Danze D562054 Installation Manual [en, es, fr]

®

3/4” Thermostatic Mixing Valve Trim

Installation Instructions

Instrucciones de instalación de las piezas exteriores de la válvula

mezcladora termostática de 3/4"

Instructions d’installation de la manette de

manœuvre du mitigeur 3/4 po

Model / Modelo / Modèle

D5620 Series

Installation Instructions

Instrucciones para

la instalacion

Guide d'installation

Toll free service / Linea telefonica gratis / Numéro sans frais

US: 1-888-328-2383

Canada: 1-800-487-8372

TABLE OF CONTENTS

PG

English section

Spanish section

French section

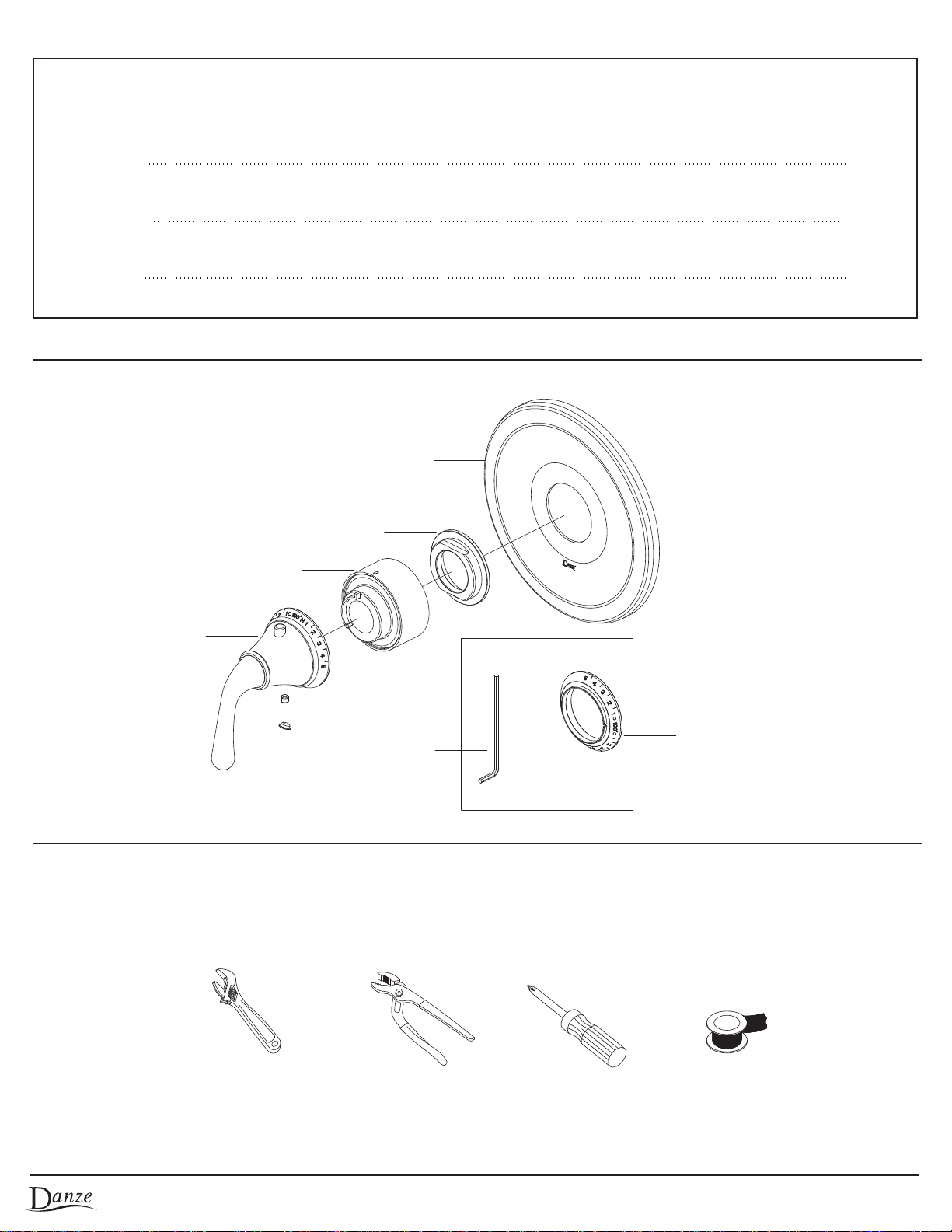

Before Your Installation

Check to make sure you have the following parts indicated below.

Escutcheon

Handle Trim Ring

Limit Stop

1

12

23

Handle Assembly

Hex Wrench

Tools Required

Alternative Black

Temperature Dial

Phillips screwdriverAdjustable wrench Pipe tapeGroove joint plier

®

© 2008 Danze, Inc. All rights reserved.

1

Operation Manual

DANZE ALWAYS RECOMMENDS THAT PLUMBING PRODUCTS BE INSTALLED BY A LICENSED PROFESSIONAL.

WARNING!

Do not rotate cartridge stem without trim in place or designated in the adjustment procedure.

