Page 1

CALL 1-888-328-2383 OR VISIT WWW.DANZE.COM

© 2007 DANZE, INC. ALL RIGHTS RESERVED.

Español, página “Español - 1”

Français, page “Français - 1”

Homeowner Care Manual

Toilets. Lavatories. Bidets.

Pub No. DP620002/06-07.01

Page 2

IntroductIon to danze

Thank you for choosing Danze. We believe that elements in your bathroom

should awaken your senses like a splash of cool water. That’s what you will experience with Danze.

Danze is a manufacturer of high quality decorative plumbing products for your

powder room, kitchen and bath. We offer a broad variety of products, designs &

finishes to suit your own particular needs. You can feel confident that our products will provide years of beauty and trouble-free performance.

danze VItreous chIna Products

Danze vitreous china products include toilets, bidets and lavatories. Our fixtures

reflect state-of-the-art design and engineering, and meet or exceed the most

rigorous plumbing codes throughout North America. Operating fixtures are

equipped with first quality valves and accessories to give you years of troublefree service.

Should you have questions about your Danze purchase, contact us at our website

www.danze.com, or call our technical service center during business hours at

888-328-2383.

Danze, Inc. reserves the right to make product specification changes and to

change or discontinue models without notice or obligation in North America.

troubleshootIng

This troubleshooting guide will assist you with any difficulties with your new

Danze fixtures.

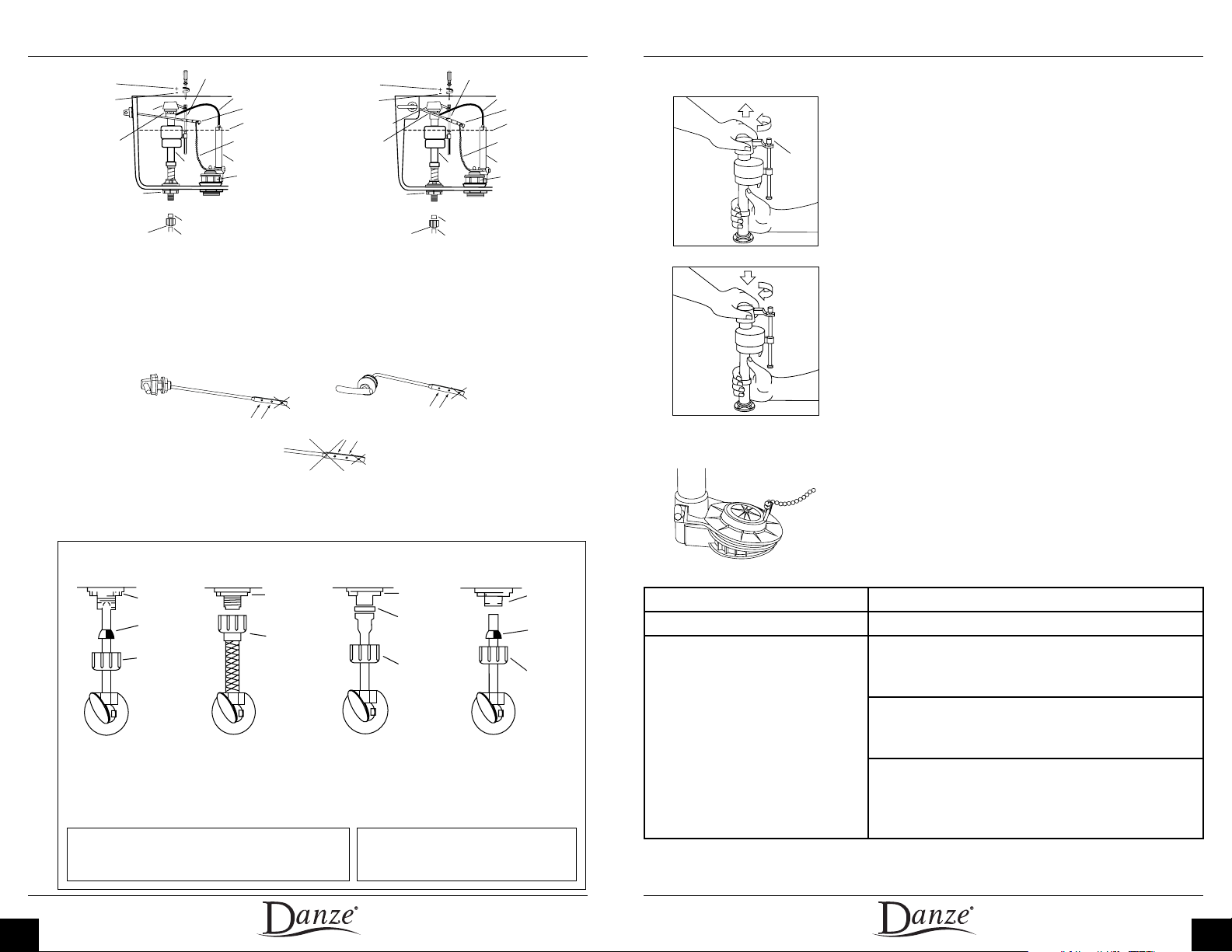

Tips for adjusting your new toilet tank components:

Adjusting the water level in the tank

•

The water level in the tank needs to be at the correct level for optimum

performance. Each toilet tank has a water level line marked on the inside

back wall of the tank. Move the float cup up or down to change the water

level in the tank. Grasp the top of the water level adjustment rod and turn

to move the float cup.

