Page 1

Data sheet

Brazed heat exchanger XB

Description

The XB is a range of copper brazed plate heat

exchangers for use in District Heating (DH)

and District Cooling (DC) applications, e.g.

domestic hot water production, district heating

substation to separate the network from house

installation or as pressure breakers. The range

consist of numerous individual plate sizes of

which several can be delivered with different

corrugation depth or pattern, thus ensuring that

the optimal heat exchanger can be selected for

all applications.

Main data:

- Min. temperature −10 °C

Max. temperature +180 °C

- Max. working pressure 25 bar

- Flow media

DH: Circulation water / glycolic water up to

50 %

DC: ethylene-, propylene-glycolic water,

ethanol-water solutions and other suitable

heat transfer media. (Please contact your

Danfoss representative).

- Connection size DN (threaded or flanged)

20 -100

Approvals:

• CE certificate according (PED) 97/23/EC

• GOST/Russia

• SVGW/Switzerland

• VA/Denmark

© Danfoss | 2016.08

VD.JQ.C2.02 | 1

Page 2

Data sheet Brazed heat exchanger XB

Ordering

Explanation, XB type

XB 51L – 1 – 10 Number of plates

Pass of the heat exchanger

1 = 1-pass

2 = 2-pass

Plate type

Plate size

B = Brazed heat exchanger

Plate types

Several of the heat exchangers can be delivered

in three different basic corrugations: H M L

making them optimal for different applications.

Please see the characteristics below.

H- types M- typ e L-type

Channel Small Medium

Angle if

chevron

pattern

Heat transfer Relatively

Pressure

drop

Obtuse Acute

high

Relatively

high

Mix of H/L

Medium Relatively

Medium Relatively

Large

low

low

The heat exchanger can consist of plates type L

or plates type H.

The H- type plate has larger herring bone angle

than the L- type plate. H- type plate fits better for

certain temperatures than L- type. H- type heat

exchangers have better heating capacity, but

they also have higher pressure loss.

The plate set can also be a combination of these

two types. If every other plate is H-type plate and

every other plate is L-type plate, the combination

is called type M.

L- t ype

H- type

Micro Plate Heat Exchanger (MPHE) principle:

Traditionally the different versions have been

created by using different angles in the chevron

pattern of the heat exchanger plates.

However new and more efficient heat transfer

patterns have been developed. Characteristic

for the pattern is that the corrugation consists

of dimples in different size and shape, creating

Micro Plate heat exchangers. Micro Plate heat

exchangers offers same heat transfer with lower

weight, size and pressure drop. Besides better

heat transfer Micro Plate heat exchangers offers

higher mechanical strength.

