Page 1

X5 AC Drive

user's manual

Page 2

Need Help?

This manual answers most installation and startup questions

that may arise. However, if you have any problems,

please let your first call be to us.

Vacon, Inc.

Chambersburg, PA 17202

Normal business hours:

(North America)

8:00 AM to 5:00 PM, Eastern time

+1 877-Vacon06

(+1 877-822-6606)

After-hours support is also available

and Vacon, Inc. are trademarks of Vacon Plc, a member of Vacon Group.

All other product names are trademarks of their respective companies.

Copyright 2009, Vacon, Incorporated. All rights reserved.

Page 3

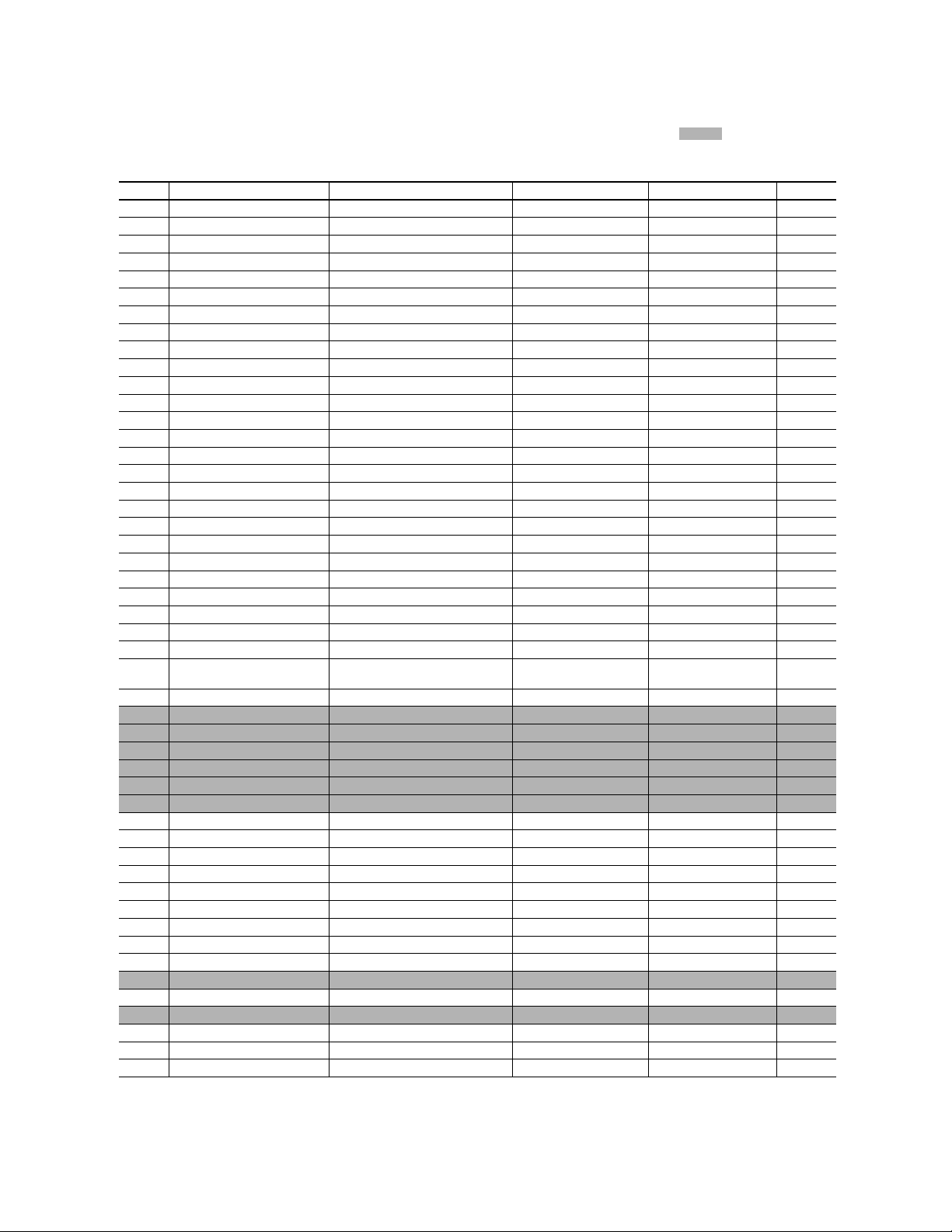

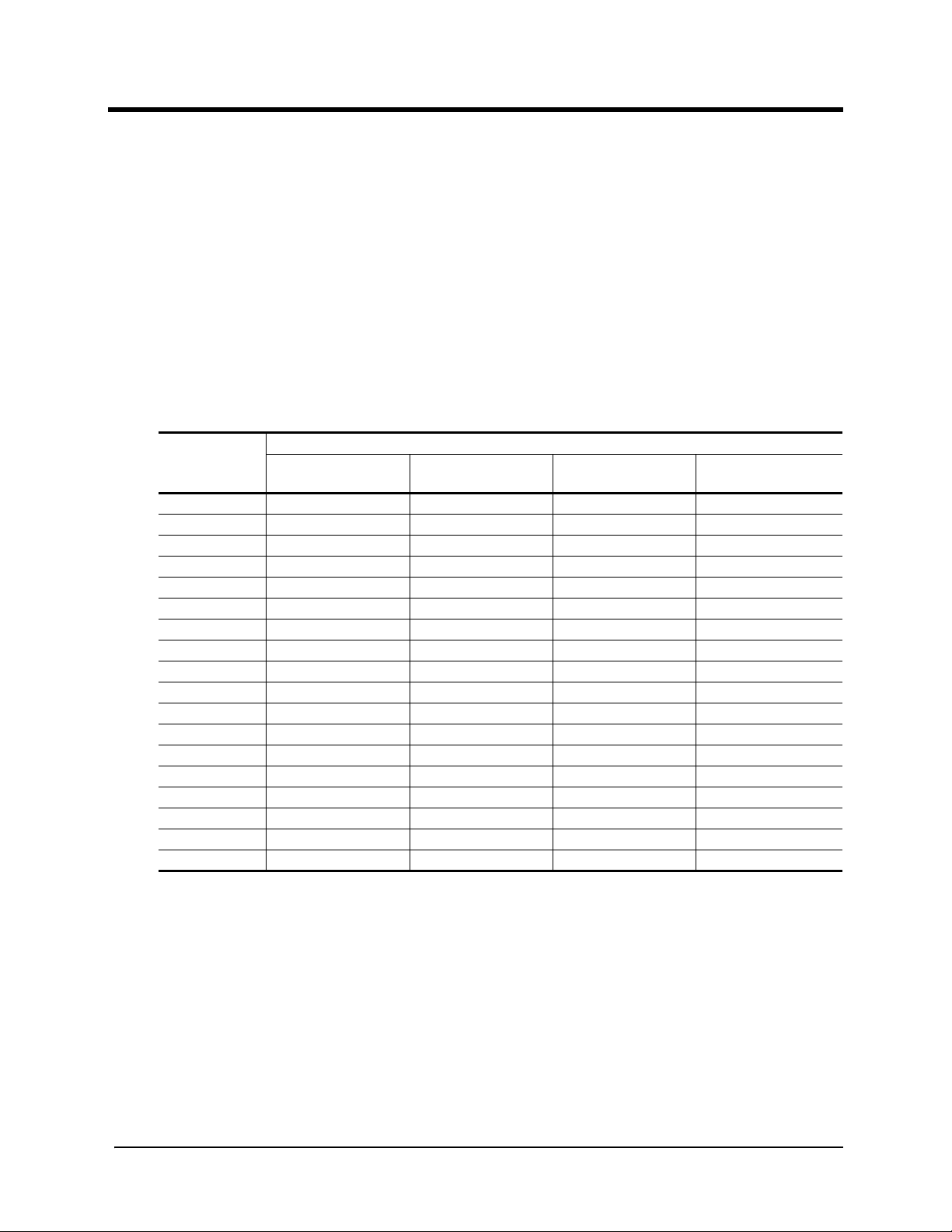

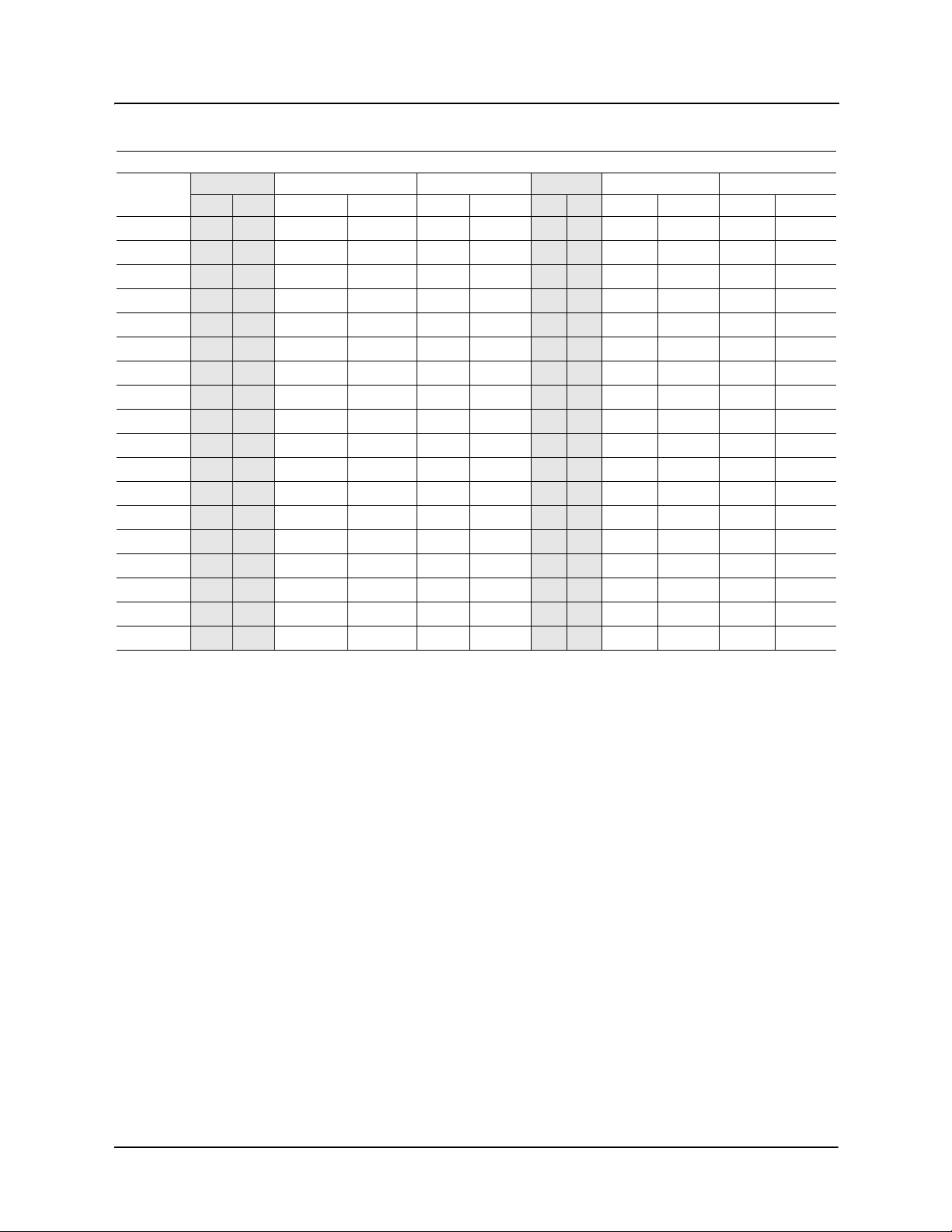

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type = Level 1 parameter

= cannot change in Run

Summary of X5 Parameters

No. Parameter Name Options Default User Setting See Page

001 Model Number Model dependent Read-only 71

002 Software Rev 0.00-99.99 Read-only 71

003 Rated Current 0.0-200.0 A Read-only 71

005 Serial No. 1 0-65535 Read-only 71

006 Serial No. 2 0-65535 Read-only 71

007 USB Soft. Rev 0.00 - 99.99 Read-only 71

008 Option Installed text string Read-only 71

009 Fbus Soft. Rev 0.00 - 99.99 Read-only 71

030 Pwr Down Date dd/mm/yy Read-only 71

031 Pwr Down Time Dd/hh/mm (Dd = Tu, Th, etc.) Read-only 72

102 Output Freq 0.0-400.0 Hz Read-only 72

103 Output Voltage 0-600 V Read-only 72

104 Output Current 0.0-200.0 A Read-only 72

105 Drive Load -200.0-200.0% Read-only 72

106 Load Torque -200.0-200.0% Read-only 72

107 Drive Temp -20.0-200.0 °C Read-only 72

108 Total Run Time 0.0-6553.5 h Read-only 72

109 Power On Hours 0-65535 h Read-only 72

110 Stator Freq 0.0-400.0 Hz Read-only 72

111 DC Bus Voltage 0 - 1000 Vdc Read-only 72

115 Drive Power Out 0.0-200.0% Read-only 72

116 Out Power (kW) 0.0 - 327.67 Read-only 72

117 MWh Meter 0 - 32767 Read-only 72

118 kWh Meter 0.0 - 999.9 Read-only 72

120 Today’s Date MM/dd/YY Read-only 73

121 Today’s Time hh:mm Read-only 73

Show Clock Parameters

150

(Parameters 151-179)