2

Page 3

Adjusting the tank lever:

Use 1st and 2nd hole (not the

3rd), and insert hook from

front....

Use 1st and 2nd hole (not the

3rd), and insert hook from

front....

.... NOT the rear

These parts must be used as illustrated to

insure water-tight connection. Use of existing

coupling nut or cone washer may result in

water leakage. Water supply tube or pipe must

extend at least 1/2" inside threaded shank of

valve (does not apply to flanged tubing).

Use existing spiral cone

washer. Fluidmaster®

cone washer may not

seal completely on spiral

type supply line.

Use existing

coupling nut

and washer.

Caution: Overtightening of lock nut or coupling

nut could result in breakage and potential

flooding.

Caution: Do not use cone washer

with plastic supply line.

Metal/copper

tubing

Vinyl/braided

connector

Metal flanged

tubing

Metal spiral

tubing

Lock nut

Lock nut

Lock nut

Lock nut

Cone

washer

Existing

cone

washer

Coupling

nut

Coupling

nut

Coupling

nut

Existing

coupling

nut

Water

shut-off

Water

shut-off

Water

shut-off

Water

shut-off

Existing

washer

Lift arm

first

Critical water

level mark (C.L.)

must be 1" above

overflow pipe

Top

Float cup

Valve

body

Fill valve

Shank

Washer

Threaded

shank

Lock nut

Cone washer

Parts for water

connection

Coupling nut

(hand tight only)

Flapper

Flush valve

Flapper chain

Water level

Tank lever

Refill tube

Water level

adjustment rod

To raise

water level

To lower

water level

Critical water

level mark (C.L.)

must be 1" above

overflow pipe

Top

Float cup

Valve

body

Fill valve

Shank

Washer

Threaded

shank

Lock nut

Cone washer

Parts for water

connection

Coupling nut

(hand tight only)

Flapper

Flush valve

Flapper chain

Water level

Tank lever

Refill tube

Water level

adjustment rod

To raise

water level

To lower

water level

•

When connecting the stainless steel chain to the tank lever arm, use the 1st

or 2nd hole closest to the tank lever (do not use the hole at the end of the

arm) and insert the hook from the front to the back. This will reduce the

chance for the flapper to hang up.

Connecting the water supply line:

•

Removing cap from pilot valve

•

Lift the lever arm and rotate the cap counter-

clockwise approximately 1/8 turn. Lift cap assembly off fill valve.

Replace cap by engaging lugs and rotating cap

1/8 turn clockwise.

Make certain that cap is turned into locked position. Valve may not turn on if the cap is not

fully turned to the locked position.

Removing/replacing the soft flapper

•

Disconnect chain hook from tank lever.

Remove soft silicone flapper from tabs on either

side of flush valve body.

3

Reverse steps to replace.

Symptom Action

No water flow when flushed Replace fill valve seal.

Water will not shut off Flapper is hanging up. Place hook for flapper

in 1st or 2nd hole closest to the tank lever and

thread the hook from front to back.

Flapper is not sealing. Insure chain has some

slack when at rest and check the seal and rim

of the flush valve for damage or obstructions.

Insure water is not flowing into the overflow

tube. If so, lower water level by grasping the

top of water level adjustment rod and turning

to move float cup.

4

Page 4

Water will not shut off Debris inside the head may be obstructing the

seat. Remove cap, clean debris away and reassemble.

Refill tube is inserted too far into overflow

tube (below tank water level). Attach refill tube

adaptor to top of flush valve overflow. Flow

from the refill tube must be positioned directly

over the overflow tube.

Water dripping from cap during refill

Water dripping from air ports

during refill

Too little water in bowl Insure refill hose is directed into overflow tube

Poor Flush Adjust water level in tank to line marked on the

No Flush Flapper chain is not connected. The chain

Noise Debris inside the head may be creating noise/

This is normal for pilot type valves. This feature

allows the pilot valve orifice to self clean during refill. The water may continue to drip for

10 or 15 seconds at the end of the refill cycle.

It should stop when float rises to the full “off”

position.

This may indicate a very low water pressure

condition. The dripping should stop when float

rises to the “off” position.

and the flow is not obstructed or restricted.

inside back wall.

Fully open water supply shut-off valve.

Clear obstructions from the bowl rim holes, jet,

or trapway.

should be attached to the tank lever and the

flapper.

Too much slack in the flapper chain. Insure

chain has some slack when at rest but can fully

lift the flapper when the tank lever is actuated.

vibration when the fill valve is flowing. Remove

cap, clean debris away and reassemble.

The flow rate of the incoming water supply may be excessively high. Partially close

the water supply stop to reduce the noise.

Open / close the water supply stop to achieve

approximately 60 second tank refill time.

care & MaIntenance

Vitreous China Plumbing Fixtures

Clean the surface of your vitreous china toilet or lavatory with a mild

•

cleaner/soap and soft cloth.

Do not use abrasive cleansers, abrasive pads or steel wool to clean vitreous

•

china surfaces as it can result in scratching and dulling of the surface.

Do not use in-tank drop-in toilet bowl cleaners containing chlorine

•

or bleach. Do not expose plastic trim parts to strong oxidizing agents,

chlorine, or acid levels of lower than 5.0 ph. Most bowl/tile cleaners

contain such agents.

Use of in-tank drop-in cleaners containing chlorine or bleach can cause

•

tank component failure and damage. Our warranty excludes such

failures.

Use of in-tank drop-in cleaners containing chlorine or bleach voids

•

Fluidmaster® warranty and will result in damage to tank components

and may cause flooding and property damage.