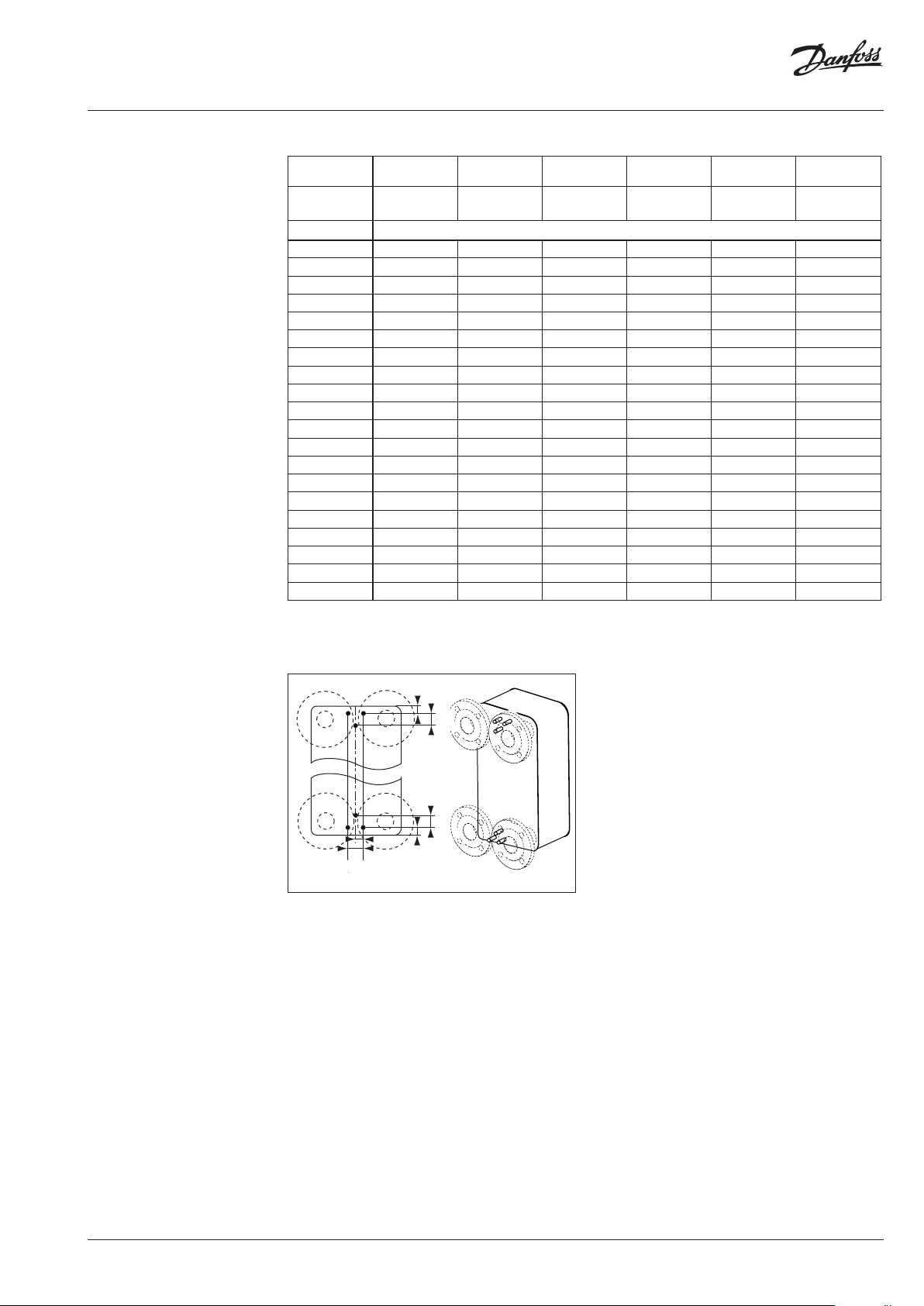

1-pass brazed heat exchangers type XB

Typ e XB 04-1 XB 24-1

Connec tion

No of plates, n Code No.

8 00 4B 1011 -

10 0 04B1012 00 4B1027

16 0 04B10 14 004B1028

20 00 4B1016 004 B1029

26 00 4B10 17 004 B1031

30 004B1019 0 04B1032

36 004 B1021 004B1033

40 004B10 23 004B103 4

50 004 B1024 004B1067

60 004B1026 004B1068

70 - 004B1069

Thread G ¾ Thread G ¾

Micro Plate

2 | © Danfoss | 2016.08

VD.JQ.C2.02

Page 3

Data sheet Brazed heat exchanger XB

Ordering (continued)

1-pass brazed heat exchangers type XB

Typ e XB51L-1 * XB51L-1 SB * XB51L-1 SB XB 70L-1

Connection

Thread Thread Flange Flange Flange Flange

G 2 G 2 DN 50 DN 65/100

2)

1)

DN 65/100

No of plates, n Code No.

10 00 4B 1141 - - - - -

16 00 4B 1142 - - - - -

20 00 4B1532 - - - - -

26 00 4B1533 - - - - -

30 004B 1194 00 4B134 5 - - - -

36 0 04B 1195 00 4B134 6 - - - -

40 00 4B119 6 0 04B1347 - - - -

50 0 04B119 7 00 4B134 8 - 004B2425 004B2000 004B 2012

60 00 4B 1198 - 0 04B13 50 004B2430 004B2001 004 B2013

70 0 04 B1199 - 00 4B1351 004 B2435 004B2002 004 B2014

80 004B1200 - 00 4B1352 004 B2440 004B2003 004 B2015

90 004B12 01 - 004B13 53 004B24 45 004B2004 00 4B2016

100 00 4B1202 - 0 04B1355 004 B2450 004B2005 0 04B2017

110 0 04B1203 - 00 4B1356 00 4B2455 004B2006 004B2 018

120 004B1204 - 00 4B1357 004B2460 004B2007 004B2 019

130 004 B1534 - - - - -

140 00 4B1536 - - 00 4B2470 004B2008 004B2020

160 - - - 004B248 0 004B2009 004 B2021

180 - - - 004B2490 004 B2010 004B2022

200 - - - 004B2499 0 04 B20 11 004B2023

1)

prim ary side (PN 25) / secondary si de (PN 16)

2)

delive red with mounting brackets e x factory

* Special versions; SB: T his version includes 6 supp orting bolts M12×20

XB 70M-1

2)

1)

XB 70H -1

DN 65/100

2)

1)

25

50

50

25

50

25

SB version: Supporting bolts in the front.