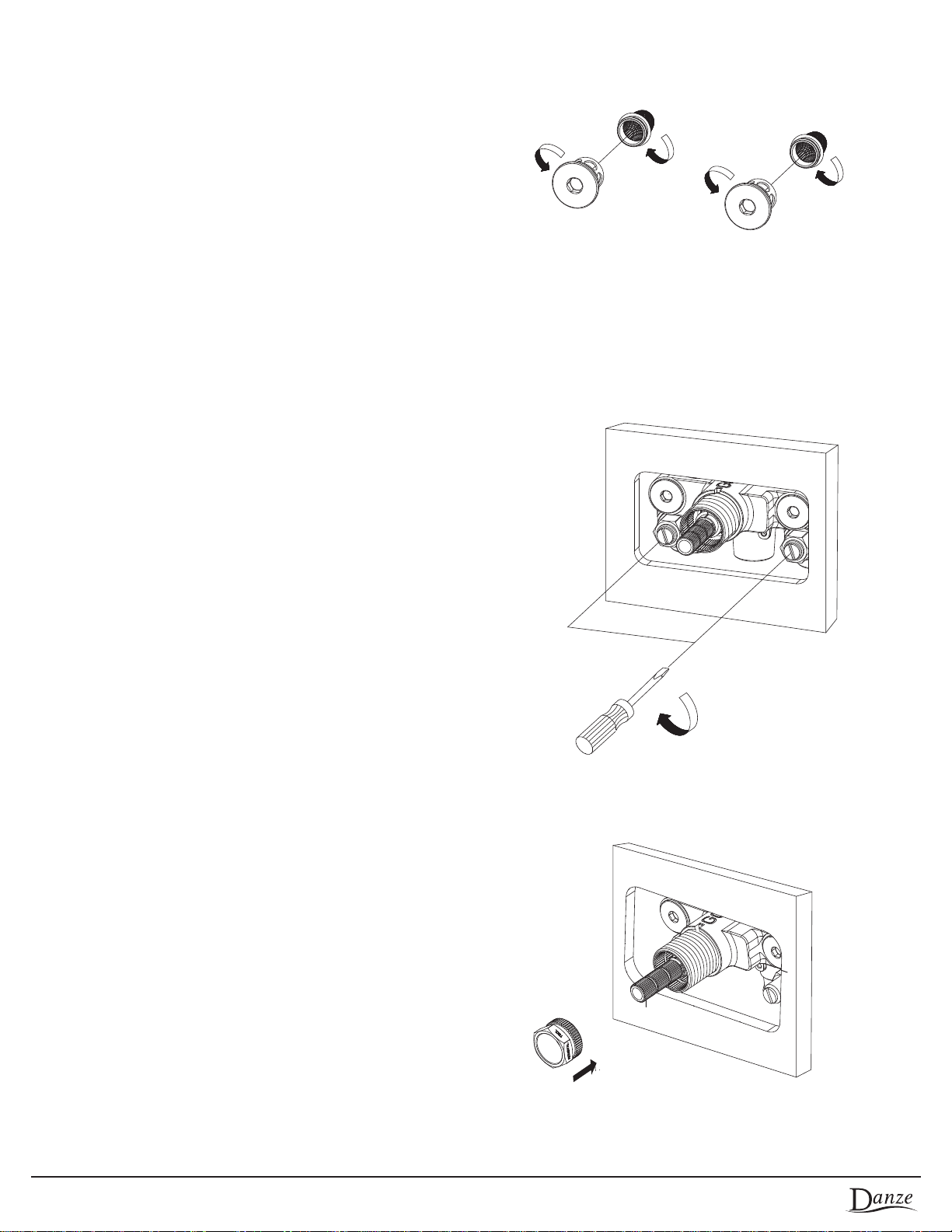

1.