151 Tiime Zone Setup text string 12 (-5 East. US) 73

152 TOD Run Enable 0-23 hours, 0-59 min 12:00 73

154 TOD Run Disable 0-23 hours, 0-59 min 12:00 73

156 TOD Run En 2 0-23 hours, 0-59 min 12:00 73

158 TOD Run Dis 2 0-23 hours, 0-59 min 12:00 74

160 Weekend TOD En 0-23 hours, 0-59 min 12:00 74

162 Weekend TOD Dis 0-23 hours, 0-59 min 12:00 74

171 Reminder 1 Conf. text string 0 (disabled) 74

172 Reminder 1 Time 1-32000 hours 1 74

173 Reminder 1 ETA +/- 32000 hours Read-only 74

174 Reminder 2 Conf. text string 0 (disabled) 74

175 Reminder 2 Time 1-32000 hours 1 74

176 Reminder 2 ETA +/- 32000 hours Read-only 74

177 Reminder 3 Conf. text string 0 (disabled) 75

178 Reminder 3 Time 1-32000 hours 1 75

179 Reminder 3 ETA +/- 32000 hours Read-only 75

201 Input Mode text string Local Only 75

202 Rev Enable text string Forward 75

203 Stop Key Re mot e text string Coast 76

204 Ref Select text string Vin1 76

205 Vin1 Config text string 0-10V 77

206 Vin1 Offset 0.0% to 100.0% 0.00% 77

text string 0 (No) 73

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

DPD00089A - iii - © 2009 Vacon Incorporated All Rights Reserved

Page 4

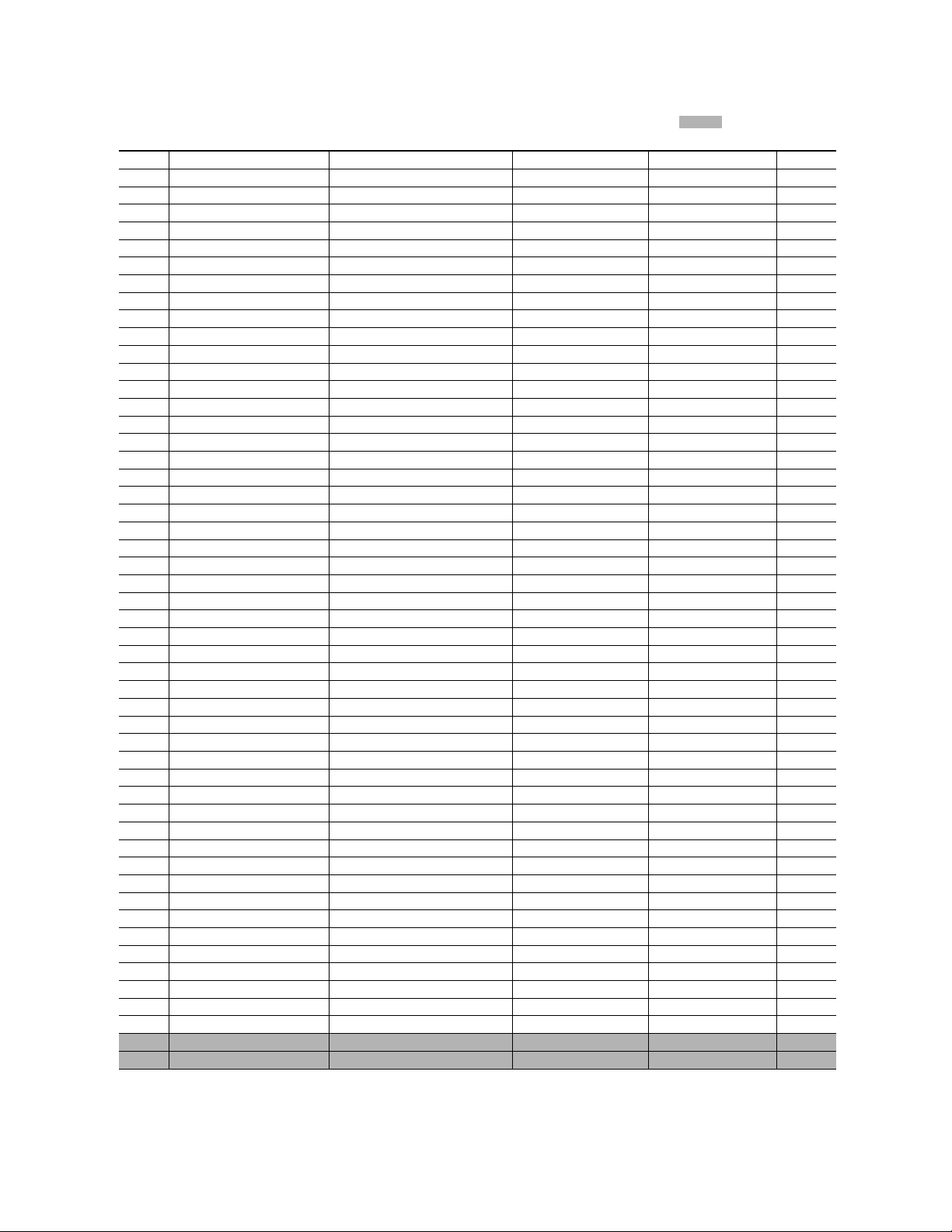

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type = Level 1 parameter

No. Parameter Name Options Default User Setting See Page

207 Vin1 Span 10.0% to 200.0% 100.00% 77

208 Cin Config text string 0-20mA 50 77

209 Cin Offset 0.0% to 100.0% 0.0% 77

210 Cin Span 10.0% to 200.0% 100.0% 78

211 Vin2 Config text string 0-10V 78

212 Vin2 Offset 0.0% to 100.0 % 0.00% 78

213 Vin2 Span 10.0% to 200.0% 100.00% 78

214 Vin1 Filter Time 0 to 1000 ms 20 ms 78

215 Cin Filter Time 0 to 1000 ms 20 ms 78

216 Vin2 Filter Time 0 to 1000 ms 20 ms 78

217 Trim Ref Enable (Set k-Factor) text string 0 78

218 Trim % Factor -100.0 - 100.0% 0.0% 79

222 Ref Loss Config text string No Fault 79

301 Min Frequency 0.0 - Max Freq. 0.0 Hz 79

302 Max Frequency 20.0 - 400.0 Hz 60.0 Hz 79

303 Preset Freq 1 Min Freq-Max Freq 5.0 Hz 79

304 Preset Freq 2 Min Freq-Max Freq 10.0 Hz 79

305 Preset Freq 3 Min Freq-Max Freq 20.0 Hz 79

306 Preset Freq 4 Min Freq-Max Freq 30.0 Hz 79

307 Preset Freq 5 Min Freq-Max Freq 40.0 Hz 79

308 Preset Freq 6 Min Freq-Max Freq 50.0 Hz 79

309 Cut-off Freq 0.0 - 5.0 Hz 0.0 Hz 79

310 Preset Freq 7 Min Freq-Max Freq 60.0 Hz 79

311 Preset Freq 8 Min Freq-Max Freq 0.0 Hz 79

312 Preset Freq 9 Min Freq-Max Freq 2.5 Hz 79

313 Preset Freq 10 Min Freq-Max Freq 7.5 Hz 79

314 Preset Freq 11 Min Freq-Max Freq 15.0 Hz 79

315 Preset Freq 12 Min Freq-Max Freq 25.0 Hz 79

316 Preset Freq 13 Min Freq-Max Freq 35.0 Hz 79

317 Preset Freq 14 Min Freq-Max Freq 45.0 Hz 79

318 Preset Freq 15 Min Freq-Max Freq 55.0 Hz 79

380 Keeper Input Cfg text string 4 (disabled) 79

381 Keeper Max Scale 0-32000 1000 80

382 Keeper Save Time 00:00 - 23:59 0:00 80

384 Keeper Save Rate text string 0 (24 hour) 80

385 Keeper Input Value 0-32000 Read-only 80

386 Keeper Time Rate text string 1 (minute) 80

387 Keeper Rec. Num 0-255 Read-only 80

388 Active Kpr. Record 0-255 Read-only 80

389 Keeper Units text string 1 (GPM) 81

401 Ramp Select text string ART-DI 81

402 Accel Time 1 0.1-3200.0 sec 5.0 sec 81

403 Decel Time 1 0.1-3200.0 sec 5.0 sec 81

404 Accel Time 2 0.1-3200.0 sec 3.0 sec 82

405 Decel Time 2 0.1-3200.0 sec 3.0 sec 82

406 DC Inject Config text string DC at Stop 82

407 DC Inject Time 0.0-5.0 sec 0.2 sec 82

408 DC Inject Level 0.0% to 100.0% 50.0% 82

409 DC Inj Freq 0.0 to 20.0 Hz 0.0 Hz 82

410 DB Config text string Internal 83

414 S Ramp Rounding 1 - 100% 25% 83

= cannot change in Run

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

DPD00089A - iv - © 2009 Vacon Incorporated All Rights Reserved

Page 5

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type =Level 1 parameter

No. Parameter Name Options Default User Setting See Page

415 Accel Time 3 0.1-3200.0 sec 10.0 sec 83

416 Decel Time 3 0.1-3200.0 sec 10.0 sec 83

417 Accel Time 4 0.1-3200.0 sec 15.0 sec 84

418 Decel Time 4 0.1-3200.0 sec 15.0 sec 84

490 App Macro text string Factory 84

491 Seq Appl text string Disabled 84

492 SIO Visible text string No 84

501 V/Hz Select text string Linear Fixed 85

502 Voltage Boost 0.0-50% 1.0% 85

503 V/Hz Knee Freq 25.0-400.0 Hz 60.0 Hz 85

504 Skip Freq Band 0.2-20.0 Hz 0.2 Hz 86

505 Skip Freq 1 Min Freq-Max Freq 0.0 Hz 86

506 Skip Freq 2 Min Freq-Max Freq 0.0 Hz 86

507 Skip Freq 3 Min Freq-Max Freq 0.0 Hz 86

508 Skip Freq 4 Min Freq-Max Freq 0.0 Hz 86

509 Rated Mtr Volt 100V-690V Model dependent 86

510 Rated Mtr FLA 50% - 200% of ND Rating ND Rating 86

511 Rated Mtr RPM 0-24000 rpm 1750 rpm 86

512 Midpoint Freq 0.0 Hz-V/Hz Knee Freq 60.0 Hz 86

513 Midpoint Volt 0.0-100.0% 100.0% 86

514 Motor RS 0.0-655.35 Ohms Model dependent 86

515 Power Factor 0.50-1.00 0.80 86

516 Slip Comp Enable text string No 87

517 Single Phase text string No 87

519 Find Mtr Data Not active / Motor RS Not active 87

520 Filter FStator 1 - 100 ms 8 ms 87

521 Start Field En text string No 87

522 Filter Time Slip 10 - 1000 ms 100 ms 88

523 Id Percent 0 - 200% Read-only 88

524 Iq Percent 0 - 200% Read-only 88

525 Power Fail Config text string CTS No Msg 88

526 UV Ride-Thru En text string w/ LVT 88

600 Current Lim Sel text string 0 89

601 Cur Lim Mtr Fwd 5%-150% 120% 89

602 Cur Lim Mtr Rev 5%-150% 120% 89

603 Cur Lim Reg Fwd 5%-150% 80% 89

604 Cur Lim Reg Rev 5%-150% 80% 89

605 Cur Lim Freq 0.0 - 400.0 Hz 3.0 Hz 89

606 Ramp Time CL 0.1-3200.0 sec 1.0 sec 89

607 Cur Limit Minimum 0 - 50% 10% 89

608 Restart Number text string 0 90

609 Restart Delay 0-60 sec 60 sec 90

610 Timed OL Select text string 0 (Std Ind 60s) 90

613 Max Regen Ramp 100 - 1000% 300% 91

614 Stability Gain 0 - 10 Model Dependent 91

615 Stability Rate 0 - 1000 Model Dependent 91

700 Vmet Config text string Freq Out 91

701 Vmet Span 0.0-200.0% 100.0% 91

702 Imet Config text string Drive Load 92

703 Imet Span 0.0-200.0% 100.0% 92

704 Imet Offset 0.0-90.0-% 0.0% 92

= cannot change in Run

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

DPD00089A - v - © 2009 Vacon Incorporated All Rights Reserved

Page 6

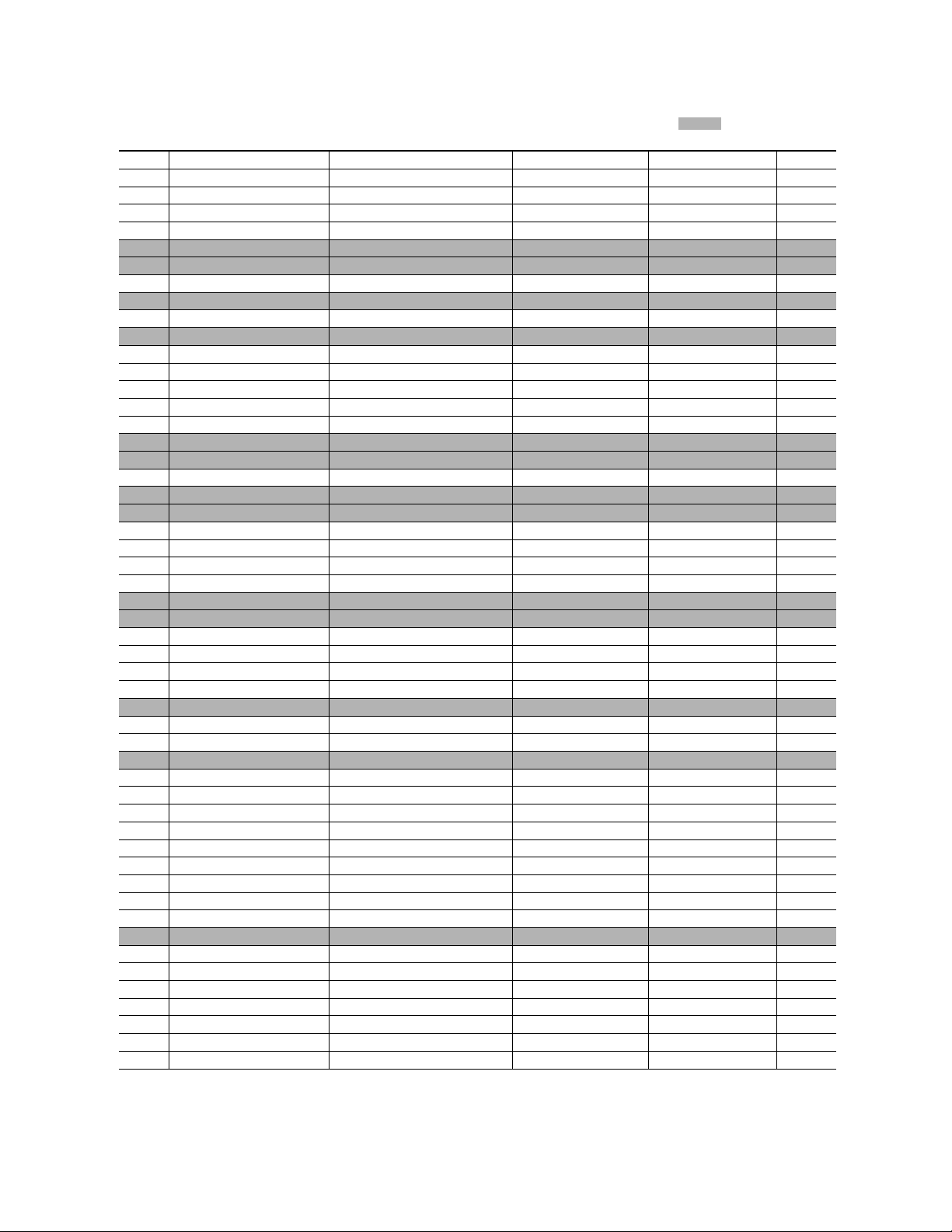

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type = Level 1 parameter

No. Parameter Name Options Default User Setting See Page

705 Relay 1 Select text string 1 (Drv Fault) 93

706 Relay 2 Select text string 2 (Drive Run) 93

707 DO1 Select text string 0 (Drv Ready) 93

708 DO2 Select text string 6 (At Speed) 93

719 Digital Input Filter Time 1-1000 msec 5 msec 94

720 Active Logic text string 1 (Active High) 94

721 DI1 Configure text string 0 (Preset 1) 95

722 DI2 Configure text string 1 (Preset 2) 95

723 DI3 Configure text string 2 (Preset 3) 95

724 DI4 Configure text string 6 (Alt Ramp) 95

725 DI5 Configure text string 7 (Fault Reset) 95

726 MOL Polarity text string 1 (NO Operate) 96

727 MOL Configure text string 21 (MOL) 95

740 Thres 1 Select text string 9 (Load High) 96

741 Thres 1 High -300.00 to 300.00% 100.00% 96

742 Thres 1 Low -300.00 to 300.00% 0.00% 96

743 Thres 2 Select text string 15 (Current High) 97

744 Thres 2 High -300.00 to 300.00% 100.00% 97

745 Thres 2 Low -300.00 to 300.00% 0.00% 97

746 Timer 1 Type text string 0 (On Delay) 97

747 Timer 1 Signal text string 1 (Drv Fault) 97

748 Timer 1 Time 0.0 - 320.0 sec 1.0 sec 97

749 Timer 2 Type text string 0 (On Delay) 97

750 Timer 2 Signal text string 1 (Drv Fault) 98

751 Timer 2 Time 0.0 - 320.0 sec 1.0 sec 98

794 Drive Name text string serial number 98

799 Config USB Mode text string 0 (Disabled) 98

801 Program Number 0-9999 0 99

802 Start Options text string 0 (LS Lockout) 99

803 PWM Frequency 0.6-16.0 kHz 3.0 kHz 100

804 Display Mode text string 0 = Std Disply 100

805 Display Units alphanumeric 0 (blank) 100

809 Display Scale 1-65535 18000 100

810 Language text string 0 (English) 100

811 Access Code 0-9999 0 101

812 Freq Ref Output text string 0 (6FS) 101

813 Speed Ratio 0.0-200.0% 100.0% 101

814 Display Status text string 0 (Drive load) 101

816 Fly Catch Mode text string 0 (Sweep FWD) 101

819 Flt Text #1 text string User Flt 1 101

825 Flt Text #2 text string User Flt 2 102

850 PID Configure text string 0 (No PID) 102

851 PID FBk Config text string 0 (Vin1) 102

852 PID Prop Gain 0-2000 0 102

853 PID Int Gain 0-10000 0 102

854 PID Feed Gain 0-2000 1000 102

855 PID Error 1 0.00-100.00% Read-only 102

856 PID Error 2 0.00-100.00% Read-only 102

857 PID High Corr 0.00-100.00% 100.00% 103

858 PID Low Corr 0.00-100.00% 0.00% 103

859 PID Deriv Gain 0-200 0.00% 103

= cannot change in Run

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

DPD00089A - vi - © 2009 Vacon Incorporated All Rights Reserved

Page 7

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type = Level 1 parameter

No. Parameter Name Options Default User Setting See Page

860 PID Sleep Cfg text string 0 (disabled) 103

861 PID Sleep Lvl 0.00-100.00% 0.00% 103

862 PID Wake-up Lvl 0.00-100.00% 100.00% 103

863 Sleep Delay Time 0.0-300.0 sec 0.0 sec 103

864 Wake-up Delay 0.0-300.0 sec 0.0 sec 103

865 PID Feedback 0.00-100.00% Read-only 103

866 PID Reference 0.00-100.00% Read-only 103

867 PID User Units text string 0 (No) 103

880 FBus Read 1 0-65535 103 104

881 FBus Read 2 0-65535 104 104

882 FBus Read 3 0-65535 105 104

883 FBus Read 4 0-65535 107 104

884 FBus Read 5 0-65535 909 104

890 FBus Write 1 0-65535 907 104

891 FBus Write 2 0-65535 402 104

892 FBus Write 3 0-65535 403 104

893 FBus Write 4 0-65535 920 104

894 FBus Write 5 0-65535 921 104

900 SIO Protocol text string 0 (RTU N81) 104

901 SIO Baud Rate text string 2 (9600) 104

902 Comm Drop # 1-247 1 104

903 SIO Timer 0.0-60.0 sec 1.0 sec 104

904 SIO Cntl Word Bit 0-15 0x0000 105

905 Ext Ref Freq1 Min-Max Freq 0.0 Hz 105

906 Ext Ref Freq2 Min-Max Freq 0.0 Hz 105

907 Cntl Word 2 Bit 0-15 0x0000 105

908 Status Word Bit 0-15 Read-only 105

909 DI Status Bit 0-14 Read-only 106

910 Vin1 Status 0.00-100.00% Read-only 106

911 Cin Status 0.00-100.00% Read-only 106

912 Vin2 Status 0.00-100.00% Read-only 106

913 Output Status Bit 0-5 Read-only 106

914 Vmet Status 0.00-100.00% Read-only 106

915 Imet Status 0.00-100.00% Read-only 106

916 Infrared Baud text string 2 (9600) 106

917 FBus Port Config text string 1 (485 w/ctl) 107

920 SIO Vmet Level 0.00-100.00% 100.00% 107

921 SIO Imet Level 0.00-100.00% 100.00% 107

926 Status Word 2 Bit 0-2 Read-only 107

930 Seq Cntl 1 Bit 0-15 (hex control) 0x0000 108

931 Seq Cntl 2 Bit 0-15 (hex control) 0x0000 108

932 Seq Cntl 3 Bit 0-15 (hex control) 0x0000 108

933 Seq Cntl 4 Bit 0-15 (hex control) 0x0000 108

934 Seq Cntl 5 Bit 0-15 (hex control) 0x0000 108

935 Seq Cntl 6 Bit 0-15 (hex control) 0x0000 108

936 Seq Cntl 7 Bit 0-15 (hex control) 0x0000 108

937 Seq Cntl 8 Bit 0-15 (hex control) 0x0000 108

938 Seq Cntl 9 Bit 0-15 (hex control) 0x0000 108

939 Seq Cntl 10 Bit 0-15 (hex control) 0x0000 108

940 Seq Cntl 11 Bit 0-15 (hex control) 0x0000 108

941 Seq Cntl 12 Bit 0-15 (hex control) 0x0000 108

942 Seq Cntl 13 Bit 0-15 (hex control) 0x0000 108

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

= cannot change in Run

DPD00089A - vii - © 2009 Vacon Incorporated All Rights Reserved

Page 8

X5 AC Drive User’s Manual X5 Parameter Summary Table

Bold type = Level 1 parameter

No. Parameter Name Options Default User Setting See Page

943 Seq Cntl 14 Bit 0-15 (hex control) 0x0000 108

944 Seq Cntl 15 Bit 0-15 (hex control) 0x0000 108

945 Seq Cntl 16 Bit 0-15 (hex control) 0x0000 108

946 Seq Cntl 17 Bit 0-15 (hex control) 0x0000 108

947 Seq Cntl 18 Bit 0-15 (hex control) 0x0000 108

948 Seq Cntl 19 Bit 0-15 (hex control) 0x0000 108

949 Seq Cntl 20 Bit 0-15 (hex control) 0x0000 108

950 Seq Cntl 21 Bit 0-15 (hex control) 0x0000 108