Special versions

Special versions for different mediums,

connections/couplings, max. operating

pressures, materials and capacities are available

on request. Please contact the local sales

representative for details

VD.JQ.C2.02

© Danfoss | 2016.08 | 3

Page 4

Data sheet Brazed heat exchanger XB

Ordering (continued)

2-pass brazed heat exchangers type XB

Typ e XB0 4-2 XB51L-2

Connection

No of plates 1), n Code No.

10/10 - 00 4B114 7

16/16 - 00 4B114 8

20/20 00 4B1036 0 04 B1149

26/26 0 04B1037 0 04 B1150

30/30 004B103 8 00 4B1292

36/36 00 4B1039 00 4B1293

40/40 004B1040 00 4B129 4

46/46 004B1041 0 04B1295

50/50 004B1042 00 4B129 6

56/56 004B1043 00 4B129 7

60/60 004B1044 004 B1298

66/66 - 0 04B1299

70/70 - 004B1300

1)

afterheating/preheating

Thread G ¾ Thread G 2

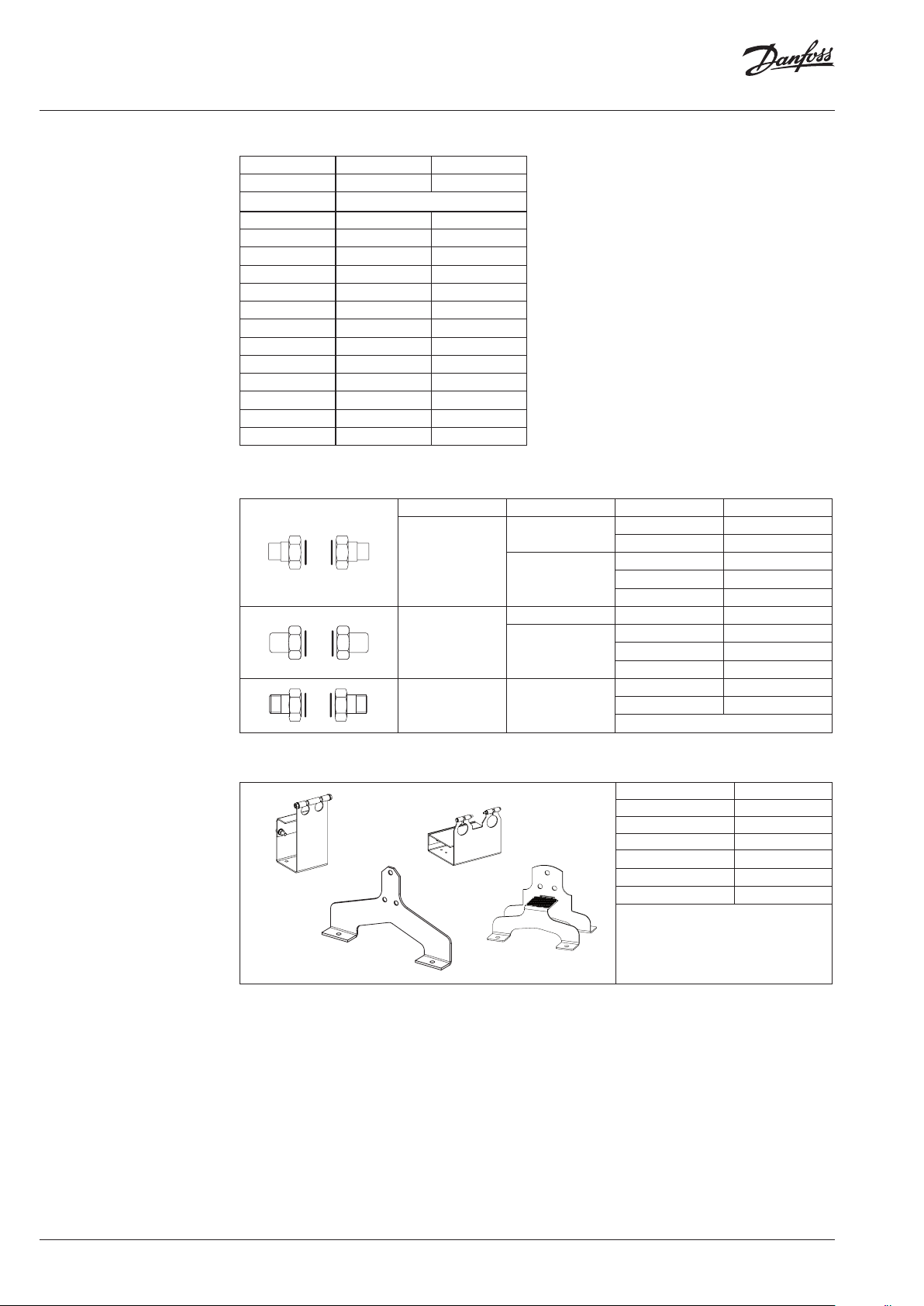

Accessories: Tailpieces

Description Suitable for Connection Code No.

Solder tailpieces

Weld-on tailpieces

Threaded tailpieces XB04, XB24

XB04, XB24

XB51L

XB04, XB24 G ¾ / DN 20 004B2944

XB51L

G ¾ / 15 mm 004B2945

G ¾ / 18 mm 004B2946

G 2 / 28 mm 004B2 910

G 2 / 35 mm 00 4B2 911

G 2 / 42 mm 00 4B2912

G 2 / DN 32 004B2907

G 2 / DN 40 004B2908

G 2 / DN 50 004B2909

G ¾ / G ¾ 004 B2947

G ¾ / G 1 004B2953

1)

1)

One set contains 2 tai lpieces with union nuts and g askets

Accessories: Mounting brackets for brazed heat exchanger type XB

Suitable for Code No.

XB04, XB24 004B2948

XB51SB, 30-60 plates 00 4B1788

XB0 4, 24

XB70

1)

The b rackets are delivered with XB70, the y will thus be needed only fo r service or special pu rposes.

XB51

XB51SB

XB51SB , 70-100 pl ates 00 4B178 9

XB51SB , 110-160 plates 004B1790

XB51 004B2923

XB70 004B2925

1)

4 | © Danfoss | 2016.08

VD.JQ.C2.02

Page 5

Data sheet Brazed heat exchanger XB

Ordering (continued)

Accessories: Insulation for 1-pass

