Page 1

Data Sheet

Water regulating valves

Type WVTS

Thermostatic operated water valve

Opens on rising sensor temperature

Thermostatic operated water valve type WVTS

is suitable for controlling the temperature of a

ow of water or neutral brine.

WVTS opens on rising sensor temperature and

is indirect servo operated thermostatic valve.

It is suitable for controlling temperature in

industrial applications by regulating the

quantity of cooling water or neutral brine that

cools down the process.

The valves are self-acting, i.e. they operate

without the supply of auxiliary energy such as

electricity or compressed air.

The required temperature is maintained

constant without unnecessary use of cooling

water in cooling systems.

The operating economy and-eciency are

maximized.

Features:

• Insensitive to dirt

• Insensitive to water pulsating pressure

• Proven reliable through decades

• Easy to service

• Built-in pilot lter

• Long lifetime

• High performance

• Very high capacity

• Both welding and thread connection anges

AI214786434421en-000602

Page 2

Danfoss

16D71

Danfoss

16D61

Type

WVTS for neutral media

Operation

Servo-operated

Temperature range

0 – 30 °C

25 – 65 °C

50 – 90 °C

Max. sensor temperature

57 °C

90 °C

125 °C

Features

Description

Media

Fresh water, neutral brine

Media temperature range

- 25 – 90 °C

Permissible working pressure PB

10 bar

Max. test pressure

16 bar

Opening dierential pressure

WVTS 32 – WVTS 40: min. 0.5 bar; max. 4 bar

WVTS 50 – WVTS 100: min. 0.3 bar; max. 4 bar

Water regulating valves, Type WVTS

Product specication

Technical data

Table 1: Type and media

Table 2: Sensor side

Table 3: Liquid side

Valves are supplied with capillary tube gland. Dierent lengths of capillary tube are available.

If WVTS is required with an opening dierential pressure of 1 – 10 bar, the valve servo spring must be replaced. See

Ordering.

Material

Parts in contact with the medium.