Toilet Seats

Clean the surface of your toilet seat with a mild cleaner/soap and soft cloth.

•

Do not use abrasive cleansers, abrasive pads or steel wool to clean the

toilet seat surfaces as it can result in scratching and dulling of the surface.

danze VItreous chIna Warranty

Five (5) Year Limited Warranty – Vitreous China

Danze, Inc. (Danze) warrants to the original purchaser of this product that the vitreous china portion will be free from defects in material and workmanship under

reasonable use for a period of five (5) years from the date of original purchase, as

shown on the original consumer-purchaser’s receipt.

Limited Warranty On Parts

Danze warrants to the original consumer-purchaser of this product that the following parts will be free from defects in material and workmanship under reasonable use for a period of years stated below from the date of original purchase:

Five (5) years:

Fluidmaster® fill valve

•

Tank lever

•

Three (3) years:

Flapper

•

5

6

Page 5

One (1) year:

Toilet seat

•

Any components not mentioned above shall be covered to the extent indicated

by the original equipment suppliers’ warranties. All above mentioned products

and parts installed in accepted commercial installations carry a one (1) year limited warranty.

As the exclusive remedy for any breach of the above warranties, Danze agrees,

at Danze’s option, to repair or replace these products or any parts thereof, which

proves, upon inspection by Danze, to be defective in material or workmanship

during the above stated periods of warranty coverage.

Danze will not be liable for any labor, shipping, freight, or any other costs or

charges incurred in connection with removal or replacement of the product or

otherwise acting upon the above warranties, or for any costs associated with

repair or replacement of any other personal property, building or installation materials. Installation or use of the product not in accordance with product instructions or improper use, abuse or neglect of, or accident to the product, or moving

the product from the location of its original installation will void the above warranties. Do not use in-tank drop-in toilet bowl cleaners containing bleach or

chlorine. Use of such products will result in damage to tank components and

may cause flooding and property damage. Use of such products will void this

warranty.

If the Federal Consumer Product Warranties Act applies to the original purchaser

of this product, then any implied warranties which may be applicable under state

law, such as any implied warranty or merchantability or any implied warranty of

fitness for a particular purpose, are limited to one (1) year.

Other than as described above, Danze disclaims any and all other warranties,

express or implied, including any warranties of merchantability or fitness for a

particular purpose. In no event shall Danze be liable to anyone, including without

limitation the original purchaser, for any damages for loss of business opportunities or profits or any business interruption or for any special, incidental or consequential damages.

The above warranties give you specific legal rights, and you may also have other

rights which vary from state to state. Certain federal and state laws may limit or

disallow disclaimers of incidental or consequential damages and/or limitations on

implied warranties.

To obtain warranty service, contact Danze at our website www.danze.com, or call

our technical service center during business hours at 888-328-2383.

Manual del ProPIetarIo

Inodoros. Lavabos. Bidés.

PresentacIón de danze

Gracias por haber elegido Danze. Consideramos que los elementos que componen su cuarto de baño deberían reavivar sus sentidos como el agua fresca. Y esto

es lo que deseamos que sienta con Danze.

Danze fabrica material sanitario decorativo de calidad superior para su medio

baño, cocina y cuarto de baño. Le ofrecemos una amplia variedad de productos,

modelos y acabados que se adaptan a sus necesidades particulares. Puede estar

seguro de que nuestros productos le brindarán años de belleza y de servicio sin

problemas.

Productos de Porcelana VItrIfIcada de danze

Los productos de porcelana vitrificada de Danze comprenden inodoros, bidés

y lavabos. Nuestros aparatos sanitarios son el resultado del diseño y de las tecnologías más modernas y cumplen o superan las exigencias más rigurosas de los

códigos de plomería en Norteamérica. Nuestros aparatos están equipados con

válvulas y accesorios de primera calidad que le ofrecerán años de servicio sin

problemas.

Si tiene alguna pregunta sobre algún producto de Danze, comuníquese con

nosotros en nuestra página web www.danze.com, o llame a nuestro centro de

servicios técnicos en horas normales de oficina, en el teléfono 888-328-2383.

Danze, Inc. se reserva el derecho de efectuar cambios en las características técnicas de sus productos, de cambiar de modelos o de interrumpir su fabricación sin

aviso previo y sin ninguna otra obligación en Norteamérica.

solucIón de ProbleMas

Si tiene dificultades con su nuevo material sanitario de Danze, vea la sección de

solución de problemas.

Consejos para el ajuste de los componentes del tanque del inodoro:

Regulación del nivel de agua de la cisterna

•

Para que la cisterna funcione adecuadamente, su nivel de agua ha de ser

el correcto. Cada cisterna lleva en su parte interior trasera una línea que

indica el nivel de agua. Mueva el flotador hacia arriba o hacia abajo para

cambiar el nivel de agua de la cisterna. Sujete la parte superior de la varilla

de regulación del nivel de agua y vuelva a mover el flotador.

7

Español - 1

Page 6

Ajuste de la palanca de descarga :

Tubo de

metal/cobre

Tubo de metal

abocardado

Tubería de metal

en espiral

Connector de

vinil/trenzado

Contratuerca

Contratuerca

Contratuerca

Contratuerca

Arandela

cónica

Tuerca de

unión

Tuerca de

unión

Arandela

existente

Tuerca de

unión

existente

Tuerca de

unión

Arandela

cónica

exitente

Cierre la

llave de paso

Cierre la

llave de paso

Cierre la

llave de paso

Cierre la

llave de paso

Se deben usar estas piezas en la forma indicada para asegurar

que no haya fugas en las conexiones. El uso de la tuerca de

unión o arandelas cónicas existente puede resultar en fugas de

agua. El tubo de suministro de agua se debe extender 1/2" como

mínimo dentro del vástago roscado de la válvula este procedimiento (no es aplicable cuando se utiliza un tubo de conexión

abocardado).

