Data sheet

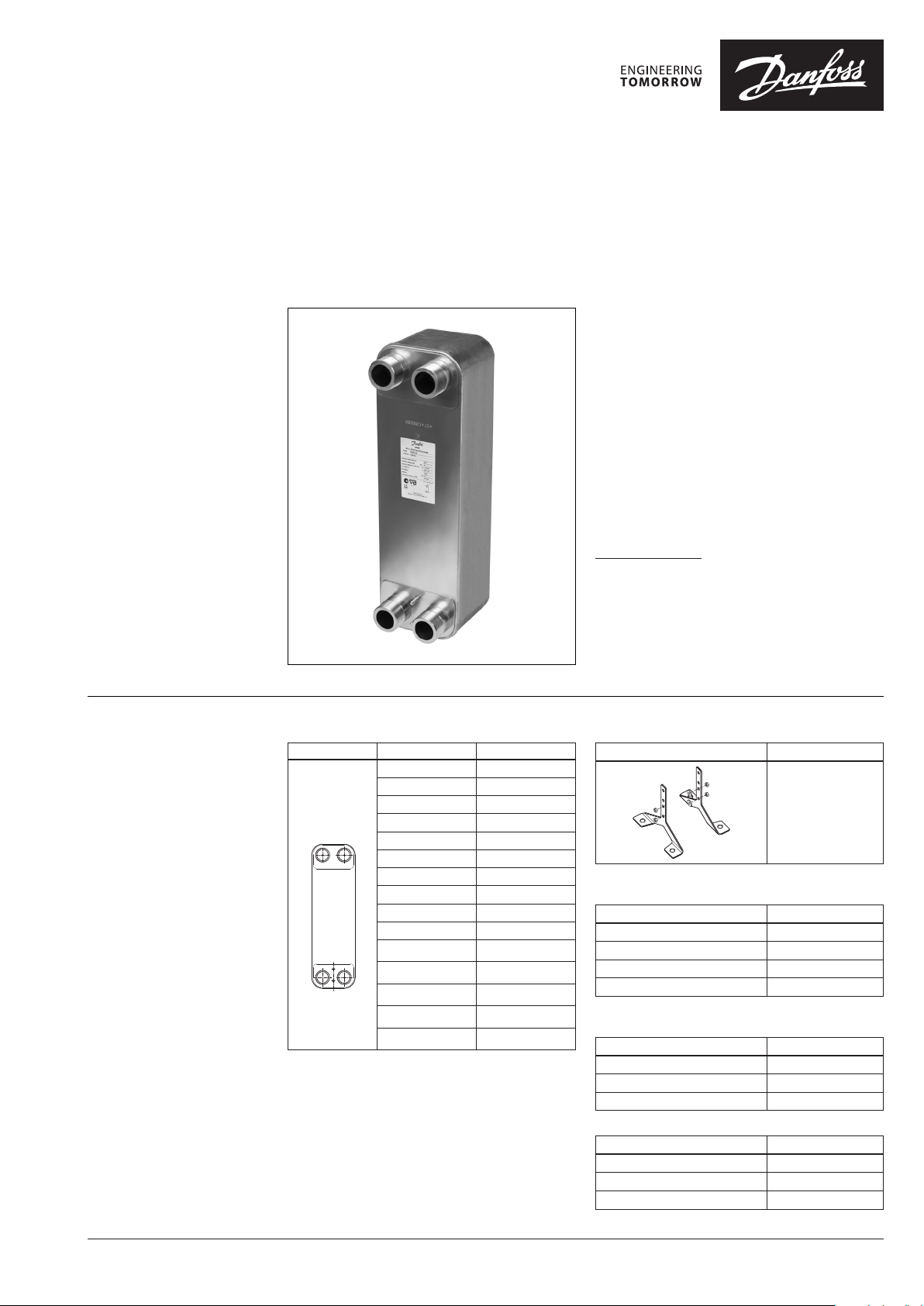

Micro Plate Heat Exchanger (MPHE): XB59

Description Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss.

Characterized by their unique plate pattern,

MPHEs enable heat to be transferred more

efficient than any previous model of heat

exchangers.

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• More flexible design

• Longer life time

more on:

store.danfoss.com

XB59 is copper brazed heat exchanger, designed

and configured for District Heating, District

Cooling and other Heating applications.

Ordering

Heat exchanger XB59 M-1

Picture No. of plates, n Code No.

30 00 4B1920

36 00 4B1921

40 004 B1922

50 00 4B1923

60 004B193 2

70 00 4B1933

80 004 B1934

90 004 B1936

100 00 4B1937

110 0 04B193 8

120 004 B1939

140 00 4B1940

160 00 4B1941

180 004B19 42

200 00 4B1943

Approval:

Pressure Equipment Directive (PED).

Accessories - Bracket set XB59

Picture Code No.

Accessories - Insulations

Type coverage (p late nos) Code No.

30-50

51-100

101-14 0

141-20 0

Accessories - Tailpieces

Solder Code No. *

28 mm pipes 004B2 910

35 mm pipes 004B2 911

42 mm pipes 00 4B2912

00 4B1245

079 G1671

079 G1672

079 G1673

079 G1674

Weld- on Code No. *

DN 32 004B2907

DN 40 004B2908

DN 50 004B2909

* Set of two pie ces.

