Page 1

X5EIP01 Ethernet IP Option Board with

115 VAC Encoder Interface

Installation Manual

DPD00111

Page 2

Need Help?

This manual answers most installation and startup questions

that may arise. However, if you have any problems,

please let your first call be to us.

Vacon, Inc.

Chambersburg, PA 17202

Normal business hours:

(North America)

8:00 AM to 5:00 PM, Eastern time

+1 877-Vacon06

(+1 877-822-6606)

After-hours support is also available

and Vacon, Inc. are trademarks of Vacon Plc, a member of Vacon Group.

All other product names are trademarks of their respective companies.

Copyright 2009, Vacon, Incorporated. All rights reserved.

Page 3

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 3

Installing the X5EIP01 Ethernet IP Option Board

with 115 VAC Encoder Interface

Introduction

The X5 frequency converters can be connected to Ethernet using an Ethernet IP option board, the X5EIP01.

Every device connected to an Ethernet network has two identifiers: a MAC address and an IP address. The MAC

address (formatted as xx:xx:xx:xx:xx:xx, where xx is a hexadecimal byte) is unique to the device and cannot be

changed. The Ethernet board’s MAC address can be found on the sticker attached to the board or by using various

network configuration tools.

In a local network, IP addresses can be defined by a user as long as all units connected to the network are given the

same network portion of the address. For more information about IP addresses, contact your Network

Administrator. Overlapping IP addresses cause conflicts between devices.

The X5EIP01 also provides the option of controlling the X5 AC drive from 115 VAC control signals, or of connecting a

shaft-mounted encoder to the drive to improve speed regulation. Up to five channels of 115 VAC control are available

for use in selecting direction, preset speeds, or other drive functions.

With this option, an encoder with a nominal rating of up to 2048 pulses per revolution can be connected to the X5

unit to improve speed load regulation of the drive. Overall encoder frequency at maximum process speed must be

limited to 100kHz.

This option also provides two additional control relays, each rated for 115 VAC, 1 amp, or for 230 VAC, 0.5 amp.

NOTE: This network communication interface included with the X5 option is warranted

to meet the core specifications for Modbus TCP. Many existing software applications are

custom-engineered and may contain “brand-specific” communication that will not be

supported by the X5 without modification. No guarantee of compatibility with any

specific system is made. The user is responsible for any interface software and

hardware needed to make an application function.

Applicable Documents

This manual is supplied as a supplement to the X5 AC Drive User’s Manual (DPD 00089, previously Form 1434).

Option Kit Contents

The option kit includes the following materials:

Part Number Description

25100067C Ethernet IP Option Board

32100391 Flexible cable assembly

Installation Procedures

SENSITIVE EQUIPMENT

This assembly contains static-sensitive components. It should be handled only by a static-safe installer,

using a grounded wrist strap.

Failure to observe this precaution may cause premature equipment failure.

Email: usa@vacon.com • Fax 717-264-3115

!

WARNING

Page 4

4 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

!

DANGER

HAZARDOUS VOLTAGE

• Disconnect all power before servicing a drive unit or its components. WAIT 5 MINUTES until the DC

bus capacitors discharge.

• Ensure that any other power sources that may feed control logic have been disconnected.

• DO NOT short across DC bus capacitors or touch unshielded components or terminal strip screw

connections with voltage present.

• Install all covers before applying power or starting and stopping the drive.

• The user is responsible for conforming to all applicable code requirements with respect to grounding

all equipment.

• Many parts in a drive, including printed circuit boards, operate at line voltage. DO NOT TOUCH. Use

only electrically-insulated tools.

Before servicing any drive.

• Disconnect all power.

• Place a “DO NOT TURN ON” label on the drive disconnect.

• Lock the disconnect in the open position.

Failure to observe these precautions will cause shock or burn, resulting in severe personal injury

or death.