Use la arandela cónica de metal

ya existente. La arandela cónica

Fluidmaster® puede no resultar

en un sellado perfecto en los

tubos de suministro tipo espiral.

Use la tuerca

de unión y

arandela

existente.

Advertencia: El ajuste excesivo de la contratuerca o

tuerca de unión puede resultar en rotura e inundación.

Advertencia: No use arandelas cónicas con tubería de plástico.

Levante

el brazo

primero

Para subir en

nivel de agua

Para bajar en

nivel de agua

La marca del punto

crítico del nivel del

agua (C.L.) debe

estar a 1" sobre el

tubo de rebalse

Contratuerca

Tuerca de unión

(ajustar a mano)

Componentes para

la conexión del agua

Arandela cónica

Cuerpo

de la

válvula

Tope

Válvula

de

llenado

Arandela

del

vástago

Varilla de ajuste

del nivel de agua

Tubo de llenado

Palanca de la cisterna

Nivel de agua

Cadena del tapón

Válvula de descarga

Obturador

Vástago

con rosca

Flotador

Para subir en

nivel de agua

Para bajar en

nivel de agua

La marca del punto

crítico del nivel del

agua (C.L.) debe

estar a 1" sobre el

tubo de rebalse

Contratuerca

Tuerca de unión

(ajustar a mano)

Componentes para

la conexión del agua

Arandela cónica

Cuerpo

de la

válvula

Tope

Válvula

de

llenado

Arandela

del

vástago

Varilla de ajuste

del nivel de agua

Tubo de llenado

Palanca de

la cisterna

Nivel de agua

Cadena del tapón

Válvula de

descarga

Obturador

Vástago

con rosca

Flotador

use el 1r o 2o agujero (no use el

3r agujero) y inserte el gancho

de adelante....

use el 1r o 2o agujero (no use el

3r agujero) y inserte el gancho

de adelante....

.... NO el atrás

•

Cuando conecte la cadena de acero inoxidable a la palanca del tanque, use

el 1r o 2° agujero más próximo a la palanca (no use el agujero del extremo).

Inserte el gancho de adelante hacia atrás. Esto reducirá la posibilidad de

que el obturador se enganche y se trabe.

Para remover la tapa de la válvula piloto

•

Levante el brazo de la palanca y gire la tapa un

octavo de vuelta en sentido contrario a las agujas del reloj. Levantando, saque el ensamblaje de

la tapa de la válvula de llenado.

Vuelva a colocar la tapa encajando los pernos

guía y girando la tapa un octavo de vuelta en

sentido de las agujas del reloj.

Asegúrese de que la tapa esté en posición de

cerrado. La válvula puede no abrise si la tapa

no está completamente cerrada.

Remover o cambiar el obturador siliconado

•

Desconecte el gancho de la cadena de la palanca

de descarga.

Conexión del suministro de agua :

•

Español - 2

Remueva el obturador de los pernos en los costados de la válvula de descarga.

Para volver a colocar, siga los mismos pasos a la

inversa.

Síntoma Solución

Al descargar, el agua no fluye Reemplazo del sello de la válvula de llenado.

El agua no cesa de salir El obturador está trabado. Coloque el gancho

para el obturador en el primer o segundo agujero próximo a la palanca del tanque, inser tándolo de adelante hacia atrás.

El obturador no cierra bien . Asegúrese que

la cadena esté floja cuando no está en uso y

revise el sellado y borde de la válvula de descarga para ver si están dañados u obstruidos.

Español - 3

Page 7

El agua no cesa de salir Asegúrese de que el agua no está fluyendo en

el tubo de rebalse. Si es así, baje el nivel del

agua sujetando la parte superior de la varilla

de regulación del nivel del agua y girando para

mover el flotador.

Pueden haber residuos obstruyendo el sello.

Remueva la tapa, limpie los residuos y vuelva

a colocarla.

El tubo de llenado ha sido inser tado muy abajo en el tubo de rebalse (más bajo que nivel

del agua del tanque). Coloque el adaptador

del tubo de llenado en la par te superior de

la válvula de descarga. El flujo del tubo de llenado debe estar directamente sobre el tubo

de rebalse.

La tapa gotea durante el llenado

Esto es normal para las válvulas piloto. Esta es

una característica que permite el autolimpiado

del orificio de la válvula durante el llenado. El

agua puede gotear unos 10 o 15 segundos al

finalizar el ciclo de llenado. El goteo debe parar

cuando el flotador suba a la posición “off”.

El agua gotea por los orificios

de aire durante el llenado

Ésta pueda ser una indicación de baja presión

de agua El goteo debe parar cuando el flotador suba a la posición “off”.

No hay suficiente agua en el

inodoro

Asegúrese que la manguera de llenado va directamente al tubo de rebalse y que no haya

obstrucciones.

Poca descarga de agua Sitúe el nivel de agua de la cisterna en la línea

marcada en la parte interior trasera.

Abra completamente la llave de paso del

agua.

Quite cualquier obstáculo que pueda haber en

los orificios, chorros o en el sifón del inodoro.