951 Seq Cntl 22 Bit 0-15 (hex control) 0x0000 108

952 Seq Cntl 23 Bit 0-15 (hex control) 0x0000 108

953 Seq Cntl 24 Bit 0-15 (hex control) 0x0000 108

954 Seq Cntl 25 Bit 0-15 (hex control) 0x0000 108

955 Seq Count 1 0-65535 0 109

956 Seq Count 2 0-65535 0 109

957 Seq Count 3 0-65535 0 109

958 Seq Count 4 0-65535 0 109

959 Seq Count 5 0-65535 0 109

960 Seq Count 6 0-65535 0 109

961 Seq Count 7 0-65535 0 109

962 Seq Count 8 0-65535 0 109

963 Seq Count 9 0-65535 0 109

964 Seq Count 10 0-65535 0 109

965 Seq Count 11 0-65535 0 109

966 Seq Count 12 0-65535 0 109

967 Seq Count 13 0-65535 0 109

968 Seq Count 14 0-65535 0 109

969 Seq Count 15 0-65535 0 109

970 Seq Count 16 0-65535 0 109

971 Seq Count 17 0-65535 0 109

972 Seq Count 18 0-65535 0 109

973 Seq Count 19 0-65535 0 109

974 Seq Count 20 0-65535 0 109

975 Seq Count 21 0-65535 0 109

976 Seq Count 22 0-65535 0 109

977 Seq Count 23 0-65535 0 109

978 Seq Count 24 0-65535 0 109

979 Seq Count 25 0-65535 0 109

980 Seq Decision 1 Bit 0-15 0x0000 109

981 Seq Decision 2 Bit 0-15 0x0000 109

982 Seq Decision 3 Bit 0-15 0x0000 109

983 Seq Decision 4 Bit 0-15 0x0000 109

984 Seq Decision 5 Bit 0-15 0x0000 109

1500 Last Fault All fault options Read-only 109

1527 9th Fault All fault options Read-only 109

1554 8th Fault All fault options Read-only 109

1581 7th Fault All fault options Read-only 109

1608 6th Fault All fault options Read-only 110

1635 5th Fault All fault options Read-only 110

1662 4th Fault All fault options Read-only 110

1689 3rd Fault All fault options Read-only 110

1716 2nd Fault All fault options Read-only 110

1743 1st Fault All fault options Read-only 110

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be

addressed by Modbus address 40201.

= cannot change in Run

DPD00089A - viii - © 2009 Vacon Incorporated All Rights Reserved

Page 9

X5 AC Drive User’s Manual Table of Contents

CONTENTS

Summary of X5 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Overview of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 User’s Manual Publication History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2: Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Interpreting Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Power and Current Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Control Features Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3: Receiving and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Dissipation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Cover Assembly and Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Serial Number Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6 Conduit Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.7 Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 4: Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 General Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.2 Considerations for Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.3 Considerations for Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Input Line Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.2 Line Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.3 Phase Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.4 Single-phase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.5 Ground Fault Circuit Interrupters (GFCI) . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.6 Motor Lead Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.7 Using Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Terminals Found on the X5 Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.1 Description of the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.2 Typical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5 Dynamic Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

DPD00089A - ix - © 2009 Vacon Incorporated All Rights Reserved

Page 10

X5 AC Drive User’s Manual Table of Contents

4.6 Terminals Found on the X5 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.6.1 Description of the Control Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.6.2 Typical Connection Diagrams for Digital Inputs . . . . . . . . . . . . . . . . . . 41

4.6.3 Typical Connection Diagrams for Analog Inputs . . . . . . . . . . . . . . . . . . 42

4.6.4 Typical Connection Diagrams for Analog Outputs . . . . . . . . . . . . . . . . 42

4.6.5 Modbus Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.7 Reducing Current Surges and Voltage Transients . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5: Operation and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3 LCD Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.2 X5 Keypad Status and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.3 Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.4 Other Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.4 Keypad Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.1 Accessing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.2 Changing the Display Scroll Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.3 Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.4 Restoring Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.5 Viewing Parameters That Have Changed . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.6 Using Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6 Measuring Stator Resistance (RS Measurement) . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6.1 Activating Automatic RS Measurement via Keypad . . . . . . . . . . . . . . . 51

5.6.2 Activating Automatic RS Measurement via Serial Link (Modbus) . . . . 52

5.7 Storing Data and Reflashing Using a Flash Memory Device . . . . . . . . . . . . . . . . . 52

5.7.1 Storing Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.2 Recalling Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.7.3 Storing Keeper Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.7.4 Reflashing the X5 Using the USB Port and a Flash Memory Device . . 53

5.8 Using the Keeper Data Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.1 Keeper Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.2 Setting up the Keeper Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.9 Using the X5 Real-Time Clock and Other Special Features . . . . . . . . . . . . . . . . . . 57

5.9.1 Enabling the X5 Based on Time of Day (TOD) . . . . . . . . . . . . . . . . . . . 57

5.9.2 Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.9.3 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.9.4 Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 6: Using Macro Mode and Getting a Quick Start . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1 Entering Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.2 Description of Parameters Used in Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3 Macro Mode Applications and Included Parameters . . . . . . . . . . . . . . . . . . . . . . . . 63

6.4 Getting a Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

DPD00089A - x - © 2009 Vacon Incorporated All Rights Reserved

Page 11

X5 AC Drive User’s Manual Table of Contents

Chapter 7: X5 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.2 Level 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 Description of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.4 Using the X5 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.4.1 Enabling the X5 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.4.2 Controlling the X5 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . 111

7.4.3 Sequencer State Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . 113

7.4.4 Advancement on Drive State Conditions . . . . . . . . . . . . . . . . . . . . . . . 118

7.4.5 Sequencer Decision Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.4.6 Sequencer Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.4.7 Sample Sequencer Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Blank Worksheet to Remove and Copy. . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 8: Troubleshooting and Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter 9: X5 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Appendix A: Parameter 201 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Appendix B: Binary-Hexadecimal Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

DPD00089A - xi - © 2009 Vacon Incorporated All Rights Reserved

Page 12

Chapter 1: Introduction

1.1 Product Overview

The X5 AC drive provides an economical, powerful solution for a large array of industrial

®

applications. It features remote communications capability (using Ethernet, Devicenet, Modbus

Modbus

®

TCP/IP protocols), a keypad for easy configuration, and standard NEMA 4X / IP66 and

and

NEMA 12 / IP55 enclosures that eliminate the need for mounting in a separate enclosure. A USB

interface allows you to copy parameters from drive to drive, and to download data logs. Like the X4

AC drive, it provides a robust, compact solution for industrial applications, but with more capability.

The X5 product family includes a wide variety of models to suit almost any input voltage

requirement. An ‘x’ in the following table indicates what models are currently available. Refer to

“Chapter 2: Technical Characteristics” on page 14 for help in interpreting model numbers.

Input Voltage

Horsepower

1xxx x

2xxx

3xxx

5xxx

7.5 x x x

10 x x x

15 x x x

20 x x x

25 x x x

30 x x x

40 x x

50 x x

60 x x

75 x x

100 x x

125 x x

150 x x

200 x x

115 Vac

1 Phase

230 Vac

3 Phase

460 Vac

3 Phase

575 Vac

3 Phase

1.2 Overview of This Manual

This manual contains specifications, receiving and installation instructions, configuration,

description of operation, options, and troubleshooting procedures for X5 AC drive devices.

For experienced users, a Quick-Start section begins on page 69. A summary of parameters begins on

page iii of this manual.

DPD00089A - 12 - © 2009 Vacon Incorporated All Rights Reserved

Page 13

X5 AC Drive User’s Manual Chapter 1: Introduction

1.3 User’s Manual Publication History

Date Form Number Nature of Change

July 2007 1434 First release

Added information regarding new models, new parameters,

April 2008 1434A

June 2008 1434B

Changed installation diagrams to reflect changes in product;

changed photographs of product; added information to Chapter 2

October 2008 DPD00089

April 2009 DPD00089A Revised EU Declaration of Conformity

on current surges and voltage transients; added parameters 614-

15, 719, and changed ranges for parameters 862-864. Made

changes to Sect. 7.4.3, Sequencer State Configuration Overview.

Made corrections throughout manual.

Added Appendix for Parameter 201.

Corrected Figure 7-3 in Sequencer section.

Updated Vacon corporate information.

and model options.

DPD00089A - 13 - © 2009 Vacon Incorporated All Rights Reserved

Page 14

Chapter 2: Technical Characteristics

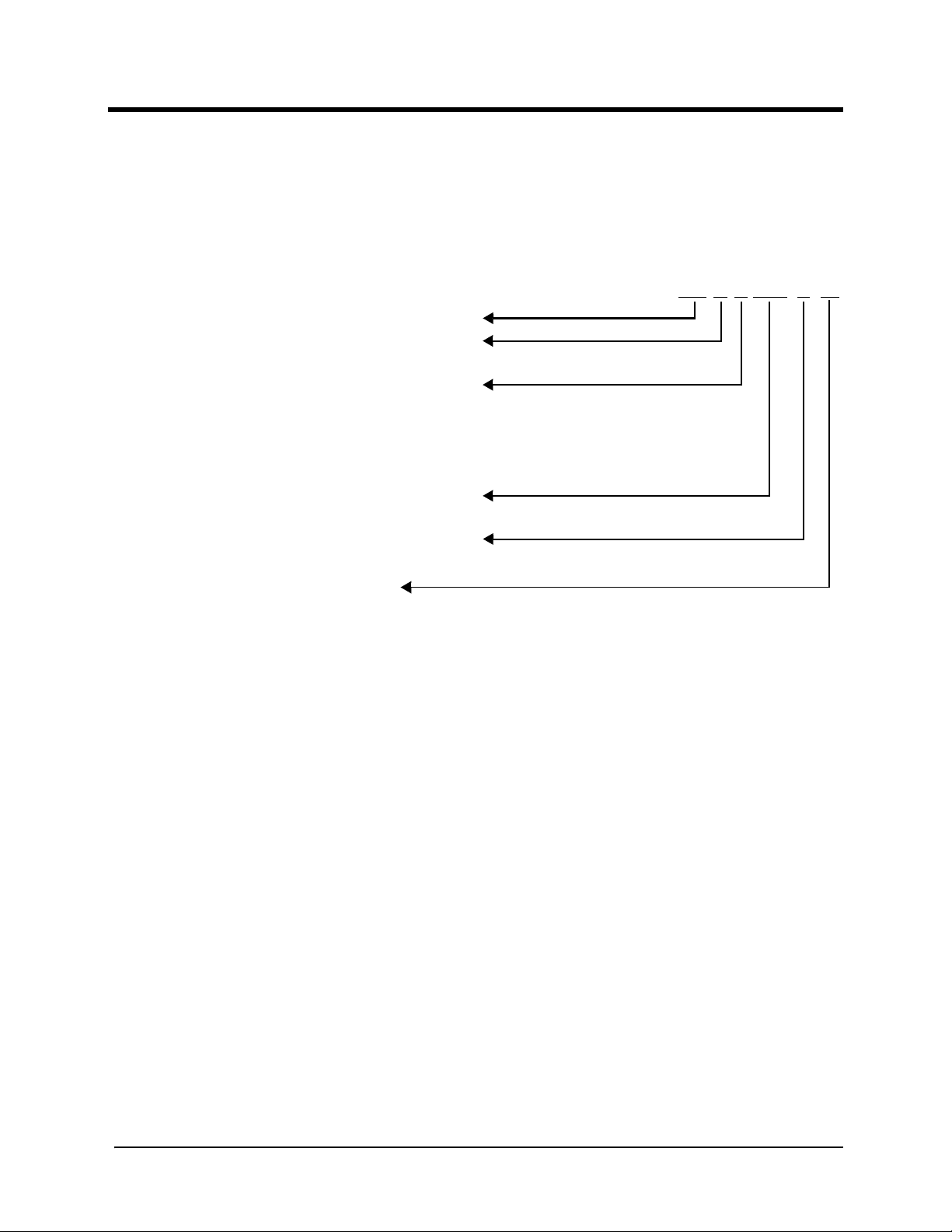

2.1 Interpreting Model Numbers

The model number of the X5 AC drive appears on the shipping carton label and on the technical data

label on the model. The information provided by the model number is shown below:

X5 C 2 0030 C 09

X5 Series

Torque:

C = Constant - Normal duty

Input Voltage:

2 = 230 Vac, Three-phase

4 = 460 Vac, Three-phase

5 = 575 Vac, Three-phase

Horsepower:

Examples: 0030 = 3 HP; 0300 = 30 HP

Enclosure:

C = NEMA 4X / IP66

D = NEMA 12 / IP55

Optional configuration

(see following section for more information)

X5 Models without option card capability

Smaller horsepower models (30 HP or less) of X5 drives with optional configuration -09 have the

same electrical capabilities as the other X5 models, but do not support option cards. These smallerframe models are offered in smaller enclosures (frame size 0, 1, and 2). Table 2-1 shows the model

and size relationships of all the X5 drives.