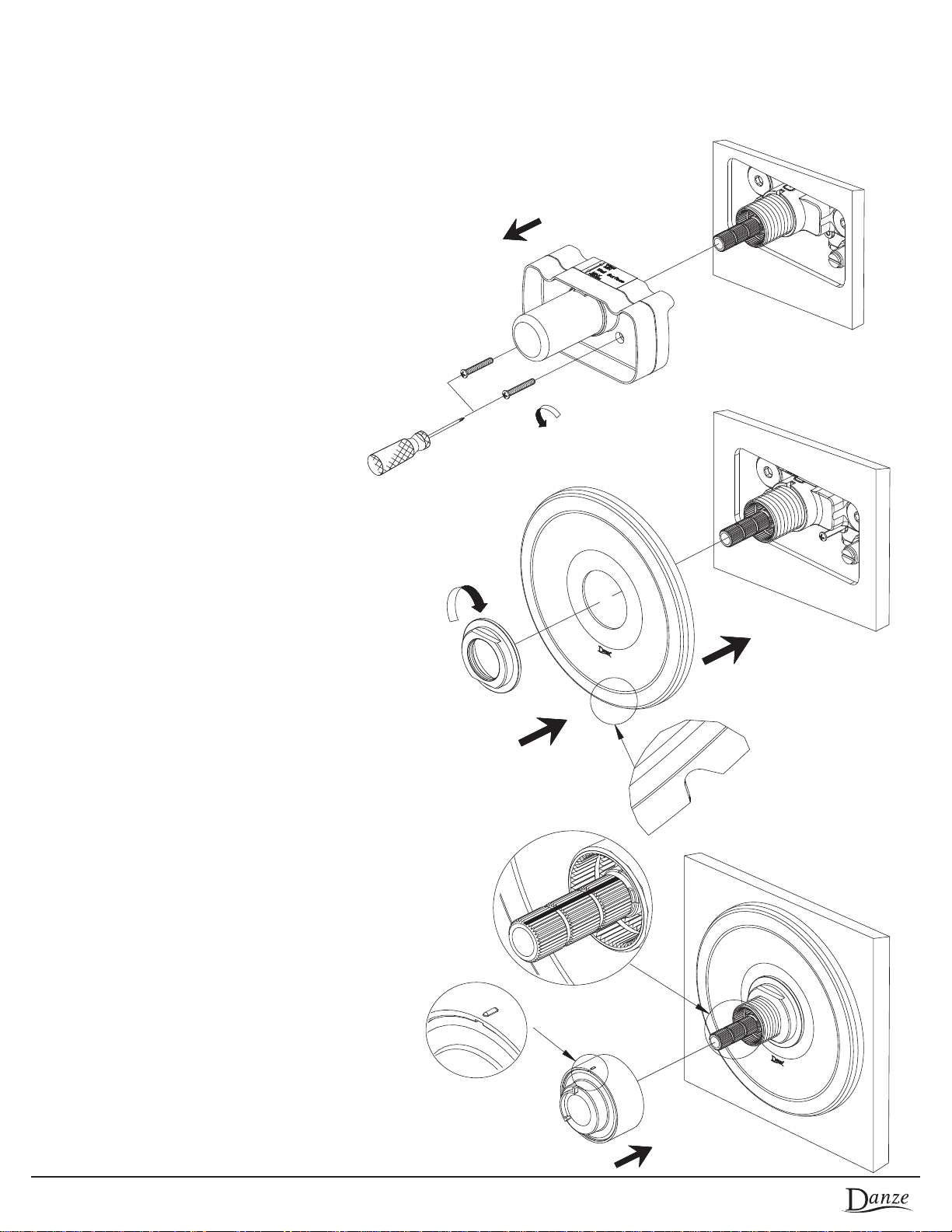

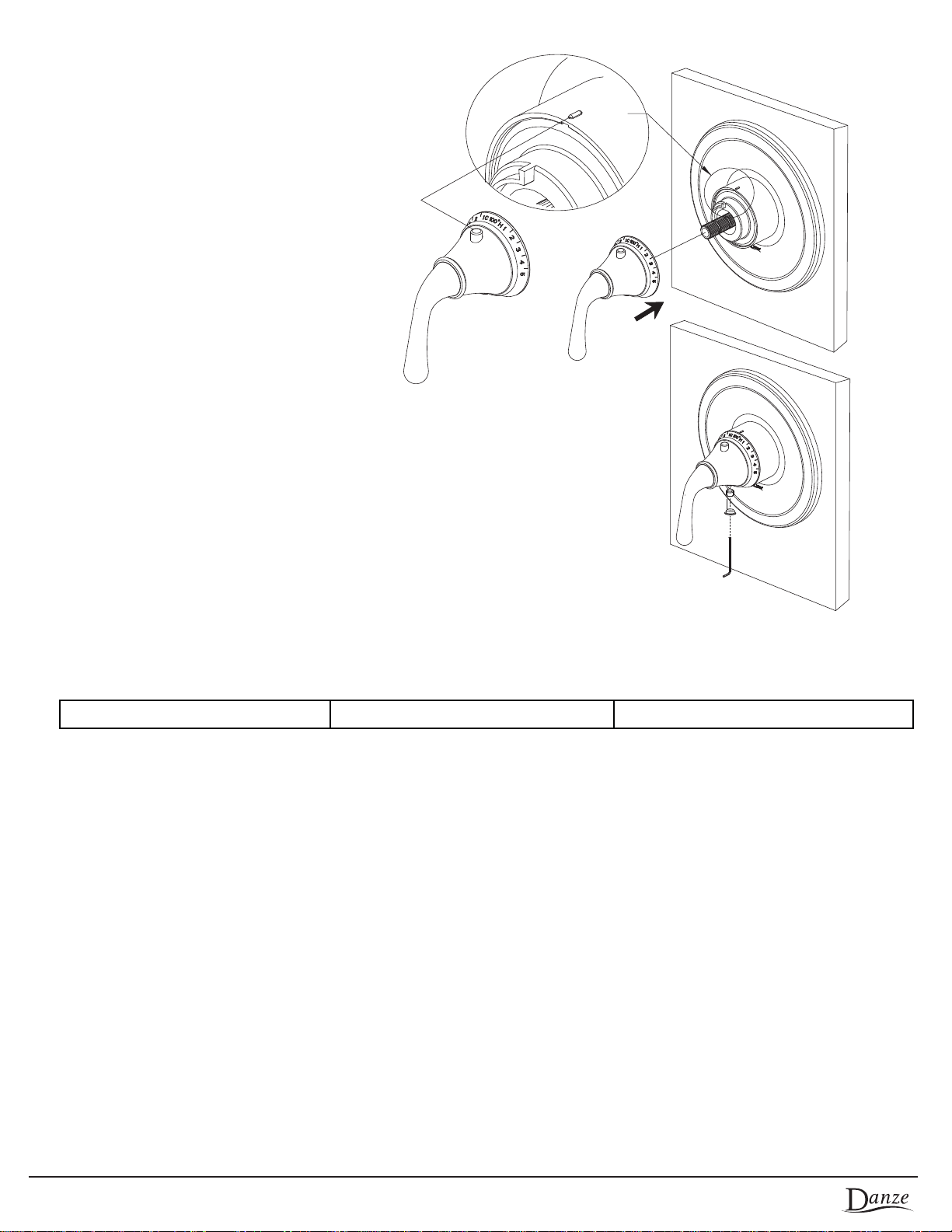

NOTE : Before trim installation, make sure the

finished wall falls between the limits marked on the

plaster guard.

Remove the plaster guard from the 3/4” mixing valve.

2.

Place the gasket and escutcheon over valve stem and attach with

handle trim ring. Secure the wall escutcheon by rotating the handle

trim ring clockwise.

Note: locate the notch in the escutcheon at the bottom.

3.

Install limit stop, making sure the gun sight and notch on

the valve cartridge stem are all aligned (see illustration).

2

© 2008 Danze, Inc. All rights reserved.

