DARLEY HEF Operating Instructions Manual

OPERATING INSTRUCTIONS

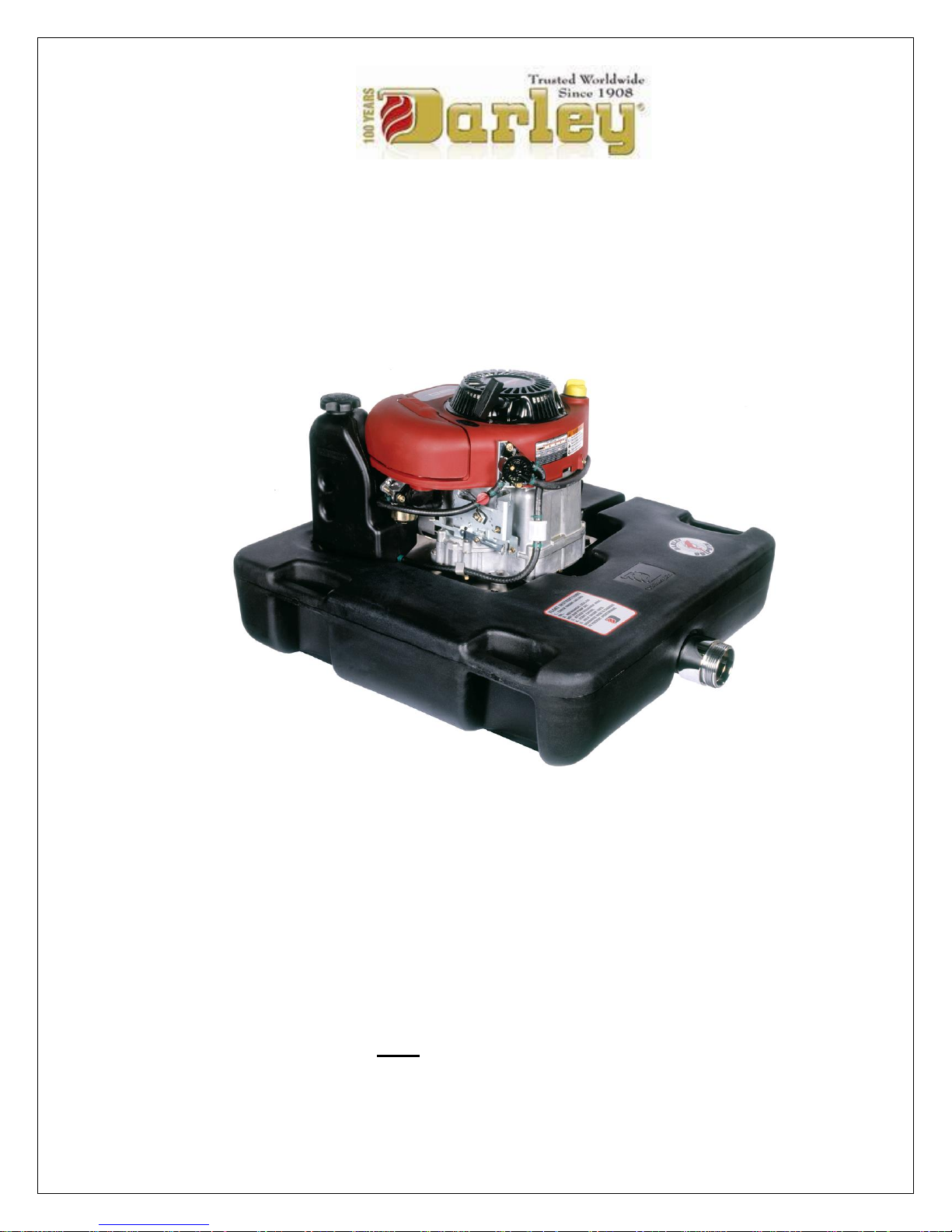

HEF DOLPHIN FLOAT PUMP

Corporate Office: Pump Manufacturing: Apparatus Division:

325 Spring Lake Drive 1051 Palmer St. 920 Kurth Rd.

Itasca, Illinois 60143-2072 Chippewa Falls, WI 54729 Chippewa Falls, WI 54729

800-323-0244, fax (708) 345-8993 800-634-7812, Fax (715) 726-2656 800-527-0068, Fax 726-2648

WWW.DARLEY.COM

This manual is for DARLEY FIRE PUMP:

Model: HEF Pump Serial Number: ________

Introduction

This manual provides information for the use and understanding of this manual, correct

operation, maintenance, troubleshooting of the Darley HEF Dolphin Float Pump, definition of

terms, and contacts. Please read and understand these instructions thoroughly before putting

this system into service. Doing so will ensure optimum performance and long life of your

Darley Floating Pump.

This manual is divided into eight sections, each section details an important portion of this

manual and pump.

Section 1 Definition of Symbols

Section 2 Operation

Section 3 Pump Assembly/Disassembly

Section 4 Components

Section 5 Maintenance Schedule

Section 6 Troubleshooting

Section 7 Definition of Terms and Operating Characteristics of

Pumps.

Section 8 Contacts

Section 1

Definition of Symbols

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

IMPORTANT

Throughout this manual will find Caution, Warning and Danger symbols.

Please pay close attention to these symbols as they are for your safety.

- Signifies an imminently hazardous situation that

could result in death or serious injury.

- Signifies a potentially hazardous situation that could

result in death or serious injury.

- Signifies a potentially hazardous situation that

might result in minor or moderate injury.

- Signifies a potentially hazardous situation that

might result in property damage.

Intentionally ignoring any of these identified hazards is not

recommended. W.S. Darley does not advise such actions or take

responsibility for the actions of any operator of this unit.

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

Section 2

Operation

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

Operating Instructions

For Darley “DOLPHIN” Floating Fire Pump

Do not use this pump for hose testing. Such testing could

result in major pump or engine damage. Such damage may cause

explosion, overheating of the engine and/or pump, and bodily harm.

PREPARATIONS FOR PUMPING

Make sure to read the engine instruction manual before usage.

Check the engine oil level before starting the engine.

Check the fuel level before starting the engine.

Do not run the pump dry or at high speed unless it is placed in water of adequate

depth.

Connect the discharge hose to the pump.

Ensure the discharge breather check valve; located near the Darley emblem on

the float; is working, clean and clear of debris.

Start the engine.

Place float pump in the water immediately after starting. This Float pump is self-

priming due to a flooded suction. The pump will prime more quickly if the engine

is run at lower speeds.

Slowly open the engine throttle once the pump is primed and discharging water.

Recommendations

Do not allow unusual elevation of the discharge hose, this may

cause the float to overturn.

When pumping salt water or dirty water, flush pump with clean water after usage.

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

Section 3

Maintenance (Assembly/Disassembly)

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

PUMP DISASSEMBLY

Drawing DHC1204

For pump overhaul or disassembly follow the corresponding steps

Drain oil and gas from engine, ensuring there is no fuel in the tank or lines.

o There may be small residual amounts of oil remaining in the engine (up to 8

ounces), which may read at the very end of the dipstick (see photo below).

If the oil level is up as high as the H on the dipstick, below the ADD mark,

the oil needs to be further drained prior to tipping the engine.

Remove the (3) bolts holding the support plate (6) to the float (5).

Remove the pump discharge pipe from the pump discharge.

Remove the engine and pump by tilting the engine forward and lifting the

assembly clear of the float. Only tilt the engine so the exhaust faces down.

Titling the engine in other directions may damage the engine. It

may also cause fuel to leak out causing a hazardous spill.

The suction head (11) may now be removed from pump casing (8) using the

tapped pusher holes if necessary.

Remove the impeller bolt (15). Remove the engine spark plug and insert a clean

rope into bore to prevent engine rotation and ease removal of the impeller bolt

(15) (see photo below).

Prepared by: RJG Rev. A

Approved by: TED Date: 03/04/10

Revised by: TED Rev. Date: 30June2015

1200627.doc

Loading...

Loading...