brazed heat exchangers type XB

Typ e XB51-1 XB 70-1

No of plates

10

16 -

20 -

26 -

30 -

36 -

40 -

50

60

70

80

100

110

140 004B3735

160 -

200 -

00 4B1924

00 4B1935 004B2535

00 4B1950 004B255090

004B1960

Code No.

-

004B2570120

004B2599180 -

Accessories: Insulation for 2-pass

brazed heat exchangers type XB anger

Typ e

No of plates

1)

afterheating/preheating

1)

30/30

36/36

40/40

50/50

56/56

60/60

66/66

70/70

Accessories: Insulation properties

Typ e

Heat conductivity, λ W/mK 0,035 0,042

Max temperature

Wall thickness mm 20 30

Permanent

Short term peak 160 180

°C

PU (Polyurethane)

see page 12 for XB51

130 150

Coated steel sheet and polyester insulation,

see page 12 for XB70

XB51-2

Code No.

00 4B1935

00 4B195046/46

004B3730

004B3735

VD.JQ.C2.02

© Danfoss | 2016.08 | 5

Page 6

Data sheet Brazed heat exchanger XB

Technical data

1-pass brazed heat exchangers type XB

Typ e XB 04-1 X B24 -1 XB51 L-1

Max. working pressure (bar) 25 (16)

Min. / Max. temperature 2) (°C) -10/180

Flow medium

Volume/channel (litres) 0,060 0,10 0 0,210 0,55/0,70

Connection type Cylindrical external thread acc. to DIN ISO 228/1 Flange, DN

Connection size G ¾ G ¾ G 2 65 4)/100 5)

Plate material Stainless steel, EN 1.4404 (AISI 316L)

Brazing material Copper

1)

16 bar versio ns are available on enquir y (all types except XB 0 4-1, 24-1). XB 70-1 secondar y side: max. working pre ssure 16 bar

2)

At flow te mperatures below 2 °C gl ycolic water must be used

3)

Primary side / secondary side

4)

Flanges PN 25 acc. to EN 1092, facing t ype B (B1)

5)

Flanges PN 16 acc. to EN 1092, facing t ype B (B1)

DC: ethylene-, propylene-glycolic water, ethanol-water solutions and other suitable heat

DH: Circulation water / glycolic water up to 50 %

transfer media. (Please contac t your Danfoss representative).