No descargue el agua La cadena del tapón no está colocada. La

cadena debería estar sujeta a la palanca y al

tapón.

No descargue el agua Cadena del tapón demasiado larga. Com-

pruebe que la cadena tenga cierta holgura

cuando no se utilice, pero ha de ser capaz de

levantar totalmente el tapón de la cisterna al

accionar la palanca.

Ruido La suciedad dentro de la cabeza puede crear

ruido o vibraciones cuando pasa el agua por

la válvula de llenado. Quite la tapa, limpie la

suciedad y vuelva a instalar la tapa.

El caudal de alimentación de agua quizás sea

demasiado alto. Cierre parcialmente el abastecimiento de agua para reducir el ruido. Abra

o cierre el abastecimiento de agua hasta lograr

que la cisterna se llene en unos 60 segundos.

cuIdado y MantenIMIento

Material sanitario de porcelana vitrificada

Limpie la superficie del inodoro o lavabo de porcelana vitrificada con un

•

jabón o limpiador ligero y un trapo suave.

No utilice limpiadores abrasivos, ni estropajos abrasivos ni lana de acero

•

para limpiar las superficies de porcelana vitrificada ya que podría rayar y

quitar el brillo de la superficie.

No utilice limpiadores para el depósito del inodoro que contengan cloro

•

o blanqueador. No exponga las piezas ornamentales a agentes oxidantes

fuertes, cloro, o niveles de ácido con ph inferior a 5.0. La mayoría de los

limpiadores para inodoros y azulejos contienen estos agentes.

La utilización de estos limpiadores para el depósito que contienen cloro

•

o blanqueador puede dañar los componentes del depósito. Nuestra

garantía no cubre estos daños.

La utilización de estos limpiadores que contienen cloro o blanqueador

•

anula la garantía de Fluidmaster®, causará daños en los componentes

del depósito y puede producir una inundación y daños materiales.

Asientos de los inodoros

Limpie la superficie del asiento del inodoro con un limpiador o jabón suave

•

y un trapo. No utilice limpiadores abrasivos, estropajos abrasivos ni lana

de acero para limpiar los asientos de los inodoros ya que podría rayarlos o

deslustrar la superficie.

Español - 4

Español - 5

Page 8

garantía de la Porcelana VItrIfIcada de danze

Garantía limitada de cinco (5) años – porcelana vitrificada

Danze, Inc. (Danze) garantiza al comprador original de este producto que la parte

de porcelana vitrificada no tendrá defectos de material ni de mano de obra, si

se hace un uso razonable del producto, durante un periodo de cinco (5) años

desde la fecha de compra original, con arreglo al comprobante de compra del

comprador original.

Garantía limitada para las piezas

Danze garantiza al comprador original de este producto que las piezas siguientes

no tendrán defectos de material ni de mano de obra, si se hace un uso razonable

del producto, durante el periodo que se indica abajo, desde la fecha de compra

original:

Cinco (5) años:

Válvula de llenado Fluidmaster®

•

Palanca de la cisterna

•

Tres (3) años:

Tapón

•

Un (1) año:

Asiento del inodoro

•

uso de estos producto dañará los componentes de la cisterna y puede causar

inundaciones y daños materiales. Su uso anulará esta garantía.

Si la ley ‘Consumer Product Warranties Act’ federal se aplica al comprador original

de este producto, toda garantía implícita que pudiera aplicarse de conformidad

con la legislación de un estado —como una garantía implícita de comerciabilidad

o de idoneidad para un uso determinado— se limitará a un (1) año.

Al margen de lo descrito anteriormente, Danze renuncia a cualquier otra garantía,

explícita o implícita, como las garantías de comerciabilidad o de idoneidad para

un uso determinado. Bajo ninguna circunstancia se considerará responsable a

Danze ante nadie —entre otros, el comprador original— por los daños debidos a

pérdidas de ocasiones de negocio, de beneficios o por interrupción de negocios,

ni por ningún tipo de daño especial ni indirecto.

Las garantías anteriores le otorgan determinados derechos jurídicos, a los que

podrían sumarse otros, según el estado. Algunas leyes federales o estatales pueden limitar o rechazar las descargas de responsabilidad por daños indirectos y/o

los límites impuestos a las garantías implícitas.

Para reclamar un servicio conforme a una garantía, comuníquese con Danze en

nuestra página web www.danze.com, o llame a nuestro centro de servicios técnicos en horas normales de oficina, en el teléfono 888-328-2383.

Los componentes no mencionados anteriormente estarán cubiertos por el tiempo que indiquen las garantías de los proveedores de equipos originales. Todos

los productos mencionados anteriormente y las piezas instaladas en instalaciones

comerciales aceptadas tienen una garantía limitada de un (1) año.

Danze acepta, como único recurso en caso de incumplimiento de las garantías

anteriores, y a su entera discreción, reparar o sustituir estos productos o piezas

de los productos que, previo examen de Danze, tengan defectos de material o

de mano de obra durante los periodos de garantía establecidos anteriormente.