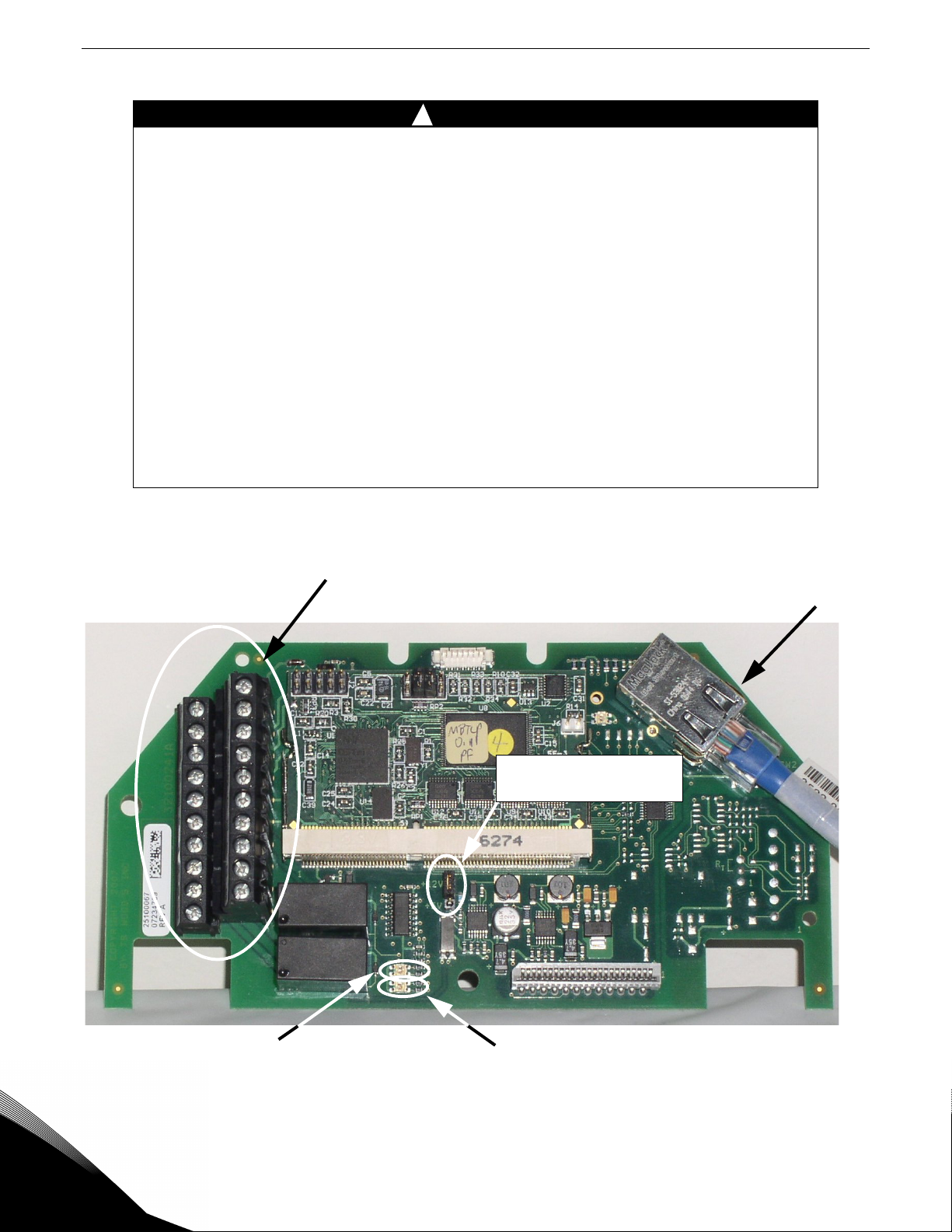

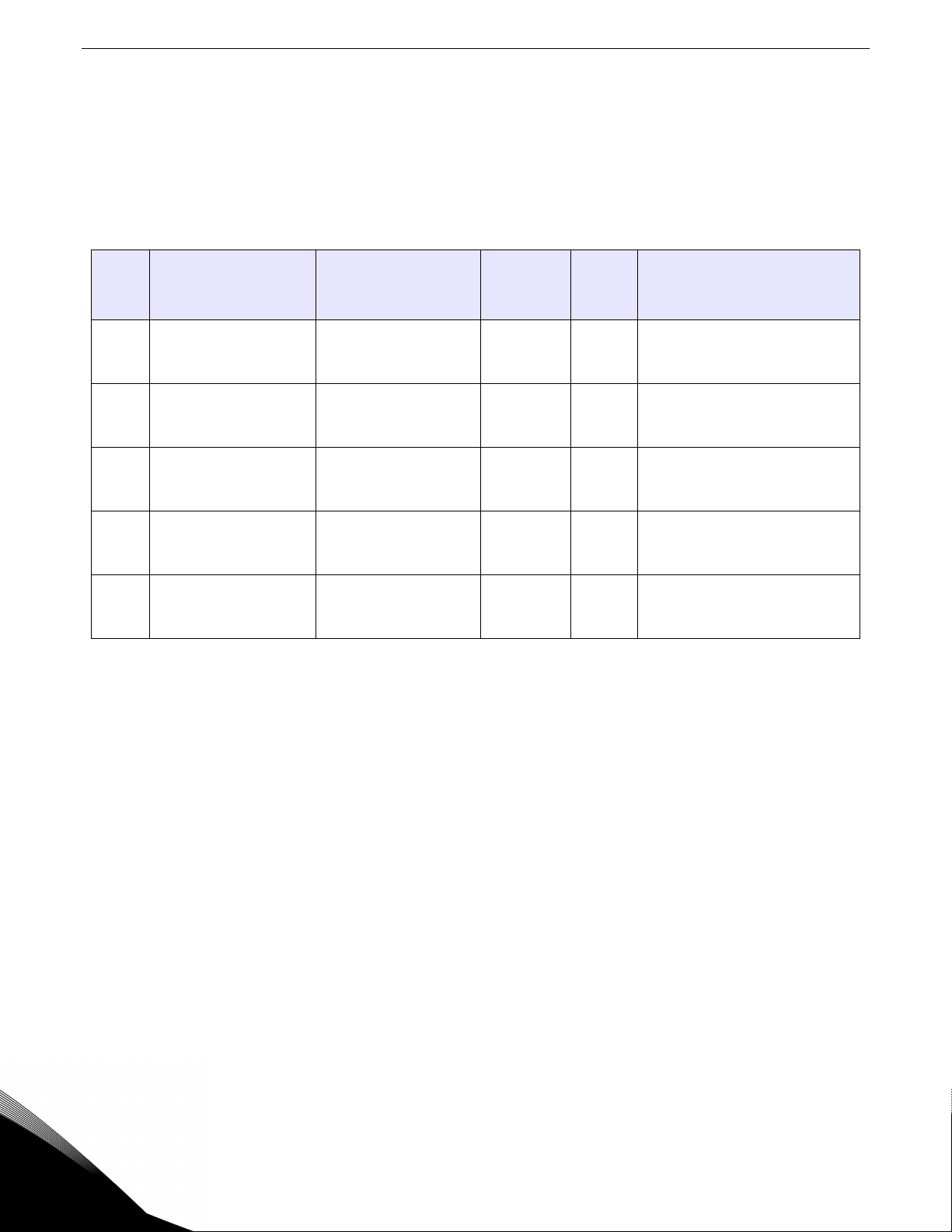

Figure 1 shows the option board and the location of the terminals and the power supply selector.

Encoder / 115 VAC Interface

Control Relay Terminals

Encoder Interface Power

Supply Selector

Ethernet Connector

Module Status LED

Figure 1: Option Board Layout

24-hour support 1-877-822-6606

Network Status LED

Page 5

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 5

Before you can install the option board, you must first remove the drive cover.

Figure 2 shows the locations of the cover screws. The torque range for the X5 Size 1 cover is 18-26 in/lbs.

Cover screw locations

Figure 2: Cover Assembly and Screw Locations

Cover screw locations

The option board is installed just above the control board in all configurations (a Size 1 unit is shown in Figure 3 for

reference). The screws labeled “A” must be removed from the X5; those labeled “B” need only to be loosened to

accept the board slot.

.

B

A

B

A

Figure 3: Option Mounting Locations

Once the board is in place, tighten the screws to a maximum of 26 in-lbs.

Email: usa@vacon.com • Fax 717-264-3115

Page 6

6 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Next, install the flexible circuit to finish the interface to the control board. (Refer to Figure 4.) To install the flexible

circuit, first remove the keypad frame (necessary in this size unit). The frame is attached with two screws in opposite

corners; the screws thread into fasteners in the plastic assembly. After the flexible circuit is installed, replace these

screws, limiting the installation torque to 12 in-lbs..

Figure 4: Flexible Circuit Interface to Control Board

115 VAC Interface / Relay / Encoder Interface Terminals

Figure 5: 115 VAC Interface / Encoder Terminals

The X5OPT01 option kit includes five 115 VAC inputs, two additional programmable relays, and an encoder interface.

The details of the terminals on the board related to the 115 VAC interface and the encoder are shown in Table 1 on

page 7:

