Ÿ

Ÿ 1 UNIT on AXS-AE20 with AXC-ZT

+3.5º -3.5º

28

Manual de Colgado / aero series / Rigging Manual

Page 29

TRANSPORTING

This section describes aero unit transport recommendations

We will start with two examples of configurations and we will recommend different ways of loading them

inside a truck.

eCP_20

eCP_20

2

1

3

eCP_20

3

PUSH

2

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

1

3

3

PUSH

2

1

2

1

3

3

PUSH

2

1

L2

L1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

L3

I

o

FI4030mA4pol.

FI-Schalter

6xMCB 16A “C” 1pol.

1xRCD 40A 30mA 4pol.

DASNET-RACK-26

eCP_20

eCP_20

Example 1: 16 x AERO-20A + 8 LX-218CA-NET

L R

LINK L

LINK R

1

3

PUSH

2

2

1

2

1

2

1

2

1

2

1

2

1

1

3

PUSH

2

1

3

PUSH

2

2

3

1

3

3

3

3

3

3

2

3

1

2

3

1

eCP_20

L2

L1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

L3

I

o

FI4030mA4pol.

FI-Schalter

6xMCB 16A “C” 1pol.

1xRCD 40A 30mA 4pol.

DASNET-RACK-26

eCP_20

IN OUT1 OUT2 OUT3 IN OUT1 OUT2 OUT3

eCP_3 eCP_3

eCP_3 eCP_3

eCP_20

IN OUT1 OUT2 OUT3 IN OUT1 OUT2 OUT3

Manual de Colgado / aero series / Rigging Manual

eCP_3 eCP_3

eCP_3 eCP_3

29

Page 30

x 4

IN OUT1 OUT2 OUT3

DASnet Splitters

4 x aero20

4 x aero20

Steel case intended for distribution of analog audio,

monitoring data and power to multiple devices.

It includes: - one input power (1 x powerCon true 1) and 3

power outputs (3 x powercon NAC3MPB).

One audio+monitoring data input,

and three audio + monitoring data ouputs

243cm / 96”

4 x aero20

4 x aero20

4 x aero20

4 x aero20

228cm / 90”

4 x aero204 x aero20

4 x aero20

4 x aero20

251cm / 99”

4 x aero20

4 x aero20

x 4

16 AERO-20A

x 1

DSP-2060A

Processors (included in the racks)

PL-20S metal transport dolly for 3/4 AER O-20A

16 AERO-20A + 8 LX-218CA-NET

x 8

Euro truck 6m Trailer

4 x aero20

4 x aero20

4 x aero20

4 x aero20

2 x LX218CA

2 x LX218CA

2 x LX218CA

2 x LX218CA

2 x LX218CA 2 x LX218CA 2 x LX218CA 2 x LX218CA

American Truck 90” x 232”

x 4

x 4

4 x aero20

4 x aero20

228cm / 90” 243cm / 96”

4 x aero20

4 x aero20

American Truck 99” x 232”

4 x aero20 4 x aero20

251cm / 99”

2 x LX218CA

2 x LX218CA

2 x LX218CA

2 x LX218CA

4 x aero20 4 x aero20

x 4

Accessories

Speaker cabling Dollies

30

x 8

x 12

x 12

Plink1_09 (power link 2,5mm2 90cm)

eCP_20 (C AT 7 ethernet cable + 3x2,5mm2, audio +data + power, 20m lenght)

eCP_3 (C AT 7 ethernet cable + 3x2,5mm2, 3m lenght)

eC_09 (CAT 7 ethernet cable; audio +data, 90cm lenght)

DASnet-Rack 26 (1 DASnet patch 26 + power distro 32Amp)

Manual de Colgado / aero series / Rigging Manual

x 2

2

1

3

3

PUSH

2

1

2

3

1

2

3

2

1

3

1

2

3

1

2

2

3

3

1

1

2

3

1

2

3

2

1

3

1

2

3

1

2

3

1

2

1

3

3

PUSH

2

2

1

3

1

2

1

3

3

PUSH

2

1

L2

L1

L3

I

o

FI4030mA4pol.