Danze no será responsable de la mano de obra, ni de los gastos de envío, flete

u otros costos o gastos que se produzcan en relación con el desmontaje o sustitución del producto o en cumplimiento de las garantías anteriores, ni de los

costos asociados a la reparación o sustitución de cualquier otro bien personal,

edificio o materiales de instalación. Las garantías anteriores se anularán si el producto no se instala o se usa de conformidad con sus instrucciones o en caso de

uso indebido, abuso, negligencia, accidente del producto o desplazamiento de

éste desde el lugar donde se instaló originalmente. No deben utilizarse limpia-

dores que se viertan en la cisterna y que contengan blanqueador o cloro. El

Español - 6

Español - 7

Page 9

Manuel d’entretIen du ProPrIÉtaIre

Tuyau en

métal/cuivre

Tuyau à bride

en métal

Tuyau spiralé

en métal

Raccord flexible

de type tressé/

en vinyle

Écrou de

blocage

Écrou de

blocage

Écrou de

blocage

Écrou de

blocage

Rondelle

conique

Écrou

d'accouplement

Écrou

d'accouplement

Rondelle

existante

Écrou

d'accouplement

existant

Écrou

d'accouplement

Rondelle

conique

existante

Robinet d'arrêt Robinet d'arrêt Robinet d'arrêt Robinet d'arrêt

Ces pièces doivent être utilisées comme le montrent les illustrations

pour assurer un raccordement étanche. L'utilisation de l'écrou

d'accouplement ou la rondelle conique existante peut produire des

fuites d'eau. Le tuyau d'alimentation d'eau doit pénétrer d'au moins

1/2 po (1,2 cm) à l'intérieur de l'about fileté du robinet à flotteur (ne

s'applique pas s'il s'agit d'un tuyau à bride).

Utiliser la rondelle conique spiralée

existante. La rondelle conique

Fluidmaster® peut ne pas obturer

complètement la conduite d'alimentation en eau spiralée.

Utiliser l'écrou

d'accouplement

et la rondelle

existante.

Avertissement : Le fait de trop serrer l'écrou de blocage ou l'écrou d'accouplement peut causer un bris et

provoquer une fuite d'eau.

Avertissement : Ne pas utiliser de

rondelle conique s'il s'agit d'une conduite d'alimentation en plastique.

Pour augmenter

le niveau d’eau

Pour baisser

le niveau d’eau

La marque indiquant

le niveau d'eau critique (C.L.) doit être

1 po (2.5 cm)

au-dessus du tuyau

de trop-plein

Écrou de blocage

Écrou d'accouplement

(serrer à la main uniquement)

Corps

de

robinet

Haut

Coupelle

flottante

Pièces pour

raccordement à l'eau

Rondelle conique

Tige filetée

Tige de réglage

de niveau d'eau

Tuyau de remplissage

Manette du réservoir

Niveau d'eau

Chaîne de levage

Soupape de chasse

Clapet

Robinet à

flotteur

Rondelle

de tige

Pour augmenter

le niveau d’eau

Pour baisser

le niveau d’eau

La marque indiquant

le niveau d'eau critique (C.L.) doit être

1 po (2.5 cm)

au-dessus du tuyau

de trop-plein

Écrou de blocage

Écrou d'accouplement

(serrer à la main uniquement)

Corps

de

robinet

Haut

Coupelle

flottante

Pièces pour

raccordement à l'eau

Rondelle conique

Tige filetée

Tige de réglage

de niveau d'eau

Tuyau de remplissage

Manette du

réservoir

Niveau d'eau

Chaîne de levage

Soupape de chasse

Clapet

Robinet à

flotteur

Rondelle

de tige

utiliser le 1er ou 2

ème

trou (ne pas

utiliser le 3

ème

trou) et insérer

le crocher de l’avant....

utiliser le 1er ou 2

ème

trou (ne pas

utiliser le 3

ème

trou) et insérer

le crocher de l’avant....

.... PAS l’arrière

Toilettes. Lavabos. Bidets.

PrÉsentatIon de danze

Nous vous remercions de choisir Danze. Nous croyons que les différents éléments de votre salle de bain doivent éveiller vos sens comme une eau fraîche

dont on s’asperge. C’est exactement l’effet que Danze produit.

Danze est un fabricant de produits de plomberie décoratifs et de grande qualité

pour votre cabinet de toilette, votre cuisine et votre salle de bain. Nous offrons

une vaste gamme de produits, de modèles et de finis qui répondent à vos besoins spécifiques. Soyez assurés que vous pourrez utiliser nos produits des années durant, sans problème et en toute beauté.

ProduIts de PorcelaIne VItrIfIÉe danze

Les produits de porcelaine vitrifiée Danze comprennent les toilettes, bidets et lavabos. Nos appareils, de conception avancée, satisfont ou dépassent les normes

des codes de plomberie les plus rigoureux d’Amérique du Nord. Les toilettes et

bidets sont munis de robinets et d’accessoires de première qualité qui fonctionneront des années durant, sans problème.

Pour toute question concernant votre achat d’un produit Danze, veuillez communiquer avec nous par le biais de notre site Web www.danze.com, ou appeler le

centre de service technique durant les heures d’ouverture au 888-328-2383.

Danze Inc. se réserve le droit d’effectuer des changements aux spécifications

des produits et de modifier ou d’arrêter la fabrication de modèles sans préavis ni

obligation en Amérique du Nord.

Réglage du levier de déclenchement :

•

Lors du raccordement de la chaîne en acier inoxydable au levier de

déclenchement, utiliser le 1er ou le 2

ème

trou le plus près de la manette du

réservoir (ne pas utiliser le trou à l’extrémité du levier) et insérer le crochet

de l’avant vers l’arrière. Ceci diminuera les possibilités que le clapet reste

coincé.

Raccordement de la conduite d’alimentation en eau :

•

dÉPannage

Ce guide de dépannage vous aidera si votre nouvel appareil sanitaire de Danze

venait à présenter une défectuosité.