DPD00089A - 14 - © 2009 Vacon Incorporated All Rights Reserved

Page 15

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

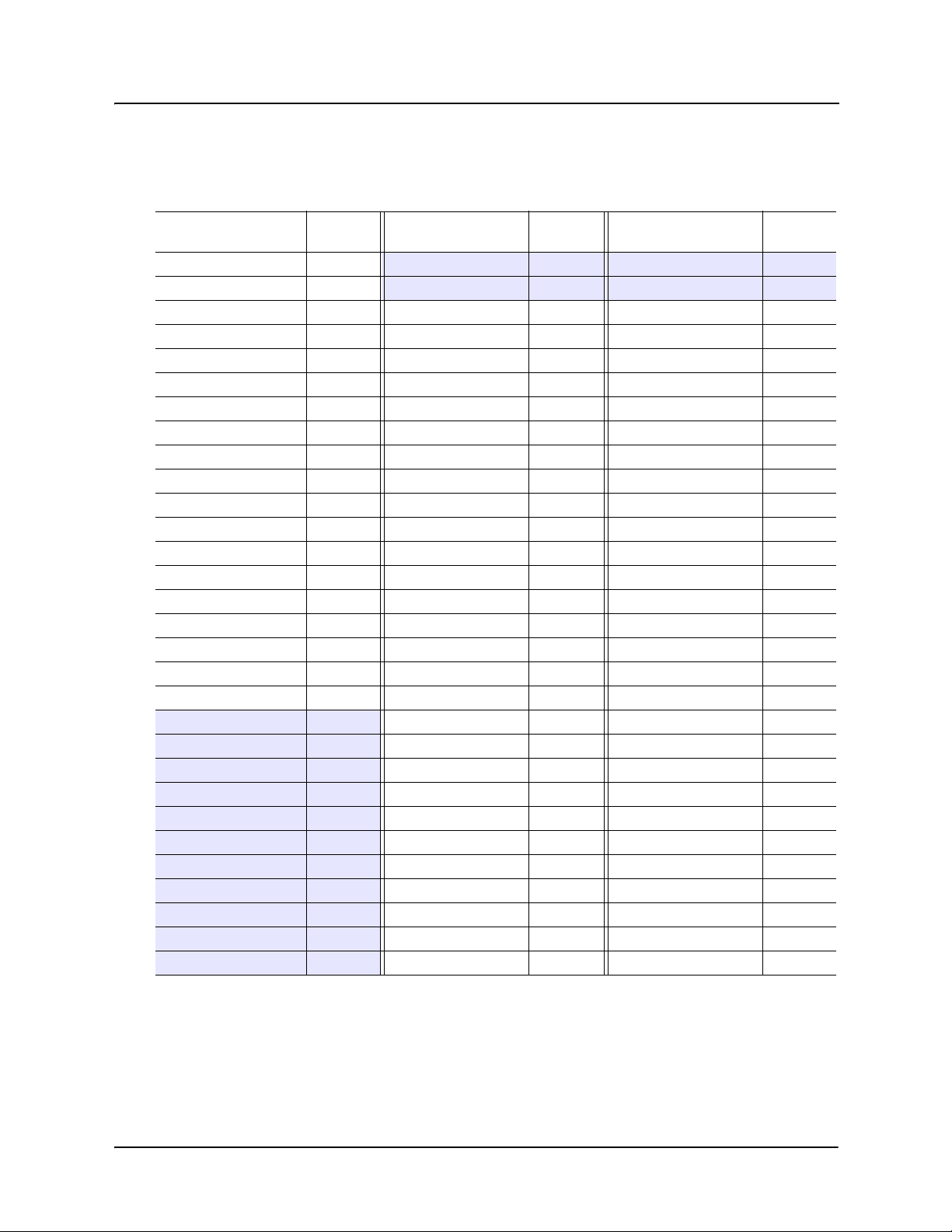

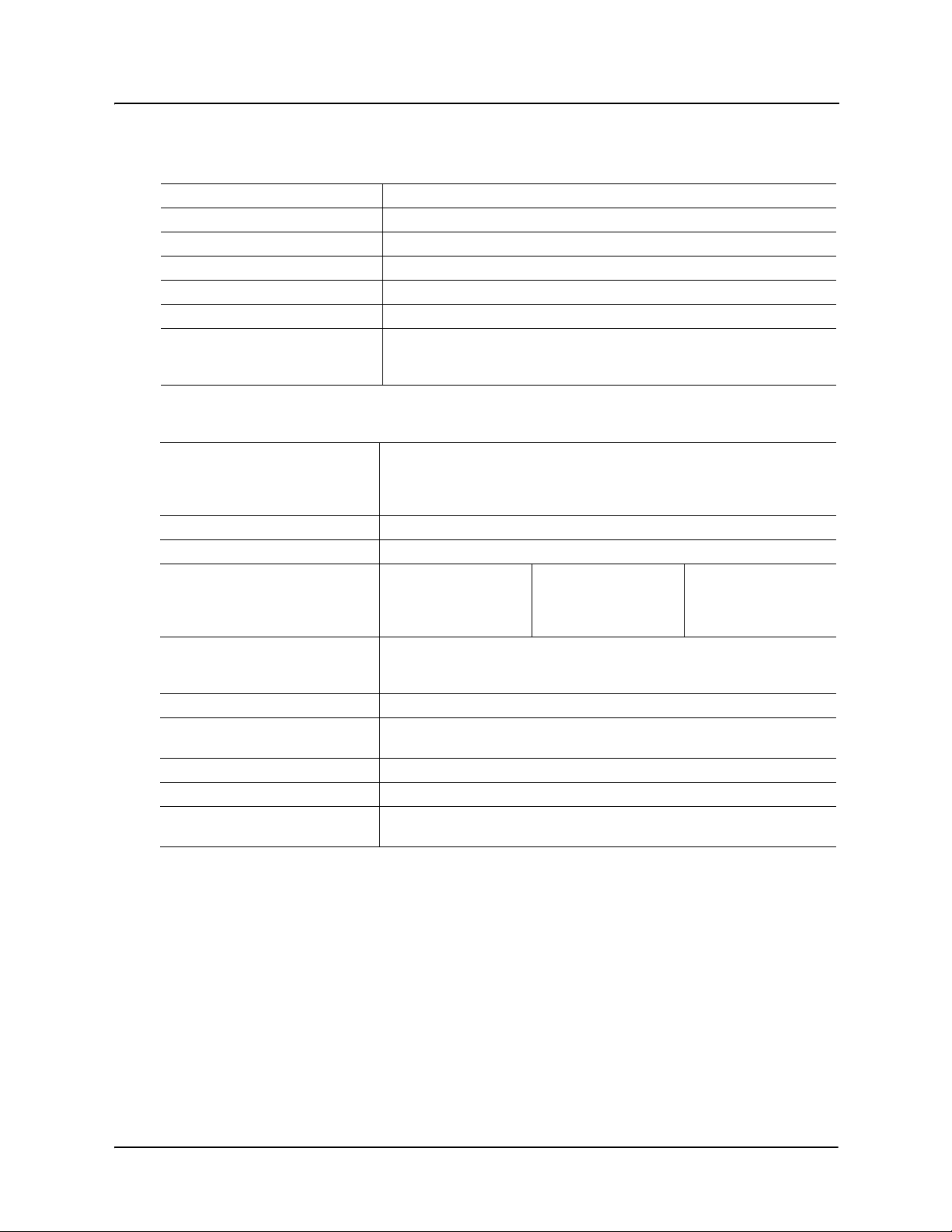

Table 2-1: Model Number / Frame Size Cross-Reference

Part #

X5C1S010C 1

X5C1S010C09 0

X5C20010C 1 X5C40010C 1 X5C50010C 1

X5C20010C09 0 X5C40010C09 0 X5C50010C09 1A

X5C20020C 1 X5C40020C 1 X5C50020C 1

X5C20020C09 0 X5C40020C09 0 X5C50020C09 1A

X5C20030C 1 X5C40030C 1 X5C50030C 1

X5C20030C09 0 X5C40030C09 0 X5C50030C09 1A

X5C20050C 1 X5C40050C 1 X5C50050C 1

X5C20050C09 1A X5C40050C09 1A X5C50050C09 1A

X5C20075C 1 X5C40075C 1 X5C50075C 1

X5C20075C09 1A X5C40075C09 1A X5C50075C09 1A

X5C20100C 2 X5C40100C 1 X5C50100C 1

X5C20100C09 2A X5C40100C09 1A X5C50100C09 1A

X5C20150C 2 X5C40150C 2 X5C50150C 2

X5C20150C09 2A X5C40150C09 2A X5C50150C09 2A

X5C20200C 3 X5C40200C 2 X5C50200C 2

X5C20250C 3 X5C40200C09 2A X5C50200C09 2A

X5C20300C 3 X5C40250C 2 X5C50250C 2

Frame

Size

Part #

X5C40250C09 2A X5C50250C09 2A

X5C40300C 2 X5C50300C 2

X5C40300C09 2A X5C50300C09 2A

X5C40400C 3 X5C50400C 3

X5C40500C 3 X5C50500C 3

X5C40600C 4 X5C50600C 4

X5C40750C 4 X5C50750C 4

X5C41000C 4 X5C51000C 4

X5C41250D 5 X5C51250D 5

X5C41500D 5 X5C51500D 5

X5C42000D 5 X5C52000D 5

Frame

Size

Part #

Frame

Size

DPD00089A - 15 - © 2009 Vacon Incorporated All Rights Reserved

Page 16

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

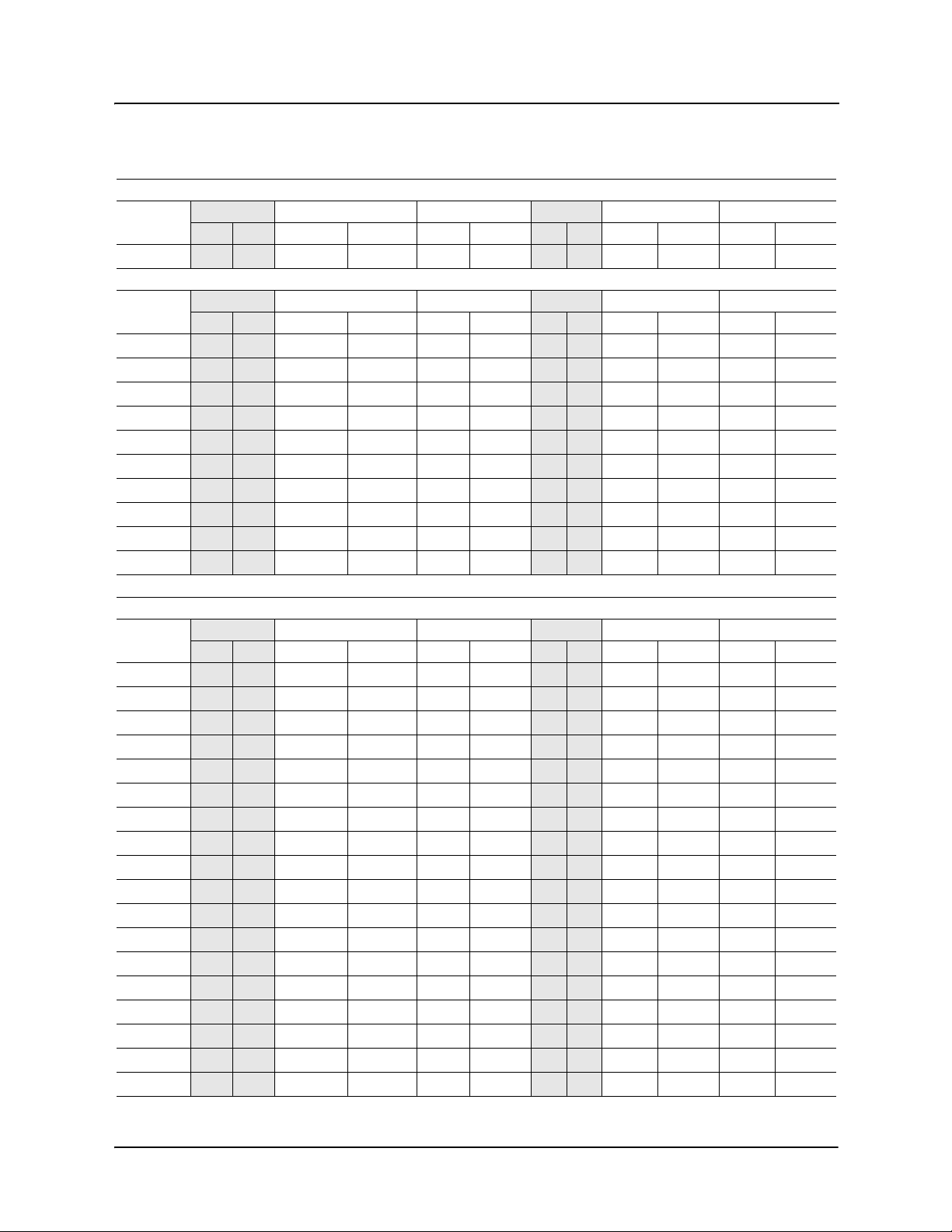

2.2 Power and Current Ratings

115 Vac Ratings

Model

number

X5C1S010C

230 Vac Ratings

Model

number

X5C20010C

X5C20020C

X5C20030C

X5C20050C

X5C20075C

X5C20100C

X5C20150C

X5C20200C

X5C20250C

X5C20300C

460 Vac Ratings

Model

number

X5C40010C

X5C40020C

X5C40030C

X5C40050C

X5C40075C

X5C40100C

X5C40150C

X5C40200C

X5C40250C

X5C40300C

X5C40400C

X5C40500C

X5C40600C

X5C40750C

X5C41000C

X5C41250D

X5C41500D

X5C42000D

Normal Duty Input current (A) Output current (A) Heavy Duty Input current (A) Output current (A)

HP kW -- 115 Vac -- 230 Vac HP kW -- 230 Vac -- 230 Vac

1 0.75 -- 15 -- 4.2 0.5 0.37 -- 11 -- 2.2

Normal Duty Input current (A) Output current (A) Heavy Duty Input current (A) Output current (A)

HP kW 200 Vac 230 Vac 200 Vac 230 Vac HP kW 200 Vac 230 Vac 200 Vac 230 Vac

1 0.75 5.6 4.8 4.8 4.2 0.5 0.37 2.9 2.5 2.5 2.2

2 1.5 9 7.8 7.8 6.8 1 0.75 5.6 4.8 4.8 4.2

3 2.2 12.7 11 11 9.6 2 1.5 9 7.8 7.8 6.8

5 4 20.2 17.5 17.5 15.2 3 2.2 12.7 11 11 9.6

7.5 5.5 29.2 25.3 25.3 22 5 4 20.2 17.5 17.5 15.2

10 7.5 37.2 32.2 37.2 28 7.5 5.5 29.2 25.3 25.3 22

15 11 52.1 46.4 48.3 42 10 7.5 37.2 32.2 37.2 28

20 15 68.3 57.4 62.1 54 15 11 52.1 46.4 48.3 42

25 18.5 82.3 73.8 78.2 68 20 15 68.3 57.4 62.1 54

30 22 96 84 92 80 25 18.5 82.3 73.8 78.2 68

NOTE: All 230 Vac models can be operated at single-phase, with 50% derating

Normal Duty Input current (A) Output current (A) Heavy Duty Input current (A) Output current (A)

HP kW 380 Vac 460 Vac 380 Vac 460 Vac HP kW 380 Vac 460 Vac 380 Vac 460 Vac

1 0.75 3.0 2.4 2.4 2.1 0.5 0.37 1.6 1.3 1.3 1.1

2 1.5 5.2 3.9 3.8 3.4 1 0.75 3.0 2.4 2.4 2.1

3 2.2 7.2 5.6 5.1 4.8 2 1.5 5.2 3.9 3.8 3.4

5 412 8.88.97.63 2.2 7.2 5.6 5.1 4.8

7.5 5.5 15 12.8 12 11 5 412 8.8 8.9 7.6

10 7.5 19.7 16.3 15.6 14 7.5 5.5 15 12.8 12 11

15 11 30.9 25.8 23 21 10 7.5 19.7 16.3 15.6 14

20 15 40 33.3 31 27 15 11 30.9 25.8 23 21

25 18 46.3 40 37 34 20 15 40 33.3 31 27

30 22 57.5 47.8 43 40 25 18 46.3 40 37 34

40 30 73.2 62.4 61 52 30 22 57.5 47.8 43 40

50 37 82 78 71 65 40 30 73.2 62.4 61 52

60 45 94 80 86 77 50 37 82 78 71 65

75 55 114 99 105 96 60 45 94 80 86 77

100 75 149 129 140 124 75 55 114 99 105 96

125 90 168 156 168 156 100 75 140 124 140 124

150 110 205 180 205 180 125 90 168 156 168 156

200 132 240 240 240 240 150 110 205 180 205 180

DPD00089A - 16 - © 2009 Vacon Incorporated All Rights Reserved

Page 17

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

575 Vac Ratings

Model

number

X5C50010C

X5C50020C

X5C50030C

X5C50050C

X5C50075C

X5C50100C

X5C50150C

X5C50200C

X5C50250C

X5C50300C

X5C50400C

X5C50500C

X5C50600C

X5C50750C

X5C51000C

X5C51250D

X5C51500D

X5C52000D

Normal Duty Input current (A) Output current (A) Heavy Duty Input current (A) Output current (A)

HP kW - 575 Vac - 575 Vac HP kW - 575 Vac - 575 Vac

1 0.75 - 2.0 - 1.7 0.5 0.37 - 1.2 - 0.9

2 1.5 - 3.6 - 2.7 1 0.75 - 2.0 - 1.7

3 2.2 - 5.0 - 3.9 2 1.5 - 3.6 - 2.7

5 4- 7.6-6.13 2.2 - 5.0 - 3.9

7.5 5.5 - 10.4 - 9.0 5 4- 7.6 - 6.1

10 7.5 - 14.1 - 11.0 7.5 5.5 - 10.4 - 9.0

15 11 - 23 - 1 7 10 7.5 - 14.1 - 11

20 15 - 31 - 22 15 11 - 23 - 1 7

25 18 - 37 - 27 20 15 - 31 - 22

30 22 - 39.5 - 32 25 18 - 37 - 27

40 30 - 49 - 41 30 22 - 39.5 - 32

50 37 - 58 - 52 40 30 - 49 - 41

60 45 - 68 - 62 50 37 - 58 - 52

75 55 - 82 - 77 60 45 - 68 - 62

100 75 - 107 - 99 75 55 - 82 - 77

125 90 - 125 - 125 100 75 - 99 - 99

150 110 - 144 - 144 125 90 - 125 - 125

200 132 - 192 - 192 150 110 - 144 - 144

DPD00089A - 17 - © 2009 Vacon Incorporated All Rights Reserved

Page 18

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

2.3 Environmental Specifications

Operating temperature -10 °C to +40 °C (14 °F to 104 °F)

Storage temperature –20 °C to +65 °C (-4 °F to 149 °F)

Humidity 0% to 95% non-condensing

Altitude 1000 m (3300 ft) without derating

Maximum vibration per EN50178 (1g @ 57-150 Hz)

Acoustic noise 80 dba sound power at 1 m (3 ft), maximum

1-5 HP models: Natural convection

Cooling

7.5 to 200.0 HP models: Forced air (temperature-controlled external fan)

The 575 Vac, 5 HP model has a fan.