1)

XB 70L-1

XB 70M-1

XB 70H -1

25(16) 1)/16

2-pass brazed heat exchangers type XB

Typ e XB04 -2 XB51L-2

Max. working pressure (bar) 25 (16)

Max. operating temp. (°C) 180

Min. operating temp.2) (°C) −10

Flow medium Circulation water / glycolic water up to 50 %

Volume/channel (litres) 0,060 0,210

Connection type Cylindrical external thread acc. to DIN ISO 228/1

Connection size G ¾ G 2

Plate material Stainless steel, mat. no. 1.4404

Brazing material Copper

1)

16 bar versio ns are available on enquir y (all types except XB 0 4-2).

2)

At flow te mperatures below 2 °C gl ycolic water must be used

1)

3)

3)

3)

To avoid corrosion and leakage in the copper

brazed plate heat exchangers please observe

Danfoss recommendations for the water quality

in the guideline on www.heating.danfoss.com

(Documentation).

For the standard range of heat exchangers

material 1.4404 (316L) has been selected to

achieve:

- good delivery service

- good balance between low price and

avoiding corrosion in the most common

applications

- 1.4404 offers better corrosion properties than

e.g. 1.4301 but is more expensive.

Attention must always be paid to the water

condition when selecting material for a heat

exchanger. The heat exchangers can be delivered

in other materials on request.

6 | © Danfoss | 2016.08

VD.JQ.C2.02

Page 7

Data sheet Brazed heat exchanger XB

Design and function

T11 - Primary side in

T12 - Primary side out

T112 - Primary side second inlet

(2-pass)

T21 - Secondary side in

T22 - Secondary side out

T212 - Secondary side second

inlet (2- pass)

The heat exchangers are made of shape-pressed

and brazed heat exchange plates, between

which the flow channels are created. The heavy

turbulence and counterflow principle enable

efficient heat transfer. The task of the heat

exchanger is to transfer heat from the primary

to secondary flow through a heat transfer plate

thus preventing the flows from mixing with each

other.

The choice of heat exchanger is determined by

the desired heat output, required temperatures

and the permitted pressure losses.

Sizing and selection Dimensioning and selection of heat exchangers

should be carried out with the support of

the Danfoss dimensioning program for heat

exchangers.

Mounting It is recommended to mount heat exchangers

on their base in vertical position. This will

assure the best venting and the least fouling.

It is recommended that all pipes connected to

the heat exchanger are equipped with shut-off

valves for maintenance purposes.

The 2-pass heat exchanger should be chosen for

domestic hot water. The 2-pass heat exchanger

will often cool the district heating water to below

25 °C. This capacity can be achieved by using a

larger temperature difference, a smaller water

flow and a heat exchanger with an optimum

heat transfer area. This will affect the choice of

motorized control valve, for instance.

The pipes must be equipped with brackets to

prevent any torsional stress concentration at the

heat exchanger’s pipe connections.

It is recommended that the heat exchanger is

equipped with insulation.

VD.JQ.C2.02

The pipes to be connected must be mounted so

that the strain caused by the thermal expansion,

for instance, does not harm the heat exchanger.

Use a safety valve between a heat exchanger and

a shut off valve on the secondary side to avoid

breaking of the heat exchanger due to thermal

expansion of liquid.

© Danfoss | 2016.08 | 7

Page 8

Data sheet Brazed heat exchanger XB

C

C1

D

B

E

F

A

C3

C2

A1

A

B

C

D

E

F

A

B

C

D

E

F

E

F

Dimensions

XB 04 … 24

XB 51 … SB

Typ e Connection

XB 04-1-… G ¾

XB0 4-2-… G ¾

XB24 -… G ¾

XB51L -…

XB51… SB

XB51… SB

XB70L-…

XB70M-…

XB70H -…

n = number of pl ates (for 2-pass heat exchan gers the sum of fterheat ing and preheating plates)

1)

Cylindrica l external thread acc , to DIN ISO 228/1

2)

Flanges PN 25 a cc, to EN 1092, facing typ e B (B1)

3)

Primary side / secondary side

4)

Flanges PN 16 acc, to EN 1092, facing t ype B (B1)

5)

For numb er of plates n < 60

6)

For numb er of plates n ≥ 60

5)

6)

1)

1)

1)

1)

G 2

2)

