Page 1

Data sheet

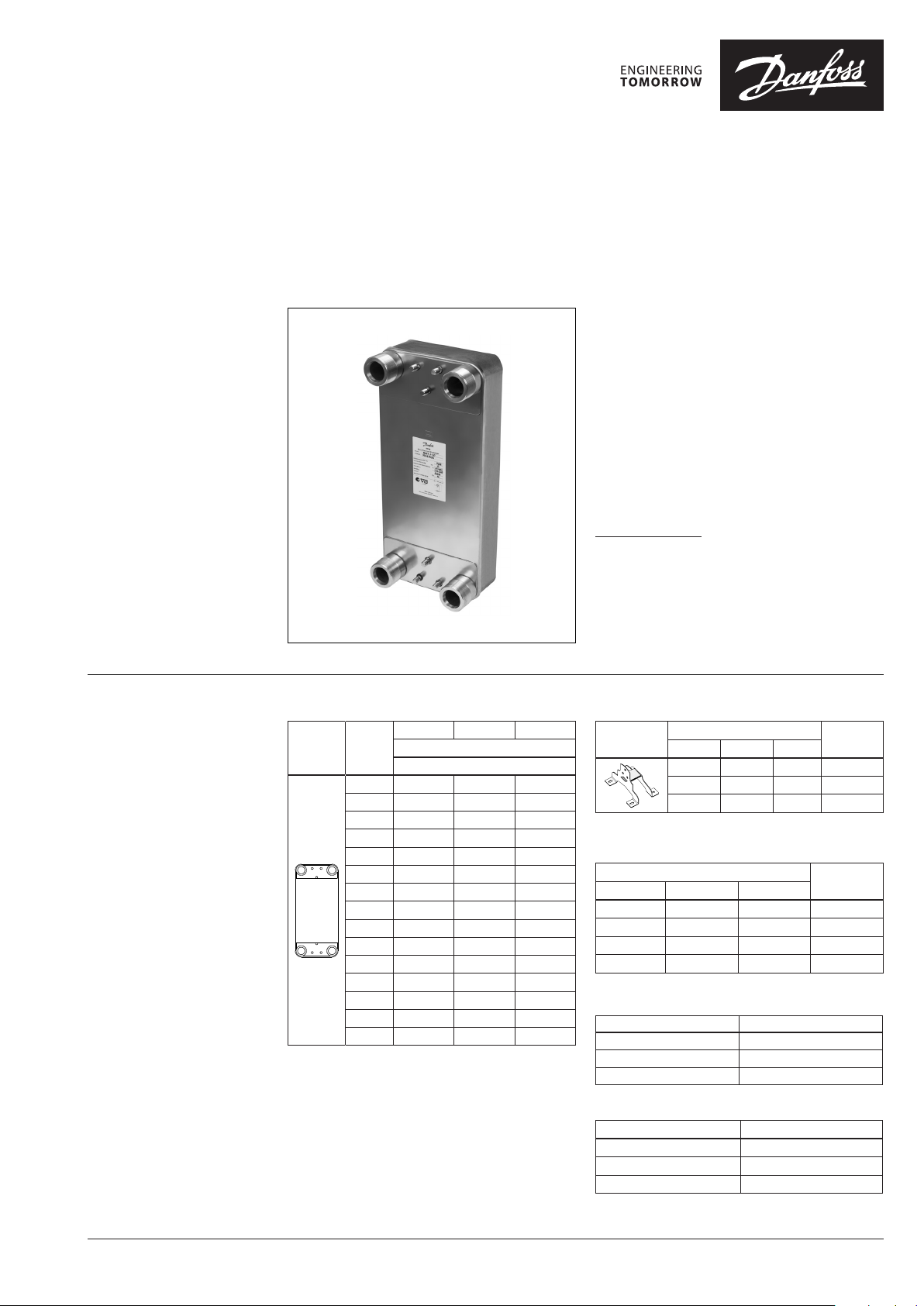

Micro Plate Heat Exchanger (MPHE): XB61

Description

Ordering

1-pass brazed heat exchangers type X B61-1

XB 61L-1SB

Picture

Note: Bracke ts must be ordered separatel y, the socalle d SB

brackets.

