Page 1

Data sheet

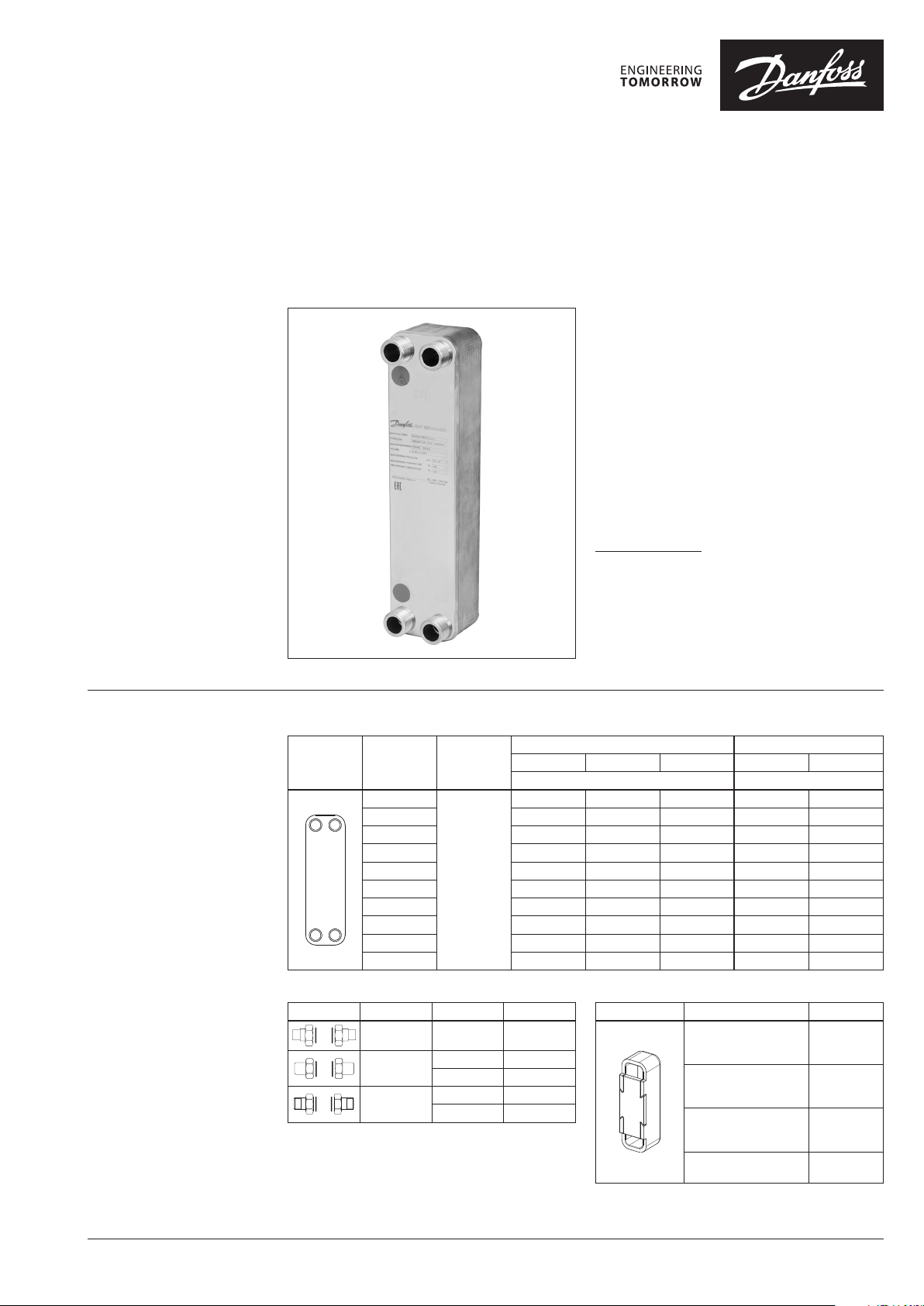

Micro plate heat exchanger (MPHE): XB05

Description

Ordering 1-pass heat exchanger

Picture

No. of

plates, n

10

16 004B3557 07 9G1232 079 G1441 079 G1243 079 G1660

20 004B3558 079G12 33 079 G1442 079G124 4 079G16 61

26 004B3559 079G12 34 079 G1443 0 79G124 5 079G16 62

30 004B3560 079 G1235 079G1444 079G1246 079G1663

36 004 B3561 07 9G1236 079G14 45 079G12 47 079G16 64

40 004B3562 079 G1237 07 9G144 6 079G12 48 079 G1665

50 004B3563 079G1238 079G14 48 07 9G1249 079 G1667

60 004B3564 079 G1239 07 9G144 9 079G12 50 079 G1668

70 00 4B3565 079G12 40 079 G1450 079 G1251 079G16 69

Connection

Thread

G ¾

Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss.