FI-Schalter

6x MC B 16A“C” 1pol.

1x RC D 40A30mA 4pol.

FUN-2-L X218C nylon cover for a stack of 3 LX-218CA-N ET

Rigging frames

Covers

FUN-4-A E20 is a protective nylon cover for 4 AERO-20A

x 2

AX-AE20

Dollies

PL-218CS

The PL-218C S dolly is used to transport

stacks of 2 or 3 LX-218C A-NET.

Page 31

Here is the second example:

eCP_20

eCP_3

eCP_3

eCP_3

eCP_20

eCP_20

eCP_20

IN OUT1 OUT2 OUT3

2

1

3

3

PUSH

2

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

1

3

3

PUSH

2

1

2

1

3

3

PUSH

2

1

L2

L1

L3

2

3

1

I

o

2

3

1

FI4030mA4pol.

FI-Schalter

2

3

1

2

6xMCB 16A“C” 1pol.

3

1

2

3

1

2

3

1

eCP_20

1xRCD 40A30mA 4pol.

eCP_3

eCP_3

DASN ET-RACK-26

IN OUT1 OUT2 OUT3

eCP_3

Example 2: 24 x AERO-20A + 12 LX-218CA-NET

2

1

3

3

PUSH

2

1

2

3

1

L R

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

1

3

3

PUSH

2

1

2

1

3

3

PUSH

2

1

L2

L1

L3

2

3

1

I

o

2

3

1

FI4030mA4pol.

FI-Schalter

2

3

1

2

6xMCB 16A“C” 1pol.

1xRCD 40A30mA 4pol.

3

1

2

3

1

2

3

1

DASN ET-RACK-26

eCP_20

eCP_20

IN OUT1 OUT2 OUT3

eCP_3

eCP_3

eCP_3

eCP_20

eCP_20

eCP_20

IN OUT1 OUT2 OUT3

Manual de Colgado / aero series / Rigging Manual

eCP_3

eCP_3

eCP_3

31

Page 32

x 4

IN OUT1 OUT2 OUT3

DASnet Splitters

4 x aero20

4 x aero20

4 x aero20 4 x aero20

Steel case intended for distribution of analog audio,

monitoring data and power to multiple devices.

It includes: - one input power (1 x powerCon true 1) and 3

power outputs (3 x powercon NAC3MPB).

One audio+monitoring data input,

and three audio + monitoring data ouputs

243cm / 96”

4 x aero20 4 x aero20

4 x aero20

4 x aero20

228cm / 90”

4 x aero20

4 x aero20

4 x aero20

4 x aero20

4 x aero20

4 x aero20

251cm / 99”

4 x aero20 4 x aero20

4 x aero20 4 x aero20

x 6

24 AERO-20A

x 2

DSP-2060A

Processors (included in the racks)

PL-20S metal transport dolly for 3/4 AER O-20A

24 AERO-20A + 12 LX-218CA-NET

x 12

3 x LX218CA 3 x LX218CA 3 x LX218CA 3 x LX218CA

Euro truck 6m Trailer

4 x aero20 4 x aero20

4 x aero20 4 x aero20

4 x aero20 4 x aero20

228cm / 90” 243cm / 96”

4 x aero20

4 x aero20

4 x aero20

4 x aero20

4 x aero20

4 x aero20

3 x LX218CA 3 x LX218CA 3 x LX218CA 3 x LX218CA

American Truck 90” x 232”

x 6

x 4

251cm / 99”

3 x LX218CA

3 x LX218CA

3x LX218CA

3 x LX218CA

4 x aero20 4 x aero20 4 x aero20

4 x aero20 4 x aero20 4 x aero20

American Truck 99” x 232”

x 4

Accessories

Speaker cabling Dollies

32

x 10

x 18

x 18

Plink1_09 (power link 2,5mm2 90cm)

eCP_20 (C AT 7 ethernet cable + 3x2,5mm2, audio +data + power, 20m lenght)

eCP_3 (C AT 7 ethernet cable + 3x2,5mm2, 3m lenght)

eC_09 (CAT 7 ethernet cable; audio +data, 90cm lenght)