24-hour support 1-877-822-6606

Page 7

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 7

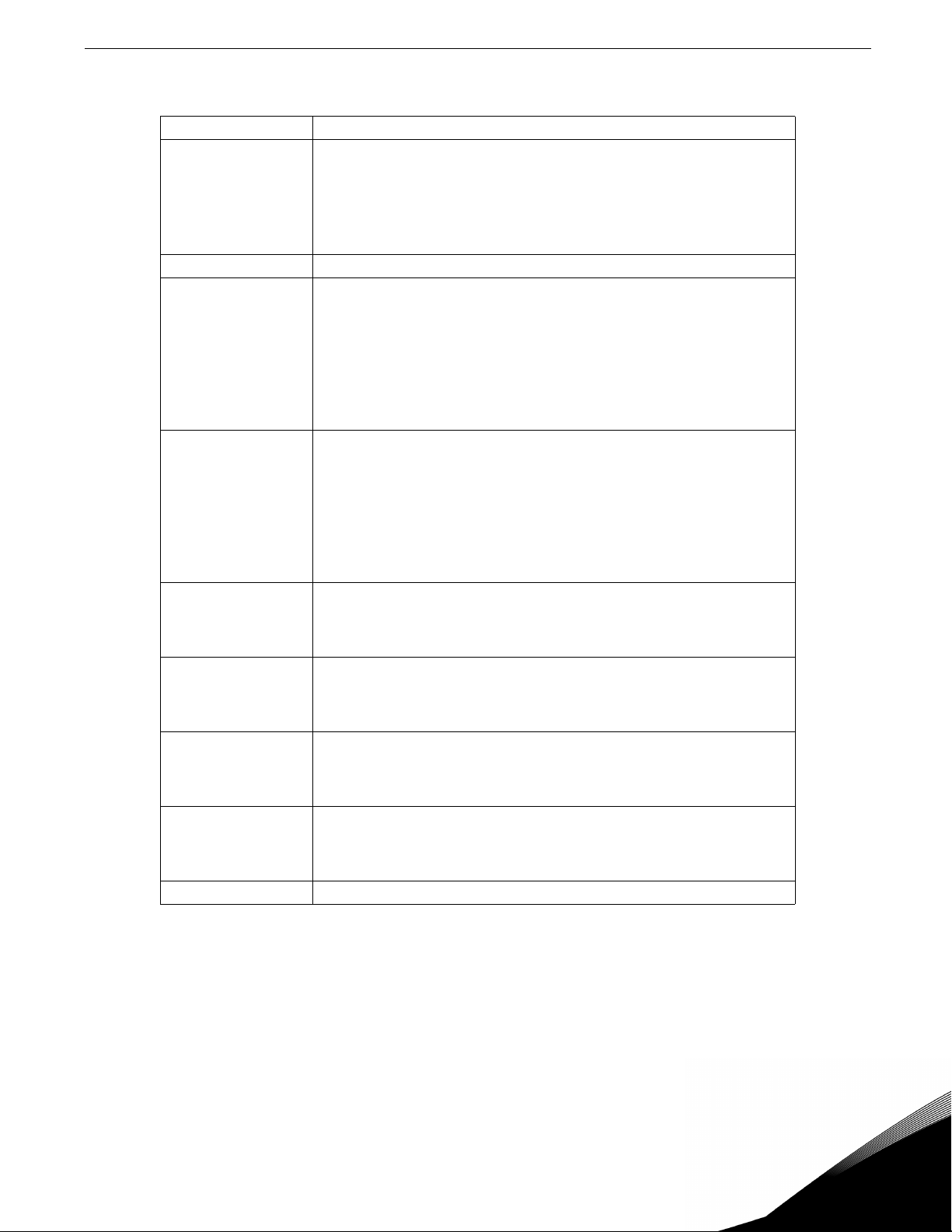

Table 1: Encoder Interface Terminals

Terminal Description

DI-A

DI-B

DI-C

DI-D

DI-E

ACn The neutral connection for the 115 VAC control inputs

NO3

RC3

NC3

NO4

RC4

NC4

A+

A-

B+

B-

C+

C-

VDC

Ecom Signal common for the encoder interface

115 VAC logic input; connect input to 115 VAC to activate.

The programmable functionality of these inputs is controlled by

parameters 728, 729, 730, 731, and 732. Each of these inputs can be

disabled or configured to emulate the function of the FWD, REV, R/J, EN,

MOL, DI1, DI2, DI3, DI4, or DI5 input terminals on the X5 control board.

Refer to the X5 User’s Manual for more information (DPD 00089).

The third auxiliary relay.

The function of this relay is set by parameter 709. Functionally, it is

capable of each of the features outlined in the X5 user manual under

parameters 705-708.

Terminal NO3 is a normally-open contact; it closes when the relay

activates. NC3 is a normally-closed contact; it opens when the relay

activates. RC3 is the common terminal associated with both contacts.

The ratings of these contacts are 115 VAC, 1 amp; and 230 VAC, 0.5 amp.

The fourth auxiliary relay.

The function of this relay is set by parameter 710. Functionally, it is

capable of each of the features outlined in the X5 user manual under

parameters 705-708.

Terminal NO4 is a normally-open contact; it closes when the relay

activates. NC4 is a normally-closed contact; it opens when the relay

activates. RC4 is the common terminal associated with both contacts.

The ratings of these contacts are 115 VAC, 1 amp; and 230 VAC, 0.5 amp.

Channel A input from the encoder. Compatible with line driver, open

collector, or totem pole outputs from an encoder. If it is an open collector

or totem pole-type, encoder outputs are used; connect the A- terminal to

Ecom.

Channel B input from the encoder. Compatible with line driver, open

collector, or totem pole outputs from an encoder. If it is an open collector

or totem pole-type, encoder outputs are used; connect the B- terminal to

Ecom.

Channel C input from the encoder, the home pulse. Compatible with line

driver, open collector, or totem pole outputs from an encoder. If it is an

open collector or totem pole-type, encoder outputs are used; connect the

C- terminal to Ecom.

Power supply terminal for use with a customer-supplied encoder. It can

be either +12 VDC or +5 VDC based on the position of the encoder interface

power supply selector shown in Figure 1. Voltage regulation: +/- 5%;

maximum current available is 100 mA.

Note that the connections described in Table 1 work only when the encoder has an internal pull-up resistor on the

open collector. Alternatively, it might be preferable to pull the + channel high, and attach the open collector to the channel. For example, if using Channel A, A+ on the option board would be tied to VDC, and A- would be connected

to the open collector coming from the encoder. The advantage in this method is that no pull-up/down resistors are

needed; if the encoder has an internal pull-up, this does not affect anything.

Email: usa@vacon.com • Fax 717-264-3115

Page 8

8 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Specifications for Encoder / 115 VAC Interface

Encoder Interface 115 VAC Interface

Speed regulation < 0.1 Hz (1) On state 90-140 VAC

Input frequency (max.) 100 kHz Off state < 10 VAC

Input voltage 10-24 VDC +/- 5% Input frequency 58-62 Hz

Suggested pull-up

resistor

Terminal block wire

limitations

(1) PID feedback plus optimal motor turning in SLV mode employed

5 VDC 500 ohms

24 VDC 3.3k ohms

12-24 AWG

On/off delay 30 ms maximum12 VDC 1k ohms

Terminal block wire

limitations

12-24 AWG

Setup and Use

The encoder interface is most effective if used in conjunction with the vector mode of operation. Refer to the X5

User’s Manual (Chapter 6) for information about using the vector mode. Three additional parameters are provided

to calibrate the encoder:

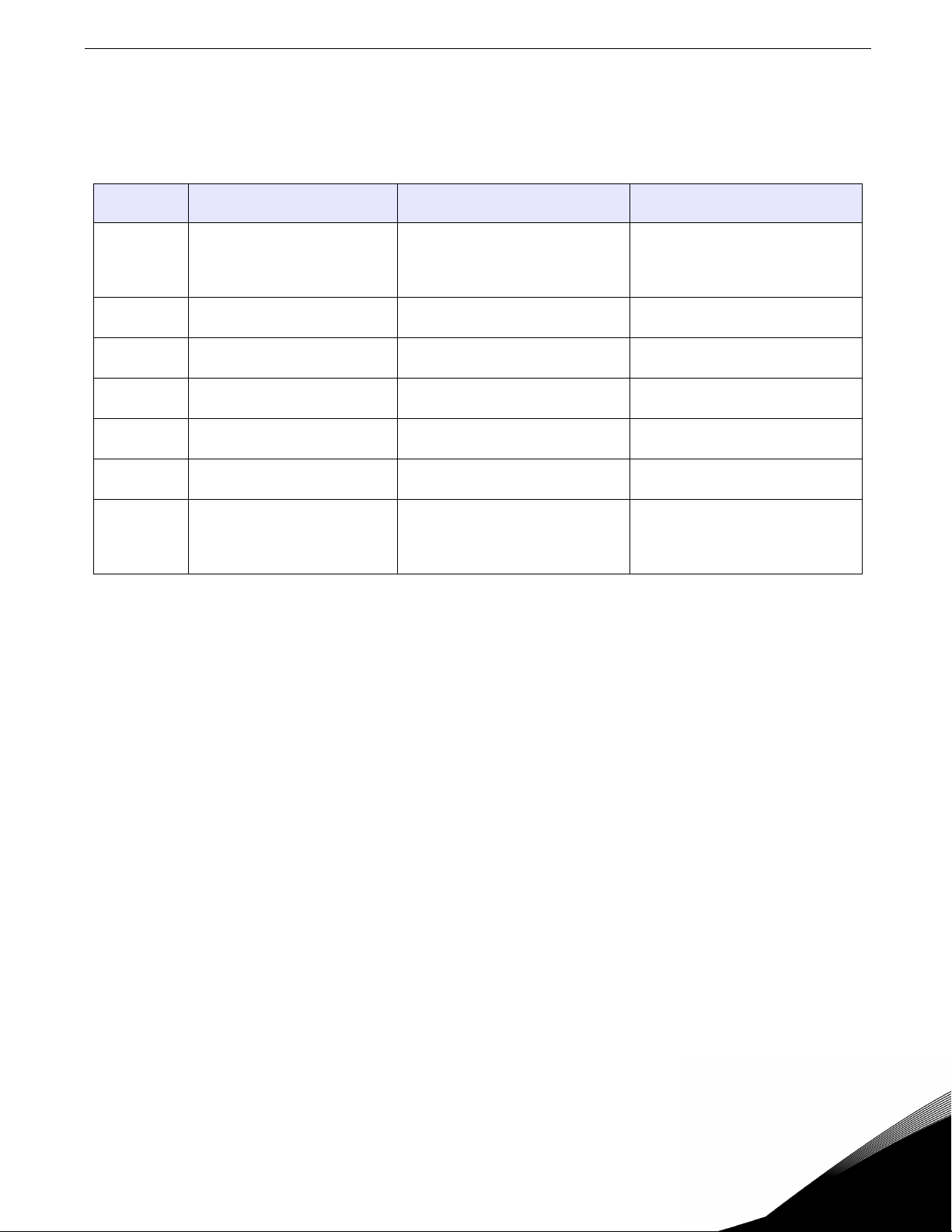

Parameter # Parameter Name Range Default Value

219 Encoder Pulses per Revolution 0-16383 1024

220 Encoder Filter Time 10-1000 ms 20 ms

221 Encoder Speed Protection 0-20.0% 0%

Parameter 219, Encoder Pulses per Revolution, can either be extracted from the encoder nameplate or the data

sheet supplied with it. Parameter 220, Encoder Filter Time, is used to filter the encoder signal in the event of noise.

Parameter 221 is for limiting the response of the drive, in the event of the loss of encoder signal.

Two other parameters are provided to allow more flexibility in encoder selection, and to improve PID application

usage:

Parameter # Parameter Name Range Default Value

Quadrature

223 EncoderType

224 Encoder Range 0-24000 rpm 0 rpm

or Single

Channel

Quadrature

Parameter 223, Encoder Type, allows the use of either quadrature or single-channel types of encoders.

Parameter 224, Encoder Range, improves PID application flexibility. This parameter should be used in situations

where the encoder feedback signal is not always directly proportional to the motor speed, for example, a winder

using an encoder mounted on an idler pulley feeding a winding spool. The PID may be attempting to maintain a

constant linear speed on the wound media, but as the diameter of the media on the spool changes, the motor turning

the spool needs to vary its speed to maintain the linear speed at the idler pulley.

When parameter 224 is set to 0, it is ignored, and the PID calculates the feedback percentage based on parameter

301, Maximum Frequency. When this parameter is set to a non-zero value, the PID uses instead Parameter 224’s

setting to calculate the feedback percentage.

Encoder feedback works similarly to an analog input as configured in parameters 850 (PID Configure), 851 (PID

Feedback), 852 (PID Prop Gain), 853 (PID Int Gain), and 859 (PID Derivative Gain). The “feed forward” options are

suggested for setting parameter 850. More specific details on each of the listed parameters can be found in the X5

User’s Manual (DPD 00089).

24-hour support 1-877-822-6606

Page 9

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 9

The encoder interface can easily serve as one of the inputs to the X5’s Keeper Function (data logging). See the X5

User’s Manual for more information.

Both the Vmet and Imet output from the drive can be configured to indicate the status of the encoder. Parameters

700 (Vmet) and 702 (Imet) that relate to the setup and calibration of the Vmet and Imet outputs, both have selections

related to the status of the encoder input.

The Program Sequencer function can also key off the encoder’s home pulse. To make use of this function, the

encoder’s home pulse (1 pulse per revolution) must be connected to the C- input of the encoder board.

Encoder Interface Troubleshooting

Any problem with the encoder interface will result in an F37 fault. Four advanced fault codes are available to help

you determine whether you have an encoder calibration problem, or a defect. For more information on

troubleshooting, refer to the Troubleshooting chapter in the X5 User’s Manual.

Using Ethernet Connections

Following are the specifications for Modbus / TCP connections:

Table 2: Ethernet Connection Specifications

Connections Interface RJ-45 Connector

Transfer cable Foiled CAT5e

Communications

Speed 10 / 100 Mb

Duplex half/full

Default IP address 0.0.0.0

To communicate with the drive over Ethernet, the drive’s IP address must be set. This is done with parameters 922-

925. After setting the IP address, be sure to cycle power off and back on for the new address to take effect.

LED Indications

The Ethernet / IP Option Board includes two LED status indicators: Network Status and Module Status. See Figure

1 on page 4 for the location of these LEDs on the board. Network status provides information on the network

connection status and Module status provides information on the Ethernet / IP module itself. The following tables

explain the meaning of the status LEDs:

Table 3: Network Status LED

Network Status

LED

Module Status

LED

If the LED is... This means...

OFF There is no power applied to the option board.

Red The option board cannot communicate on the network.

Table 4: Module Status LED

If the LED is... This means...

OFF There is no power applied to the option board.

Green The option board is operating normally.

The option board is in Standby state or the device needs

Green (flashing)

Red (flashing) The option board has detected a recoverable fault.

Red The option board has detected an unrecoverable fault.

commissioning because of a missing, incomplete, or incorrect

configuration.

Email: usa@vacon.com • Fax 717-264-3115

Page 10

10 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Getting Started

To begin communicating with the drive over Modbus / TCP, the drive’s IP address must be set (use parameters 922-

925). After setting the IP address, cycle power off and on for the new address to take effect.

For information on setting parameters, see the X5 User’s Manual.

I/O Messaging

Input / Output (I/O) polling messages are for time-critical, control-oriented data. The messages are transferred

between the devices all the time and are used for continuous control of the frequency converter. They provide a

dedicated, special-purpose communication path between a producing application (master) and one or more

consuming applications (slaves). They are exchanged across single- or multi-cast connections and typically use

high-priority identifiers.

The polling message flow is shown in Figure 6.

Data (Output Assembly)

Master

Data (Input Assembly)

Figure 6: Polling Message Diagram

Slave

X5

I/O messages 20, 21, 70, and 71 are standard Common Industrial Protocol (CIP) assemblies.

I/O messages 121, 122, 131, 132, 171, 172, 181, and 182 are vendor-specific messages that allow for customized

assemblies.