Conseils pour le réglage des composants de votre nouveau réservoir de

toilette :

Réglage du niveau d’eau dans le réservoir

•

Français - 1

Le niveau d’eau du réservoir doit être correctement réglé pour que l’appareil

offre un rendement optimal. Une ligne de repère indiquant le niveau d’eau

apparaît sur la paroi intérieure arrière de chaque réservoir de toilette.

Déplacer la coupelle flottante vers le haut ou vers le bas pour modifier le

niveau d’eau du réservoir. Saisir la partie supérieure de la tige de réglage

de niveau d’eau et la tourner pour déplacer la coupelle flottante.

Français - 2

Page 10

Enlèvement du chapeau du robinet pilote

Lever le

levier en

premier

•

Lever le levier et tourner le chapeau dans le sens

contraire des aiguilles d’une montre d’environ

1/8 de tour. Lever le chapeau du robinet à flotteur.

Remettre le chapeau en place en engageant les

oreilles et en tournant le chapeau de 1/8 de tour

dans le sens des aiguilles d’une montre.

S’assurer que le chapeau est bien tourné en

position de blocage. Le robinet pourrait ne

pas s’ouvrir si le chapeau n’est pas complètement tourné en position de blocage.

Enlèvement / remplacement du clapet en silicone mou

•

Ôter le crochet de la chaîne du levier de

déclenchement.

Enlever le clapet en silicone mou des attaches de

chaque côté du corps de la soupape de chasse.

Effectuer ces étapes dans l’ordre inverse pour

remettre en place.

Symptômes Solution

L’eau ne s’écoule pas lorsqu’on

actionne la chasse.

L’eau s’écoule continuellement.

Remplacer le joint d’étanchéité du robinet à

flotteur.

Le clapet ne descend pas complètement.

Mettre le crochet de la chaîne du clapet dans

le premier ou le deuxième trou le plus près de

la manette du réservoir et insérer le crochet de

l’avant vers l’arrière.

L’eau s’écoule continuellement.

De l’eau s’écoule du chapeau

lors du remplissage.

De l’eau s’écoule des entrées

d’air lors du remplissage

Il n’y a pas assez d’eau dans la

cuvette.

Faible débit d’eau lors de

l’actionnement de la chasse

Le clapet n’obture pas complètement. S’assurer

que la chaîne est un peu lâche lorsque le clapet

est fermé et vérifier que le joint d’étanchéité

et la bordure de la soupape de chasse ne

sont pas endommagés et que rien ne cause

d’obstruction.

S’assurer que l’eau ne coule pas dans le tropplein. Si c’est le cas, diminuer le niveau d’eau.

Pour ce faire, prendre la tige de réglage de

niveau d’eau par sa partie supérieure et la

tourner pour déplacer la coupelle flottante.

Des débris à l’intérieur de la tête peuvent obstruer le joint d’étanchéité. Enlever le chapeau,

éliminer les débris et rassembler.

Le tuyau de remplissage est inséré trop profondément dans le trop-plein (sous le niveau

d’eau du réservoir). Fixer l’adaptateur du

tuyau de remplissage sur la partie supérieure

du trop-plein de la soupape de chasse. L’eau

provenant du tuyau de remplissage doit arriver

directement au-dessus du trop-plein.

Ceci est normal pour les robinets pilotes.

Cette caractéristique permet l’autonettoyage

de l’orifice du robinet pilote durant le remplissage. L’eau peut continuer à couler durant de

10 à 15 secondes à la fin du cycle de remplissage. Ceci cessera dès que le flotteur aura atteint la position complètement “fermée”.

Ceci peut indiquer que la pression d’eau est

très basse. L’écoulement devrait cesser lorsque

le flotteur aura atteint la position complètement “fermée”.

S’assurer que le tuyau de remplissage est dirigé dans le trop-plein et que le débit d’eau

n’est pas obstrué ni réduit.

Régler le niveau d’eau du réservoir pour qu’il

atteigne la ligne de repère apparaissant à

l’intérieur de la paroi arrière.

Ouvrir complètement le robinet d’arrêt de

l’alimentation d’eau.

Français - 3

Français - 4

Page 11

Faible débit d’eau lors de

l’actionnement de la chasse

Aucun débit d’eau lors de

l’actionnement de la chasse

Bruit Des débris à l’intérieur de la tête peuvent

Nettoyer tout ce qui peut obstruer les trous

au bord de la cuvette, les jets ou l’intérieur du

siphon

La chaîne de levage n’est pas raccordée. La

chaîne doit être fixée au levier de la manette

et au clapet.

La chaîne de levage est trop lâche. S’assurer

que la chaîne est légèrement lâche lorsque la

manette de chasse n’est pas actionnée, mais

qu’elle peut lever entièrement le clapet lorsque

le levier de la manette est actionné.

produire du bruit/des vibrations lorsque le

robinet de remplissage coule. Enlever le capuchon, enlever les débris et rassembler.

Le débit de l’eau qui pénètre dans le réservoir

peut être excessivement élevé. Fermer partiellement le robinet d’arrêt de l’alimentation

d’eau pour réduire le bruit. Ouvrir/fermer le

robinet d’arrêt de façon à ce que le remplissage du réservoir s’effectue en 60 secondes

environ.

soIns et entretIen

Appareils sanitaires en porcelaine vitrifiée

Nettoyer la surface de votre toilette ou de votre lavabo en porcelaine

•

vitrifiée à l’aide d’un chiffon doux et d’un savon/nettoyant doux.