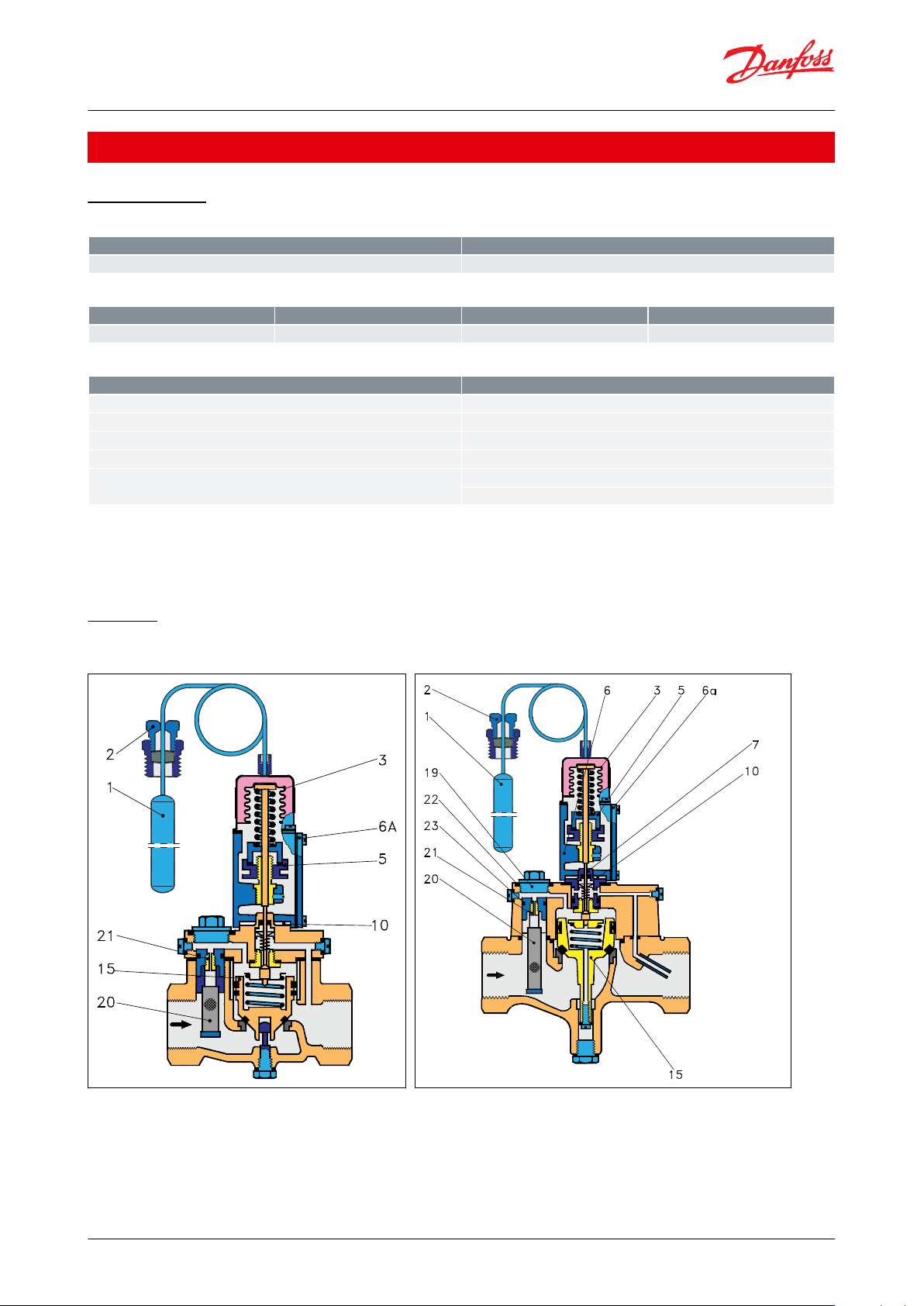

Figure 1: WVTS 32

Figure 2: WVTS 40

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 2

Page 3

Danfoss

16D60

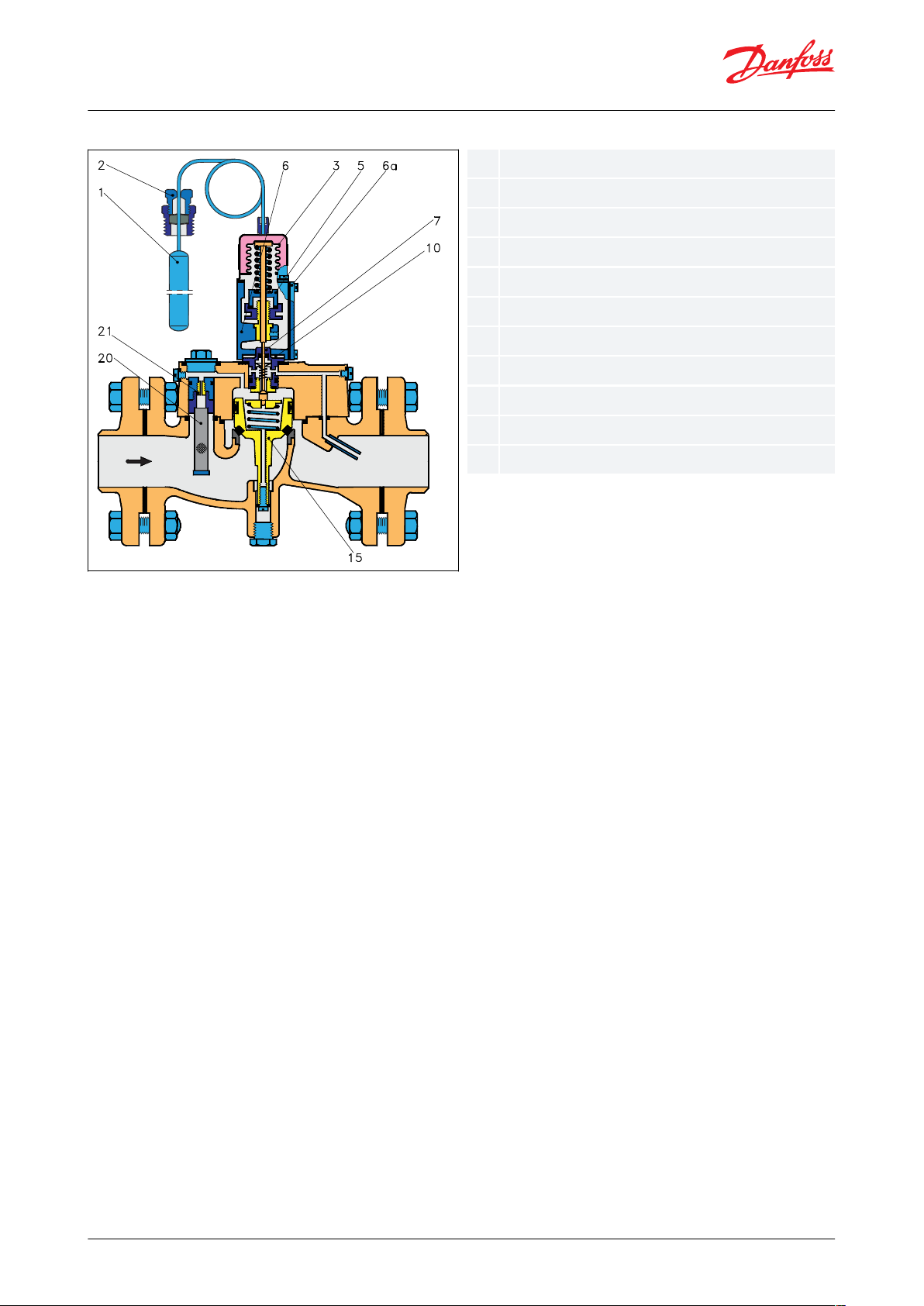

1.2.3.5.6.

6a.7.10.

15.

20.

21.