The values of the following parameters indicate which drive parameters are read or written to by the I/O assembly:

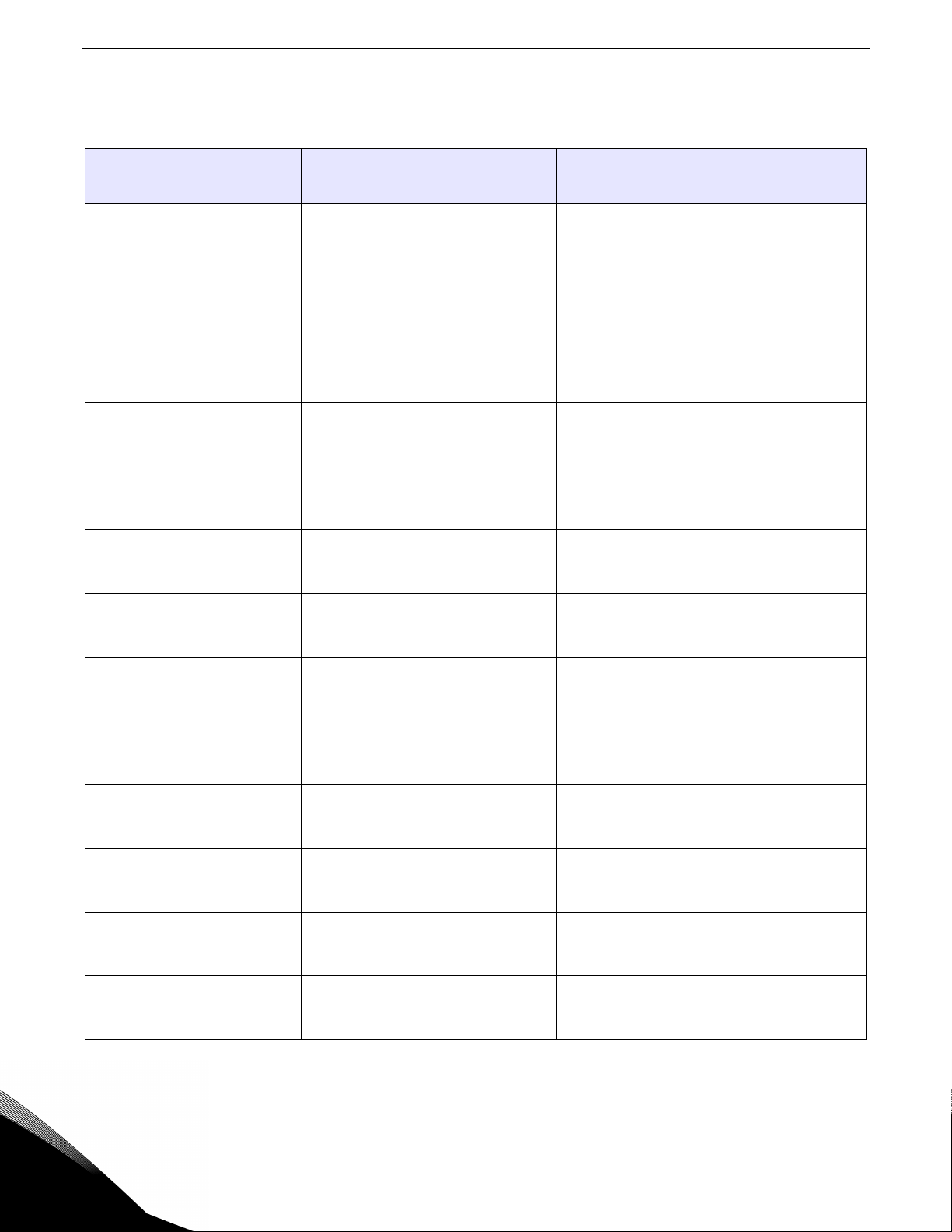

Table 5: Parameter Assignments (Parameters 880-894)

Parameter # Parameter Name Range Default

880 FBus Read 1

881 FBus Read 2 104 (Output Current)

882 FBus Read 3 105 (Drive Load)

883 FBus Read 4 107 (Drive Temp)

884 FBus Read 5 909 (DI Status)

890 FBus Write 1

891 FBus Write 2 104 (Output Current)

892 FBus Write 3 105 (Drive Load)

893 FBus Write 4 107 (Drive Temp)

894 FBus Write 5 909 (DI Status)

0-65535

0-65535

103 (Output Voltage)

103 (Output Voltage)

Examples 1 and 2 on the following pages show how using the FBus Write 2 = Parameter 402 would allow the I/O

assembly to set the drive’s acceleration rate.

24-hour support 1-877-822-6606

Page 11

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 11

Example 1: Output Assemblies

Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

20

21

121

122

131

132

0

1

2 Speed Reference (low byte)

3 Speed Reference (high byte)

0

1

2 Speed Reference (low byte)

3 Speed Reference (high byte)

0

1

2 Speed Reference (low byte)

3 Speed Reference (high byte)

4 FBus Write1 (low byte)

5 FBus Write1 (high byte)

6 FBus Write2 (low byte)

7 FBus Write2 (high byte)

0 FBus Write1 (low byte)

1 FBus Write1 (high byte)

2 FBus Write2 (low byte)

3 FBus Write2 (high byte)

0

1

2 Speed Reference (low byte)

3 Speed Reference (high byte)

4 FBus Write1 (low byte)

5 FBus Write1 (high byte)

6 FBus Write2 (low byte)

7 FBus Write2 (high byte)

8 FBus Write3 (low byte)

9 FBus Write3 (high byte)

10 FBus Write4 (low byte)

11 FBus Write4 (high byte)

12 FBus Write5 (low byte)

13 FBus Write5 (high byte)

0 FBus Write1 (low byte)

1 FBus Write1 (high byte)

2 FBus Write2 (low byte)

3 FBus Write2 (high byte)

4 FBus Write3 (low byte)

5 FBus Write3 (high byte)

6 FBus Write4 (low byte)

7 FBus Write4 (high byte)

8 FBus Write5 (low byte)

9 FBus Write5 (high byte)

NetRef NetCtrl Fault Reset Run Rev Run Fwd

NetRef NetCtrl Fault Reset Run Rev Run Fwd

NetRef NetCtrl Fault Reset Run Rev Run Fwd

Fault Reset Run Fwd

Email: usa@vacon.com • Fax 717-264-3115

Page 12

12 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Example 2: Input Assemblies

Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

70

71

171

172

181

182

0

1

2 Speed Actual (low byte)

3 Speed Actual (high byte)

0 At Ref Ref from Net Ctrl from Net Ready Running 2 (Rev) Running 1 (Fwd) Warning Faulted

1Drive State

2 Speed Actual (low byte)

3 Speed Actual (high byte)

0 At Ref Ref from Net Ctrl from Net Ready Running 2 (Rev) Running 1 (Fwd) Warning Faulted

1Drive State

2 Speed Actual (low byte)

3 Speed Actual (high byte)

4FBus Read1 (low byte)

5FBus Read1 (high byte)

6FBus Read2 (low byte)

7FBus Read2 (high byte)

0FBus Read1 (low byte)

1FBus Read1 (high byte)

2FBus Read2 (low byte)

3FBus Read2 (high byte)

0 At Ref Ref from Net Ctrl from Net Ready Running 2 (Rev) Running 1 (Fwd) Warning Faulted

1Drive State

2 Speed Actual (low byte)

3 Speed Actual (high byte)

4FBus Read1 (low byte)

5FBus Read1 (high byte)

6FBus Read2 (low byte)

7FBus Read2 (high byte)

8FBus Read3 (low byte)

9FBus Read3 (high byte)

10 FBus Read4 (low byte)

11 FBus Read4 (high byte)

12 FBus Read5 (low byte)

13 FBus Read5 (high byte)

0FBus Read1 (low byte)

1FBus Read1 (high byte)

2FBus Read2 (low byte)

3FBus Read2 (high byte)

4FBus Read3 (low byte)

5FBus Read3 (high byte)

6FBus Read4 (low byte)

7FBus Read4 (high byte)

8FBus Read5 (low byte)

9FBus Read5 (high byte)

Running 1 (Fwd) Faulted

24-hour support 1-877-822-6606

Page 13

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 13

Control Supervisor Behavior

The State Transition diagram in Figure 7 provides a graphical description of the states and corresponding state

transitions for the control supervisor.