Ne pas employer de nettoyants abrasifs, de tampons abrasifs ni de laine

•

d’acier pour nettoyer les surfaces en porcelaine vitrifiée, car cela pourrait

rayer ou ternir la surface.

Ne pas employer de nettoyants pour cuvette à installer dans le réservoir,

•

qui contiennent du chlore ou du javellisant. Ne pas exposer les pièces

de garniture en plastique à des oxydants forts, du chlore ou des niveaux

d’acidité inférieurs à 5,0 ph. La plupart des nettoyants pour tuiles/cuvettes

contiennent de telles substances.

Le fait d’employer des nettoyants pour cuvette à installer dans le

•

réservoir, qui contiennent du chlore ou du javellisant peut endommager

les composants du réservoir et nuire à leur bon fonctionnement. Notre

garantie ne couvre pas ce genre de défectuosité.

Le fait d’employer des nettoyants pour cuvette à installer dans le

•

réservoir, qui contiennent du chlore ou du javellisant annulera la garantie

de Fluidmaster®, endommagera les composants du réservoir et peut

causer une inondation ainsi que des dommages matériels.

Sièges de toilette

Nettoyer la surface de votre siège de toilette à l’aide d’un nettoyant/savon

•

doux et d’un chiffon doux. Ne pas employer de nettoyants abrasifs, de

tampons abrasifs ni de laine d’acier pour nettoyer les surfaces du siège de

toilette, car il y a risque de rayer ou de ternir la surface.

garantIe de la PorcelaIne VItrIfIÉe de danze

Garantie limitée de cinq (5) ans – porcelaine vitrifiée

Danze, Inc. (Danze) garantit à l’acheteur initial de ce produit que la portion en

porcelaine vitrifiée sera exempte de vices de matériaux et de fabrication, lors

d’un usage raisonnable, pour une période de cinq (5) ans à compter de la date

d’achat initial indiquée sur le coupon de caisse de l’acheteur consommateur initial.

Garantie limitée sur les pièces

Danze garantit à l’acheteur consommateur initial de ce produit que les pièces

suivantes seront exemptes de vices de matériaux et de fabrication, lors d’un usage raisonnable, durant le nombre d’années indiqué ci-dessous, à compter de la

date d’achat initial :

Cinq (5) ans :

Robinet à flotteur Fluidmaster®

•

Manette de réservoir

•

Trois (3) ans :

Clapet

•

Un (1) an :

Siège de toilettes

•

Tout composant qui n’est pas mentionné ci-dessus doit être couvert selon

l’étendue indiquée par les garanties des fournisseurs du matériel d’origine.

Tous les produits et pièces mentionnés ci-dessus installés dans les établissements commerciaux acceptés sont couverts par une garantie limitée de

un (1) an.

Pour remédier à tout manquement aux garanties mentionnées ci-dessus, Danze

accepte uniquement, au choix de Danze, de réparer ou de remplacer ces produits ou toutes pièces de ces derniers qui, après inspection par Danze, s’avéreront

Français - 5

Français - 6

Page 12

présenter des vices de matériaux ou de fabrication alors qu’ils sont couverts par

une garantie selon les périodes indiquées ci-dessus.

Danze ne sera responsable d’aucuns frais de main-d’œuvre, de transport ni

d’aucuns autre frais ou coût encourus en rapport avec l’enlèvement ou le remplacement du produit ou la conformité aux garanties ci-dessus, ni d’aucuns frais

associés à la réparation ou au remplacement de tout autre bien personnel, édifice ou matériaux d’installation. Si l’installation ou l’utilisation du produit n’est

pas conforme aux instructions du produit ou si le produit est l’objet d’un usage impropre, d’un abus ou d’une négligence, ou d’un accident, ou encore si

le produit est déplacé de l’endroit où il a été initialement installé, les garanties

ci-dessus ne seront plus valides. Ne pas employer de nettoyants pour cuvette à

installer dans le réservoir, qui contiennent du javellisant ou du chlore. Le fait

d’employer de tels produits endommagera les composants du réservoir et

peut causer une inondation ainsi que des dommages matériels. L’emploi de

tels produits annulera cette garantie.

Si la loi fédérale sur les garanties relatives aux produits de consommation

s’applique à l’acheteur initial de ce produit, alors toute garantie tacite pouvant

s’appliquer en vertu de la loi provinciale, telle que toute garantie tacite quant au

caractère marchand ou toute garantie tacite quant à l’adaptation à l’usage, est

limitée à un (1) an.

À l’exception de ce qui est énoncé ci-dessus, Danze n’honorera aucune autre

garantie, expresse ou tacite, incluant toute garantie quant au caractère marchand ou à l’adaptation à l’usage. Danze ne sera en aucun cas responsable envers

qui que ce soit, incluant sans limitation l’acheteur initial, de tout dommage pour

perte d’occasion d’affaires ou de profits ou de toute interruption d’exploitation

ou de tous dommages spéciaux, fortuits ou indirects.

Les garanties ci-dessus vous accordent des droits juridiques définis et vous pouvez avoir d’autres droits, qui varient d’une province à une autre. Certaines lois

fédérales et provinciales peuvent limiter ou rejeter les limitations de dommages

fortuits ou indirects et/ou les limitations sur les garanties tacites.

Pour obtenir du service sous garantie, communiquer avec Danze par le biais de

notre site Web www.danze.com ou appeler notre centre de service technique

durant les heures d’ouverture au 888-328-2383.

Français - 7

Loading...

Loading...