DASnet-Rack 26 (1 DASnet patch 26 + power distro 32Amp)

Manual de Colgado / aero series / Rigging Manual

x 2

2

1

3

3

PUSH

2

1

2

3

1

2

3

2

1

3

1

2

3

1

2

2

3

3

1

1

2

3

1

2

3

2

1

3

1

2

3

1

2

3

1

2

1

3

3

PUSH

2

2

1

3

1

2

1

3

3

PUSH

2

1

L2

L1

L3

I

o

FI4030mA4pol.

FI-Schalter

6x MC B 16A“C” 1pol.

1x RC D 40A30mA 4pol.

FUN-3-L X218C nylon cover for a stack of 3 LX-218CA-N ET

Rigging frames

Covers

FUN-4-A E20 is a protective nylon cover for 4 AERO-20A

x 2

AX-AE20

Dollies

PL-218CS

The PL-218C S dolly is used to transport

stacks of 2 or 3 LX-218C A-NET.

Page 33

ANNEX I : Tools for rigging systems

For best results when hanging aero series 2 systems, it is mandatory the use of Ease Focus 2 simulation

software which can be downloaded for free from the support section of our website . www.dasaudio.com

The download file contains the software and data files with gll files for acoustic systems.

The user should be aware that any deviation in the actual installation of the system with respect to

the simulated data can affect the system’s coverage, especially in the long throw. Therefore DAS can

provide clinometers and laser meters to accurately perform the installation of the system:

Leica Disto D5 Laser Meter

Clinometer which is attached to the top

cabinet of the array and sensor module.

TEQSAS LAP-TEQ

Manual de Colgado / aero series / Rigging Manual

33

Page 34

ANNEX II : Maximum load capacity for AX-AE20

AX-AE20

AX-AE20 modular flybar set is comprised of two side panels of steel and aluminum and a

central crossbar (PICKUP-AX-AE20).

The maximum load capacity is 20 units * (pick-up point dependent) with a 5:1 safety factor.

For systems of 12 units or more, an additional bar should be added and the array will hang

from two lift motors for greater security and control over the angle of the system at all times.

AERO-20A load limitation: * On the side panels the maximum number of units that can be flown

are screen printed depending on the pick-up point marked by the software (or vertical axis of the

center of gravity of the system). Consulting the EASE Focus 2 software we will determine the number

of units which can be flown from each pick-up point.

pick-up point

maximum

number of units

These limitations depend on the load of the vertical axis position of the center of

gravity of the system:

From points 2 to 20 regardless of whether you use a motor or two, a maximum of

20 AERO-20A units can be flown.

At point 1, 19 units of AERO-20A can be flown.

At point 21, 19 units of AERO-20A can be flown.

Pick-up point - vertical axis of the center of gravity

In the image at the right you can see the vertical axis of the center

of gravity for the system passing through the pick-up point number

11.

pick-up

point

The pick-up point shown in the software is placed in alignment

with the vertical axis of the center of gravity for the system. The

position of this vertical axis obviously depends on the number of

boxes, the angle between them and full vertical angle. The loading

limitations are displayed by the software and depend on the vertical

axis that position the center of gravity.

34

Manual de Colgado / aero series / Rigging Manual

Page 35

For example, lets take a system of 16 AERO- 20A units. If we consult the

panel lettering of the AX-AE20, we observe that 16 units can be flown when

the vertical axis of the center of gravity is aligned with any of the 21 hanging

positions.

In the simulation attached, the system is flown at 10 meters with -6.98º of

inclination. No warning of maximum load appears.

The warnings of maximum load appear ONLY if the number of cabinets is

greater than 19 units. For more than 19 units, the warnings of load appear and

we should check where the vertical axis of the center of gravity for the system

is situated.