2.4 Electrical Specifications

X5C1x models: 115 Vac, 1 phase, +/- 10% 1 HP

Input voltage

Line frequency 50 / 60 Hz ±2 Hz

Source kVA (maximum) 10 times the unit rated kVA, 65kA maximum (see note below)

DC bus voltage for:

Overvoltage trip

Dynamic brake activation

Nominal undervoltage (UV) trip

Control system

Output voltage 3-phase: 0 to 100% of incoming voltage (0-230 Vac for 115 Vac models)

Overload capacity

Frequency range 0.1 to 400 Hz

Frequency stability 0.1 Hz (digital), 0.1% (analog) over 24 hours +/- 10 °C

Frequency setting

X5C2x models: 200-230 Vac, 3 phase, +/- 15% 1-30 HP

X5C4x models: 380-460 Vac, 3 phase, +/- 15% 1-200 HP

X5C5x models: 575Vac, 3 phase, +/-15% 1-200 HP

115/230 Vac models

406 Vdc

388 Vdc

199 Vdc

V/Hz or Sensorless Vector Control (SVC)

Carrier frequency = 1 - 16 kHz, programmable; 8 kHz max. for 125-200 HP

models

120% of rated RMS current for 60 seconds (normal duty rating)

150% of rated RMS current for 60 seconds (heavy duty rating)

By keypad, or by external signal (0 to 5 Vdc; 0 to 10 Vdc; 0/4 to 20 mA) or by

pulse train up to 100kHz

460 Vac models

814 Vdc

776 Vdc

397 Vdc

575 Vac models

1017 Vdc

970 Vdc

497 Vdc

Note: Unit Rated kVA = rated Voltage x rated Current x 1.732

DPD00089A - 18 - © 2009 Vacon Incorporated All Rights Reserved

Page 19

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

2.5 Control Features Specifications

0-5/10 Vdc, 0/4-20 mAdc (250 Ω load)

Vin1 reference input

Vin2 reference input

Cin reference input

Reference voltage 10 Vdc (10 mAdc maximum)

Digital inputs - 10

Digital supply voltage 24 Vdc (150 mAdc maximum)

Preset frequencies 4 inputs for 15 preset frequencies (selectable)

Digital outputs

Digital pulse train output Open collector output pulse train proportional to output frequency

Vmet analog output 0 to 10 Vdc (5 mAdc maximum)

Imet analog output 0/4-20 mAdc output into a 500 Ω load (maximum)

DC holding / injection braking

Current limit Four quadrant adjustable from 5 to 150%

Speed ramps Primary and alternate adjustable from 0.1 to 3200.0 seconds

Voltage boost Adjustable fixed boost or adjustable auto boost

Voltage characteristic V/Hz: Linear, pump, fan, or 2-piece linear. Also sensorless vector (SVC).

Timed overload

Protective features

Program Sequence Logic

Controller (PSLC)

PID Feedback

Serial communications Modbus, DeviceNet option, Ethernet IP option, Modbus TCP/IP option

6FS pulse train input from another drive, 0-1/10/100 kHz pulse input, inverted

function, 0-5-10 bipolar input, broken wire detection. Span and offset adjustment.

0-5/10 Vdc, 0-5-10 bipolar input, inverted function, broken wire detection, span and

offset adjustment. Programmable for frequency reference, current limit input, or

feedback signal.

0/4-20 mAdc (50 Ω load), inverted function, span and offset adjustment.

Programmable for frequency reference, current limit input, or feedback signal.

Off=0 to 3 Vdc; On=10 to 32 Vdc (pull-up logic), selectable between pull-up and pulldown logic

2 SPDT relay outputs - 130 Vac, 1 A/250 Vac, 0.5 A

2 open collector outputs 50 mA per device; 2 optional relays; optional encoder

interface

At start, stop, by frequency with adjustable current level and time or continuous DC

injection by digital input.

Adjustable inverse time trip (shear pin, 30 seconds, 60 seconds, 5 minutes), for

standard or inverter-duty motors

Overcurrent, overvoltage fault, ground fault, short circuit, dynamic brake overload,

drive temperature, power wiring fault, drive timed overload, input voltage quality,

overvoltage ridethrough

25-step (with ability to branch), PLC-type functionality that can control speed,

direction, and ramps based on time, analog input, digital input, or pulse input.

Addressable outputs and real-time operations possible. See “Using the X5 Program

Sequencer” on page 111.

Process control available with the use of a customer-supplied transducer, either 010 Vdc, 4-20 mA, or optical encoder input to the drive. Includes an optional sleep

mode, activated when the loop is satisfied.