© Danfoss | 2021.09 AI176986469852en-010501 | 1

Data sheet XB59

Technical data Heat exchanger XB59

Max working pressure bar 25

Min. / Max. temperature °C -10/180

Flow medium

Plate corrugation M

Volume / Channel Ltr 0.151

Connections mm G 2 x 52 (DIN ISO 228/1)

Weight kg 7 + 2.6 × n

Materials

Plate material Stainless steel, mat. no. 1.4404

Brazing Copper

Insulation

Typ e Polyurethane shell with Polyst yrene cover

Wall thickness mm 20

Note:

For more details about insulation

please contact your Danfoss sales

representative.

Heat conductivity λ W/m K 0.032

Max. temperature

Permanent

Short term peak 130

DH: Circulation water / glycolic water up to 50% DC: ethylene-, propylene-

glycolic water, ethanol-water solutions and other suitable heat transfer media

°C

(please contact your Danfoss representative).

110

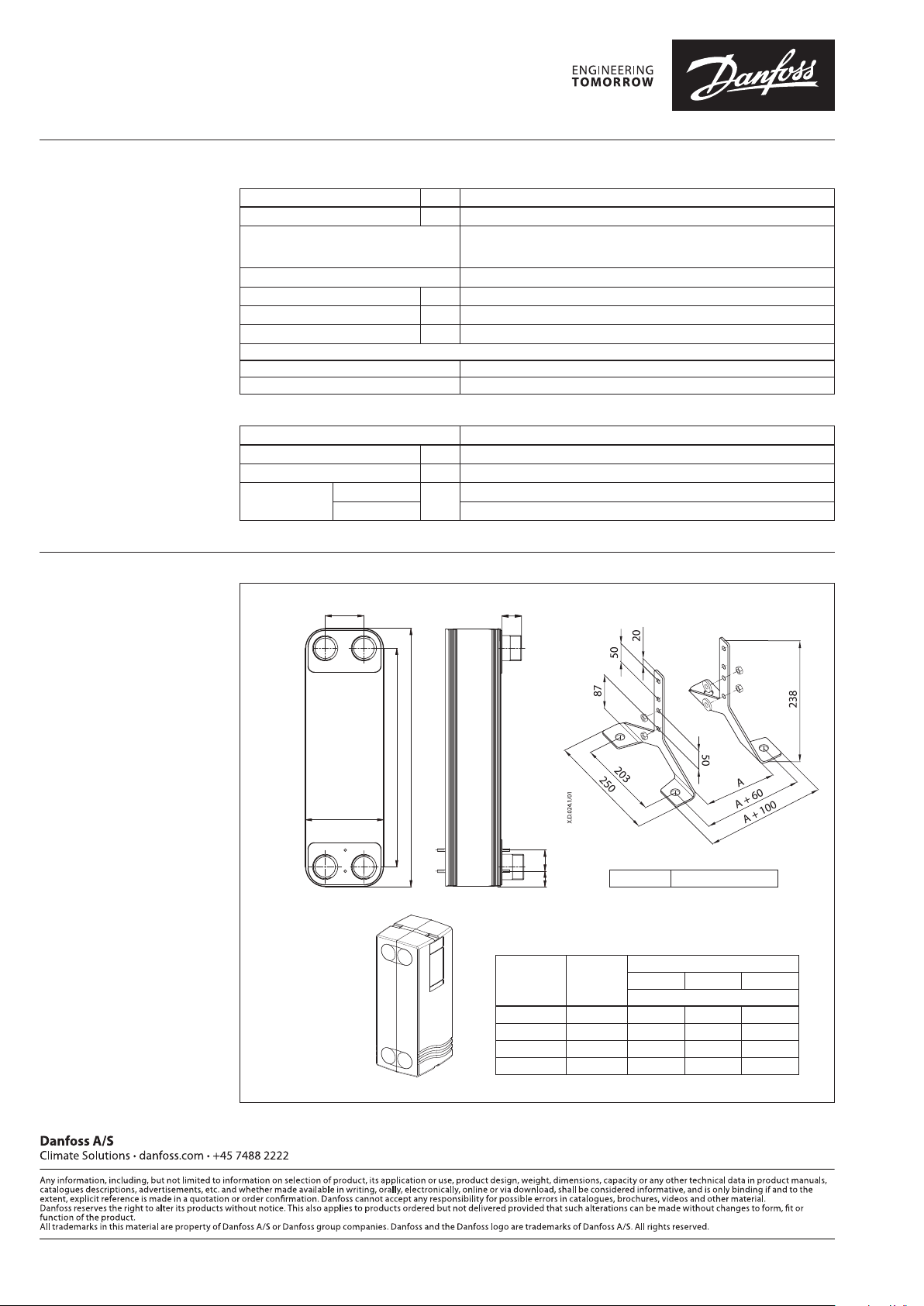

Dimensions

186

5292

613

519

5037

A (mm) M: 11.5 +1.74 × n

Insulation

Code No.

079G1671 30-50 247 662 19 2

079G1672 51-100 252 662 279

079G1673 101-14 0 257 662 349

079G1674 141-20 0 264 662 454

No. of

plates,

n

Width Height Depth

External

mm

© Danfoss | DCS-SGDPT/SI | 2021.092 | AI176986469852en-010501

Loading...

Loading...