Page 1

Data sheet

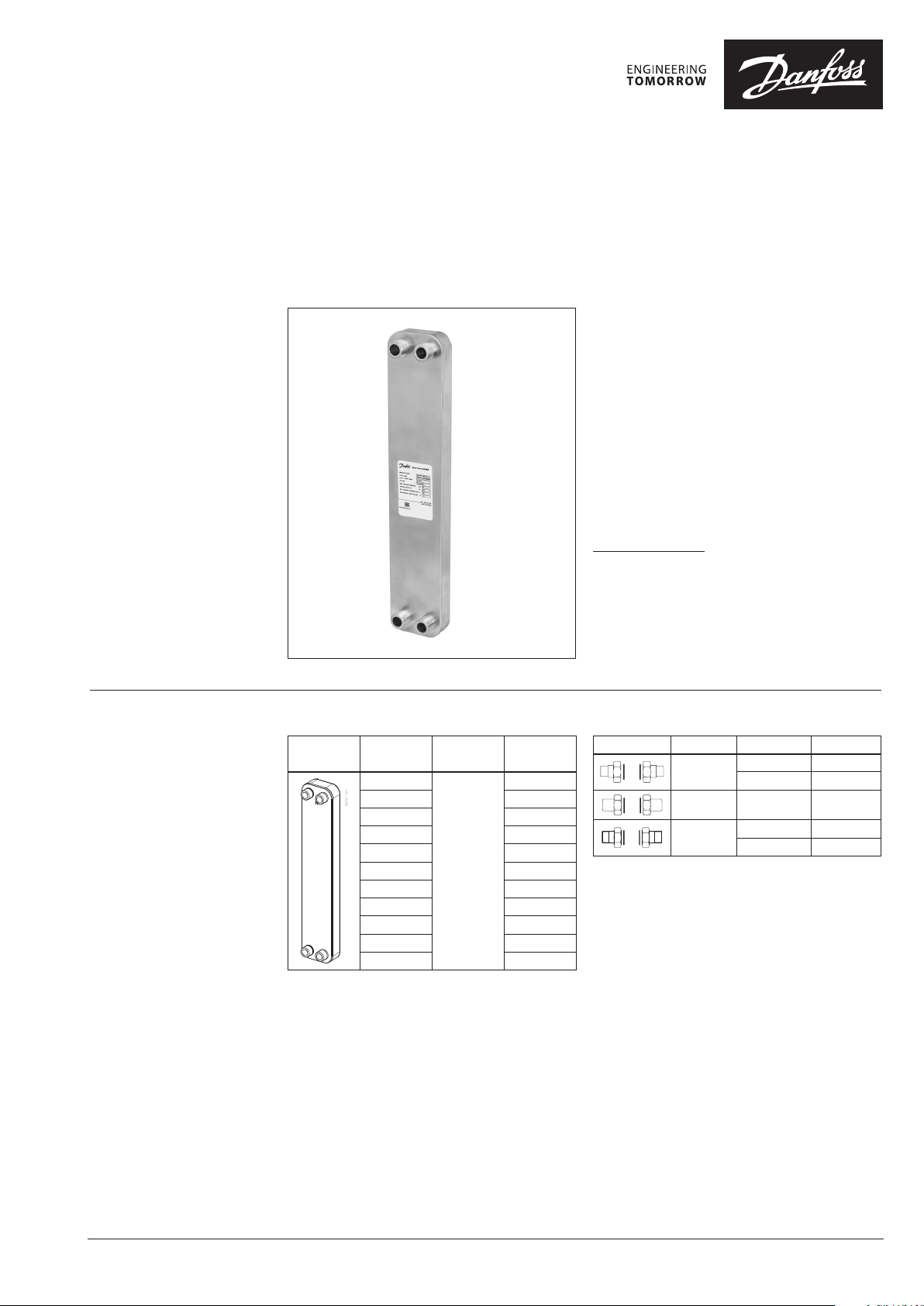

Micro Plate Heat Exchanger (MPHE): XB25

Description

Ordering 1-pass heat exchanger XB25

Picture

No. of

plates, n

10 004H4325

16 004H4326

20 004H4327

26 004H4328

30 004H4329

36 004H4330

40 004H4331

50 004H4332

60 004H4333

66 004H4334

Connection Code No.

8

Thread G ¾

004H4324

Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss.

Characterized by their unique plate pattern,

MPHEs enable heat to be transferred more

efficient than any previous model of heat

exchangers.

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• More flexible design

• Longer life time

more on:

MPHE.danfoss.com

XB25 is copper brazed heat exchanger, designed

and configured for District Heating, District

Cooling and other Heating applications.

Approval:

Pressure Equipment Directive (PED).

Accessories-Tailpieces

Picture

1)

One set contains 2 tail pieces with union nuts and gask ets

Description

Solder

tailpieces

Weld-on

tailpieces

Threaded

tailpieces

Connection Code No.

G ¾/15 mm 004B2945

G ¾/18 mm 004B2946

G ¾/DN 20 004B294 4

G ¾/G ¾ 004B2947

G ¾/G 1 004B2 953

1)

© Danfoss | 2017.09

VD.JQ.I2.02 | 1

Page 2

Danfoss can accept no responsibility for possible errors in catalogues, brochures an d other printed material. Danfoss reserves the right to alter its produ cts without notice. This also applies to

products already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

All trademarks in this material are pro perty of the respective companies. Danfoss and all Danfoss l ogotypes are trademarks of Danfoss A/S. All rights reserve d.

Danfoss A/S

Heating Segment • heating.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

Data sheet Micro Plate Heat Exchanger (MPHE) XB25

b

a

b

b

a

a

b

b

b

Technical data

Dimension

Typ e Heat exchanger XB25H

Max. working pressure bar 25

Max. operating temp.

Min operating temp -10

Flow medium

Volume / Channel Ltr 0.059

Connection type Cylindrical external thread acc. to DIN ISO 228/1

Connection size G¾”

Weight kg 0.09 x NoP + 0.99

Materials

Plate Stainless steel, EN 1.4404 (AISI 316L)

Brazing Copper (Cu); Copper-Nickel (CuNi)*

* Available on enquiry

E

20

°C

"DH: Circulation water / glycolic water up to 50% transfer media.

DC: ethylene-, propylene-glycolic water, ethanol-water solutions and other

suitable heat transfer media. (Please contact your Danfoss representative)."

Typ e

XB25 G ¾

n = number of pl ates

1)

Cylindrical ex ternal thread acc, to DIN ISO 228/1

Connection

1)

DH 180, DC 100

E

(mm)

H: 6.5 + 1.55 × n

491

442

45

94.5

Tailpieces

Picture

1)

Union nut, width across flats

a

a

a

Description

Solder

tailpieces

Weld-on

tailpieces

Threaded

tailpieces

mm

1)

Code No.

Connection

G ¾ / 15 mm 15 35 32 004B2945

G ¾ / 18 mm 18 35 32 004B2946

G ¾ / DN 20 21.2 35 32 0 04B2944

G ¾ / G ¾ ⁄” 40 32 004B29 47

G ¾ / G 1 1” 22 32 004B2953

a b SW

2 | © Danfoss | DHS-SRMT/SI | 2017.09

VD.JQ.I2.02

Loading...

Loading...