®

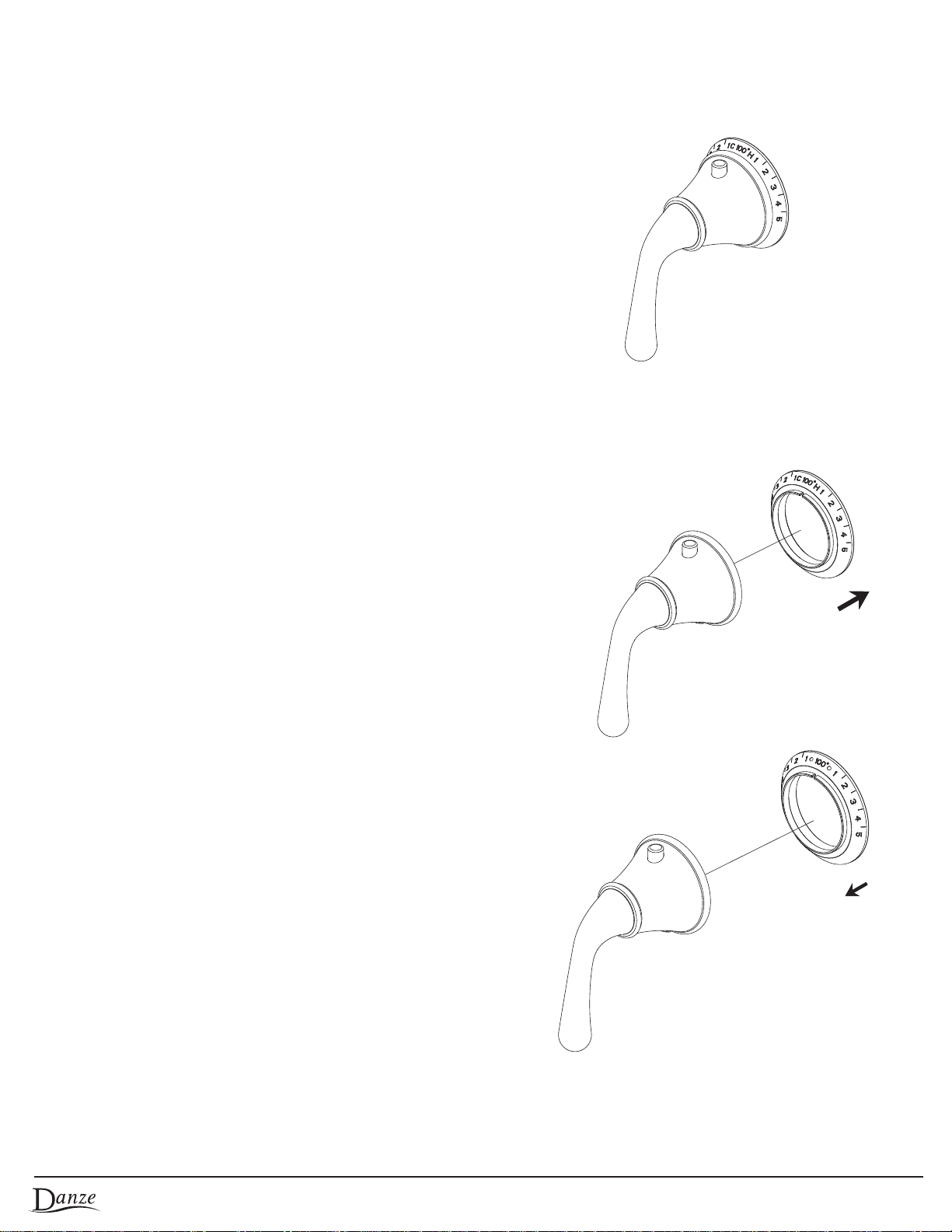

Danze provides two temperature dial alternatives with

4.

the mixing valve trim. The plated version is already

mounted to the handle.

To install the black temperature dial, remove the

4.1

plated temperature dial.

Reinstall the black temperature dial.

4.2

Note: the graduations on the temperature dial

are for reference purposes only and not

intended to represent an actual water

temperature.

®

© 2008 Danze, Inc. All rights reserved.