Sensor

Gland

Bellows element

Regulating nut

Setting element housing

Cover

Pilot orice assembly

Insulating washer

Servo piston

Filter cartridge (self-cleaning)

Equalising orice

Water regulating valves, Type WVTS

Figure 3: WVTS 50 – WVTS 100

The valve body is made of cast iron with pressed-in bronze seat. The pilot orice assembly (7) consists of a housing

with seat and pilot cone of stainless steel. A lter cartridge (20) is built into the valve cover. Here the equalising

orice is protected by a replaceable lter.

The bellows in the bellows element (3) are of tin bronze. In designing WVTS, great emphasis was placed on

producing a valve with a completely tight seat and no external leakage. The servo piston was therefore tted with a

ring of special rubber that creates an elastic seal against the valve seat.

A specially designed rubber sleeve ensures that the servo piston moves in the cylinder with minimum friction.

External valve leakage is prevented at the pilot cone where the spindle is tted with Teon cupwashers. Cover

gaskets and pilot channel seals are rubber.

The water-tight rubber seal between cover (6a) and housing (6) ensure that moisture cannot enter and freeze up the

spindle. The insulating washer (10) prevents heat transmission between valve body and setting element housing.

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 3

Page 4

_____

_ _ _ _

Standard servo spring

Special servo spring

Water regulating valves, Type WVTS

Capacity

Figure 4: Capacity graph

The capacity curves show the capacity (water quantity in [m3/h]) of the individual valve sizes as a function of

pressure drop across the valve.

The capacities are given for approx. 85% valve opening and are obtained with an oset of 4 °C (temperature rise at

sensor) on both upper and lower temperature ranges.

Installation

Valve installation:

WVTS is to be tted in the cooling water inlet with ow in the direction of the arrow and with the bellows element

facing upwards. Horizontal mounting is a must.

Sensor / bulb installation:

The bulb is to be tted where it is required to maintain or control the water temperature.

The bulb can be tted warmer or colder than the valve body, with no eect on the regulating capacity.

The bulb must be tted horizontally or with the blank end of the bulb at the lowest level.

The capitals UP and the red line on the bulb must face upwards at horizontal or inclined tting.

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 4

Page 5

WVTS 32 – WVTS 40

WVTS 50 – WVTS 100

Type

H1H2H3L

L1BøDøD

1

Net weight

WVTS 3242196

210

1382085—184WVTS 4072224

210

19830100—187WVTS 5078230

210

315

218—1651819

WVTS 6582246

210

320

224—1851824

WVTS 8090278

210

370

265—2001834

WVTS 100

100

298

210

430

315—2201844

Water regulating valves, Type WVTS

Dimensions [mm] and weights [kg]

Table 4: Dimensions and weights

Table 5: Dimensions and weights

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 5

Page 6

Valve type

Connection

Kv value [m3/h]

(1)

Code no.

Valve housing

Flange set

(2)

Special servo

spring for dier‐

ential pressure

range 1 – 10 bar

Danfoss

16D8007

WVTS 32

G 11/4

(3)

12.5

016D5032

—

016D1327

WVTS 40

G 11/2

(3)

21

016D5040

—

016D0575

WVTS 50

2 in. weld .

32

016D5050

(4)

027N3050

016D0576

WVTS 65

21/2 in. weld .

45

016D5065

(4)

027N3065

016D0577

WVTS 80

3 in. weld .

80

016D5080

(4)

027N3080

016D0578

WVTS 100

4 in. weld .

125

016D5100

(4)

027N3100

016D0579

Range [°C]

Capillary tube length [m]

Code no.

Danfoss

16D8009

0 – 30

2

016D1002

25 – 65

2

016D1003

50 – 90

2

016D1004

0 – 30

5

016D1005

25 – 65

5

016D1006

50 – 90

5

016D1007

Description

Code no.

Immersion sensor (sensor pocket)

003N0050

Capillary tube gland

(5)

003N0155

File name

Document type

Document topic

Approvals Authority

003N9613.AB

Manufacturers Declaration

PED/RoHS

Danfoss

003N9614.AA

Manufacturers Declaration

China RoHS

Danfoss

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

EAC

EAC

UA.089.D.00188-17

UA Declaration

TYSK

TYSK

Water regulating valves, Type WVTS

Ordering

Table 6: WVTS components

(1)

(1)

The Kv value is the ow quantity of water in [m3/h] with a pressure drop across the valve of 1 bar, p =1000 kg/m3.

The Kv value is the ow quantity of water in [m3/h] with a pressure drop across the valve of 1 bar, p =1000 kg/m3.

(2)

(2)

Code nos. include 2 anges.

Code nos. include 2 anges.

(3)

(3)

ISO 228-1.

ISO 228-1.

(4)

(4)

Code nos. include valve housing, ange gakets, ange bolts and screws for pilot valve.

Code nos. include valve housing, ange gakets, ange bolts and screws for pilot valve.

Table 7: WVTS, thermostatic pilot element*

NOTE:

*The pilot element includes control element and spring housing.

Table 8: Accessories

(5)

(5)

1 capillary tube gland supplied as standard accessory.

1 capillary tube gland supplied as standard accessory.

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 9: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 6

Page 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI214786434421en-000602 | 7

Loading...

Loading...