DPD00089A - 19 - © 2009 Vacon Incorporated All Rights Reserved

Page 20

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

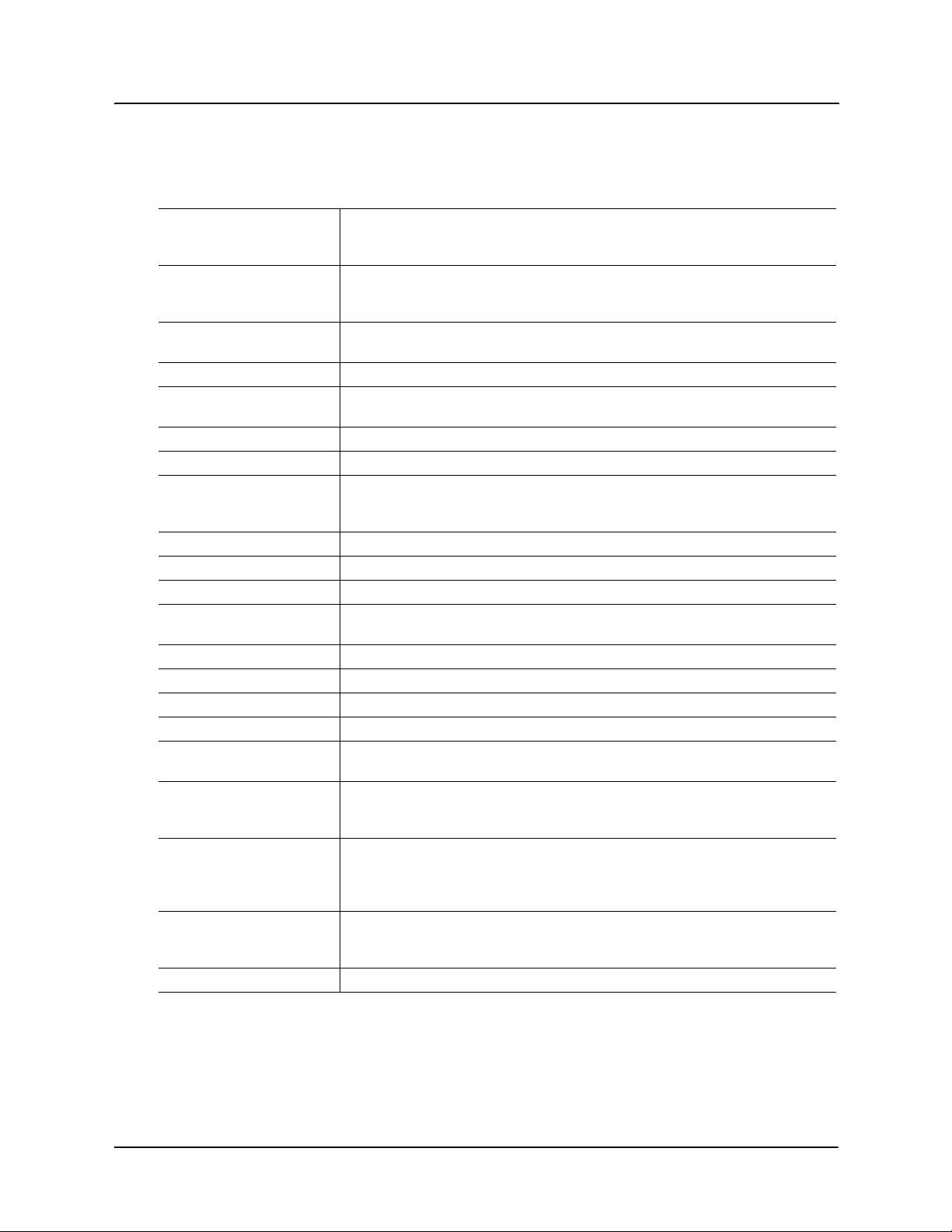

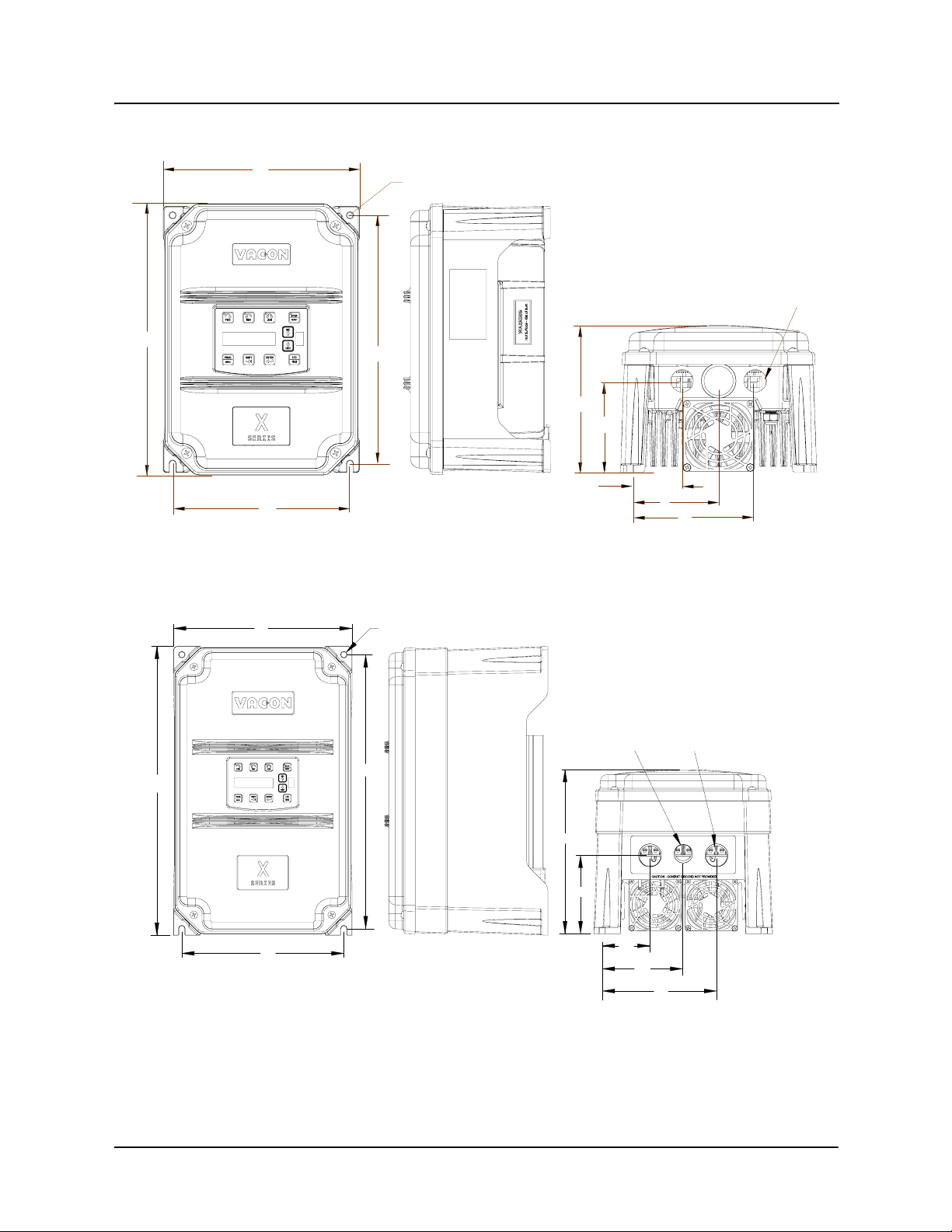

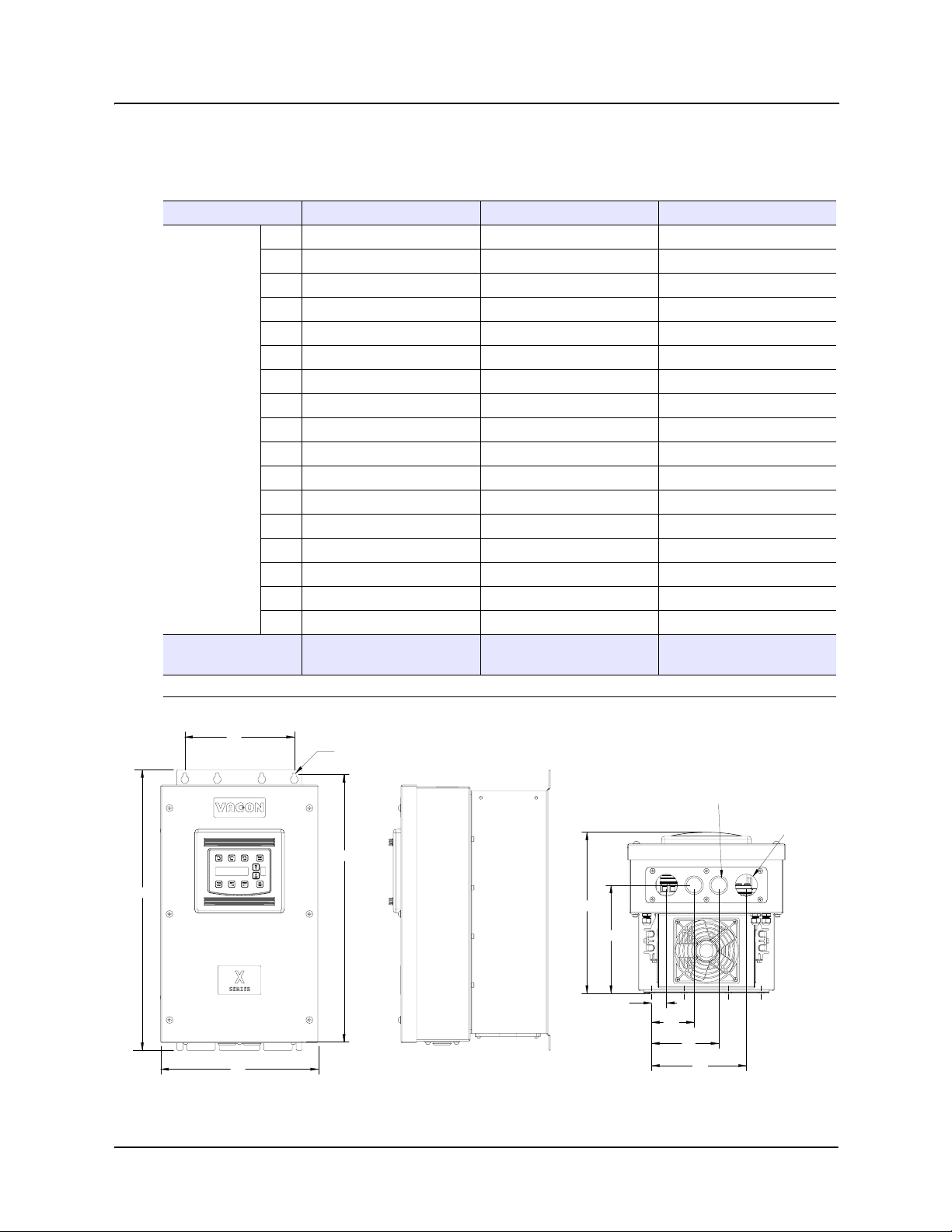

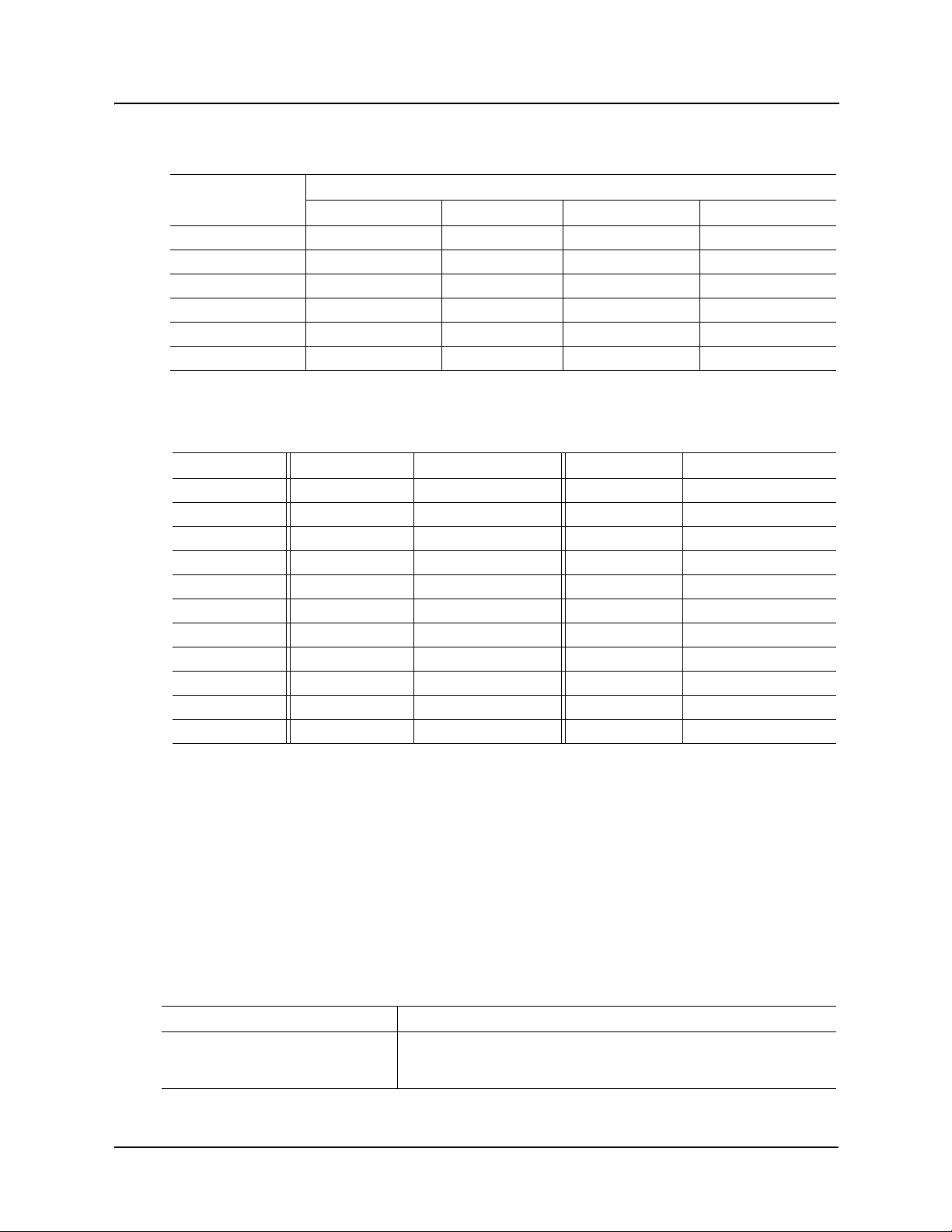

2.6 Dimensions and Weights

Table 2-2 lists dimensions and weights for the X5 frame size 0, 1, 2, and 3 models. Dimensions and

weights for the X5 frame size 4 and 5 models are shown in Table 2-3 on page 22. You may wish to

refer to the cross-reference table on page 15 for X5 model numbers / frame sizes.

See Figures 2-2, 2-2, 2-3, 2-4, 2-5, and 2-6 on pages 21 - 23 for locations of dimensions. Dimensions

A onward are in inches / millimeters (in/mm). Weight is in pounds / kilograms (lb/kg).

Table 2-2: Dimensions and Weights for Frame Sizes 0 - 2

Frame 0 1 / 1A 2 / 2A

A 9.47 (241) 12.01 (305) 17.38 (441)

B 6.50 (165) 8.72 (221) 10.75 (273)

C 6.08 (155) 8.49 (216) / 6.51 (166) 9.89 (251) / 7.91 (201)

D 8.45 (215) 11.03 (280) 16.50 (419)

E 5.69 (145) 7.88 (200) 9.76 (248)

F 0.28 (7.11) 0.28 (7) 0.41 (10)

Dimensions

in (mm)

(See X5 diagrams on pages

21 through 23)

Weight lb (kg) 8.5 (3.85) 14.0 (6.35) 29.5 (13.38)

G 3.84 (98) 4.05 (103) 4.72 (120)

H 2.77 (70) N/A N/A

J 1.93 (49) 2.31 (59) 2.88 (73)

K 2.85 (72) 3.94 (100) 4.84 (123)

L 3.75 (95) 5.56 (1.41) 6.88 (175)

M 0.88 (22) 0.88 (22) 1.38 (35)

N N/A N/A 1.13 (29)

P N/A N/A N/A

Q N/A N/A N/A

B

A

E

F

M

D

C

G

H

J

K

L

Figure 2-1: X5 Frame Size 0 Models

DPD00089A - 20 - © 2009 Vacon Incorporated All Rights Reserved

Page 21

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

E

A

B

D

)

)

C

G

L

K

J

B

FF((44ppllaacceess)

MM((33ppllaacceess)

A

D

C

G

J

E

Figure 2-2: X5 Frame Size 1 Models

K

L

B

A

E

D

F(4PLACES)

M(2PLACES)

N

C

G

J

K

L

Figure 2-3: X5 Frame Size 2 Models

DPD00089A - 21 - © 2009 Vacon Incorporated All Rights Reserved

Page 22

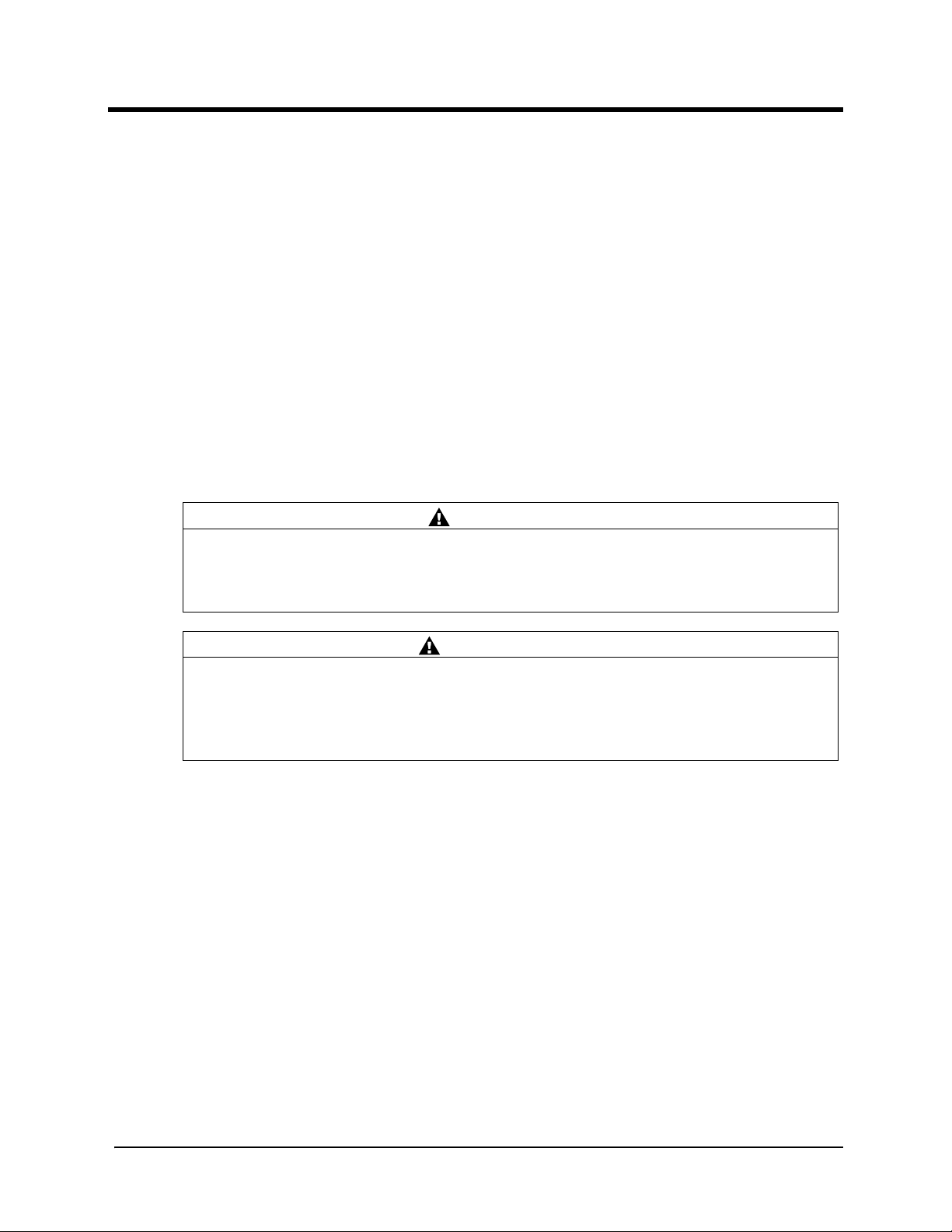

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

D

A

F(8PLACES)

B

E

C

G

J

K

L

P

M(2PLACES)

N (2 PLACES)

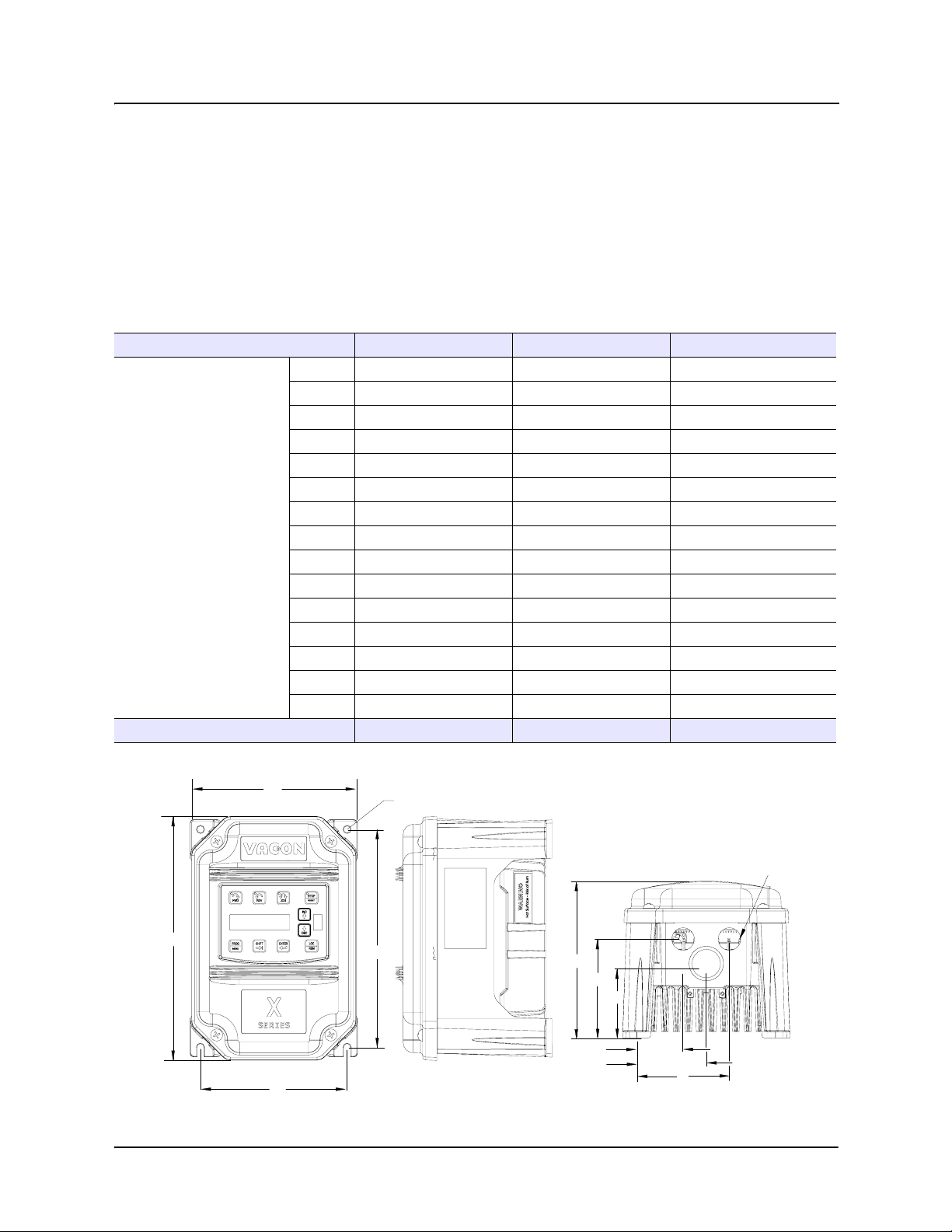

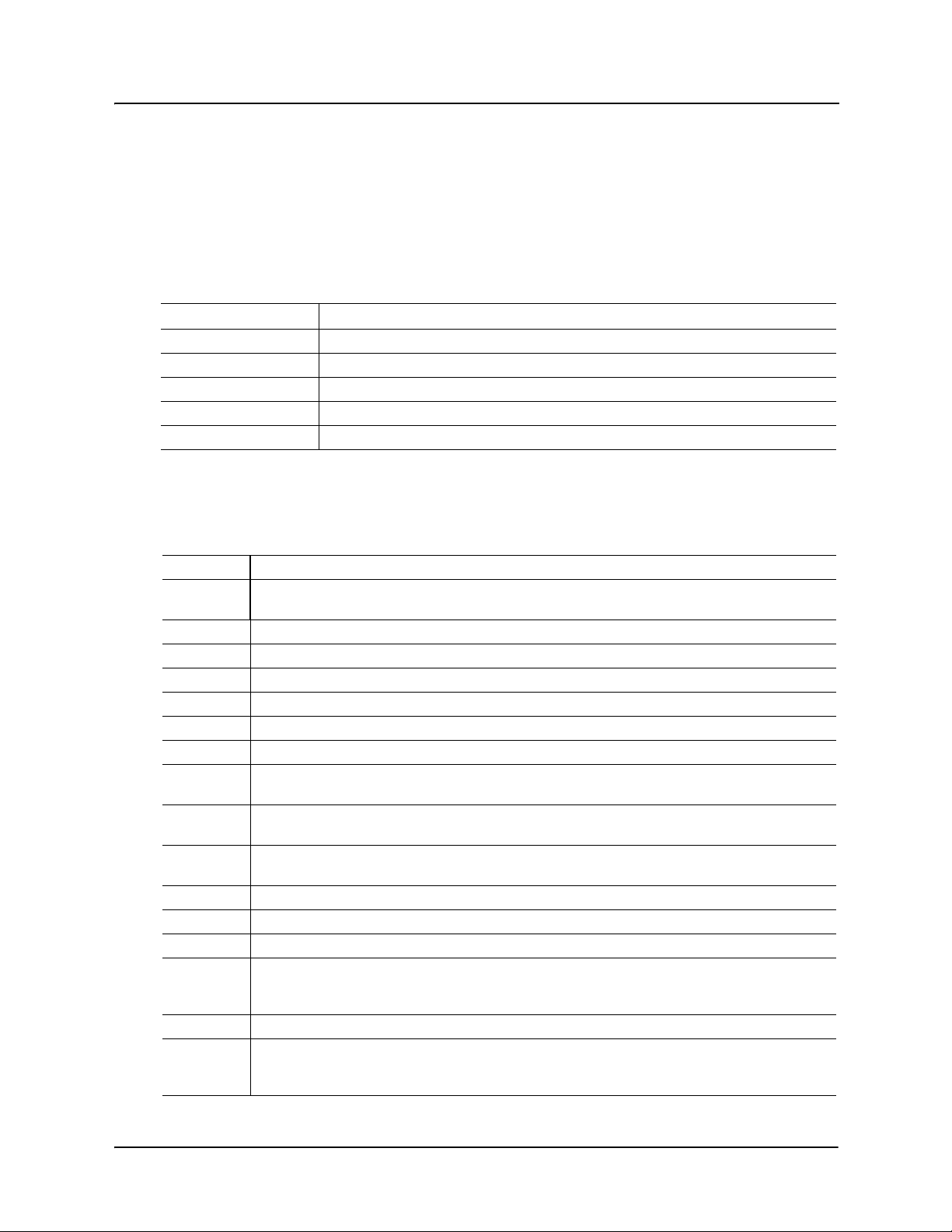

Table 2-3: Dimensions and Weights for Frame Sizes 3 - 5

Frame 3 4 5

1

A

B 11.25 (286) 12.84 (326) 16.31 (414)

C 11.73 (314) 13.80 (351) 16.88 (429)

D 19.25 (489) 28.00 (711) 45.77 (1163)

E 7.88 (200) 7.88 (200) 7.65 (194)

F 0.28 (7) 0.42 (11) 0.42 (11)

Dimensions

in (mm)

(See X5

diagrams on

pages 23 - 23)

Weight

lb (kg)

(1) For the X5C20300C, the A dimension changes to 21.00 inches (533 mm).