3

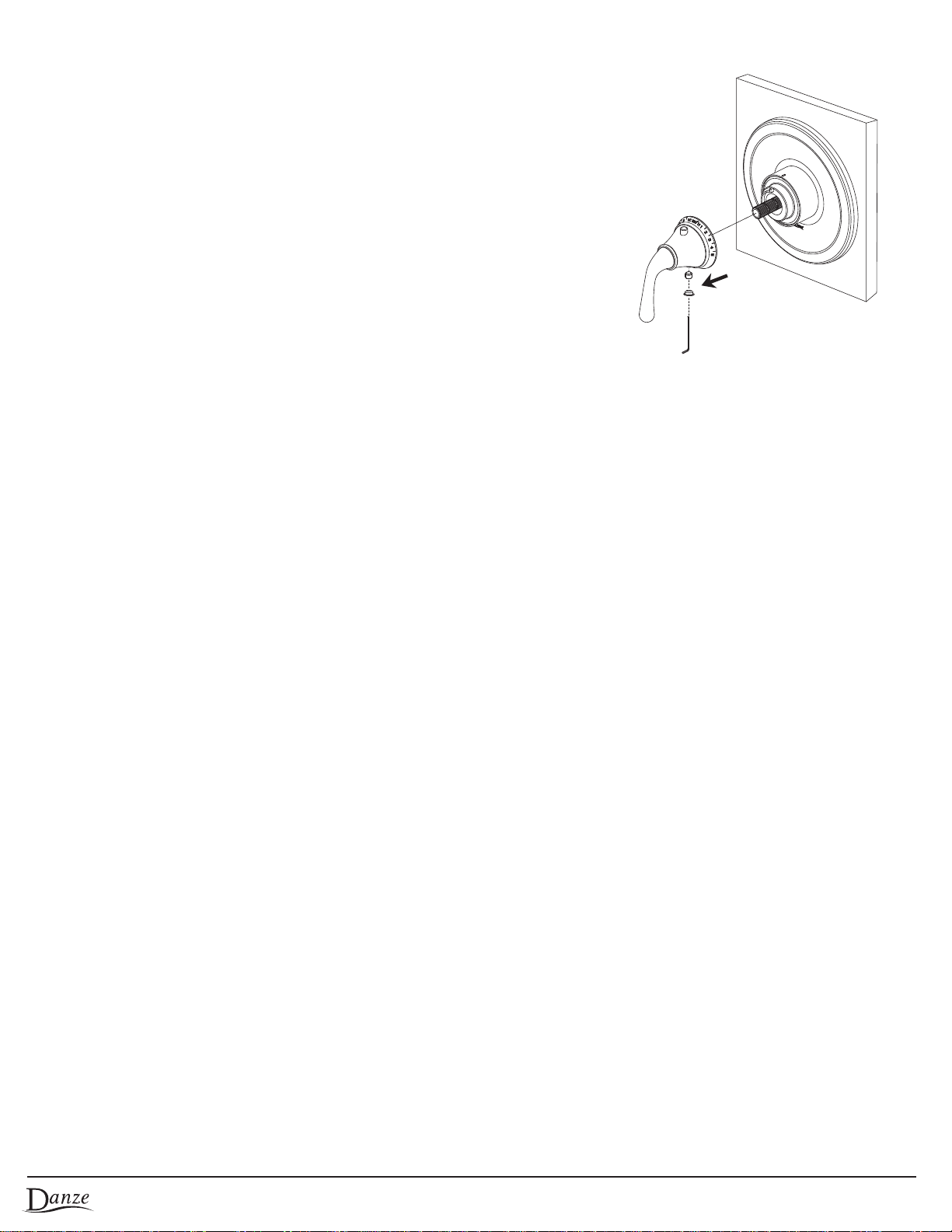

Prior to installing the handle on the thermostatic valve

5.

stem, make sure the high temperature limit over-ride

button is aligned with the gun sight on the limit stop

(see illustration). Note the gun sight on the limit stop

indicates factory calibration for high temperature limit

at 100 ºF (38 ºC).

Over-ride button is in line with the gun sight.

Install the screw in the thermostatic handle and tighten

6.

by hex wrench (supplied), then attach the handle cap.

ADJUST TEMPERATURE SETTING

7.

The valve is calibrated at the factory to deliver water at approximately 100˚F (38˚C) when the handle is positioned at the “High

Temp Override Position” (Shown in Figure 5). This temperature roughly corresponds to the 100˚F graduation line found on the

temperature dial of the valve trim and the reference mark found on the cartridge spline of this valve. Note the listed water

temperature settings are based upon our factory conditions as follows

• Hot and cold water pressure = 45 psi ( 3 bar) • Hot water temperature = 149˚ F or 65˚C • Cold water temperature = 59˚ F or 15˚C

If another range of temperatures is desired or the actual water supply conditions differ significantly, you will need to recalibrate the

valve settings according to the re-calibration procedure shown in 7.2–A shown below. If a maximum hot water temperature is

required, you also may need to re-calibrate the valve to meet your required maximum temperature output. See Setting a

Maximum Output Temperature in section 7.2 - B.

CAUTION: RISK OF SCALDING HAZARD

The valve has been calibrated at the factory to deliver water at approximately 100˚F (38˚C) at the High Temperature Override

Position. This temperature corresponds to the line marked on the valve cartridge stem. Based on the temperature and pressure

inputs used at our factory to calibrate the valve, the maximum outlet temperature is approximately 120˚F (49˚C). For calibration,

Danze assumes cold water supply to be 59˚F (15˚C) +/- 5˚F, and hot water temperature supply to be 149˚F (65˚C) +/- 5˚F. Both

hot and cold water pressure are 45psi. Any significant variation in the calibration, or any variation in the water supply

temperatures (greater than 5˚F or 3˚C) from those used at the factory during the calibration procedure, can result in water

temperatures that could present scalding dangers. It is important to check the water temperature with the temperature stem rotated

to the full counterclockwise (open) position to determine the maximum temperature of the water that will be delivered. The

responsibility for the proper installation and any recalibration of this valve lies with the installer.

4

© 2008 Danze, Inc. All rights reserved.

Remove the thermostatic handle assembly from valve.

7.1

7.2-A

7.2-B

Recalibrating Output Temperature for High Temp Over-Ride Position.

The High Temp Over-Ride Position is pre-calibrated at the factory for approximately 100˚F. If you require a different

High Temp Over-Ride position, use the following procedure:

1.) Remove the handle assembly (see 7.1)

2.) For higher temperature, rotate the cartridge stem counter-clockwise until the desired temperature is reached. For a

lower temperature rotate the cartridge stem clockwise until the desired temperature is reached.

3.) Reinstall the handle assembly(See 7.3)

Checking Valve Maximum Output Temperature

Most municipalities require a maximum output temperature for point of use mixing valves. Depending on your local

codes and your input water temperatures and pressures, your maximum output temperature will vary accordingly.

Please check your maximum output temperature using the following procedure.

1) Turn off all volume controls.

2) Depress the High Temp Over-Ride Button and rotate the Thermostatic valve handle counter-clockwise until the handle

stops rotating. Do not force the handle beyond the factory installed Maximum Temp Stops.

3) Carefully turn on the volume control and allow water temperature stream to stabilize. USE EXTREME CAUTION, AS

MIXED WATER TEMPERATURE WILL MOST LIKELY CAUSE HOT WATER SCALDING.

4) If the output temperature is above the maximum allowed output temperature as prescribed by your local building

codes or if you want to limit the maximum hot water temperature to a temperature lower than prescribed by your

building codes, please see 7.2-C below.

®

© 2008 Danze, Inc. All rights reserved.

5

7.2-C

Resetting Maximum Output Temperature of Valve

1) Turn off the volume control

2) Return the handle position to the High Temp Over-Ride Position.

3) Remove the Handle Assembly (Figure 7.1)

4) Rotate the cartridge stem clockwise by 1/8 of a turn.

5) Reinstall the Handle Assembly (Figure 7.3)

6) Check the valve maximum output temperature by following 7.2-B. If the temperature is still above your desired

temperature, repeat steps 1 through 5.