DN 50

DN 65 2) / 100

A/ A1 B

296 93 248 45 11 + 2,25 × n 20 0,9 + n × 0,085

296 93 248 45 11 + 2,25 × n 20 1,13 + n × 0,085

490 93 442 45 11 + 2,25 × n 20 1,4 + n × 0,15

466 256 380 170 12 + 2,6 × n 50 8 + n × 0,38

466 256 380 170 12 + 2,6 × n 90 18,8 + n × 0,38

3) 4)

990/ 1110 365

External dimensions [mm]

C/C1

C2/C3

861/816

180/ 203

XB 70

Weight empty

D E F

214 10 + 2,7 × n 90 40 + n × 1,50

[kg]

8 | © Danfoss | 2016.08

VD.JQ.C2.02

Page 9

Data sheet Brazed heat exchanger XB

Dimensions (continued)

Mounting brackets

50

100

40

60

20

202

Ø27

4×Ø8,5

45

100

60

180

100

XB04, 24 bracket

160

6×Ø9

238

170

270

XB51 brac ket

248

143

XB70 bracke t

180

61

225

90

40

416

326

50

VD.JQ.C2.02

© Danfoss | 2016.08 | 9

Page 10

Data sheet Brazed heat exchanger XB

a

b

a

a

b

b

b

Dimensions (continued)

Mounting brackets

A= 30-60 plates B= 70-100 plates C= 110-160 plates

Tailpieces

b

a

b

a

a

50

50

30

107

300

217

61

XB51SB

Description Connection Code No.

G ¾ / 15 mm 004B2945 15 35 32

G ¾ / 18 mm 004B2946 18 35 32

Solder tailpieces

Weld-on tailpieces

Threaded tailpieces

G 2 / 28 mm 0 04B2910 32 45 65

G 2 / 35 mm 0 04 B2 911 39 45 65

G 2 / 42 mm 0 04B 2912 51 45 65

G ¾ / DN 20 0 04B2944 21,2 35 32

G 2 / DN 32 004B2907 42, 4 45 65

G 2 / DN 40 004B2908 48,5 45 65

G 2 / DN 50 004B2909 58 43 65

G ¾ / G ¾ 004B2947 ⁄” 40 32

G ¾ / G 1 0 04B2953 1” 22 32

17

16

61

A= 110

B=19 9

C= 311

123

61

a b SW

mm

1)

10 | © Danfoss | 2016.08

1)

Union nut, width across flats

Flanges

Typ e

XB51... SB 50 90 125 18 4 25

XB70 65/100 1)90 145/180 1)18 8 25/16

XB70 65/100 1)90 145/180 1)18 4/8 1)16

1)

Primary side/secondary side

DN L1 k d

mm (bar)

2

n

PN

n

1)

d

d

n

k

L1

VD.JQ.C2.02

Page 11

Data sheet Brazed heat exchanger XB

Dimensions (continued)

Insulation program (polyurethane) for brazed heat exchangers type XB

Insulation dimensions for 1-pass

E

A

B

XB51L

E

A

B

XB70

brazed heat exchangers type XB

Typ e X B51-1 XB7 0-1

No of plates mm

10

16 -

20 -

26 -

30 -

36 -

40 -

50

60

70

80

90

100

110

120

140

160 -

180 -

200 -

00 4B1924

A= 512

B=320

E=197

00 4B1935

A= 512

B=320

E=257

00 4B1950

A= 512

B=330

E=337

004B1960

A= 512

B=340

E=392

004B3735

A= 512

B=346

E=445

-

004B2535

A=12 02

B=4 45

E=259

004B2550

A=12 02

B=4 45

E=340

004B2570

A=12 02

B=4 45

E=448

004B2599

A=12 02

B=4 45

E= 610

Insulations set o f PU type for

XB70 can be delivered o n request.

Please contact the local sales

representative for details.

Insulation dimensions for 2-pass

brazed heat exchangers type XB

Typ e 51-2

30/30

36/36

40/40

46/46

50/50

56/56

60/60

66/66

70/70

1)

mm

00 4B1935

A= 512

B=320

E=257

00 4B1950

A= 512

B=330

E=337

004B3730

A= 512

B=340

E=392

004B3735

A= 512

B=346

E=445

No of plates

1)

afterheating/preheating

VD.JQ.C2.02

© Danfoss | 2016.08 | 11

Page 12

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Brazed heat exchanger XB

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

12 | © Danfoss | DHS-SRMT/SI | 2016.08

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.JQ.C2.02

Loading...

Loading...