No. of

plates, n

30 004B1906 00 4B1913 00 4B1925

36 004B1907 00 4B1914 00 4B1926

40 004B1908 0 04B19 15 00 4B1927

50 004B1909 00 4B1916 004B1928

60 00 4B1910 0 04B 1917 0 04B1929

70 0 04 B1911 004B1918 0 04B193 0

80 00 4B1912 00 4B1919 004 B1931

90 004B3436 004B3444 004B3452

100 004 B3437 004B3445 004B3453

110 004B3438 004B3446 004 B3454

120 00 4B3439 004 B3447 004B3455

140 004B34 40 004B3448 004B3456

160 00 4B34 41 004B3449 004B3457

180 004B3442 004B3450 004B3458

200 004B3443 0 04B3451 004B3459

XB 61M-1S B

Thread (G 2)

Code No.

XB 61H-1S B

Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss.

Characterized by their unique plate pattern,

MPHEs enable heat to be transferred more

effectively than any previous model of heat

exchangers.

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• More flexible design

• Longer life time

more on:

store.danfoss.com

XB61 is copper brazed heat exchanger, designed

and configured for District Heating, District

Cooling and other Heating applications.

Approval:

Pressure Equipment Directive (PED).

Accessories - Bracket SB

Picture

1)

for dimensio ns, see page 2

Type coverage (p late nos)

H M L

30-90 30 -70 30-60 00 4B178 8

91-180 71-160 61-12 0 00 4B178 9

181-20 0 161-20 0 121-200 004B1790

1)

Code No.

Accessories - Insulations

Type coverage (p late nos)

H M L

30-90 30 -70 30-50 079 G1608

91-16 0 71-12 0 51-100 079G16 09

161-20 0 121-18 0 101-14 0 079 G1610

- 181-20 0 141-20 0 07 9G1 611

Code No.

Accessories - Tailpieces

Soldering Code No.

28 mm pipes 004B2910

35 mm pipes 004B 2911

42 mm pipes 00 4B2912

2)

Set of two pie ces.

2)

Weld- on Code No.

DN 32 004B2907

DN 40 004B2908

DN 50 004B2909

2)

© Danfoss | 2021.11 AI078686472006en-010401 | 1

Page 2

Data sheet XB61

Technical data Heat exchanger XB61-1

Max working pressure bar 25

Min. / Max. temperature

Flow medium

Plate corrugation H / M / L

Voume / Channel

Primary side vol.: (n / 2) − 1 × vol/channel

Connections G 2 × 52 mm (DIN ISO 228/1)

Weight kg 9 + 0.3*n

Materials

Plate material Stainless steel, mat. no. 1.4404 (316L)

Brazing Copper

n = Number of pl ates

Insulation

Typ e Mineral Wool with metal sheet cover

Note:

For more details about insulation

please contact your Danfoss sales

representative.

Wall thickness mm 40

Heat conductivity λ W/mK 0.039

Max.

temperature

Permanent

Short term peak 180

o

C −10/180

DH: Circulation water / glycolic water up to 50%

DC: ethylene-, propylene-glycolic water, ethanol-water solutions

and other suitable heat transfer media. (Please contact your Danfoss

Ltr

°C

representative).

H: 0.140 / M: 0.175 / L: 0.234

150

Dimensions

A (mm)

H: 12+1. 44×n

M: 12+1. 74×n

L: 12+2. 24×n

50

50

30

107

300

A= 00 4B178 8 B= 004 B1789 C= 004B1790

Code No.

217

17

16

61

61

A= 110

B=19 9

C= 311

123

61

Insulation

No. of plates, n Internal / External

Code No.

079 G1608 30-90 30 -70 30-50

079 G1609 11-16 0 7 1-120 51-10 0 292/38 0

079 G1610 161-2 00 121-180 101-14 0 372/460

07 9G1611 - 181-200 141-20 0 507/59 5

H M L

Width Highth Debth

mm

192/280

252/348 534/622

© Danfoss | DCS-SGDPT/SI | 2021.112 | AI078686472006en-010401

Loading...

Loading...