Characterized by their unique plate pattern,

MPHEs enable heat to be transferred more

effectively than any previous model of heat

exchangers.

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• More flexible design

• Longer life time

more on:

store.danfoss.com

XB05 is heat exchanger, designed and configured

for District Heating, District Cooling and other

Heating applications.

Approval:

Pressure Equipment Directive (PED).

XB05 Cu XB05 StS

XB 05M -1 XB 05X-1 XB05H-1 X B05X -1 XB05H-1

Code No. Code No.

004B3556 079 G1231 07 9G144 0 079G12 42 079 G1659

Accessories-Tailpieces

Picture Description Connection Code No.

Solder

tailpieces

Weld- on

tailpieces

Threaded

tailpieces

1)

One set contains 2 tail pieces with union nuts and gaske ts

2)

PL08 to be contacted fo r further details

G ¾ /15 mm 004B2945

G ¾ /DN 15 003H6908

G ¾ /DN 20 004B2944

G ¾ /G ¾ 004 B2947

G ¾ /G 1 004B2953

Accessories-Insulation set XB05-1

1)

Picture No. of plates, n Code No.

M: 10-26

X: 10 -20

H: 10 -36

M: 30-40

X: 26-30

H: 40-50

M: 50

X: 36-40

H: 6 0-70

M: 6 0-70

X: 50

079 G1283

079 G1284

079 G1285

079 G1286

© Danfoss | 2022.01 AI129286470501en-010403 | 1

Page 2

Data sheet XB05

b

a

b

b

a

a

b

b

b

Technical data

Dimensions

Typ e XB 05M -1 XB 05X-1 XB05H-1

Max. working pressure Cu

Max. working pressure StS / 10 10

Min. / Max. temperature °C -10/180 -10/150 -10/180

Flow medium

Volume/channel Ltr 0.021

Connection type Cylindrical external thread acc. to DIN ISO 228/1

Connection size G ¾

Weight kg 0.58 + 0.045 × n 0.51 + 0.048 × n 0.46 + 0.045 × n

Materials

Plate Stainless steel, EN 1.4404 (AISI 316L)

Brazing Copper (Cu); Stainless steel (StS)

1)

Low pressure d rop side - can be either primar y or secondary side , depends on selectio n in Hexact.

2)

High pressure d rop side - can be either primar y or secondary side , depends on selectio n in Hexact.

n = number of pl ates

bar

DH: Circulation water / glycolic water up to 50%

DC: ethylene-, propylene-glycolic water, ethanol-water solutions and other suitable heat

transfer media. (Please contac t your Danfoss representative).

L

H

1)

: 0.037

2)

: 0.026

25

0.016

Insulation

Typ e Expanded Polypropylene Insulation

Wall thickness mm 20

Heat conductivity, λ W/mK 0.036

Operating temperature

Design

Contact surface 60

°C

110

20

E

312

278

76

42

Typ e

XB05M -… G ¾

XB05X -… G ¾

XB05H -… G ¾

1)

Cylindrical ex ternal thread acc. to DIN ISO 228/1

n = number of pl ates

Connection

1)

1)

1)

E

(mm)

8 + 1.19 × n 0.58 + 0.045 × n

7.1+ 1.6 × n 0.51 + 0.048 × n

6.85 + 0.95 × n 0,46 + 0,045 × n

Weight empty

(kg)

Insulation XB05-1

No. of

plates, n

M: 10-26

X: 10 -20

H: 10 -36

M: 30-40

X: 26-30

H: 40-50

M: 50

X: 36-40

H: 6 0-70

M: 6 0-70

X: 50

A B E

348 105

Tailpieces

Picture

2)

Union nut, with a cross flats

a

a

a

Description

Solder

tailpieces

Weld- on

tailpieces

Threaded

tailpieces

E

mm

Connection

G ¾ / 15 mm 15 35 32 00 4B2945

G ¾ / 18 mm 18 35 32 004B2946

G ¾ / DN 20 21.2 35 32 004 B2944

G ¾ / G ¾ ⁄” 40 32 00 4B2947

G ¾ / G 1 1” 22 32 004B2953

Code No.

79.5 0 79G128 3

97. 5 079G12 84

111. 0 079 G1285

133.5 07 9G1286

a b SW

A

2)

mm

B

Code No.

© Danfoss | DCS-S/SI | 2022.012 | AI129286470501en-010403

Loading...

Loading...