G 7.78 (198) 8.63 (219) 12.57 (319)

H N/A 8.26 (210) 11.10 (282)

J 0.65 (17) 0.53 (13) 0.20 (5)

K 2.29 (58) 2.69 (68) 2.32 (59)

L 3.95 (100) 3.94 (100) 3.82 (97)

M 1.69 (43) 2.44 (62) 2.94 (75)

N 0.88 (22) 0.88 (22) 0.88 (22)

P 5.60 (142) 5.19 (132) 5.32 (135)

Q 7.24 (184) 7.35 (187) 7.45 (189)

R N/A 10.23 (260) N/A

S N/A 1.94 (49) 1.86 (47)

20.19 (513) 29.35 (745) 50.77 (1290)

50.0 (22.68) 95.0 (43.10) 305.0 (138.35)

Figure 2-4: X5 Frame Size 3 Models

DPD00089A - 22 - © 2009 Vacon Incorporated All Rights Reserved

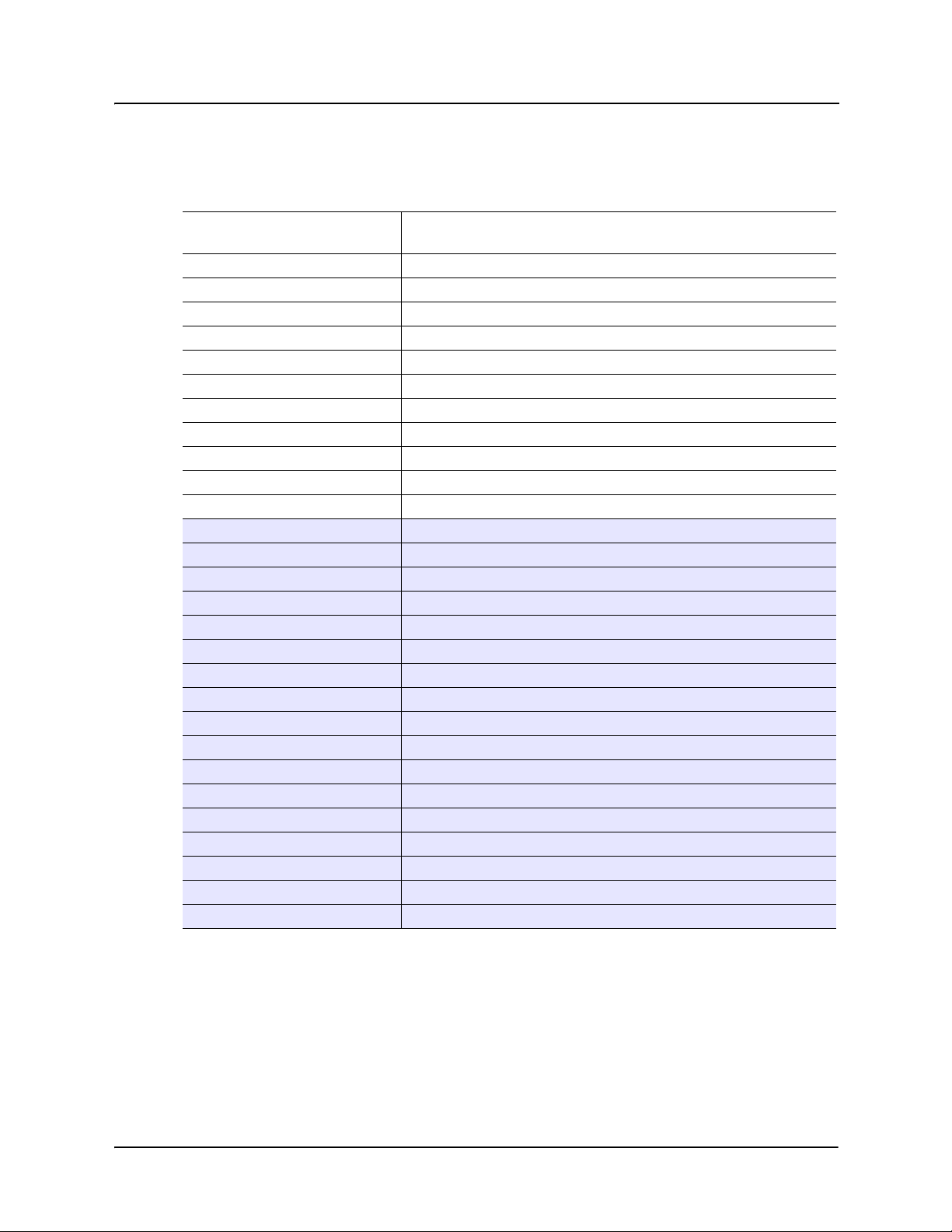

Page 23

X5 AC Drive User’s Manual Chapter 2: Technical Characteristics

E

F(8PLACES)

A

N

S

(2 PLACES)

M

(2 PLACES)

C

D

R

G

H

J

K

L

P

B

Figure 2-5: X5 Frame Size 4 Models

Q

E

F(8PLACES)

N

(2 PLACES)

M

C

G

A

D

H

(2 PLACES)

S

J

K

L

P

Q

B

Figure 2-6: X5 Frame Size 5 Models

DPD00089A - 23 - © 2009 Vacon Incorporated All Rights Reserved

Page 24

Chapter 3: Receiving and Installation

3.1 Preliminary Inspection

Before storing or installing the X5 drive, thoroughly inspect the device for possible shipping damage.

Upon receipt:

1. Remove the drive from its package and inspect exterior for shipping damage. If damage is apparent,

notify the shipping agent and your sales representative.

2. Remove the cover and inspect the drive for any apparent damage or foreign objects. (See Figure 3-1 on

page 26 for locations of cover screws.) Ensure that all mounting hardware and terminal connection

hardware is properly seated, securely fastened, and undamaged.

3. Read the technical data label affixed to the drive and ensure that the correct horsepower and input

voltage for the application has been purchased.

4. If you will be storing the drive after receipt, place it in its original packaging and store it in a clean, dry

place free from direct sunlight or corrosive fumes, where the ambient temperature is not less than -20 °C

(-4 °F) or greater than +65 °C (+149 °F).

CAUTION

EQUIPMENT DAMAGE HAZARD

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in injury or equipment damage.

ATTENTION

RISQUE DE DOMMAGES MATÉRIELS

Ne faites pas fonctionner et n’installez pas tout variateur de vitesse qui semble être endommagé.

Si cette directive n’est pas respectée, cela peut entraîner des blessures corporelles ou des

dommages matériels.

3.2 Installation Precautions

Improper installation of the X5 drive will greatly reduce its life. Be sure to observe the following

precautions when selecting a mounting location. Failure to observe these precautions may void

the warranty! See the inside front cover of this manual for more information about the warranty.

• Do not install the drive in a place subjected to high temperature, high humidity, excessive vibration,

corrosive gases or liquids, or airborne dust or metallic particles. See Chapter 2 for temperature,

humidity, and maximum vibration limits.

• Do not mount the drive near heat-radiating elements or in direct sunlight.

• Mount the drive vertically and do not restrict the air flow to the heat sink fins.

• The drive generates heat. Allow sufficient space around the unit for heat dissipation. See “Dissipation

Requirements” on page 25.

DPD00089A - 24 - © 2009 Vacon Incorporated All Rights Reserved

Page 25

X5 AC Drive User’s Manual Chapter 3: Receiving and Installation

3.3 Dissipation Requirements

Table 3-1: Dissipation Requirements for X5 Models in Enclosures (Page 1 of 2)

Model

X5C1S010C 47

X5C20010C 48

X5C20020C 71

X5C20030C 92

X5C20050C 132

X5C20075C 177

X5C20100C 263

X5C20150C 362

X5C20200C 550

X5C20250C 653

X5C20300C 779

X5C40010C 34

X5C40020C 48

X5C40030C 71

X5C40050C 91

X5C40075C 11 4

X5C40100C 155

X5C40150C 304

X5C40200C 393

X5C40250C 459

X5C40300C 458

X5C40400C 695

X5C40500C 834

X5C40600C 776

X5C40750C 988

X5C41000C 1638

X5C41250D 1656

X5C41500D 1891

Required Dissipation for Models Entirely Inside an Enclosure at

Rated Current, 3KHz Carrier Frequency (Watts)

(continued on next page)

DPD00089A - 25 - © 2009 Vacon Incorporated All Rights Reserved

Page 26

X5 AC Drive User’s Manual Chapter 3: Receiving and Installation

Table 3-1: Dissipation Requirements for X5 Models in Enclosures (Page 2 of 2)

Model

X5C42000D 2302

X5C50010C 32

X5C50020C 50

X5C50030C 66

X5C50050C 112

X5C50075C 159

X5C50100C 187

X5C50150C 334

X5C50200C 431

X5C50250C 528

X5C50300C 597

X5C50400C 742

X5C50500C 877

X5C50600C 766

X5C50750C 913

X5C51000C 1542

X5C51250D 1988

X5C51500D 2282

X5C52000D 3043

Required Dissipation for Models Entirely Inside an Enclosure at

Rated Current, 3KHz Carrier Frequency (Watts)

3.4 Cover Assembly and Torque Specifications

Figure 3-1 shows the locations of the X5 cover screws. The torque range for the X Series Size 1

cover is 18-26 in/lbs.

Cover screw locations

Figure 3-1: X5 Cover Assembly and Screw Locations

Torque specifications for control terminals and power terminals are listed in “General Wiring

Information” on page 29 .

Cover screw locations

DPD00089A - 26 - © 2009 Vacon Incorporated All Rights Reserved

Page 27

X5 AC Drive User’s Manual Chapter 3: Receiving and Installation

3.5 Serial Number Label

Vacon, Inc. warrants all AC drives for three years from date of manufacture, or two years from the

date of installation, whichever comes first. For a more detailed description of our warranty policy,

see the inside front cover of this manual, or visit the web site at http://www.vacon.com. To

determine if your drive is within the warranty time frame, find the bar code label or look in the lower

left of the technical nameplate. The serial number can be broken down as follows:

yywwxxxx = yy...year of manufacture

ww...week of manufacture

xxxx...sequential number drive during that week

3.6 Conduit Usage

The X5 drive in the NEMA 4x / IP66 enclosure is rated for 1000 psi washdown from 6 inches. To

keep this rating, the use of a sealed conduit is required. The use of a Romex-type conduit will not

prevent water entry into the enclosure. If the approved conduit is not used, all warranty claims

against water damage will be void.

3.7 Condensation

The washdown process of an X5 drive may create a temperature and humidity change in and around

the drive. If the unit is mounted in a cool environment and washed down with higher-temperature

water, as the drive cools to room temperature, condensation can form inside the drive, especially

around the display. To prevent this from happening, avoid using sealed connectors around rubbercoated cables to seal the drive. These do not allow any air transfer and hence create a level of

condensation and humidity that exceeds the drive’s rating.

DPD00089A - 27 - © 2009 Vacon Incorporated All Rights Reserved

Page 28

Chapter 4: Connections

HAZARDOUS VOLTAGE

• Read and understand this manual in its entirety before installing or operating the X5 AC drive.

Installation, adjustment, repair, and maintenance of these drives must be performed by qualified

personnel.

• Disconnect all power before servicing the drive. WAIT 5 MINUTES until the DC bus capacitors

discharge.

• DO NOT short across DC bus capacitors or touch unshielded components or terminal strip screw

connections with voltage present.

• Install all covers before applying power or starting and stopping the drive.

• The user is responsible for conforming to all applicable code requirements with respect to grounding

all equipment.

• Many parts in this drive, including printed circuit boards, operate at line voltage. DO NOT TOUCH. Use

only electrically-insulated tools.

Before servicing the drive:

• Disconnect all power.

• Place a “DO NOT TURN ON” label on the drive disconnect.

• Lock the disconnect in the open position.

Failure to observe these precautions will cause shock or burn, resulting in severe personal injury

or death.

DANGER

DANGER

TENSION DANGEREUSE

• Lisez et comprenez ces directives dans leurs intégralité avant d’installer ou de faire fonctionner le

variateur de vitesse X5. L’installation, le réglage, les réparations et l’entretien des ces variateurs de

vitesse doivent être effectuées par du personnel qualifié.

• Coupez toutes les alimentations avant de travailler sur le variateur de vitesse. ATTENDEZ CINQ

MINUTES pour que la décharge des condensateurs du bus cc s’effectue.

• NE court-cuitez PAS les condensateurs du bus cc ou ne touchez pas aux composantes non blindées

ou aux connexions des vis du bornier si l’appareil est sous tension.

• Installez tous les couvercles avant de mettre le variateur de vitesse sous tension, de le mettre en

marche ou de l’arrêter.

• L’utilisateur est responsable de la conformité avec tous les codes électriques en vigueur concernant

la mise à la terre de tous les appareils.

• De nombreuses pièces de ce variateur de vitesse, y compris les cartes de circuits imprimés,

fonctionnent à la tension du secteur. N’Y TOUCHEZ PAS. N’utilisez que des outils dotés d’une

isolation électrique.

Avant tout entretien ou réparation sur le variateur de vitesse:

• Coupez toutes les alimentations.

• Placez une étiquette «NE PAS METTRE SOUS TENSION» sur le sectionneur du variateur de vitesse.

• Verrouillez le sectionneur en position ouverte.

Si ces précautions ne sont pas respectées, cela causera une électrocution ou des brûlures, ce

qui entraînera des blessures graves ou la mort.

DPD00089A - 28 - © 2009 Vacon Incorporated All Rights Reserved

Page 29

X5 AC Drive User’s Manual Chapter 4: Connections

4.1 Introduction

This chapter provides information on connecting power and control wiring to the X5 AC drive.

4.2 General Wiring Information

4.2.1 Wiring Practices

When making power and control connections, observe these precautions:

• Never connect input AC power to the motor output terminals T1/U, T2/V, or T3/W. Damage

to the drive will result.

• Power wiring to the motor must have the maximum possible separation from all other power wiring.

Do not run in the same conduit; this separation reduces the possibility of coupling electrical noise

between circuits.

• Cross conduits at right angles whenever power and control wiring cross.

• Good wiring practice also requires separation of control circuit wiring from all power wiring. Since

power delivered from the drive contains high frequencies which may cause interference with other

equipment, do not run control wires in the same conduit or raceway with power or motor wiring.

4.2.2 Considerations for Power Wiring

Power wiring refers to the line and load connections made to terminals L1/R, L2/S, L3/T, and T1/U,

T2/V, T3/W respectively. Select power wiring as follows:

1. Use only UL-recognized wire.

2. Wire voltage rating must be a minimum of 300 V for 230 Vac systems and 600 V (Class 1 wire) for

460 or 575 Vac systems.

3. Wire gauge must be selected based on 125% of the continuous input current rating of the drive. Wire

gauge must be selected from wire tables for 75 °C insulation rating, and must be of copper construction.

The 230 V 7.5 and 15 HP models, and the 460 V 30 HP models require 90 °C wire to meet UL

requirements. See Chapter 2 for the continuous output ratings for the drive.

4. Grounding must be in accordance with NEC and CEC. If multiple X5 drives are installed near each

other, each must be connected to ground. Take care not to form a ground loop.

See Table 4-1 for a summary of wiring specifications.

DPD00089A - 29 - © 2009 Vacon Incorporated All Rights Reserved

Page 30

X5 AC Drive User’s Manual Chapter 4: Connections

Table 4-1: X5 Power Terminal Wiring Specifications

Frame Size

Specifications

Torque Nom. Torque Max. Max. Wire Size Strip Length

Size 0 12 in-lbs 13 in-lbs 12-24 AWG 5/16” (0.3125”)

Size 1 16 in-lbs 18 in-lbs 8-18 AWG 5/16” (0.3125”)

Size 2 30 in-lbs 6-8 AWG 3/8” (0.38”)

Size 3 35 in-lbs 3 AWG

Size 4 65 in-lbs 3/0 AWG

Size 5 132 in-lbs 400 MCM

Note: Wire type not specified by the manufacturer. Some types of wire may not fit within the constraints of the

conduit entry and bend radius inside the drive..