Figure 7: Control Supervisor State Transition Diagram

Table 6 on page 14 explains the state transitions pictured in the flow diagram in Figure 7.

Start Forward, Start Reverse, Change to Forward, Change to Reverse, and Stop (Not Faulted Stop) are static outputs

of the control supervisor state machine. They are commands to the drive when CtrlFromNet = 1. When CtrlFromNet

= 0, control commands are from another source.

When performing changes to achieve programmed Safe State:

• Run / Stop / Direction can be changed because CtrlFromNet must equal 1 when in the Enabled state.

• Reference in the drive can be changed to Preset Speed only if RefFromNet = 1.

Email: usa@vacon.com • Fax 717-264-3115

Page 14

14 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Table 6: Explanation of State Transitions (Page 1 of 2)

Input Conditions Results

Old State

Run1 (Fwd)

CtrlFromNet

Idle Mode

Run 2 (Rev)

Rev Mode

Fwd Mode

Event New State Action

x x xxxxx Power_Off NonExist

x

x xxxxx Reset Startup

(except

NonExist)

Faulted = 0

Ready = 0

FwdMode = 0

RevMode = 0

Run1 Var = 0

Run2 Var = 0

Faulted = 0

Ready = 0

NonExist x xxxxx Power_On Startup

FwdMode = 0

RevMode = 0

Run1 Var = 0

Run2 Var = 0

Startup x xxxxx Drive Fault Faulted

Startup x xxxxx

Initialization

Complete

Ready Ready = 1

Faulted = 1

FaultCode = x

Faulted = 1

Ready x xxxxx Drive Fault Faulted

FaultCode = x

Ready = 0

Ready 1 1 0 0 x x Run (Fwd) Enabled

Ready 1 0 1 0 x x Run (Rev) Enabled

FwdMode = 1

(Start Forward)

RevMode = 1

(Start Reverse)

Faulted = 1

FaultCode = x

(Initiate Faulted

Enabled x xxxxx Drive Fault Fault_Stop

Stop)

FwdMode = 0

RevMode = 0

Ready = 0

Enabled 1 0 0 x x x Stop Stopping (Initiate Stop)

FwdMode = 1

Enabled 1 10001 ChangeDir (Fwd) Enabled

RevMode = 0

(Change to Forward)

FwdMode = 0

Enabled 1 01010 ChangeDir (Rev) Enabled

RevMode = 1

(Change to Reverse)

24-hour support 1-877-822-6606

Page 15

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 15

Table 6: Explanation of State Transitions (Page 2 of 2)

Input Conditions Results

Old State

Run1 (Fwd)

CtrlFromNet

Enabled 1 x x x x x SafeFault Fault_Stop

Enabled 1 x x x x x SafeChange Enabled

Stopping x x x x x x Drive Fault Fault_Stop

Stopping 1 1 0 0 x x Run (Fwd) Enabled

Stopping 1 0 1 0 x x Run (Rev) Enabled

Stopping x 0 0 x x x Stop_Complete Ready

Fault_Stopped x x x x x x Fault_Stop_ Complete Faulted

Faulted x x x x x x Fault_Reset Ready

Idle Mode

Run 2 (Rev)

Rev Mode

Fwd Mode

Event New State Action

Faulted = 1

FaultCode = x

(Initiate Faulted

Stop)

FwdMode = 0

RevMode = 0

Ready = 0

Run1 Var = 0

Run2 Var = 0

FwdMode =

Run1 Var =

NOT PresetDir

RevMode = 0

Run2 Var =

PresetDir

SpeedRef =

Preset Speed

TorqueRef =

Preset Torque

Faulted = 1

FaultCode = x

(Initiate Faulted

Stop)

Ready = 0

FwdMode = 1

(Start Forward)

RevMode = 1

(Start Reverse)

Faulted = 0

Ready = 1

Explicit Messaging

Explicit Messaging is used in commissioning and configuring the Ethernet / IP board. Explicit messages provide

multipurpose, point-to-point communication paths between two devices. They provide the typical request /

response-oriented network communication used to perform node configuration and problem diagnosis. Explicit

messages typically use low-priority identifiers and contain the specific meaning of the message right in the data

field. This includes the service to be performed and the specific object attribute address.

Email: usa@vacon.com • Fax 717-264-3115

Page 16

16 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

List of Object Classes

The Communication Interface supports the following object classes:

Table 7: Object Classes

Class Object

0x28 Motor Data

0x29 Control Supervisor

0x2A AC/DC Drive

0x2B Acknowledge Handler

0x65 Parameter

List of Data Types

The attribute list in Table 8 includes information on the data type of each attribute. See Table 10 on page 18 through

Table 13 on page 21 for more detailed explanations of the Data, Structure, and Array Type codes used in the Data

Type column.

Table 8: Data Types

Data Type Name Data Type Code Data Type Description

WORD 1 16-bit word

UINT 2 16-bit unsigned integer

INT 3 16-bitsigned integer

BOOL 4Boolean

SINT 5Short integer

DINT 6Double integer

LINT 7Long integer

USINT 8 Unsigned short integer

UDINT 9 Unsigned double integer

ULINT 10 Unsigned long integer

REAL 11 Single floating-point format (IEEE 754)

LREAL 12 Double floating-point format (IEEE 754)

ITIME 13 Duration (short)

TIME 14 Duration

FTIME 15 Duration (high resolution)

LTIME 16 Duration (long)

DATE 17 Date (see Ethernet/IP spec)

TIME_OF_DAY 18 Time of day

DATE_AND_TIME 19 Date and time

STRING 20 8-bit-per-character string

STRING2 21 16-bit-per-character string

STRINGN 22 N-bytes-per-character string

SHORT_STRING 23 Short N-byte character string

BYTE 24 8-bit string

DWORD 25 32-bit string

LWORD 26 64-bit string

24-hour support 1-877-822-6606

Page 17

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 17

Ethernet Troubleshooting

Following are the advanced fault codes for the drive fault (F38) related to the option board. For more information,

see the X5 User’s Manual (Chapter 8). The option board status LEDs are described on page 9 of this manual.

Table 9: Advanced Fault Codes

Advanced

Fault Code

1 Option board loss

2 Unstable ID during power-up Option board hardware issues

3 Option board changed

4 Invalid ID Option board hardware issues

5

6 Option board software error Option board software issues

7 Option board removed

Wrong or no daughter card

installed

Fault Possible Cause Corrective Measures

Option board is disconnected or

damaged

Option board was changed during

last power-down

Option DIMM module issues

Option board was removed during

last power-down sequence

Check option board status LEDs,

ribbon cable connection, and

cycle power. Replace option

board if necessary.

Cycle power. If problem persists,

contact Vacon technical support.

If the change was intentional,

cycle power.

Cycle power. If problem persists,

contact Vacon technical support.

Cycle power. If problem persists,

contact Vacon technical support.

Cycle power. If problem persists,

contact Vacon technical support.

If the change was intentional,

cycle power. Otherwise, follow

corrective measures for fault

code 1.

Email: usa@vacon.com • Fax 717-264-3115

Page 18

18 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Appendix: X5 Communication Interface Object Profiles

In the following tables, attributes shown in bold face are stored in the non-volatile part of the drive and maintain

their values after a power loss. All other settable attributes will power up at their default values.