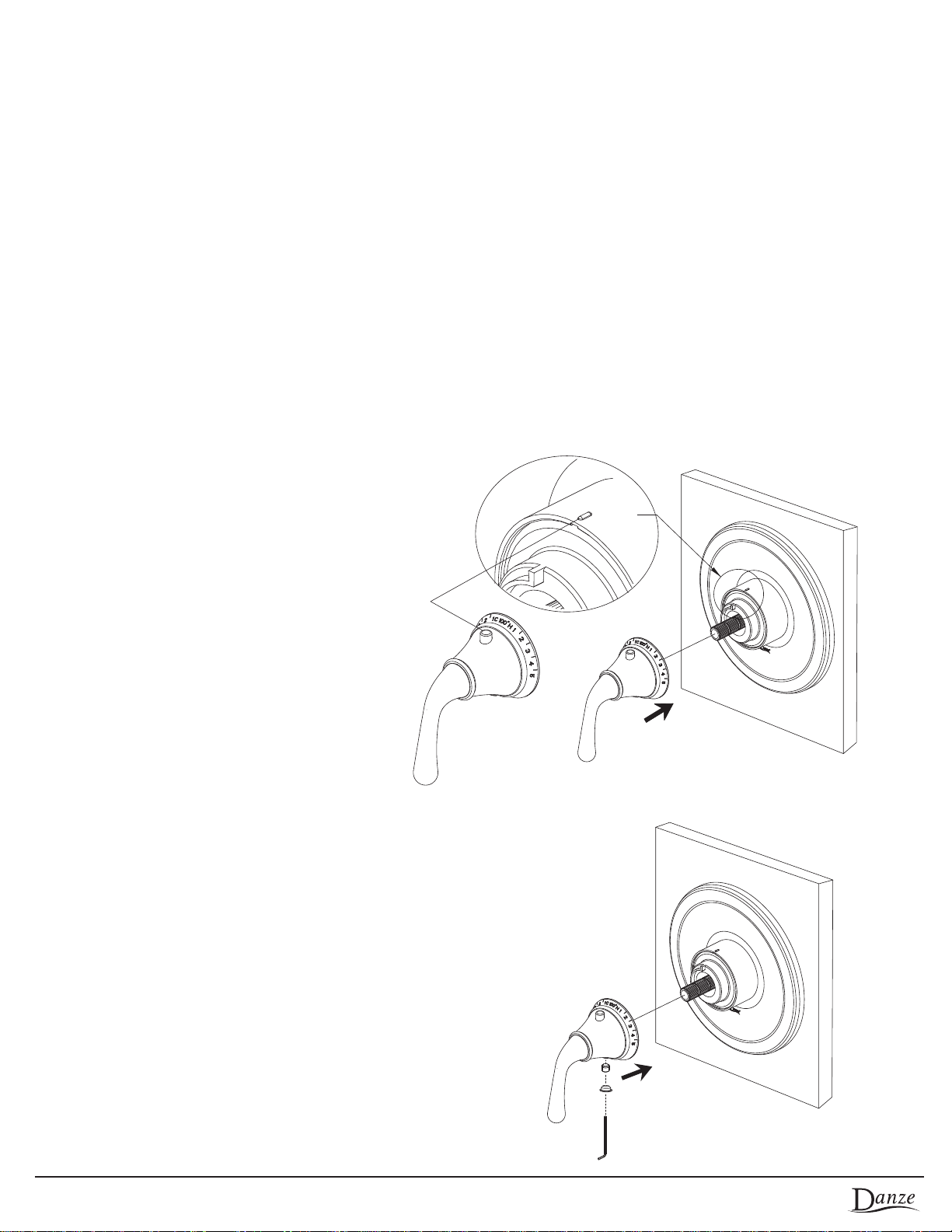

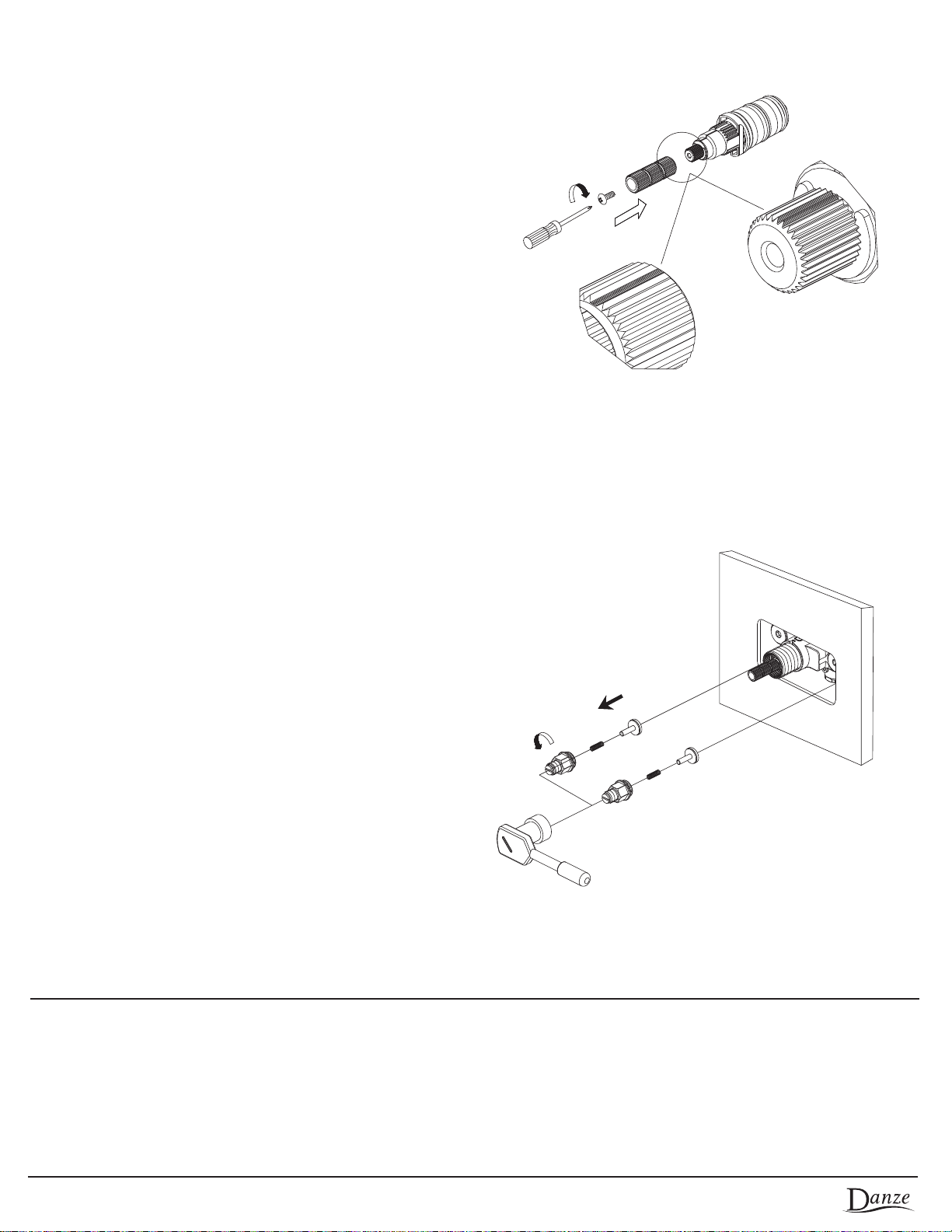

Reinstall thermostatic handle assembly.

7.3

A.

Turn off the volume control handle clockwise.

B.

Reinstall temperature selector handle. The temperature

limit over-ride button should align the gun sight on limit

stop.

Over-ride button is in line with the gun sight.

C.

Install the screw in the thermostatic handle and

tighten it by hex wrench (supplied), then attach

the handle cap.

6

© 2008 Danze, Inc. All rights reserved.