See what happens if we add four more boxes.

Now we have a total of 20 AERO-20A units and the

software warns us that only 20 units from point 2 at

20 can be flown.

In this case, we have -6.98° of inclination, the

vertical axis of the center of gravity of the system is

positioned in alignment with the pick-up point

number 20. In this case, we are within the safety

margins. Remember that from point 2 to point 20,

20 units can be flown (see above panel drawing AX-

AE20).

20 AERO-20A units - As the axis of the vertical center of gravity coincides

with the point 20, we can fly 20 units with that configuration.

Manual de Colgado / aero series / Rigging Manual

35

Page 36

ANNEX III : Advice for EASE Focus 2 use

It’s important to understand the signs of the system's total angles in the EASE Focus

2 software program.

A cluster can be flown at different angles, depending on the number of cabinets, the

angle between them and the pick-up point. The angle in the software is defined in

section View [º]

Inclining systems forwards (downwards) result in a negative angle ( ). The systems -

inclined upwards result in a positive angle ( ).+

+

Angle criteria of the cluster

-

-5º

6 AERO-20A at -5º

6 AERO-20A at +10º

+10º

36

Manual de Colgado / aero series / Rigging Manual

Page 37

Meaning of parameter DELTA EASE Focus 2:

The delta parameter marks the angle NEEDED to reach the desired angle in our system

(View [°]). This information is useful ONLY when the system is flown from a single POINT.

Imagine a system of 8 units hanging 11 meters high.

The desired angle is: View [°] -15°

As shown in the image, Delta [º] -0.69º

This means that to reach the desired -15 º, we are

lacking 0.69º when the system is flown at the point 19.

If the delta sign is negative (-), this indicates that we are

lacking 0.69 downwards.

If the delta sign is positive (+), this means that we are

lacking degrees upwards.

+

Angular criteria of delta

-

Now, we consider the opposite case.

This is the same system hanging from a single point. 8

AERO-20A units.

The desired angle: View [°] -12°

In this case Delta [º] is 0.53º

This means that if we hang the system from point 18 we

lack tilt up 0.53º to reach the desired -12º.

Manual de Colgado / aero series / Rigging Manual

37

Page 38

DELTA parameter in EASE Focus 2 software and maximum angles:

As seen before the DELTA parameter makes a difference (in excess or in lack of) between the desired angle and

the obtained angle to hang the system from a single point.

When we fly the system from TWO points, this parameter is very useful because we also determine the maximum

angles with which we can install it.

For example, suppose a set of 16 AERO-20A units:

The system is inclined -7,27º

Vertical axis position of center of gravity is aligned with

the pick-up point number 19.

To what maximum angle could we tilt down the

system?

Suppose we want to hang the system at -15°.

Let's see what happens in the software:

Observe how Delta: -8.37º

This means that we lack to reach the

desired 8.37º, -17º.

In this case the system could only have a

maximum tilt: 17-8.37 = 8.63°

since no further pick-up points are available

on the AX-AE20.

38

Indeed if we change the angle of the system to -8.63°, we see that the

pick-up point (vertical axis of center of gravity) is number 21 and delta

is zero.

Manual de Colgado / aero series / Rigging Manual

Page 39

www.dasaudio.com

RM_AE20_02_EN

DAS Audio Group, S.L.

C/. Islas Baleares, 24

46988 Fuente del Jarro

Valencia, SPAIN

Tel. +34 96 134 0860

DAS Audio of America, INC.

6900 NW 52th Street

Miami, FL. 33166 - U.S.A.

TOLL FREE: 1 888 DAS 4 USA

DAS Audio Asia PTE. LTD.

3 Temasek Avenue, Centennial

Tower #34-36

Singapore 039190

Tel. +65 6549 7760

DAS do Brasil LTDA.

Rua Dos Andradas, 382 SL

Santa Efigênia, São Paulo

Brasil. CEP: 01208-000

Tel. +551133330764

Loading...

Loading...