Table 4-2: User-Supplied Terminal Cross-Reference

Wire Size Manufacturer Manufacturer’s P/N Manufacturer Manufacturer’s P/N

3 AWG T&B 54107

2 AWG T&B 54107

1 AWG T&B 54108

1/0 AWG T&B 54152-TB Burndy YA25-L6BOX

2/0 AWG T&B 54157 Burndy YA26-L5BOX

3/0 AWG T&B 54162-TB Burndy YA27-LBOX

4/0 AWG Burndy YA28-LBOX

250 MCM Burndy YA29-LBOX

300 MCM Burndy YA30-L

350 MCM Burndy YA31-L

400 MCM Burndy YA32-L1

4.2.3 Considerations for Control Wiring

Control wiring refers to the wires connected to the control terminal strip. Select control wiring as

follows:

1. Shielded wire is recommended to prevent electrical noise interference from causing improper operation

or nuisance tripping.

2. Use only UL recognized wire.

3. Wire voltage rating must be at least 300 V for 230 Vac systems. It must be at least 600 V for 460 or

575 Vac systems.

See Table 4-3 below for a summary of control wiring specifications.

Table 4-3: X5 Control Wiring Specifications

X5 Size / Models Specifications

4.4 in-lbs maximum torque

All Sizes / Models

DPD00089A - 30 - © 2009 Vacon Incorporated All Rights Reserved

12-24 awg wire

9/32” strip length

Page 31

X5 AC Drive User’s Manual Chapter 4: Connections

4.3 Input Line Requirements

4.3.1 Line Voltage

See “Power and Current Ratings” on page 16 for the allowable fluctuation of AC line voltage for

your particular X5 model. A supply voltage above or below the limits given in the table will cause

the drive to trip with either an overvoltage or undervoltage fault.

Exercise caution when applying the X5 AC drive on low-line conditions.

For example, an X5 2000 series unit will operate properly on a 208 Vac line, but the maximum

output voltage will be limited to 208 Vac. If a motor rated for 230 Vac line voltage is controlled by

this drive, higher motor currents and increased heating will result.

Therefore, ensure that the voltage rating of the motor matches the applied line voltage.

4.3.2 Line Capacity

If the source of AC power to the X5 AC drive is greater than 10 times the kVA rating shown in Ta ble

4-4 below, an isolation transformer or line reactor is recommended. Consult the factory for

assistance in sizing the reactor.

Table 4-4: X5 Line Capacity (kVA)

Drive HP 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200

Transformer

kVA

Note: X5 AC drive devices are suitable for use on a circuit capable of delivering not more than 65,000 rms

symmetrical amperes at 10% above the maximum rated voltage.

9 13 18 23 28 36 42 57 70 90 112 150 180 220 250

4.3.3 Phase Imbalance

Phase voltage imbalance of the input AC source can cause unbalanced currents and excessive heat

in the drive’s input rectifier diodes and DC bus capacitors. Phase imbalance can also damage motors

running directly across the line. The phase imbalance should not exceed 2% of the voltage rating; if

it does, the drive should be derated as a single-phase drive.

CAUTION

EQUIPMENT DAMAGE HAZARD

Never use power-factor correction capacitors on motor terminals T1/U, T2/V, or T3/W of the X5 AC

drive. Doing so will damage the semiconductors.

Failure to follow this instruction can result in injury or equipment damage.

ATTENTION

RISQUE DE DOMMAGES MATÉRIELS

Ne raccordez jamais de condensateurs de correction du facteur de puissance aux bornes T1/U, T2/V, ou

T3/W du moteur du variateur de vitesse X5. Car cela endommagera les semiconducteurs.

Si cette directive n’est pas respectée, cela peut entraîner des blessures corporelles ou des

dommages matériels.

DPD00089A - 31 - © 2009 Vacon Incorporated All Rights Reserved

Page 32

X5 AC Drive User’s Manual Chapter 4: Connections

4.3.4 Single-phase Operation

X5 AC drive 230 Vac, 5-HP models are designed for both three-phase and single-phase input power.

If one of these models is operated with single-phase power, use any two line input terminals. The

output of the device will always be three-phase.

The safe derating of the X5 series of drives is 50% of the nominal current (HP) rating. Consult the

factory with the particular application details for exact derating by model.

4.3.5 Ground Fault Circuit Interrupters (GFCI)

The GFCI breakers are designed for residential use to protect personnel from stray currents to

ground. Most GFCI breakers will shut off at 5 mA of leakage. It is not uncommon for an AC drive

to have 30 to 60 mA of leakage.

4.3.6 Motor Lead Length

It is recommended that the total lead length should not exceed the motor manufacturer’s guidelines.

Line disturbance and noise can be present in motor wiring of any distance. As a rule of thumb, any

non-inverter duty motor should have a reactor or filter added when the motor lead length exceeds

150 feet. The carrier frequency for the drive should also be reduced using parameter 803 (PWM

Frequency).

Nuisance trips can occur due to capacitive current flow to ground. These currents can cause shock

to personnel and can create problems within the motor. Care should be taken when working in these

areas.

Some applications can have a restricted lead length because of type of wire, motor type, or wiring

placement. Consult the factory and the motor manufacturer for additional information.

4.3.7 Using Output Contactors

Contactors in the output wiring of an AC drive may be needed as part of the approved safety circuit.

Problems can arise if these contactors are opened for the safety circuit and the drive is left in run

mode of operation. When the contactor is open, the drive is in a no-load, no-resistance state, but is

still trying to supply current to the motor. However, when the contactor closes, the drive sees the

motor resistance and instantly demands current. This inrush of current when the contactor closes can

fault or cause failure to the drive.

To prevent problems, interlock an auxiliary contact to the drive’s Run or Enable circuit to stop the

drive when the contactor opens. In this way, the drive will be disabled and no inrush will occur when

the contactor is closed again.

DPD00089A - 32 - © 2009 Vacon Incorporated All Rights Reserved

Page 33

X5 AC Drive User’s Manual Chapter 4: Connections

4.4 Terminals Found on the X5 Power Board

4.4.1 Description of the Terminals

Table 4-5 describes the X5 power terminals.

Table 4-5: Description of X5 Power Terminals

Terminal Description

L1/R

L2/S

L3/T

T1/U

T2/V

T3/W

Note that earth ground is on the terminal strip (see Figure 4-1). Dynamic brake (DB) connections are

not on the terminal strip, but on “fast on” (spade) connectors for models up to 30 HP, and on the

terminal strip for models 40 HP and larger. See page 36 for specific information about dynamic

braking.

These terminals are the line connections for input power. (Single-phase 230 Vac,

models connect to any two of these terminals.)

These terminals are for motor connections.

5 HP

Figure 4-1: X5 Power Terminals

DPD00089A - 33 - © 2009 Vacon Incorporated All Rights Reserved

Page 34

X5 AC Drive User’s Manual Chapter 4: Connections

Figure 4-2: Power Terminals on Higher-HP Models

4.4.2 Typical Power Connections

See Section 4.3 starting on page 31 for input line requirements.

Note that when testing for a ground fault, do not short any motor lead (T1/U, T2/V, or T3/W) back

to an input phase (L1/R, L2/S, or L3/T).

It is necessary to provide fuses and a disconnect switch for the input AC line in accordance with all

applicable electrical codes. The X5 AC drive is able to withstand a 150% overload for 60 seconds

for heavy duty rating, and 120% overload for normal duty rating.

The fusing and input protection of the drive must always meet UL, NEC (National Electric Code),

and CEC (Canadian Electric Code) requirements. All fuse ratings included in Table 4 -6 below are

for reference only and do not supersede code requirements. The recommended supplier is Bussman.

Table 4-6: Fuse Ratings (Page 1 of 2)

Fuse Size

115 Vac

Model Number

X5C1S010C 20 — — — — —

X5C20010C — 10 6 — — —

X5C20020C — 15 10 — — —

X5C20030C — 20 15 — — —

X5C20050C — 30 25 — — —

X5C20075C — 40 35 — — —

X5C20100C — 50 40 — — —

X5C20150C — 70 60 — — —

X5C20200C — 90 80 — — —

X5C20250C — 100 90 — — —

X5C20300C — 125 110 — — —

JJS/JJN

Fuse Size

208 Vac

JJS/JJN

Fuse Size

230 Vac

JJS/JJN

Fuse Size

380 Vac

JJS

Fuse Size

460 Vac

JJS

Fuse Size

575 Vac

JJS

DPD00089A - 34 - © 2009 Vacon Incorporated All Rights Reserved

Page 35

X5 AC Drive User’s Manual Chapter 4: Connections

Table 4-6: Fuse Ratings (Page 2 of 2)

Fuse Size

115 Vac

Model Number

X5C40010C — — — 6 6 —

X5C40020C — — — 10 6 —

X5C40030C — — — 10 10 —

X5C40050C — — — 15 15 —

X5C40075C — — — 20 20 —

X5C40100C — — — 25 20 —

X5C40150C — — — 40 35 —

X5C40200C — — — 50 40 —

X5C40250C — — — 60 50 —

X5C40300C — — — 80 60 —

X5C40400C — — — 100 80 —

X5C40500C — — — 110 100 —

X5C40600C — — — 125 100 —

X5C40750C — — — 150 125 —

X5C41000C — — — 200 175 —

X5C41250D — — — 225 200 —

X5C41500D — — — 250 225 —

X5C42000D — — — 300 300 —

X5C50010C — — — — — 6

X5C50020C — — — — — 6

X5C50030C — — — — — 10

X5C50050C — — — — — 10

X5C50075C — — — — — 15

X5C50100C — — — — — 20

X5C50150C — — — — — 30

X5C50200C — — — — — 40

X5C50250C — — — — — 50

X5C50300C — — — — — 50

X5C50400C — — — — — 70

X5C50500C — — — — — 80

X5C50600C — — — — — 90

X5C50750C — — — — — 110

X5C51000C — — — — — 150

X5C51250D — — — — — 175

X5C51500D — — — — — 200

X5C52000D — — — — — 250

JJS/JJN

Fuse Size

208 Vac

JJS/JJN

Fuse Size

230 Vac

JJS/JJN

Fuse Size

380 Vac

JJS

Fuse Size

460 Vac

JJS

Fuse Size

575 Vac

JJS

DPD00089A - 35 - © 2009 Vacon Incorporated All Rights Reserved

Page 36

X5 AC Drive User’s Manual Chapter 4: Connections

4.5 Dynamic Braking

The X5 AC drive is supplied with an integrated dynamic braking (DB) resistor, and is designed to

have adequate dynamic braking for most applications. In cases where short stopping times or high

inertia loads require additional braking capacity, install an external resistor.

Note: For Size 4 (60-100 HP) and Size 5 (125-200 HP) models, additional external dynamic braking

requires a kit that provides the connections to the braking transistors. The XDBKITS4 and

XDBKITS5 kits can be purchased through local distributors.

If an external resistor is used for dynamic braking, the internal resistor must be disconnected. To

install an external resistor, first disconnect the internal DB resistor (or resistors in 460 and 575 Vac

models) and properly terminate the wires leading to it. Then connect the external resistor fast-on

terminals where the internal resistor had been connected.

Changes to parameter 410 must be made when using external DB resistors.

Verify with the manufacturer of the selected resistor that the resistor is appropriate for your

application. Contact Vacon’s Electronic Application Engineering group for further assistance with

other possible sizing limitations.

Refer to Tabl e 4-7 for information about dynamic braking capacity for each X5 model.

Table 4-7: X5 Dynamic Braking Capacity (Page 1 of 2) (* Note that the asterisked X5 model numbers cannot

have external braking added)

Standard

Resistance

Model KW

1S010* .75 125 164% -- -- --

20010* .75 125 164% -- -- --

20020* 1.5 125 82% -- -- --

20030* 2.2 125 55% -- -- --

20050 3.7 60 68% 43 3,555 95%

20075 5.5 60 45% 30 5,096 91%

20100 7.5 60 34% 27 5,662 76%

20150 11 60 23% 20 7,644 68%

20200 15 30 34% 10 15,288 102%

20250 18 30 27% 10 15,288 82%

20300 22 30 23% 10 15,288 68%

40010* .75 500 163% -- -- --

40020* 1.5 500 82% -- -- --

40030* 2.2 500 54% -- -- --

40050 3.7 120 136% 100 6,084 163%

40075 5.5 120 91% 75 8,112 145%

(ohms)

Standard DB

(% of Drive

Power)

Min. Allowed

Res. (ohms)

Max. Peak

Watts

Max. Ext. DB

(% of Drive

Power)

DPD00089A - 36 - © 2009 Vacon Incorporated All Rights Reserved

Page 37

X5 AC Drive User’s Manual Chapter 4: Connections

Table 4-7: X5 Dynamic Braking Capacity (Page 2 of 2) (* Note that the asterisked X5 model numbers cannot

have external braking added)

Standard

Resistance

Model KW

40100 7.5 120 68% 75 8,112 109%

40150 11 120 45% 47 12,944 116%

40200 15 120 34% 47 12,944 87%

40250 18 120 27% 47 12,944 69%

40300 22 120 23% 39 15,600 70%

40400 29.8 60 34% 20 30,420 102%

40500 37.3 60 27% 20 30,420 82%

40600 45 60 23% 15 40,560 91%

40750 55 60 18% 10 60,840 109%

41000 75 60 14% 10 60,840 82%

41250 90 60 11% 10 60,840 65%

41500 110 60 9% 10 60,840 54%

42000 132 60 7% 10 60,840 41%

50010 .75 120 1058% 110 8,607 1154%

50020 1.5 120 529% 110 8,607 577%

50030 2.2 120 353% 110 8,607 385%

50050 3.7 120 212% 110 8,607 231%

50075 5.5 120 141% 91 10,404 186%

50100 7.5 120 106% 91 10,404 139%

50150 11 120 71% 62 15,269 136%

50200 15 120 53% 62 15,269 102%

50250 18 120 42% 62 15,269 82%

50300 22 120 35% 62 15,269 68%

50400 29.8 60 53% 24 39,447 132%

50500 37.3 60 42% 24 39,447 106%

50600 45 60 35% 15 63,115 141%

50750 55 60 28% 15 63,115 113%

51000 75 60 21% 20 63,115 85%

51250 90 60 17% 10 94,672 102%

51500 110 60 14% 10 94,672 85%

52000 132 60 11% 10 94,672 63%

(ohms)

Standard DB

(% of Drive

Power)

Min. Allowed

Res. (ohms)

Max. Peak

Watts

Max. Ext. DB

(% of Drive

Power)

DPD00089A - 37 - © 2009 Vacon Incorporated All Rights Reserved

Page 38

X5 AC Drive User’s Manual Chapter 4: Connections

4.6 Terminals Found on the X5 Control Board

4.6.1 Description of the Control Terminals

Figure 4-3 shows the control terminals found on the I/O board of the X5 AC drive. See page 19 for

specifications. Table 4-9 on page 41 shows how to use the control terminals for preset speeds.

The drive’s control terminals are referenced to earth ground through a resistor / capacitor network.

Use caution when connecting analog signals not referenced to earth ground, especially if the

communications port (J3) is being used. The J3 port includes a common reference that can be

connected to earth ground through the host PLC or computer.

Figure 4-3: X5 Control Terminals

DPD00089A - 38 - © 2009 Vacon Incorporated All Rights Reserved

Page 39

X5 AC Drive User’s Manual Chapter 4: Connections

Table 4-8: Description of X5 Control Terminals (Page 1 of 2)

Terminal Description

Vmet Analog output 1, which is a dedicated voltage output.

The default signal range is from 0 to 10 Vdc (5 mA maximum). It is proportional to the variable

configured by parameter

is running via parameter

Imet Analog output 2, which is a dedicated current output.

The default signal ranges from 0 to 20 mAdc (50 to 500 Ω). It is proportional to the variable

configured by parameter

running via parameters

Vin1 Analog Input 1, which is used to provide speed references.

The default input signal is 0 to 10 Vdc (the type of input signal is selected with parameter

(Vin1 Config)

; see page 77). Parameters 206 (Vin1 Offset) and 207 (Vin1 Span) may be used to

offset the starting value of the range and the size of the range, respectively; see page 77 for

more information.

If a 0 to 20 mAdc input signal is configured, the burden is 250 Ω. If a 0 to 10 Vdc input signal is

configured, the input impedance is 475 kΩ.

A potentiometer with a range of 1 to 10 kΩ is suggested for this input.

+10 This terminal is a +10 Vdc source for customer-supplied potentiometers. The maximum load on

this supply cannot exceed 10 mAdc.

Cin+ / Cin- Current Input.

The default input signal is 4-20 mA, although this range may be adjusted by using parameters

209 (Cin Offset) (which configures an offset for the range) and 210 (Cin Span) (to reduce or

enlarge the range — for example, setting this parameter to 50% results in a range of 4-12 mA).

See page 77 for more information on these parameters.

The burden for this terminal is 50 Ω.

Vin2 Voltage Input 2, which is used to provide speed references.