®

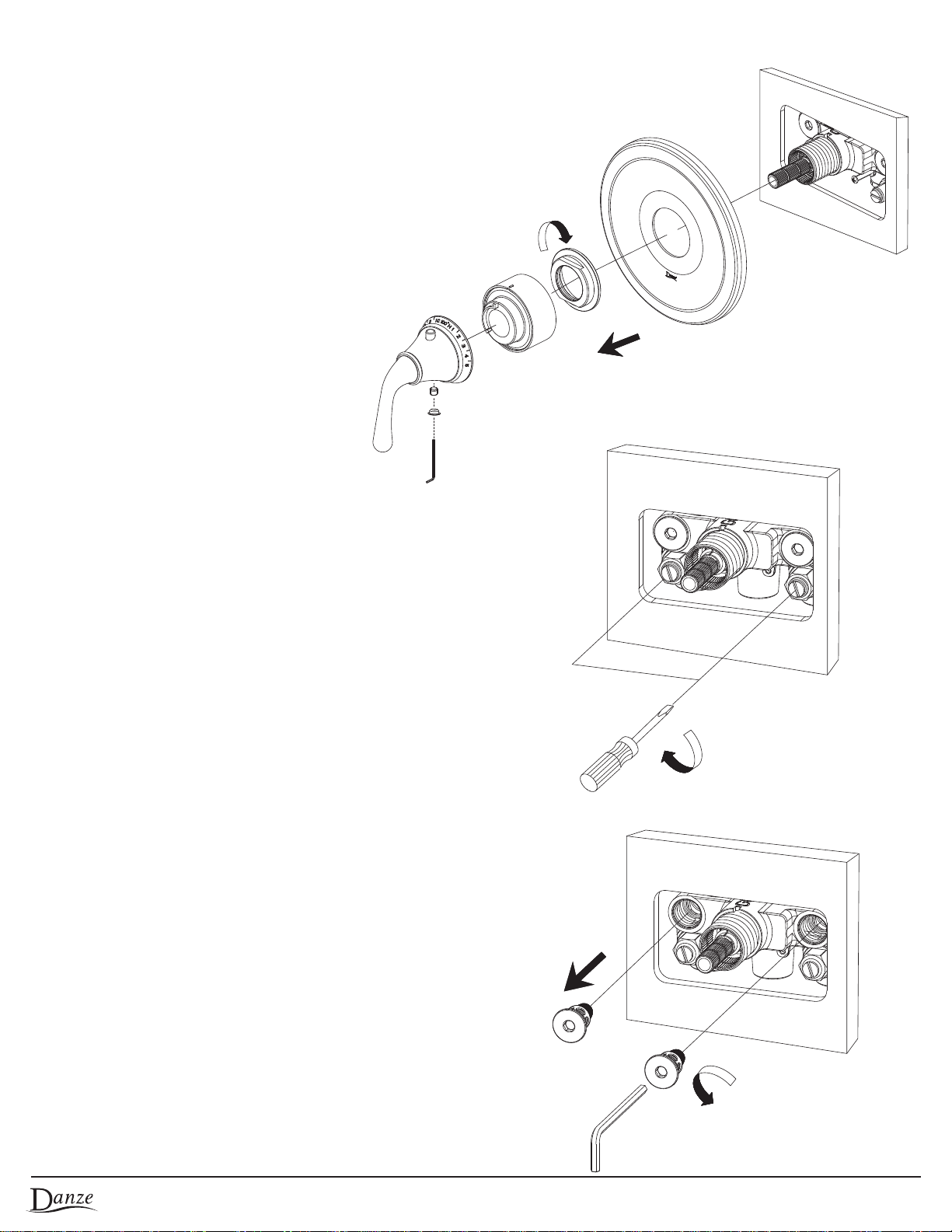

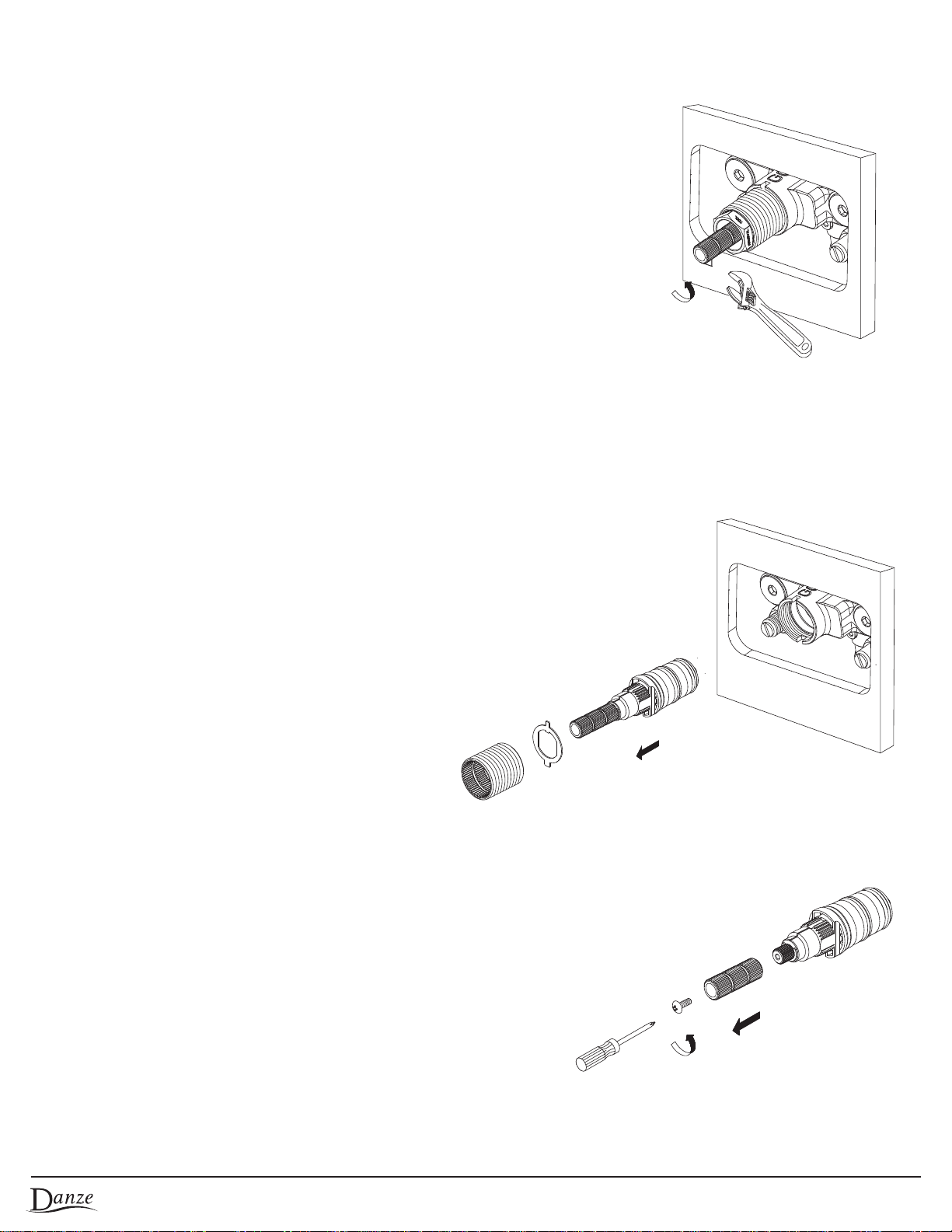

Parts Replacement/servicing

1.

Remove the trim from valve body.

Filter screen valve replacement/servicing

A.

Turn off the stops with screwdriver.

B.

Remove the filter screen valves using hex wrench

(included)

®

© 2008 Danze, Inc. All rights reserved.

7

C.

Remove the filter screen and use water to flush out the

sediment or debris.

D.

Reinstall the filter screen valves.

E.

Turn stops on and reinstall trim.

Thermostatic Cartridge replacement/servicing

A.

Close hot and cold supply valves located either side of

the mixing valve body.

Attach the sleeve removal tool (supplied) to the cartridge

B.

sleeve.

8

© 2008 Danze, Inc. All rights reserved.

®

C.

Use an adjustable wrench to turn the sleeve removal tool

counter-clockwise to remove the sleeve.

D.

Remove the metal washer. Extract Cartridge from valve:

grasp stem with pliers and carefully pull thermostatic

cartridge straight out of socket. Take care not to damage

spline on stem.

Remove the stem extension using screwdriver and

E.

replace the thermostatic cartridge.

®

© 2008 Danze, Inc. All rights reserved.

9

Reinstall the stem extension and slide cartridge into valve

F.

socket : THE NOTCH OF STEM EXTENSION SHOULD BE

IN LINE WITH THE NOTCH OF CARTRIDGE STEM.

G.

Reinstall washer and sleeve.

H.

See temperature calibration section for setting max.

temperature.

I.

Reinstall trim to valve.

Check Valve Replacement/Servicing

A.

Turn off water supply to valve.

B.

With a socket wrench of H7/8" (21mm) and at least 1

3/16" (30mm) in depth, remove the check valve from

valve body counterclockwise.

C.

Replace with new check valve and reinstall it to valve

body by doing the step B in reverse, making sure the

check valve is fully opened in the valve body.

D.

Reinstall the trim to valve body.

Warranty + Support

Danze faucets are covered by a manufacturer's "limited lifetime" warranty for manufacturing defects.

Tech Support

Toll Free Service Line

US : 1-888-328-2383

Canada : 1-800-487-8372

Website : www.danze.com

10

© 2008 Danze, Inc. All rights reserved.

®

Loading...

Loading...