Table 10: Motor Data Object

(Class Code 0x28, Motor Data Class (40) - Instance Attributes (1)

Default,

# Attribute Name Services

6

0x06

7

0x07

9

0x09

12

0x0C

15

0x0F

RatedCurrent[100mA]

RatedVoltage[V]

RatedFrequency[Hz]

PoleCount Get_Attribute_Single

BaseSpeed[RPM]

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Minimum,

Maximum

(1)

360

0

65535

230

100

690

60

0

400

2

2

16

1760

1

24000

Data

Type

2

2

2

2 Number of poles in the motor

2

Rated Electrical Frequency

Description

Rated Stator Current

Units: [100mA]

Rated Base Voltage

Units: [V]

Units: [Hz}

Nominal speed at rated

frequency from nameplate

Units: [RPM]

(1) The default value shown in this column is model-dependent.

24-hour support 1-877-822-6606

Page 19

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 19

Table 11: Control Supervisor Object

(Class Code 0x29, Control Supervisor Class (41) - Instance Attributes (1)

# Attribute Name Services

3

0x03

4

0x04

5

0x05

6

0x06

7

0x07

8

0x08

9

0x09

10

0x0A

12

0x0C

13

0x0D

15

0x0F

Run1

Run2

NetCtrl

State Get_Attribute_Single

Running1 Get_Attribute_Single

Running2 Get_Attribute_Single

Ready Get_Attribute_Single

Faulted Get_Attribute_Single

FaultRst

FaultCode Get_Attribute_Single

CtrlFromNet Get_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Default,

Minimum,

Maximum

0

0

1

0

0

1

0

0

1

N/A

0

7

N/A

0

1

N/A

0

1

N/A

0

1

N/A

0

1

0

0

1

N/A

0

65535

N/A

0

1

Data

Type

Description

4 Run Forward Request

4 Run Reverse Request

4

Requests Run/Stop control to be

local or from network

State of Control Supervisor Instance:

1 = Startup

2 = Not_Ready

8

3 = Ready

4 = Enabled

5 = Stopping

6 = Fault_Stop

7 = Faulted

Running Forward Status:

4

0 = Other state

1 = Running Forward

Running Reverse Status:

4

0 = Other state

1 = Running Reverse

Ready to Accept a Run Event:

4

0 = Other state

1 = Ready to accept a Run event

Fault Occurred:

4

0 = No faults present

1 = Fault occurred (latched)

Fault Reset Request:

4

0 = No action

0 -> 1 = Fault reset request

1 = No action

If in faulted state, FaultCode

indicates the fault that caused the

2

transition to be in a faulted state. The

fault codes are listed in the Ethernet/

IP specifications

Status of Run / Stop control source:

4

0 = Control is local

1 = Control is from the network

Email: usa@vacon.com • Fax 717-264-3115

Page 20

20 vacon X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board

Table 12: AC/DC Drive Object

(Class Code 0x2A, AC/DC Drive Class (42) - Instance Attributes (1)

# Attribute Name Services

3

0x03

4

0x04

6

0x06

7

0x07

8

0x08

9

0x09

17

0x11

18

0x12

19

0x13

20

0x14

21

0x15

29

0x1D

AtReference Get_Attribute_Single

NetRef

Get_Attribute_Single

Set_Attribute_Single

DriveMode Get_Attribute_Single

SpeedActual(RPM) Get_Attribute_Single

SpeedRef[RPM}

Get_Attribute_Single

Set_Attribute_Single

CurrentActual[100mA) Get_Attribute_Single

OutputVoltage[V] Get_Attribute_Single

AccelTime[100ms]

DecelTime[100 ms]

LowSpdLimit[RPM]

HighSpdLimit[RPM]

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

Get_Attribute_Single

Set_Attribute_Single

RefFromNet Get_Attribute_Single

Default,

Minimum,

Maximum

N/A

0

1

0

0

1

1

1

1

N/A

0

10000

1800

0

12000

N/A

0

1000

N/A

0

690

30

1

32000

30

1

32000

0

0

12000

1800

0

12000

N/A

0

1

Data

Type

Description

4 1 = Drive actual at speed reference

Requests speed reference to be local

or from the network:

0 = Set Reference to local control

4

1 = Set Reference to DN control

Note that the actual status of torque

or speed reference is reflected in

attribute 29, RefFromNet.

8 1 = Open loop speed (Frequency)

Actual drive speed (best

3

approximation)

Units: RPM

3

3

3

Speed reference

Units: RPM

Actual motor phase current

Units: 100mA

Output Voltage

Units: Volts

Acceleration time

2

Time from 0 to HighSpdLimit

Units: 100ms

Deceleration time

2

Time from HighSpdLimit to 0

Units: 100ms

2

2

Minimum speed limit

Units: RPM

Maximum speed limit

Units: RPM

Status of speed reference:

4

0 = Local speed reference

1 = Ethernet / IP speed reference

24-hour support 1-877-822-6606

Page 21

X5EIP01 Ethernet IP with 115 VAC / Encoder Interface Option Board vacon 21

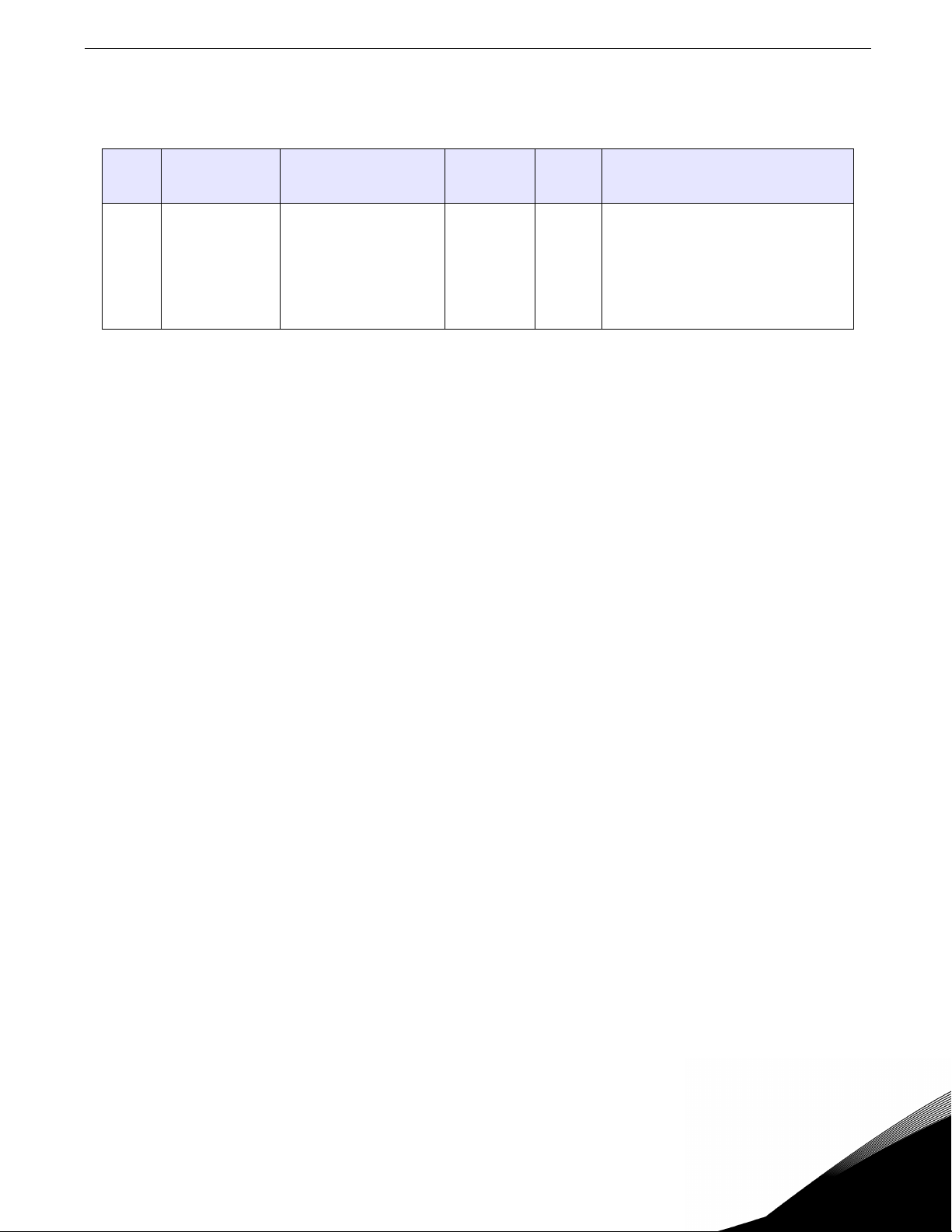

Table 13: Parameter Object

(Class Code 0x65, Parameter Class (101) - Class Attributes (1-999)

# Attribute Name Services

1

0x01

N/A

Get_Attribute_Single

Set_Attribute_Single

Default,

Minimum,

Maximum

N/A

N/A

N/A

Data

Type

2

Description

These instances give direct access to

all drive parameters where the

instance number corresponds to the

parameter number. See the X5

User’s Manual (Ch. 7) for more

information on specific drive

parameters.

Email: usa@vacon.com • Fax 717-264-3115

Page 22

head office and production:

Vaasa

Vacon Plc

Runsorintie 7

65380 Vaasa

firstname.lastname@vacon.com

telephone: +358 (0)201 2121

fax: +358 (0)201 212 205

production:

Suzhou, China

Vacon Suzhou Drives Co. Ltd.

Building 11A

428# Xinglong Street, SIP

Suchun Industrial Square

Suzhou 215126

telephone: + 86 512 62836630

fax: + 86 512 62836618

Naturno, Italy

Vacon S.R.I

Via Zone Industriale, 11

39025 Naturno

sales companies and representative offices:

production:

Chambersburg, USA

3181 Black Gap Road

Chambersburg, PA 17202

TB Wood's (India) Pvt. Ltd.

#27, 'E' Electronics City

Hosur Road

Bangalore - 560 100

India

Tel. +91-80-30280123

Fax. +91-80-30280124

finland

Helsinki

Vacon Plc

Äyritie 8

01510 Vantaa

telephone: +358 (0)201 212 600

fax: +358 (0)201 212 699

Tampere

Vacon Plc

Vehnämyllynkatu 18

33580 Tampere

telephone: +358 (0)201 2121

fax: +358 (0)201 212 750

australia

Vacon Pacific Pty Ltd

5/66-74, Micro Circuit

Dandenong South, VIC 3175

telephone: +61 (0)3 9238 9300

fax: +61 (0)3 92389310

austria

Vacon AT Antriebssysteme GmbH

Aumühlweg 21

2544 Leobersdorf

telephone: +43 2256 651 66

fax: +43 2256 651 66 66

belgium

Vacon Benelux NV/SA

Interleuvenlaan 62

3001 Heverlee (Leuven)

telephone: +32 (0)16 394 825

fax: +32 (0)16 394 827

brazil

Vacon Brazil

Alameda Mamoré, 535

Alphaville - Barueri -SP

Tel. +55 11 4166-5707

Fax. +55 11 4166-5567

canada

Vacon Canada

221 Griffith Road

Stratford, Ontario N5A 6T3

telephone: +1 (519) 508-2323

fax: +1 (519) 508-2324

china

Vacon Suzhou Drives Co. Ltd.

Beijing Branch

A528, Grand Pacific Garden Mansion

8A Guanghua Road

Beijing 100026

telephone: + 86 10 51280006

fax: +86 10 65813733

czech republic

Vacon s.r.o.

Kodanska 1441/46

110 00 Prague 10

telephone: +420 234 063 250

fax: +420 234 063 251

france

Vacon France

ZAC du Fresne

1 Rue Jacquard - BP72

91280 Saint Pierre du Perray CDIS

telephone: +33 (0)1 69 89 60 30

fax: +33 (0)1 69 89 60 40

germany

Vacon GmbH

Gladbecker Strasse 425

45329 Essen

telephone: +49 (0)201 806 700

fax: +49 (0)201 806 7099

Vacon OEM Business Center GmbH

Industriestr. 13

51709 - Marienheide

Germany

Tel. +49 02264 17-17

Fax. +49 02264 17-126

india

Vacon Drives & Control Plc

Plot No 352

Kapaleeshwar Nagar

East Coast Road

Neelangarai

Chennai-600041

Tel. +91 44 244 900 24/25

italy

Vacon S.p.A.

Via F.lli Guerra, 35

42100 Reggio Emilia

telephone: +39 0522 276811

fax: +39 0522 276890

the netherlands

Vacon Benelux BV

Weide 40

4206 CJ Gorinchem

telephone: +31 (0)183 642 970

fax: +31 (0)183 642 971

norway

Vacon AS

Bentsrudveien 17

3080 Holmestrand

telephone: +47 330 96120

fax: +47 330 96130

romania

Vacon Romania - Reprezentanta

Cuza Voda 1

400107 Cluj Napoca

Tel. +40 364 118 981

Fax. +40 364 118 981

russia

ZAO Vacon Drives

Ul. Letchika Babushkina 1,

Stroenie 3

129344 Moscow

telephone: +7 (495) 363 19 85

fax: +7 (495) 363 19 86

ZAO Vacon Drives

2ya Sovetskaya 7, office 210A

191036 St. Petersburg

telephone: +7 (812) 332 1114

fax: +7 (812) 279 9053

slovakia

Vacon s.r.o. (Branch)

Seberiniho 1

821 03 Bratislava

Tel. +421 243 330 202

Fax. +421 243 634 389

spain

Vacon Drives Ibérica S.A.

Miquel Servet, 2. P.I. Bufalvent

08243 Manresa

telephone: +34 93 877 45 06

fax: +34 93 877 00 09

sweden

Vacon AB

Anderstorpsvägen 16

171 54 Solna

telephone: +46 (0)8 293 055

fax: +46 (0)8 290 755

thailand

Vacon South East Asia

335/32 5th-6th floor

Srinakarin Road, Prawet

Bangkok 10250

Tel. +66 (0)2366 0768

ukraine

Vacon Drives Ukraine (Branch)

42-44 Shovkovychna Str.

Regus City Horizon Tower

Kiev 01601, Ukraine

Tel. +380 44 459 0579

Fax +380 44 490 1200

united arab emirates

Vacon Middle East and Africa

Block A, Office 4A 226

P.O.Box 54763

Dubai Airport Free Zone

Dubai

Tel. +971 (0)4 204 5200

Fax: +971 (0)4 204 5203

united kingdom

Vacon Drives (UK) Ltd.

18, Maizefield

Hinckley Fields Industrial Estate

Hinckley

LE10 1YF Leicestershire

telephone: +44 (0)1455 611 515

fax: +44 (0)1455 611 517

united states

Vacon, Inc.

3181, Black Gap Road

Chambersburg, PA 17202

telephone: +1 (877) 822-6606

fax: +1 (717) 267-0140

Loading...

Loading...